Method for making hammer stem for forging equipment

A manufacturing method and technology of forging equipment, which are applied in forging/pressing/hammer devices, manufacturing tools, heat treatment equipment, etc., can solve the problems of difficult control of metallurgical composition, low service life of hammer rods, and poor mechanical properties of steel billets. Easy to quench cracks, not easy to quench cracks, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

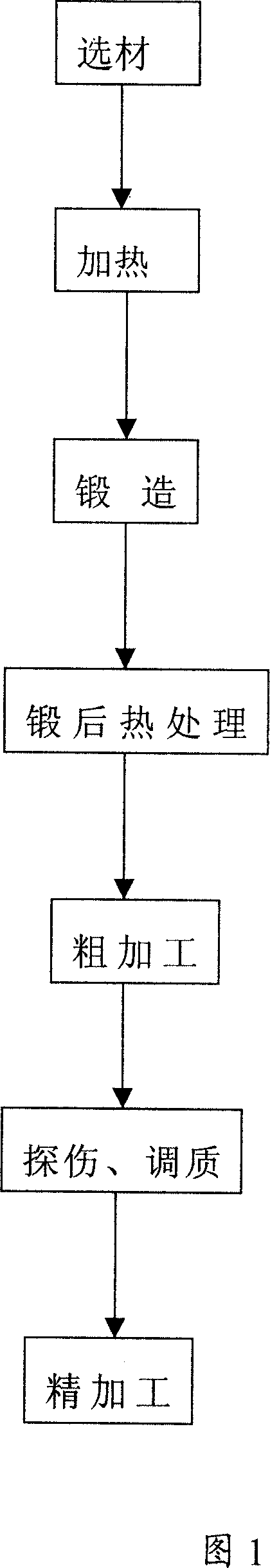

[0022] Taking the manufacture of a 10-ton hammer rod for forging equipment as an example, according to the process shown in Figure 1, the specific manufacturing process is as follows:

[0023] (1) Material selection, steel ingots, rolled materials or forged materials obtained by ladle refining or electroslag remelting process are selected as forging blanks, the utilization rate of steel ingots should reach 75% to 77%, the forging ratio of rolled materials and forged materials It should be ≥5, and its ultrasonic flaw detection defect equivalent should be ≤φ2. The principle of material selection is to make the optimal choice according to the above requirements under the guidance of the design department, according to the tonnage of the equipment and the characteristics of the process operation, with due consideration of the manufacturing quality and cost.

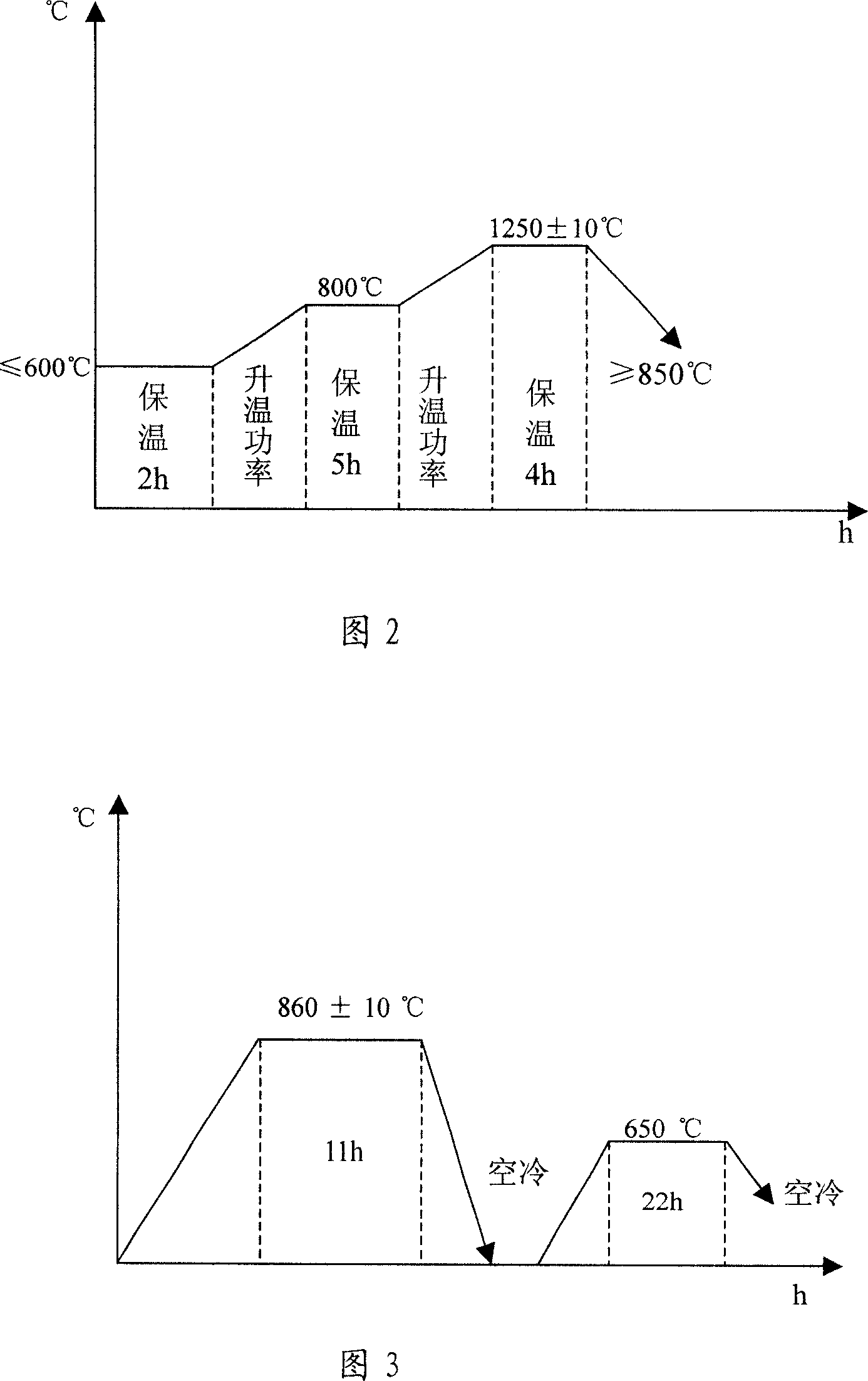

[0024] (2) Heating, put the forging blank into the furnace when the furnace temperature is ≤600°C, carry out the first stag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com