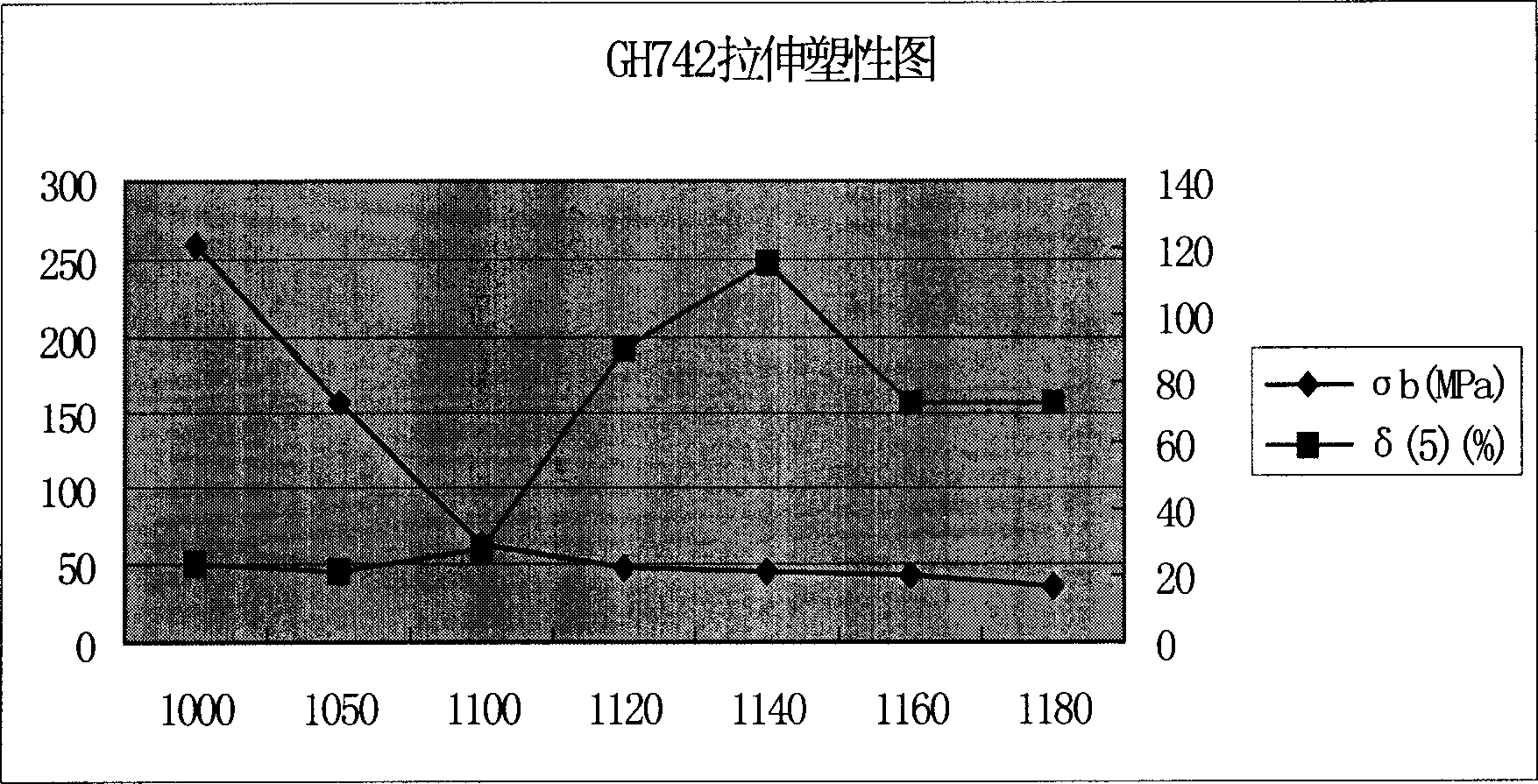

Heat keeping and forging and blank cogging method for GH742 alloy large steel ingot

A technology for alloy ingots and ingots, applied in metal processing equipment and other directions, can solve the problems of long production time, narrow plastic deformation temperature, and limited shape of alloy billets, so as to increase the plastic deformation time, slow down the temperature drop rate, and reduce heat loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

[0030] A steel company implements the patent of the invention, and hot-forges the vacuum self-consumption remelting ingot of multi-furnace GH742 superalloy (ingot size: φ165~φ600, taking φ508mm as an example) on a forging press (4000 tons, hydraulic pressure) Billets, forging alloy billets of finished product specifications (finished product specifications φ360mm, φ200mm, φ130mm, taking φ360mm as an example): first, select specific binders and specific non-metallic insulation materials for the insulation of GH742 alloy large steel ingots Coating; the specific binder is a high-temperature binder, and commercially available glass powder with a softening point temperature above 800°C can be used. The non-metallic insulation material is thermal insulation asbestos, and commercially available thermal insulation asbestos blankets with aluminum silicate fibers can be used; Second, use a specific binder to bond and wrap a specific non-metallic ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com