Metal material, method for producing the same, and electrical electronic component using the same

A metal material, electrical conductivity technology, applied in the direction of metal material coating process, contact parts, metal layered products, etc., can solve the problems of fretting wear, reduced conduction between terminals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

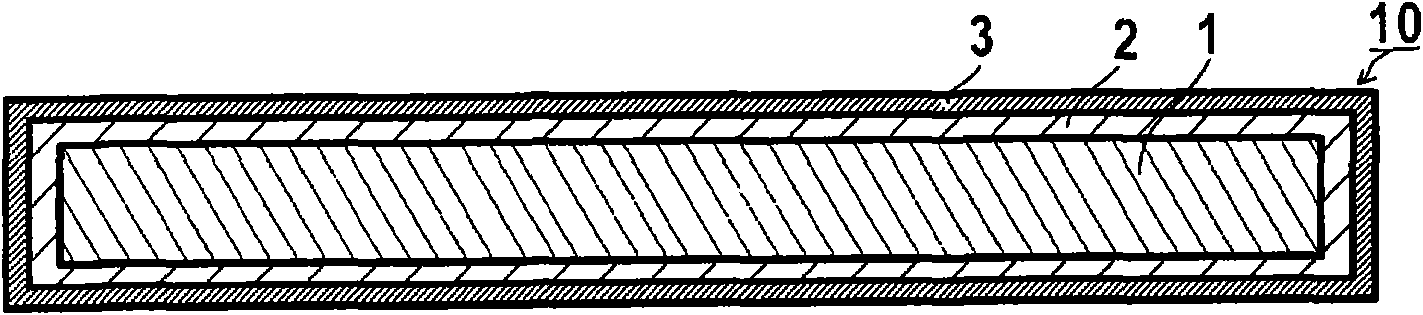

Embodiment 1

[0059]Electrolytic degreasing and pickling are performed on the conductive substrate of a copper-zinc alloy (CDA No.C26800) with a thickness of 0.3mm and a width of 180mm, and then the metal or alloy shown in the item [Surface] of Table 1 is covered by plating Formed on the substrate, each plating metal material is fabricated. Next, each of the prepared metal plating materials was subjected to a film-forming treatment using an organic compound shown in the item [Organic Film] in Table 1 to form a metal material with an organic film thickness of about 0.01 μm, and the test results of the present invention were respectively obtained. Objects 1 to 13 and test objects c1 to c7 for comparison. In addition, regarding the Sn alloy in the examples, the plating thickness was adjusted according to the stoichiometry of each alloy component (here, the atomic number ratio or the mass ratio described in the footnote of Table 1), and then the plating thickness was adjusted at 300° C.×15 minu...

Embodiment 2

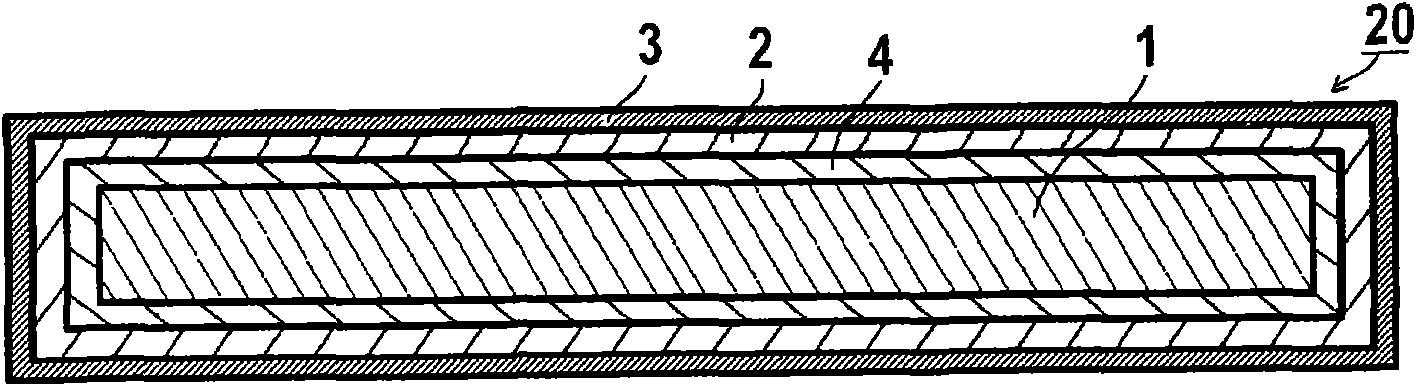

[0104] Electrolytic degreasing and pickling are performed on the conductive substrate of copper-tin alloy (CDA No.C52100) with a thickness of 0.25mm and a width of 100mm, and then the metal or alloy shown in the [intermediate layer] item of Table 3 is plated Overlay was formed on this substrate with a thickness of 0.2 μm. In addition, about the material which forms 2 layers of intermediate|middle layers, each 0.1 micrometer was formed in order of 1st layer / 2nd layer, and it describes in Table 3. In addition, the metal or alloy shown in the item [Surface layer] is coated and formed on the above-mentioned intermediate layer by plating, and each plated metal material is produced. Next, each of the prepared metal plating materials was subjected to a film-forming treatment using an organic compound shown in the item [Organic Film] of Table 3 to form a metal material with an organic film thickness of about 0.01 μm, and the test results of the present invention were respectively obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com