Aero-engine blade tenon roughening texture coating treatment method and engine blade

A technology for aero-engines and engine blades, applied in the direction of engine components, machines/engines, coatings, etc., can solve problems such as fretting damage, shedding, and fracture, and achieve the effects of prolonging service life, enhancing hardness, and reducing friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example example 1

[0044] Step 1: Pre-treatment of the tenon surface 1, polishing the processed surface of the tenon to a mirror surface, ensuring that the roughness is less than 0.05um, and ultrasonic cleaning with alcohol for 20 minutes.

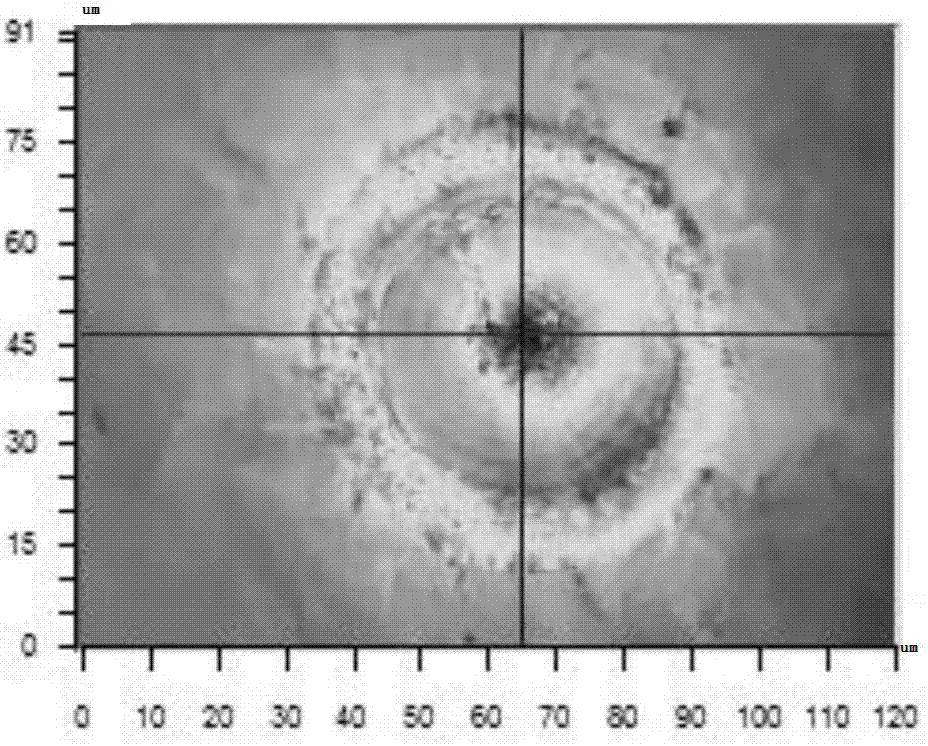

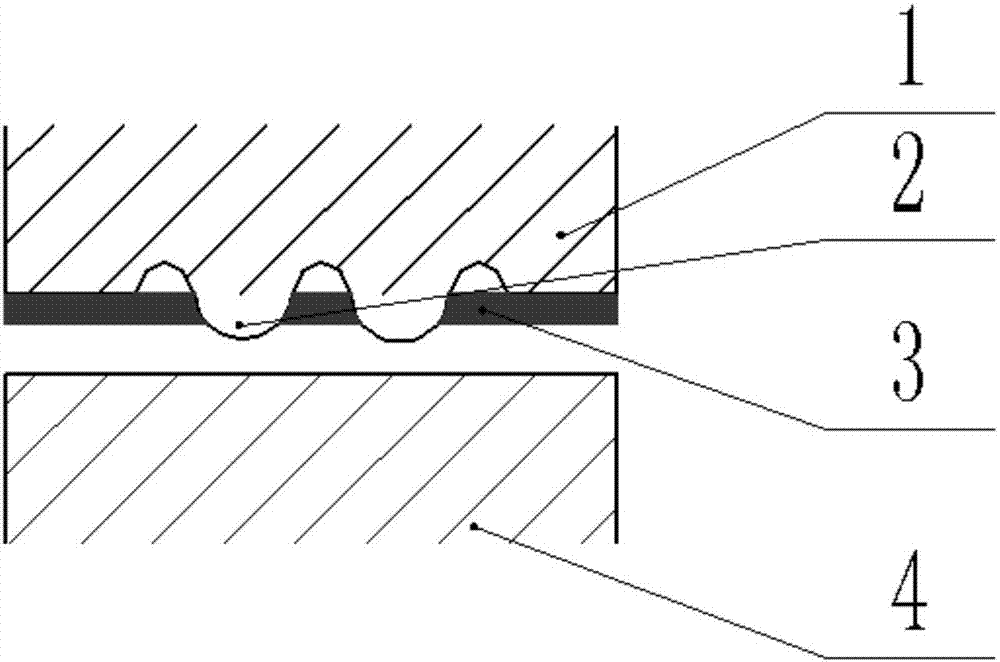

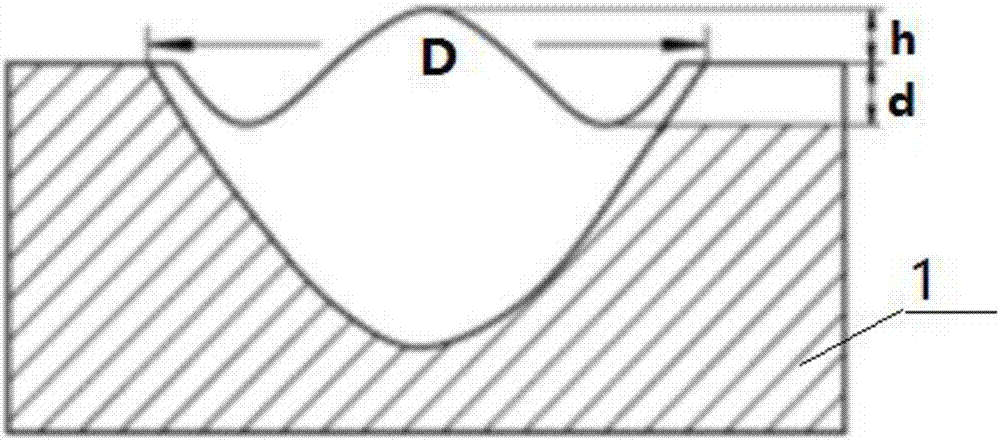

[0045] Step 2: Texturize the tenon surface 1. SPI fiber laser is used to roughen the tenon surface 1, that is, the upper surface. The output is collimated parallel light, the divergence angle is less than 0.4mrad, and the output beam quality is M 2 <1.1, the spot diameter is not more than 5mm, the output power is 100W, the pulse frequency is 10KHz, the laser wavelength is 1064nm, and the pulse width is 10us. Nitrogen was selected as the auxiliary gas, the blowing angle of the auxiliary gas was 20° to the normal direction of the workpiece, the gas flow rate was 10ml / min, and the textured morphology was spherical crown.

[0046] Step 3: Prepare the coating process. Ultrasonic clean the mortise obtained by laser texturing with alcohol and acetone for 20 minutes...

example example 2

[0052] Step 1: Pre-treatment of the tenon surface 1, polishing the processed surface of the tenon to a mirror surface, ensuring that the roughness is less than 0.05um, and ultrasonic cleaning with alcohol for 20 minutes.

[0053] Step 2: Texturize the tenon surface 1. SPI fiber laser is used to roughen the tenon surface 1, that is, the upper surface. The output is collimated parallel light, the divergence angle is less than 0.4mrad, and the output beam quality is M 2 <1.1, the spot diameter is not greater than 5mm, the output power is 200W, the pulse frequency is 60KHz, the laser wavelength is 1064nm, and the pulse width is 35us. Nitrogen was selected as the auxiliary gas, the blowing angle of the auxiliary gas was 40° to the normal direction of the workpiece, the gas flow rate was 200ml / min, and the textured morphology was spherical crown.

[0054] Step 3: Prepare the coating process. Ultrasonic clean the mortise obtained by laser texturing with alcohol and acetone for 20 min...

example example 3

[0059] Step 1: Pre-treatment of the tenon surface 1, polishing the processed surface of the tenon to a mirror surface, ensuring that the roughness is less than 0.05um, and ultrasonic cleaning with alcohol for 20 minutes.

[0060] Step 2: Texturize the tenon surface 1. SPI fiber laser is used to roughen the tenon surface 1, that is, the upper surface. The output is collimated parallel light, the divergence angle is less than 0.4mrad, and the output beam quality is M 2 <1.1, the spot diameter is not more than 5mm, the output power is 400W, the pulse frequency is 120KHz, the laser wavelength is 1064nm, and the pulse width is 70us. Nitrogen is selected as the auxiliary gas, the blowing angle of the auxiliary gas is 0-60° to the normal direction of the workpiece, the gas flow rate is 450ml / min, and the textured morphology is spherical crown.

[0061] Step 3: Prepare the coating process. Ultrasonic clean the mortise obtained by laser texturing with alcohol and acetone for 20 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimple diameter | aaaaa | aaaaa |

| Pit depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com