Built-in steel column in steel shear structure post-pouring section and pouring method thereof

A post-cast section and steel column technology, applied to building components, building structures, walls, etc., can solve problems such as imperfect structural form and installation, high cost of fire-fighting coating, and influence on assembly construction progress, etc., to achieve reduction The effect of assembling the construction process, eliminating potential safety hazards, and increasing the connection strength and connection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

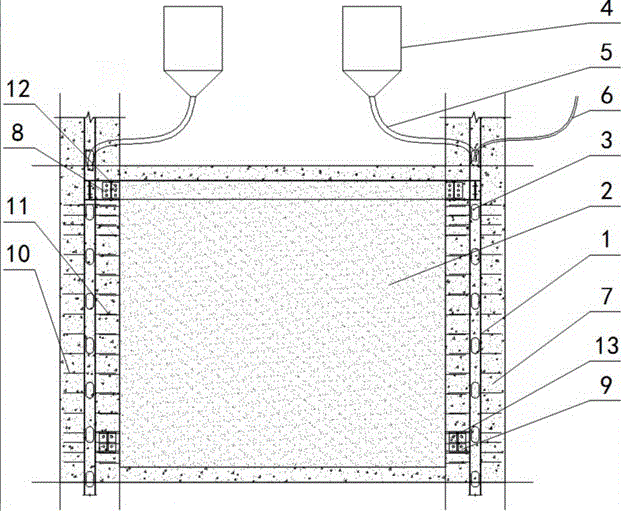

[0023] Below in conjunction with embodiment the present invention is described in further detail:

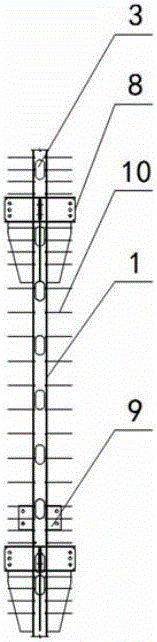

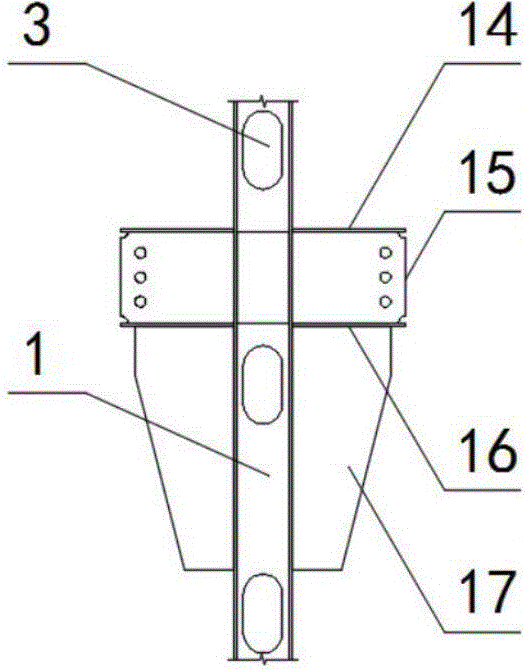

[0024] A steel shear structure with built-in steel columns in the post-casting section, the structure is as follows figure 2 As shown, a hollow column body 1 is included, and the column body 1 is provided with a main beam node 8, a column wall node 9, a connecting steel bar 10 and a pouring channel 3, and the main beam node 8 is arranged on the same side as the steel beam node 12 On the column body 1 at the corresponding position, the column wall node 9 is arranged on the column body 1 corresponding to the wall column node 13, the connecting steel bar 10 is arranged on the column body 1 from top to bottom, and the pouring channel 3 is arranged on the column body 1 through from top to bottom.

[0025] Described cylinder 1 is made by profile, steel bar or sheet material processing, and cylinder 1 can be pipe material, also can be various profiles such as H steel, channel steel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com