Wheel radial positioning device

A radial positioning and wheel technology, applied in positioning devices, clamping, supporting and other directions, can solve the problems of high cost, poor operability, and low efficiency of large-stroke pneumatic chucks, and achieve simple structure, low manufacturing cost, and convenience. processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

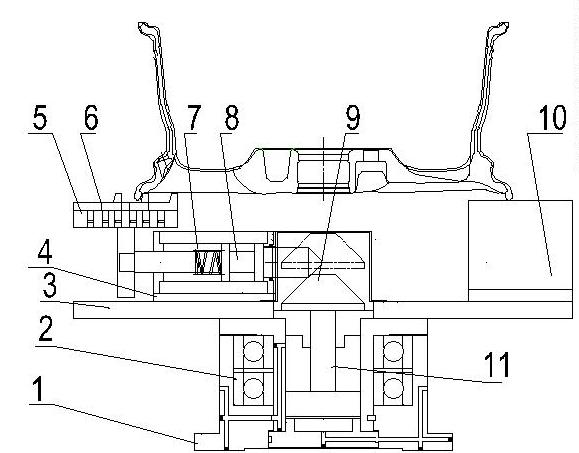

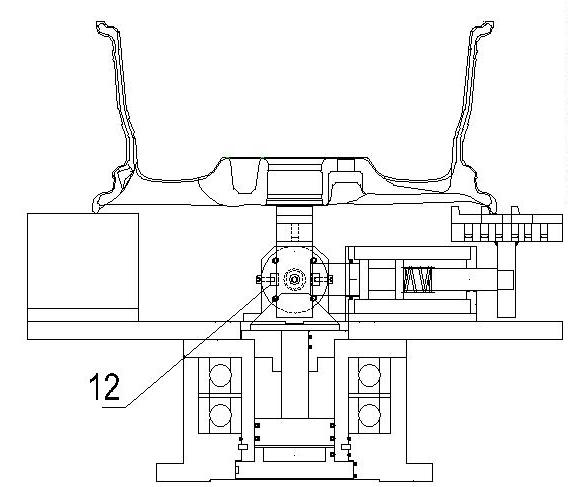

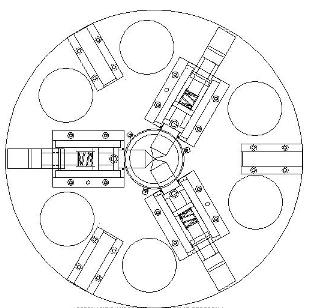

[0011] The details and working conditions of the specific device proposed according to the present invention will be described below in conjunction with the accompanying drawings.

[0012] The device is composed of a base 1, a bearing 2, a disc 3, a sliding seat 4, a jaw seat 5, a jacking block 6, a spring 7, a jacking shaft 8, a cylinder 11, an end face positioning block 10, a flat key 12 and a plug 9. 11 is connected on the base 1 through the bearing 2, the disc 3 is fixed on the cylinder 11, the slide seat 4 and the end face positioning block 10 are installed on the disc 3, and the top shaft 8 is formed by the flat keys 12 installed on the inner sides of the slide seat 4 Guided, reset by the spring 7; the plug 9 is fixed at the end of the output rod of the cylinder 11, the claw seat 5 is installed at one end of the top shaft 8, and the top block 6 is directly inserted into its positioning hole.

[0013] During the working process, the front of the wheel is first placed flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com