Roller rolling press pump

A roller and rolling technology, applied in the field of roller rolling pumps, can solve the problems of rollers on one side of the raceway, troublesome use, inconvenient opening and closing, etc., and achieve fast clamping and positioning, easy manufacturing and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

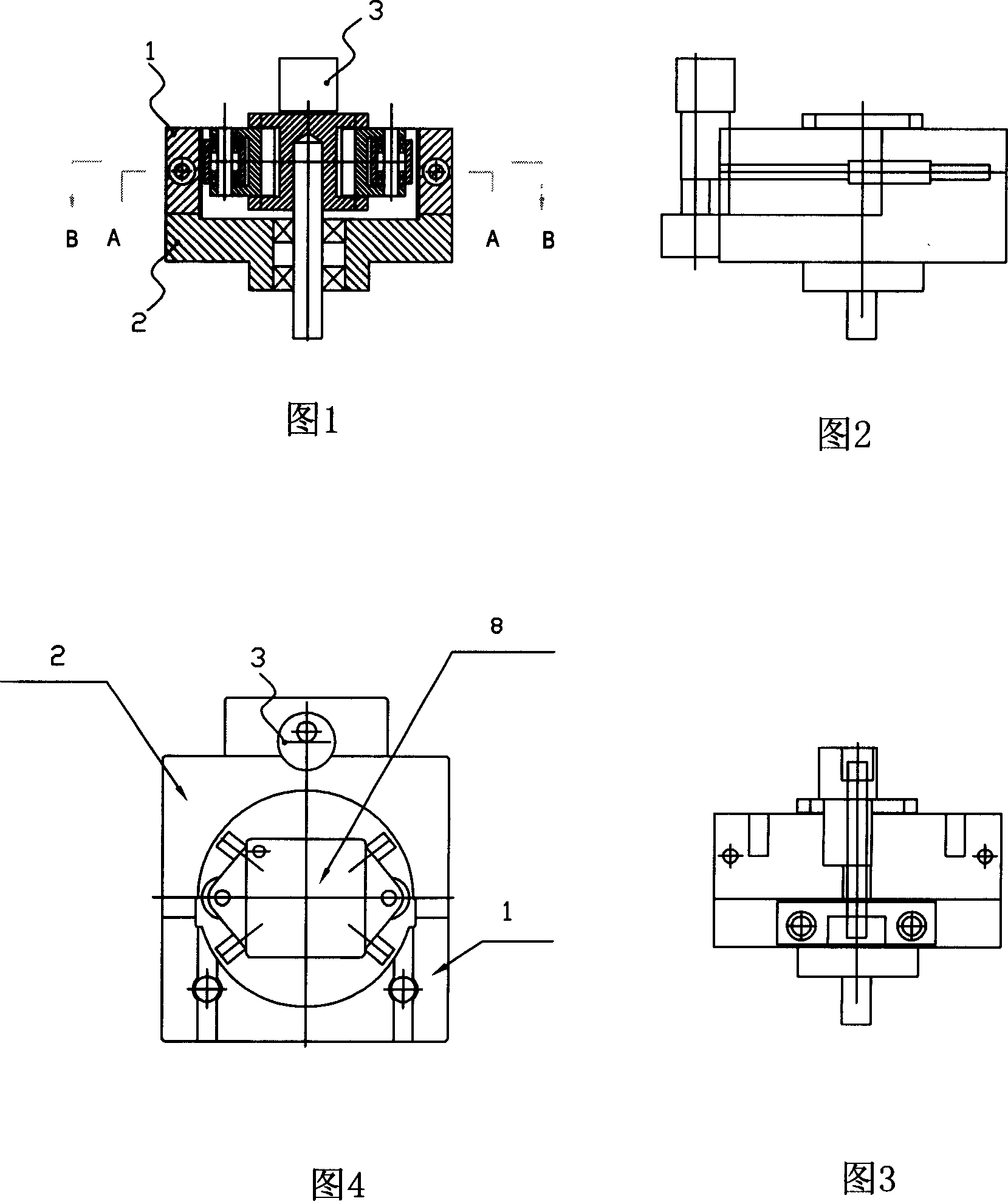

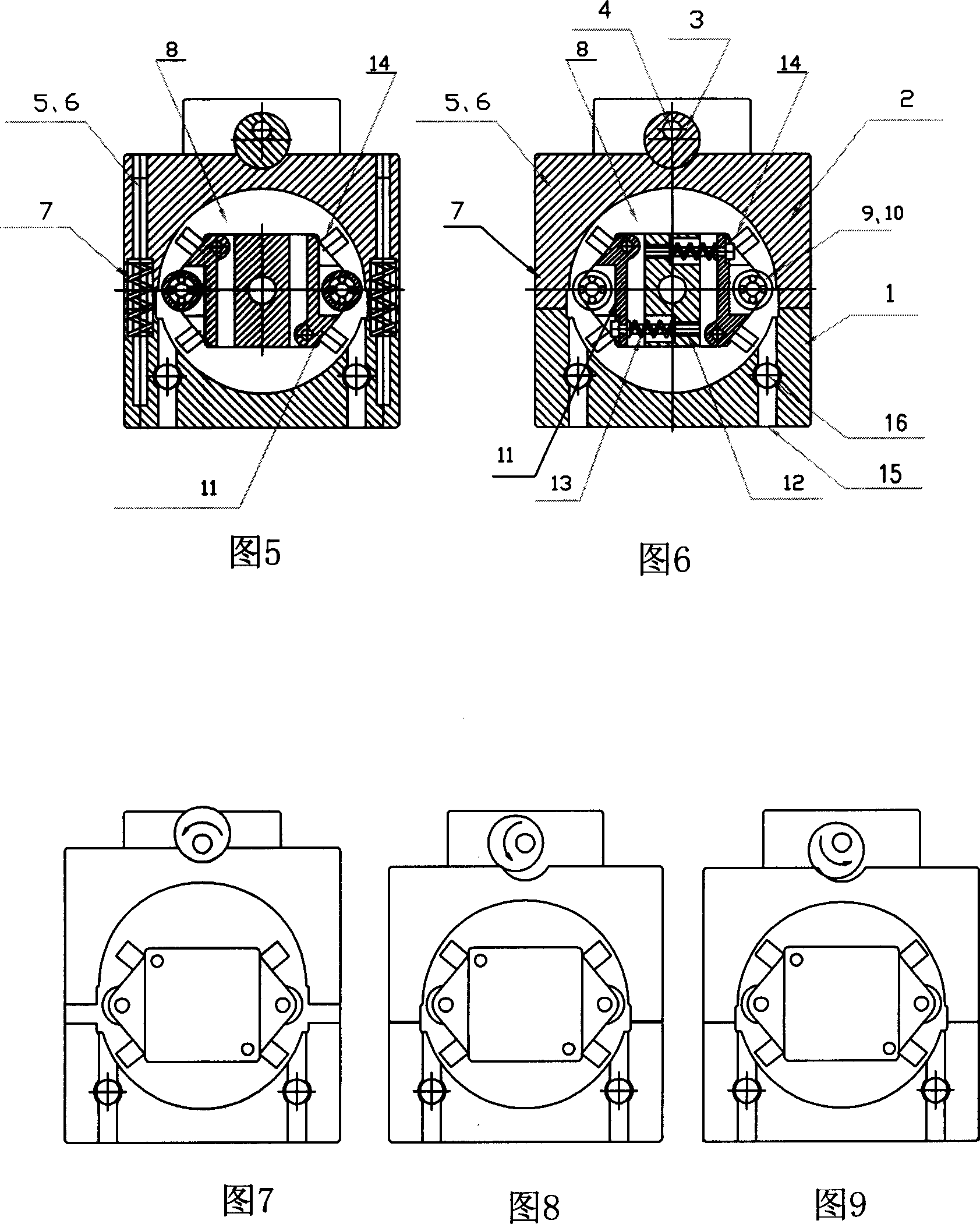

[0029] The roller rolling pump of the present invention shown in Fig. 1 to Fig. 6 is composed of a split pump body 1, a pump body slider 2 and a pump core assembly 3, and the pump body slider 2 is opened in the middle of one side of a rectangular block. There is a semicircular notch. The pump body 1 is a stepped rectangular block. There is a corresponding semicircular notch in the middle of the upper part. After the two cooperate to form a round hole, the side of the semicircular hole of the pump body slider becomes a raceway. The pump body There are also conduit inlet and outlet holes 15 and conduit fixing columns 16 on the top; on the pump body joint surface combined with the pump body slider, there are protruding slider guide rods 5, and on the joint surface of the pump body slider, there is a There is a corresponding slider guide rod hole 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com