Height-adjustable loading-unloading-transportation device

A conveying device and high-level technology, applied in the directions of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient loading and unloading of small vehicles, inconvenient loading and unloading personnel, and inability to move telescopic belt conveyors. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

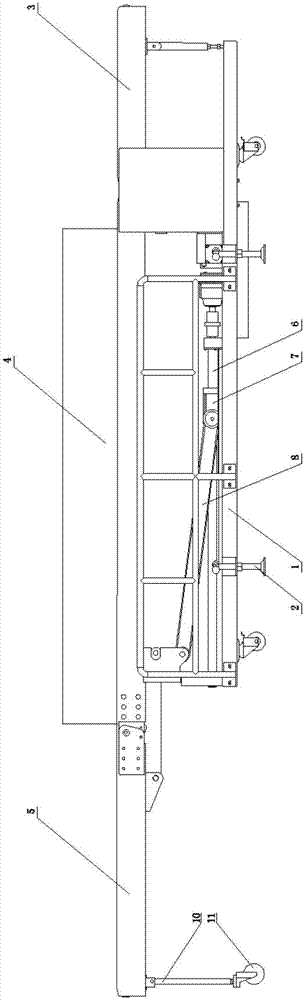

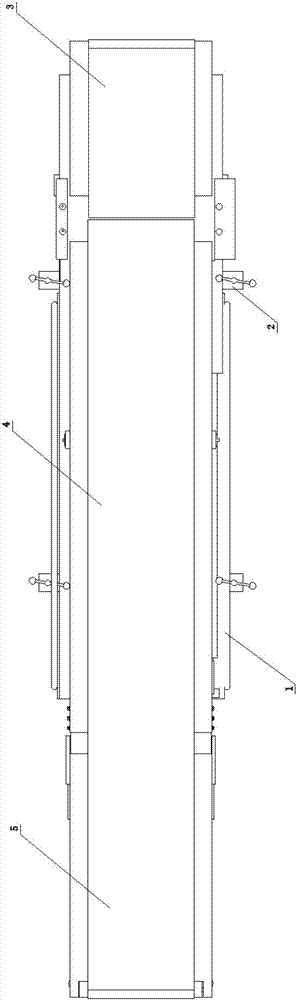

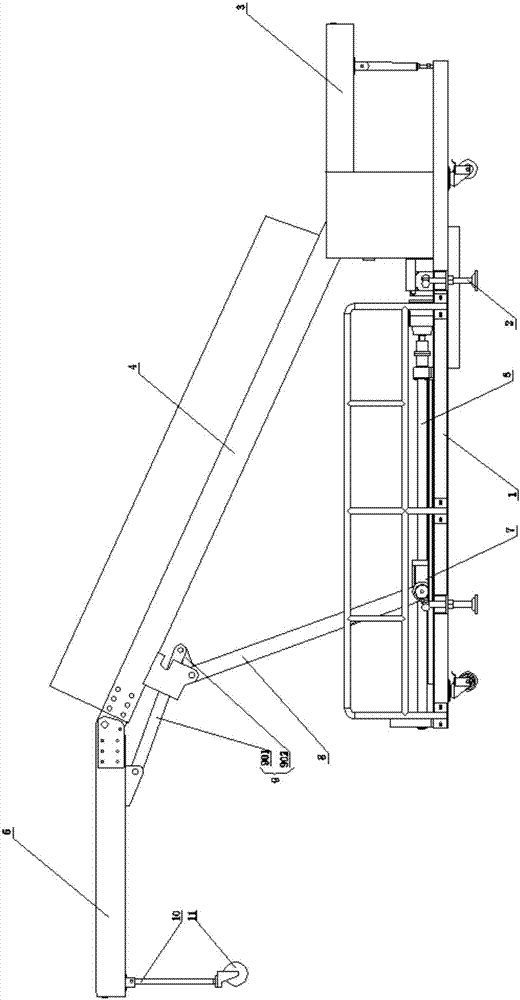

[0029] Such as figure 1 , figure 2 and image 3 As shown, a height-adjustable loading and unloading conveying device includes: a chassis 1, and the bottoms of the front and rear ends of the chassis 1 are respectively provided with sliding wheels, which can facilitate the movement of the chassis 1 through the sliding wheels. The lifting leg 2 is provided with a circular base at the bottom of the lifting leg 2, and when the chassis 1 moves to the working position, the chassis is fixed on the ground by the lifting leg 2.

[0030] A rear fixed conveying section 3 is installed above the rear end of the chassis 1 through a connecting piece. The rear fixed conveying section 3 is arranged horizontally, and its rear end is docked with the transport vehicle to facilitate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com