Construction technology of straw concrete formwork-removing-free dense-rib laminated floor slab

A technology of superimposed floor slabs and construction technology, which is applied in the direction of floors, building components, buildings, etc., can solve the problems of complex formwork support and demolition process, poor thermal insulation and sound insulation effects, and high cost of formwork, so as to achieve vibration and compactness, improve The effect of pouring quality and construction site safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

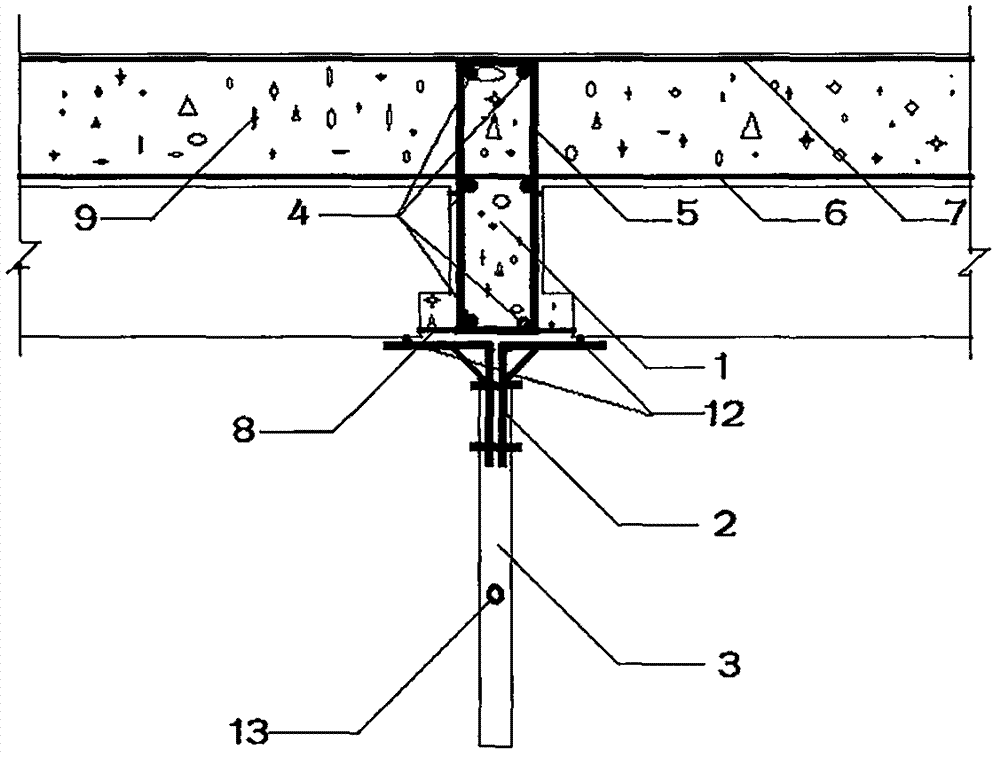

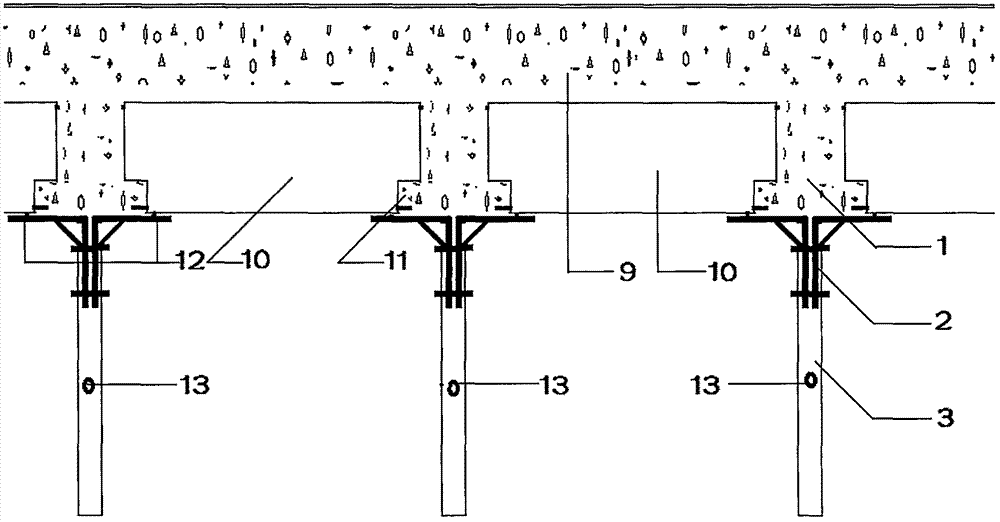

[0017] First of all, ribbed bottom formwork 2 adopts a pair of L-shaped thin-walled steels that are symmetrical to each other, and the side walls are perforated. Paste a 3-5 mm thick sealing foam strip 12 on the rib beam bottom form 2 to prevent grout from leaking when pouring concrete. When the ribbed bottom formwork 2 is supported, the lower vertical support bar 3 should be tightly connected with the ribbed bottom formwork 2 through spring pads; after the ribbed bottom formwork is supported and reinforced, a crane is used to install and lay the demolition-free formwork 10 in sequence, The inner side of the reserved groove 11 of the non-demolition formwork 10 at both ends should be tightly bonded with the pre-attached sealing foam strip 12, and then the rib beam reinforcement cage is installed. The rib beam stirrups are composed of 5; after the rib beam reinforcement cage is in place and connected with the joints such as the reserved head 8 of the lower reinforcement of the n...

Embodiment 2

[0019] While the steel bars are being bound, a small vibrator 13 should be fixed on the vertical support bar 3 at the lower part of the platform; after the steel bar work is completed, the ribbed beam concrete 1 and the composite cast-in-place slab concrete 9 should be poured at the same time, and the concrete should be opened successively during pouring The small-scale vibrator 13 on the lower vertical support bar 3 vibrates to make the dense ribbed concrete 1 and the composite cast-in-place slab concrete 9 smooth and dense.

Embodiment 3

[0021] Open the small vibrator 13 in a certain order and time to vibrate the pumped concrete. After the rib beam bottom formwork 2 and the dismantling-free formwork 10 support are completed, the large-fluid concrete is poured sequentially and uniformly according to the direction determined by the construction plan from far to near by using a distribution machine, and the pouring speed and quantity of concrete are controlled by a special person. While the concrete is being poured, the small vibrator 13 fixed on the vertical support bar 3 at the lower part of the concrete is opened by a manual button or a remote control device. The on-site conditions are determined, about 1 to 3 minutes. After the concrete is level and dense, close the small vibrator 13, pour concrete backwards in turn, and open the small vibrator 13. When opening the small vibrator 13, attention should be paid to whether there is deformation or displacement in the lower vertical support bar 3, rib beam bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com