Method and device for thermal-assisted laser peen forming

An auxiliary laser and shot peening technology, applied in the field of material processing, can solve the problems of reduced absorption layer function, poor temperature resistance of absorption layer, unfavorable energy saving, etc., and achieve surface quality improvement, fatigue resistance and stress corrosion resistance. The effect of improved, good surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

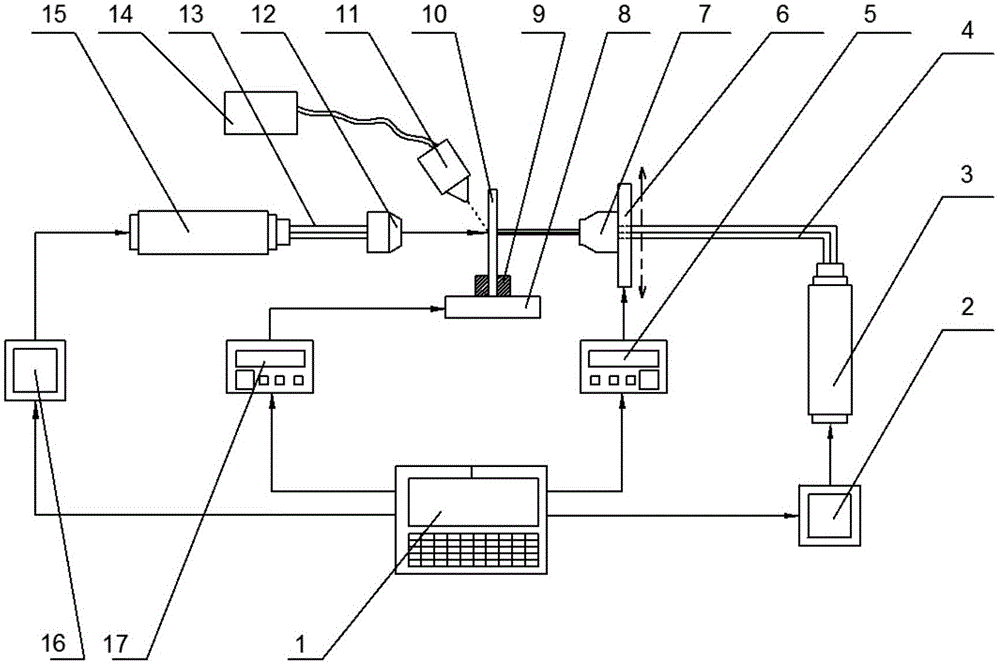

[0050] This embodiment provides a heat-assisted laser shot peening forming method and device. in:

[0051] The heat-assisted laser peening forming method provided by this embodiment includes the following steps: calculating the processing trajectory by computer simulation according to the processing requirements of the processed parts, and calculating the laser peening (peening laser) and local laser thermal assistance (heating laser) The parameters mainly include: spot size, laser energy, scanning speed, scanning track and the relative position of two spots, and the control program of the central control processor is written accordingly. The central control processor controls the two lasers (the shot peening laser and the heating laser) to be turned on simultaneously. The shot peening laser emits high-energy short-pulse laser and irradiates it on the covering layer on the surface of the workpiece through the spot adjustment device. The covering layer absorbs the energy Conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com