On-line compensating method for locus coordinates of moving robot

A technology of running trajectory and compensation method, applied in the direction of manipulator, program-controlled manipulator, manufacturing tool, etc., to achieve the effect of precise processing size and large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

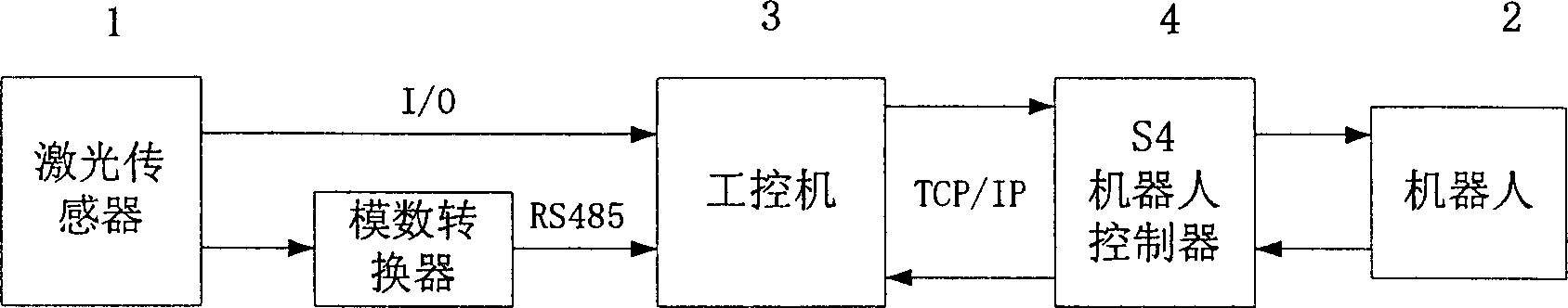

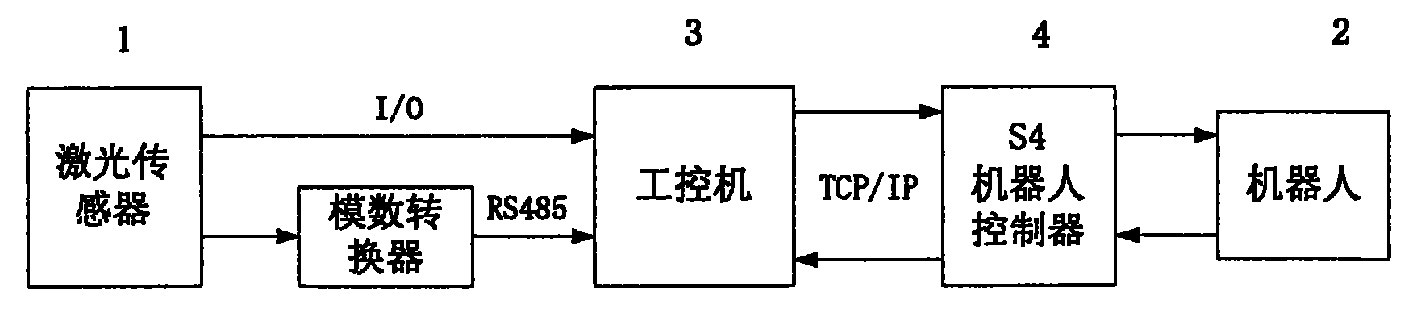

[0011] Such as figure 1 As shown, the sensor 1 is installed at the end of the arm of the robot 2. Before the robot 2 performs the operation, the robot 2 carries the laser sensor 1 to detect the shape of the detected surface of the workpiece, and obtains the voltage analog signal about the shape and position of the section steel, and converts it through A / D The controller is sent to the industrial control computer 3, and the computer 3 performs data processing and calculation, and the computer 3 sends a message request to the robot controller 4, and transmits the coordinate data of the processed graphic elements of the section steel after compensation, and at the same time provides the entry of the basic processing graphic subroutine Assign values to the coordinate variables of the graphics elements, and the computer 3 sets the Boolean variable of the corresponding basic graphics subroutine entry to "1". The robot controller 4 returns the result to the calling process through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com