Universal internal rotation machine device for engineering wheels and machining method thereof

A technology of internal rotation machine and wheel, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of large amount of subsequent machining, insufficient strength of automobile rim, and improvement of production efficiency, so as to reduce the workload of machining , Avoid internal damage to the workpiece and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

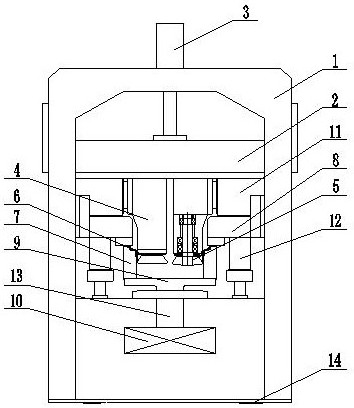

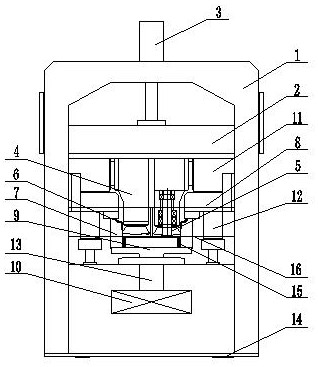

Image

Examples

Embodiment 1

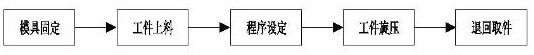

[0047] (1) Mold fixation: Choose a mold with the same shape and shape as the 10.0 / 2.0-25 engineering wheel, fix the mold on the rotating platform of the internal rotation machine device, and adjust the level and verticality;

[0048] (2) Workpiece loading: place the 25-inch wheel blank workpiece in the mold, pay attention to the external steps to fit the mold, and then use the pressing mechanism to compress the blank workpiece;

[0049] (3) Program setting: According to the 10.0 / 2.0-25 wheel drawing size requirements, compile the spinning processing program on the automatic control system interface, set the front wheel and back wheel to feed at 45°, and then press 90° vertically Feed down, and the feed rate of the front wheel is 2.0mm, the feed rate of the back wheel is 1.0mm, the height of the wheel step is increased from 48mm of the blank to 60mm, and the processing value of the inner diameter is set to 608±0.5mm;

[0050] (4) Workpiece spinning: After the programming is com...

Embodiment 2

[0053] (1) Mold fixing: Choose a mold with the same shape as the 8.0-15 engineering wheel, fix the mold on the rotating platform of the internal rotation machine device, and adjust the level and verticality;

[0054] (2) Workpiece loading: place the 15-inch wheel blank workpiece in the mold, pay attention to the external steps to fit the mold, and then use the pressing mechanism to compress the blank workpiece;

[0055] (3) Program setting: According to the 8.0-25 wheel drawing size requirements, compile the spinning processing program on the interface of the automatic control system, set the front wheel and the back wheel to feed at 45°, and then vertically downward at 90° Give, and the feed rate of the front spinner wheel is 2.5mm, the feed rate of the back spinner wheel is 1.2mm, the height of the wheel step is increased from 40mm of the blank to 56.5mm, and the processing value of the inner diameter is set to 371±0.5mm;

[0056] (4) Workpiece spinning: After the programmin...

Embodiment 3

[0059] (1) Mold fixing: Choose a mold with the same shape as the 8.0-15 engineering wheel, fix the mold on the rotating platform of the internal rotation machine device, and adjust the level and verticality;

[0060] (2) Workpiece loading: place the 15-inch wheel blank workpiece in the mold, pay attention to the external steps to fit the mold, and then use the pressing mechanism to compress the blank workpiece;

[0061] (3) Program setting: According to the 8.0-25 wheel drawing size requirements, install the profiling mold, the front wheel and the back wheel respectively correspond to different profiling curves, after profiling, the height of the wheel step is 40mm from the rough Increase to 56.5mm, inner diameter setting processing value is 371±0.5mm;

[0062] (4) Workpiece spinning: start the switch, the workpiece starts to rotate counterclockwise with the rotating platform at 300r / min, the pressing mechanism presses the workpiece again, and the two side-by-side rotating whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com