Clamp for ultrasonic welding machine

An ultrasonic and fixture technology, applied in the ultrasonic field, can solve the problems of unable to maintain the leveling state, take a lot of time, affect the automatic production rhythm and product quality, and achieve the effect of improving the working rhythm, improving the welding quality, and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

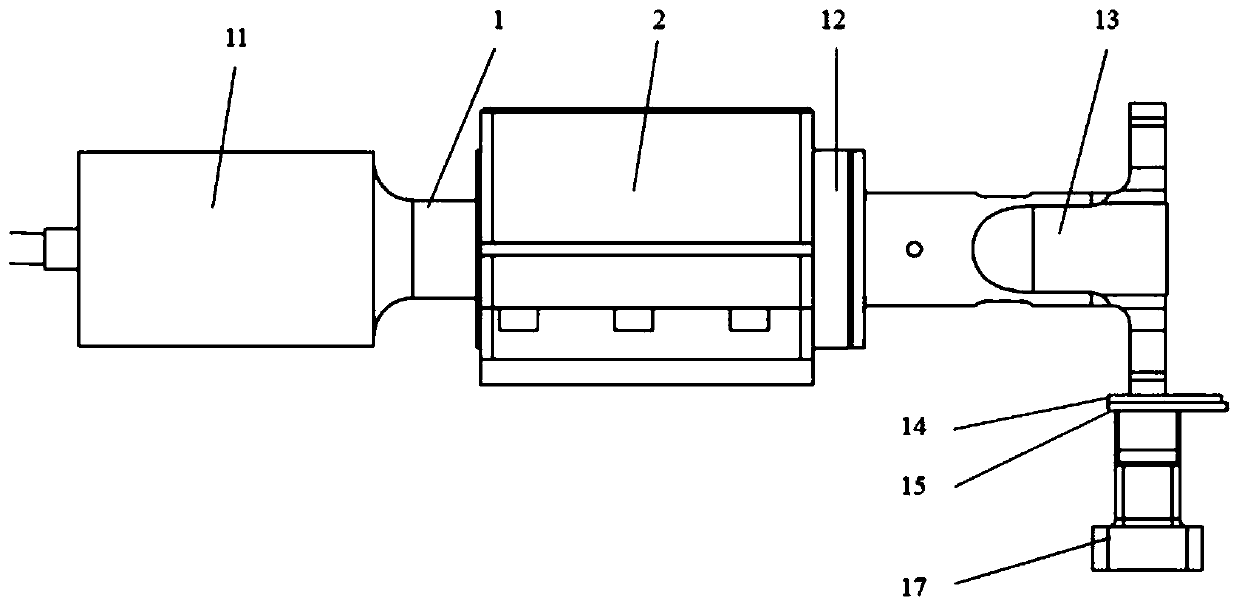

[0015] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a fixture for an ultrasonic welder, including: a weldment 15, and also includes a triplet 1, a fixture 2, a transducer 11, an amplitude modulator 12, a welding head 13, The welding area 14 and the anvil 17; the right side of the transducer 11 is connected with a triplet 1; the right side of the triplet 1 is connected with an amplitude modulator 12; the right side of the amplitude modulator 12 is connected with a Welding head 13; the lower end of the welding head 13 is provided with a welding area 14; the welding piece 15 is arranged on the anvil 17; the welding area 14 is in contact with the welding piece 15; the clamp 2 is arranged in a triple group 1 on the outer surface.

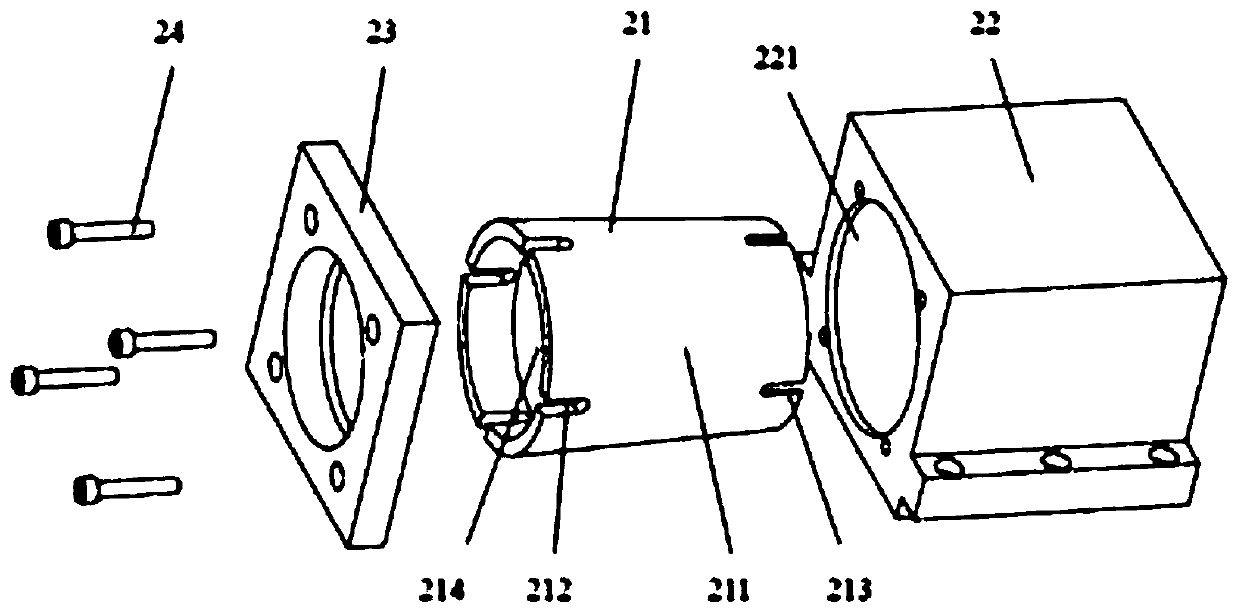

[0016] Such as figure 2 As shown, the specific structure of the clamp 2 is: comprising a first bushing 21, a first frame 22, a first cover plate 23 and a first screw 24; the first bushing 21 is arranged...

Embodiment 2

[0019] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a fixture for an ultrasonic welder, including: a weldment 15, and also includes a triplet 1, a fixture 2, a transducer 11, an amplitude modulator 12, a welding head 13, The welding area 14 and the anvil 17; the right side of the transducer 11 is connected with a triplet 1; the right side of the triplet 1 is connected with an amplitude modulator 12; the right side of the amplitude modulator 12 is connected with a Welding head 13; the lower end of the welding head 13 is provided with a welding area 14; the welding piece 15 is arranged on the anvil 17; the welding area 14 is in contact with the welding piece 15; the clamp 2 is arranged in a triple group 1 on the outer surface.

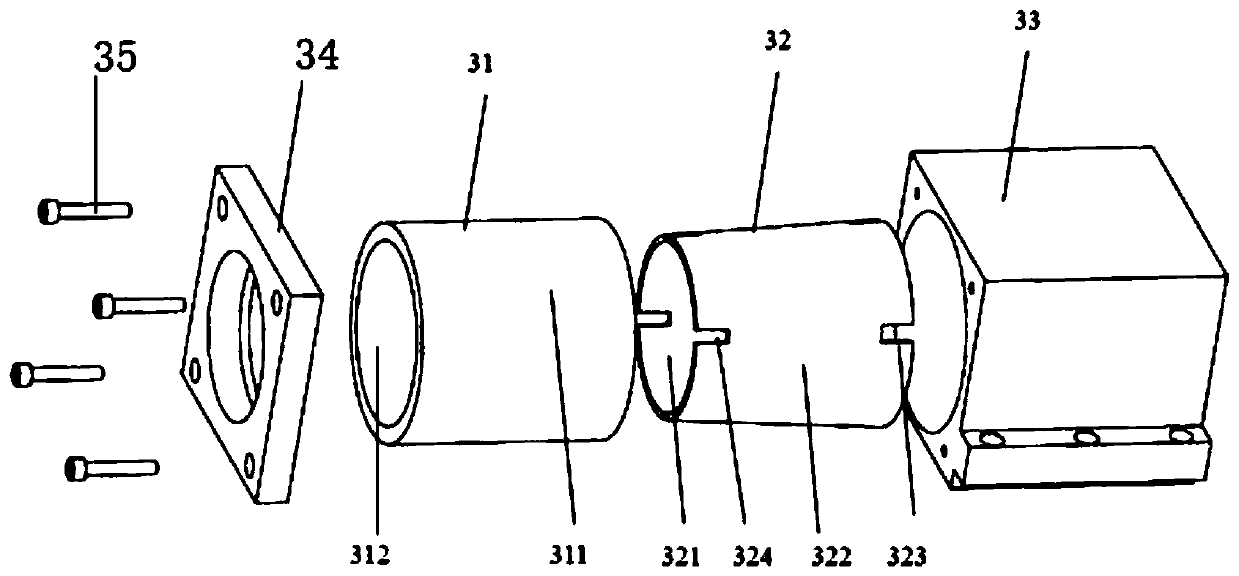

[0020] Such as image 3 As shown, the specific structure of the clamp 2 is: including a second bushing 31, a third bushing 32, a second base 33, a second cover plate 34 and a second screw 35; the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com