Patents

Literature

91results about How to "Avoid fretting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

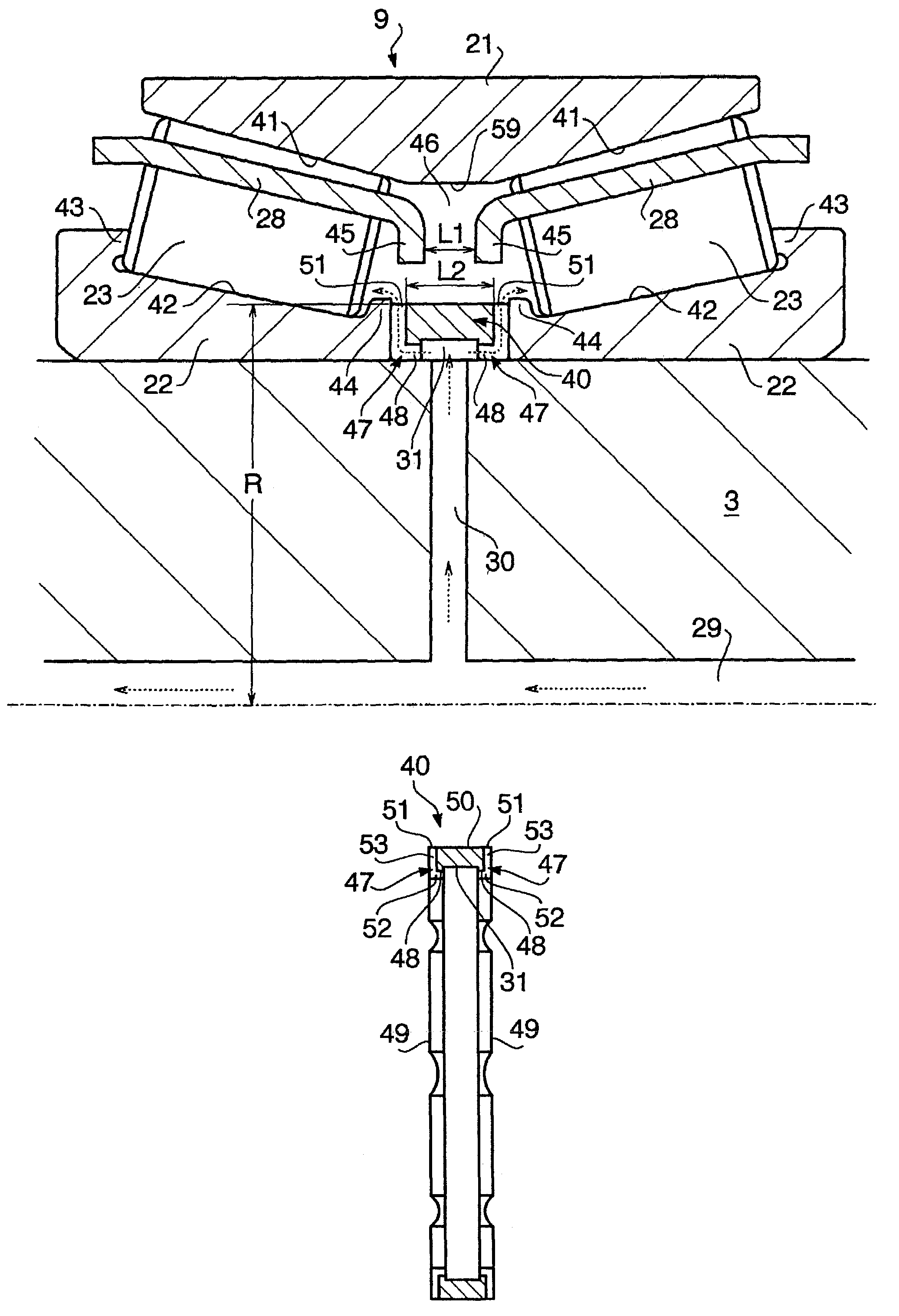

Roller bearing oil feed device

A roller bearing oil feed device includes a plurality of rolling elements arranged in a plurality of rows in the axial direction between an outer ring and an inner ring, the inner ring being divided for each row of the rolling elements and a ring-shaped spacer being interposed at the position of this division, the inner rings and spacer being fitted onto a rotary shaft. A circumferential groove is provided in the inner peripheral section of the spacer and oil feed holes communicating with the circumferential groove are provided in the rotary shaft. An oil feed passage having an inlet opening into the circumferential groove and an outlet opening to a corner on at least one side in the axial direction of the spacer is provided in the spacer.

Owner:ISUZU MOTORS LTD +1

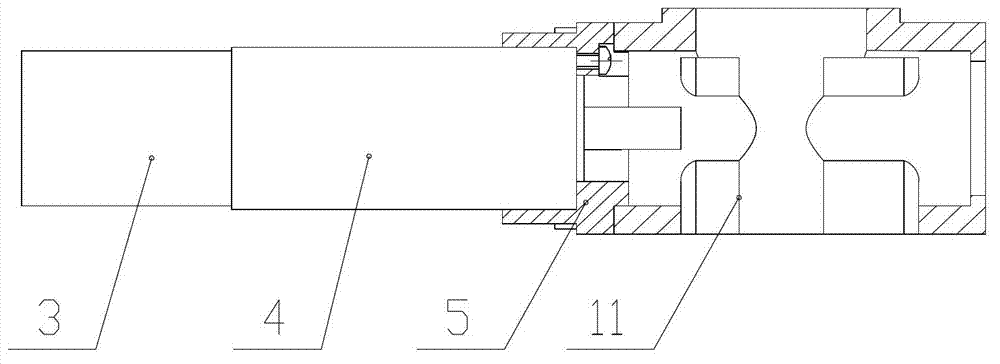

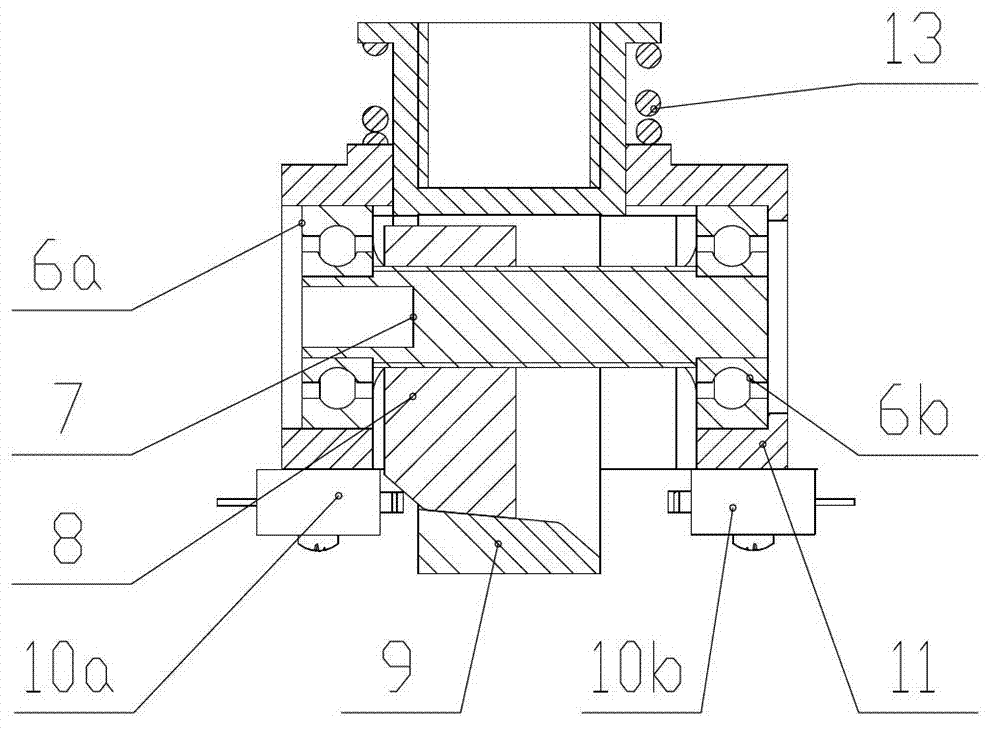

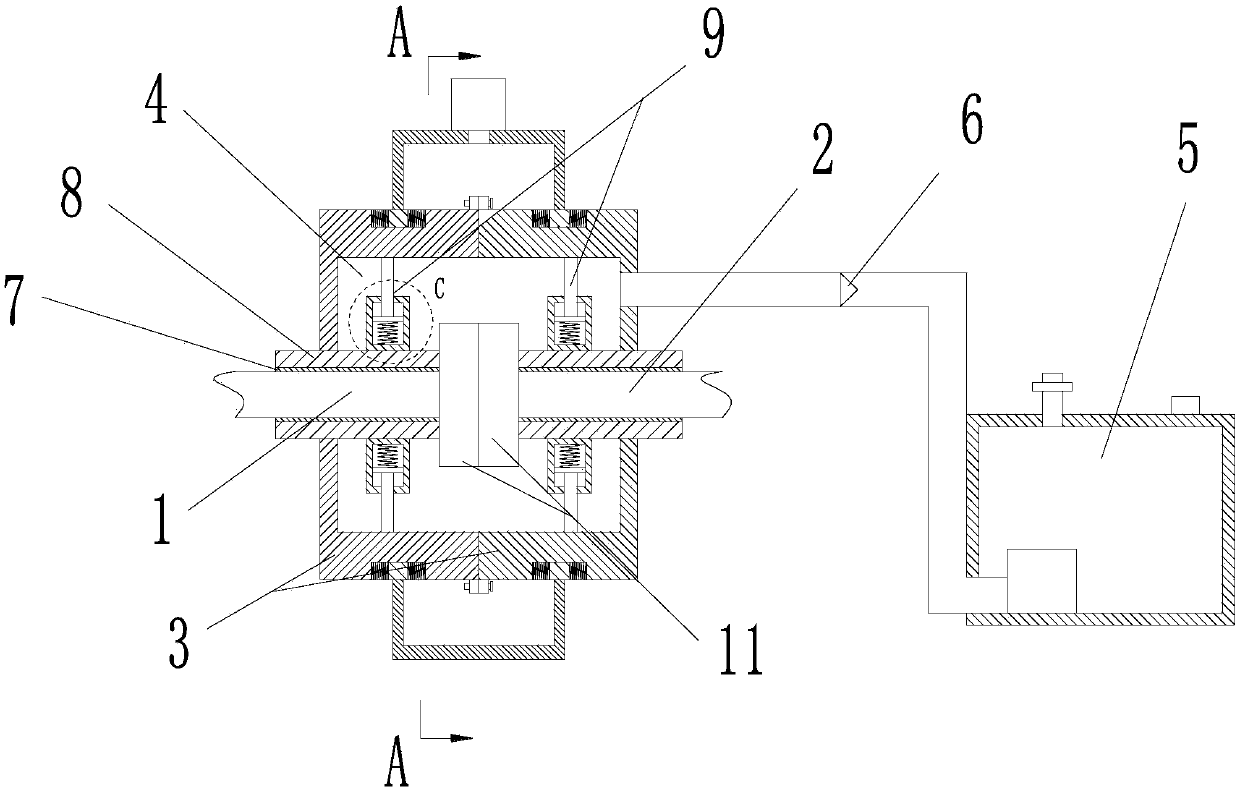

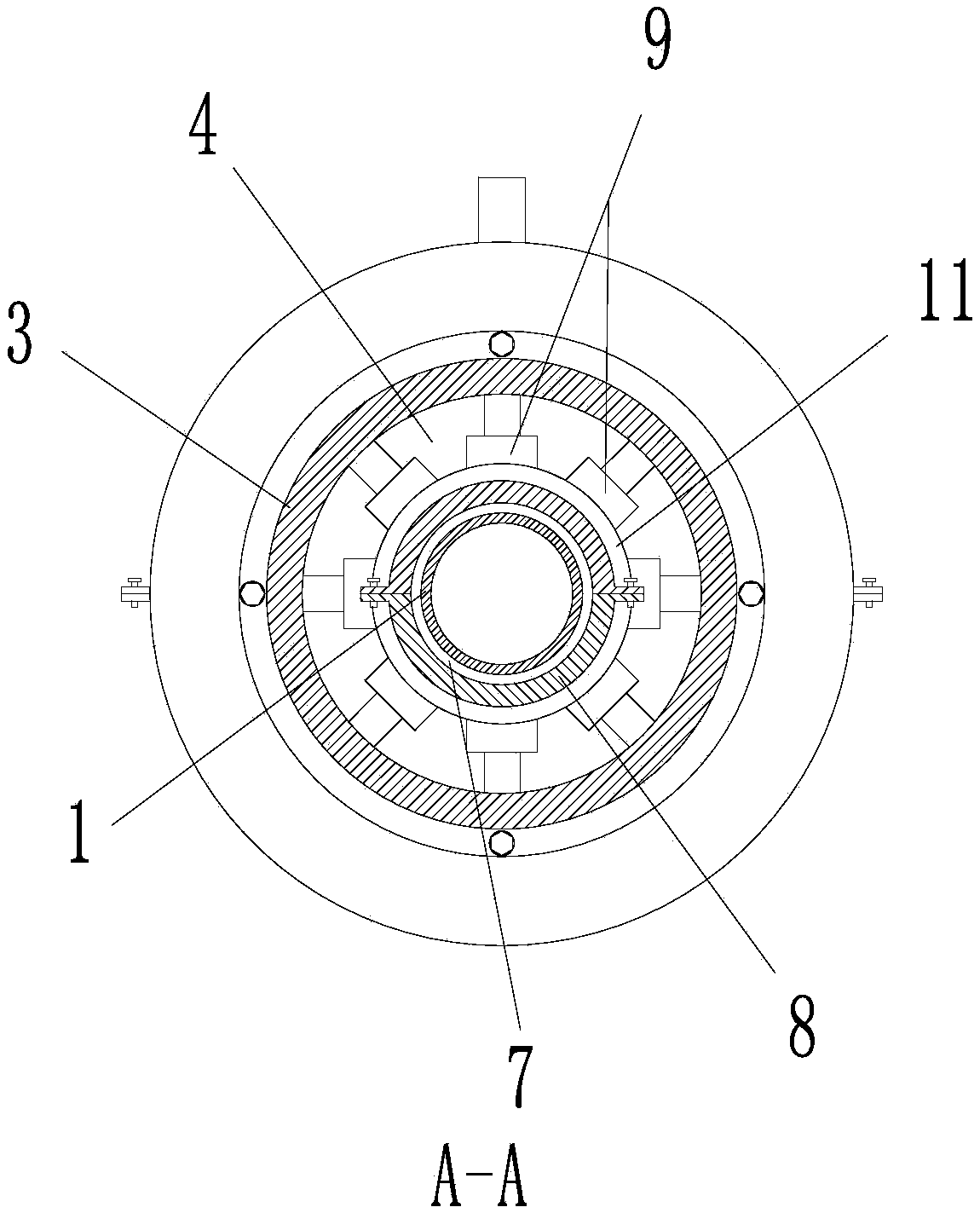

Repeatable locking device for magnetically levitated flywheel

InactiveCN102826237ARealize repeatable locking functionReduce volumeSpacecraft guiding apparatusFreewheelReusability

The invention discloses a repeatable inner locking device for a magnetically levitated flywheel; the device mainly comprises a flywheel system, a locking transmission mechanism and a locking maintaining mechanism; the flywheel system mainly comprises a flywheel rotor and a flywheel stator shaft; the locking transmission mechanism mainly comprises a motor, a gearbox, a left bearing compression ring, a left bearing, a right bearing and a lead screw; the locking maintaining mechanism mainly comprises a lock head, a lock sleeve, a micro switch, a fixed seat, a damping washer, a reset spring, a position adjusting stud, a locking gland and a buffer rubber pad; according to the repeatable inner locking device for the magnetically levitated flywheel, the repeatable inner locking device is arranged in the center of the flywheel rotor, and is fixedly arranged on the flywheel stator shaft through a fastening screw; and the inner locking device protects the magnetically levitated flywheel system, and has the advantages of reusability, high reliability, small size, light weight, simple structure and the like.

Owner:ZHENGZHOU UNIV

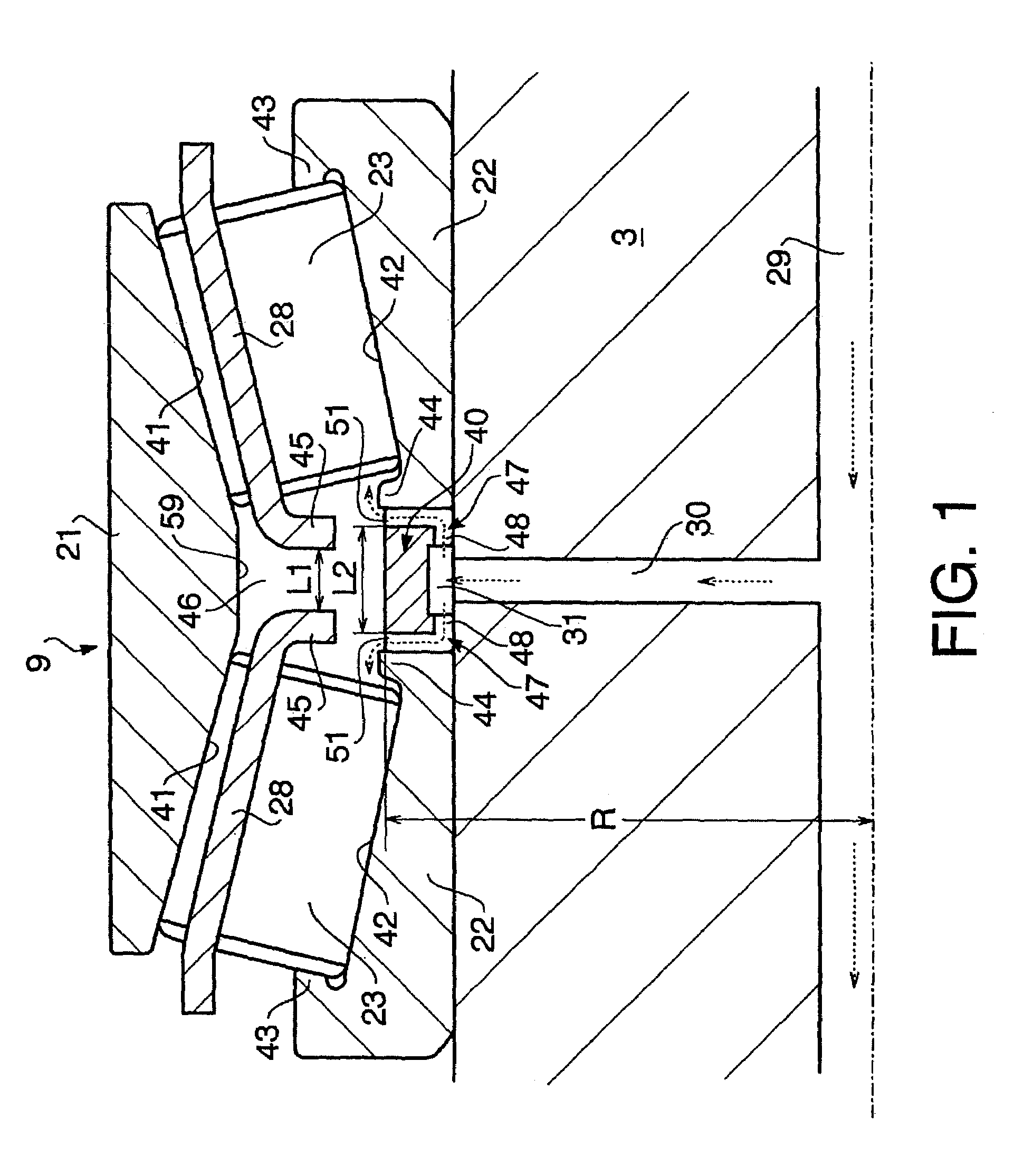

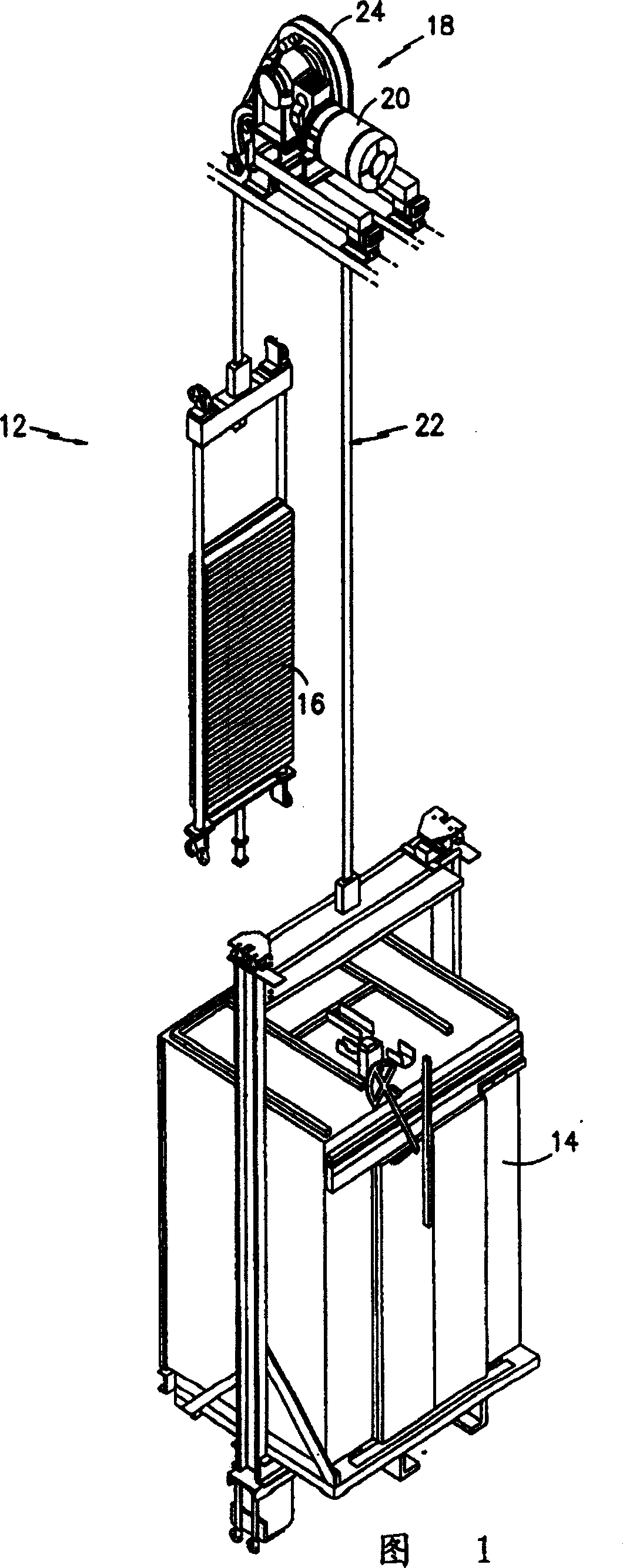

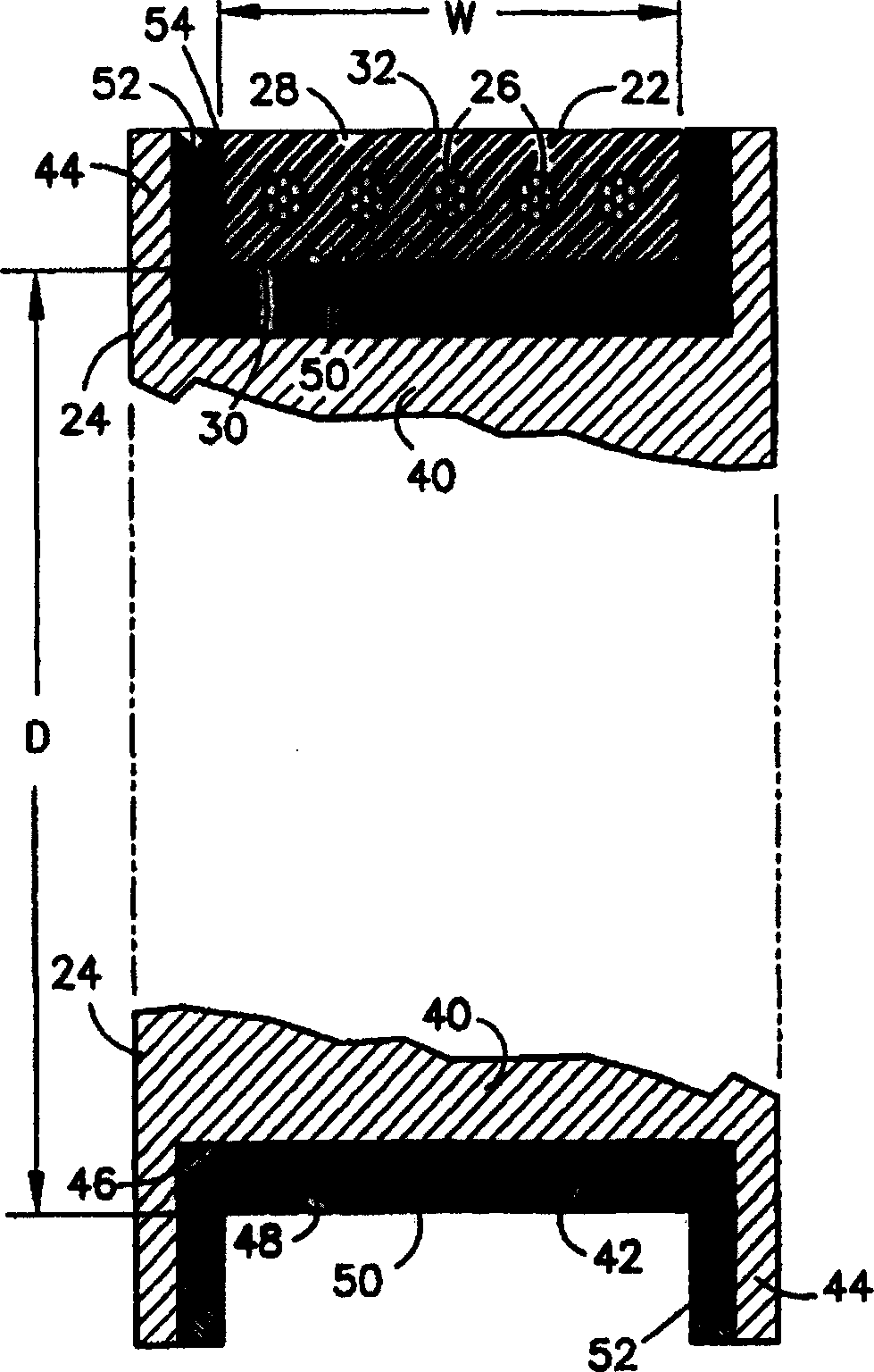

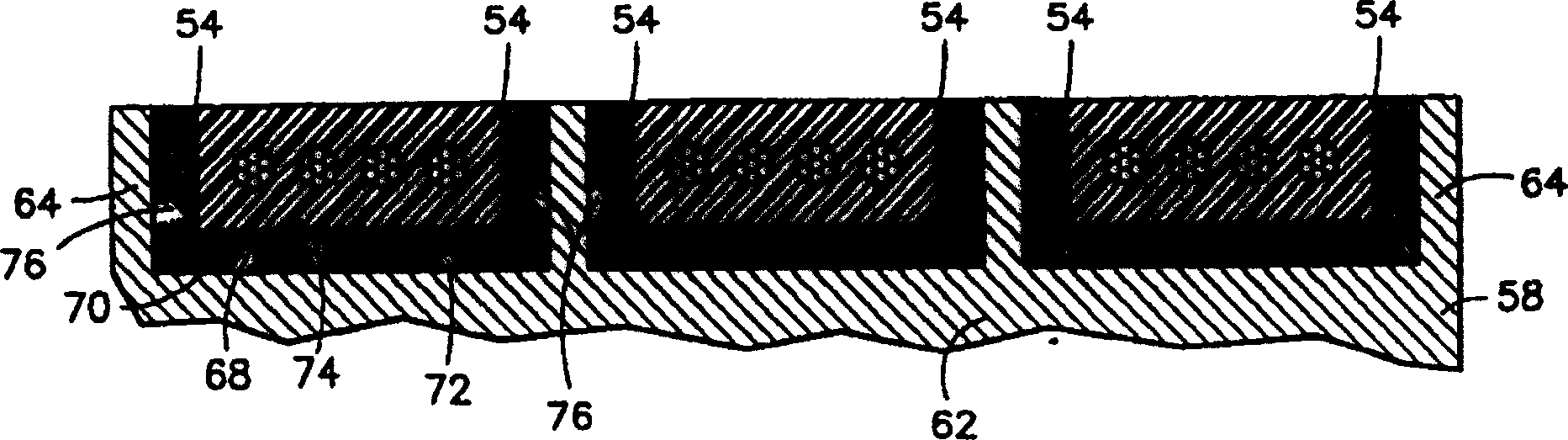

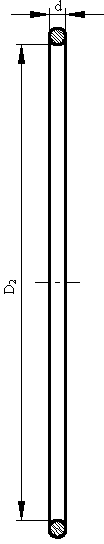

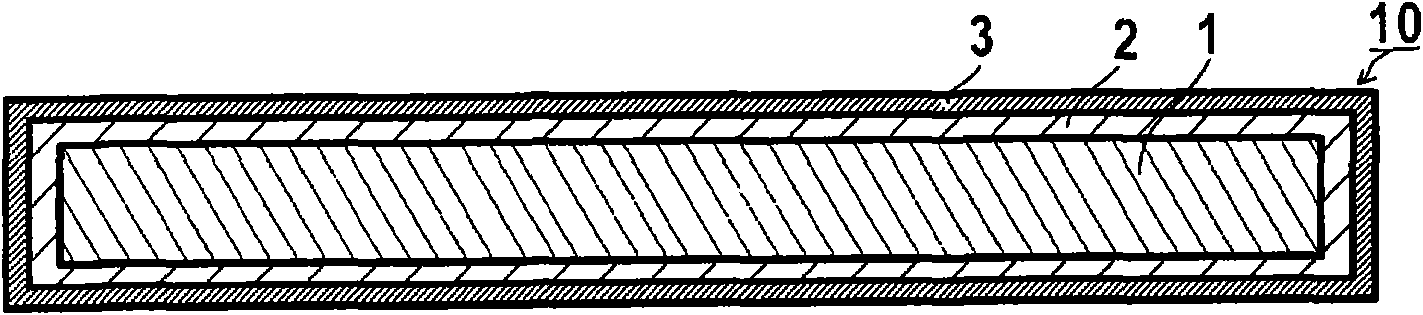

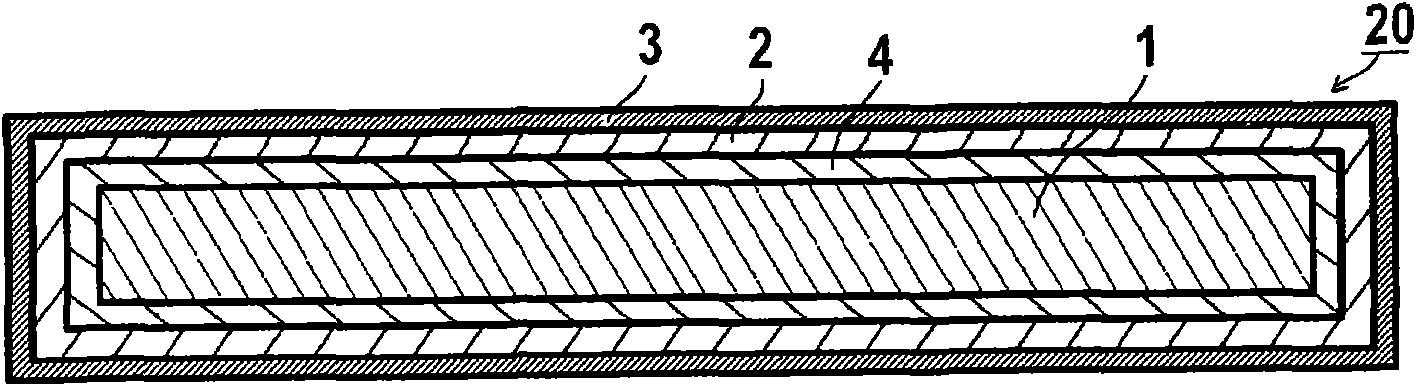

Tension member for elevator

InactiveCN1222656CPressure can be evenly distributedLow priceElevatorsDomestic articlesElevator systemMetallic materials

A tension member (22) for an elevator system (12) has an aspect ratio of greater than one, where aspect ratio is defined as the ratio of tension member width w to thickness t (w / t). The increase in aspect ratio results in a reduction in the maximum rope pressure and an increased flexibility as compared to conventional elevator ropes. As a result, smaller sheaves may be used with this type of tension member (22). In a particular embodiment, the tension member includes a plurality of individual load carrying ropes (26), formed from metallic material encased within a common layer of coating. The coating layer (28) separates the individual ropes (26) and defines an engagement surface for engaging a traction sheave (24).

Owner:OTIS ELEVATOR CO

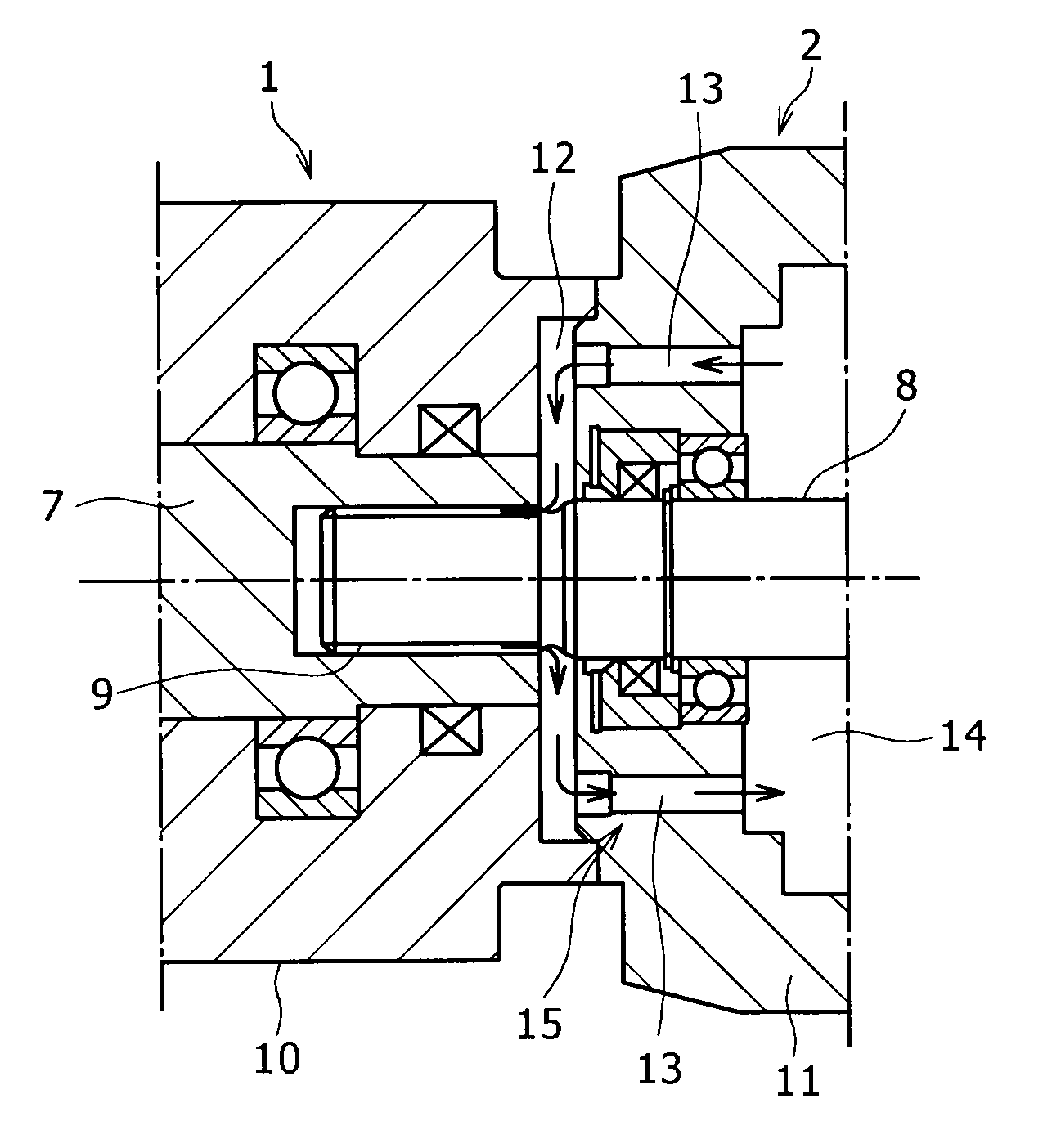

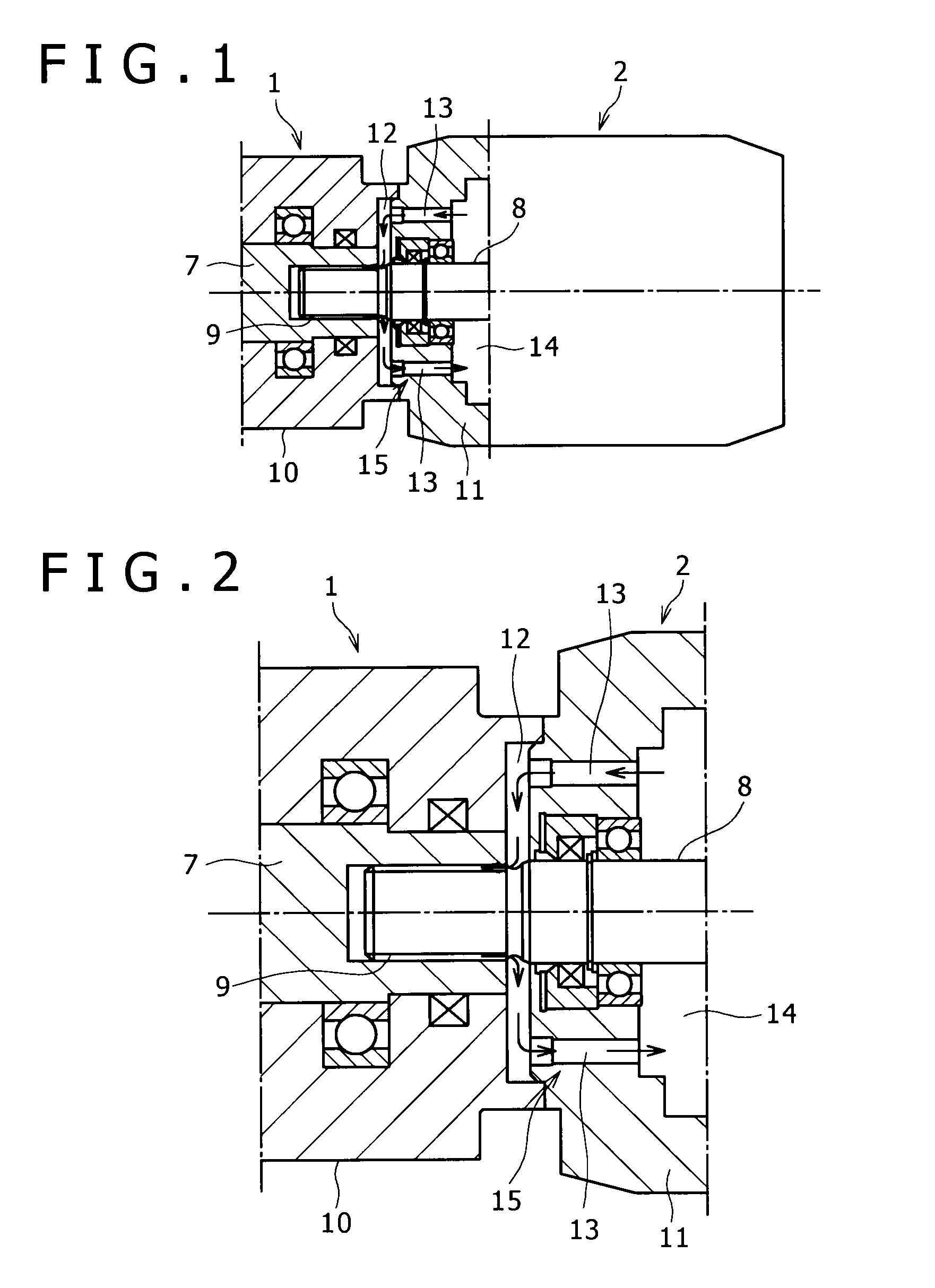

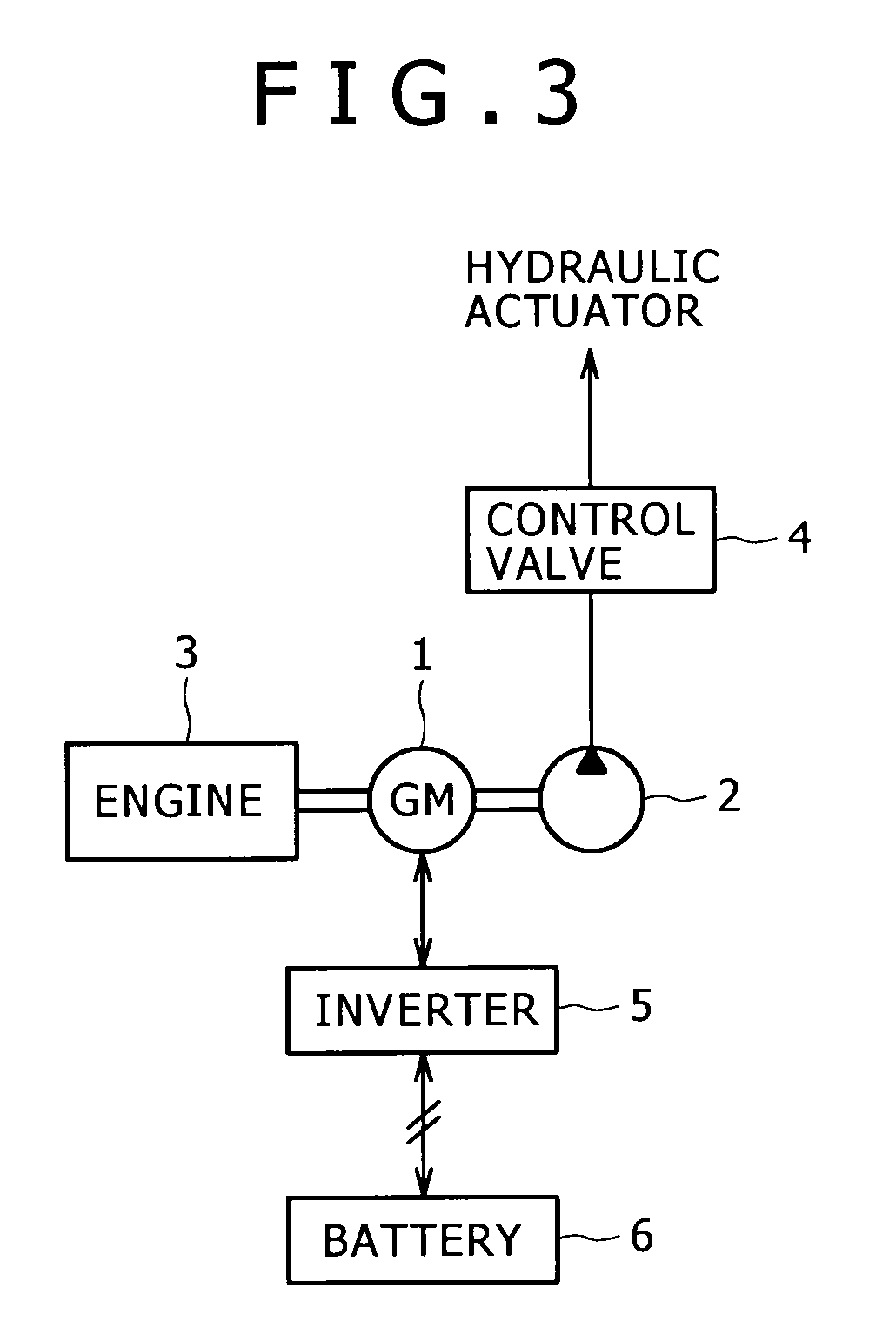

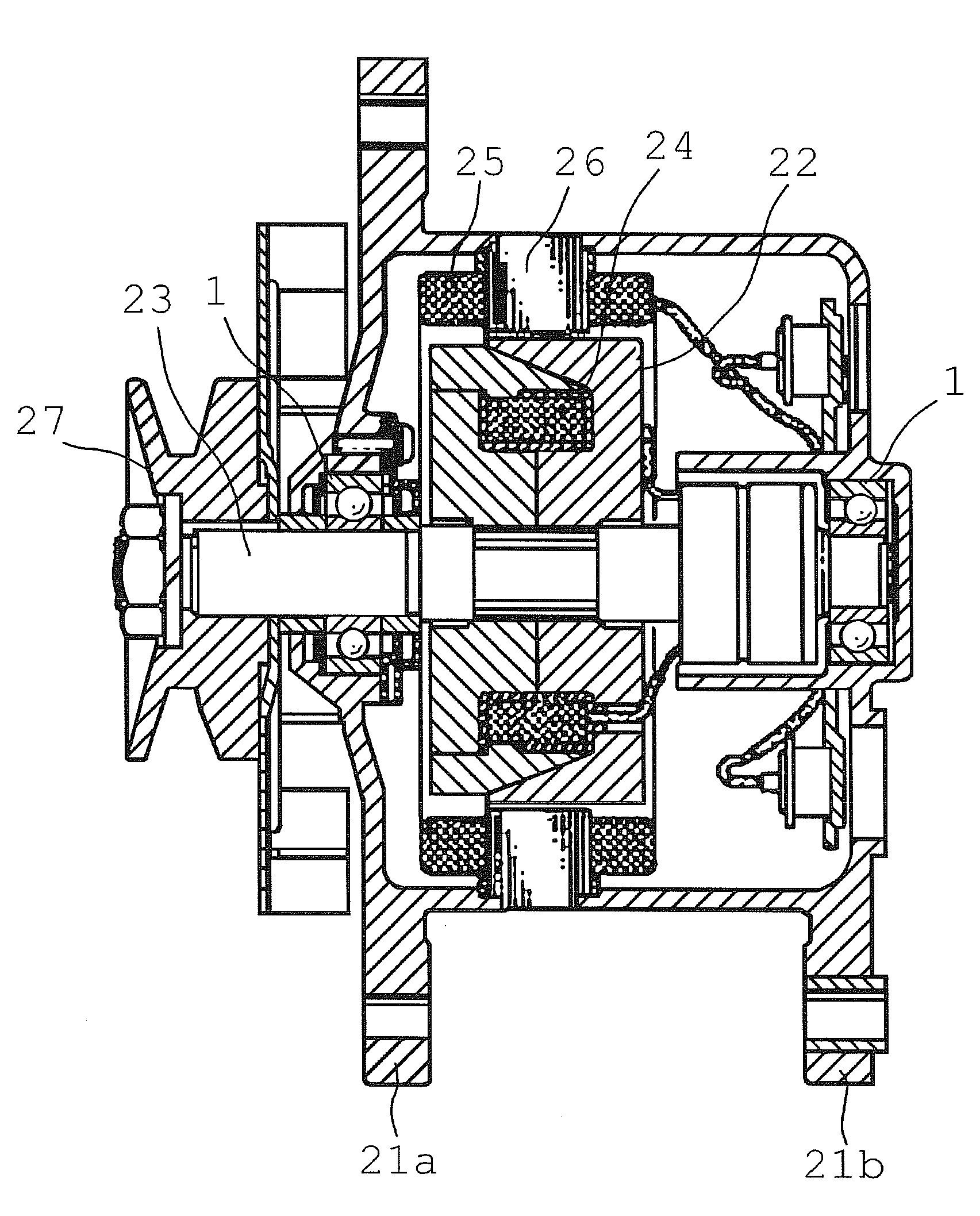

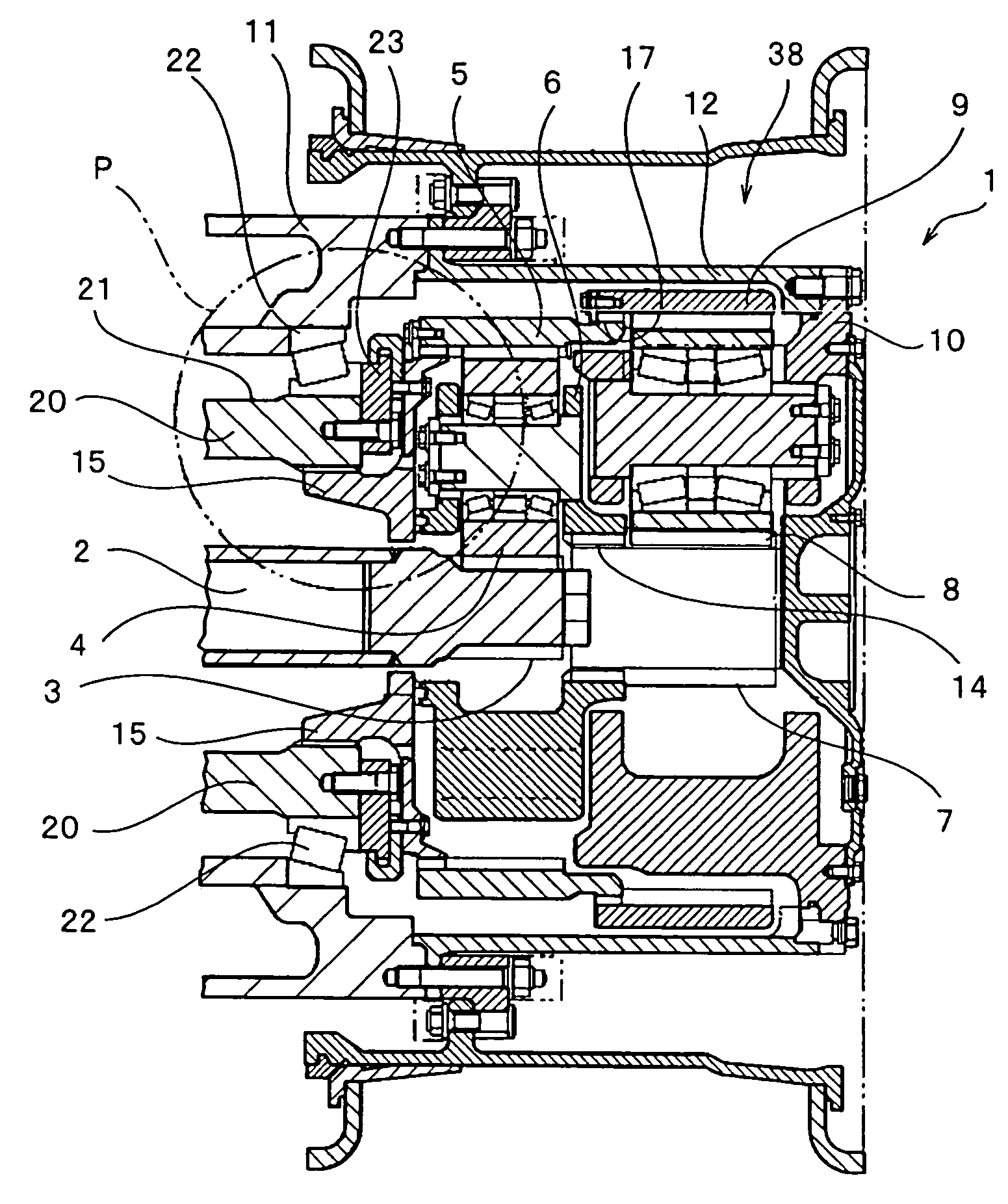

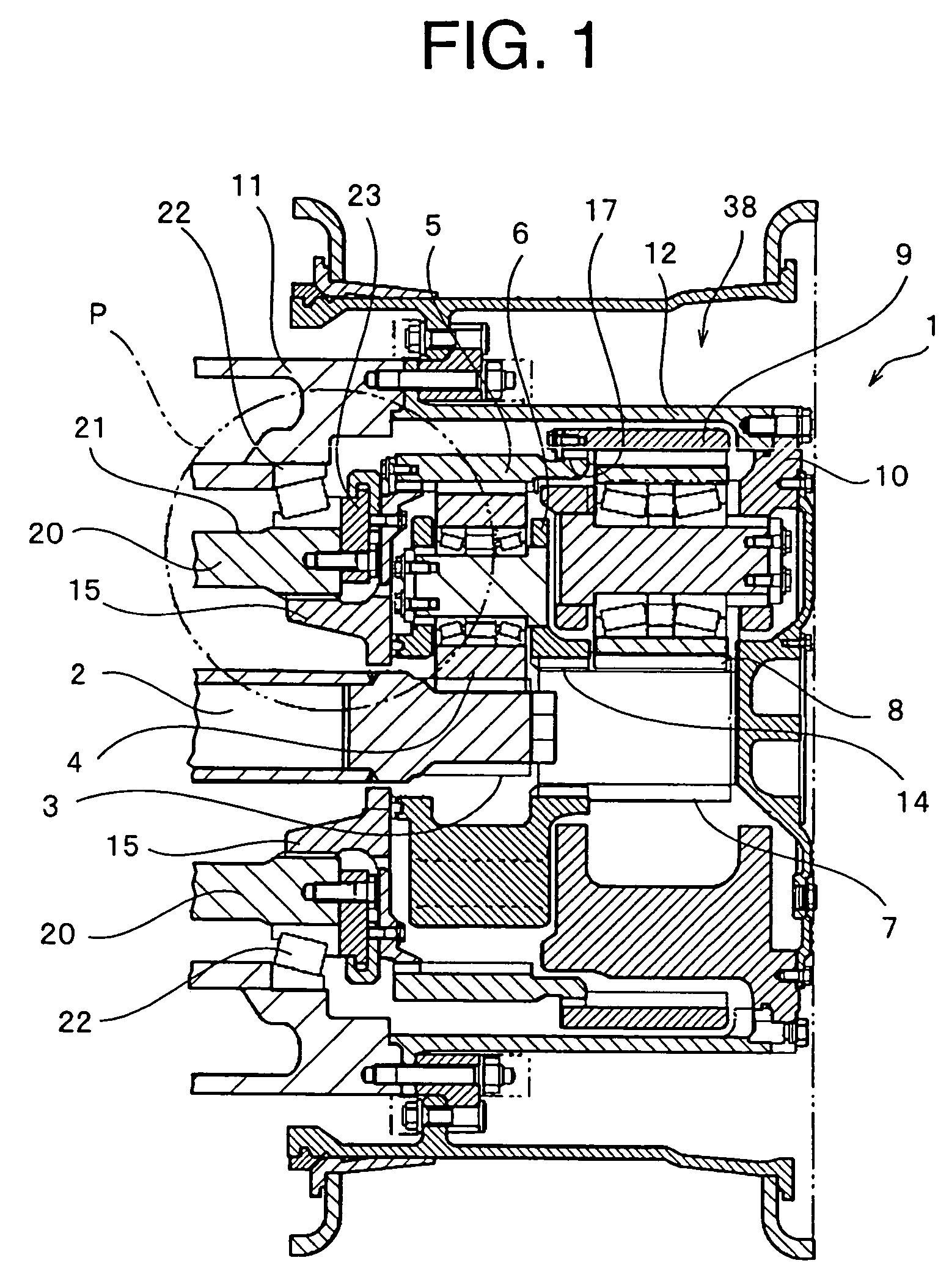

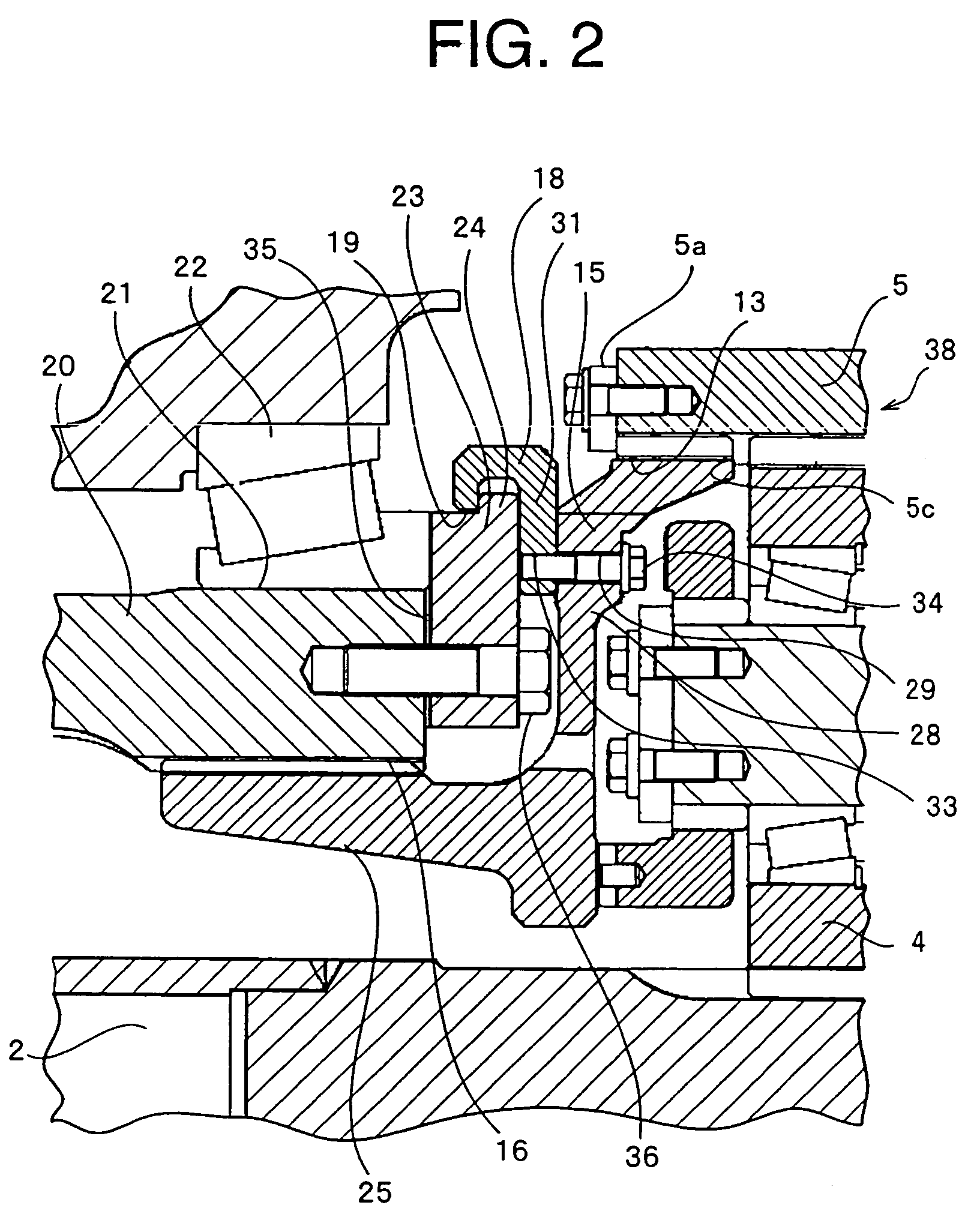

Hybrid working machine

ActiveUS20100193296A1Improve reliabilityInhibit wearClutchesGear lubrication/coolingCouplingHydraulic pump

As lubricating construction for a spline coupling portion for connecting a rotating shaft of a generator-motor and a rotating shaft of a hydraulic pump both actuated by an engine, a lubricating oil chamber communicating with the spline coupling portion is formed within a motor casing of the generator-motor, while in a pump casing of the hydraulic pump there is formed an oil passing hole providing communication between the lubricating oil chamber and an oil chamber in the hydraulic pump on an outer periphery side of the rotating shaft of the hydraulic pump, thereby forming an oil passage for allowing working oil present within the hydraulic pump to circulate through a route including the spline coupling portion.

Owner:KOBELCO CONSTR MASCH CO LTD

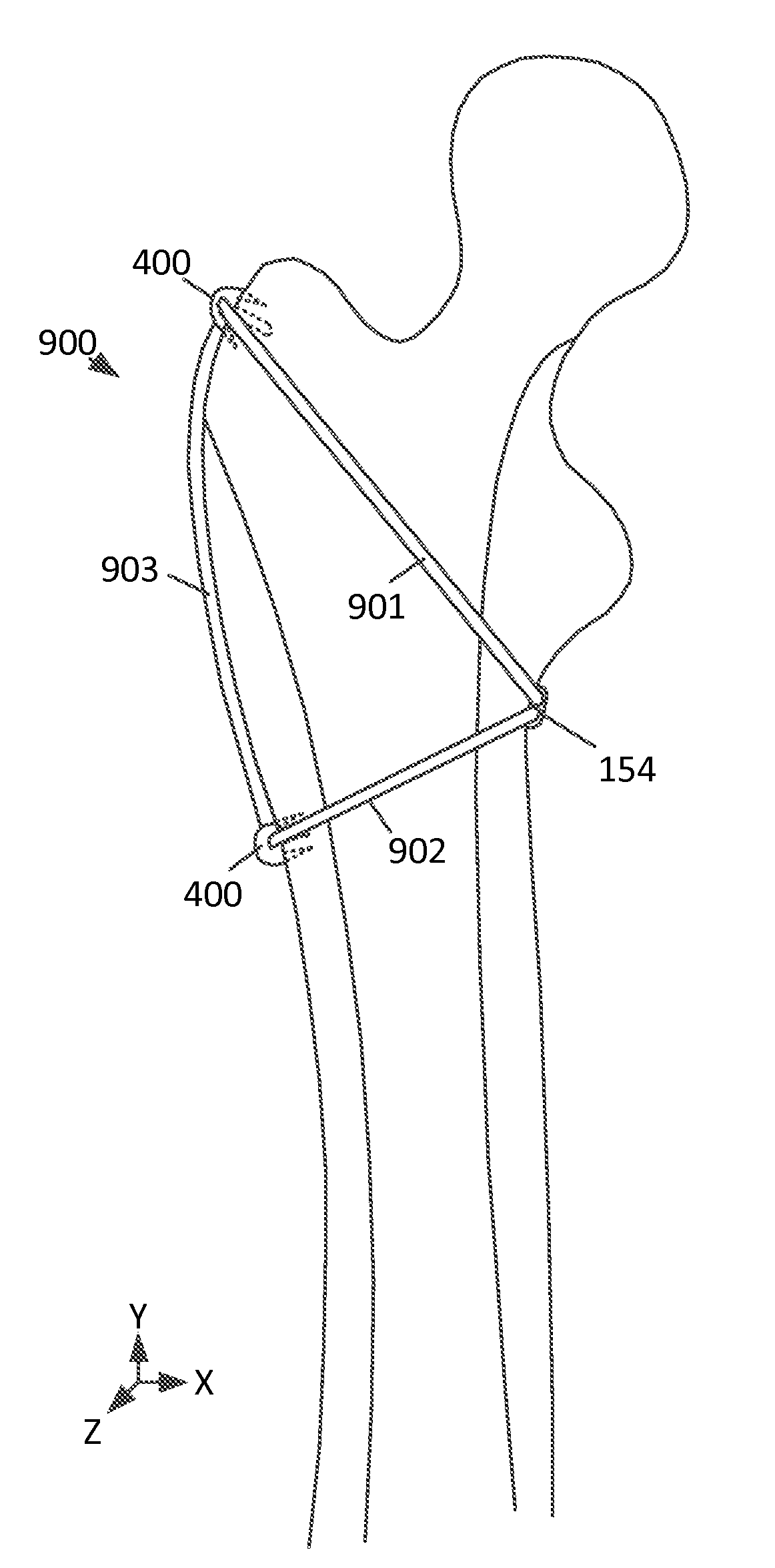

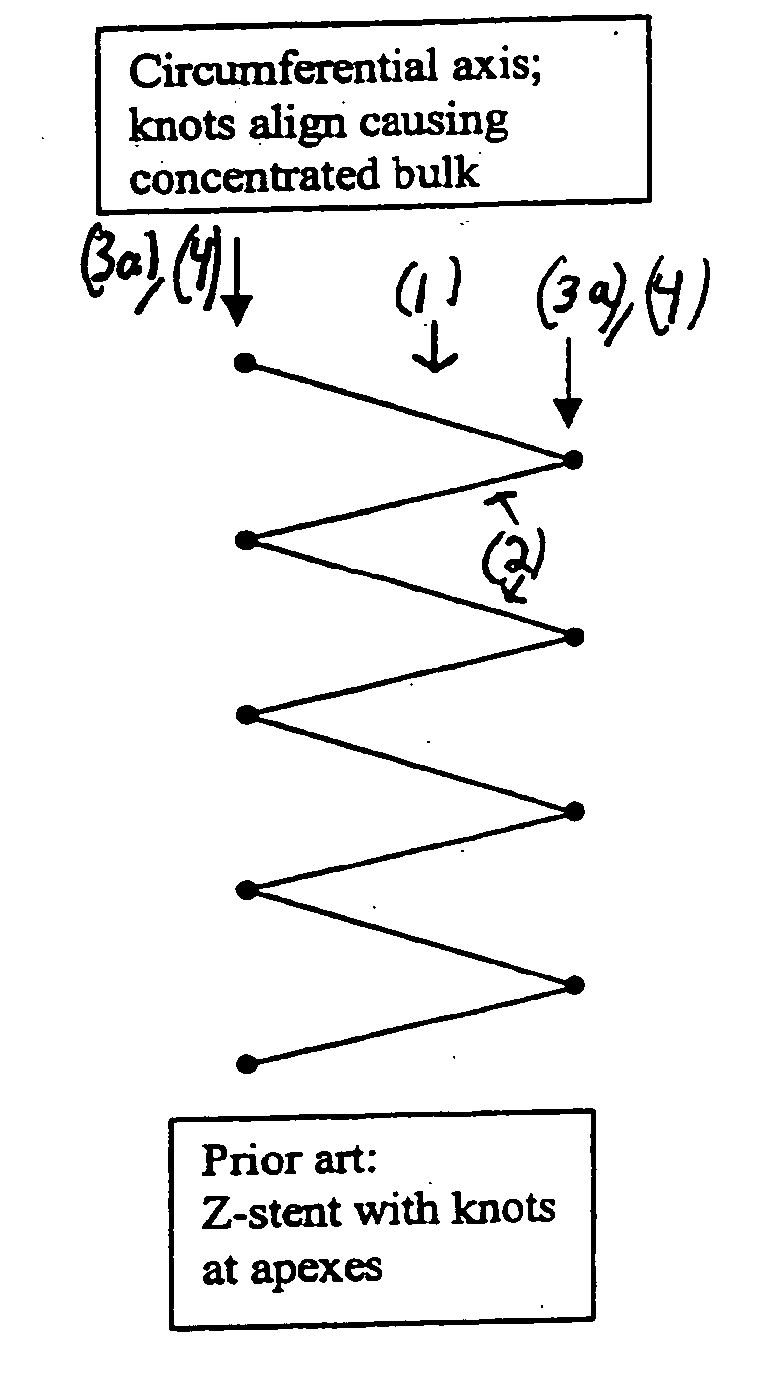

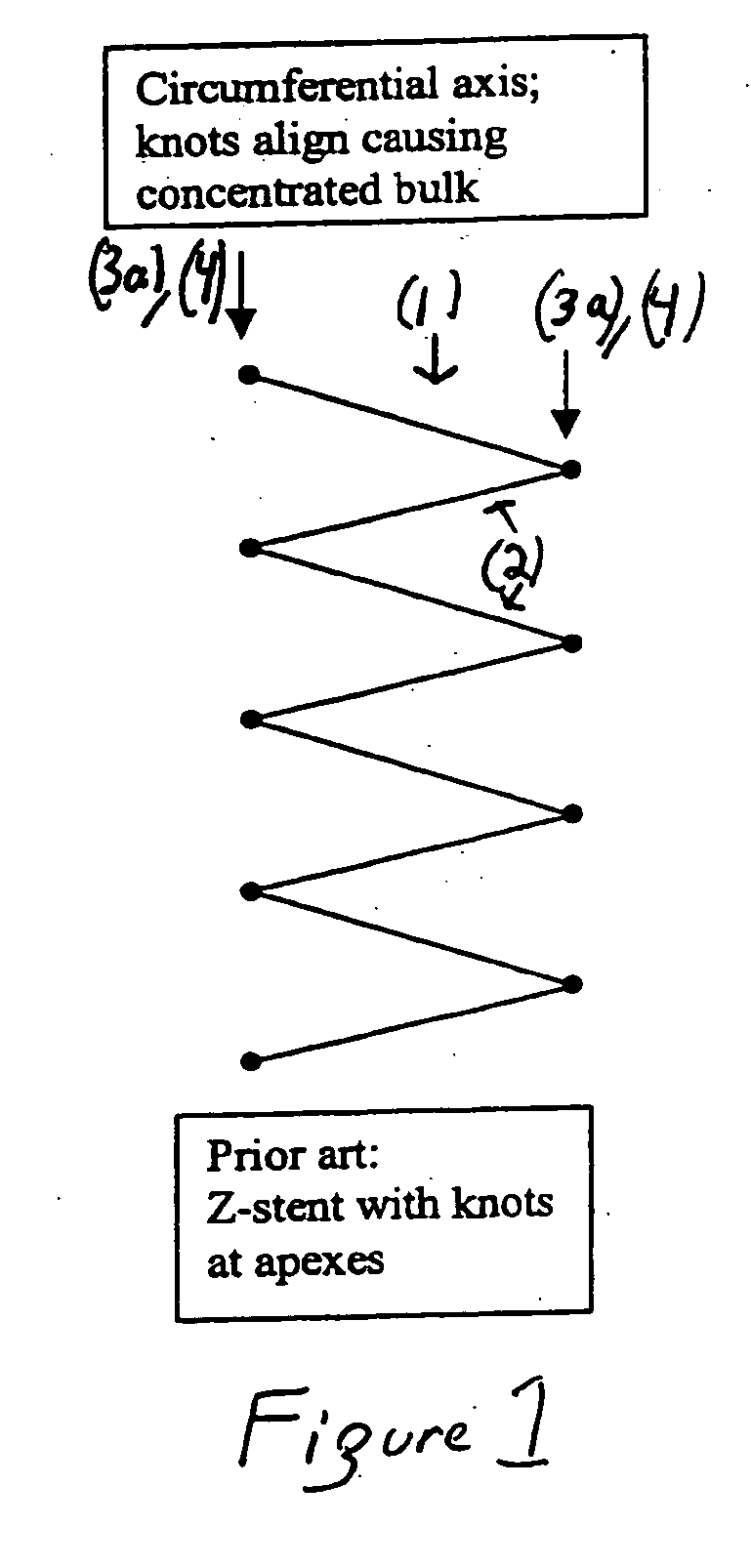

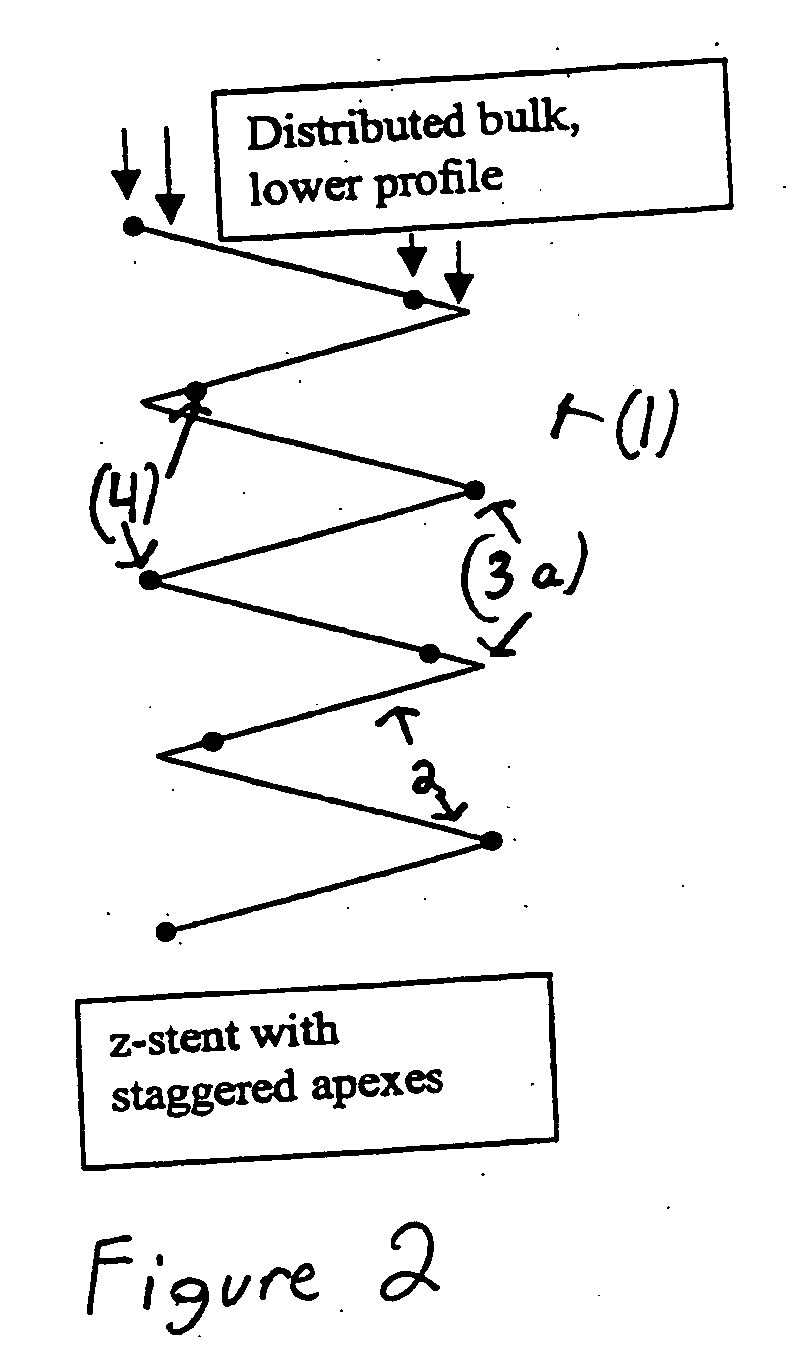

Stent graft device

A stent graft device for implanting in a body lumen, comprising a stent with non-staggered or staggered apexes, said stent comprising a plurality of stent sections, bendable connecting members forming said non-staggered or staggered apexes and connecting each of said stent sections to other stent sections to form a zigzag pattern, wherein said stent is staggerdly sutured to a graft by a plurality of suture knots, and wherein said suture knots and staggered apexes are staggered when said stent sections are crimped, and methods of use thereof.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

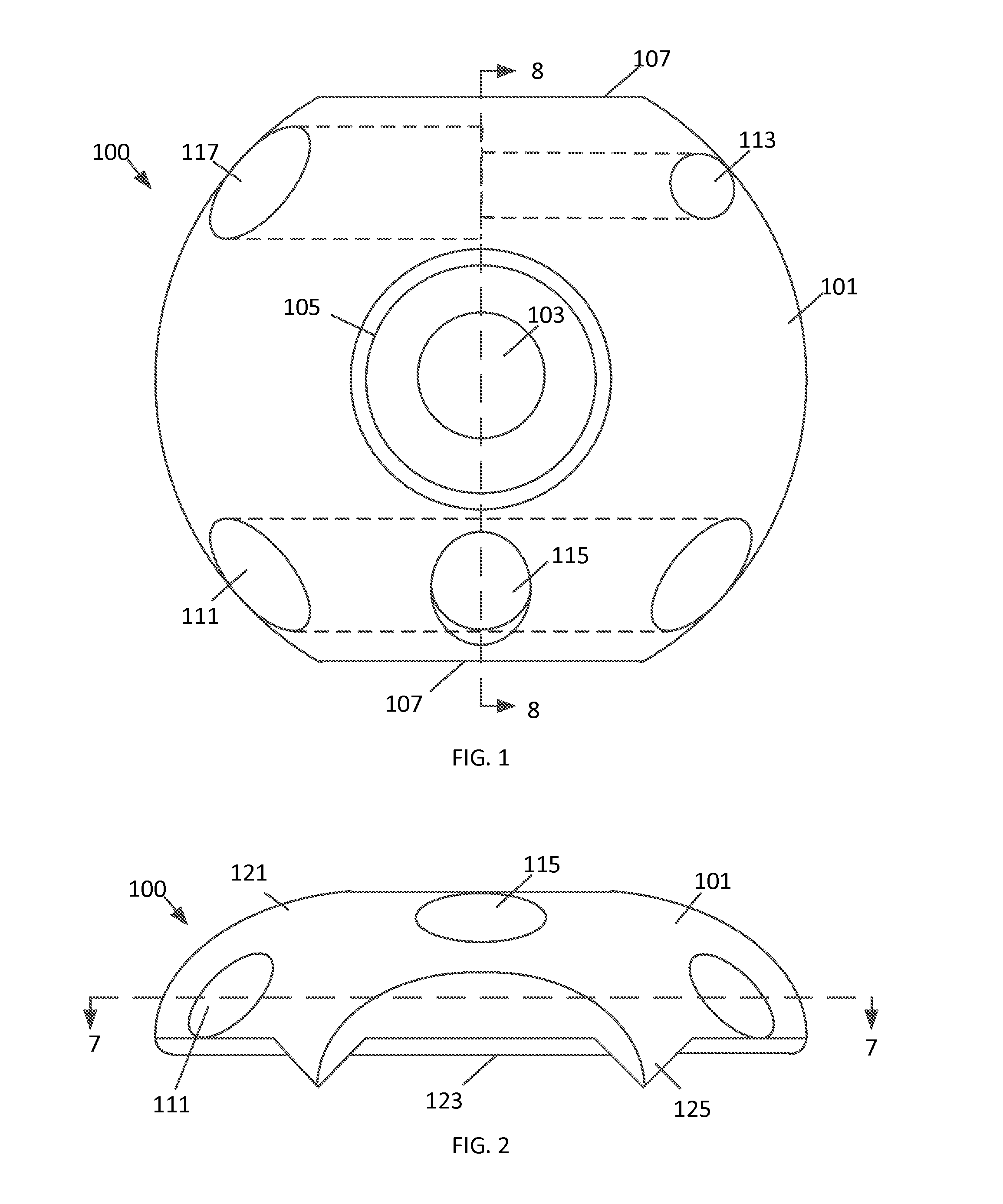

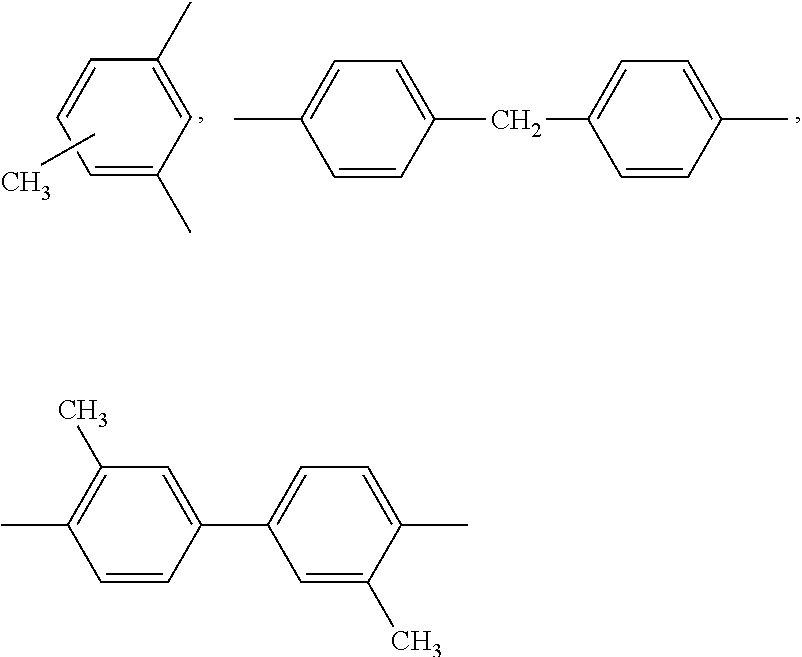

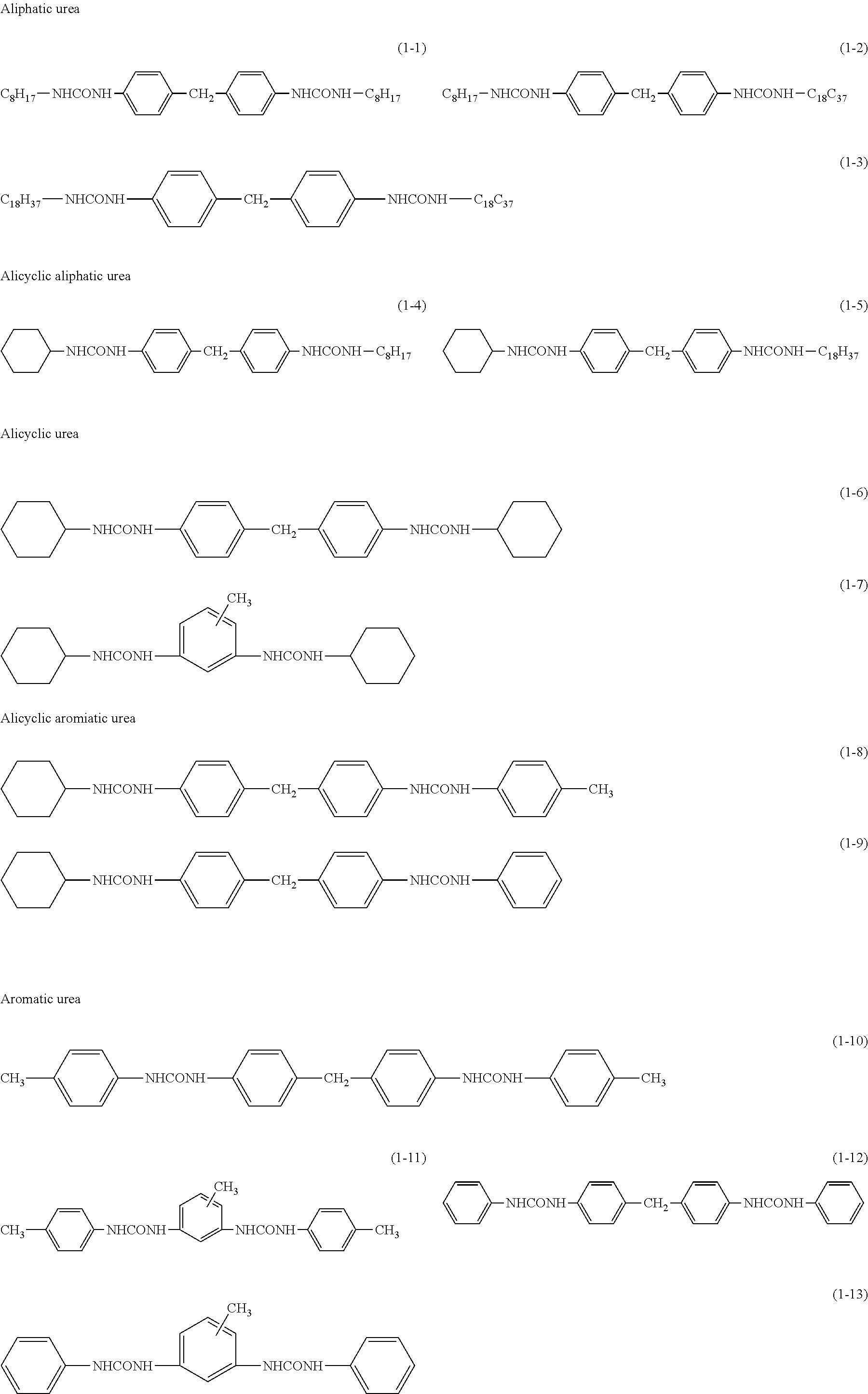

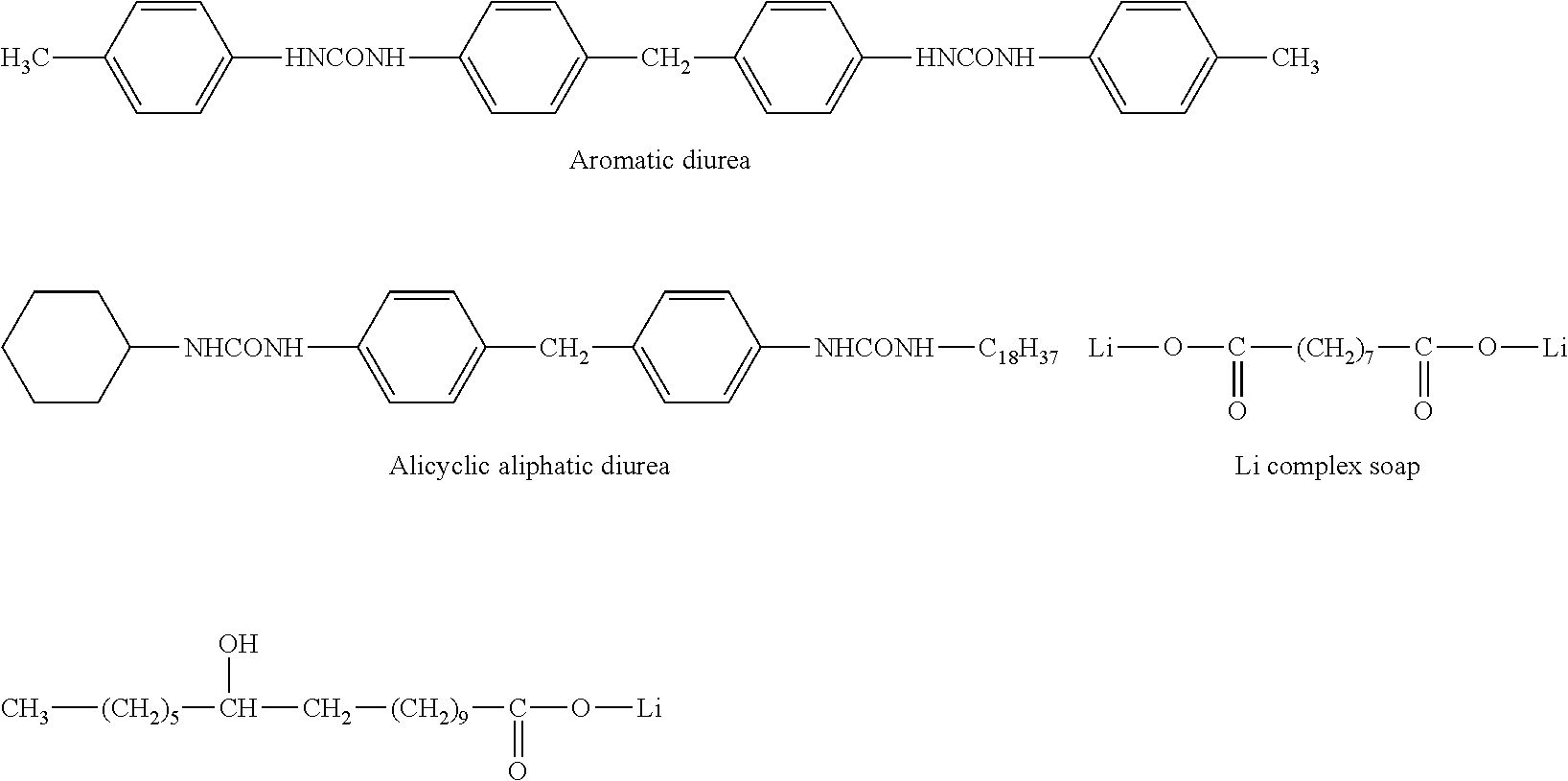

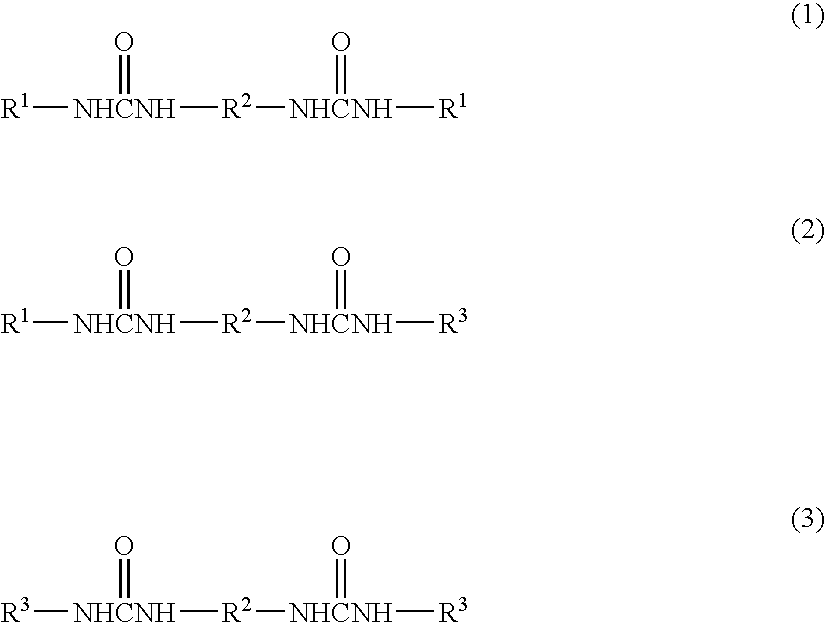

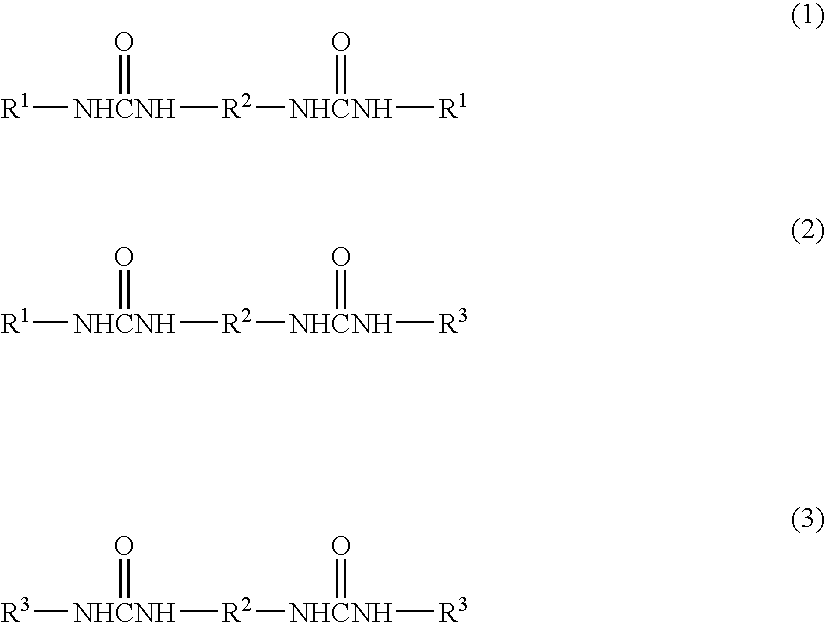

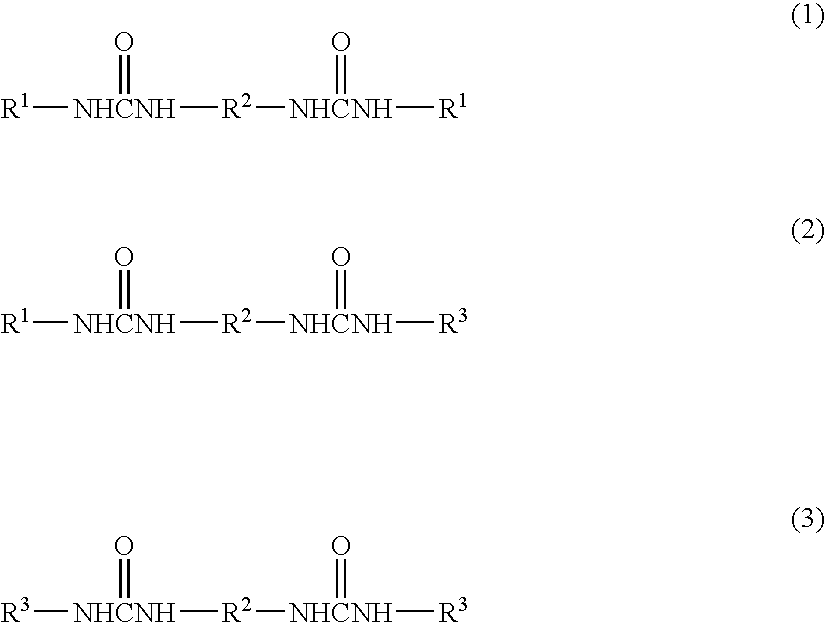

Grease composition

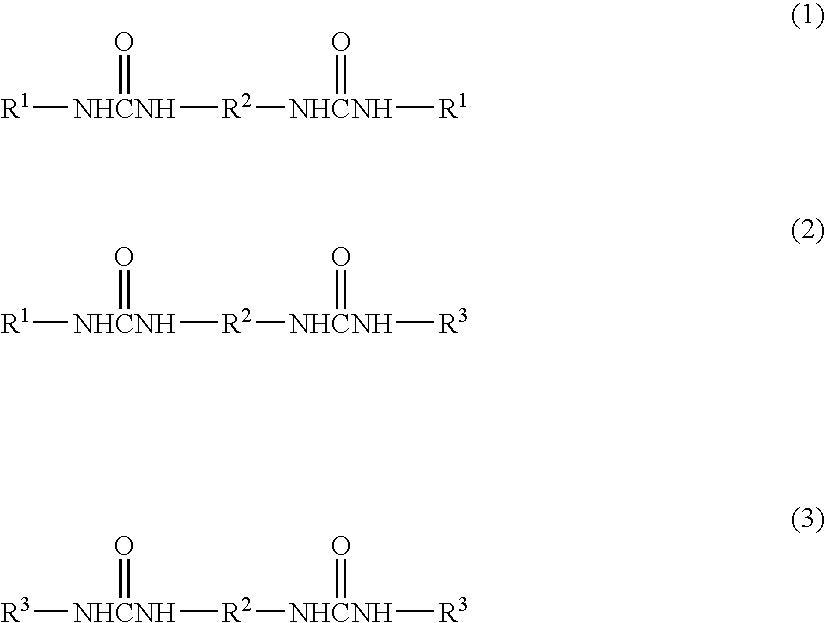

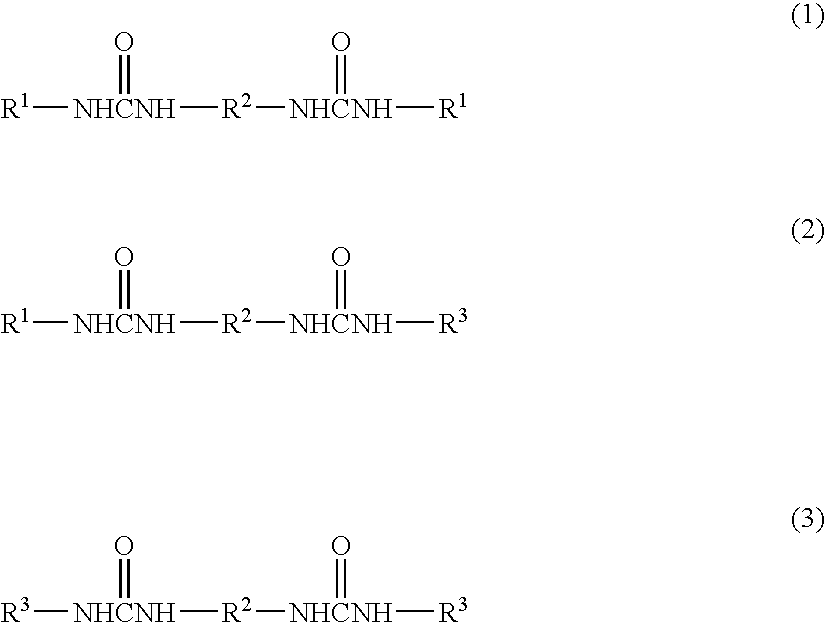

A grease composition containing a lubricant base oil, diurea compounds represented by the following general formulas (1) to (3), and at least one species selected from the group consisting of paraffin oxides and phosphorus compounds; wherein respective contents of the diurea compounds represented by the following general formulas (1) to (3) satisfy conditions defined by the following expressions (4) and (5); and wherein the total content of the paraffin oxides and phosphorus compounds is 0.1 to 15 mass % based on the total amount of the grease composition: where R1 is a hydrocarbon group containing an aromatic ring, R2 is a divalent hydrocarbon group, and R3 is a hydrocarbon group containing an aliphatic ring; 5≦W1+W2+W3≦30 (4) 0.3≦(W1+0.5×W2) / (W1+W2+W3)≦0.7 (5) where W1, W2, and W3 are respective contents (mass %) of the diurea compounds represented by general formulas (1) to (3) based on the total amount of the grease composition.

Owner:NIPPON OIL CORP

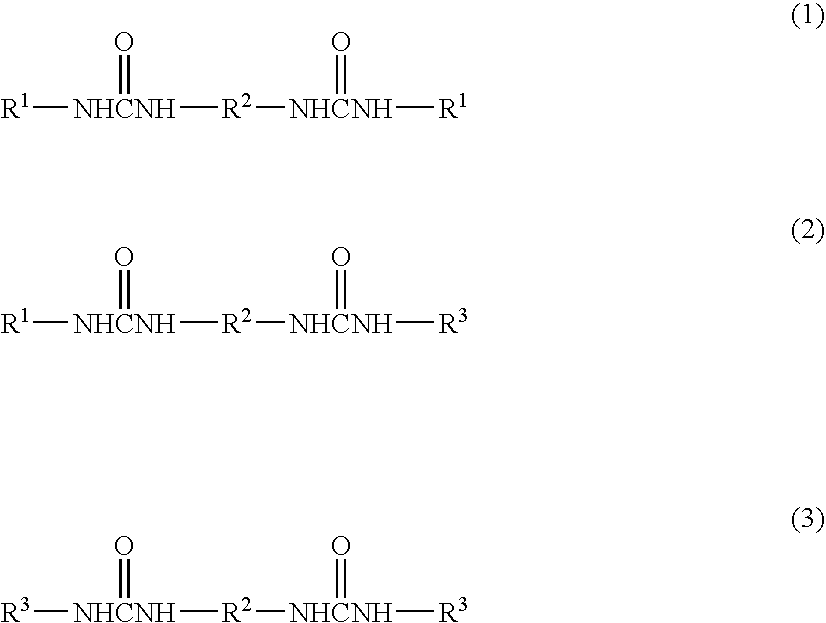

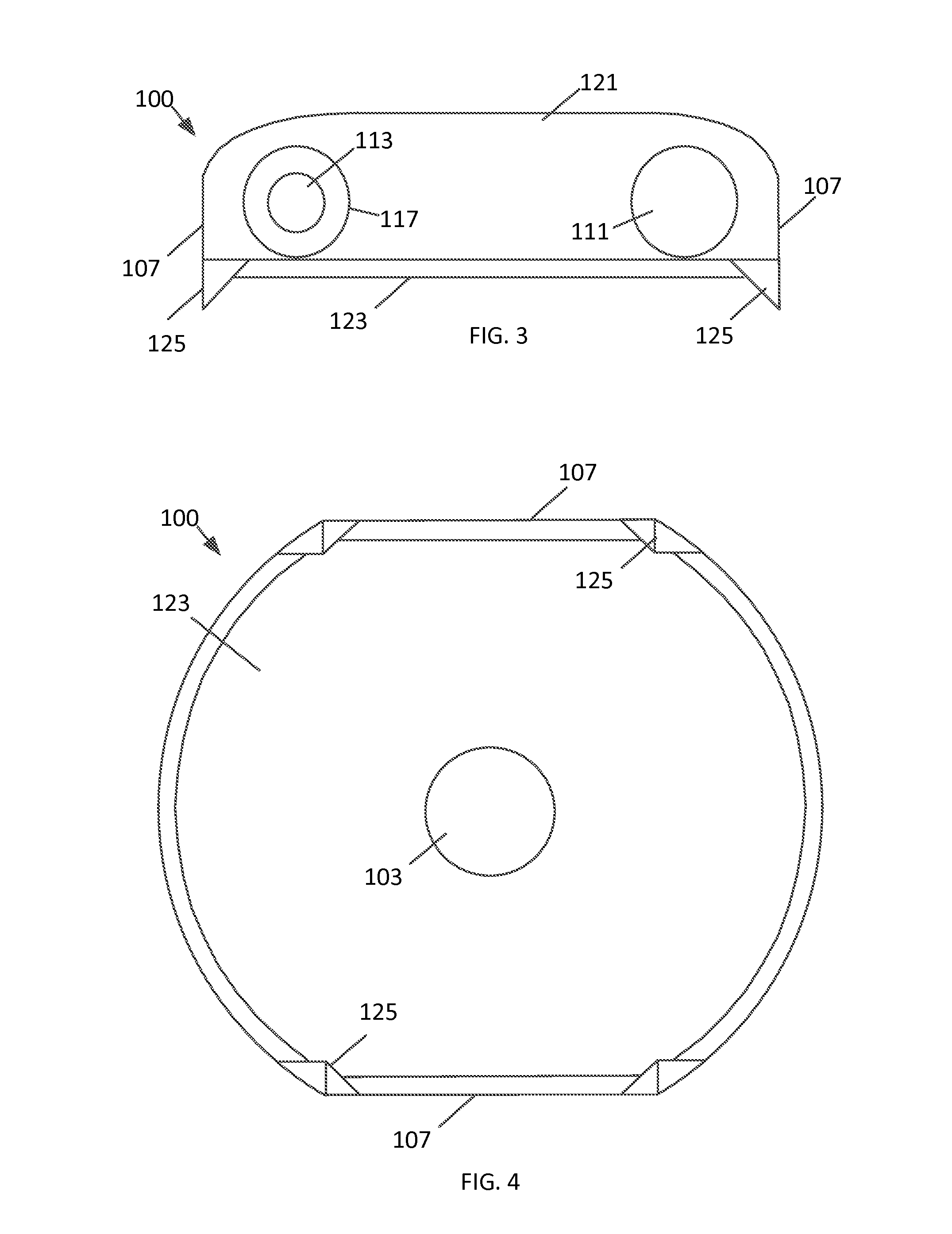

Cable anchor systems and methods

InactiveUS20130304133A1Maintain tensionPrevent slidingSuture equipmentsInternal osteosythesisLocking mechanismPortacaval

The cable system includes a cable, cable anchors and / or cable crimps. The cable anchors and cable crimps have mounting holes that are used to secure the cable anchors and cable crimps to bones of patients with bone screws. Once the cable anchors and / or cable crimps are attached to the bone, the cable wrapped around the bone and placed through the cable anchors and cable crimps. The cable is tensioned and a locking mechanism is used to lock the cable crimp to the cable. The cable anchors and cable crimps prevent the cable from moving on the bone.

Owner:TRAUNER KENNETH B

Grease Composition, Grease-Enclosed Bearing, and One-Way Clutch

InactiveUS20090005272A1Prevent peelingRestrain hydrogen brittleness-caused peculiar peelingBearing componentsThickenersOil and greaseHydrogen

The present invention provides a grease composition capable of effectively preventing a rolling surface from having hydrogen brittleness-caused peeling, a grease-enclosed bearing in which the grease composition is enclosed, and a one-way clutch in which the grease composition is enclosed at a sliding portion. The grease composition contains a base grease consisting of a base oil and a thickener and an additive added to the base grease. The grease composition is capable of preventing hydrogen brittleness-caused peeling from occurring on a frictionally worn surface of a bearing portion containing an iron-based metal material or a newly generated surface consisting of the iron-based metal material exposed owing to wear. The additive contains at least one aluminum-based additive selected from among an aluminum powder and inorganic aluminum compounds. The mixing ratio of the aluminum-based additive to 100 parts by weight of the base grease is set to 0.05 to 10 parts by weight.

Owner:NTN CORP

Grease composition with improved Anti-fretting properties at low temperatures

Owner:KYODO YUSHI CO LTD

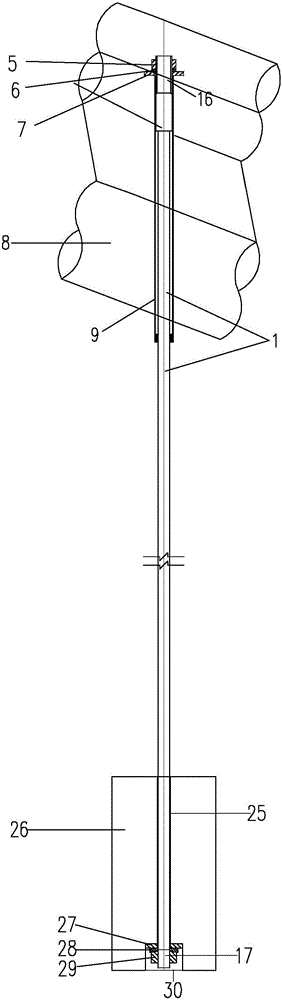

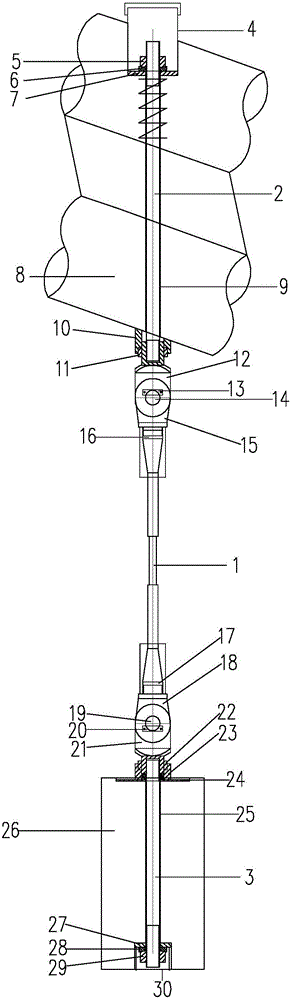

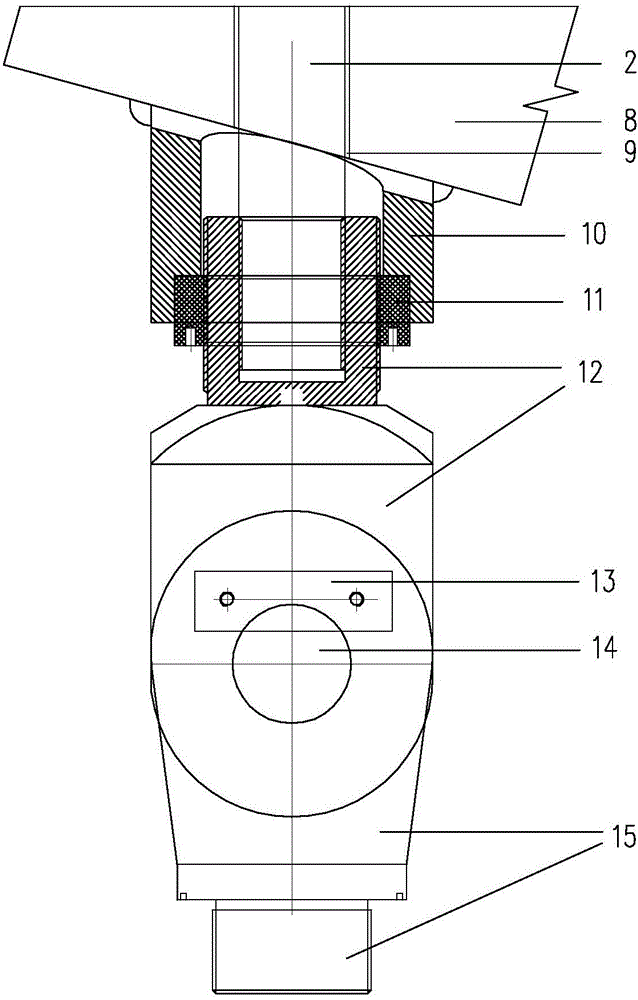

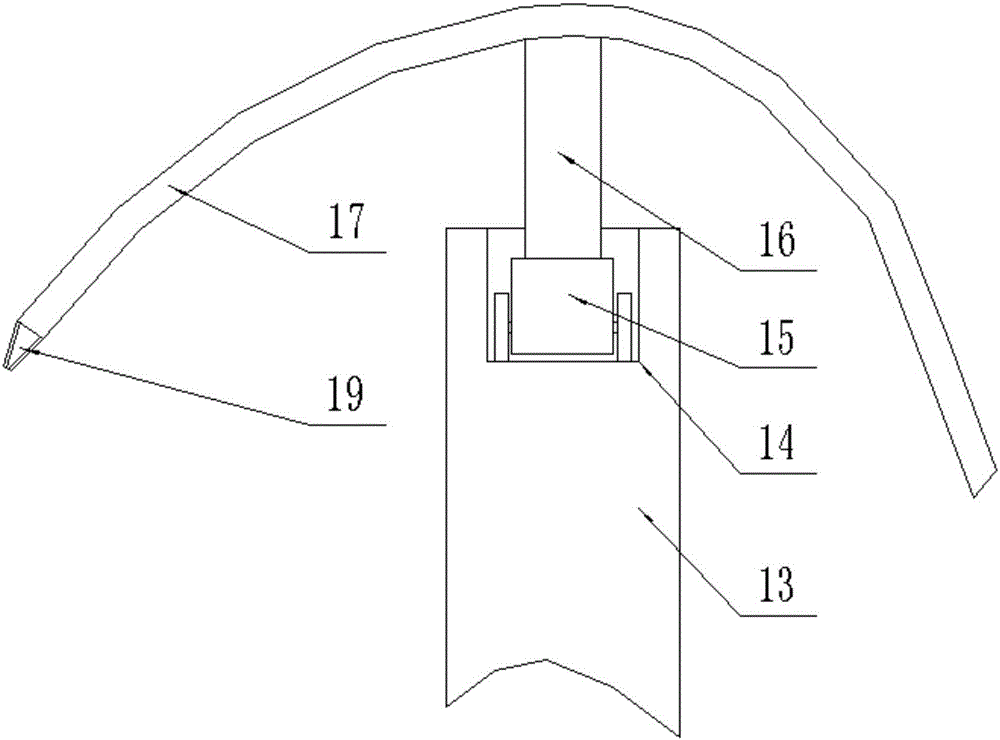

Three-section hinging type arch bridge suspender system with rigid rods combined with flexible cable

ActiveCN105780641ASolve the problem of horizontal stressResolve the breakBridge structural detailsHorizontal stressFlexible cable

The invention discloses a three-section hinging type arch bridge suspender system with rigid rods combined with a flexible cable. The three-section hinging type arch bridge suspender system comprises a suspender cable body, an upper steel rod, a lower steel rod and connecting components, wherein the upper steel rod and the lower steel rod are the rigid rods; the suspender cable body is the flexible cable; the two sections of rigid rods are located on the upper end and the lower end; the upper steel rod is fixedly connected with an upper anchor unit embedded in an arch rib of an arch bridge; the lower steel rod is fixedly connected with a lower anchor unit embedded in a cross beam of the arch bridge; the upper end of the suspender cable body is hinged with the upper steel rod through the upper connecting component; the lower end of the suspender cable body is hinged with the lower steel rod through the lower connecting component; therefore, a three-section hinging type structure with the rigid rods on two ends and the flexible cable in the middle is formed. The suspender system is adjustable, detectable and replaceable, is convenient for replacing and adjusting the suspender force, and solves the problem that horizontal stress is generated on the steel rods since centralizing error of upper and lower embedded pipe holes is caused by the deformation of the arch rib or exogenic action stressed by the cross beam during the new bridge construction or operation process.

Owner:GUANGDONG HELI CIVIL ENG CO LTD

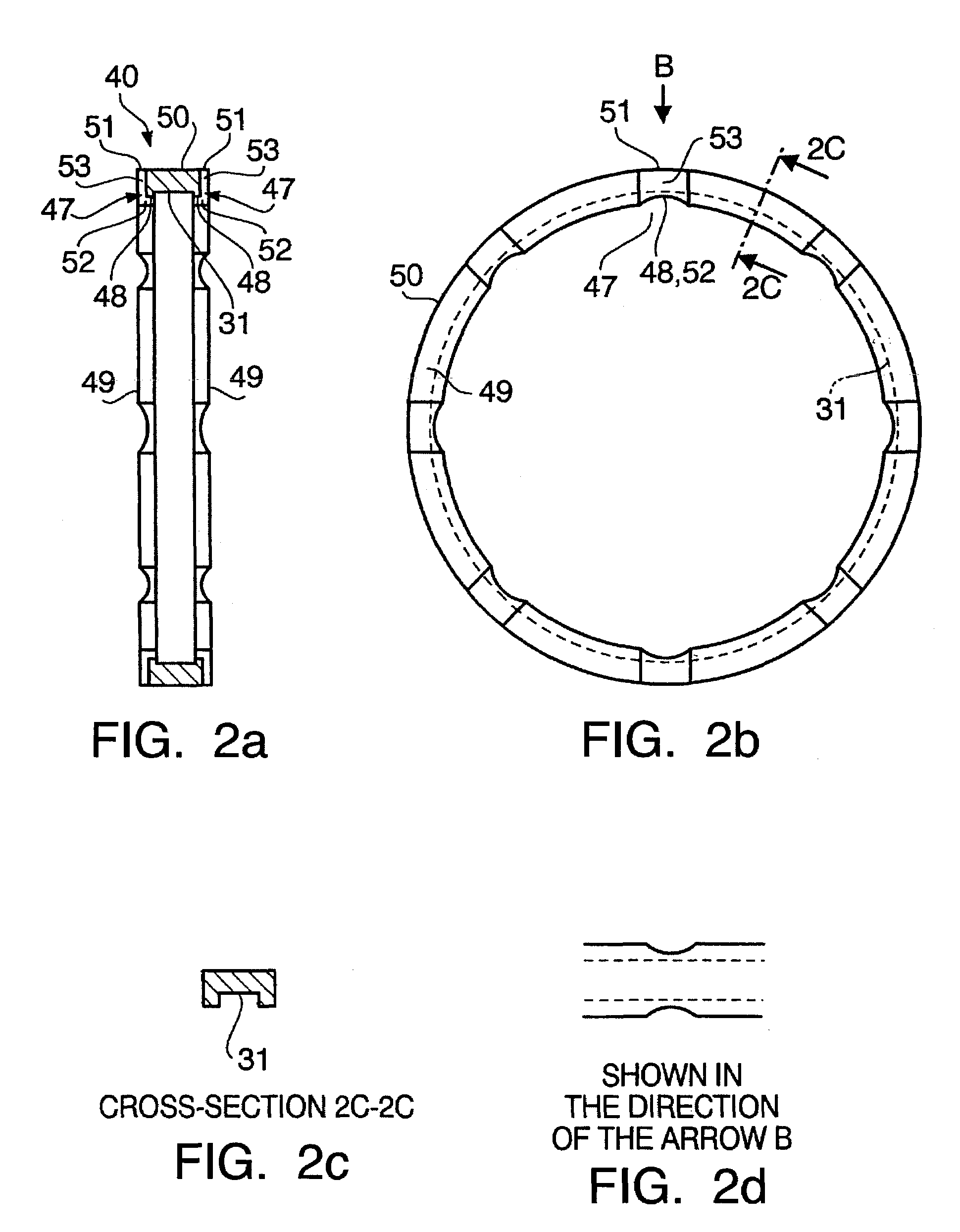

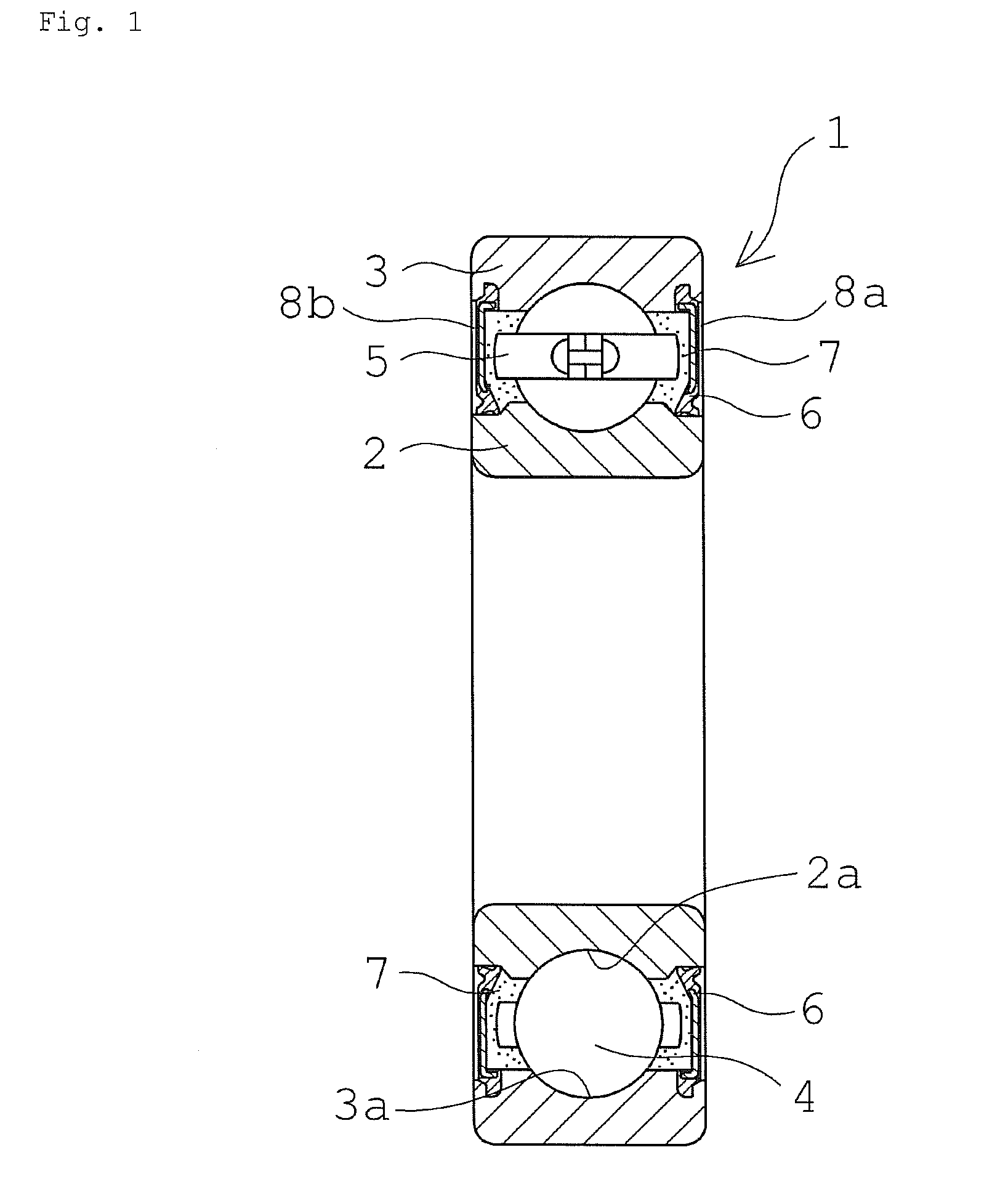

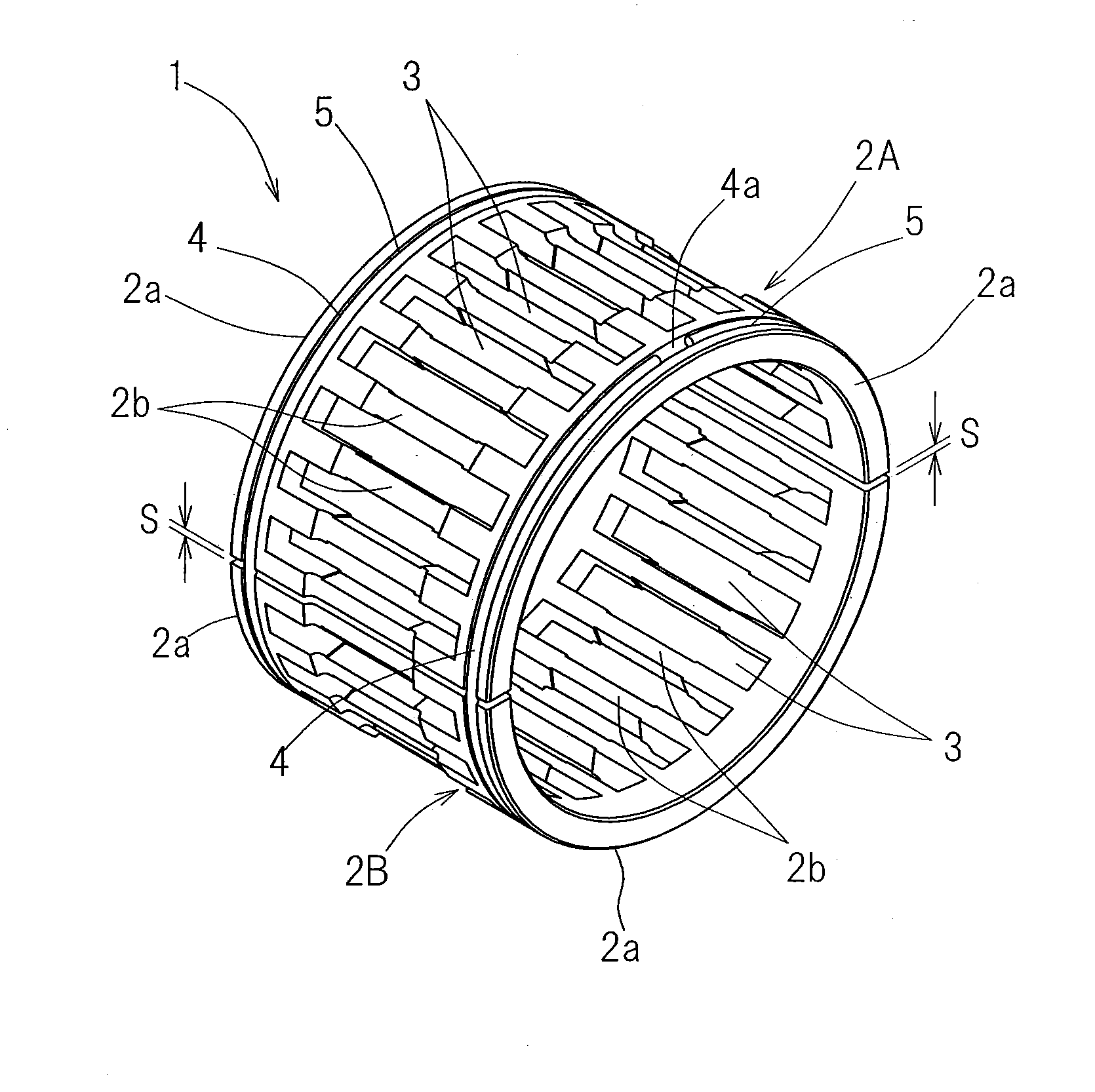

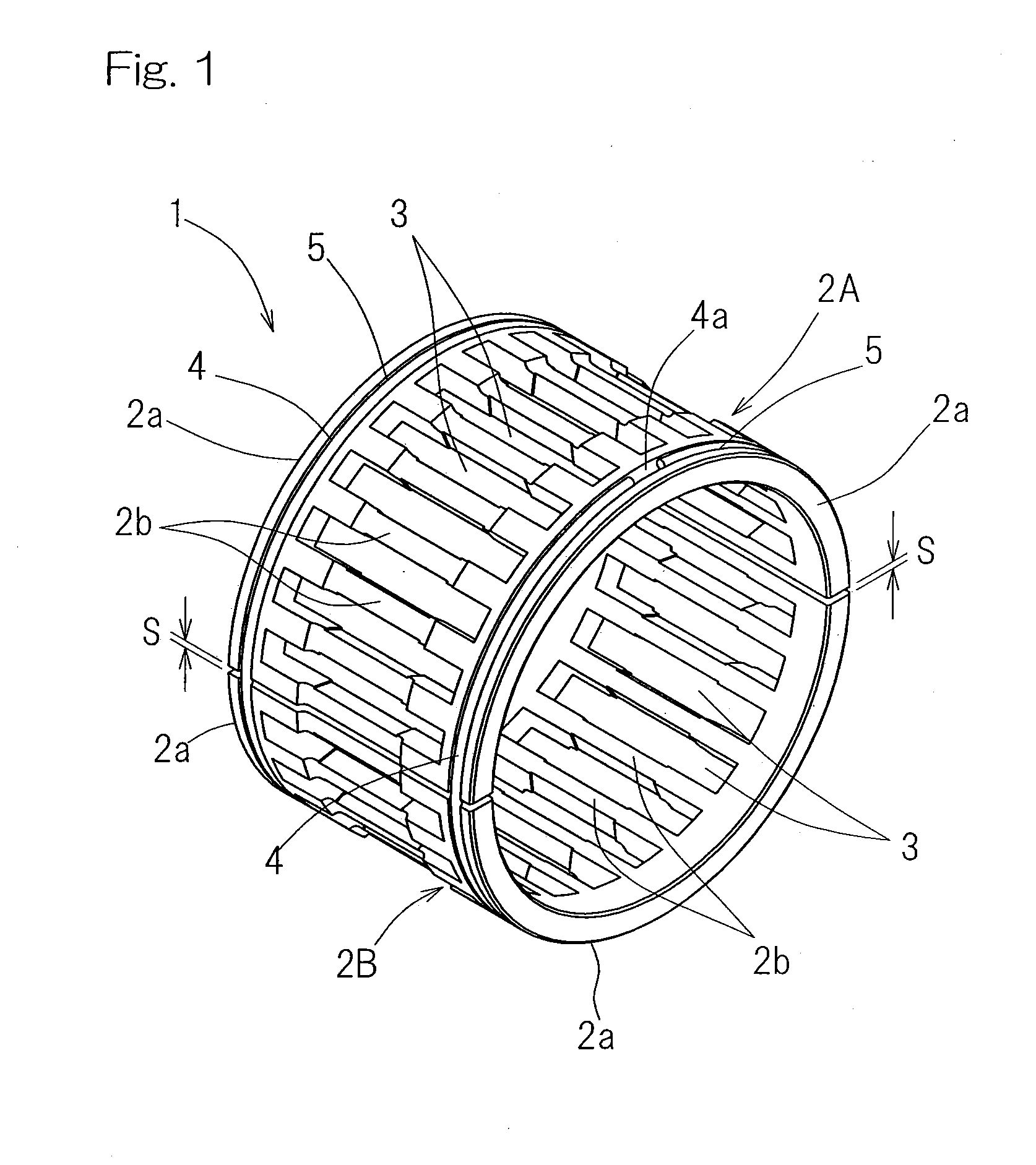

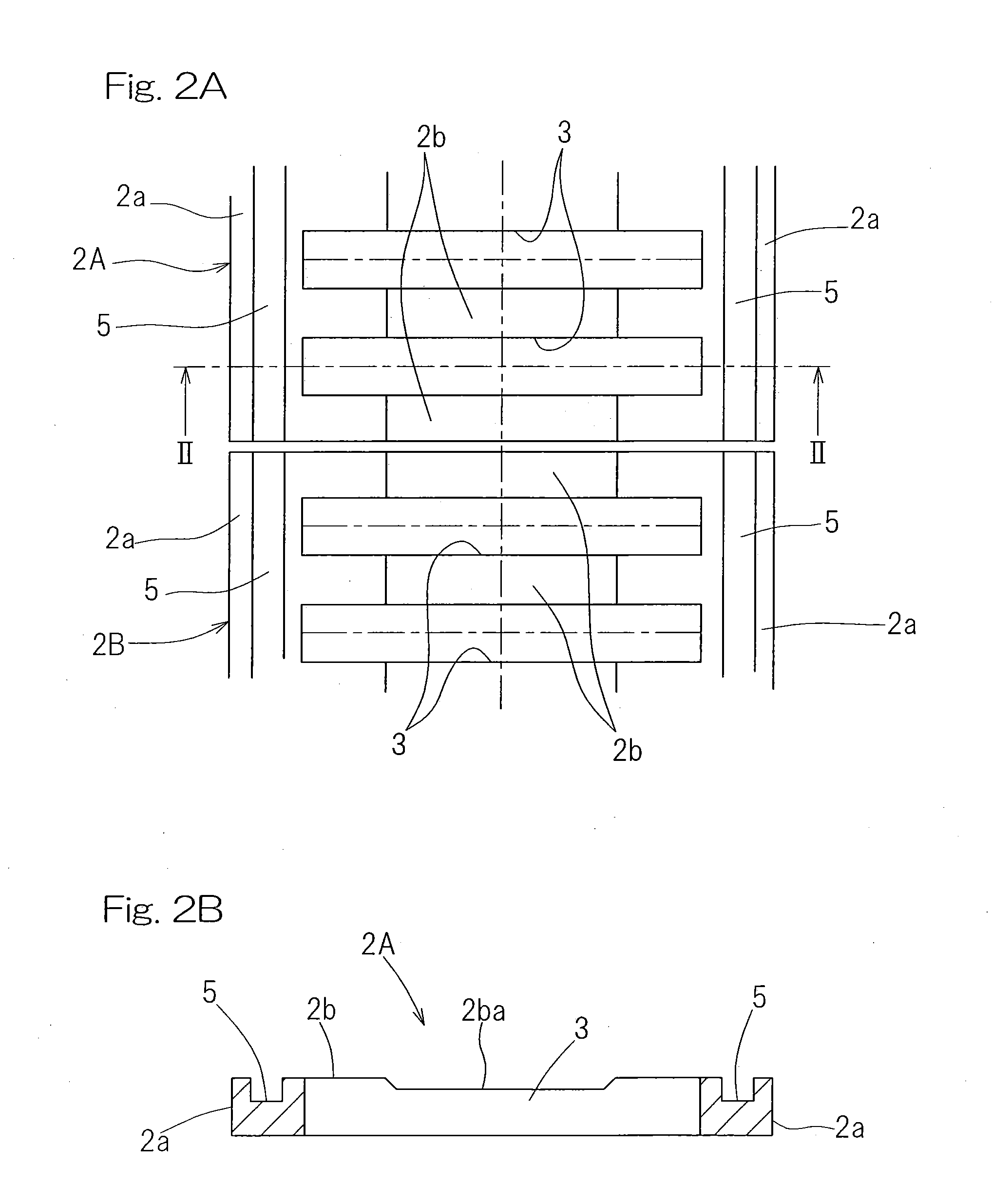

Rolling bearing

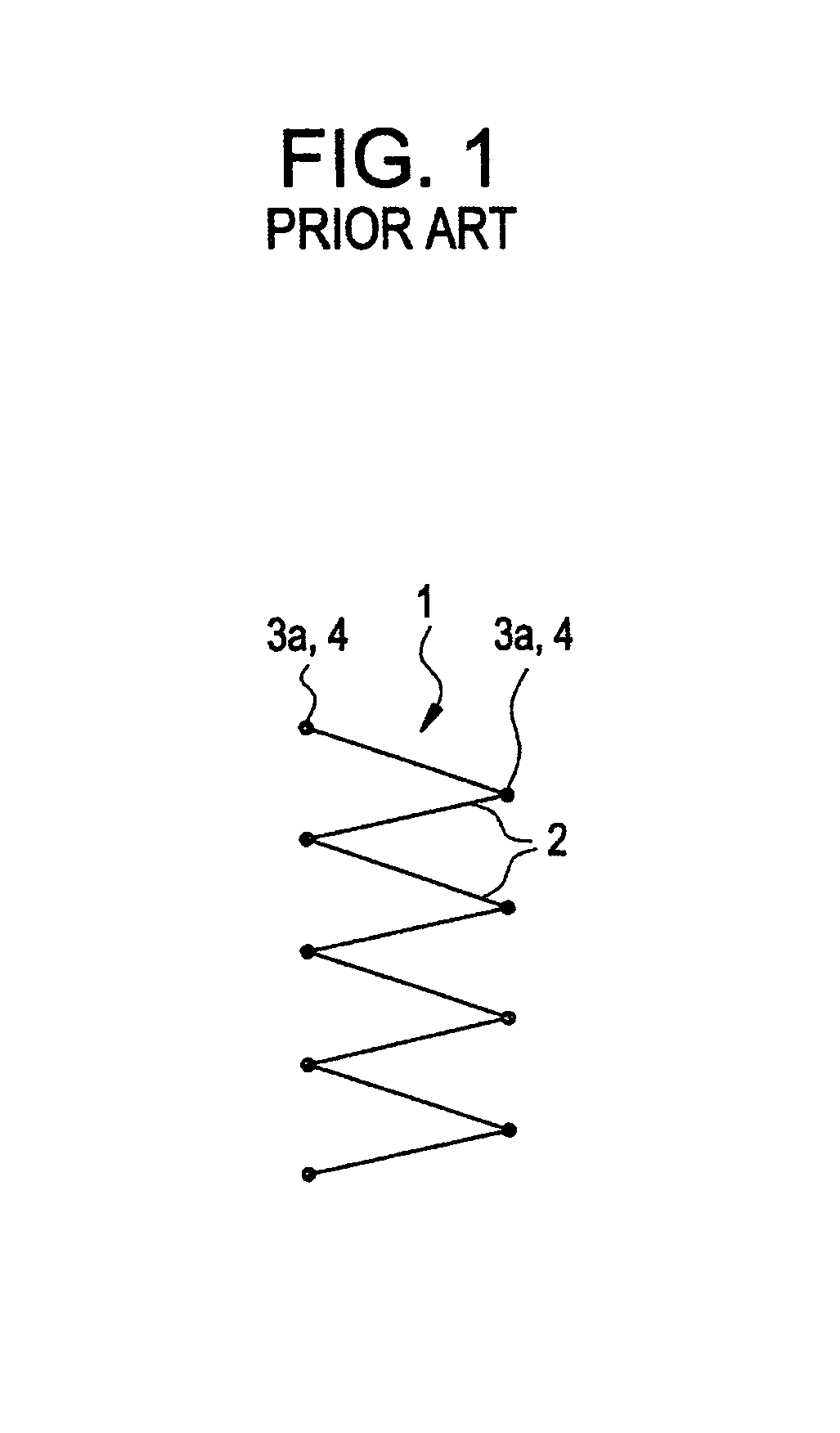

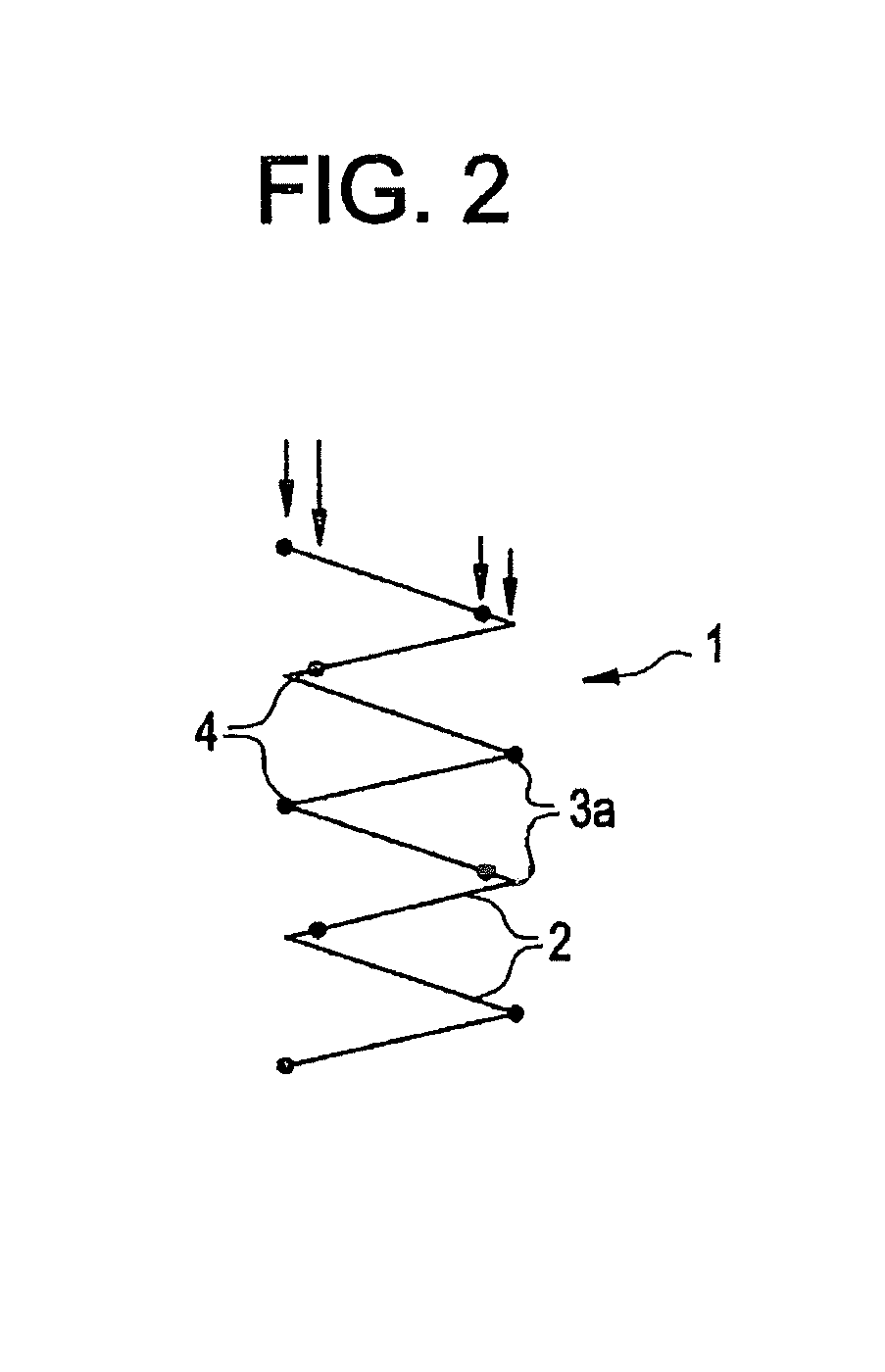

ActiveUS20120207422A1Easy to assembleLow costShaftsBearing componentsRolling-element bearingMechanical engineering

Two or more arcuate members (2A, 2B), each having a plurality of pockets (3) defined therein for accommodating corresponding rollers, are placed one above the other to form a ring shaped assembly and are subsequently connected non-separably together by means of a retention ring (4) to thereby complete the cage (1). The arcuate members (2A, 2B) are so connected together that its inner periphery may assume a position radially inwardly of the outer diameter of a shaft such that in a condition having been assembled onto the shaft, they can displace in a direction radially outwardly against an elastic compressive force of the retention ring (4) to invite a circumferential gap (S) at each joint between the arcuate members (2A, 2B).

Owner:NTN CORP

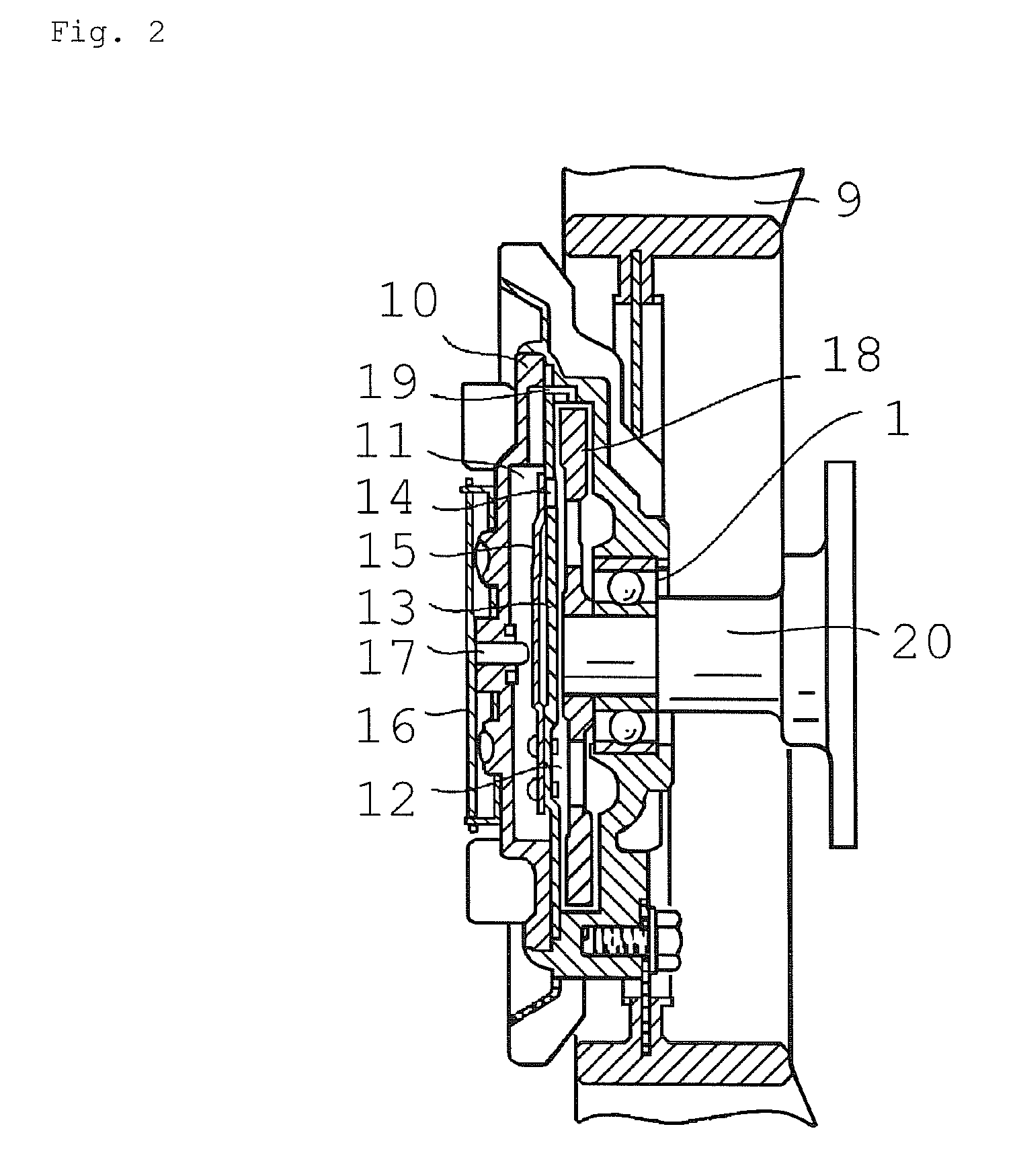

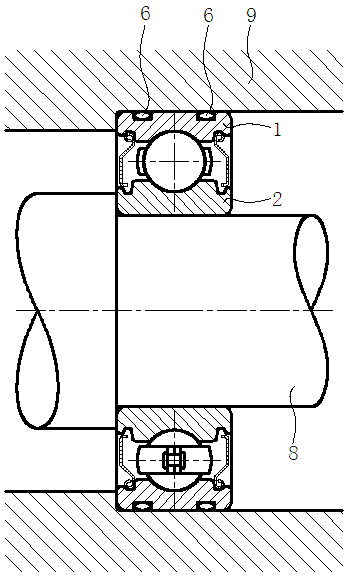

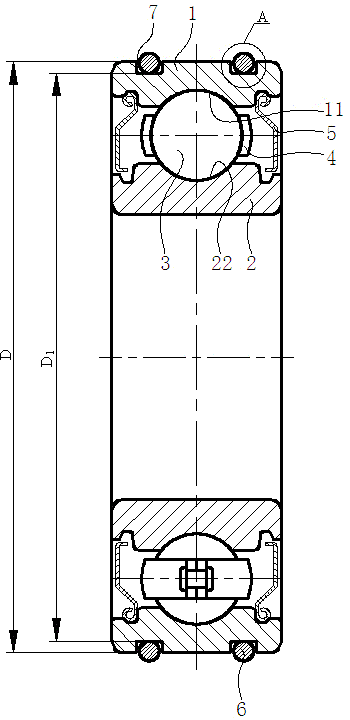

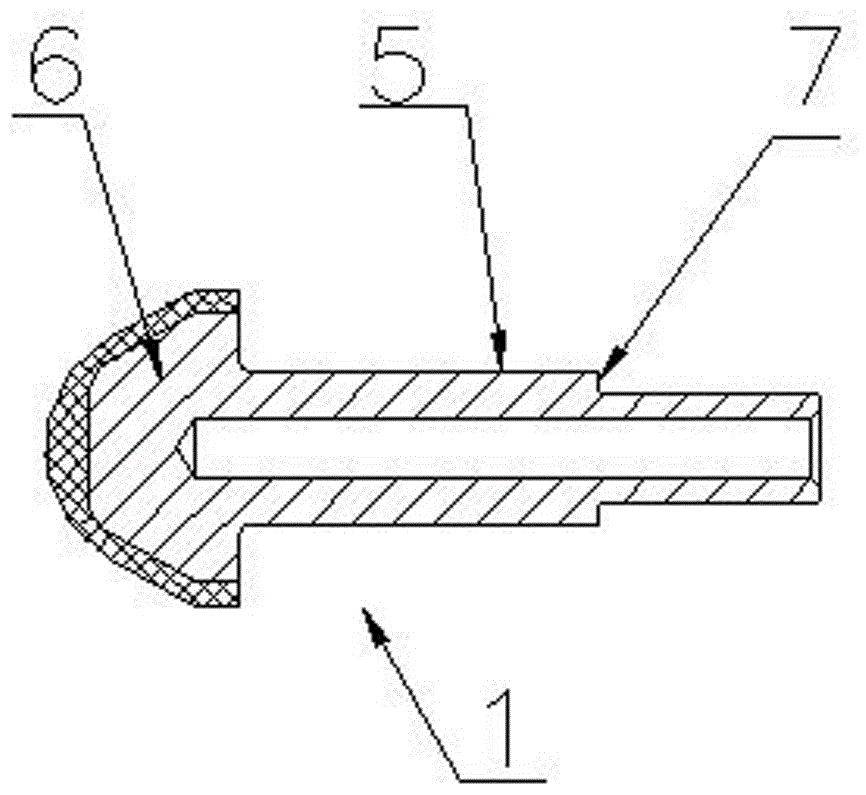

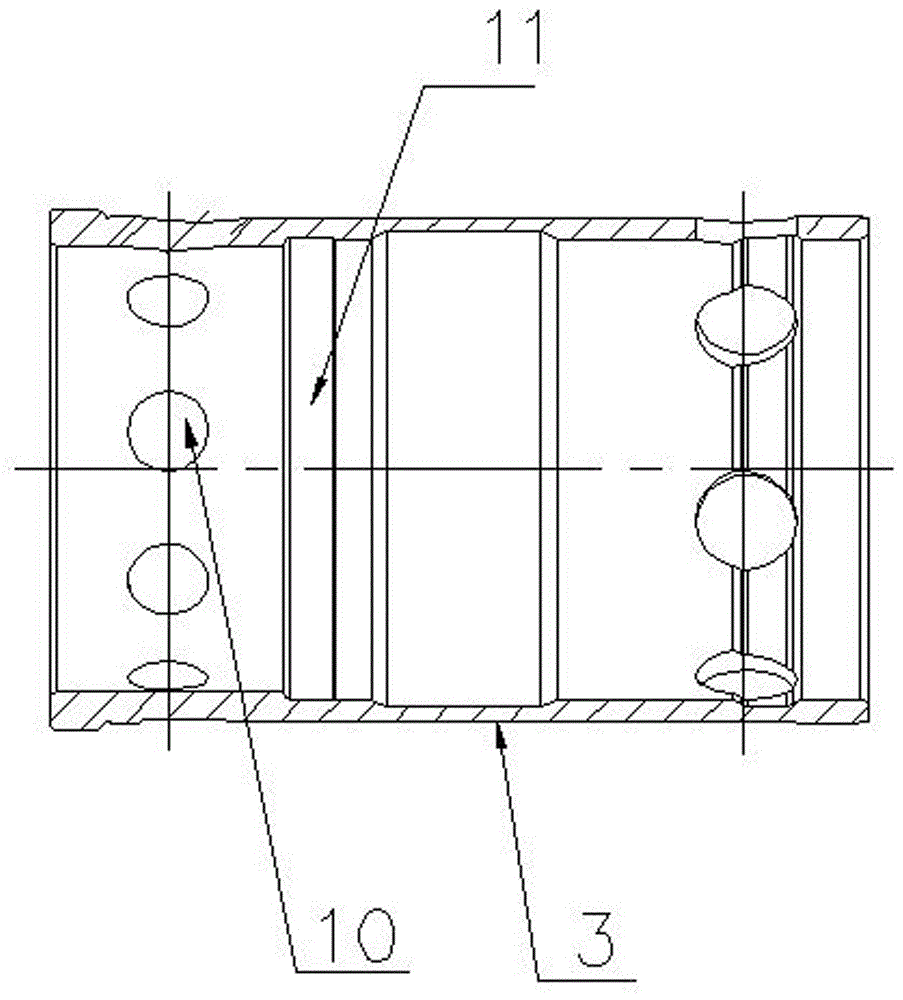

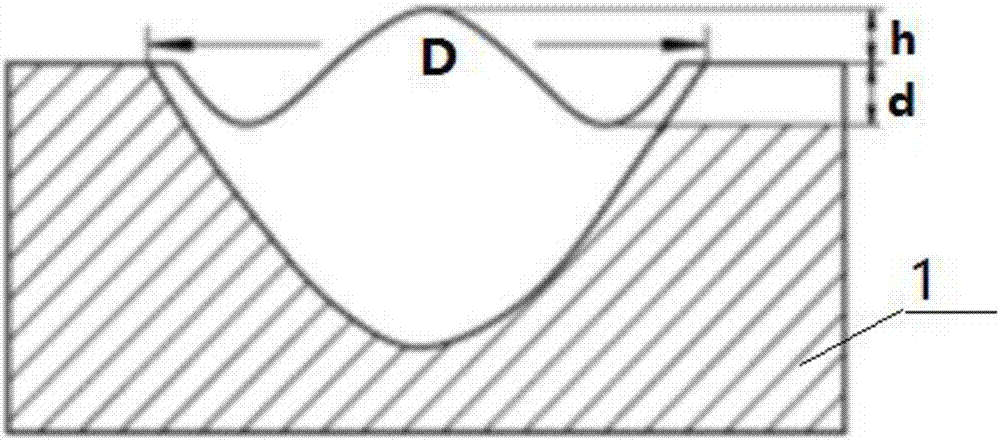

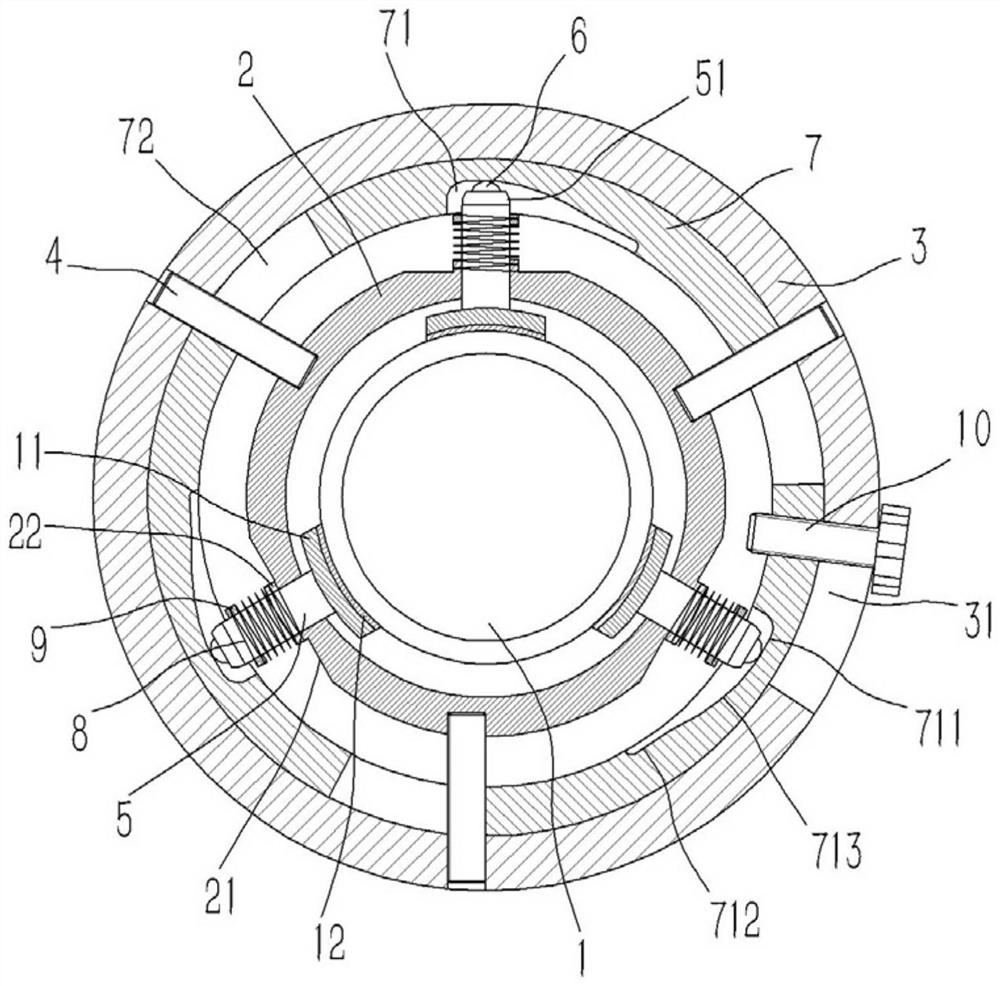

Rolling bearing

ActiveCN104314972ASo as not to damageGuaranteed anti-creep performanceBall bearingsBearing unit rigid supportFill rateRolling-element bearing

A rolling bearing comprises an outer ring (1), an inner ring (2), a plurality of rolling bodies (3) and a retainer (4). The outer peripheral surface of the outer ring (1) is provided with one or more annular grooves (7) along the circumferential direction; the groove (7) is provided with an O-shaped ring (6) protruding from the outer peripheral surface of the outer ring (1); the O-shaped ring (6) has a circular cross section; both ends of the inner bottom surface of the groove (7) are slot bottom circular beads; the O-shaped ring (6) has inner diameter tension rate x equal to (D1-D2) / D2, filling rate of area y equal to pi(d / 2)<2> / [h*(D-D1) / 2-(r<2>-pi*r<2> / 4)*2], a crushing rate z equal to deltad / d, wherein x, y and z satisfy the relations of: 1.3%<=x<=5%, 50%<=y<100%, and 21%<=z<=30%. The rolling bearing is easy for installation and can reliably prevent the outer ring (1) from wriggling.

Owner:三环集团有限公司

Drive shaft reduction gear

A drive shaft reduction gear using a planetary gear mechanism and having a high durability, wherein a rotation of a drive shaft is transmitted to a wheel hub via the planetary gear mechanism, a ring gear hub provided in a first ring gear in the planetary gear mechanism is hooked to a bearing holder attached to an axle housing via a split ring, thereby a movement in an axial direction of the first ring gear is regulated, and further, a shaft portion provided in the ring gear hub is non-rotatably supported by an inner peripheral surface of a shaft end portion of the axle housing.

Owner:KOMATSU LTD

Stent graft device

A stent graft device for implanting in a body lumen, comprising a stent with non-staggered or staggered apexes, said stent comprising a plurality of stent sections, bendable connecting members forming said non-staggered or staggered apexes and connecting each of said stent sections to other stent sections to form a zigzag pattern, wherein said stent is staggerdly sutured to a graft by a plurality of suture knots, and wherein said suture knots and staggered apexes are staggered when said stent sections are crimped, and methods of use thereof.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Metal material, method for producing the same, and electrical electronic component using the same

InactiveCN101688312APrevent discolorationAvoid corrosionHot-dipping/immersion processesLiquid surface applicatorsSurface layerEther

Owner:FURUKAWA ELECTRIC CO LTD

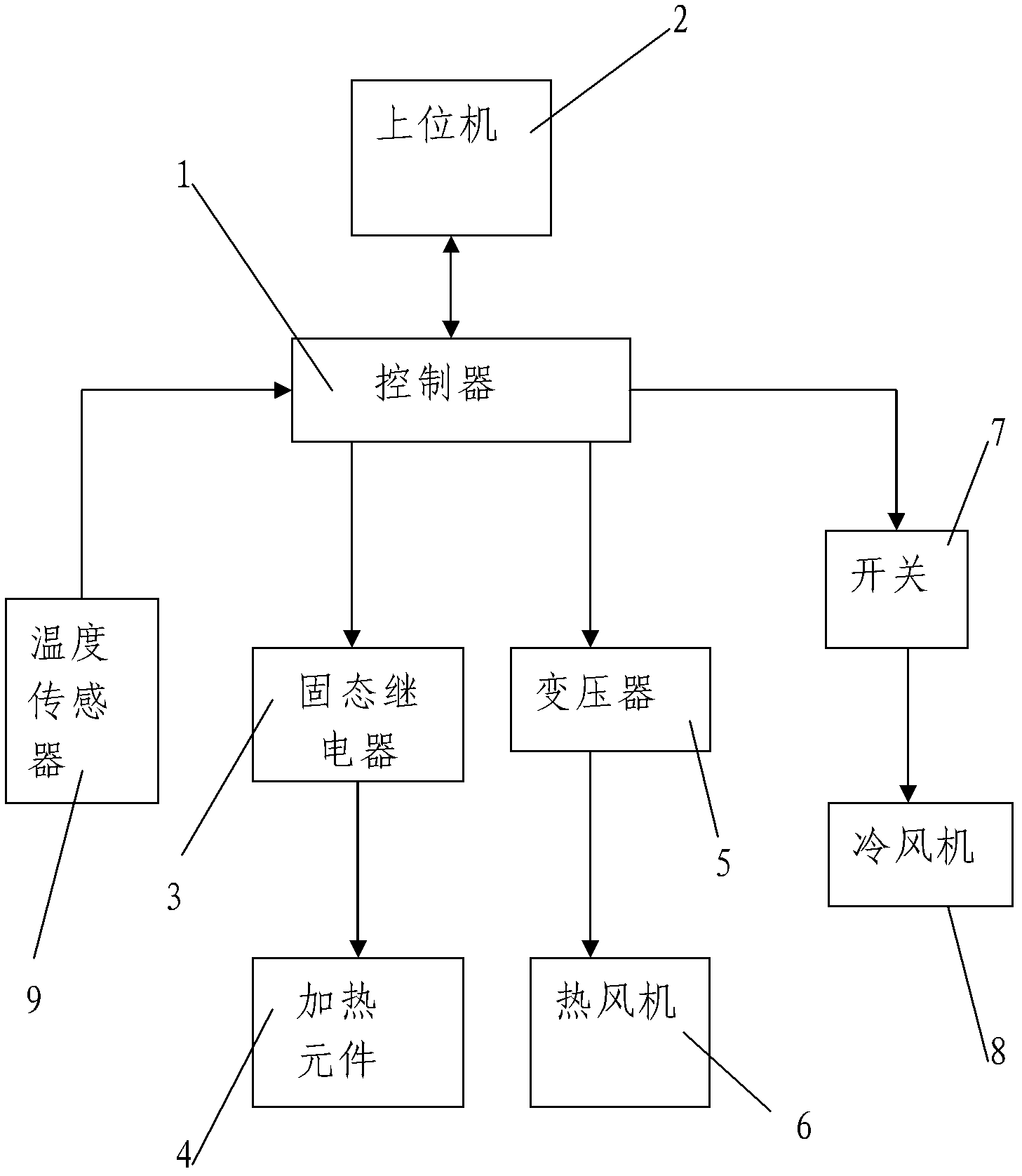

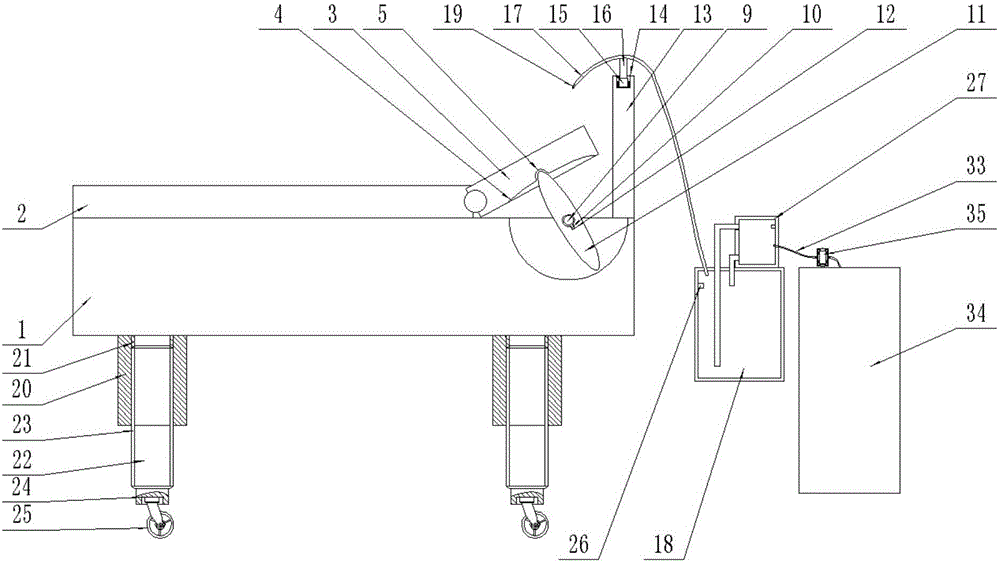

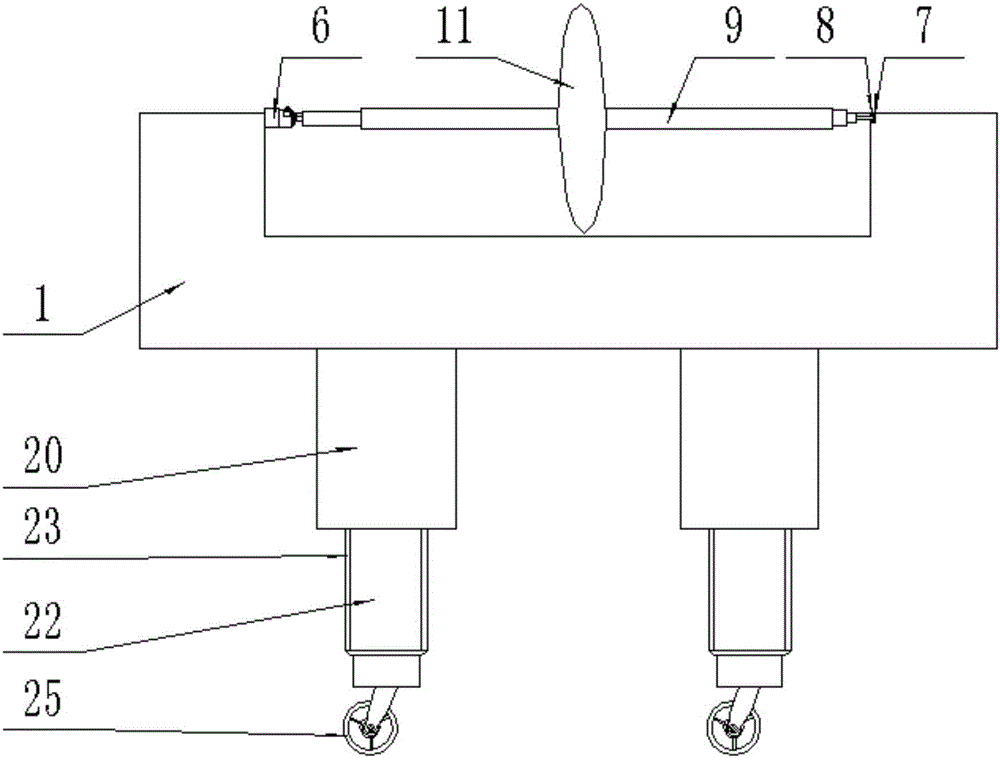

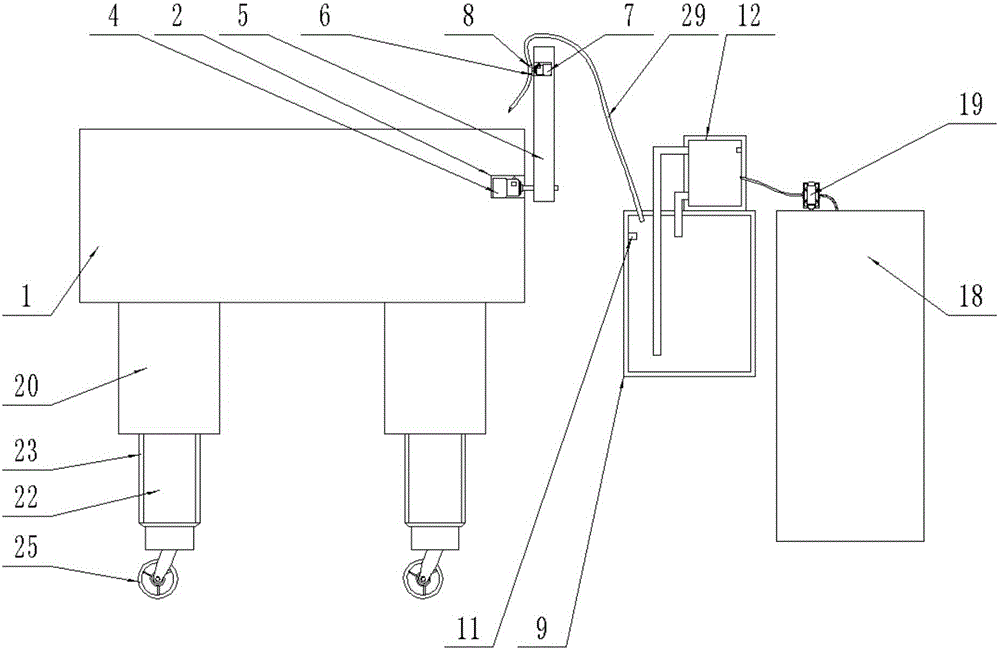

Control system for desk type reflow soldering machine

InactiveCN103128399ASmooth connectionReasonable designPrinted circuit assemblingTemperature control using electric meansTransformerControl system

The invention discloses a control system for a desk type reflow soldering machine. The control system for the desk type reflow soldering machine comprises a controller 1, an upper computer, a solid state relay, a transformer, a switch and a temperature sensor, wherein the solid state relay carries out an automatic adjustment on the power of a heating element under the control of the controller, the transformer carries out the automatic adjustment on the voltage of a hot air machine under the control of the controller 1, the switch is used for control of on-off of an air cooler and the temperature sensor carries out a real-time detection on the temperature inside a furnace of a controlled reflow soldering machine. The solid state relay and the heating element are connected to form a heating system. The transformer and the hot air machine are connected to form a hot air circulating system. The switch and the air cooler are connected to form a refrigerating system. The upper computer, the temperature sensor, the solid state relay, the transformer and the switch are connected with the controller. The control system for the desk-type reflow soldering machine is simple in structure and convenient to operate. A mixed heating mode combined the hot air and an infrared is forcibly used to achieve the welding work under the static state, so the fully automated operation of the whole technique process is achieved.

Owner:SHAANXI ZIZHU ELECTRON

Safety protection device for natural gas booster station pipeline

The invention provides a safety protection device for a natural gas booster station pipeline for preventing pipeline flange leakage, and relates to the technical field of safety of natural gas pipelines. The safety protection device for the natural gas booster station pipeline comprises a left pipeline and a right pipeline, the left pipeline and the right pipeline are connected through a flange, afirst protective cover is arranged outside the flange in a sleeved mode, and the two ends of the first protective cover are in sealing connection with the outer wall of the left pipeline and the outer wall of the right pipeline respectively to form a first gas storage cavity; and vibration damping devices are arranged between the outer wall of the left pipeline and the inner wall of the first protective cover and between the outer wall of the right pipeline and the inner wall of the first protective cover respectively. The protective device can prolong the service life of a flange connectingpiece, so that the possibility of air leakage between the flanges is reduced, and the safety performance of the booster station pipeline is improved.

Owner:SEPCO ELECTRIC POWER CONSTR CORP

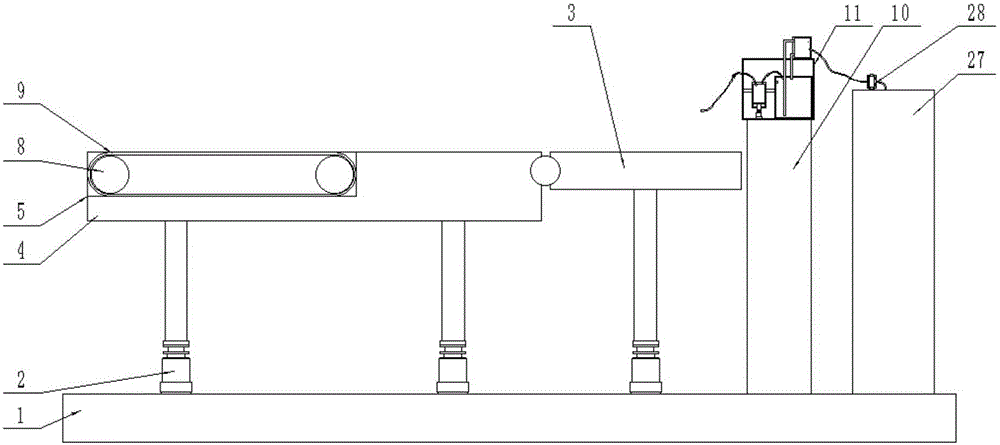

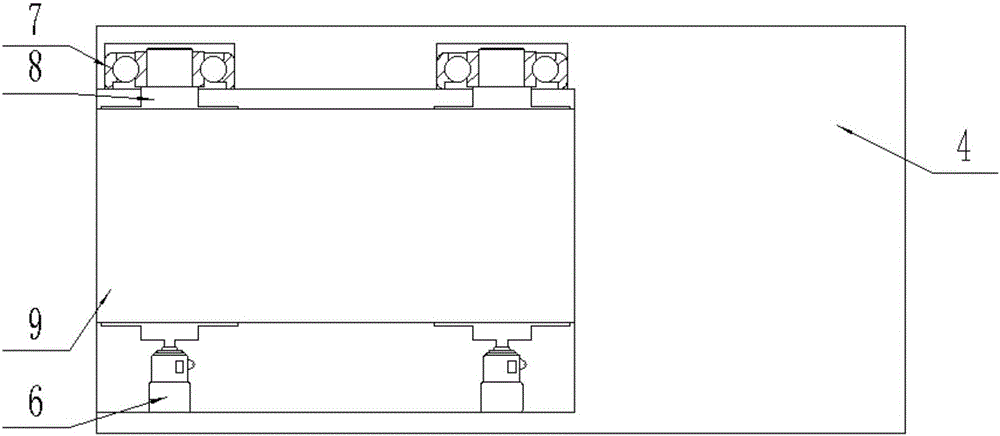

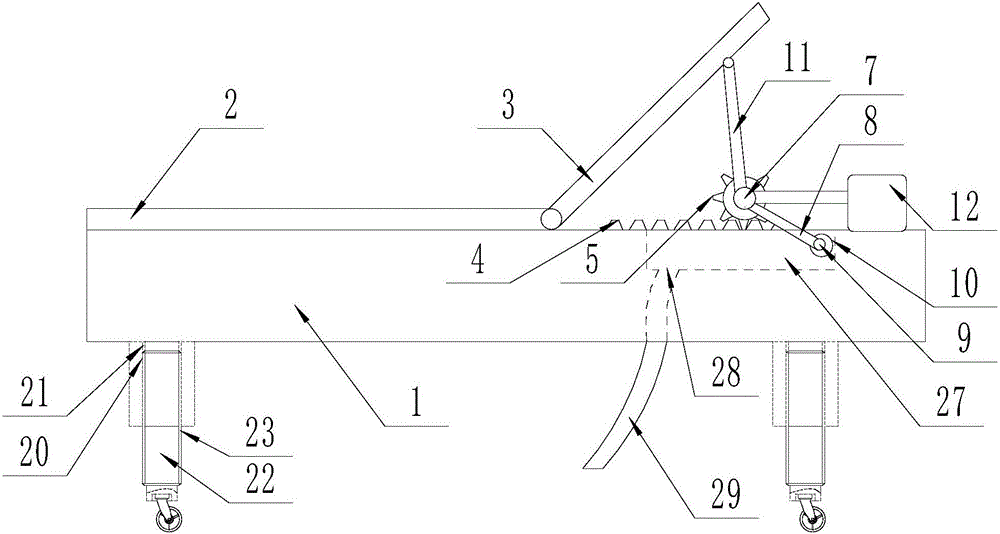

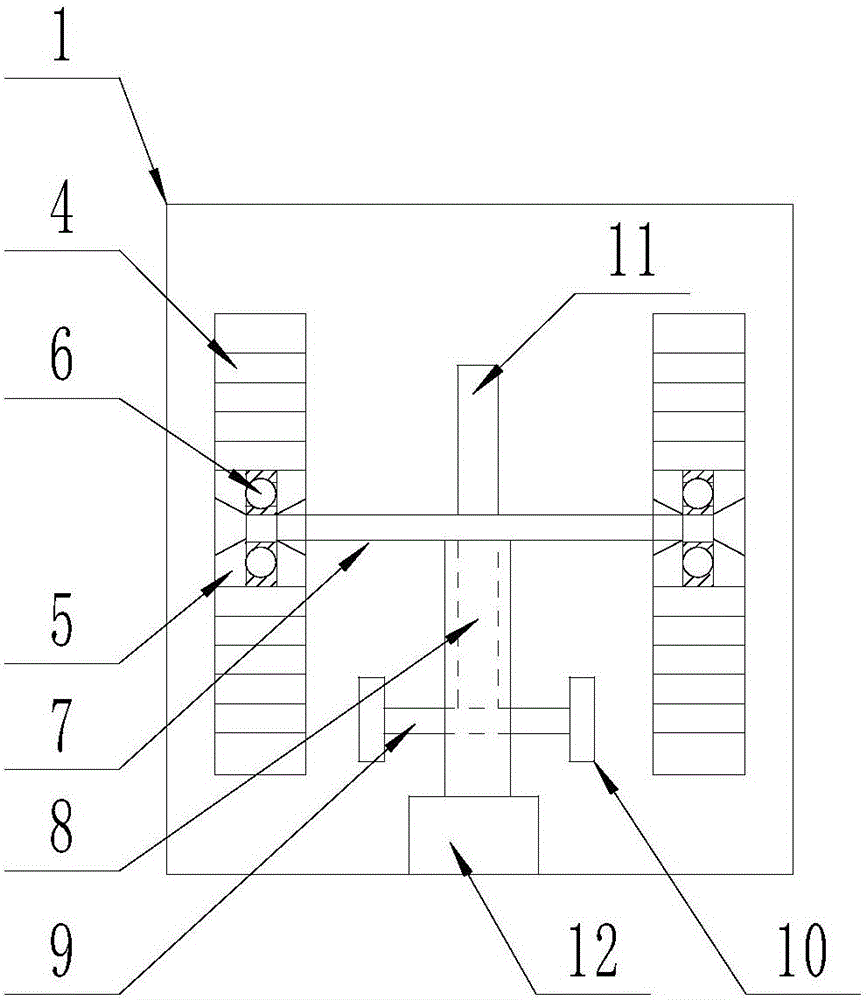

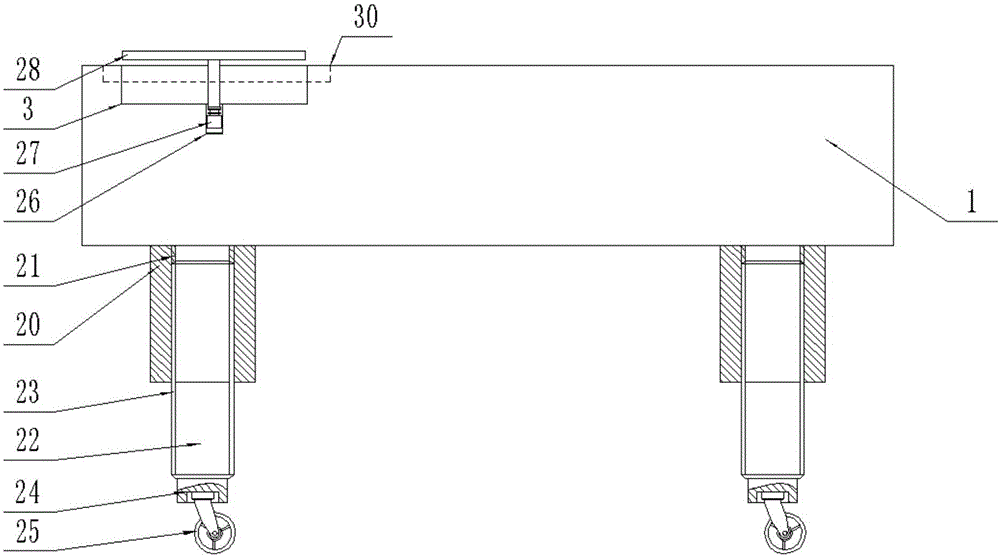

Medical inspection device for ear-nose-throat department

The invention discloses a medical inspection device for an ear-nose-throat department. The medical inspection device comprises a board body, three pairs of extension-retraction motors which are telescopic upwards are arranged on the board body, a back plate is arranged on the extension-retraction end of one pair of extension-retraction motors in a hinged mode, a bed body is fixed to the extension-retraction ends of two pairs of extension-retraction motors, and the bed body is connected with the back plate in a hinged mode; a rectangular groove is inwards formed in one side surface of the bed body, a group of a rotating motor and bearings are arranged on the each end of the two opposite side surfaces in the rectangular groove, belt pulleys are fixed with the rotating end of each group of the rotating motor, and the belt pulleys are inserted in the bearings, a conveying belt is arranged on a group of belt pulleys in a sleeving mode, a bed-head board is arranged on the board body and located on one side surface of the back plate, and the bed-head board is provided with a drug feeding mechanism. The medical inspection device for the ear-nose-throat department has the advantages of being simple in structure and strong in practicality.

Owner:尤孙文

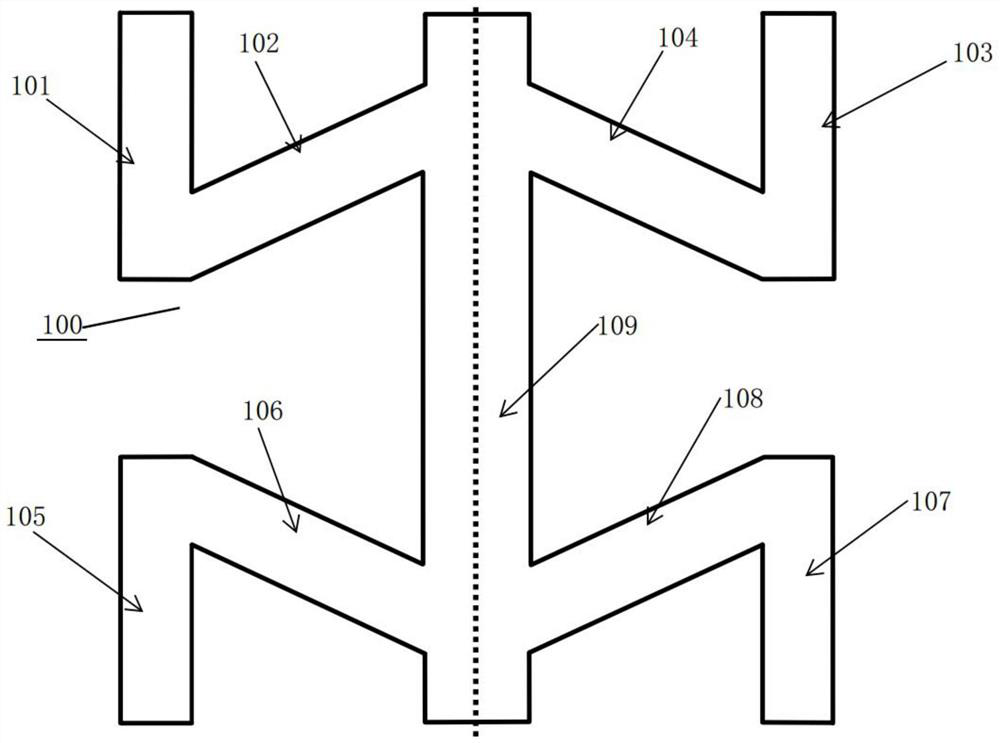

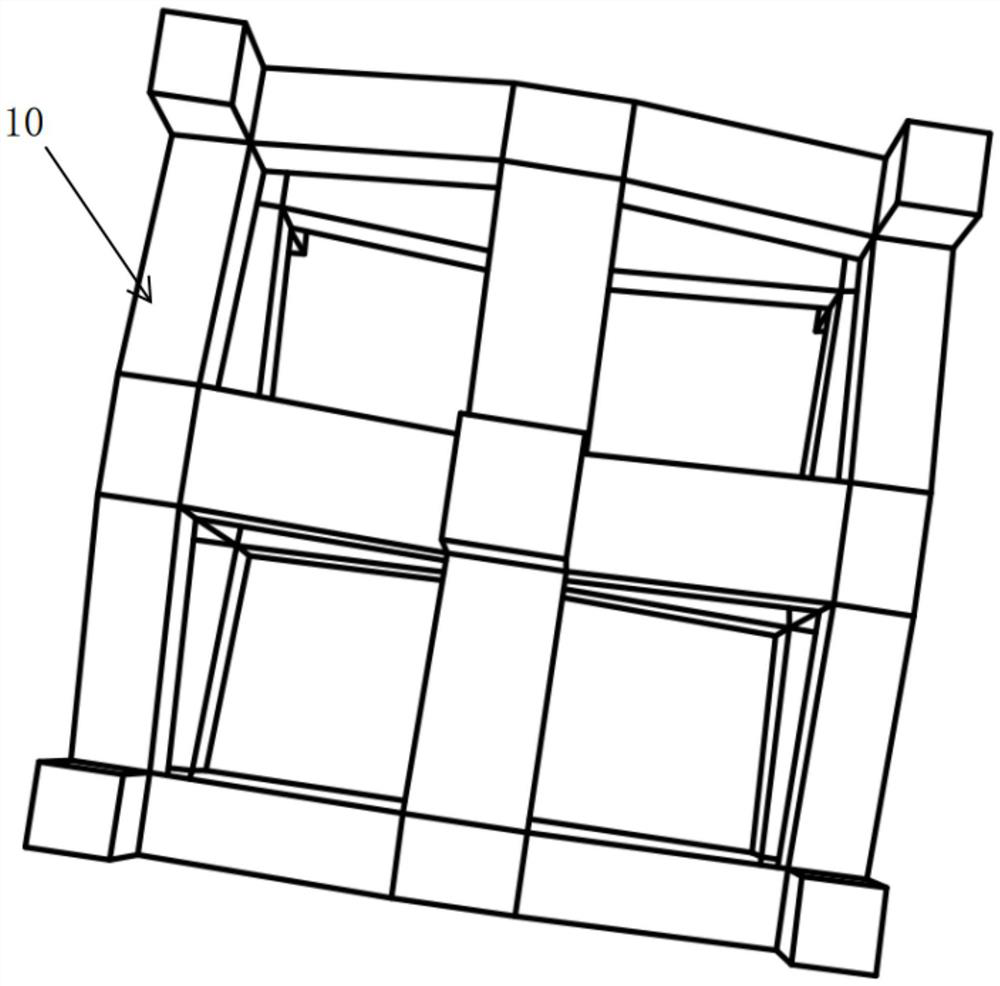

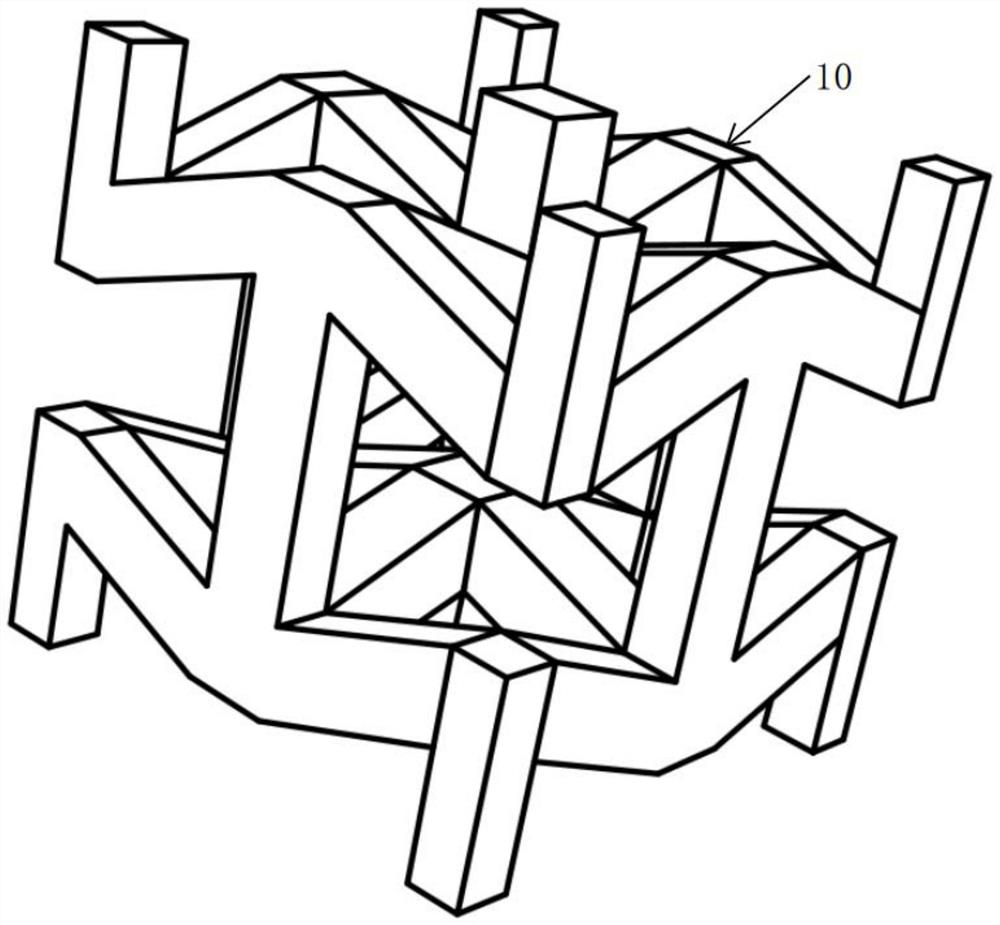

Anti-loosening bone fixing implant and design method thereof

InactiveCN113332003APromote ingrowthImprove stability and longevityBone implantJoint implantsOsseointegrationOrthopedic department

The invention discloses an anti-loosening bone fixing implant and a design method thereof, and relates to the field of orthopedic medical instruments. The anti-loosening bone fixing implant comprises a bone fixing implant body. The bone fixing implant body is of a porous gradient structure formed by arranging negative Poisson's ratio unit cells and positive Poisson's ratio unit cells in a spatial dispersion mode, according to the stress condition, the negative Poisson's ratio unit cells are arranged on the side, subjected to tension, of the implant body, and the positive Poisson's ratio unit cells are arranged on the side, subjected to pressure, of the implant body. The negative Poisson's ratio unit cells and the positive Poisson's ratio unit cells are all of a three-dimensional porous structure, and the porous gradient structure is formed by arranging the negative Poisson's ratio unit cells and the positive Poisson's ratio unit cells in the axial direction and the radial direction, so that the elasticity modulus of the bone implant body is in gradient distribution. According to the anti-loosening bone fixing implant and the design method thereof, the effects of preventing loosening and falling off and improving fatigue strength can be achieved, bone ingrowth and osseointegration are facilitated, the stability of the implant is improved, and the service life of the implant is prolonged.

Owner:XI AN JIAOTONG UNIV

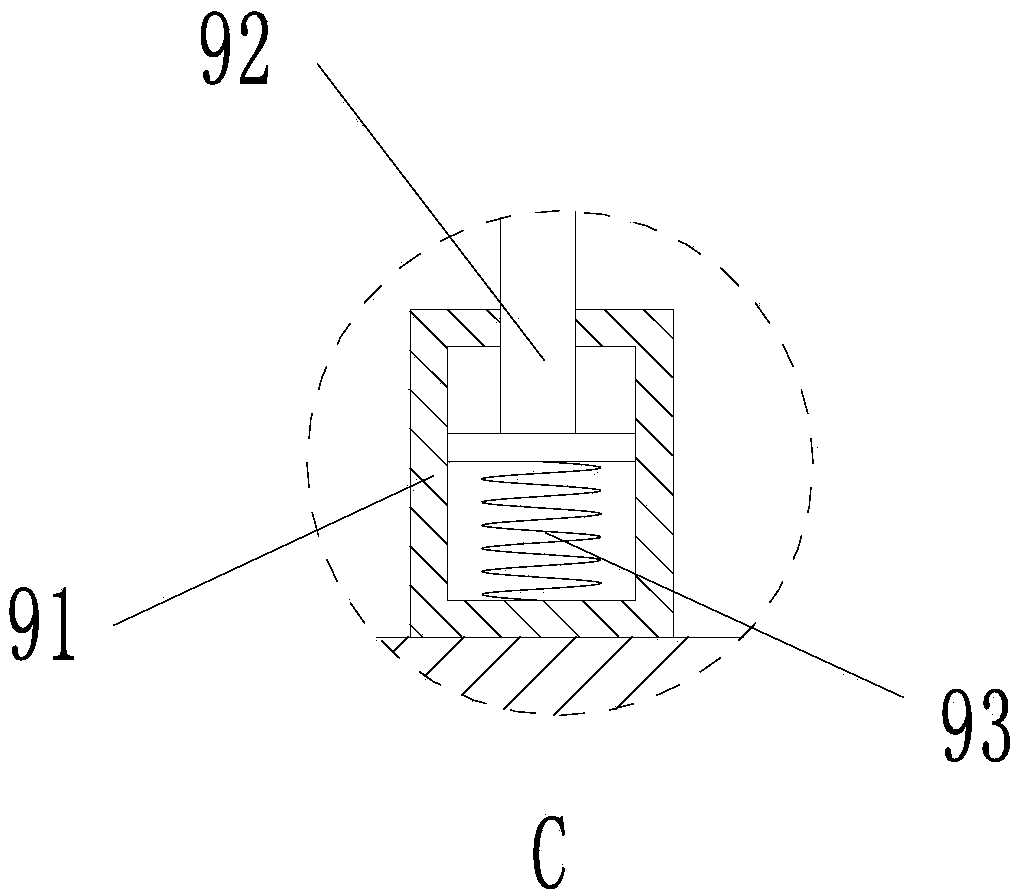

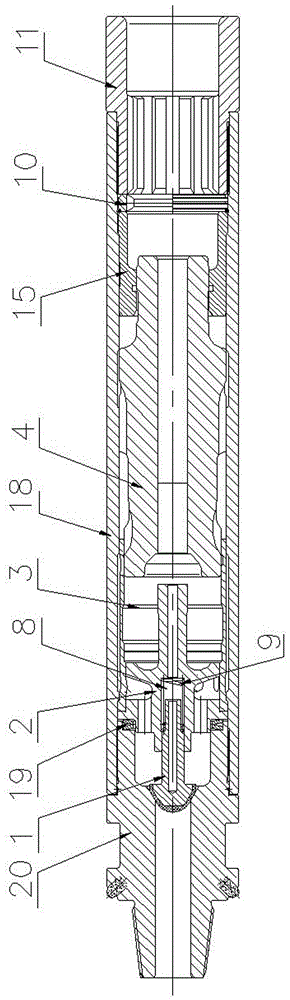

Quick energy saving impactor used for well

The invention provides a quick energy saving impactor used for a well. The quick energy saving impactor comprises a check valve, an air distributing seat, an inner cylinder and a piston, wherein the check valve comprises a long shaft part and a head part; one end, which is far away from the head part, of the long shaft part is provided with a shaft shoulder; the long shaft part is sheathed with the air distributing seat; the air distributing seat is provided with a mounting hole; the long shaft part is sheathed with a spring; one end of the spring is spaced through the shaft shoulder; the other end of the spring is in contact with the bottom of the mounting hole. The quick energy saving impactor has the advantages of reasonable structure design, small pressure loss and good energy saving effect, solves the problems that an impactor in well construction is always subjected to back-filling blockage and piston lubrication is poor and also solves the technical problems that a piston cylinder is always broken, the gas consumption of the impactor is high and working efficiency is low due to a short oriented surface.

Owner:SHANDONG TIANRUI HEAVY IND CO LTD

Nursing hospital bed for medical otology

The invention discloses a nursing hospital bed for the medical otology. The nursing hospital bed comprises a nursing bed body. A backrest adjusting mechanism, a supporting mechanism and a medicine feeding mechanism are arranged on the nursing bed body. The backrest adjusting mechanism is formed by a bed board, a backrest board, an arc groove, a deep groove, a rotating motor, a groove, a bearing, a rotating shaft, a rectangular key, an oval rotating shaft and a rectangular groove, wherein the bed board is arranged on the upper surface of the nursing bed body, and the area of the bed board accounts for 3 / 4 of the area of the nursing bed body; the backrest board has a hinge connected to the surface of one side of the bed board; the arc groove is transversely formed in the lower surface of the backrest board; the deep groove is transversely formed in the middle line position of the arc groove; the rotating motor and the groove are formed in the two opposite sides, located at the backrest board, of the nursing bed body respectively; the bearing is embedded into the groove; one end of the rotating shaft is fixed to the rotating end of the rotating motor, and the other end of the rotating shaft is inserted into the bearing; the rectangular key is arranged on the side surface of the rotating shaft; the oval rotating shaft is arranged on the rotating shaft in a sleeving mode; the rectangular groove is formed in the oval rotating shaft. The nursing hospital bed for the medical otology has the advantages of being simple in structure and high in practicability.

Owner:佛山市南海康佩斯医疗器械有限公司

Grease composition

A grease composition containing a lubricant base oil, diurea compounds represented by the following general formulas (1) to (3), and at least one species selected from the group consisting of paraffin oxides and phosphorus compounds; wherein respective contents of the diurea compounds represented by the following general formulas (1) to (3) satisfy conditions defined by the following expressions (4) and (5); and wherein the total content of the paraffin oxides and phosphorus compounds is 0.1 to 15 mass % based on the total amount of the grease composition:where R1 is a hydrocarbon group containing an aromatic ring, R2 is a divalent hydrocarbon group, and R3 is a hydrocarbon group containing an aliphatic ring;5≦W1+W2+W3≦30 (4)0.3≦(W1+0.5×W2) / (W1+W2+W3)≦0.7 (5)where W1, W2, and W3 are respective contents (mass %) of the diurea compounds represented by general formulas (1) to (3) based on the total amount of the grease composition.

Owner:NIPPON OIL CORP

Special tool for milling and processing K2 side bearing axial trough

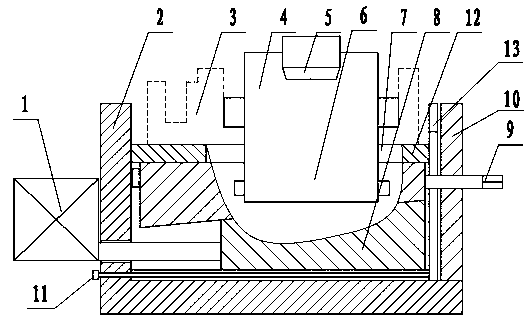

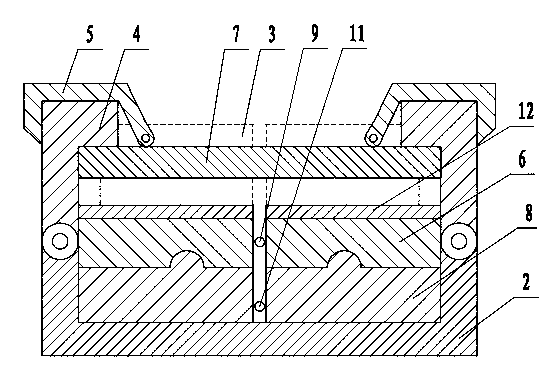

ActiveCN103056685AAvoid frettingEasy to fixPositioning apparatusMetal-working holdersEngineeringUltimate tensile strength

The invention discloses a special tool for milling and processing a K2 side bearing axial trough and belongs to the technical field of a mechanical processing tool. The tool comprises a recessed base of which the upper surface is provided with an opening, an upper tapered wedge and a lower tapered wedge are arranged in the base, two slopes of the upper tapered wedge and the lower tapered wedge are matched, left sides and right sides of the upper tapered wedge and the lower tapered wedge are matched with the inner surface of the vertical end plate of the base, a pressing plate and an upper limiting mechanism which limits the motion of the pressing plate are arranged on the upper portion of the upper tapered wedge, and the side of the lower tapered wedge is connected to a piston rod of a cylinder, which is arranged on the outer wall of the base. During the process of the K2 side bearing, the detection and classification process of the trough vertical face is omitted, the processing efficiency is improved, the assisting time is saved, the labor intensity is reduced, the efficacy is improved, and the processing quality is guaranteed.

Owner:CRRC SHIJIAZHUANG CO LTD

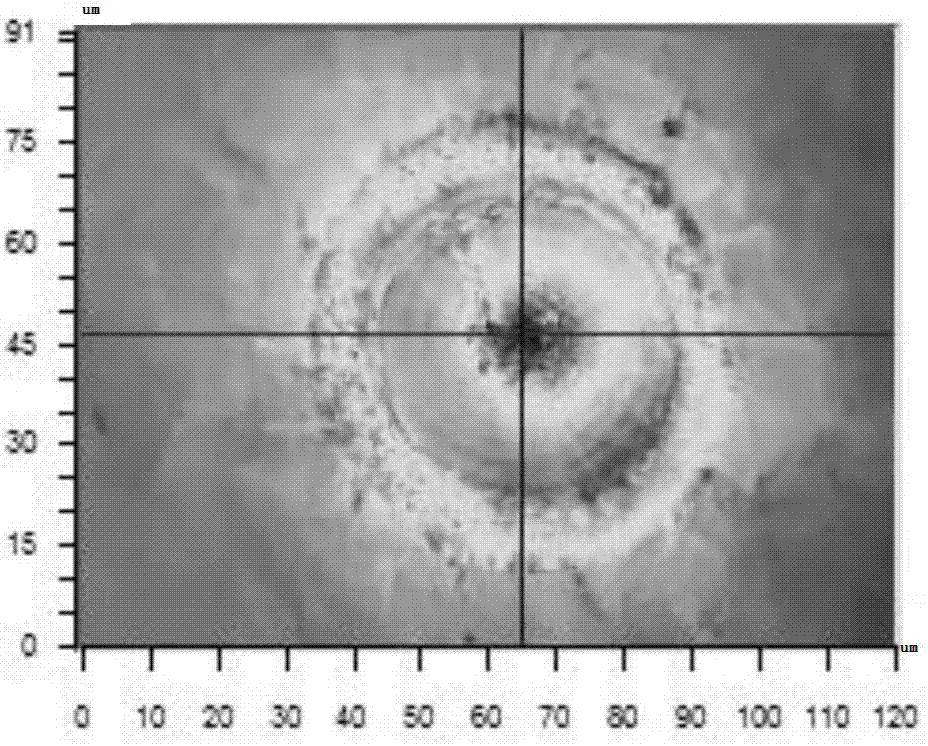

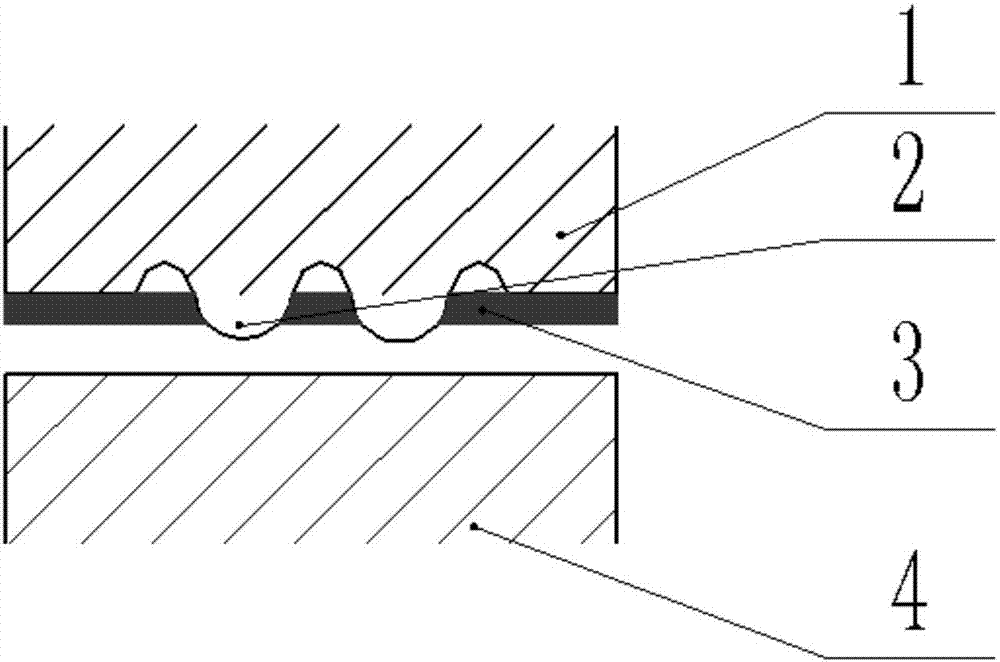

Aero-engine blade tenon roughening texture coating treatment method and engine blade

ActiveCN107475666AHigh hardnessAvoid frettingBlade accessoriesVacuum evaporation coatingComposite structureFriction reduction

The invention provides an aero-engine blade tenon roughening texture coating treatment method and an engine blade. The aero-engine blade tenon roughening texture coating treatment method comprises the following steps that the surface of a tenon is subjected to pretreatment; the surface of the tenon is subjected to roughening machining, and a spherical-crown-shaped type with the roughening shape being convex in the middle and concave at the two edges is obtained; coating technique preparation is conducted; a Zr transitional layer is deposited; and an MoS2 soft coating is deposited. According to the aero-engine blade tenon roughening texture coating treatment method and the engine blade, the tenon part of the aero-engine blade adopts a roughening (a concave-convex composite structure) texture and a soft coating composite structure; the roughened surface hardening effect is utilized to enable the tenon to be tightly engaged with a mortise, fretting damage is avoided, and meanwhile the soft coating can achieve the friction reduction and abrasion resistance effects; and the concave pit part of a roughening structure can also collect a soft coating material. All the structural functions are coordinated and coupled, the connecting reliability between the tenon and the mortise can be effectively reinforced, the fatigue strength of the surface of the tenon is improved, friction and abrasion are reduced, the fretting damage and fatigue breakage are avoided, the connecting reliability of the tenon and the mortise of the aero-engine blade are greatly improved, and the service life is greatly prolonged.

Owner:JIANGSU UNIV

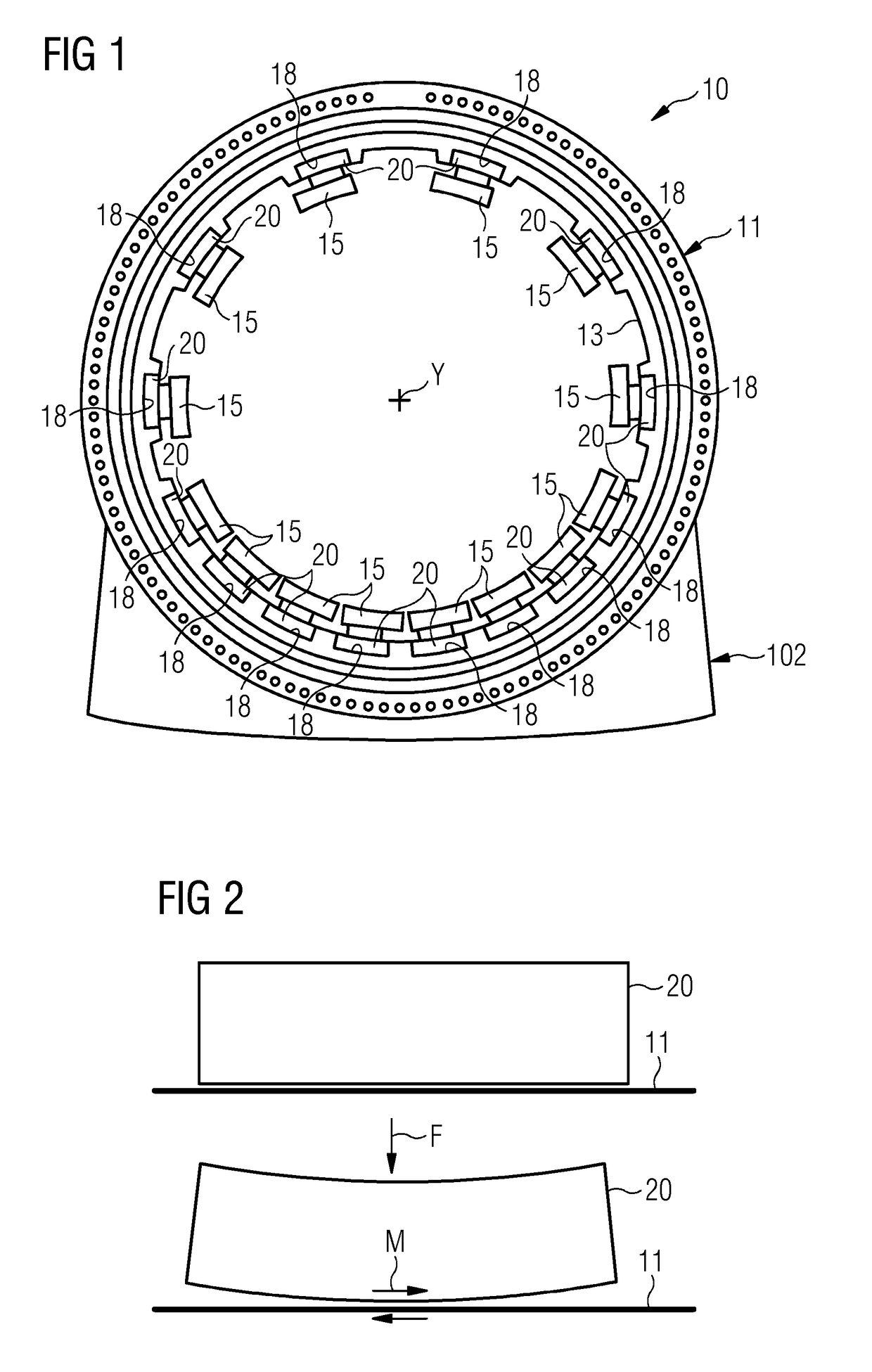

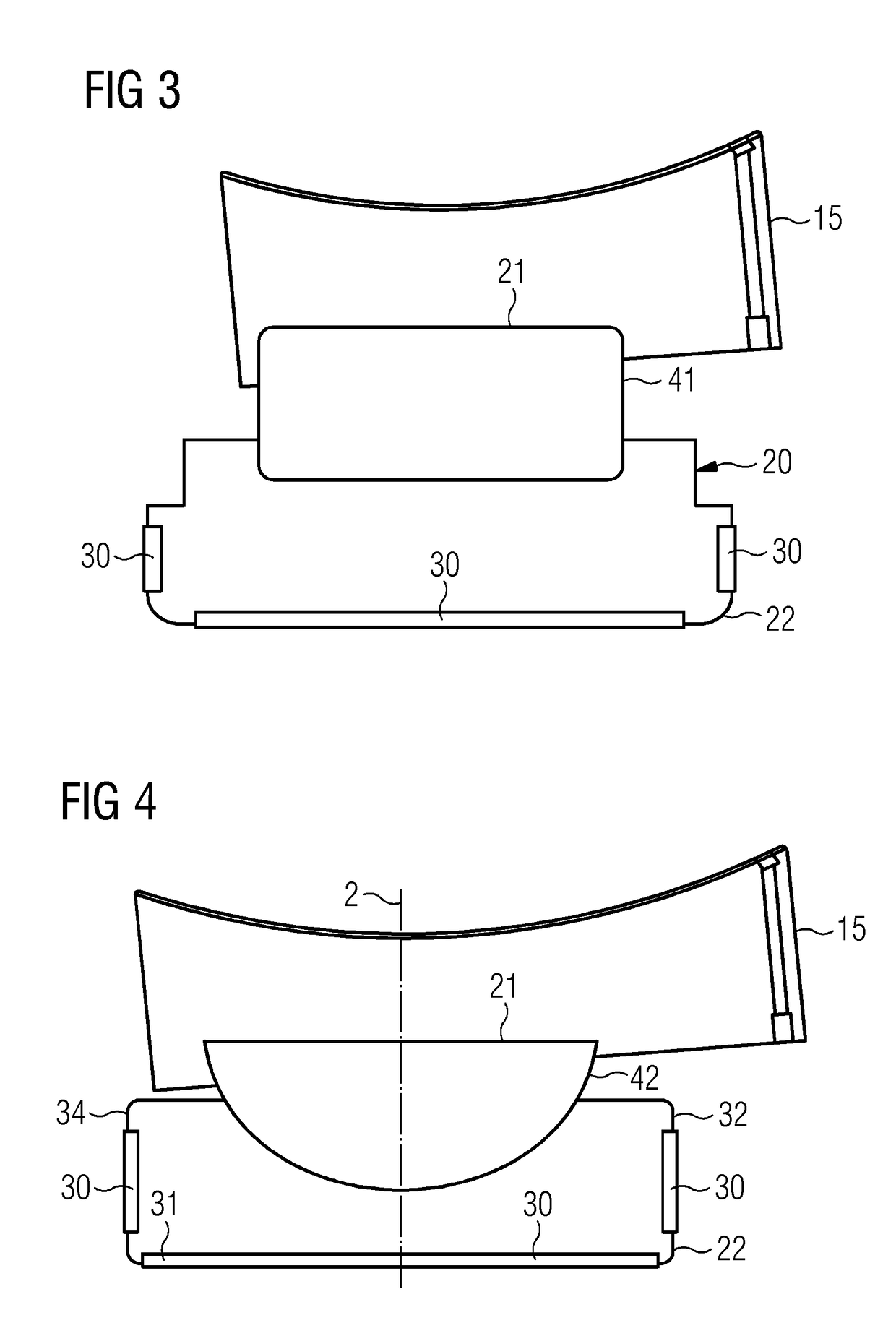

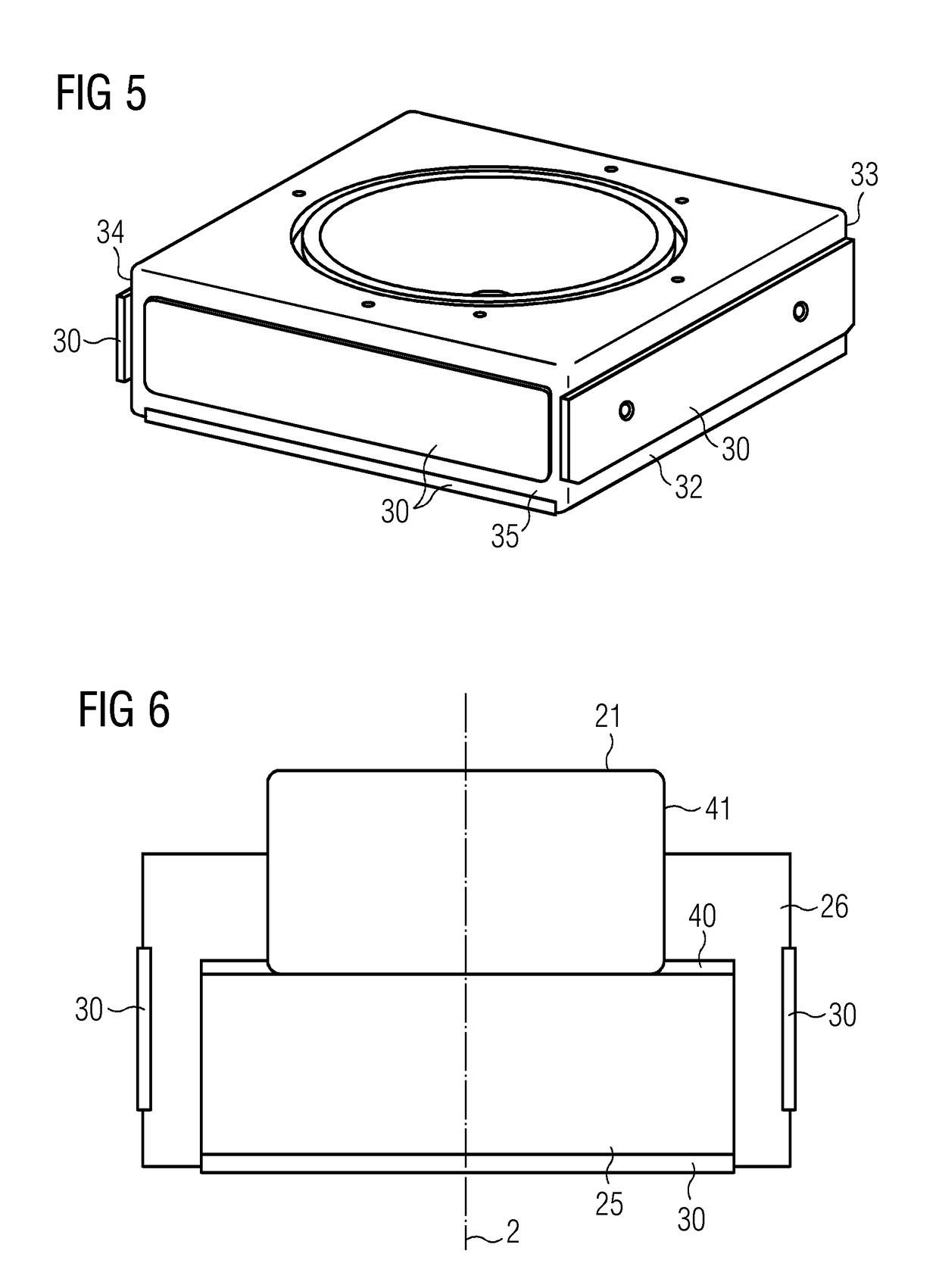

Fluid film bearing for a wind turbine

ActiveUS20190085829A1Simply and easily and reconfiguredEasy to manufactureShaftsBearing componentsTurbineFluid bearing

A fluid bearing for a wind turbine includes: a bearing housing, a plurality of bearing pads inside the bearing housing and circumferentially distributed around a longitudinal axis of the fluid bearing, a plurality of supporting structures, each supporting structure having at least a first interface detachably connected to a respective seat provided in the bearing housing and at least a second interface detachably connected to a respective bearing pad of the plurality of bearing pads, each supporting structure allowing tilting of the respective bearing pad with respect to the bearing housing.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

A Focusing and Locking Structure on a Precision Optical Instrument

Owner:佛山市三水力达精密金属制品有限公司

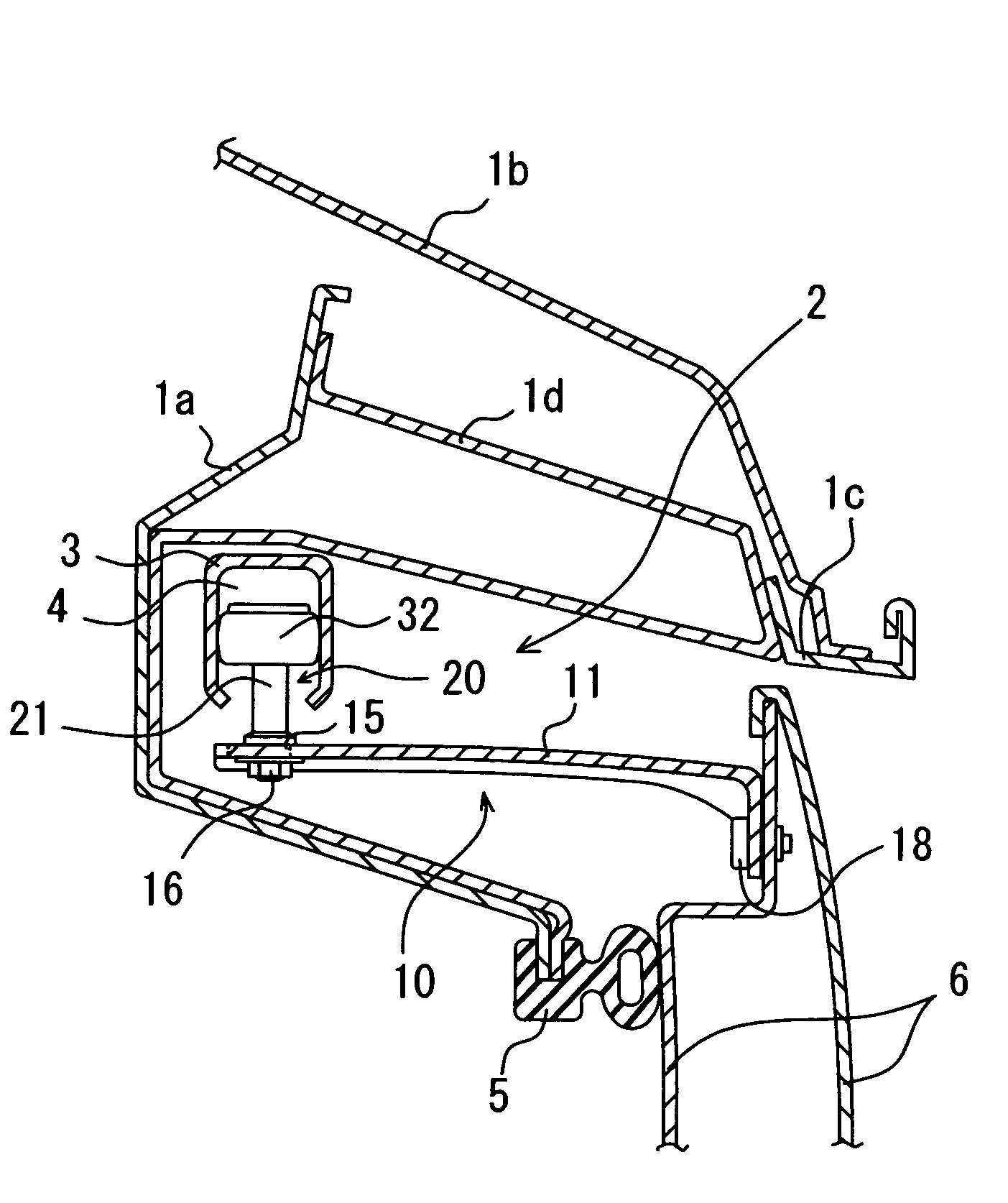

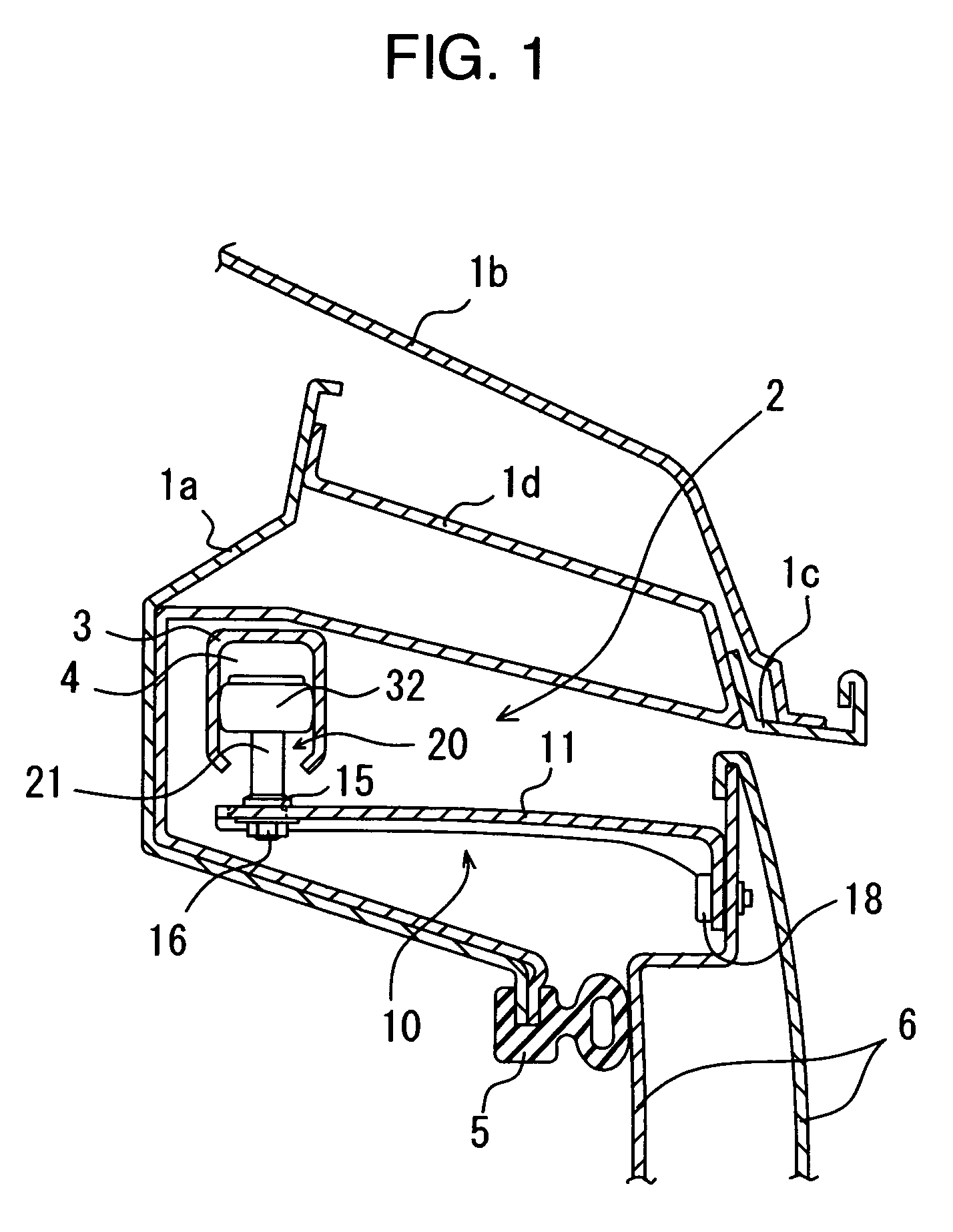

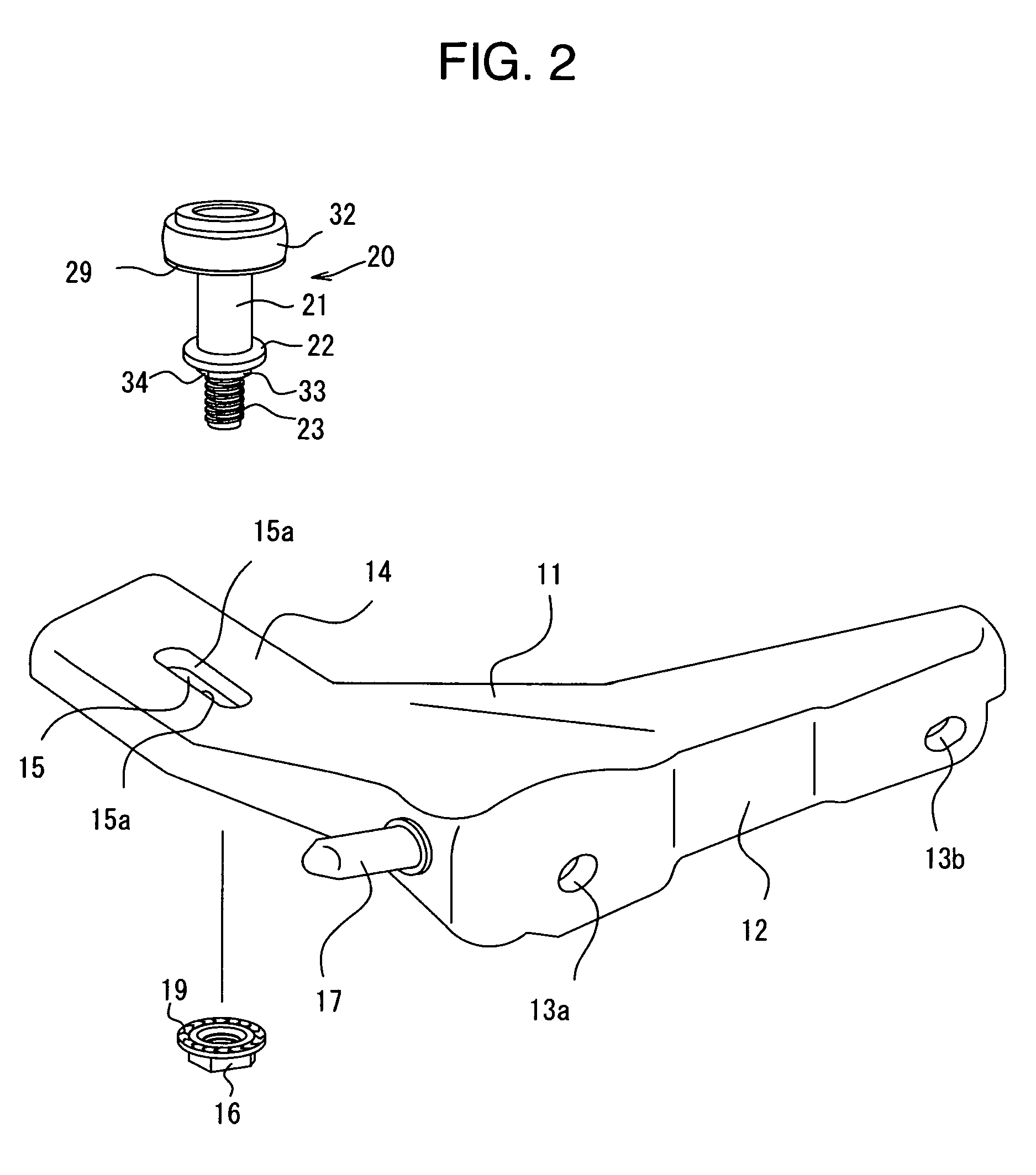

Guide roller of slide door for vehicle

In order to provide a guide roller which can be readily mounted on a support member and readily adjusted in position without reducing strength of a support shaft, according to the invention, when inserting a screw part of the shaft through a long hole of the support member and fixing the shaft by a nut on a back side, the screw part is inserted while contacting notched planes with contact parts, and an insertion position of the screw part is made adjustable in the long hole. It is possible, without necessity to form an engaging part for calking in the columnar shaped support shaft, to prevent reduction in strength of the guide roller, to position the guide roller with respect to a rail only by screwing the guide roller to the support member after previously fixing the support member to the slide door, and to make the operation efficient.

Owner:DAIDO METAL CO LTD

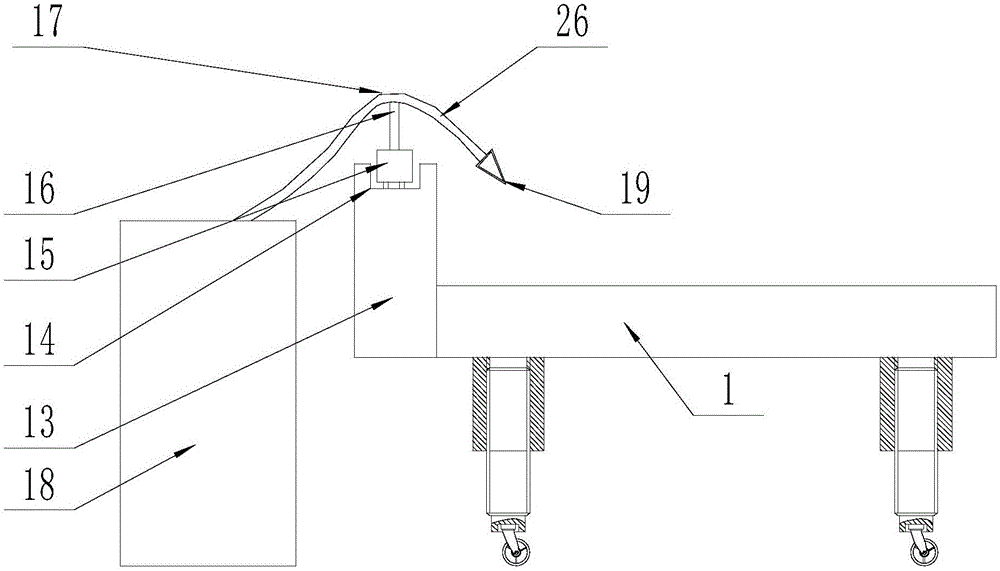

Medical otology nursing bed

The invention discloses a medical otology nursing bed which comprises a cleaning bed body. An intelligent adjusting unit, a supporting mechanism and a cleaning mechanism are arranged on the cleaning bed body, and the cleaning mechanism is formed by a bedside backup plate arranged on one upper surface of the cleaning bed body, a sliding chute formed in the upper surface of the bedside backup plate, a drive cart embedded in the sliding chute, a vertical rod fixed on the upper surface of the drive cart, a cleaning hose arranged on the upper surface of the vertical rod and a cleaning bed and a spray gun which are arranged at two end of the vertical rod. The medical otology nursing bed has the advantages of simpleness in structure and high practicability.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

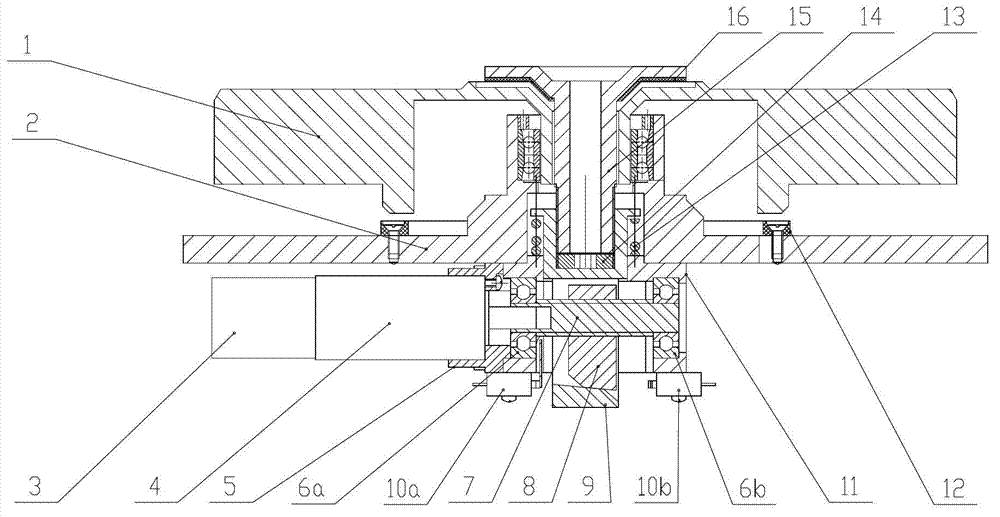

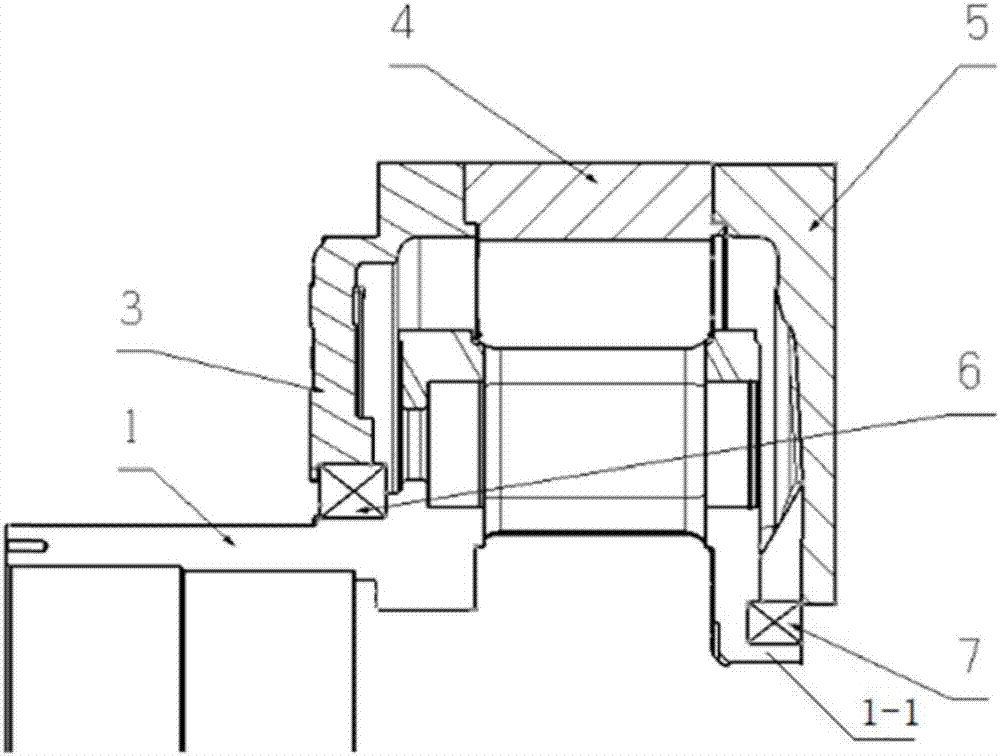

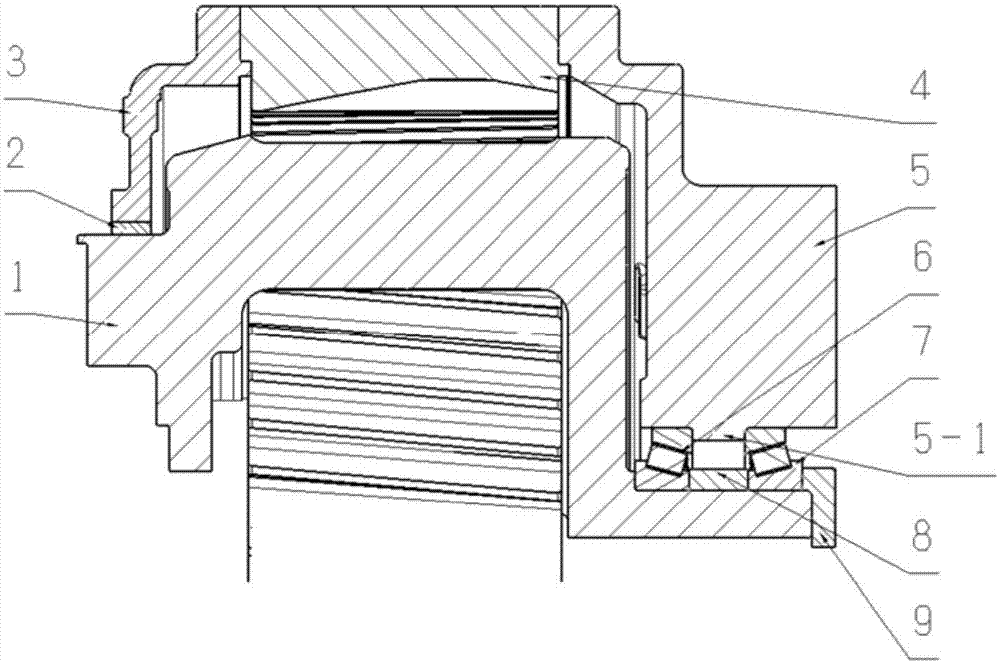

Large wind power gearbox planetary bracket bearing arrangement structure

ActiveCN107387743ASimple installation and disassemblyImprove securityMachines/enginesMechanical power transmissionMechanical engineeringWind power

The invention discloses a large wind power gearbox planetary bracket bearing arrangement structure which is good in safety and reliability and low in cost. The large wind power gearbox planetary bracket bearing arrangement structure further comprises a pressing plate (9). A left bearing (6) and a right bearing (7) are small conical roller bearings of the same specification. The axial width of an assembling portion (1-1) of a planetary bracket (1) is larger than the sum of the axial width of the left bearing (6) and the axial width of the right bearing (7). The axial width of a downwind-direction box body (5) corresponds to the axial width of the assembling portion (1-1) of the planetary bracket (1), and the inner wall of the downwind-direction box body (5) is provided with an isolation portion (5-1) extending inwards. The right bearing (6) is also assembled between the assembling portion (1-1) of the planetary bracket (1) and the downwind-direction box body (5), the right end face of the right bearing (6) closely adjoins with the left end face of the isolation portion (5-1), and the left end face of the right bearing (7) closely adjoins with the right end face of the isolation portion (5-1). The pressing plate (9) is assembled to the right end of the planetary bracket (1), and the left end face of the pressing plate (9) closely adjoins with the right end face of the right bearing (7).

Owner:CHONGQING WANGJIANG IND

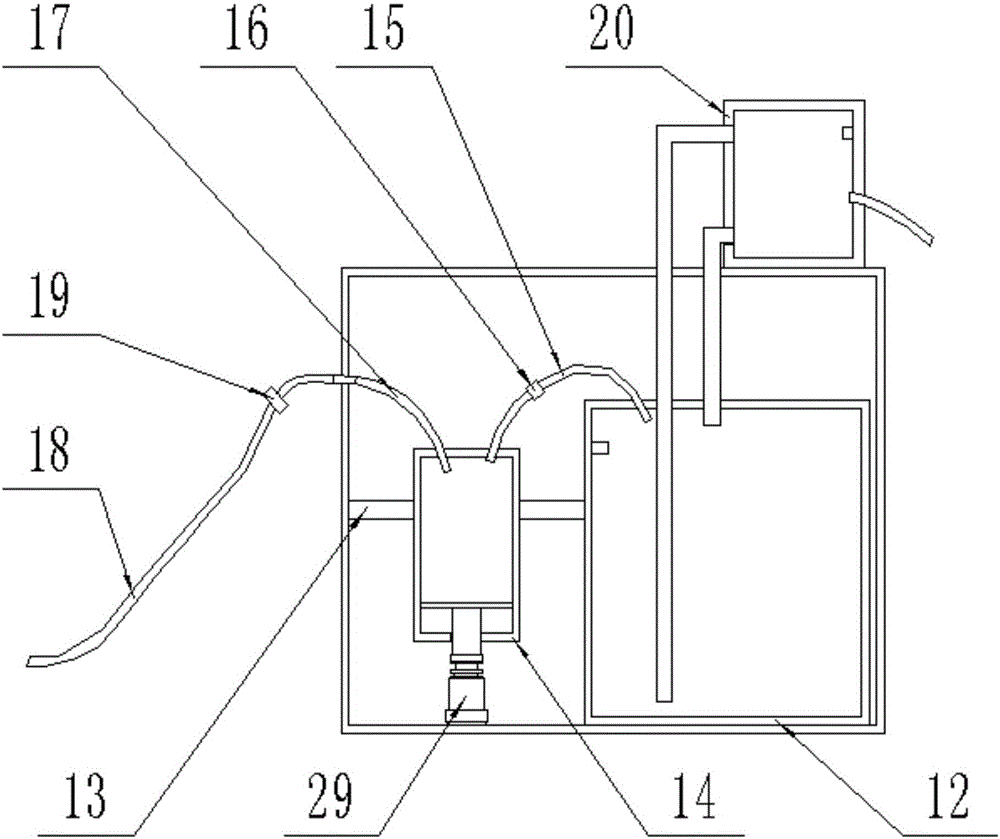

Medical cleaning equipment for otology

The invention discloses medical cleaning equipment for otology, which comprises a cleaning bed. A head part adjusting mechanism, a supporting and adjusting mechanism, a cleaning and flushing mechanism and a moving and adjusting mechanism are arranged on the cleaning bed; the moving and adjusting mechanism is formed by a circular groove inwards arranged on the side surface of the head part of the cleaning bed, a rotary motor fixedly embedded in the circular groove and provided with a horizontal rotary end, a swinging arm fixedly sleeved on the rotary end of the rotary motor, a circular groove A arranged in the side surface of one end of the swinging arm, a rotary motor A embedded in the circular groove A, a cleaning diversion hose sleeved on a rotary end of the rotary motor A, and a cleaning box and a spray gun respectively connected to two ends of the cleaning diversion hose. The medical cleaning equipment for otology provided by the invention has the beneficial effects of simple structure and high practicability.

Owner:慈文学

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com