Integral type die and method for processing building member for exposing reinforcing steel bars

A technology for exposed steel bars and building components, applied in molds, manufacturing tools, unloading devices, etc., can solve the problems of complicated steel bar connection construction, prolong the construction period, increase economic expenditure, etc., to ensure compactness, improve quality, and protect the whole performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

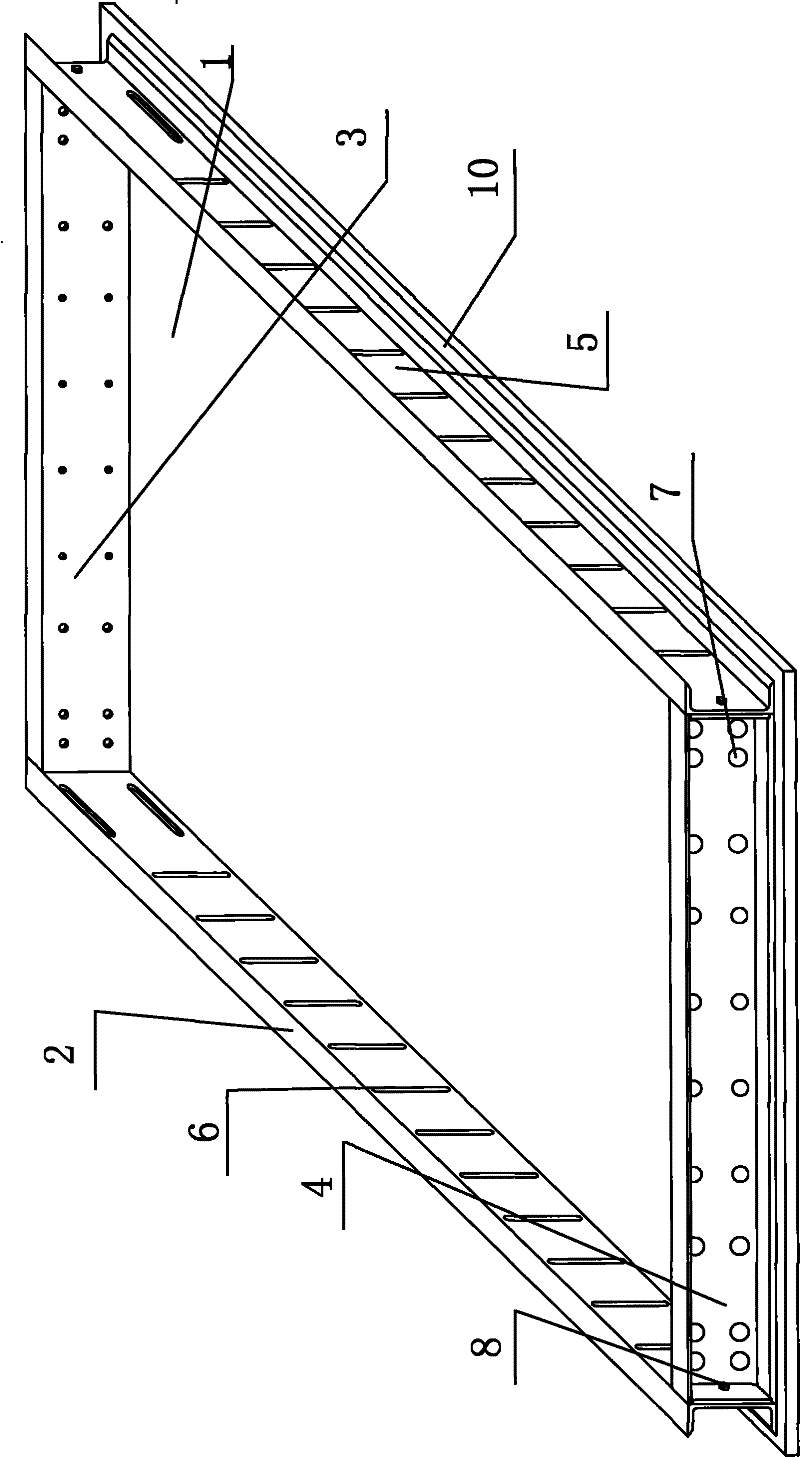

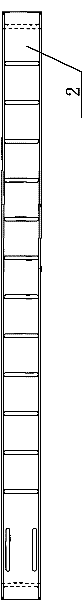

[0021] Integral mold used for the processing of building components with steel bars exposed, its composition includes: mold body 1, said mold body 1 has a left formwork 2, the upper end of said left formwork 2 is connected to upper formwork 3, and the lower end is connected to lower formwork 4, The upper template 3 and the lower template 4 are connected to the right template 5 at the same time, the left template 2, the upper template 3, the right template 5, and the lower template 4 are connected in sequence, and the mold body 1 is connected to the bottom template 10.

Embodiment 2

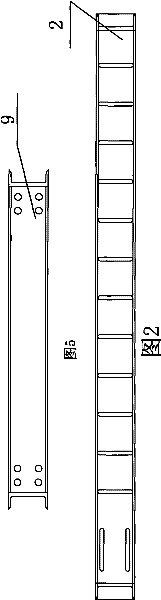

[0023] The integral type described in embodiment 1 makes the mold used for the processing of building components exposed to steel bars, and the left template 2 and the right template 5 have oblong holes 6 extending vertically in the horizontal direction, and the upper template 3 and the lower template 4 have Circular holes 7, and the connection between the templates is fixed with bolts 8.

Embodiment 3

[0025] The mold used for the processing of the integral type exposed steel bar building components described in embodiment 1, the middle part of the lower template 9 used when the described prefabricated component is used in the window part has no round hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com