Control system for desk type reflow soldering machine

A technology of reflow soldering machine and control system, which is applied in electric temperature control, manufacturing tools, welding equipment, etc. It can solve the problem of poor welding effect, low heating efficiency and poor temperature adjustability of narrow pitch and small SMD components. And other problems, to achieve the effect of good welding effect, high heating efficiency and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

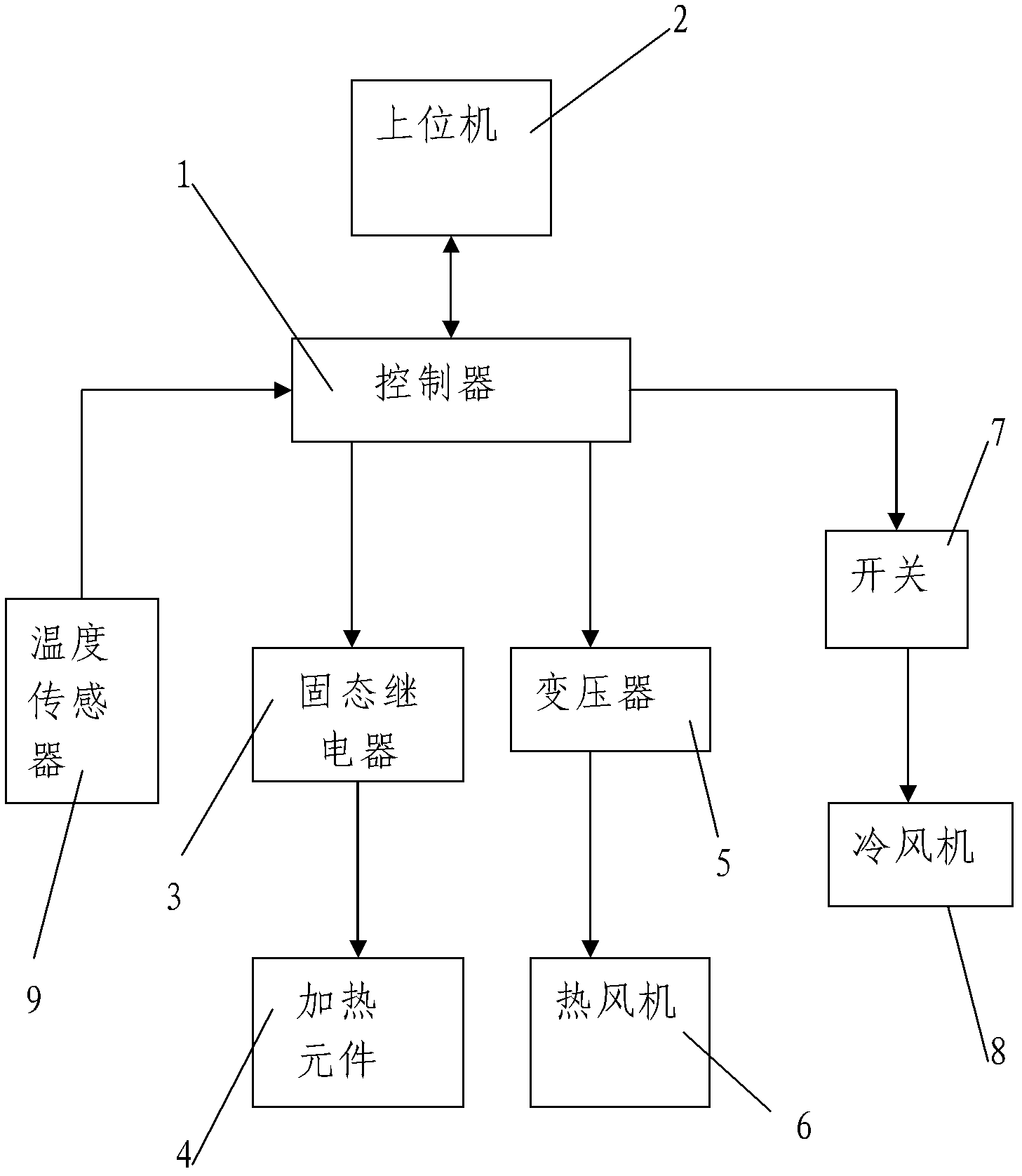

[0022] Such as figure 1 As shown, the present invention includes a controller 1, a host computer 2 that transmits setting parameters and operation instructions to the controller 1 while receiving and displaying the output information of the controller 1, and automatically controls the power of the heating element 4 under the control of the controller 1. Regulated solid state relay 3, a transformer 5 that automatically adjusts the voltage of the hot air blower 6 under the control of the controller 1, a switch 7 that performs on-off control of the cold air blower 8 under the control of the controller 1, and controls the controlled reflow soldering The temperature sensor 9 for real-time detection of the furnace temperature of the machine; the solid state relay 3 and the heating element 4 are connected to form a heating system, the transformer 5 is connected to the hot air blower 6 to form a hot air circulation system, and the switch 7 is connected to the cooling fan 8 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com