Welding clamp of winding pipe assembly

A technology for welding fixtures and components, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inaccurate welding position, low product qualification rate, and many preparations, so as to improve work efficiency and location. Accurate, avoids the effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

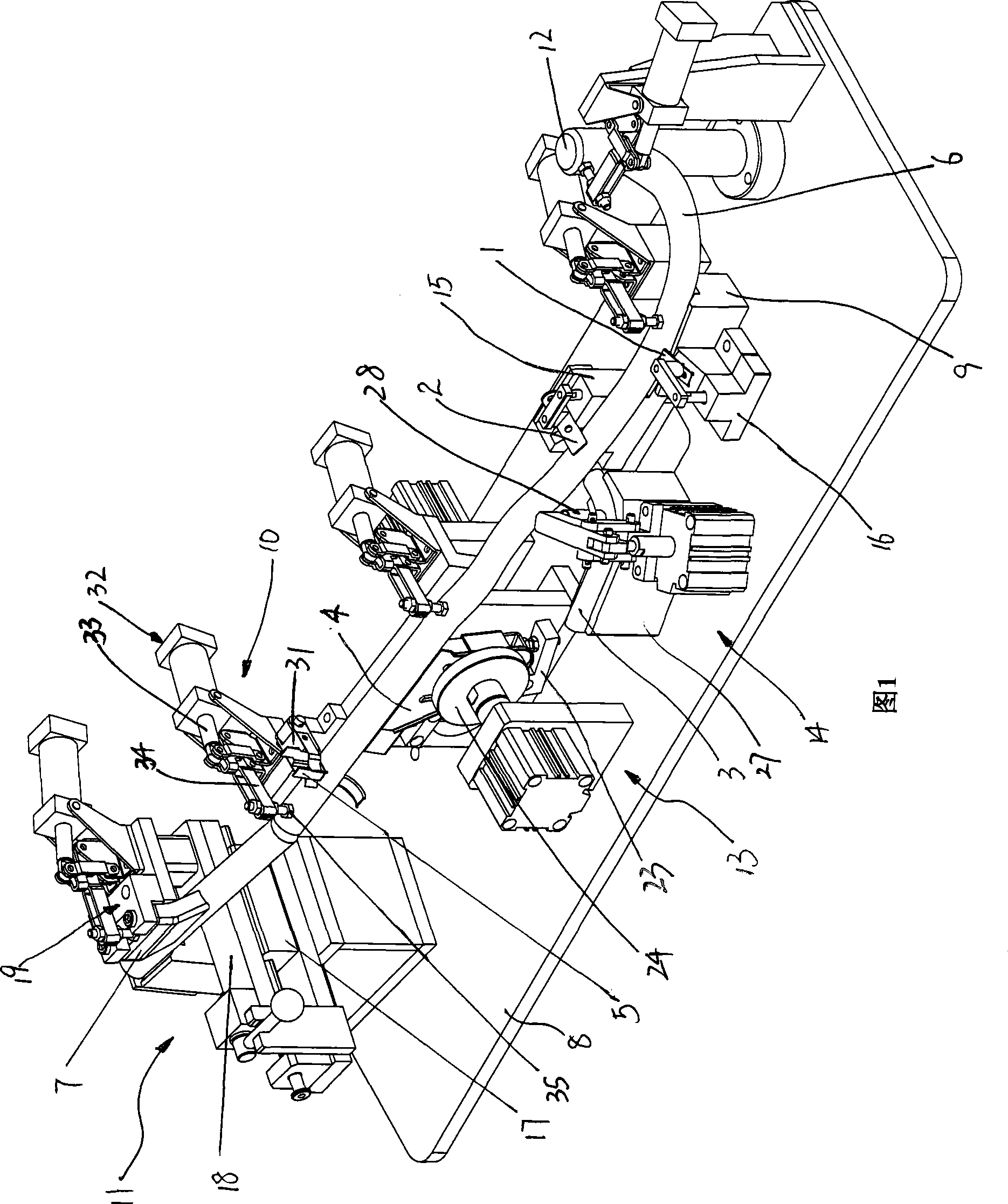

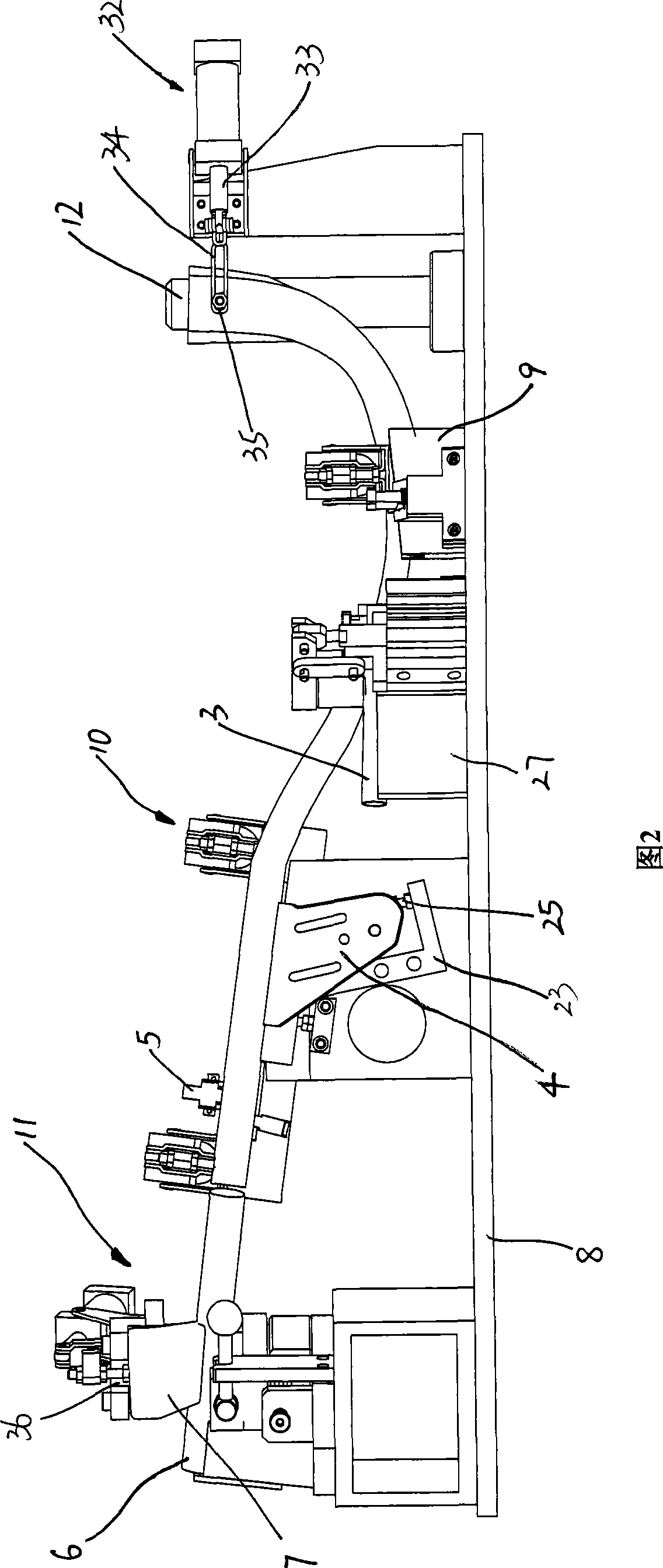

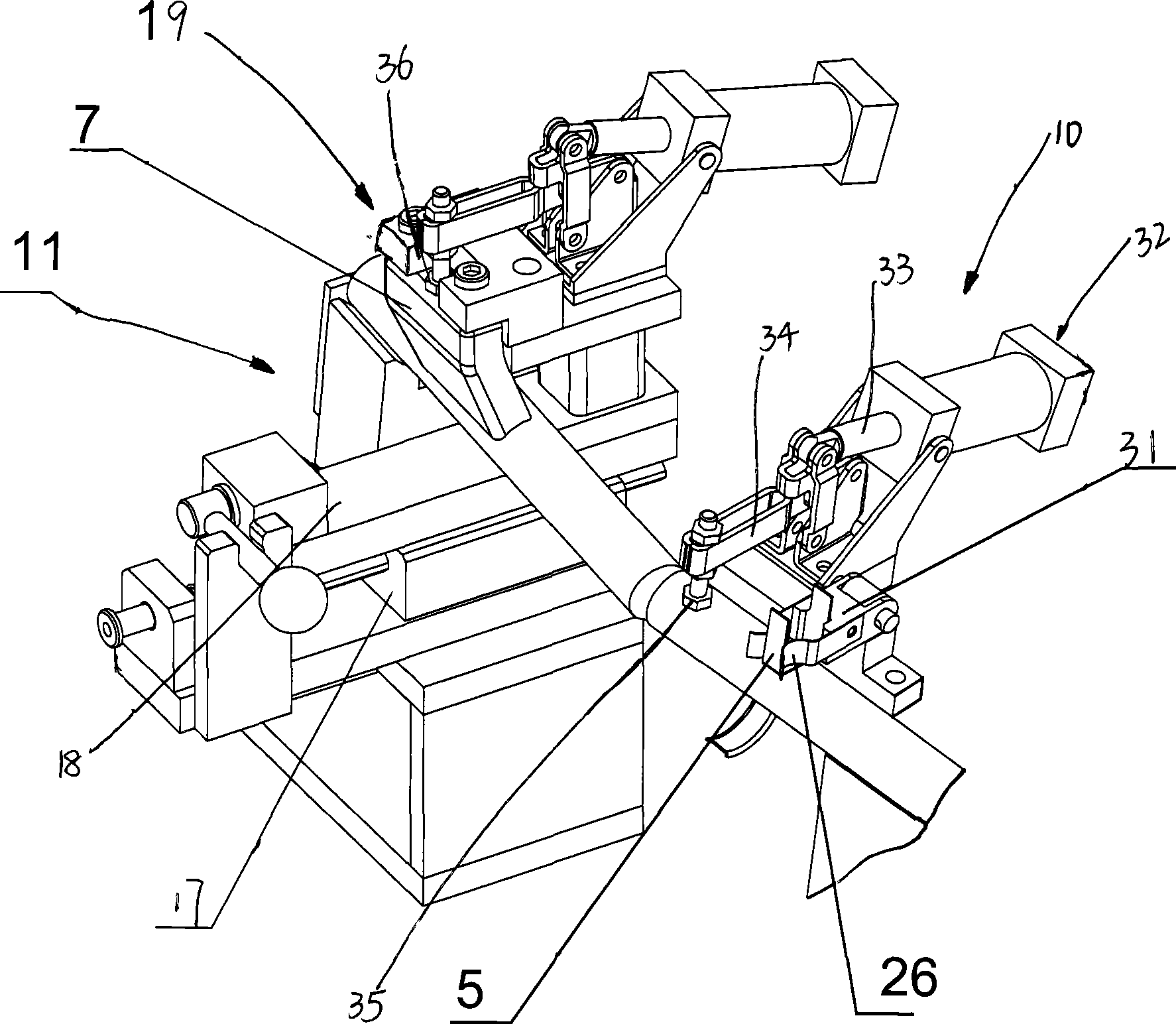

[0023] Referring to accompanying drawings 1 to 6, a welding fixture for an elbow assembly includes a base frame 8, a support mold 9 fixedly arranged on the base frame 8 and supporting the workpiece to be welded, and partially pressed against the workpiece to be welded. A plurality of clamping devices 10 for fixing workpieces to be welded on the surface. A plurality of supporting molds 9 are distributed on the base frame 8 according to the direction of the right curved pipe 6 , and support the right curved pipe 6 .

[0024] The clamping device 10 includes a first cylinder 32, the first cylinder 32 has a first piston rod 33, the end of the first piston rod 33 is rotatably connected with a swing arm 34, and the end of the swing arm 34 is fixedly connected with a pressure head 35 . When the first cylinder 32 is driven, it can control the first piston rod 33 to move, so that the swing arm 34 rotates around the hinge, and the pressure head 35 rotates with the swing arm 34 and can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com