Combined ladder key structure and construction method

A construction method and a combined technology, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problem of insufficient durability and reliability of landslide or slope treatment, loss of prestressed relaxation of anchor cables, and restrictions on the effective use of anti-slide piles, etc. problems, to achieve the effect of improving collaborative work ability, reducing project cost, and excellent support ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

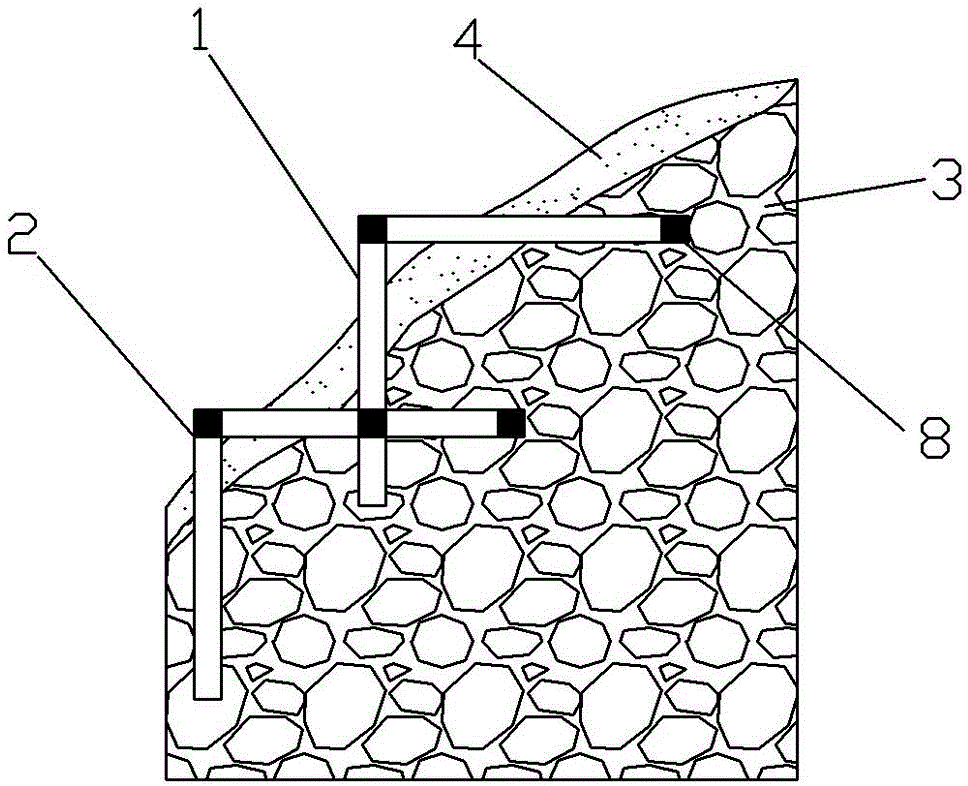

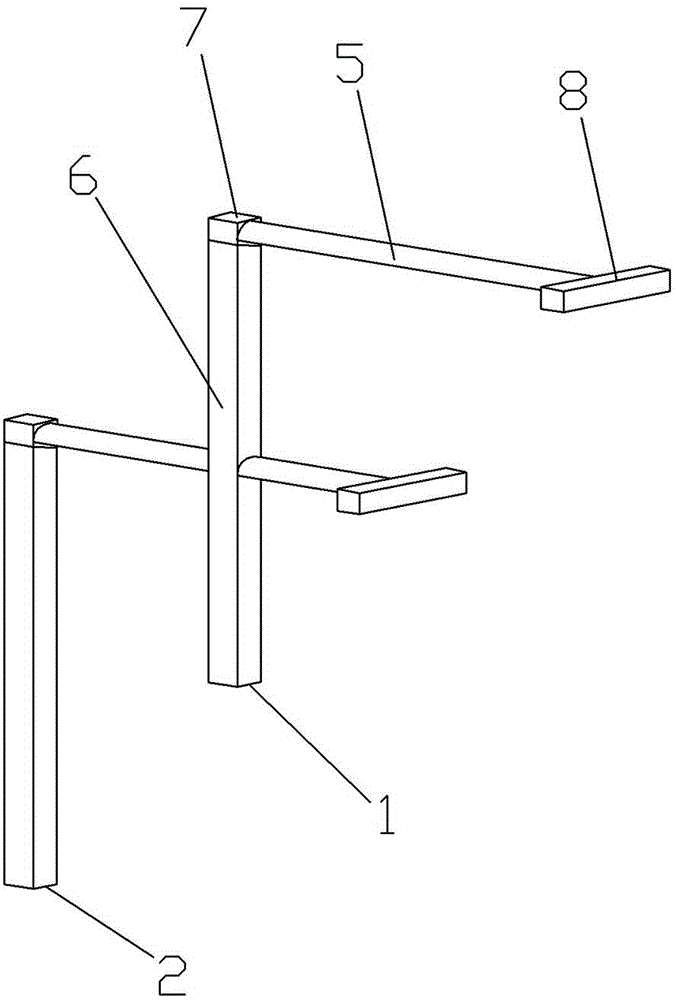

[0037] Such as Figure 1 to Figure 5As shown, the present invention provides a combined ladder key structure, comprising an upper ladder key unit 1 and a lower ladder key unit 2, and both the upper ladder key unit 1 and the lower ladder key unit 2 include a horseshoe-shaped cross arm 5, a rectangular vertical leg 6 and The horizontal locking key 8, the rectangular vertical leg 6 and the horizontal locking key 8 are all rectangular in cross-section, and the cross-section of the horseshoe-shaped cross arm 5 is horseshoe-shaped. , the other end of the horseshoe-shaped cross arm 5 is placed into the bedrock 3 and is perpendicular to the horizontal locking key 8 and is rigidly connected; the upper ladder key unit 1 and the lower ladder key unit 2 are connected in a ladder shape, and the rectangular vertical The leg 6 and the horseshoe-shaped cross arm of the lower ladder key unit 2 are vertically intersected and connected rigidly; The pile end rigid connection portion 7 of the ver...

Embodiment 2

[0049] The present invention provides a combined ladder key structure, including an upper ladder key unit and a lower ladder key unit. The difference between Embodiment 2 and Embodiment 1 is that the length of the stable bedrock insertion section of the horseshoe-shaped cross arm is set to 8m. The length of the horizontal locking key is 4 times the width of the rectangular vertical leg. The cross-sectional areas of the rectangular vertical leg and the horizontal locking key are both rectangular and equal in size. The cross-section of the pile body of the rectangular vertical leg and the horizontal locking key The length is 4m, the width is 3m, and the inner space of the pile body of the horseshoe-shaped transverse arm is 0.5m.

[0050] A construction method of a combined ladder key structure, the difference from the embodiment is that in step b: welding and binding the rectangular vertical legs of the upper ladder key unit to the reinforcement cage, using segmental binding of s...

Embodiment 3

[0052] Such as Figure 6 and Figure 7 As shown, the present invention provides a combined ladder key structure, which is different from Embodiment 1 in that: between the upper ladder key unit 1 and the lower ladder key unit 2, there is also a device connecting the upper ladder key unit 1 and the lower ladder key unit. The middle ladder key unit 10 of unit 2, the upper ladder key unit 1, the lower ladder key unit 2 and the middle ladder key unit 10 all include a horseshoe-shaped cross arm, a rectangular vertical leg and a horizontal locking key; the cross section of the rectangular vertical leg and the horizontal locking key They are all rectangular, and the cross-section of the horseshoe-shaped cross-arm is horseshoe-shaped. One end of the horseshoe-shaped cross-arm exposes the sliding body and is rigidly connected and fixed on the top of the rectangular vertical leg. Rigid connection, the horseshoe-shaped cross arm, rectangular vertical leg and horizontal locking key are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com