Patents

Literature

70results about How to "Vibrate compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mold for concrete axial tension test piece and rod piece pre-embedding method by using the mold

ActiveCN104236964AImprove verticalitySimplify the embedding processPreparing sample for investigationEngineeringPre embedding

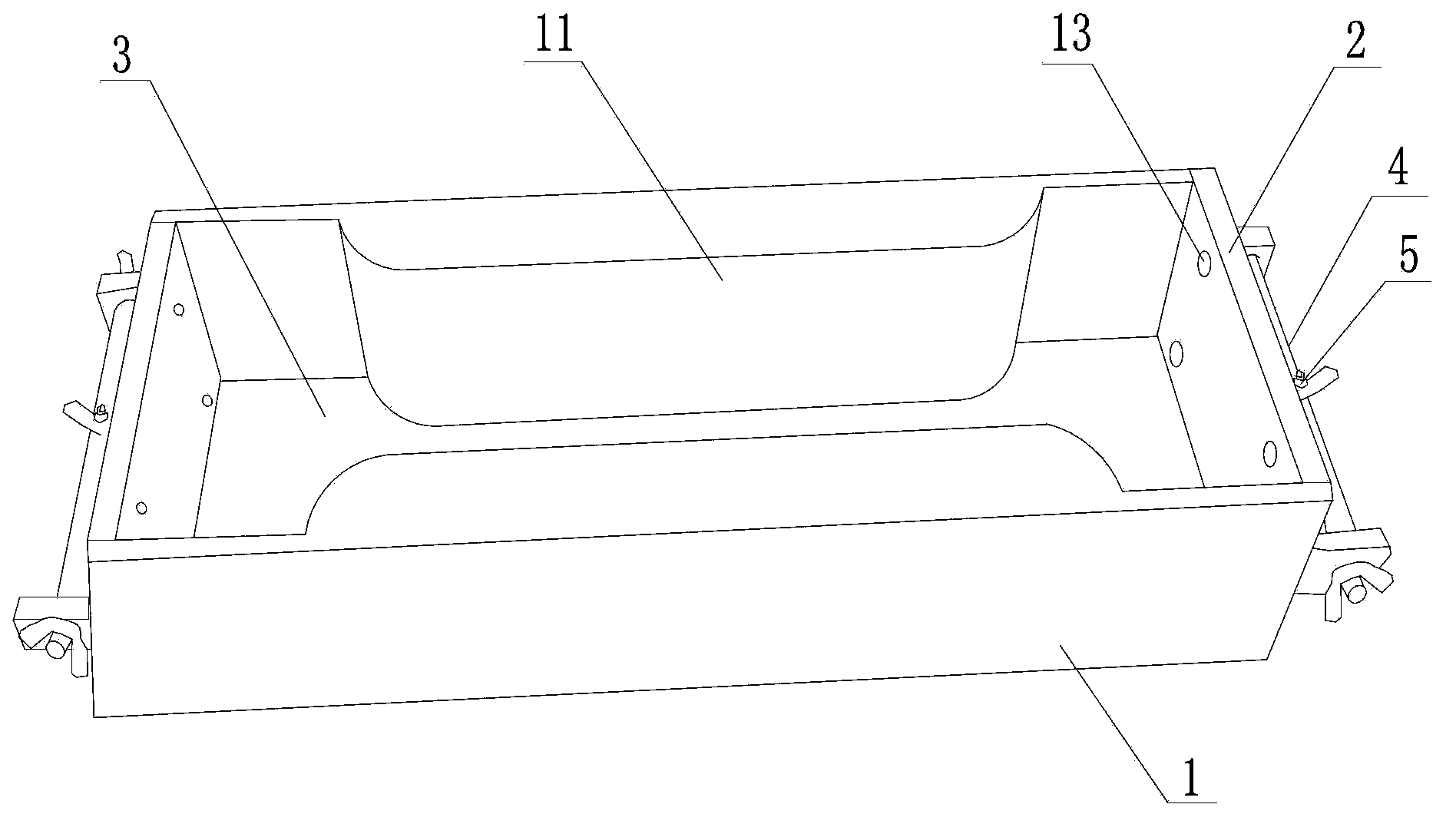

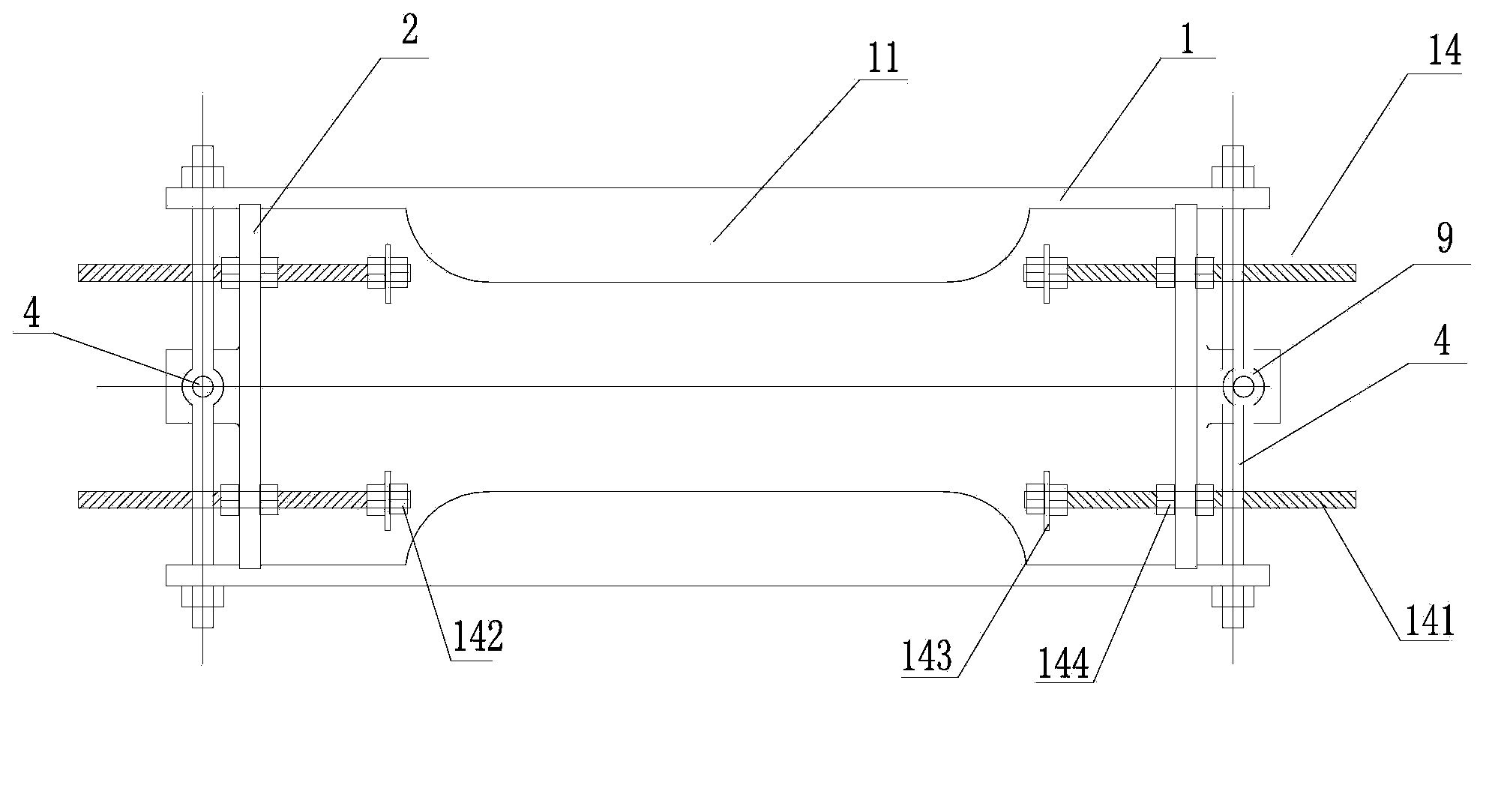

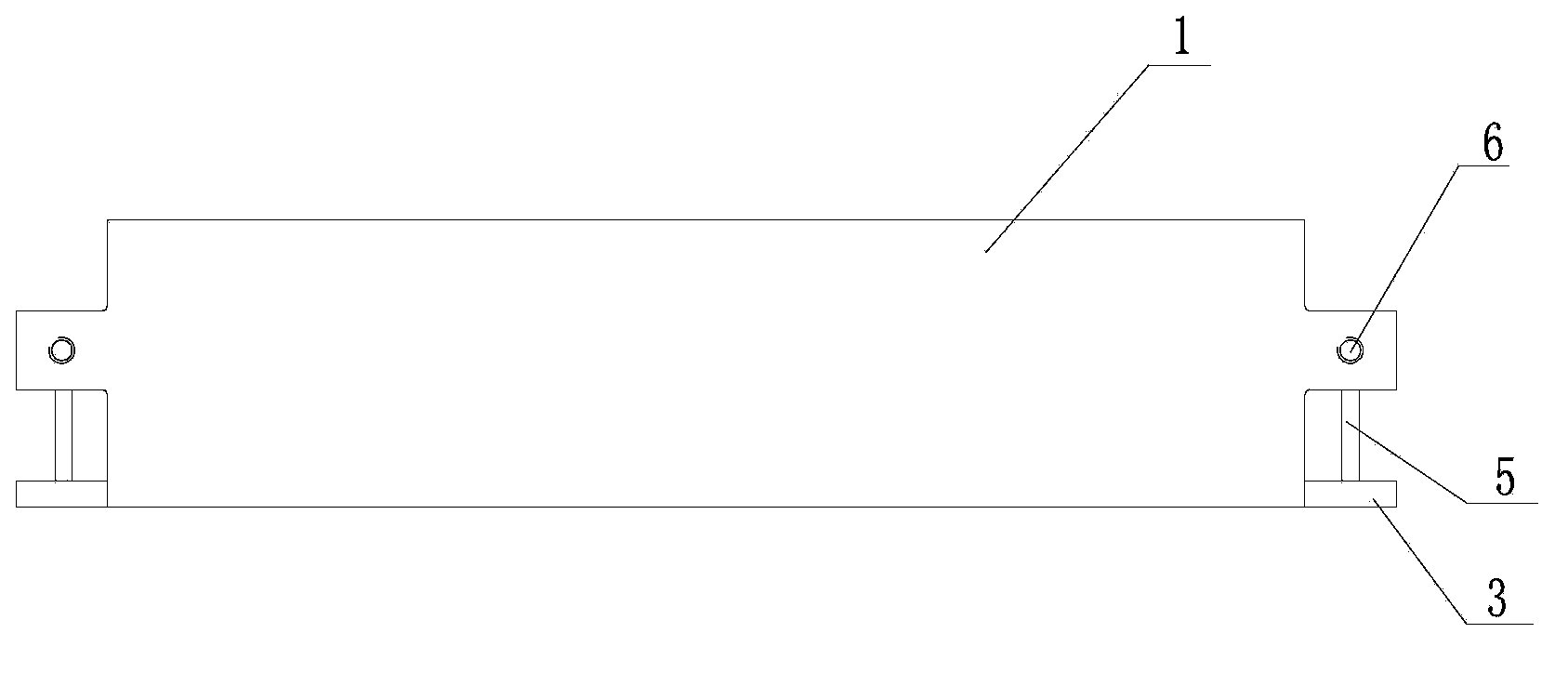

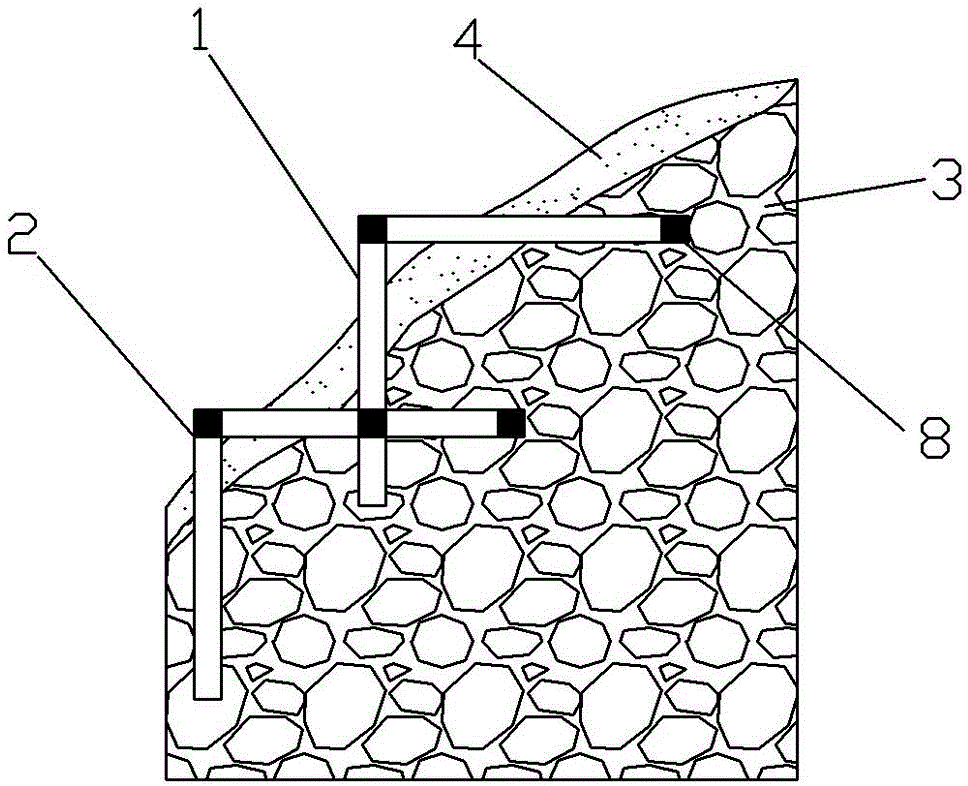

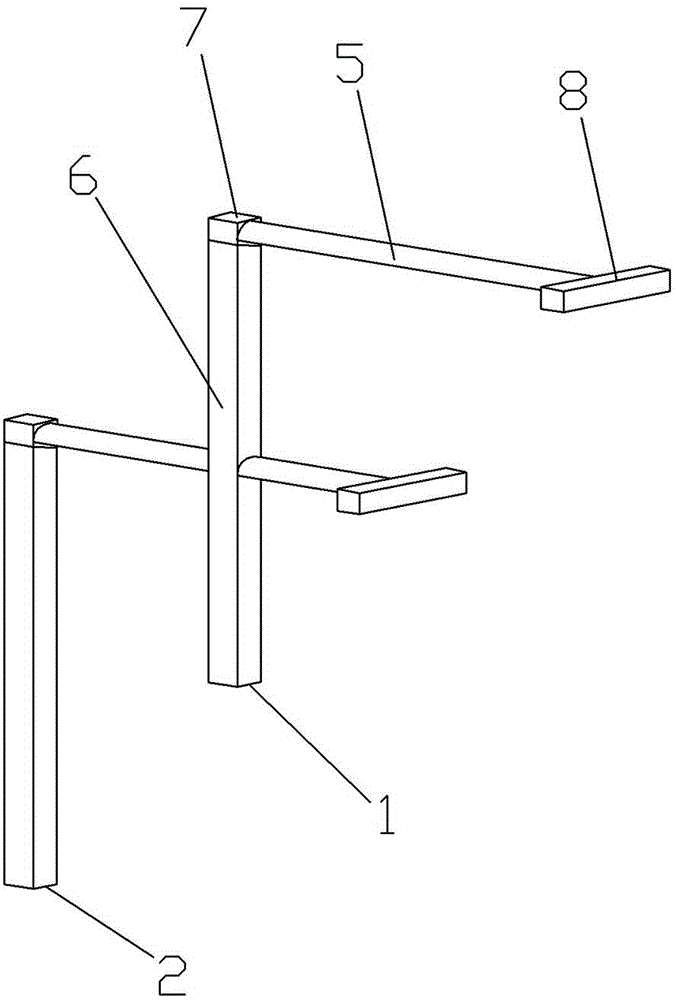

The invention relates to a test mold, and particularly relates to a dumbbell-shaped mold used for concrete uniaxial tension test, and a rod piece pre-embedding method. The mold for the concrete axial tension test piece comprises a bottom plate. Two opposite sides of the bottom plate are fixedly connected with side plates; the other two opposite sides of the bottom plate are provided with end part plates; the bottom plate, the side plates and the end part plates are combined to form a hollow box with the top opening; the opposite sides of the two side plates are convex at the middle parts to form lug bosses; two sides of each side plate are provided with insert holes protruding out of the planes of the end part plates; a horizontal rod is connected between the directly opposite insert holes of the two side plates; a through hole I is formed in the middle of the horizontal rod; a vertical rod penetrates through the through hole and then is inserted in a fixed hole arranged in the bottom plate; the end part plates are limited by the horizontal rod and the vertical rod; a through hole II is formed in each end part plate respectively; and pre-embedding pieces are inserted into the through holes II. The manufacturing precision of the test piece is high and a flow for manufacturing the test piece is simple.

Owner:青岛理正建设科技有限公司

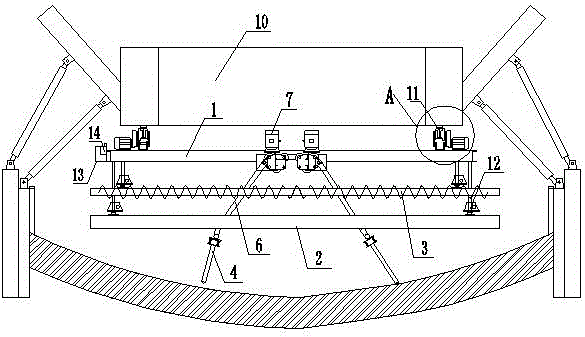

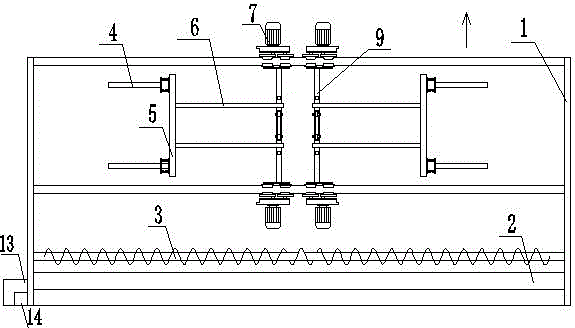

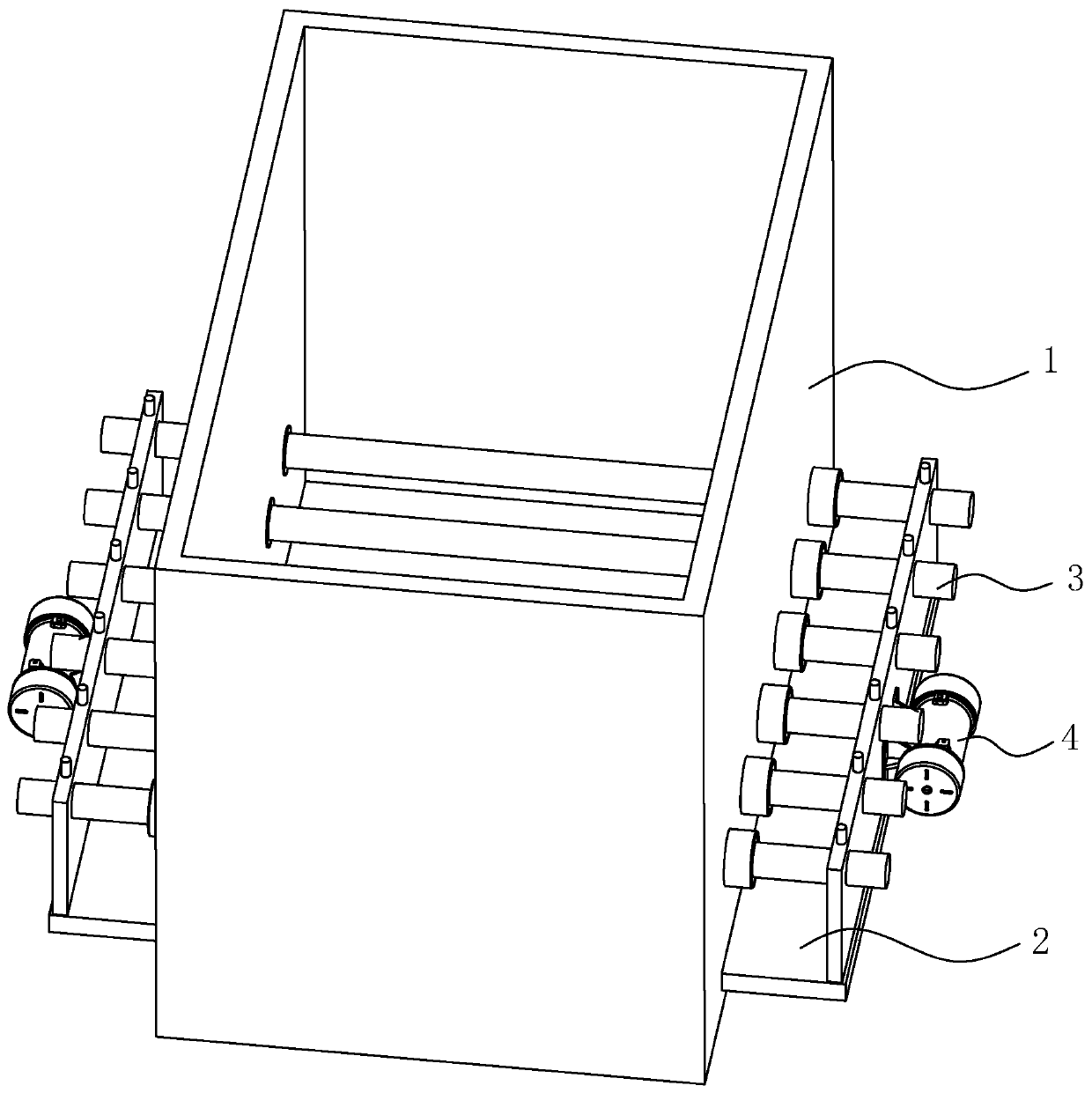

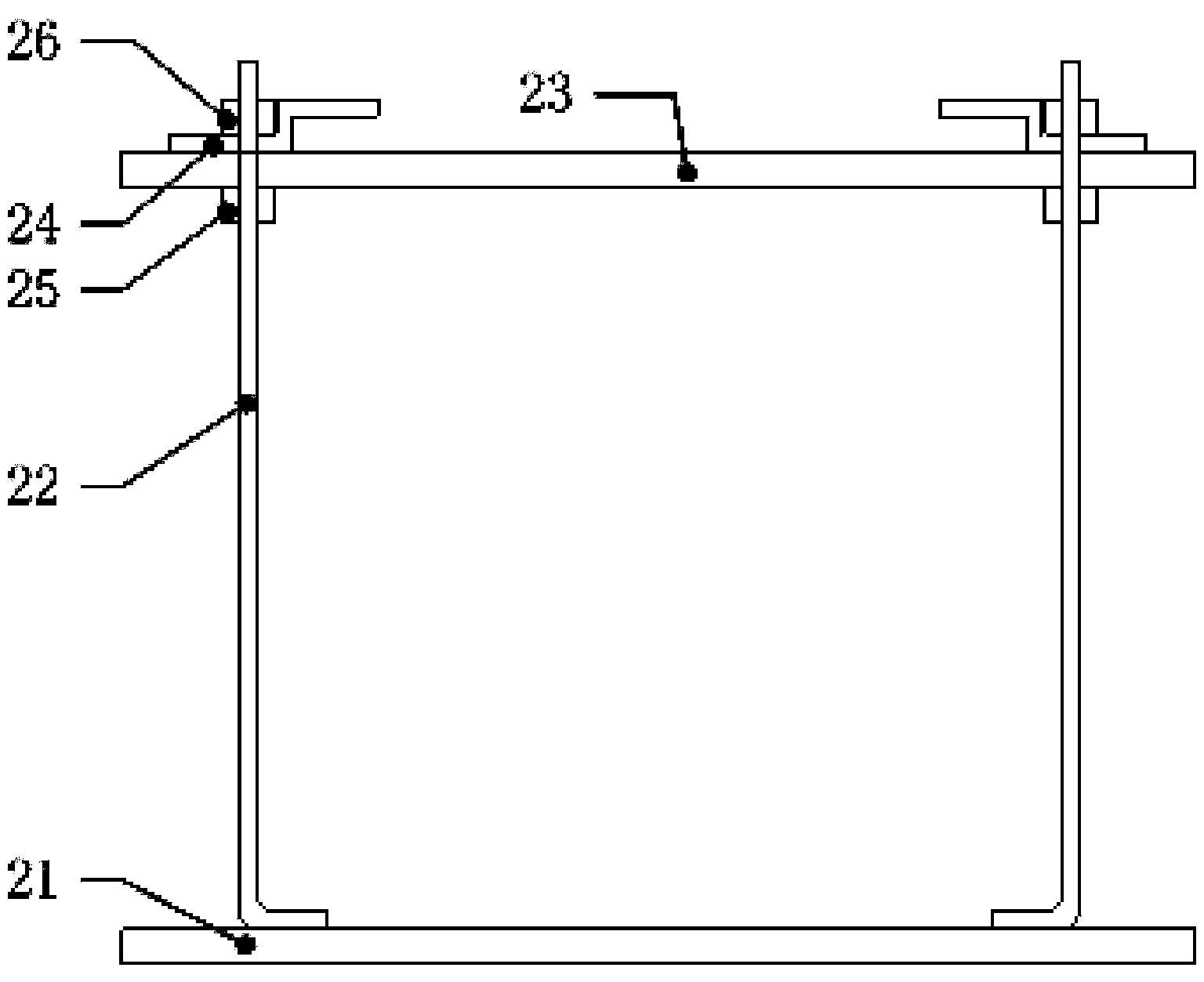

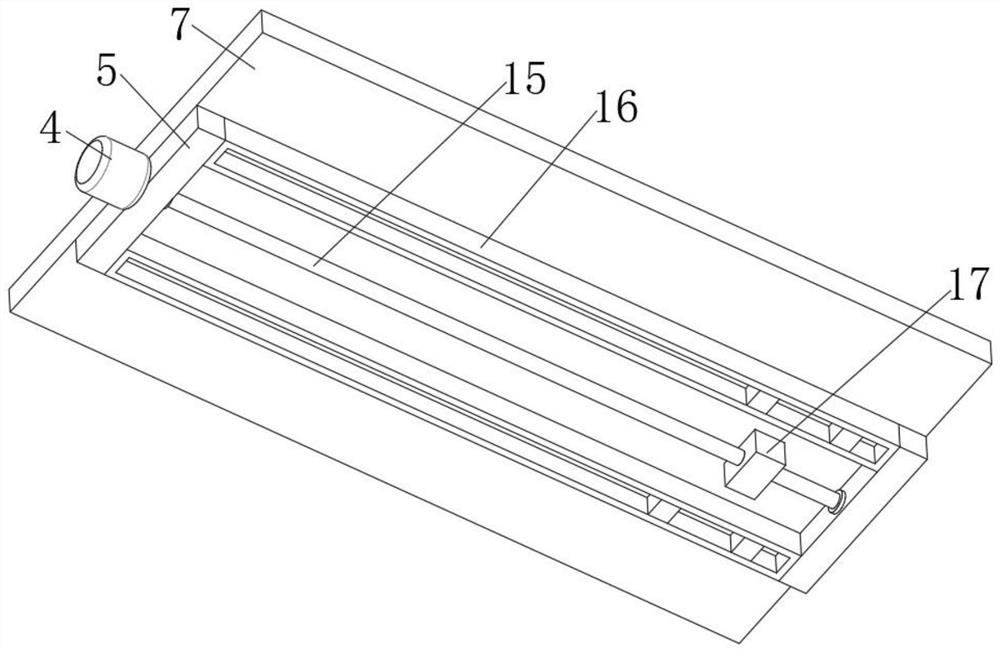

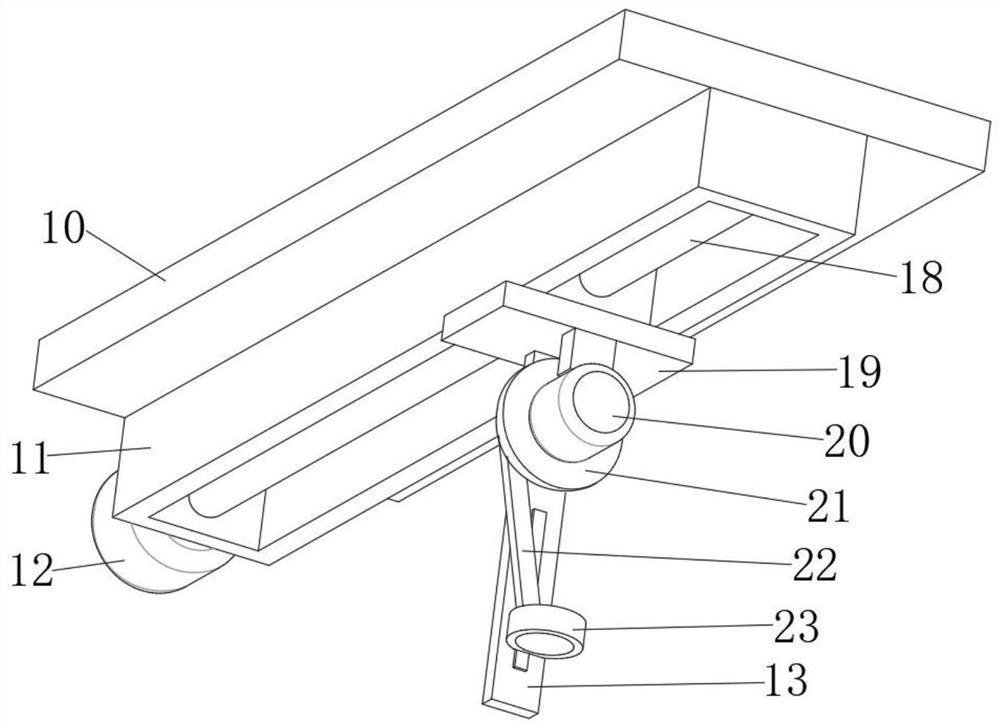

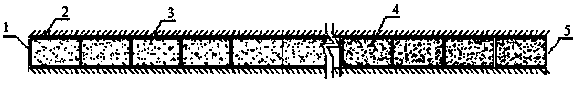

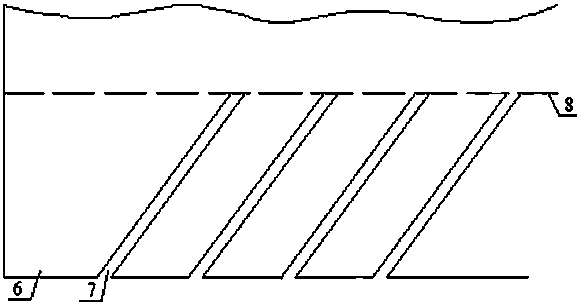

Full-automatic high-frequency vibrating leveling machine for tunnel inverted arch

ActiveCN105952469AImprove work efficiencyVibrate compactUnderground chambersTunnel liningCushionLeveling effect

The invention discloses a full-automatic high-frequency vibrating leveling machine for a tunnel inverted arch and belongs to the technical field of road and bridge machinery. The vibrating leveling machine comprises a longitudinal travelling track arranged at the lower end of an inverted arch trestle, a travelling frame arranged at the lower end of the longitudinal travelling track and moving along the longitudinal travelling track, and a vibrating device and a material distributing and leveling device which are hung below the travelling track and are sequentially arranged in the front and the back, wherein the vibrating device and the material distributing and leveling device are connected with the travelling frame by a lift cylinder, and the vibrating device transversely moves along a track on the travelling frame. The full-automatic high-frequency vibrating leveling machine is mainly used for deep vibrating of a tunnel bed concrete cushion and mud extracting and leveling of the surface of the cushion, can carry out the vibrating leveling operation in a narrow space below the tunnel inverted arch, and is high in working efficiency, dense in vibrating, simple in construction process and good in mud extracting and leveling effects. According to the invention, the operation is simple and is executed by one people, the operation and stop of the machine can be controlled remotely, and the use is extremely convenient.

Owner:TANGSHAN XINGDOU ROAD&BRIDGE MACHINERY CO LTD

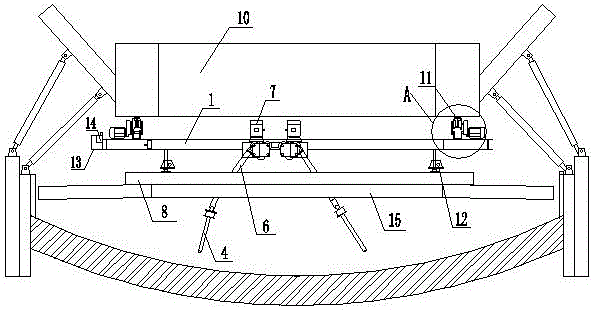

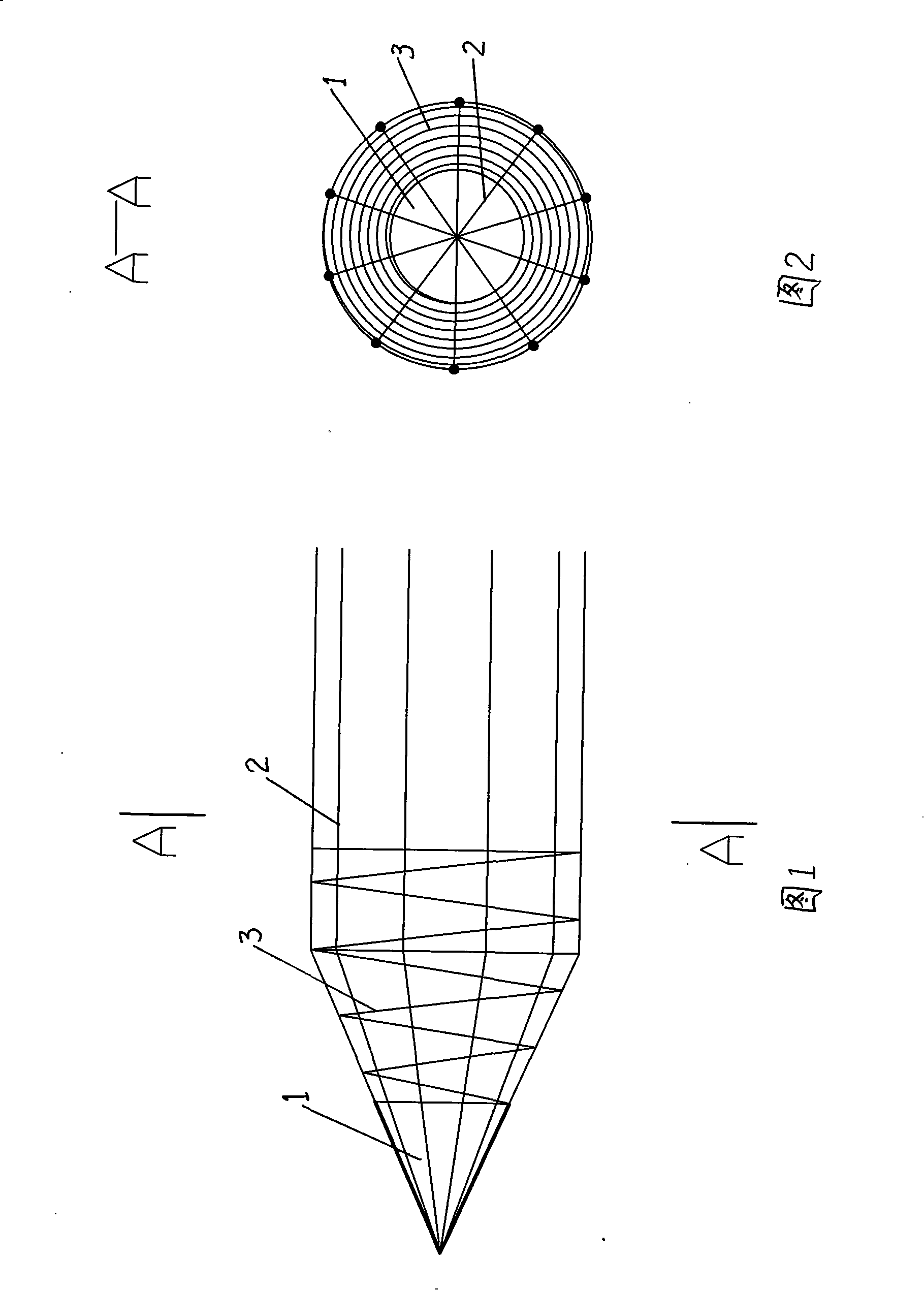

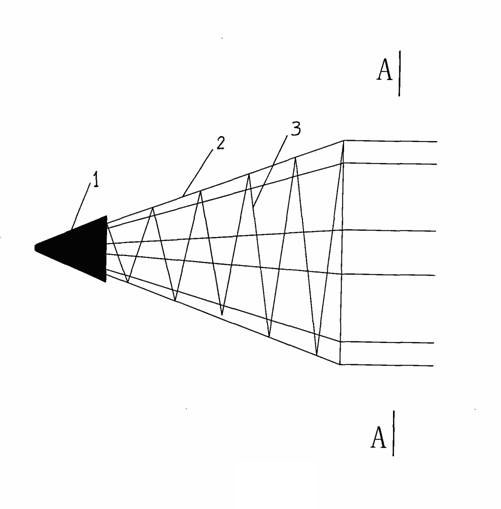

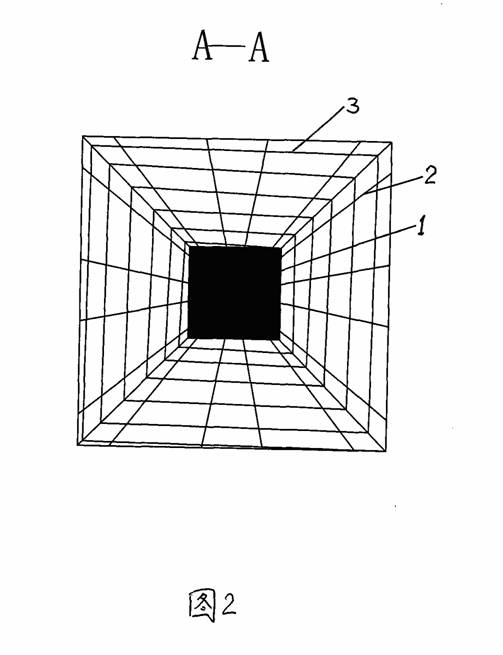

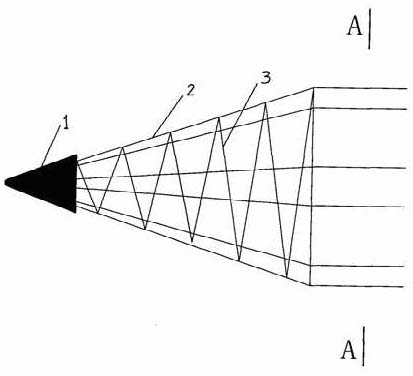

Prestressing force pipe pile precast pile tip and its production process

InactiveCN101307597AEasy pouringGuarantee product qualityBulkheads/pilesFoundation engineeringEngineering

The invention relates to the architecture field and relates to a preformed pile point for a prestressed tubular pile, wherein, anchor bars are welded continuously on the inner circumference of the steel point; the outer layers of the anchor bars are bound and fastened by annular spirally reinforced columns; and prestressing tendon hole sites are preserved on a placing concrete body. The preformed pile point for the prestressed tubular pile is a unique preformed pile point with the prestress performance; the pile point is integrated into a whole with a square pile; the bearing capacity of a pile point part is improved; and the pile point is difficult to break and maintains the same service life with the pile. The method for producing the pile point guarantees the product quality, saves the labor and a great number of steel products, is safe and reliable, improves the durability and the earthquake resistance, and meets the demand of architectural pile foundation engineering.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

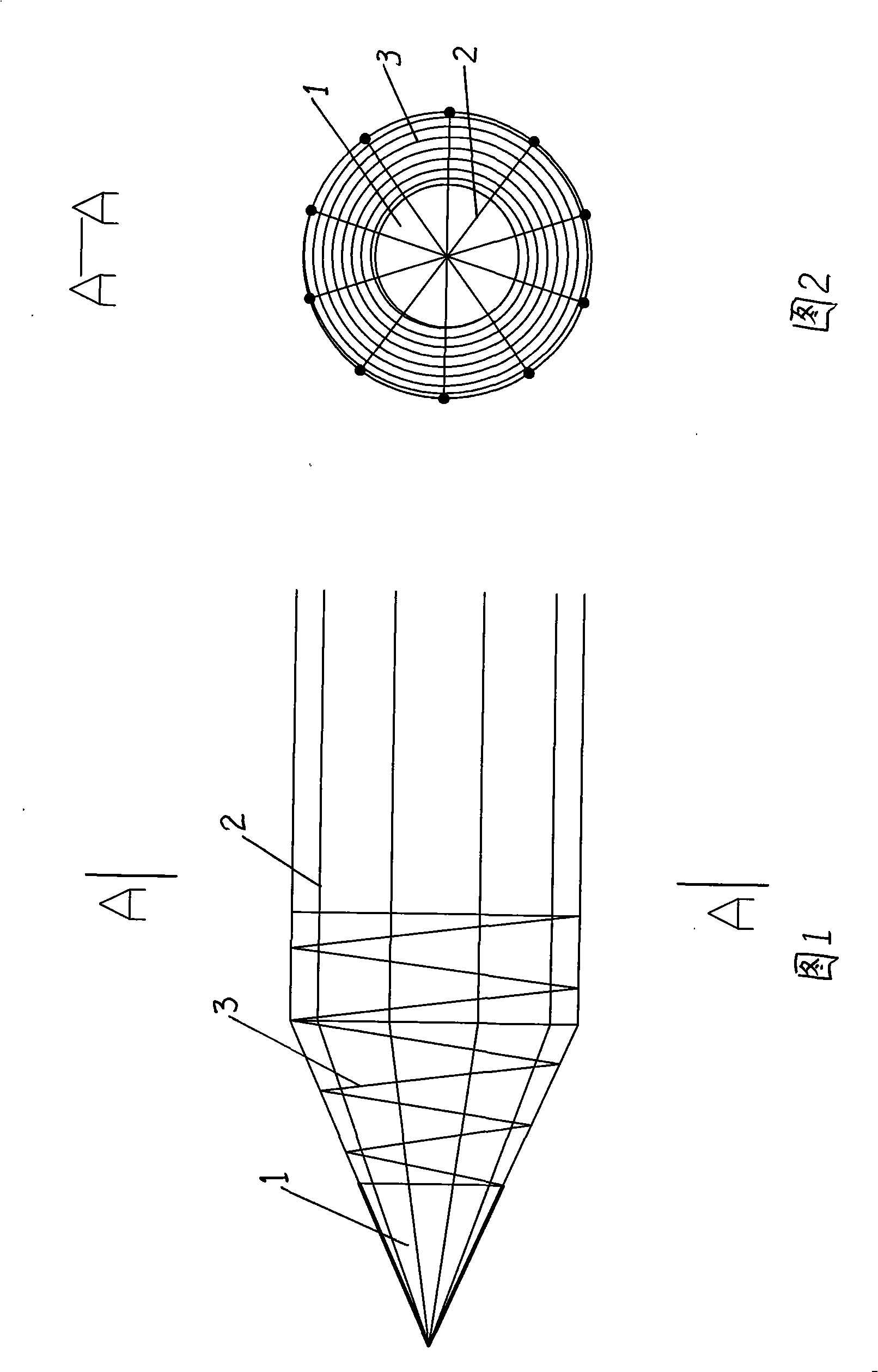

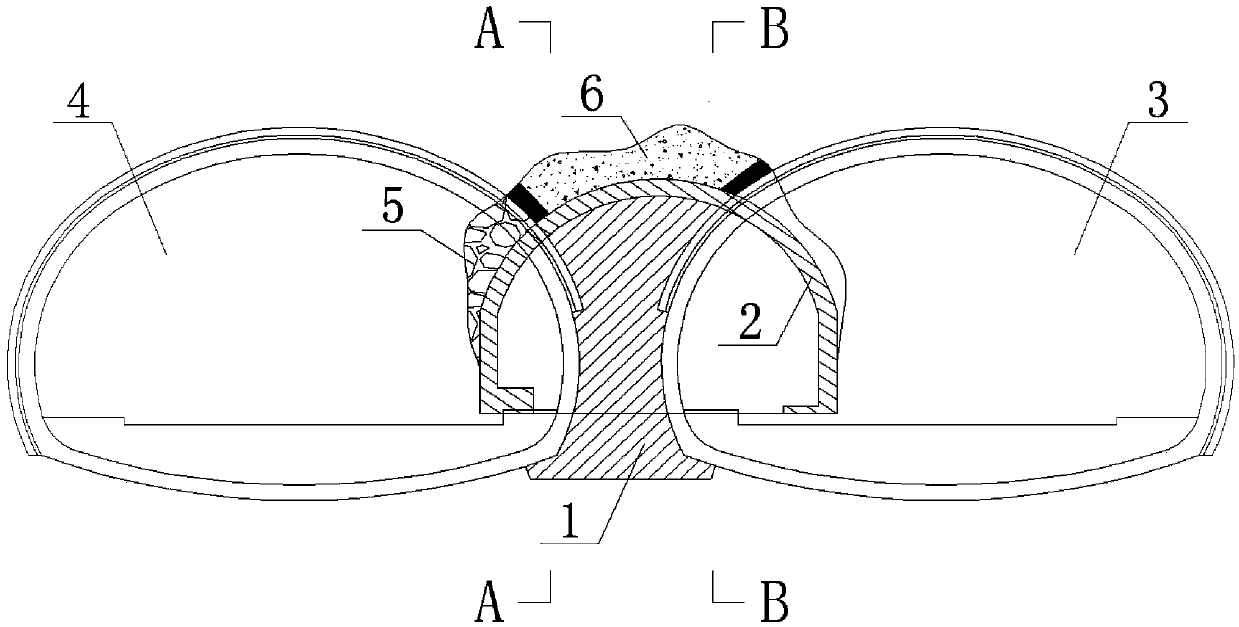

Middle separation wall top original lining cavity backfilling construction method when single-hole tunnel is changed into multiple arches

InactiveCN103953366AReduce the amount of groutLow costUnderground chambersTunnel liningRebarShotcrete

The invention discloses a middle separation wall top original lining cavity backfilling construction method when a single-hole tunnel is changed into multiple arches. The method sequentially comprises the following steps that a, a middle separation wall is cast; b, an anterior hole is constructed; c, hole slag dug from the anterior hole is used for filling back a cavity arranged at one side of a posterior hole to the digging outline part of the posterior hole; d, a steel bar net is paved on the top of the backfilled hole slag, and then, concrete is sprayed on the surface of the steel bar net; e, an end template is arranged along a tunnel longitudinal frame, in addition, the end template, the surrounding rock and the original lining are fixedly built through lining by using anchor bolts; f, a side template is erected at the digging outline part of the anterior hole; g, concrete is filled and is compactly vibrated and smashed; h, the posterior hole is constructed; i, the original lining of the existing tunnel in the anterior hole and the posterior hole is dismounted. The construction method has the advantages that the original tunnel top cavity backfilling problem is effectively solved, so the pressure of the surrounding rock is uniformly transmitted onto a support protection structure, the stress uniformity and the structure completeness of the lining can be ensured, and the loading capability and the durability are improved.

Owner:CHANGAN UNIV +1

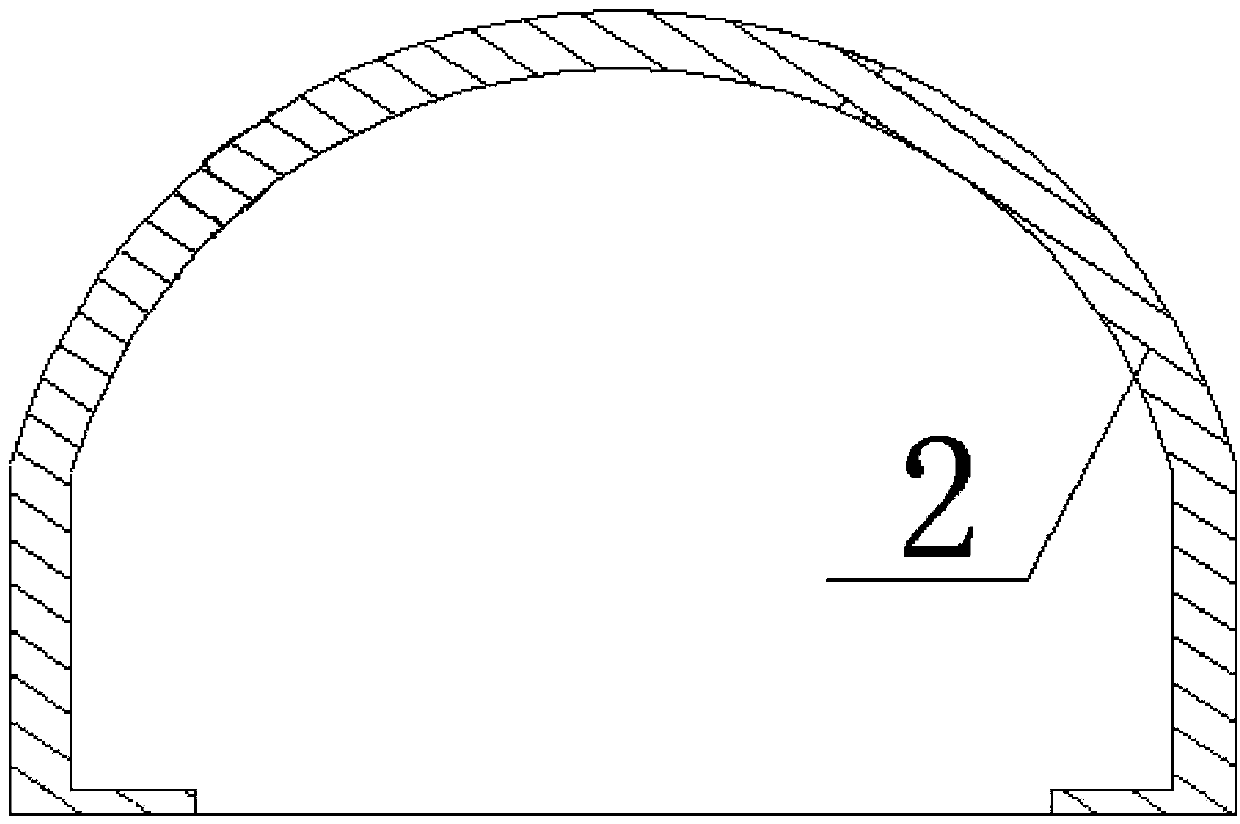

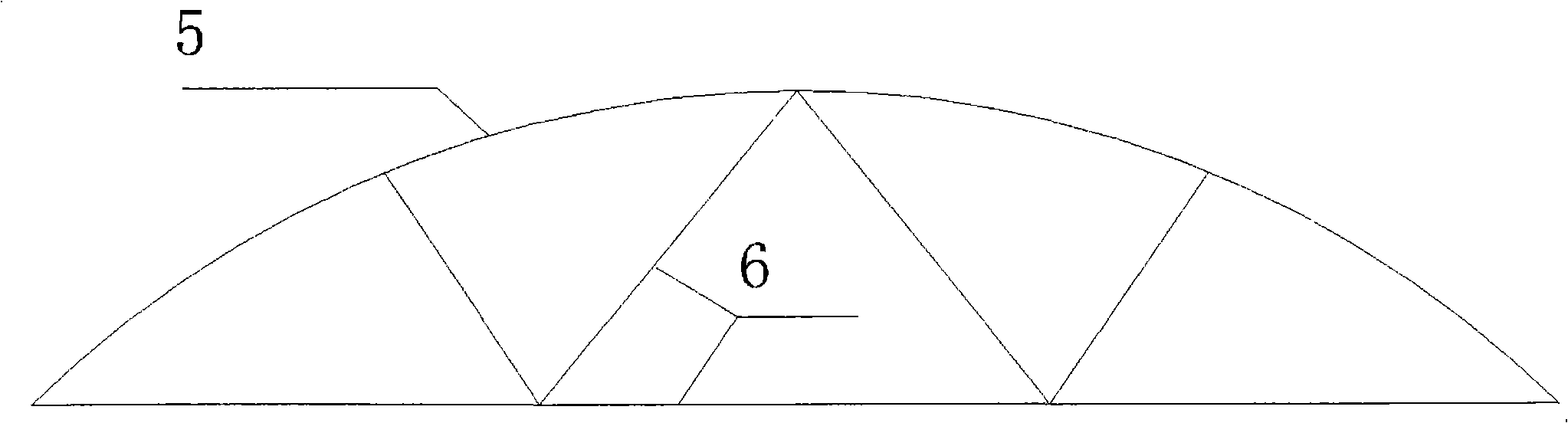

Construction method for special structure layer of cone bottom wheat-immersion

InactiveCN101294420AGuaranteed StrengthGuaranteed stabilitySpecial buildingExtraordinary structuresFalseworkShaped beam

Owner:CHINA CONSTR SIXTH ENG DIV CORP +1

Production process of external wall panel of prefabricated concrete shear wall

ActiveCN110614718ASmooth and efficient production lineImprove efficiencyConstruction materialCeramic shaping apparatusProduction lineUltimate tensile strength

The invention discloses a production process of an external wall panel of a prefabricated concrete shear wall, and relates to the technical field of building construction processes. The production process comprises the following steps of mold clearing, mold mounting, bottom layer bar mounting, bottom layer burying, bottom layer distribution, extrusion plate pavement, external page mesh pavement, concrete pouring and compacting, aftertreatment, component maintenance, mold dismounting, component hoisting and finished product storage. According to the process, existing production process processes are overturned, production line production becomes smooth and efficient from originally jamming, component quality is greatly improved, potential safety hazards of components are reduced, labor intensity is greatly reduced, and cost is reduced; and special tools are adopted for mold dismounting and mounting, operation is simple and rapid, and a solid foundation is laid for automation of the nextstep.

Owner:山东联强建筑工业科技有限公司

Construction method of bridge bearing platform

ActiveCN110965473AImprove final qualityVibrate compactFoundation engineeringBridge erection/assemblyElectric machineryRebar

The invention relates to a construction method of a bridge bearing platform, and belongs to the field of bearing platform construction. The method comprises the following steps of S1, pre-constructionwork is performed; S2, cushion concrete is poured; S3, bearing platform steel bars are installed; S4, A bearing platform formwork is installed, a plurality of vibrating openings are formed in the lower part of the formwork, a vibrating rod is inserted into the vibrating opening such that the vibrating rod is made to transversely penetrate through the whole bearing platform, attention is paid to that the vibrating rod does not make contact with the reinforcing steel bar and the formwork, temporary sealing is conducted between the vibrating plates and the vibrating opening through foam blocks,then the two vibrating plates are welded to the formwork, the two ends of the vibrating rod are connected with the two vibrating plates correspondingly, and vibrating motors are arranged on the vibrating plates; S5, concrete is poured; S6, the formwork is dismantled, and geotextile covering and watering maintenance are conducted on the bearing platform; and S7, foundation pit backfilling is performed. The construction method has the effect of improving the vibrating quality of concrete at the bottom of the bearing platform.

Owner:四川宝鑫建设有限公司

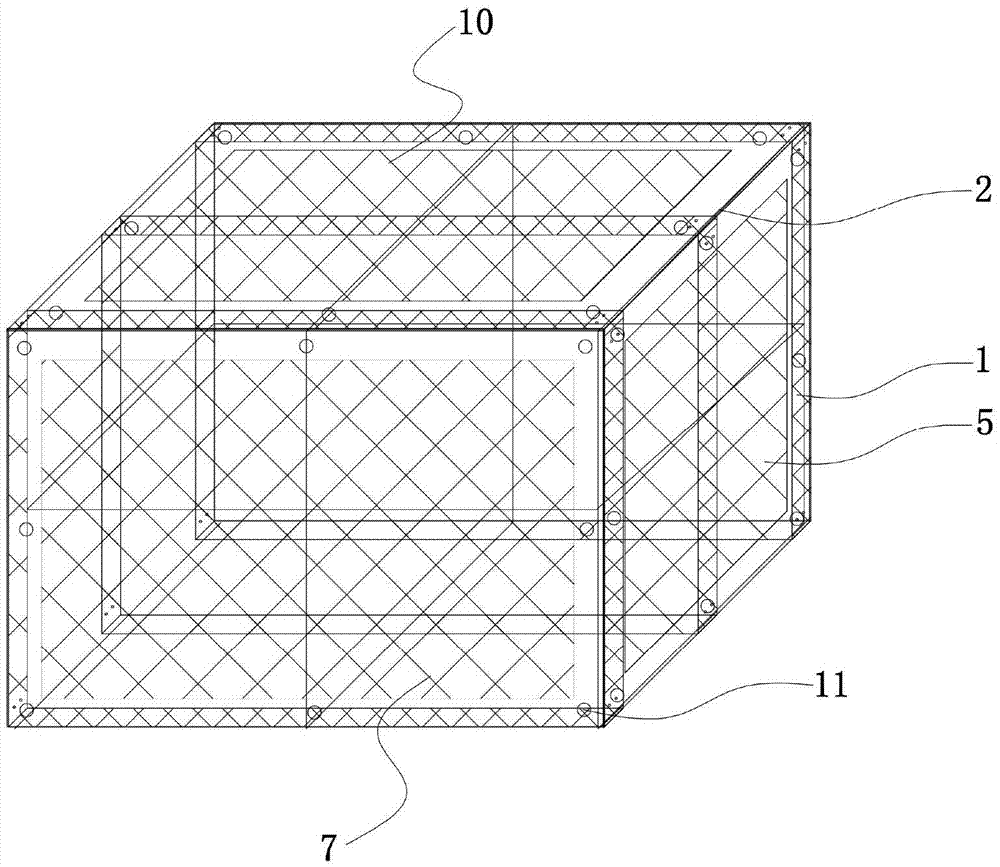

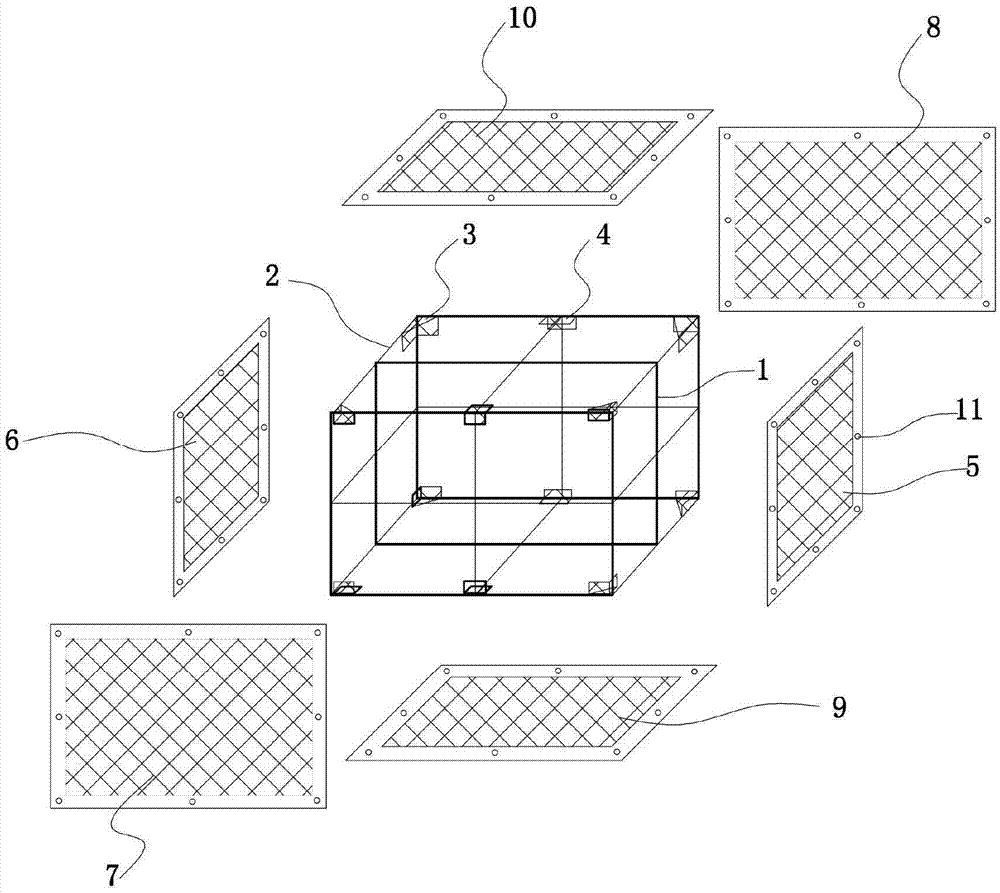

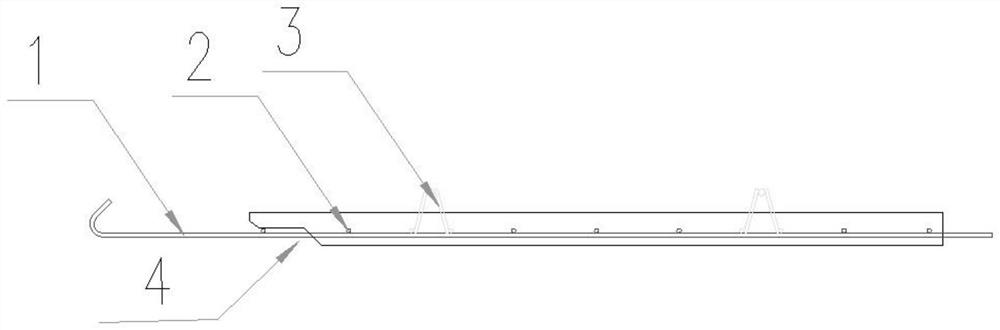

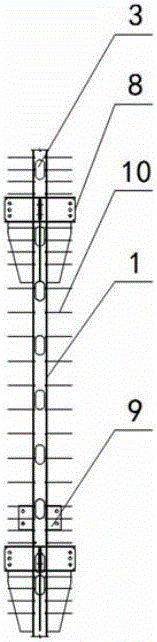

Integral type die and method for processing building member for exposing reinforcing steel bars

InactiveCN102126246AQuality improvementThe location of the reinforcement is accurateDischarging arrangementMouldsRebarPrecast concrete

The invention relates to an integral type die and method for processing a building member for exposing reinforcing steel bars. In the traditional cast-in-place concrete structure, the connection of reinforcing steel bars needs to be finished before concrete is poured, thus the structure is not suitable for an assembly type construction method of a precast concrete structure, brings more inconvenience to the construction, prolongs the construction period, increases the economic expenditure and causes waste. The integral type die for processing a building member for exposing the reinforcing steel bars comprises a die body (1), wherein the die body comprises a left template (2); the upper end of the left template is connected with an upper template (3) and the lower end is connected with a lower template (4); the upper template and the lower template are simultaneously connected with a right template (5); the left template (2), the upper template (3), the right template (5) and the lower template (4) are sequentially connected; and the die body (1) is connected with a bottom template (10). The invention is suitable for industrially producing building members.

Owner:HEILONGJIANG YUHUI NEW BUILDING MATERIAL

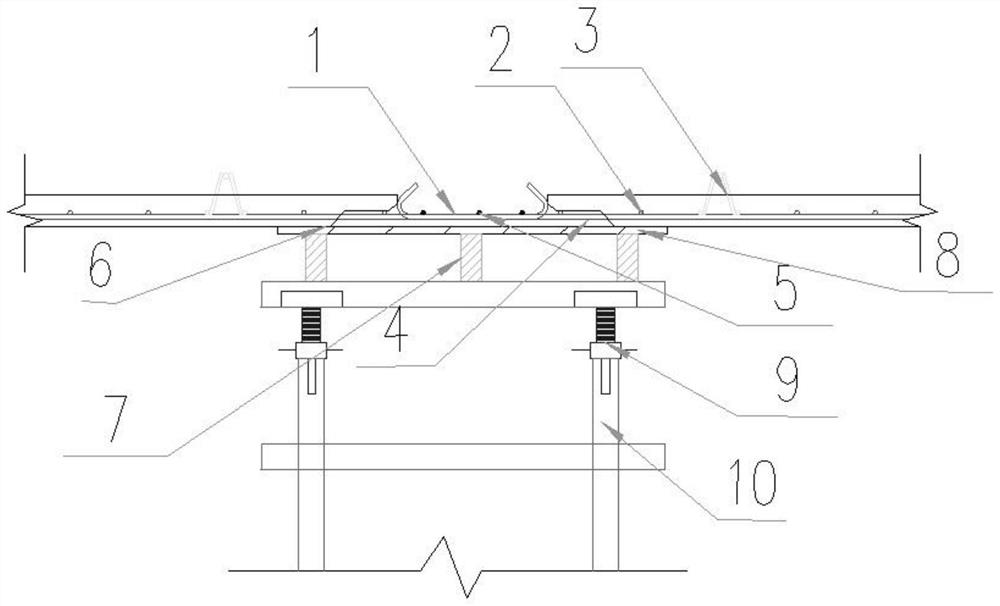

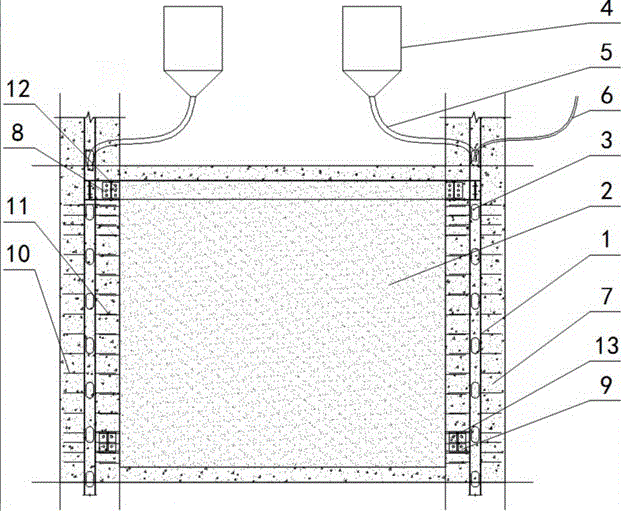

Construction technology of straw concrete formwork-removing-free dense-rib laminated floor slab

The invention provides a construction technology of a straw concrete formwork-removing-free dense-rib laminated floor slab. A floor bottom formwork is formed by combining a prefabricated straw lightweight aggregate concrete slab and a rib beam bottom formwork and used as a supporting base of a straw concrete removing-free formwork after concrete is poured, so that the straw concrete removing-free formwork is firm and reliable; through connecting of a vertical supporting rod spring cushion and the rib beam bottom formwork, a vibration exciter is fixed on a vertical supporting rod; and by controlling opening and closing of the vibration exciter, vibration of the vibration exciter is transmitted to the rib beam bottom formwork through the vertical supporting rod, vibration of the rib beam bottom formwork is transmitted to the straw concrete removing-free formwork, even and effective vibration of the whole floor slab is achieved, vibrating is more compact, damage to the straw concrete removing-free formwork caused by impact load and trampling of people on the slab on steel bar are avoided, a construction site is safer, and the pouring quality of concrete is improved.

Owner:QIQIHAR UNIVERSITY

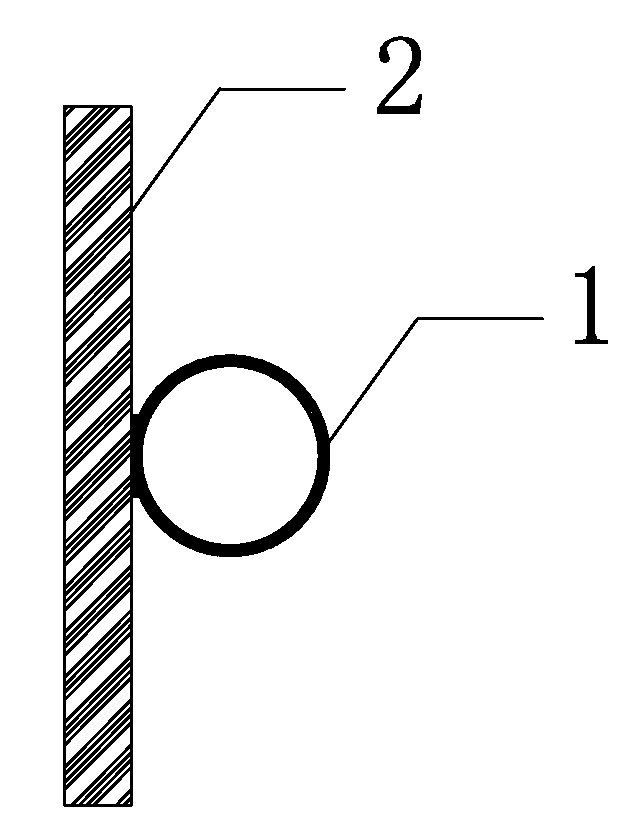

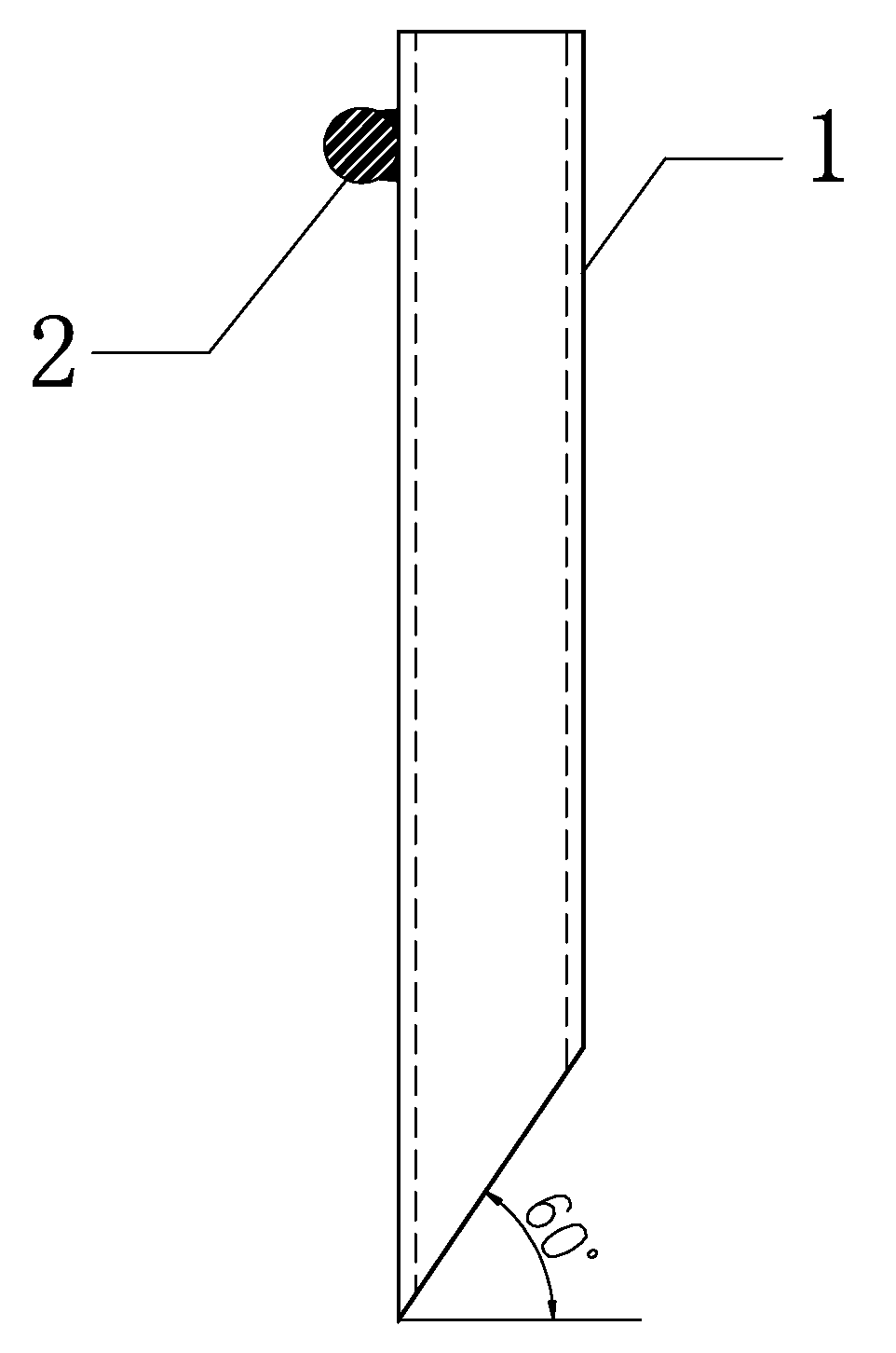

Tamping assist device for concrete pouring and manufacture method thereof

ActiveCN103669875AImprove vibrationEasy to operateBuilding material handlingRebarUltimate tensile strength

A tamping assist device used for concrete pouring of intensive steel bar frame columns and nodes is matched with a vibration tamping rod for vibration tamping construction, comprises a tamping assist cylinder and a handle, and is characterized in that the tamping assist cylinder (1) is a steel tube with the diameter 20mm or more larger than the diameter of the vibration tamping rod, the diameter of the tamping assist cylinder (1) is 50-60mm, the wall thickness of the tamping assist cylinder (1) is 3.6-5mm, the length of the tamping assist cylinder (1) is 200mm larger than the thickness of a platform to be formed by pouring, the upper end of the tamping assist cylinder is a flat mouth, an oblique pointed end with an angle less than 30 degrees is arranged at the lower end of the tamping assist cylinder, the handle (2) is a steel rod with the length of 300-400mm and with the diameter of 20-25mm, and the middle of the handle (2) and the upper portion of the tamping assist cylinder (1) are fixed together by welding. The tamping assist device used for the concrete pouring of the intensive steel bar frame columns and the intensive steel bar frame nodes and a manufacture method thereof have the advantages of coordinating with vibration tamping, facilitating the vibration tamping, being convenient to operate, reducing operation procedures and labor intensity of field operation staff, and improving production efficiency.

Owner:MCC5 GROUP CORP SHANGHAI

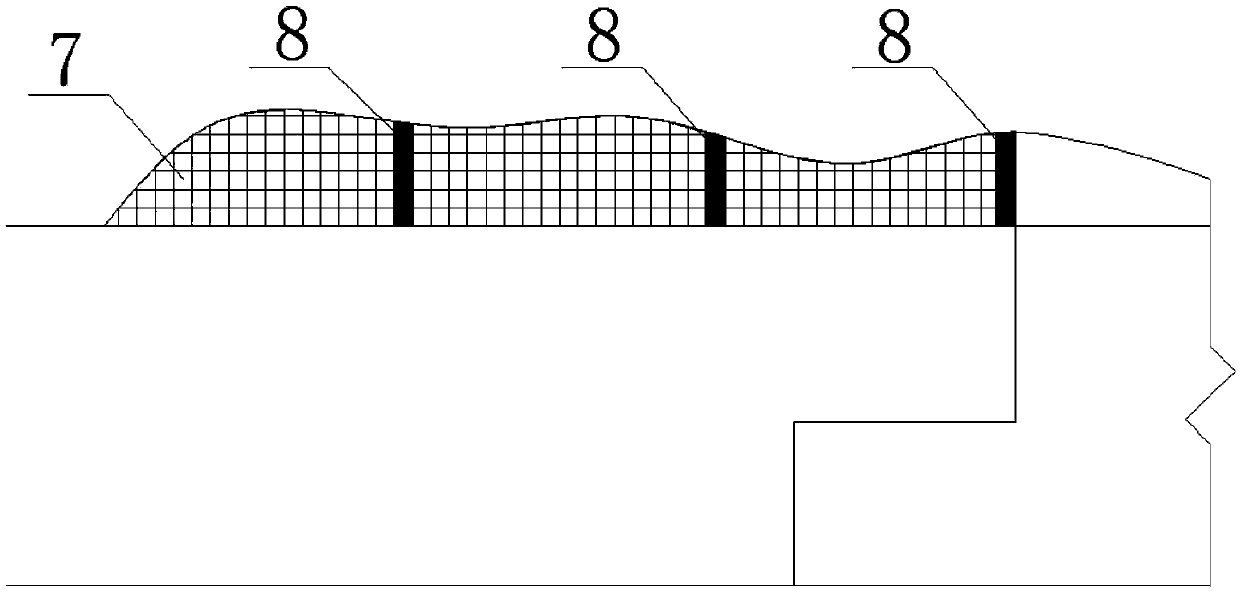

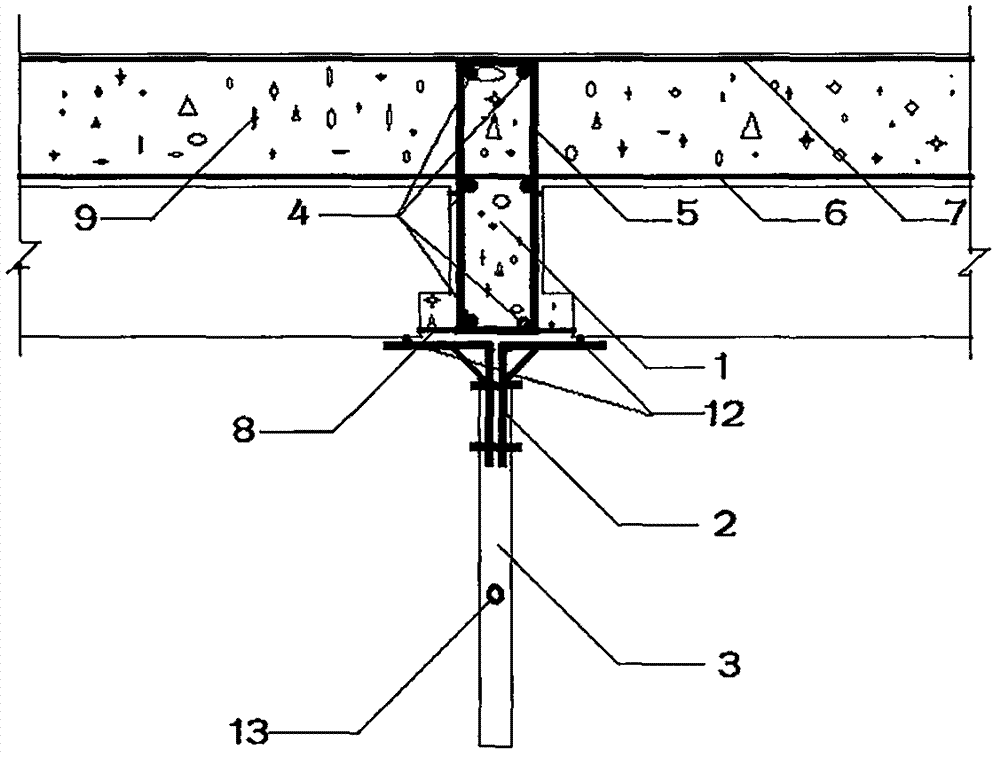

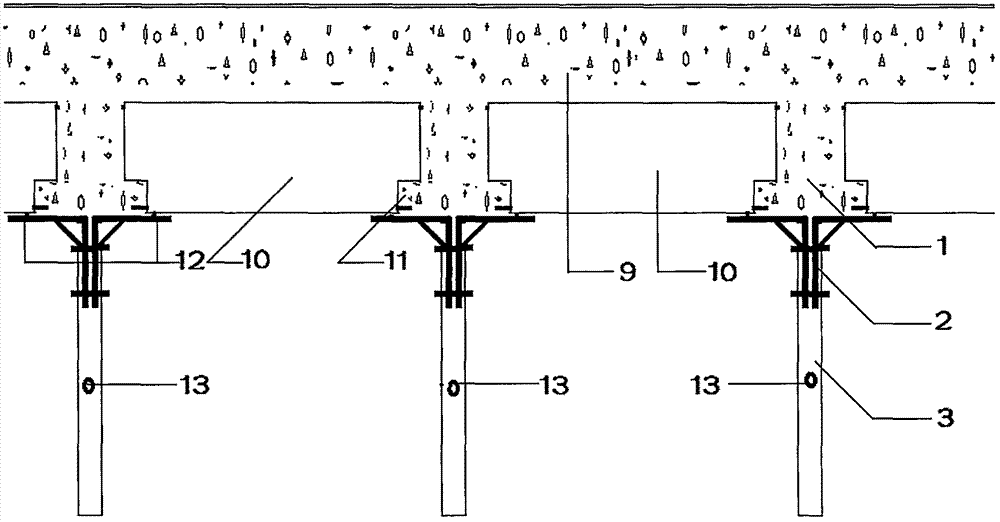

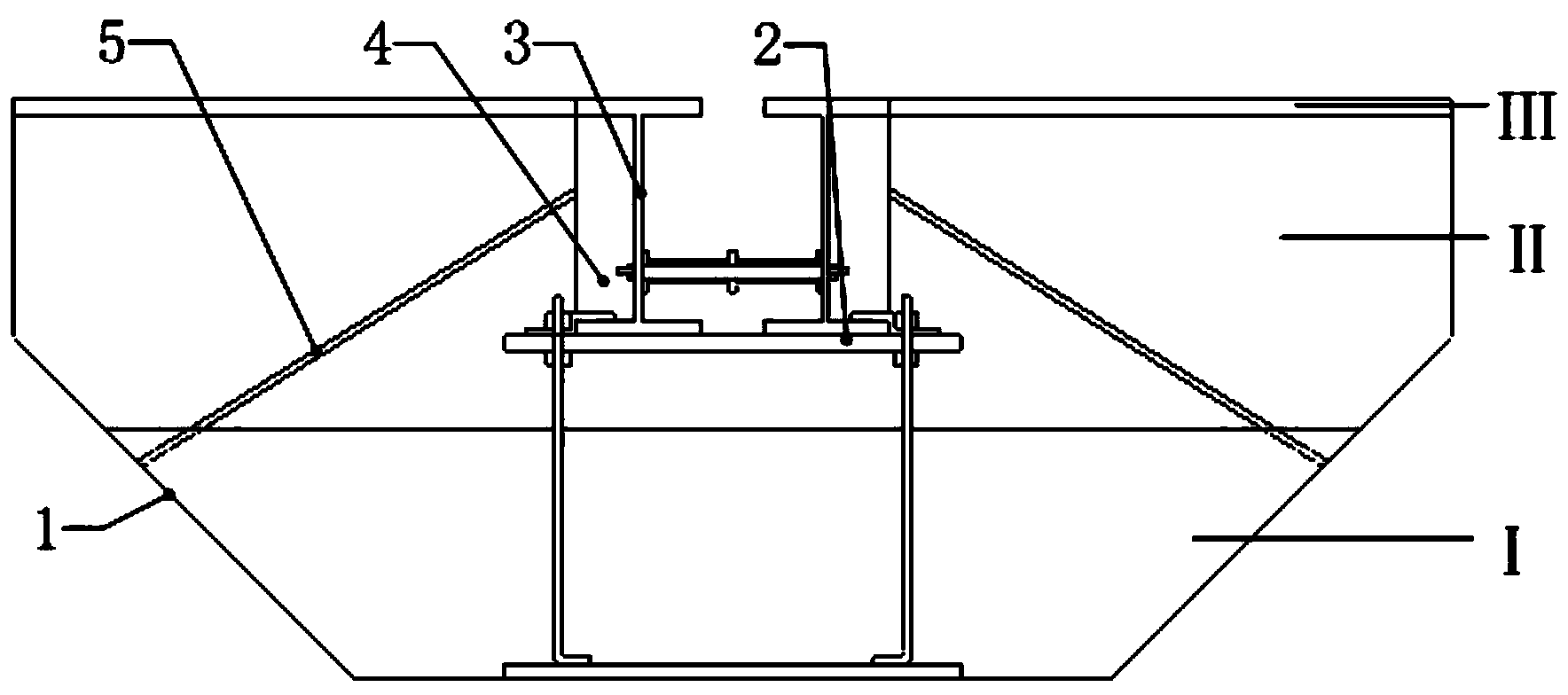

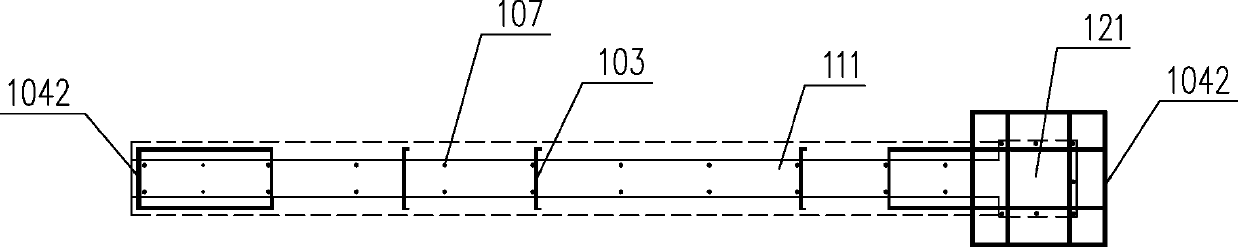

Traction runway for automobile safety crash laboratory and layered construction method of the traction runway

ActiveCN103821061AGuaranteed flatnessReduce riskVehicle testingTemporary pavingsCrash testRoad surface

The invention provides a traction runway for an automobile safety crash laboratory. The traction runway comprises a foundation trench, a plurality of groups of supporting devices, a concrete layer and an asphalt layer, wherein the plurality of groups of supporting devices are arranged in the foundation trench and are connected with each other; the concrete layer is poured between the supporting devices and the foundation trench; the asphalt layer is paved on the upper surface of the concrete layer; each supporting device comprises a height adjusting bracket, an H-steel supporting mechanism, a plurality of H-steel reinforcing ribs and restrained steel bars, wherein the height adjusting bracket is arranged on the bottom of the foundation trench, the H-steel supporting mechanism is assembled above the height adjusting bracket, the plurality of H-steel reinforcing ribs are fixedly connected to two sides of the H-steel supporting mechanism, one ends of the restrained steel bars are connected to the H-steel reinforcing ribs, and the other end of the restrained steel bars are obliquely inserted into the restrained steel bars located in the foundation trench; the concrete layer is divided into a bottom concrete layer and a middle concrete layer, wherein the bottom concrete layer is lower than the height adjusting bracket, the middle concrete layer is poured on the bottom concrete layer, and the poured concrete layer is lower than the upper surface of the H-steel supporting mechanism. The traction runway has the beneficial effects that the flatness of the traction runway can be adjusted step by step, and asphalt is paved on the topmost layer, so that a pavement can be repaired at any time, and furthermore, the accuracy of an automobile crash test is ensured.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

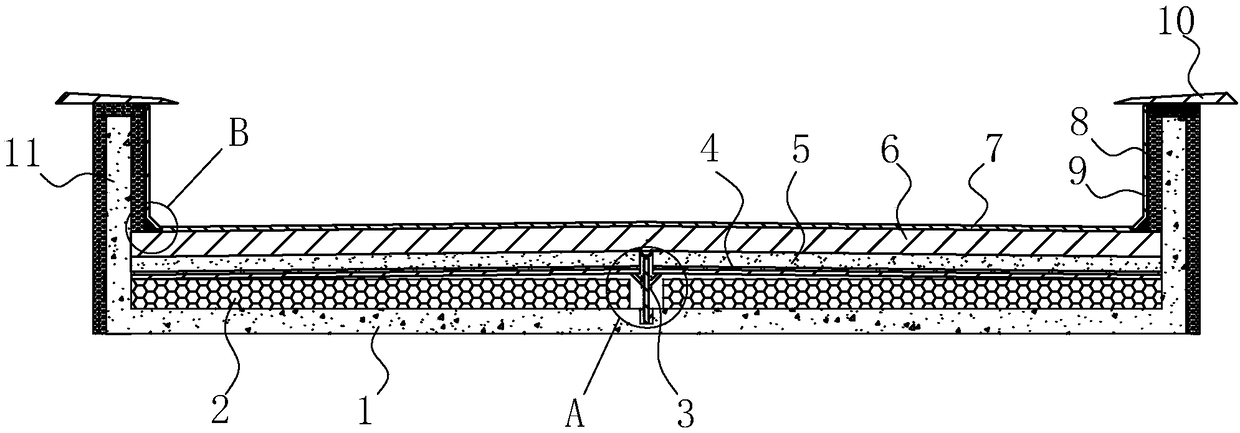

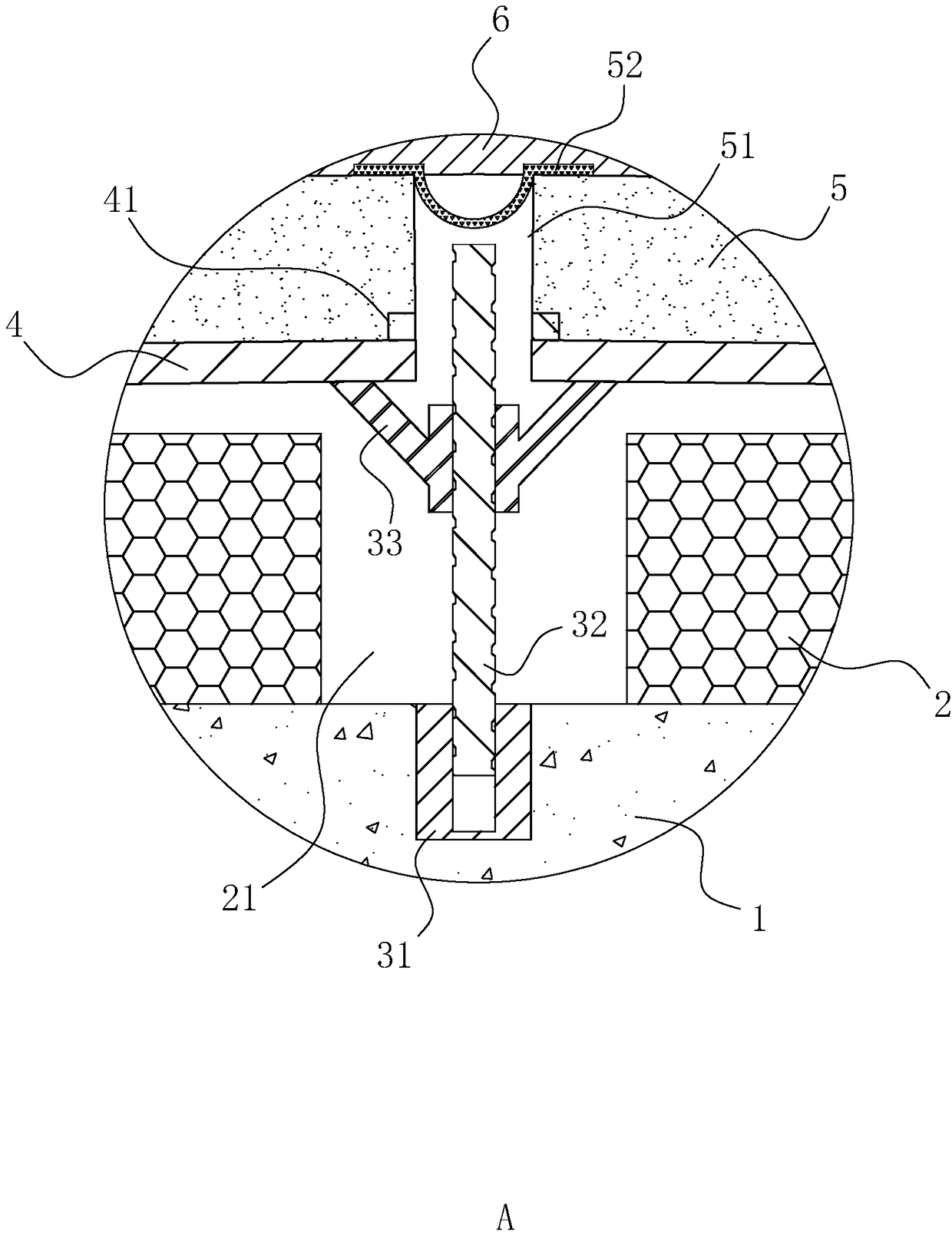

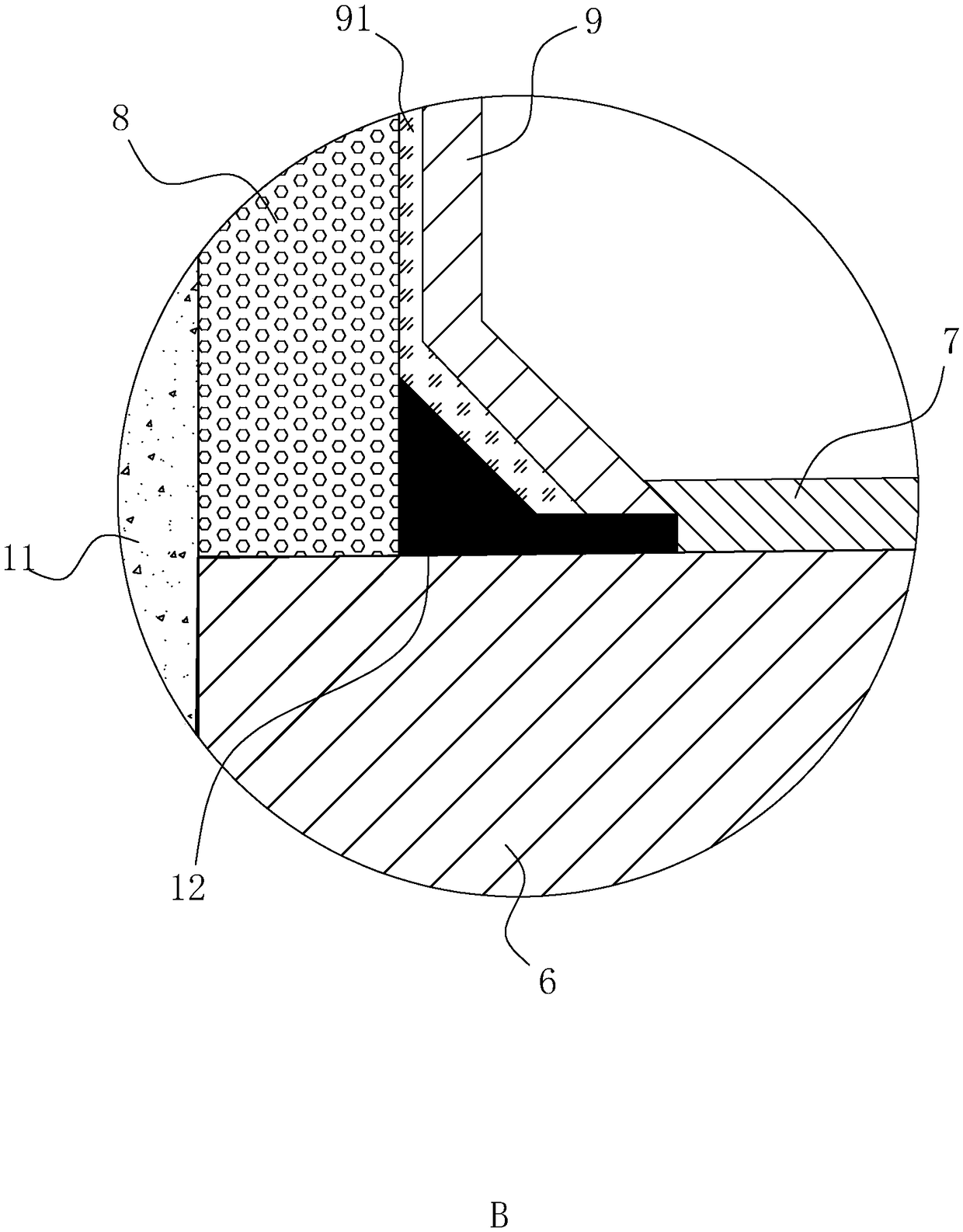

Roof waterproof structure and construction technology thereof

ActiveCN108797903AEasy to adjustVibrate compactRoof covering insulationsProtection layerMaterials science

The invention discloses a roof waterproof structure and a construction technology thereof, and relates to the technical field of building construction. According to the key points of the technical scheme, the roof waterproof structure comprises a heat preservation layer, a stainless steel plate layer, a slope finding layer, a waterproof coiled material and a protective layer which are sequentiallylaid on the upper portion of a concrete base layer from bottom to top; the stainless steel plate layer is formed by splicing two parts, one or more adjusting mechanisms which are fixed to the concrete base layer are mounted at the spliced position of the stainless steel plate layer, and the adjusting mechanisms are used for adjusting the height between the spliced ends of the stainless steel plate layer and the concrete base layer; the slope finding layer and the stainless steel plate layer fixedly form a whole, and a post-pouring strip is arranged on the position, on the spliced seam position of the stainless steel plate layer, of the slope finding layer; and the waterproof coiled material is fixed to the slope finding layer, and the post-pouring strip is covered with the waterproof coiled material. According to the roof waterproof structure and the construction technology thereof, the problem that during roof waterproof construction at present, the accurate slope is difficult to find for the slope finding layer is solved, and the roof waterproof construction efficiency is improved advantageously.

Owner:温州市申宏建设有限公司

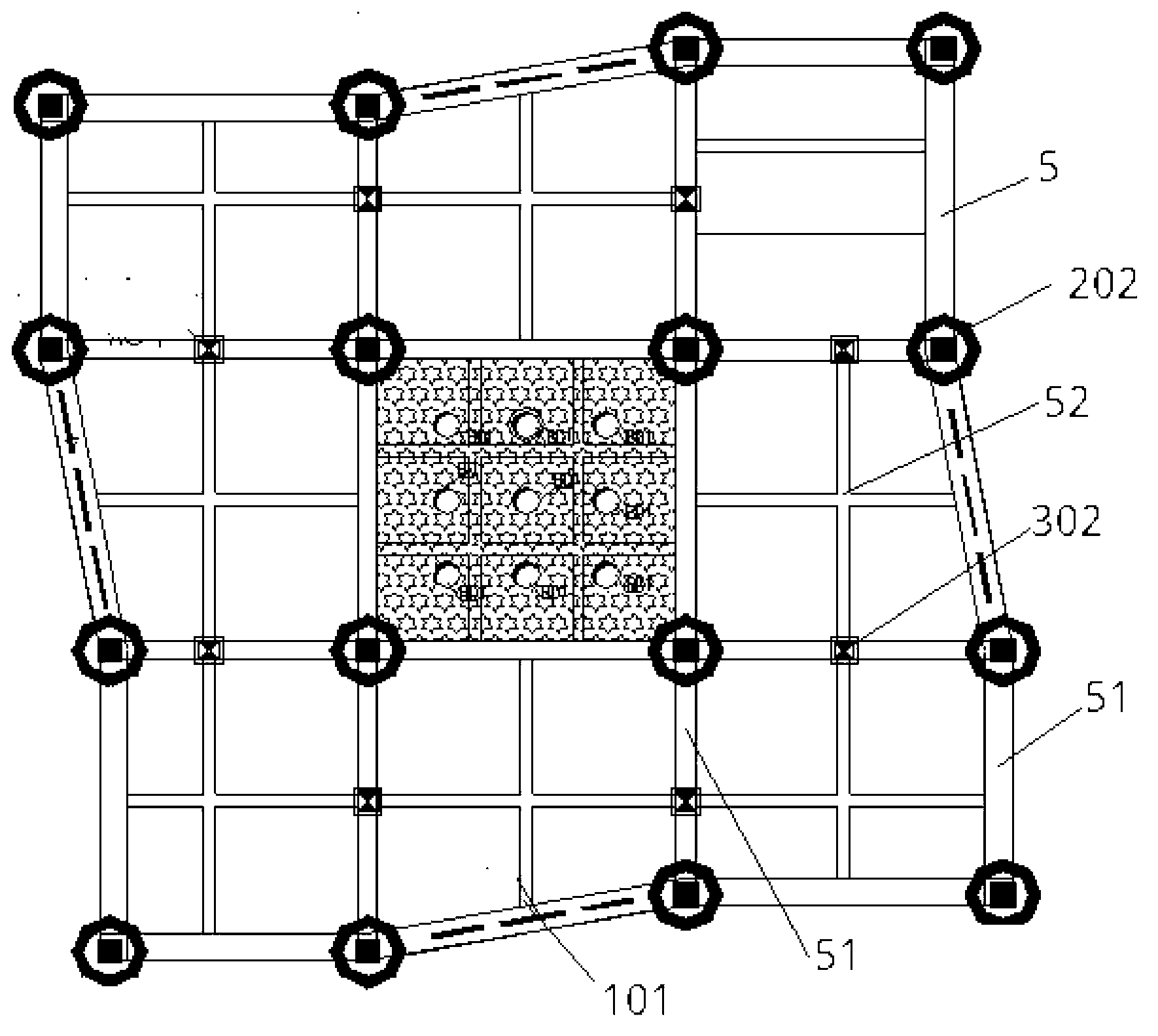

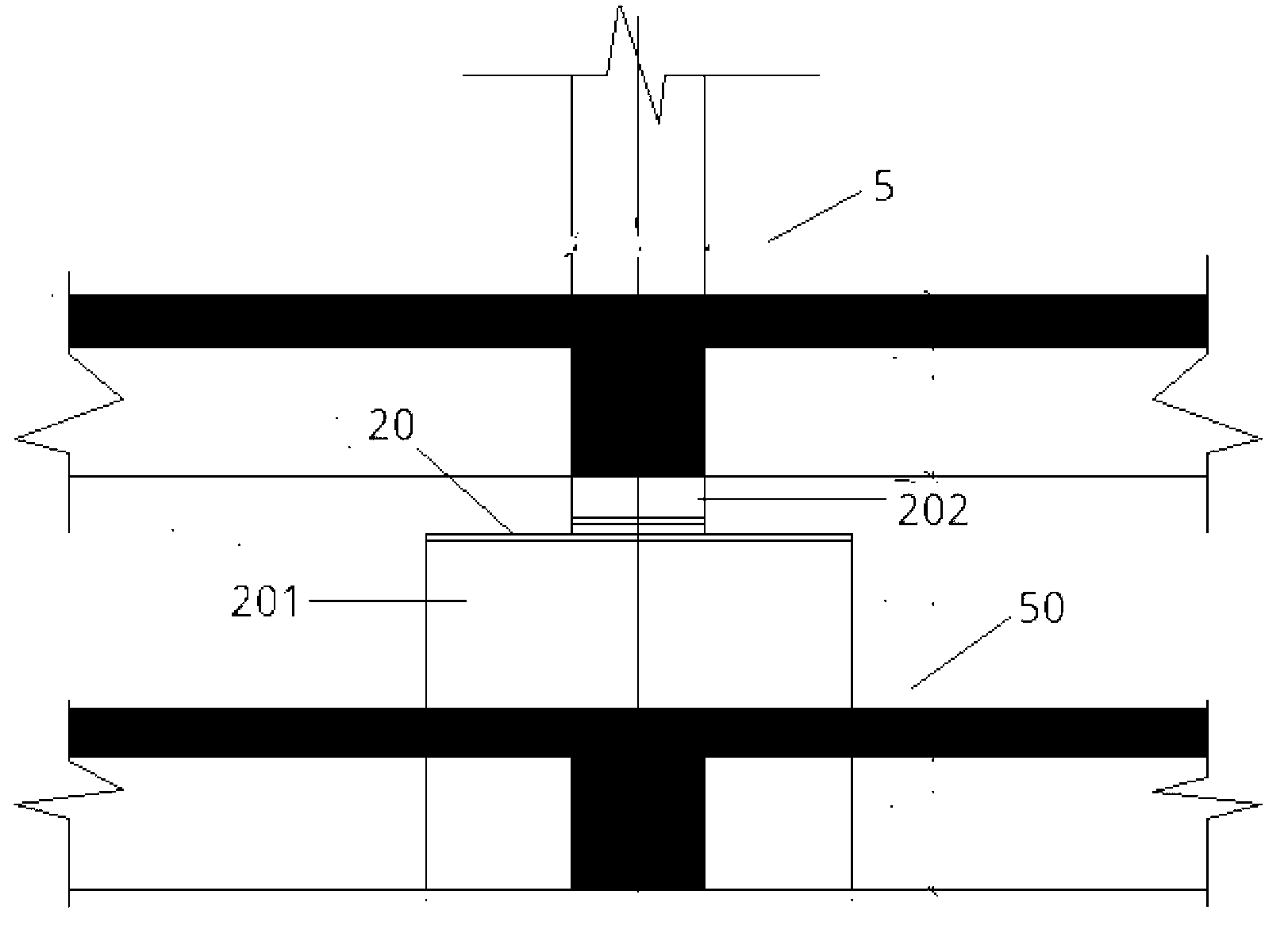

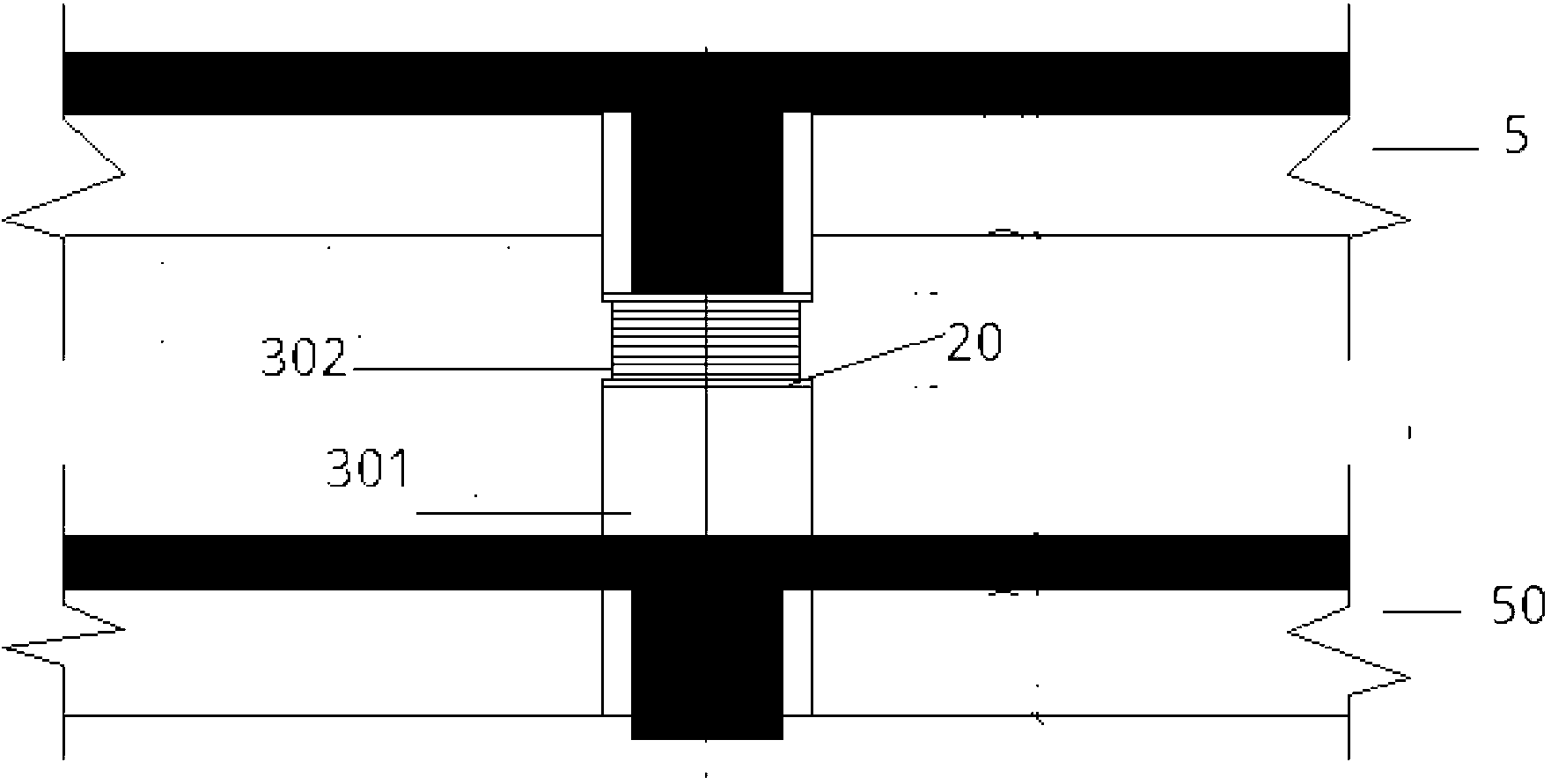

Hybrid controlled damping structure construction method

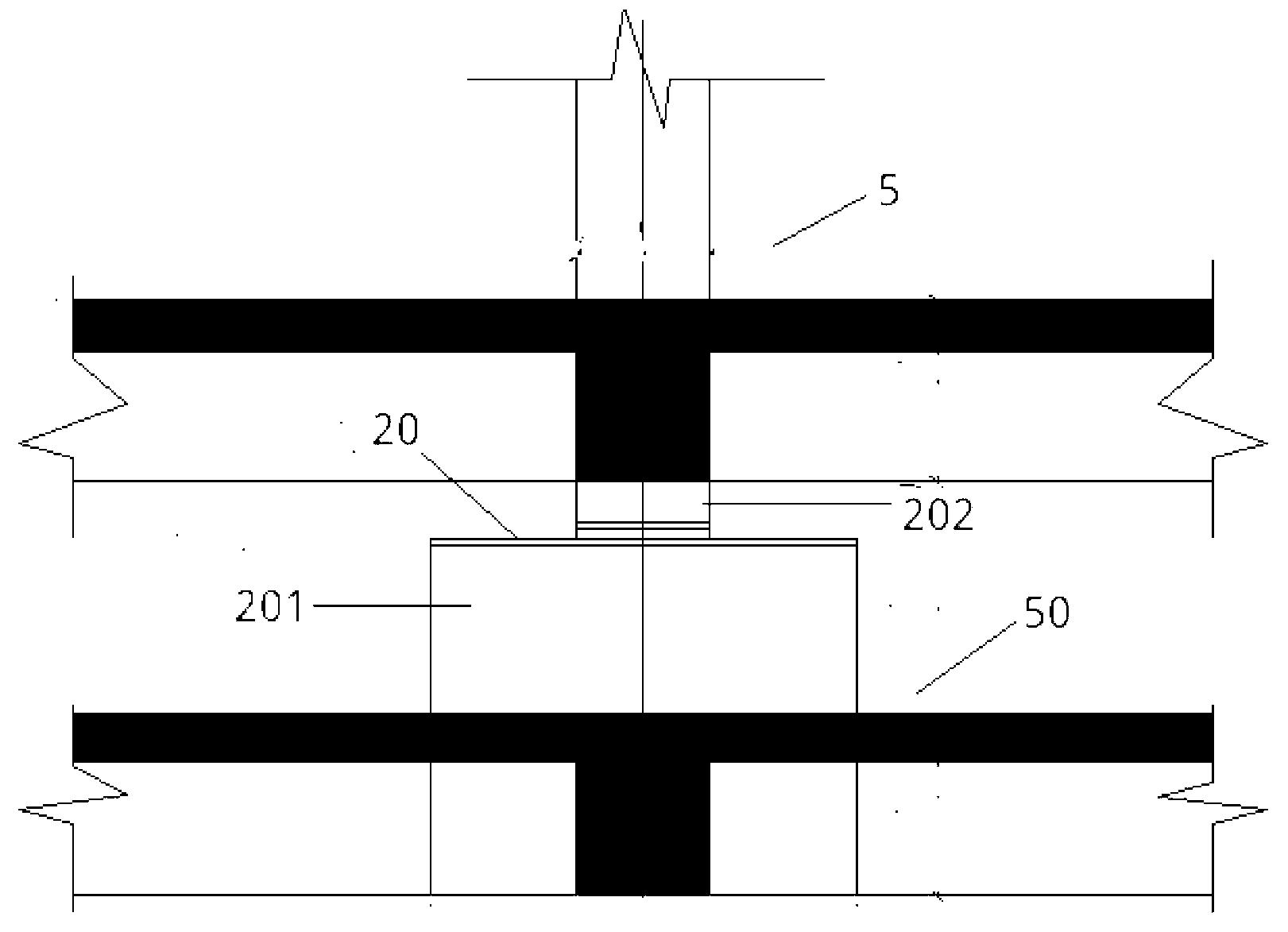

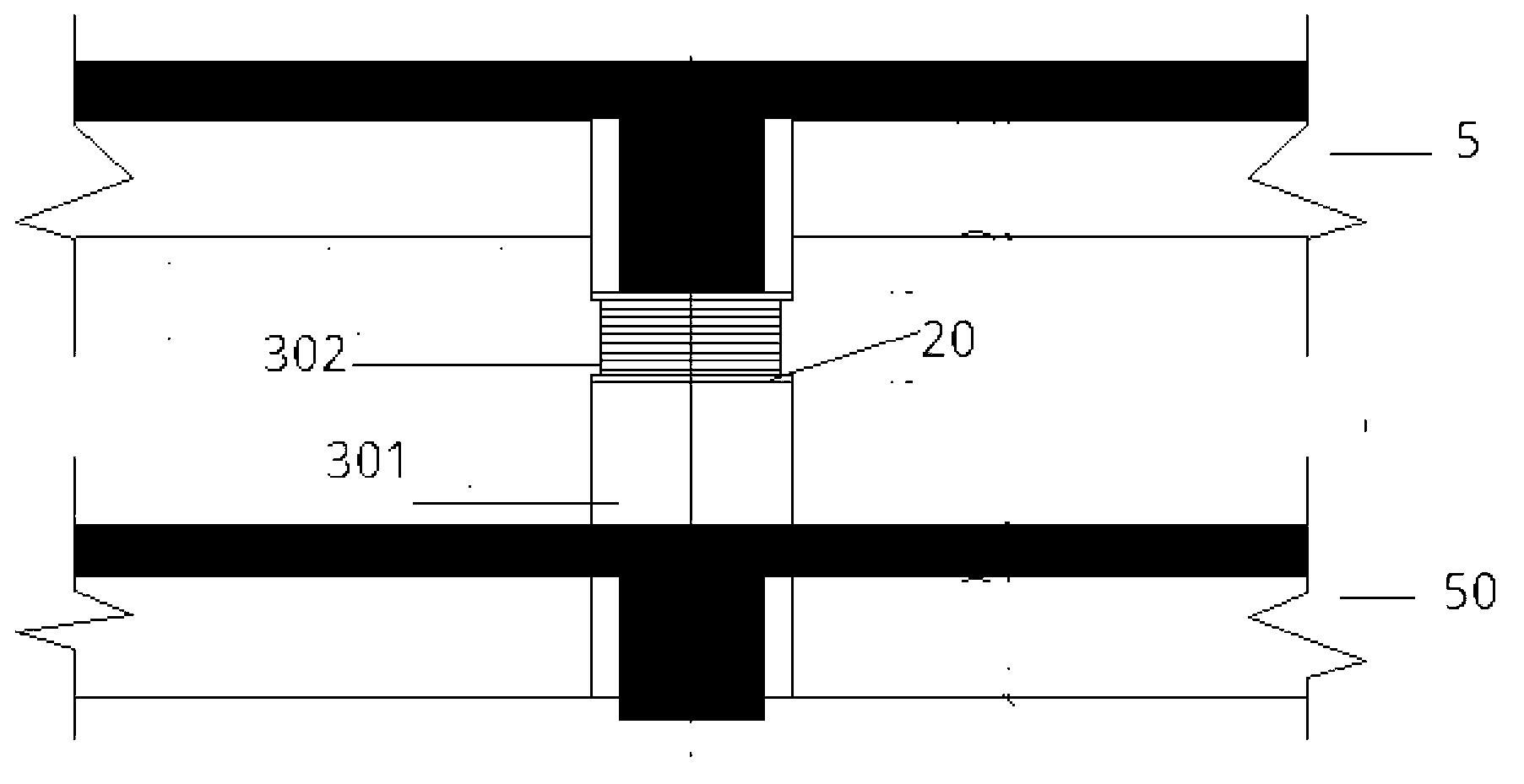

ActiveCN103174231AReduce section sizeImprove shock absorptionBuilding material handlingShock proofingPre embeddingCross point

The invention discloses a hybrid controlled damping structure construction method. The hybrid controlled damping structure comprises a damping framework. The damping framework is composed of an upper framework and a lower framework. A flat plate slipping support is arranged between the lower portion of a framework stand column and the lower framework, wherein the framework stand column is arranged at a cross point of a longitudinal and transverse main framework beam of the upper framework. A lamination rubber support is arranged between the lower portion of a framework stand column and the lower framework, wherein the framework stand column is arranged at a cross point of an auxiliary framework beam of the upper framework. A viscous damper is arranged on the main framework beam on the outermost side of the damping framework, two ends of the viscous damper are fixed on viscous damper supports, and the two viscous damper supports are respectively pre-embedded and fixed on the main framework beam on the outermost side of the upper framework and the main framework beam on the outermost side of the lower framework. According to the hybrid controlled damping structure construction method, a hybrid controlled damping system is formed by lamination rubber shock insulation, the flat plate slipping support and the viscous damper, respective advantages of the devices are exerted, earthquake energy is dissipated, and therefore an ideal damping effect is achieved.

Owner:ZHEJIANG HAITIAN CONSTR GROUP

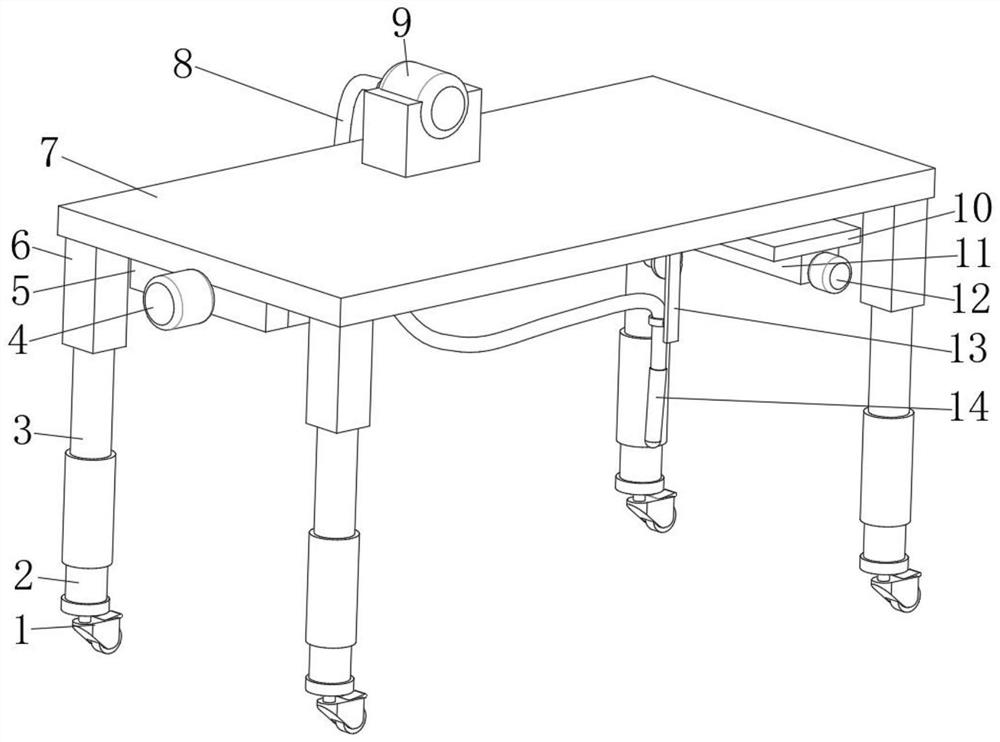

Movable concrete mechanical vibrating device

InactiveCN112252731AVibrate a wide rangeIncrease the vibration areaBuilding material handlingElectric machineryStructural engineering

The invention belongs to the technical field of concrete vibration, and particularly relates to a movable concrete mechanical vibrating device. Aiming at the problems that when concrete is vibrated, adevice needs to be continuously pushed manually to move, and manpower is consumed, the following scheme is proposed, the movable concrete mechanical vibrating device comprises a top plate, two firstmounting blocks which are symmetrically distributed are fixed to the outer wall of the bottom of the top plate, first rectangular grooves are formed in the outer wall of the bottom of the first mounting blocks, first sliding rails are fixed to the inner walls of the left sides and the right sides of the first rectangular grooves, sliding blocks are slidably connected to the inner walls of the first sliding rails, and first movable plates are fixed to the outer walls of the bottoms of the sliding blocks. Through the arrangement of a third motor, a rotating disc, a connecting rod, a mounting sleeve and a fixing plate, an output shaft of the third motor drives the rotating disc to rotate so as to drive the upper end of the connecting rod to do circular motion, the lower end of the connectingrod drives the mounting sleeve to move up and down, so that a vibrating rod continuously moves up and down in concrete, the honeycomb pitted surfaces with different depths of the concrete are vibratedand compacted, the vibrating efficiency is high, and manpower is saved.

Owner:曾祥瑞

Rock breaking method of cartridge type static cracking agent

The invention relates to a rock breaking method of a cartridge type static cracking agent, and belongs to the technical field of rock breaking methods of static cracking agents. The problems that in the static cracking rock breaking technological process, the water-cement ratio and the size preparation quantity are not easy to control can be solved. A cylindrical non-woven bag is filled with static cracking agent powder to be made into the cartridge type static cracking agent, and after the static cracking agent is soaked in water to achieve the saturated water absorption state, drilled holesare filled with the static cracking agent section by section through a bakelite tamping bar. According to the rock breaking method, the static cracking rock breaking operation link can be simplified,the water-cement ratio can be controlled, and the conventional grouting filling application mode of the static cracking agent can be broken through.

Owner:TAIYUAN UNIV OF TECH

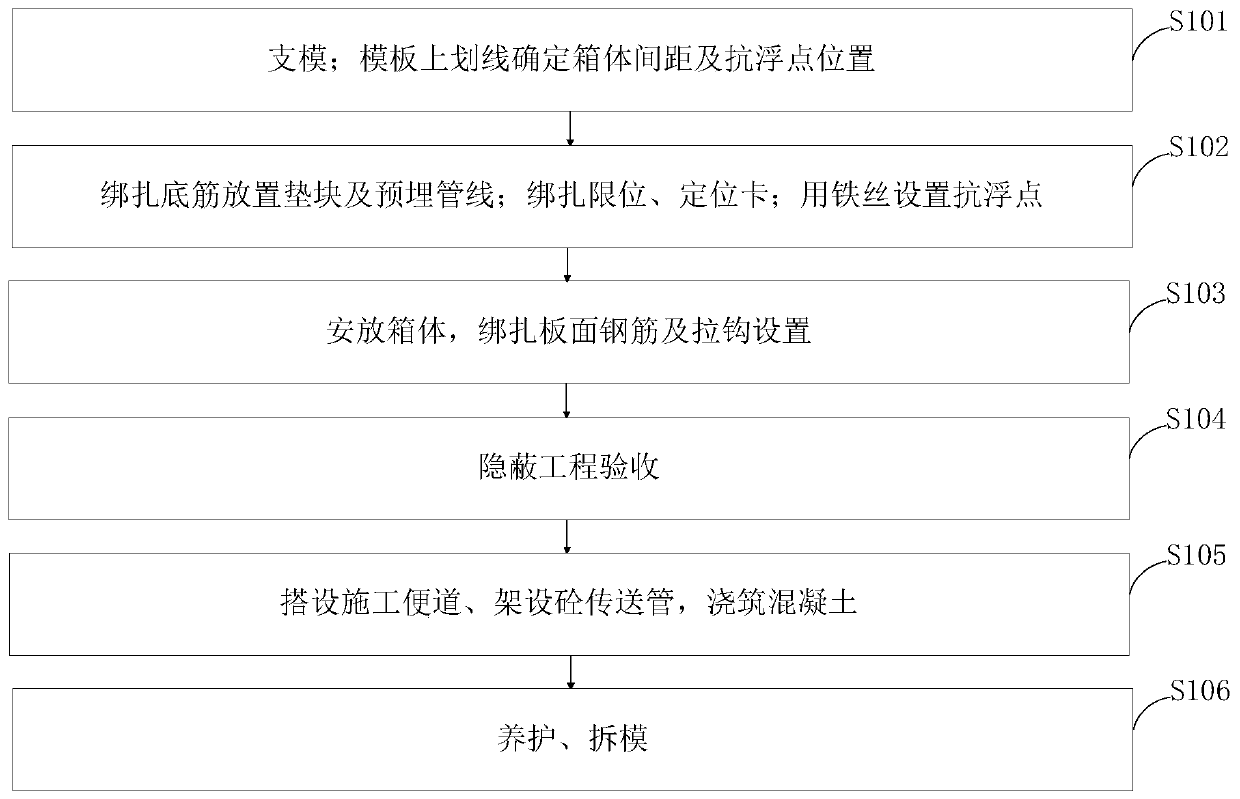

Manufacturing process for coarse aggregate active powder concrete prefabricated bridge panel

ActiveCN109291240AQuality is easy to controlHigh strengthFeeding arrangmentsBridge structural detailsEngineeringPlastic film

The invention relates to the technical field of bridge panel manufacturing, and discloses a manufacturing process for a coarse aggregate active powder concrete prefabricated bridge panel. The manufacturing process comprises the following steps of: a, bundling a bridge panel reinforcing mesh in a mould; b, preparing materials: b1, sampling and detecting; b2, preparing coarse aggregate active powderconcrete; c, automatically distributing; d, covering the plastic film with a stripe which completes flat plate vibration; and e, curing. A prefabricated panel manufactured by the process has the characteristics of being ultra-high in strength, high in toughness, high in elastic modulus, low in shrinkage and excellent in durability; and the whole process can realize standard operation, and qualityof the prefabricated bridge panel is stable.

Owner:南京市公共工程建设中心 +2

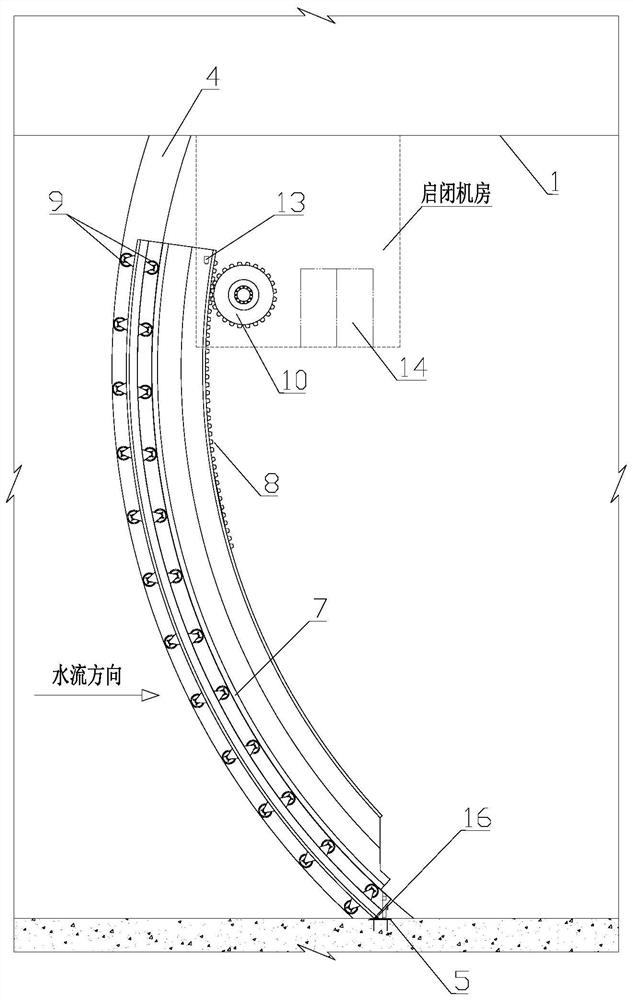

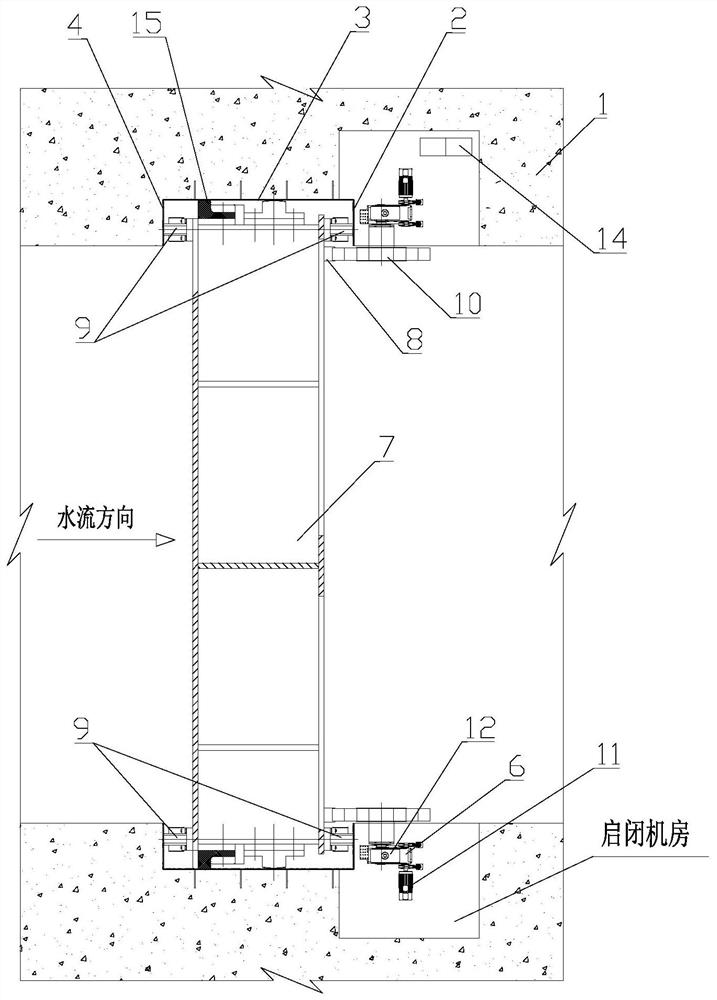

Supporting-arm-free working radial gate device of spillway and construction method

ActiveCN113073617ASimple structureGuaranteed uptimeBarrages/weirsHydro energy generationGear wheelControl theory

The invention discloses a supporting-arm-free working radial gate device of a spillway. The device comprises a radial gate and gate bodies located on the two transverse sides of the radial gate; the inner walls of the two sides of each gate body are each provided with a sliding rail and an opening and closing and control device; the two sides of radial gate are each provided with a guide wheel matched with the corresponding sliding rail; the two sides of radial gate are each provided with a guide rail; and transmission gears of the opening, closing and control devices are matched with the guide rails so as to drive the radial gate to ascend or descend along the inner walls of the gate bodies. The supporting-arm-free working radial gate device of the spillway is simple in structure and convenient to install and maintain, the structure is greatly simplified after a supporting arm is omitted, the mounting and maintenance workload is small, and operation is convenient; and after a bracket of a spillway gate pier is removed, the structure is simple, the construction procedures are reduced, and the construction difficulty is lowered.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

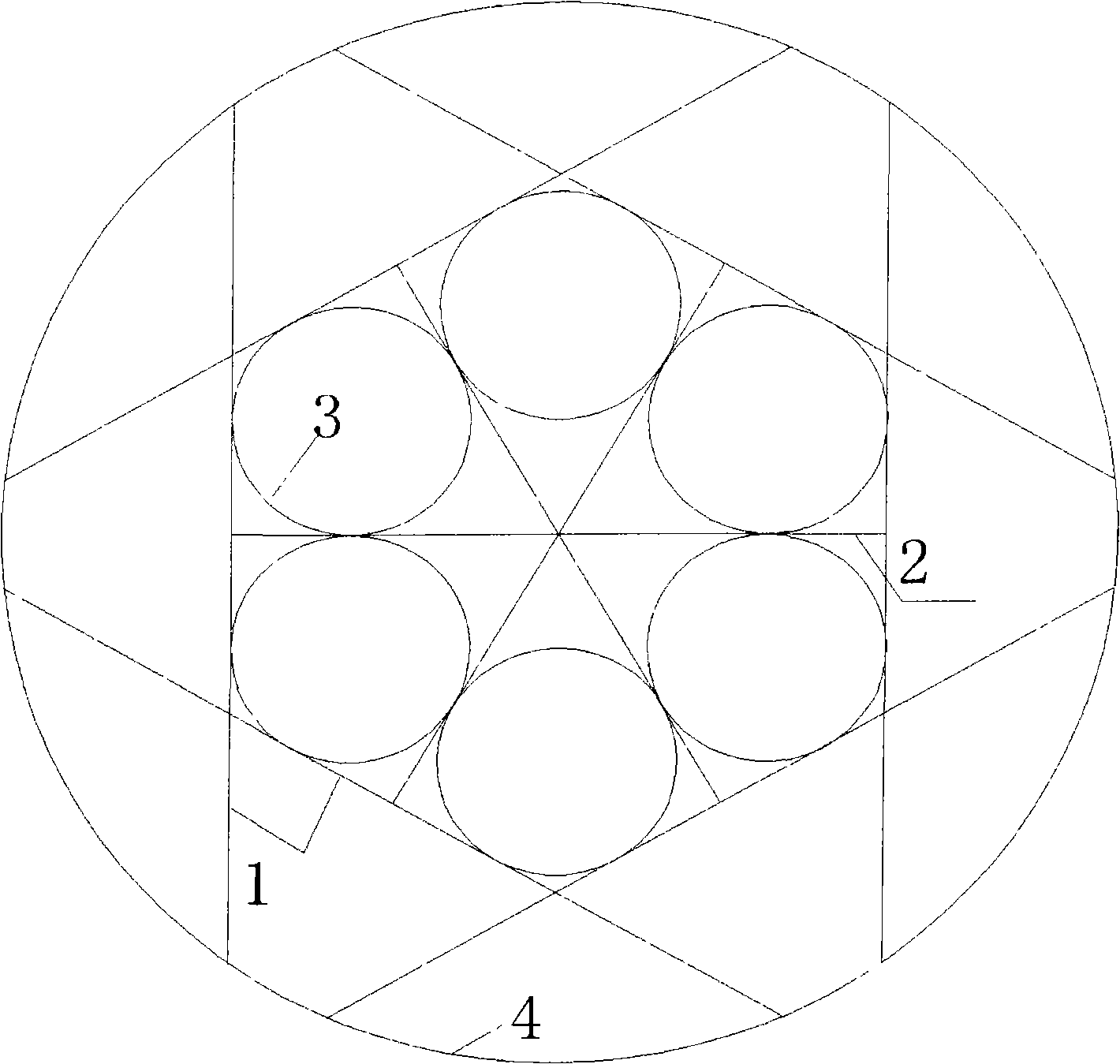

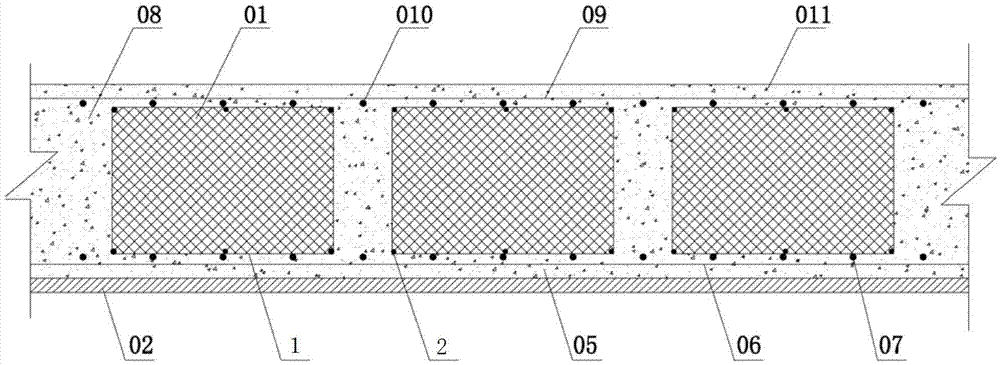

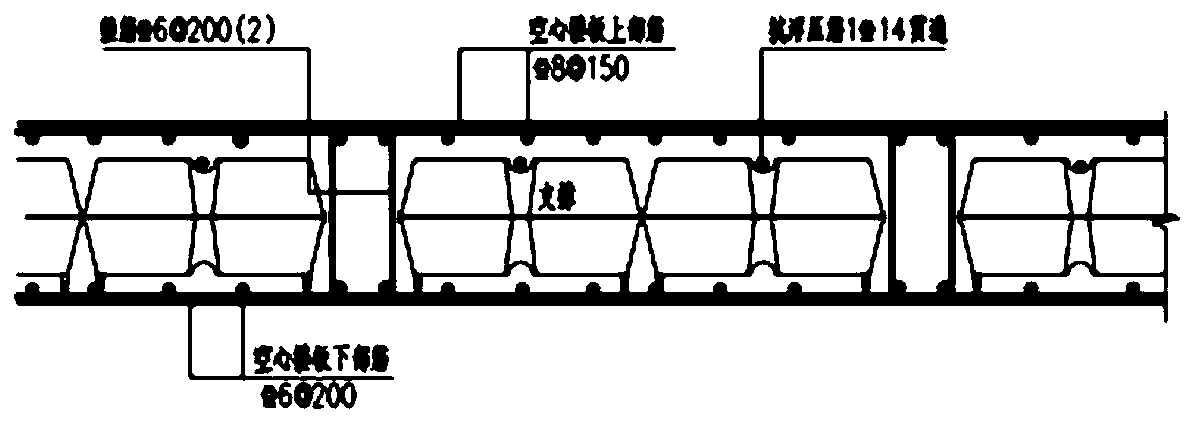

Hollow hidden beam plate structure formed by net pieces and supporting rebar cast-in-place concrete and process

PendingCN106948534AReduce construction proceduresReduce construction difficultyFloorsWeb structureRebar

The invention discloses a hollow hidden beam plate structure formed by net pieces and supporting rebar cast-in-place concrete and a process. The hollow hidden beam plate structure comprises net boxes, a rebar net cloth body and a concrete filling body. The rebar net cloth body comprises an upper layer net cloth body and a lower layer net cloth body which are arranged in an up-down spaced mode. The net boxes are uniformly arranged between the upper layer net cloth body and the lower layer net cloth body at intervals. Outside space of the net boxes are filled with the concrete filling body extending toward the outer sides of the upper layer net cloth body and the lower layer net cloth body. The lower portion of the concrete filling body is supported and shaped through a supporting formwork. The concrete filling body is poured from bottom to top. Air mixed in the concrete filling body is extruded into the net boxes from the two sides of the net boxes and discharged upward through the tops of the net boxes till covers the net boxes, and the net boxes block concrete outside to form a whole hollow hidden beam plate. A hollow or open web structure is formed, supporting rebars takes part in force bearing of the structure to strengthen the building structure, accordingly the construction efficiency is improved, and the energy-saving and environmental-friendly requirement of construction is met.

Owner:刘鹏

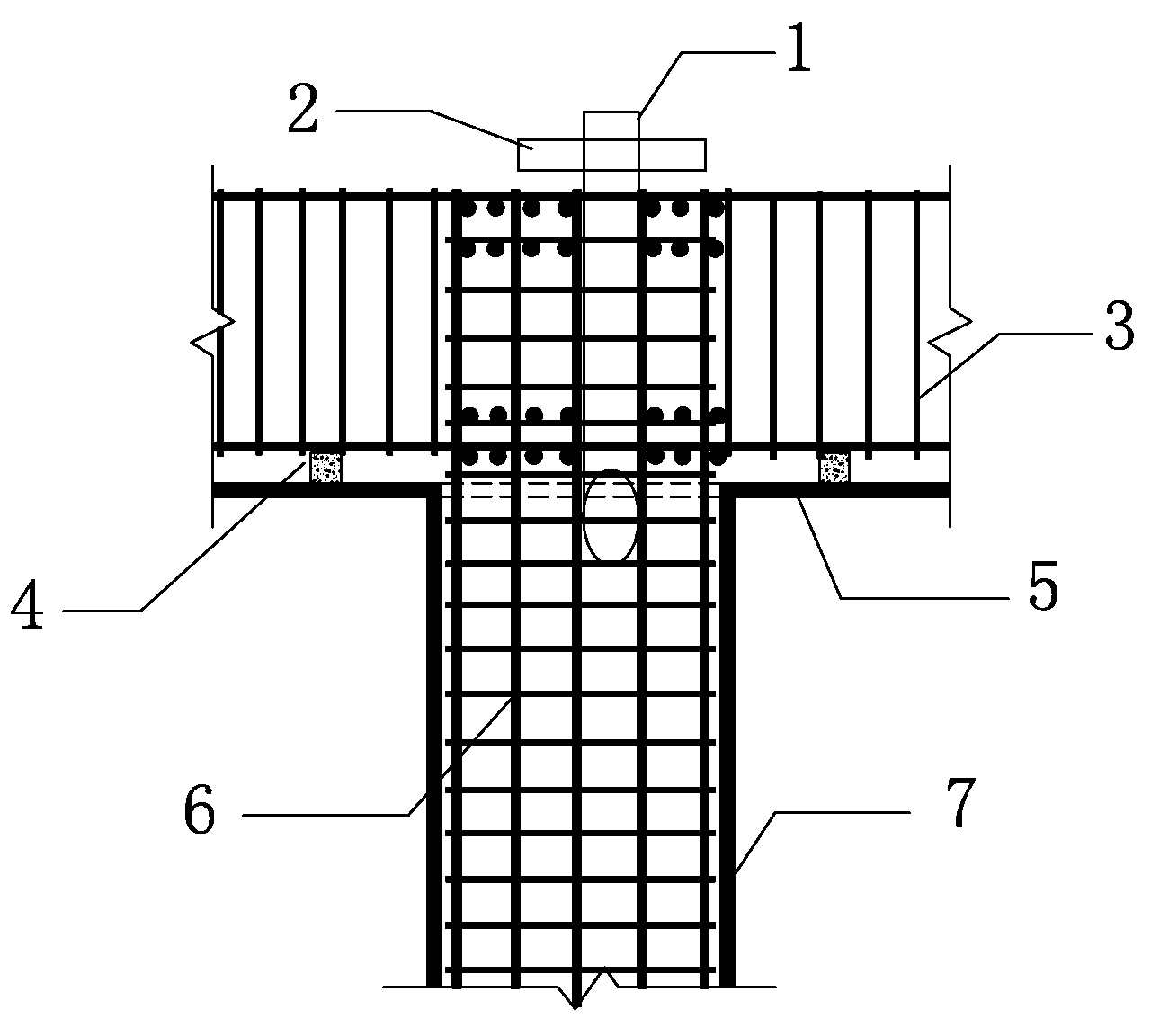

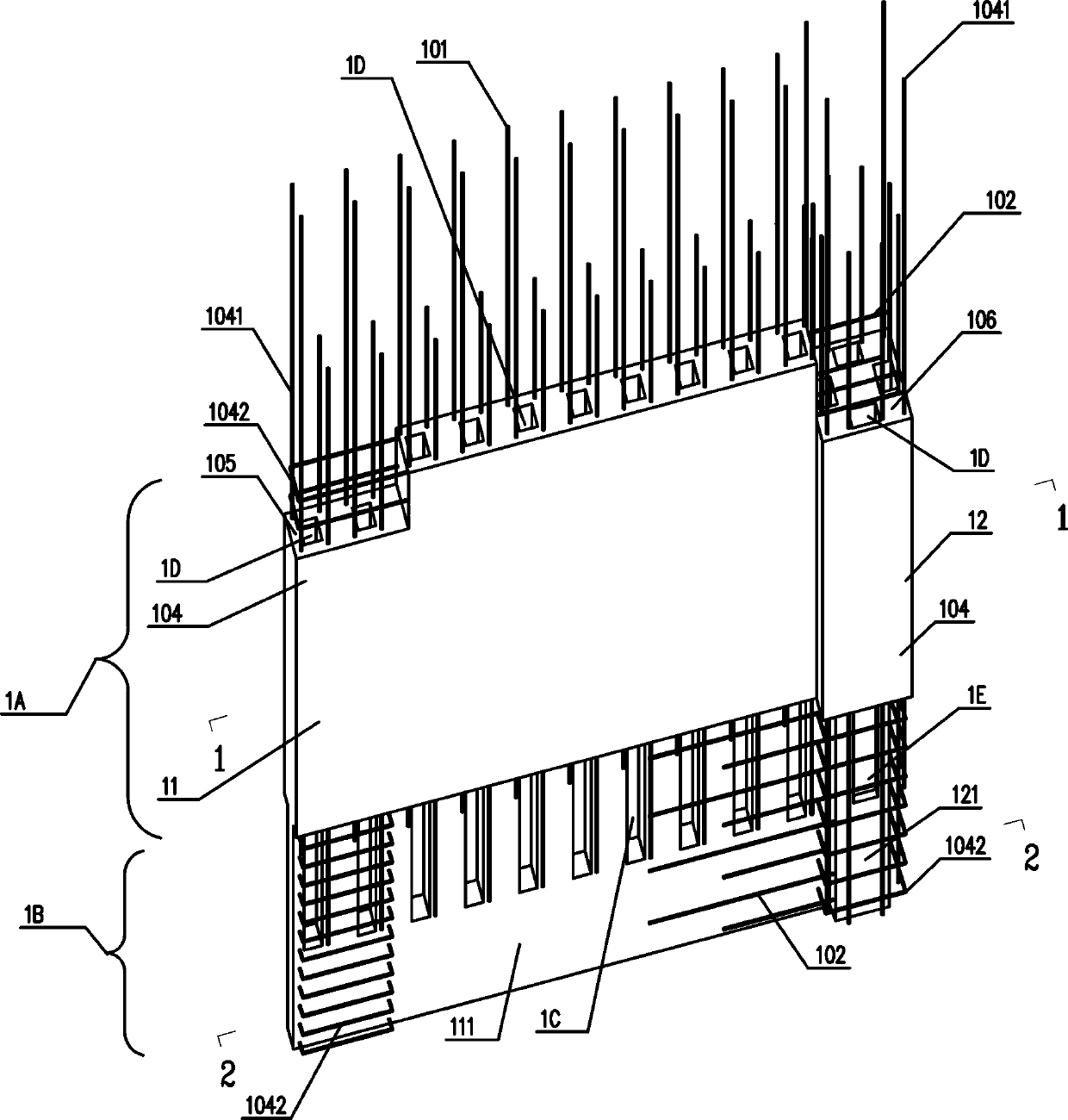

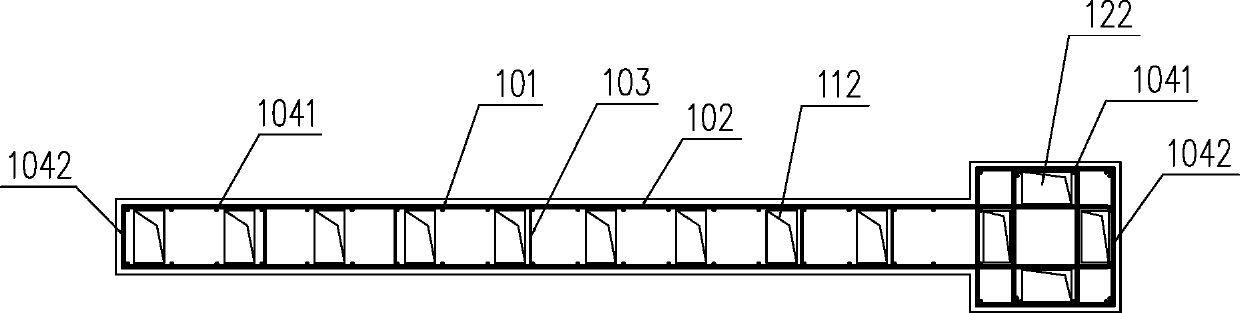

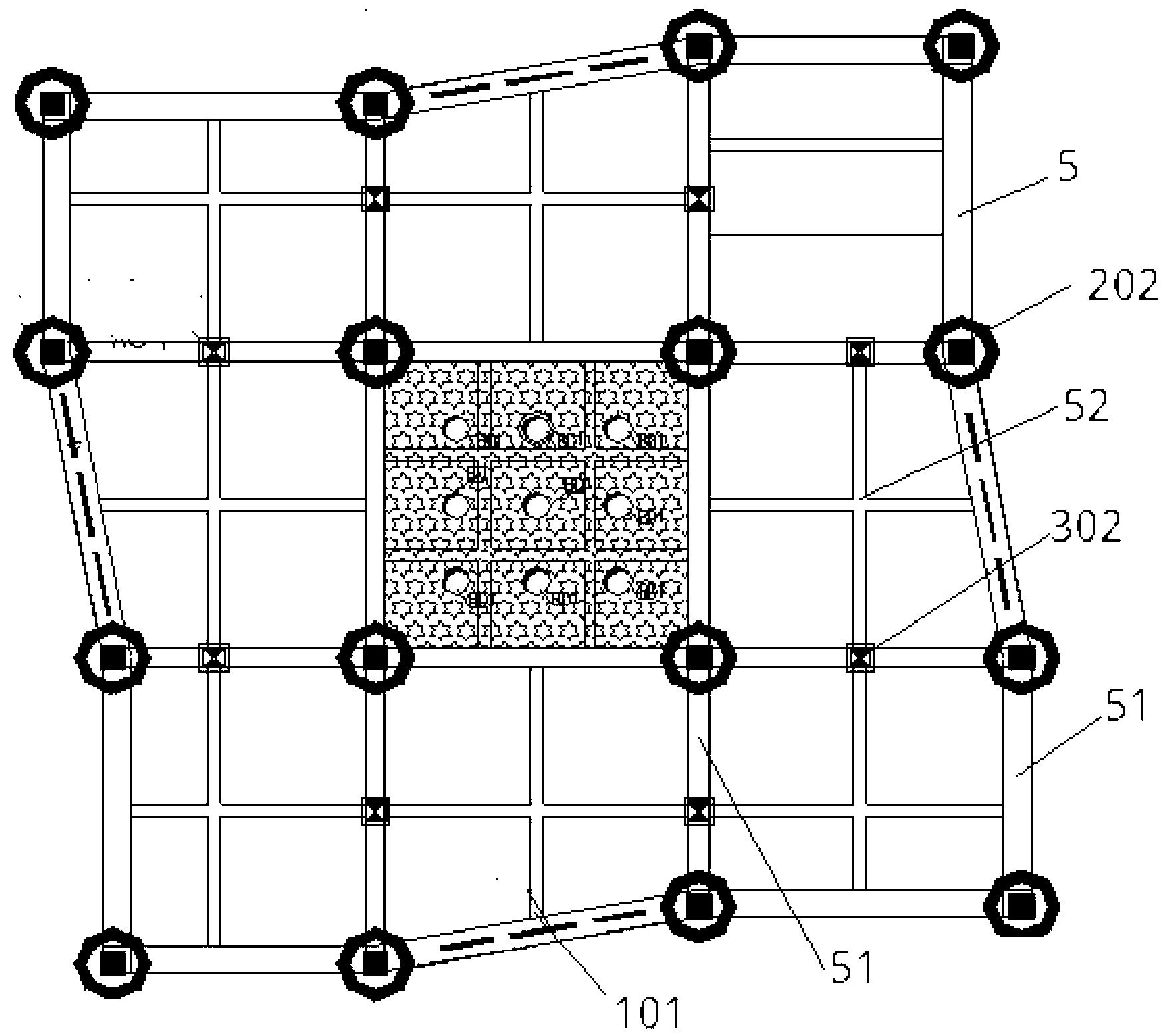

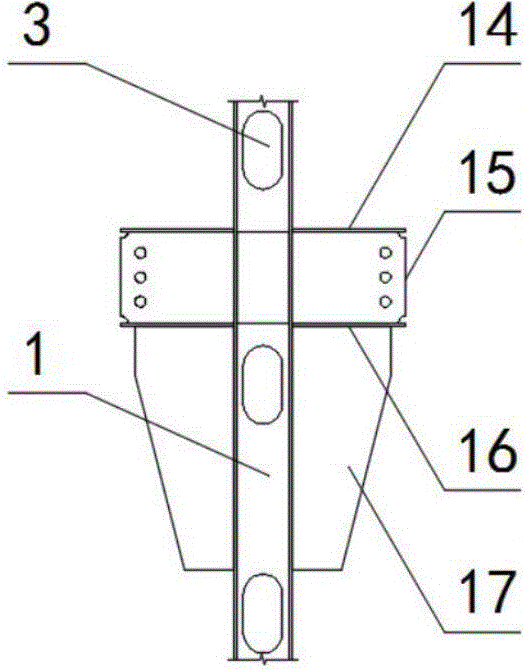

Fabricated concrete variable-section end-column-type shear wall member and construction method thereof

PendingCN107762001AResolve connectionConvenient welding operationWallsMould auxillary partsArchitectural engineeringRebar

The invention belongs to the technical field of building materials and building construction and particularly relates to a fabricated concrete variable-section end-column-type shear wall member and amanufacturing mould and construction method thereof. The fabricated concrete variable-section end-column-type shear wall member comprises a shear wall limb (11) and an end column (12), and the end column (12) is directly connected with one side end of the shear wall limb (11). Through the variable section, steel bar joints (1F) of vertical steel bars (101) on the two sides of the lower section (1B) of the member and edge member vertical steel bars (1041) are exposed. The problem of unstable connection between the vertical steel bars (101) and the edge member vertical steel bars (1041) of the end-column-type shear wall member is conveniently solved through a welding connecting method. Through an overall prefabricated mode, the problem of connection of horizontal steel bars (102) and the problem that various steel bars cannot be mutually connected to form a steel bar framework are solved. By forming a shear wall limb vertical hole channel (112) and an end column vertical hole channel (122) which are special for cast-in-place concrete (32), the cast-in-place concrete (32) is easy to pour, vibrate and compact, the quality defect is avoided, and detection and acceptance are facilitated.By arranging an L-shaped connecting beam support (105) or a connecting beam support platform (106), connecting beams or frame beams are conveniently mounted.

Owner:姚伟华 +1

Prestressing force pipe pile precast pile tip and its production process

InactiveCN101307597BUnique prestressing propertiesWith prestressing propertiesBulkheads/pilesEarthquake resistancePre stress

The invention relates to the architecture field and relates to a preformed pile point for a prestressed tubular pile, wherein, anchor bars are welded continuously on the inner circumference of the steel point; the outer layers of the anchor bars are bound and fastened by annular spirally reinforced columns; and prestressing tendon hole sites are preserved on a placing concrete body. The preformedpile point for the prestressed tubular pile is a unique preformed pile point with the prestress performance; the pile point is integrated into a whole with a square pile; the bearing capacity of a pile point part is improved; and the pile point is difficult to break and maintains the same service life with the pile. The method for producing the pile point guarantees the product quality, saves thelabor and a great number of steel products, is safe and reliable, improves the durability and the earthquake resistance, and meets the demand of architectural pile foundation engineering.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

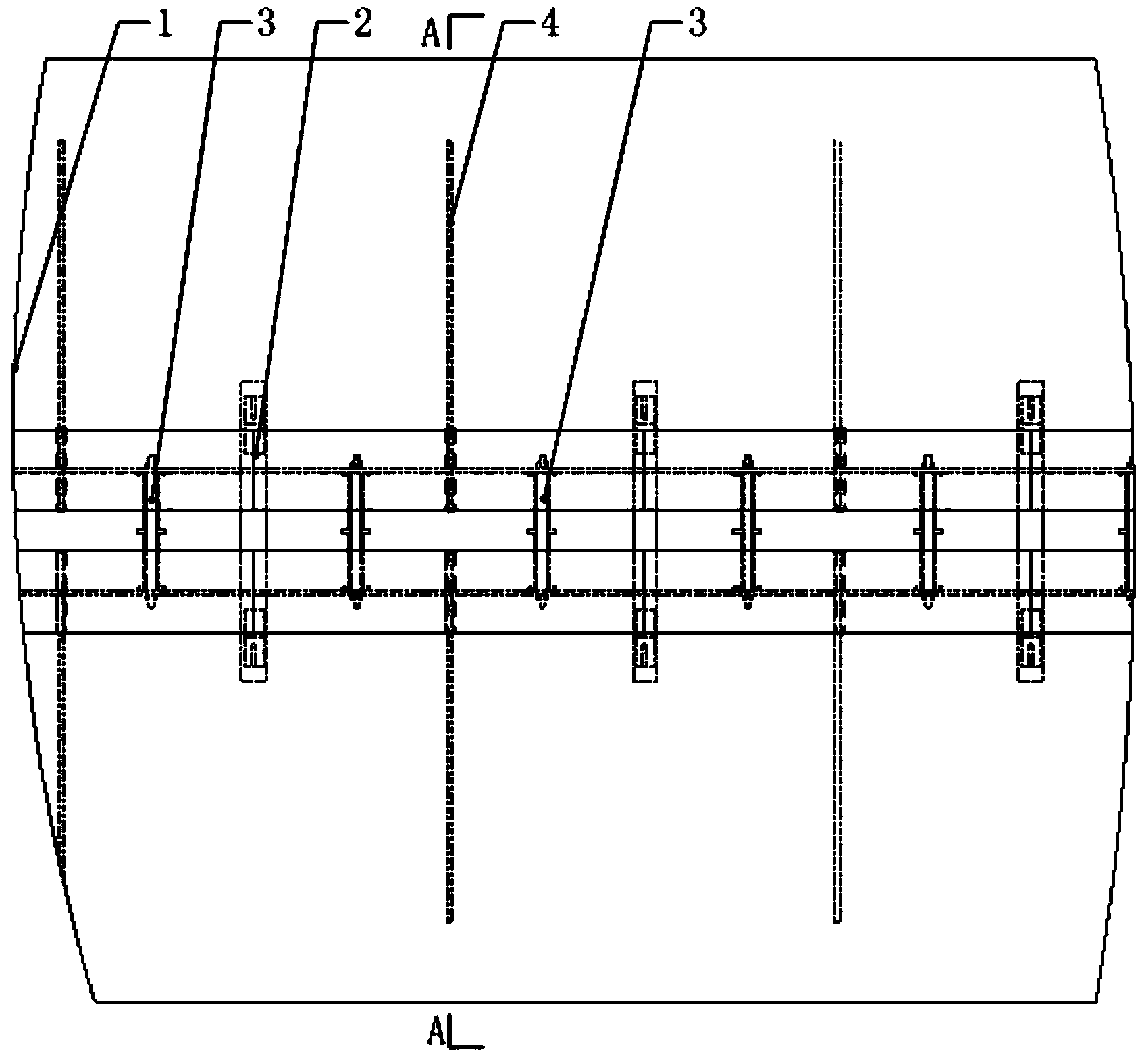

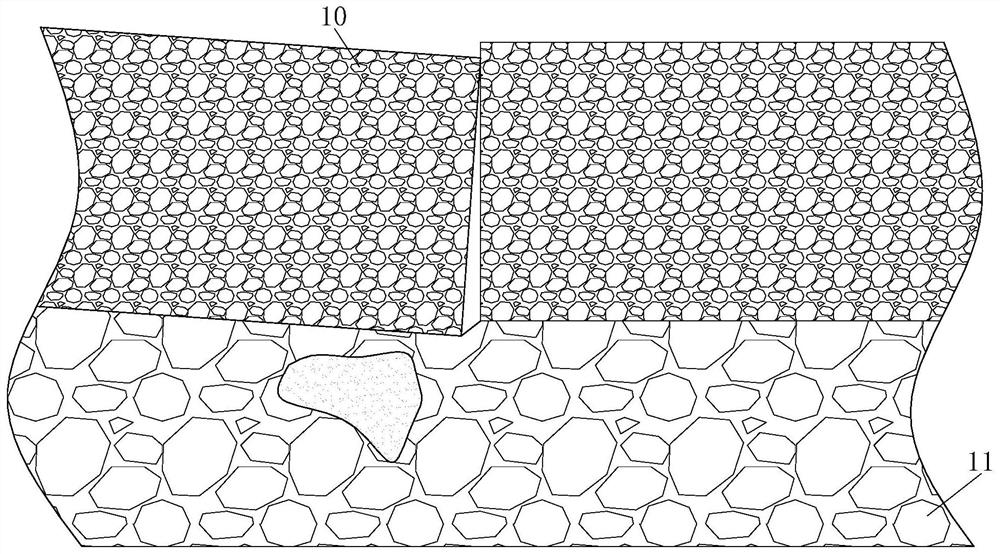

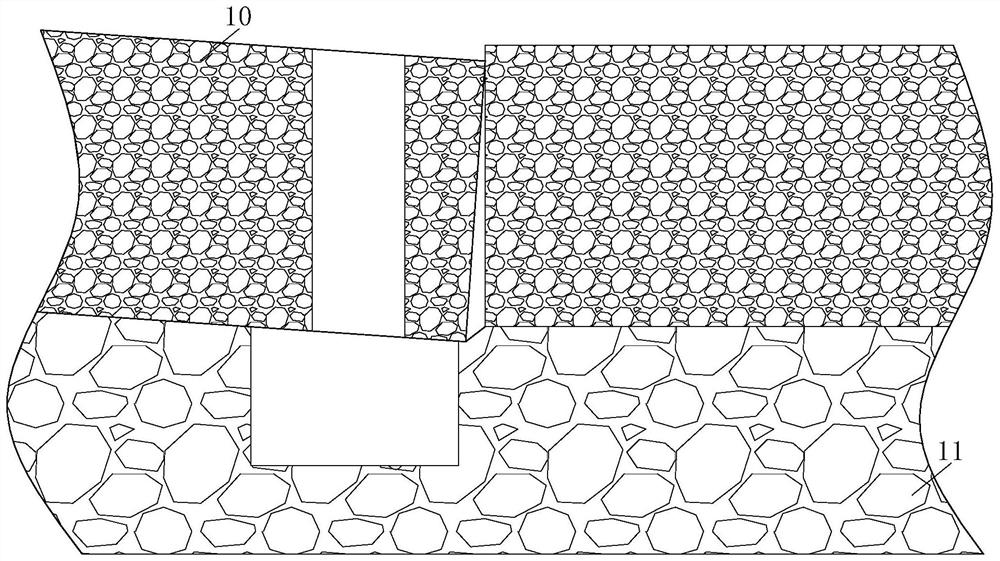

Laminated slab post-pouring joint structure and construction method

PendingCN114033167AGood for vibrating and compactingReduce concrete stressForms/shuttering/falseworksBuilding material handlingSteel tubePipe

The invention discloses a laminated slab post-pouring joint structure and a construction method, and relates to the technical field of building construction. The laminated slab post-pouring seam structure and the construction method specifically comprise the following steps that firstly, surveying and setting out are conducted, a beam or a wall and a post-pouring seam formwork system are erected, and the post-pouring seam formwork system is mainly composed of a steel pipe, square timber, an adjustable jacking, multiple layers of plywood and self-adhesive rubber sealing strips; the self-adhesive rubber sealing strip can be adhered to the template, is good in sealing performance, and can be recycled for multiple times after the template is removed. According to the laminated slab post-pouring joint structure and the construction method, the contact face of the straight section of a traditional prefabricated slab is optimized into a structure with the narrow left portion and the wide right portion, the end of the prefabricated slab and the formwork form a reserved groove, an inverted-T-shaped structure is formed after concrete pouring, the overall shape of the prefabricated slab and a cast-in-place layer is increased, the shape is divided into oblique steps, concrete pouring and vibrating compaction are facilitated, and the model reduces the concrete pressure at the slurry leakage position and reduces the slurry leakage rate.

Owner:CHINA MCC17 GRP

Prestressing force square pile precast pile tip and its processing method

The invention relates to the architecture field and relates to a preformed pile point for a prestressed square pile, wherein, anchor bars are matched with and welded on the inner circumference of the steel point; the outer layers of the anchor bars are bound and fastened by annular spirally reinforced columns; and prestressing tendon hole sites are preserved on a placing concrete body. The preformed pile point for the prestressed square pile has an unique structural shape; the prestressing tendon hole sites are preserved on concrete body; the pile point is integrated into a whole with the square pile; the bearing capacity of a pile point part is improved; and the pile point is difficult to break and maintains the same service life with the pile. The method for producing the pile point changes side concrete placement into concrete placement in the vertical direction, thereby the placement is convenient and dense without pore space due to primary concrete vibrating. Moreover, the methodguarantees the product quality, saves the labor and a great number of steel products, and is safe and reliable; the pile point is dense, has no crack, has high strength and impact resistance and strong penetration factor; and the durability and the crack resistance of the square pile are improved.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

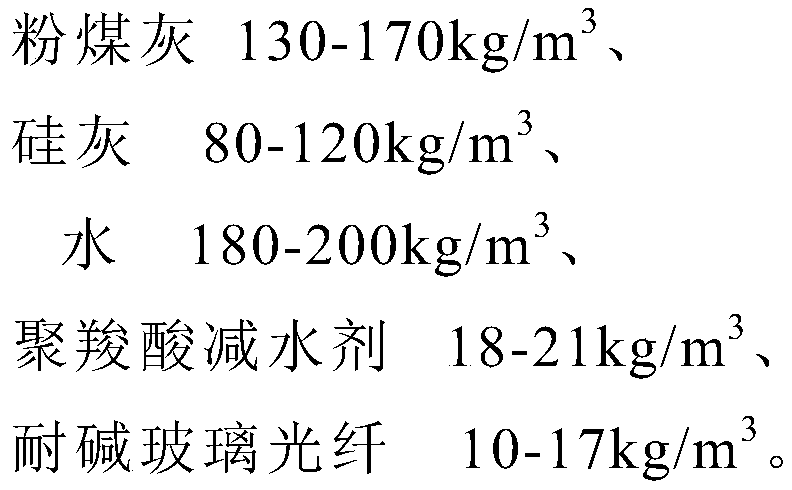

Glass optical fiber surface treating agent, alkali-resistant glass optical fiber and light-transmitting concrete prefabricated part

The invention relates to a glass optical fiber surface treating agent, an alkali-resistant glass optical fiber and a light-transmitting concrete prefabricated part, and belongs to the technical fieldof concrete. The glass optical fiber surface treating agent is prepared from the following components in parts by weight: 100 parts of ethylene vinyl acetate copolymer emulsion, 5 to 9 parts of a silane coupling agent, 4 to 6 parts of a film-forming agent, 8 to 10 parts of a surfactant and 150 to 200 parts of deionized water. The glass optical fiber surface treating agent can improve the alkali resistance of the glass optical fiber, and the durability of concrete can be improved when the treated glass optical fiber is applied to the concrete.

Owner:浙江广天构件集团股份有限公司

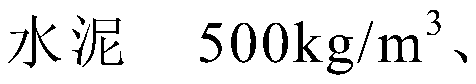

Construction method and application of load reducing component on underground garage hollow floor

InactiveCN111561094AGuaranteed sensory qualityLight weightFloorsCharacter and pattern recognitionArchitectural engineeringRebar

The invention belongs to the technical field of construction of load reducing components on underground garage hollow floors, and discloses a construction method and application of a load reducing component on an underground garage hollow floor. The construction method is characterized in that a box body space and anti-floating point positions are determined through scribing on a formwork; bottombars are bound, cushion blocks are placed and pipelines are pre-buried; spacers are bound and limited; the anti-floating points are arranged by using iron wires; a box body is placed, plate surface reinforcing steel bars are bound and drag hooks are arranged; inspection and approval of concealed work are carried out; a construction access road is arranged in an built mode, a concrete conveying pipe is arranged in an erected mode, and concrete is poured; maintenance and mold stripping are carried out. According to the construction method and application of the load reducing component on the underground garage hollow floor, in the concrete pouring process control, vibration needs to be compact, it is guaranteed that vibration leakage and mortal runout do not occur, and the sensory quality ofa concrete component is guaranteed; and finally, protection of the finished product with an optimized design structure is controlled; and a cast-in-place concrete hollow floor formed by the load-reducing component can save a large amount of steel, the concrete, formwork materials and labor, and the hollow floor is light in self weight and high in bearing capacity.

Owner:关蕙

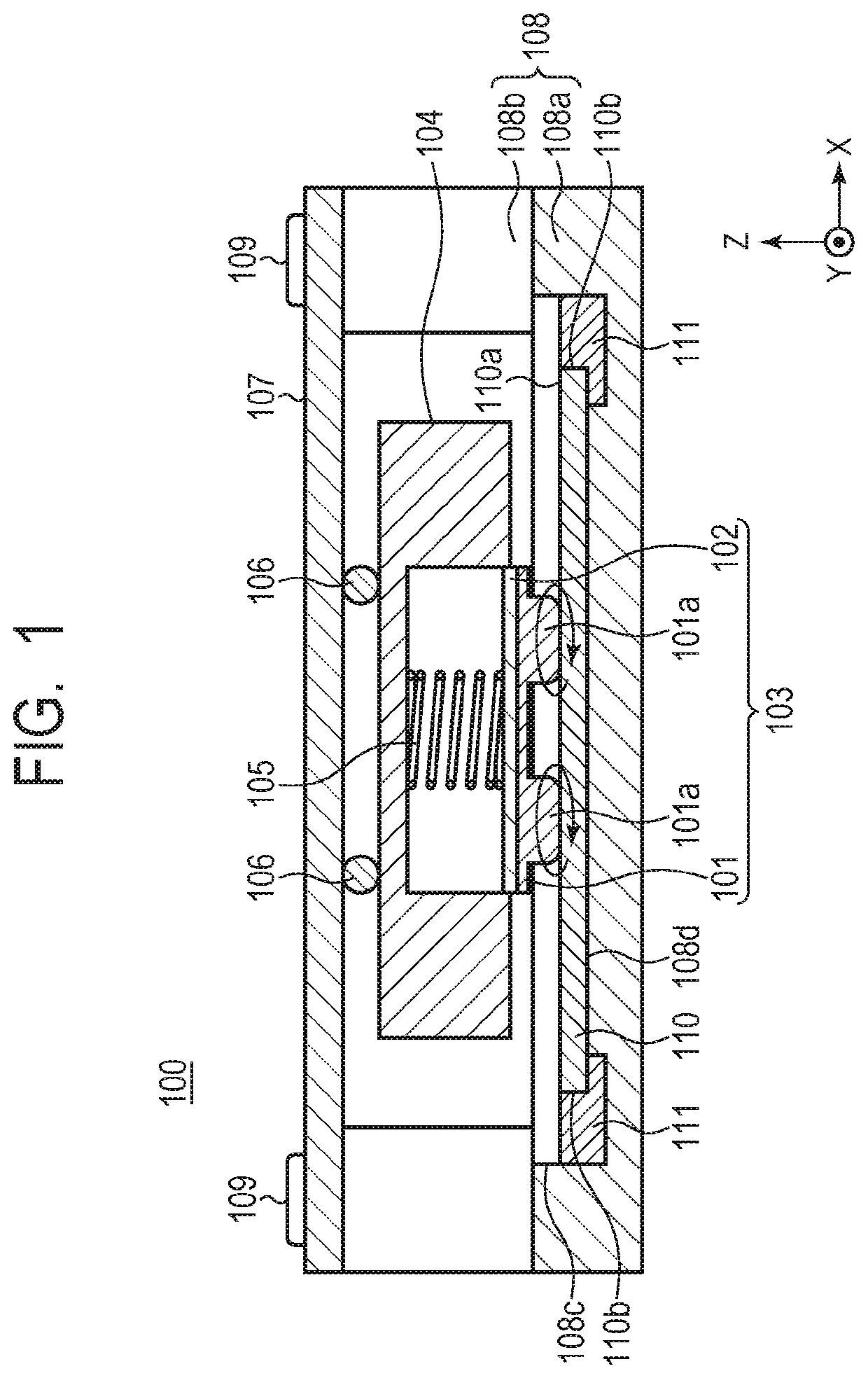

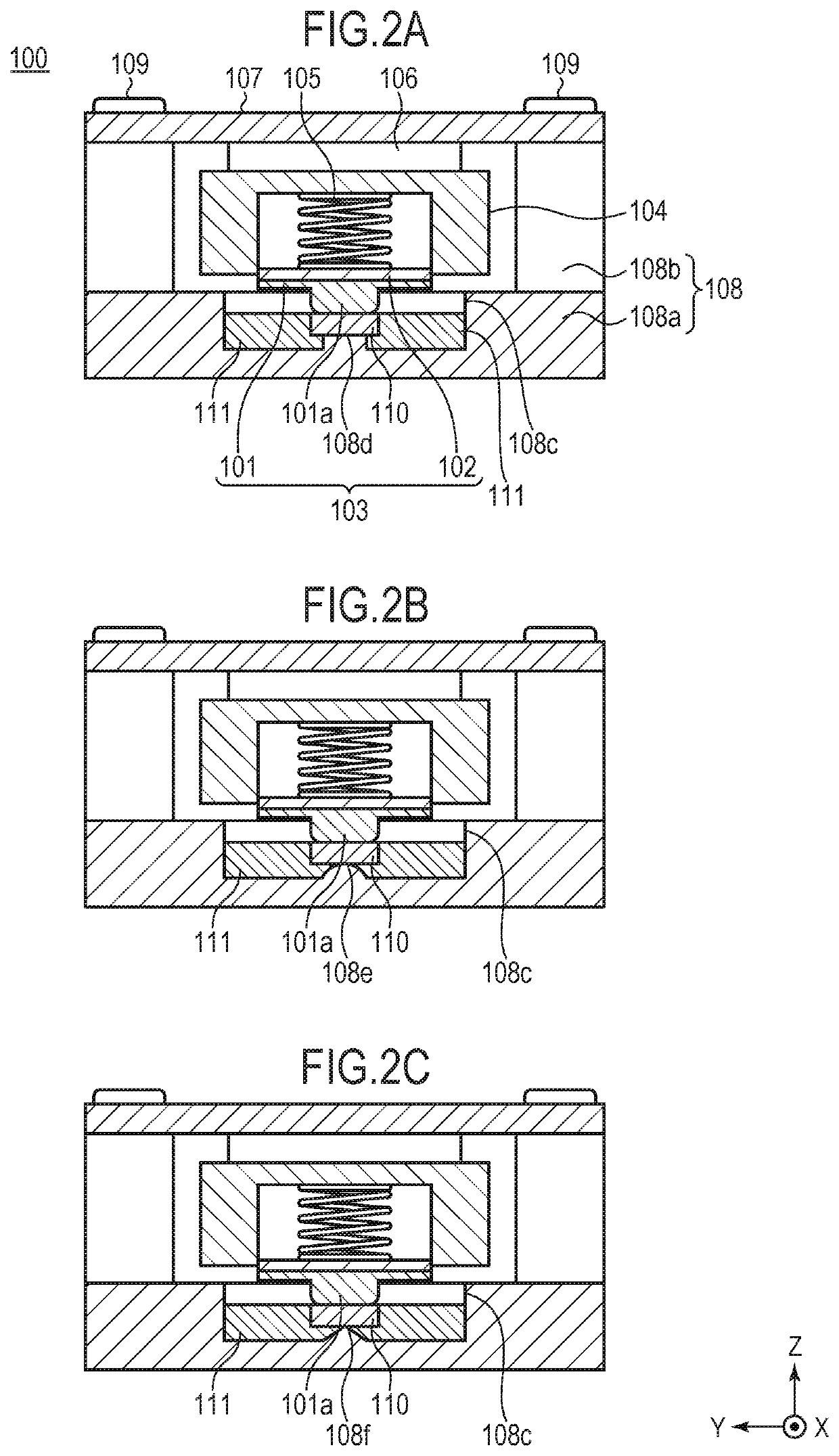

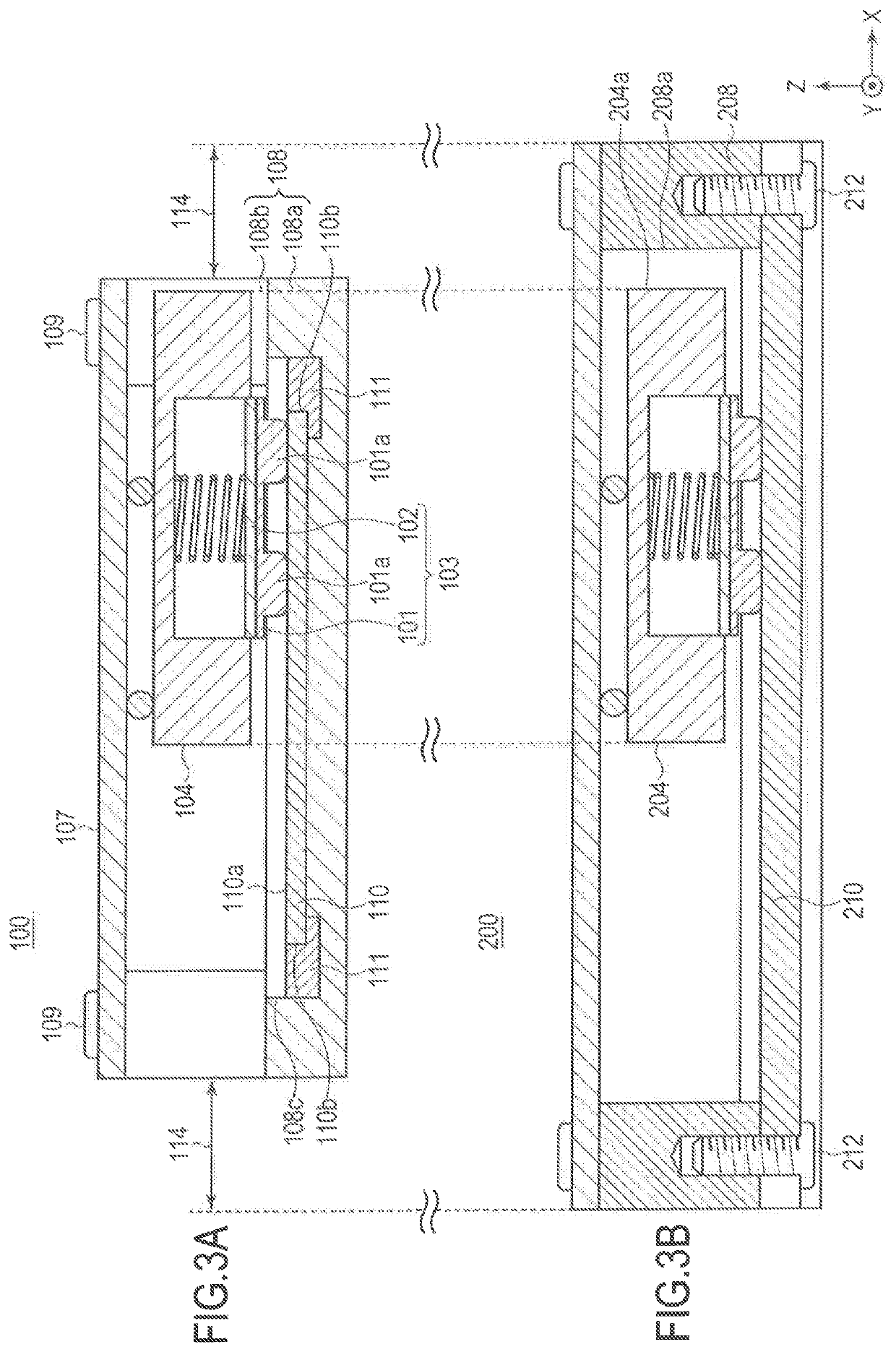

Vibration wave motor and optical apparatus using vibration wave motor

ActiveUS10938326B2Vibrate compactPiezoelectric/electrostriction/magnetostriction machinesProjector focusing arrangementEngineeringWave motor

Disclosed is a vibration wave motor including: a vibrator provided with a piezoelectric element and a vibration plate; a frictional member having a frictional contact surface coming into contact with the vibrator; a fixing member having a recess to which the frictional member is fixed; and pressurizing unit that pressurizes the vibrator toward the frictional member, wherein the vibrator and the frictional member make relative movement using vibration generated from the vibrator, a fixing material for fixing the frictional member is provided between the frictional member and the fixing member, and the frictional member is fixed by coming into contact with the fixing member.

Owner:CANON KK

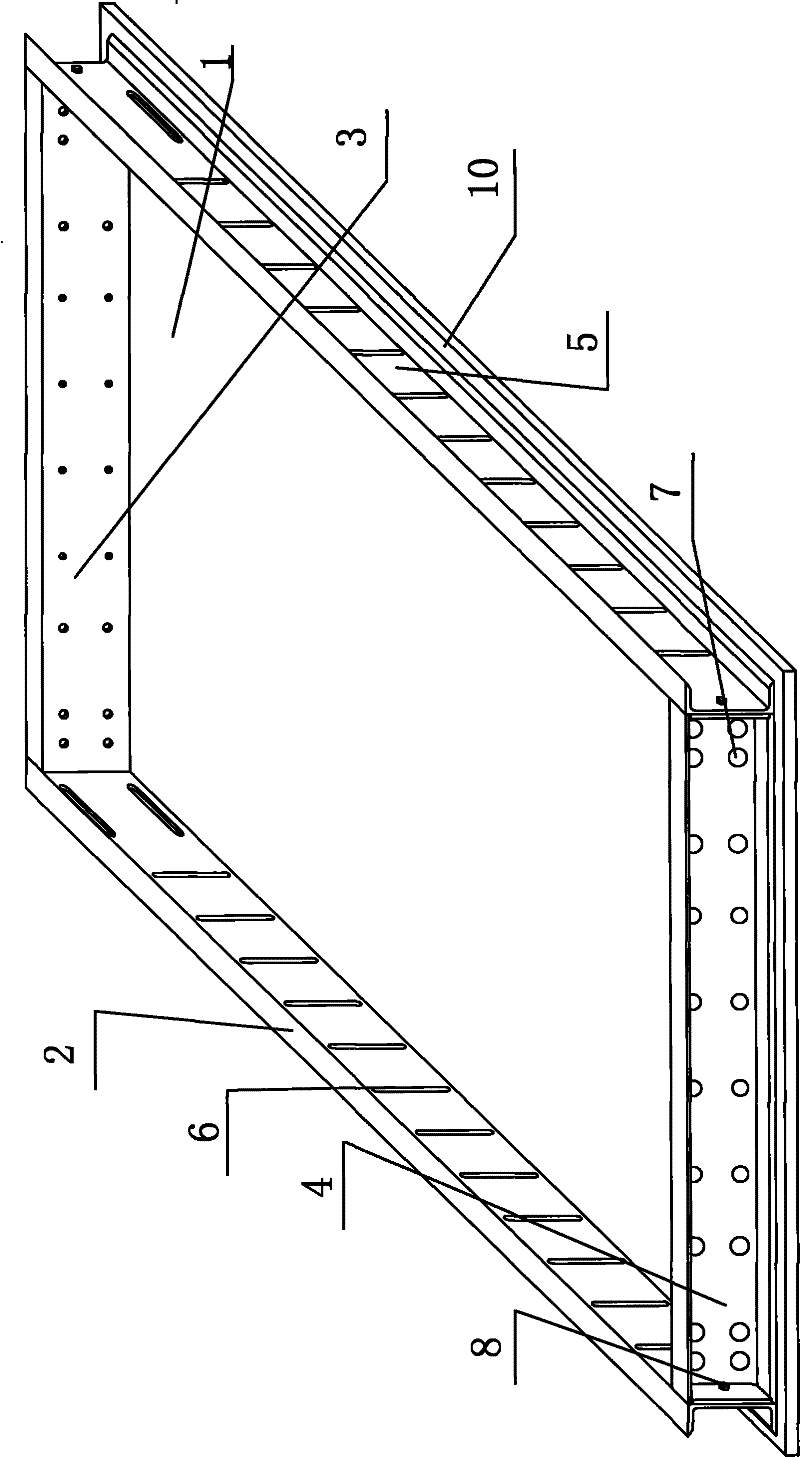

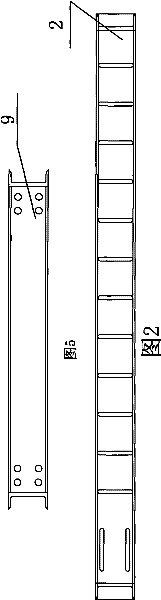

Combined ladder key structure and construction method

InactiveCN104895090AImprove collaboration performanceImprove the comprehensive effect of technology and economyExcavationsReinforced concreteLandslide

The invention relates to the technical field of landslide control and foundation pit support, and concretely relates to a combined ladder key structure and a construction method. The combined ladder key structure comprises ladder key units. Each ladder key unit is formed by a U-shaped cross arm, a rectangular vertical leg and a transverse locking key, wherein one end of the U-shaped cross arm is exposed out of a slide body and rigidly connected to the top of the rectangular vertical leg; the other end of the U-shaped cross arm is placed in a base rock, perpendicular to and in a rigid connection with the transverse locking key; adjacent ladder key units are connected in a stair shape; the rectangular vertical leg of the ladder key unit on the upper part vertically inserted through U-shaped cross arms of the ladder key units on the lower part, and rigidly connected to the same; and the U-shaped cross arm, the rectangular vertical legs and the transverse locking keys are all made from reinforced concrete. By the use of the combined ladder key structure and the construction method, great slide resistance performance, small engineering work, simple construction, low cost and great supporting effect can be achieved.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Mixed control damping structure with overall reset function

InactiveCN103174232AReduce section sizeImprove shock absorptionShock proofingControl theoryViscous damper

The invention discloses a mixed control damping structure with an overall reset function. The mixed control damping structure with the overall reset function comprises a damping frame which is formed by an upper portion frame and a lower portion frame, a flat-plate sliding support is arranged between the lower portion of the frame stand column of the cross point of the vertical and the horizontal main frame beams of the upper portion frame and the lower portion frame, a laminate rubber support is arranged between the lower portion of the frame stand column of the cross point of the sub-frame beams of the upper portion frame and the lower portion frame, and a viscous damper is arranged on the outermost main frame beam of the damping frame. The construction damping structure of the mixed control damping structure with the overall reset function comprehensively adopts laminate rubber shock isolation, the flat plate sliding support and the viscous damper to form a mixed control damping system, respective advantages of devices are played, earthquake energy is dissipated, and therefore an ideal damping effect is achieved.

Owner:ZHEJIANG HAITIAN CONSTR GROUP

Built-in steel column in steel shear structure post-pouring section and pouring method thereof

The invention discloses a built-in steel column in a steel shear structure post-pouring section and a pouring method thereof. The built-in steel column comprises a hollow column body; a main beam node, a column wall node and a pouring channel are formed in the column body; the main beam node is arranged on the column body; the design elevation corresponds to the position of a shear wall steel beam node; the column wall node is arranged in a position where the column body corresponds to a wall column node of a shear wall; the pouring channel is through inside and outside from top to bottom and is arranged on the column body. The pouring method comprises the following steps: pouring concrete into a post-pouring section node through a conveying pipe and the pouring channel by adopting a pouring funnel; vibrating while pouring, so that the post-pouring section node and the shear wall are condensed into an overall wall surface with a flush surface. The built-in steel column is connected with an exposed reinforcing steel bar of the shear wall, so that after the column body and the reinforced concrete shear wall are condensed into a whole, the aseismic strength of a whole building is enhanced. The built-in steel column disclosed by the invention has the effects that the structure is simple, the in-place is accurate, the assembly speed can be increased, and the comprehensive cost can be reduced, and is suitable for a multi-rise assembled residential building system.

Owner:曲周县和盛新型建筑材料有限公司

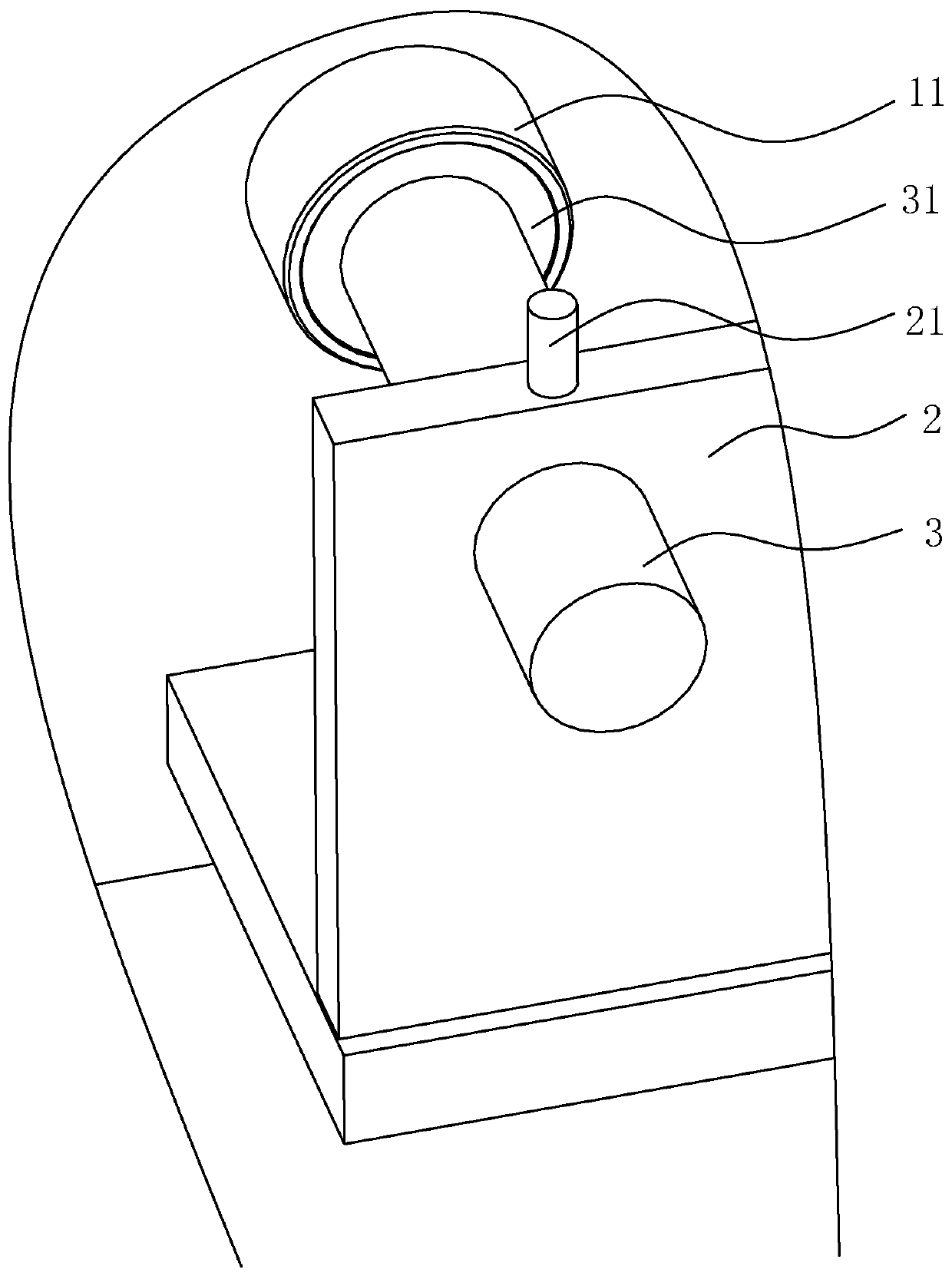

Cement pavement repairing method

ActiveCN114032750AReduce volumeEasy to carryClimate change adaptationRoads maintainenceRoad engineeringArchitectural engineering

The invention belongs to the technical field of road engineering, and particularly relates to a cement pavement repairing method which comprises a bag body, an extension part and a connecting part. According to the method, a repairing bag is placed in the area needing to be grouted before grouting, then grouting is conducted in the repairing bag, filled grout is wrapped by the arranged repairing bag, leakage of the grout is prevented, then the grouting pressure is guaranteed, a settled panel can be lifted, and smooth pavement repairing is guaranteed; when grouting is not carried out, the repairing bag is in a folded state, the size is small, the repairing bag is more convenient to carry, meanwhile, the bag body of the repairing bag is folded into a cylindrical shape, the folded repairing bag is more attached to a drilled hole, and then the repairing bag can enter a damaged part of a roadbed through a hole in a pavement slab more easily; and by arranging the extension part, the repair bag is prevented from being blocked in the hole of the pavement slab, the repair bag can be better unfolded during grouting, and the repairing quality is improved.

Owner:中国安能集团科工有限公司

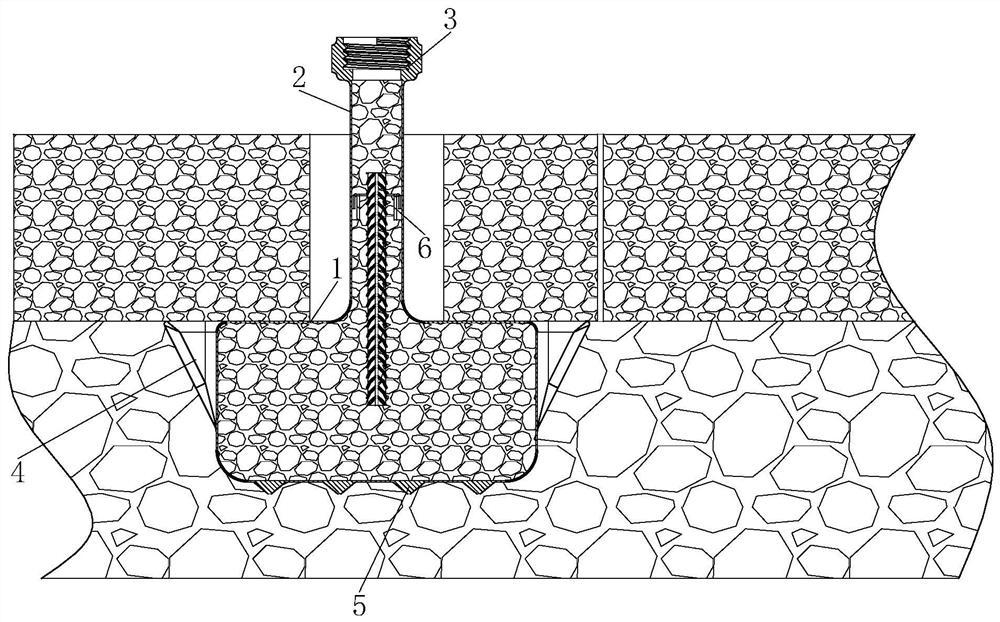

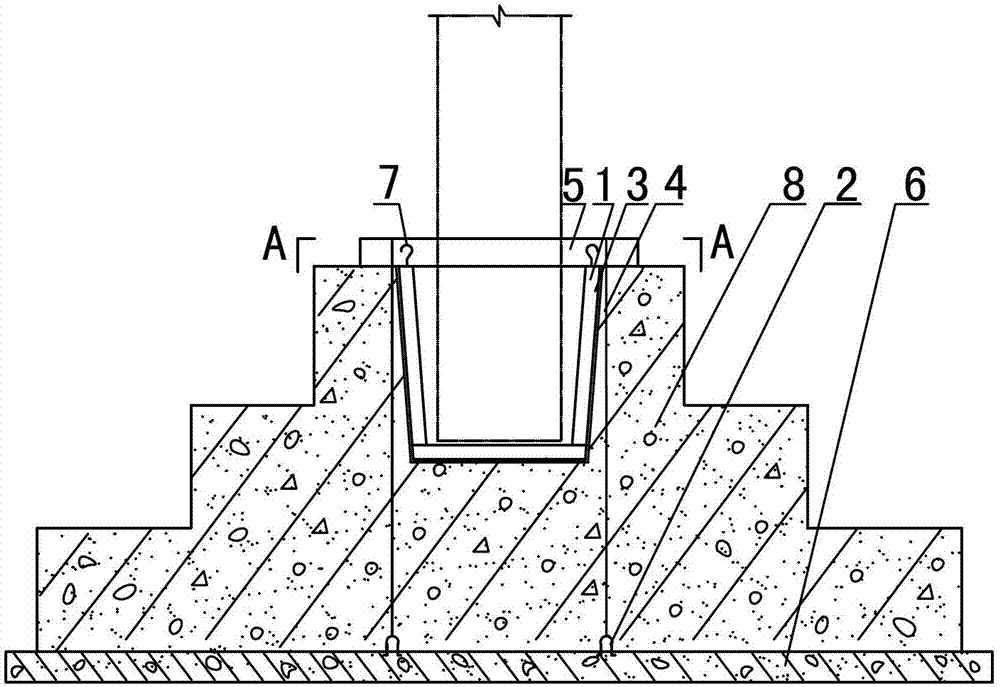

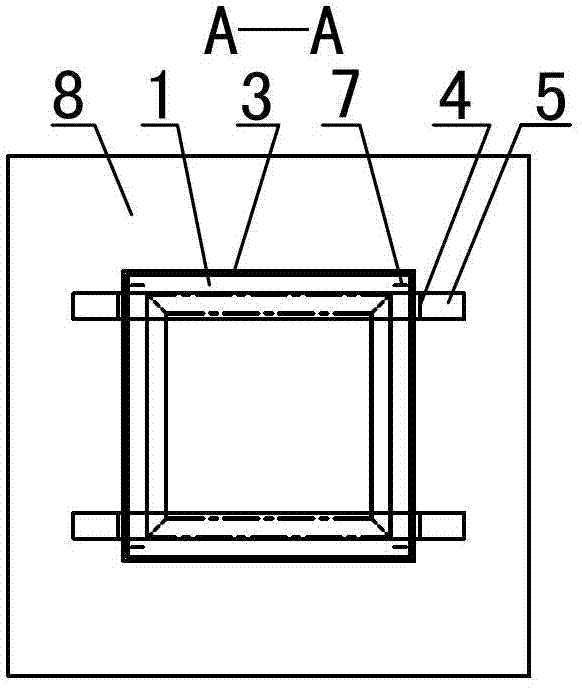

Independent basic construction inner template device with cup opening smaller than 600*600 mm<2> and construction method thereof

InactiveCN103174156BThe extraction process is smoothEliminate the adsorption phenomenon that is not easy to pull outFoundation engineeringArchitectural engineeringFrustum

The invention belongs to a small-size cup opening independent basic construction method, and in particular relates to an independent basic construction inner template device with a cup opening smaller than 600*600 mm<2> and a construction method thereof. The independent basic construction inner template device comprises a basic concrete cushion layer, an outer template and a frustum cup opening inner template, and is characterized in that a bottom-sealed frustum cup opening inner template device is arranged on the top in the outer template and consists of a bottom-sealed frustum cup opening inner template, a plastic cloth layer, an inner template pull-out hook and a component for preventing the cup opening inner template from floating. The independent basic construction inner template device is rational in design and simple and practical; the inner template can be effectively prevented from floating; the forming quality of the cup opening is high; furthermore, concrete is compactly vibrated; the cup opening is formed at one time; during pouring, the concrete is prevented from entering the cup opening; manual cleaning and correction of the bottom of a cup are not needed; the cost is reduced; the working efficiency is improved; and the independent basic construction inner template device is very convenient to operate and use.

Owner:DALIAN YIHUA CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com