Centre drive dual-mould disc casting machine and casting method thereof

A center-driven, casting machine technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

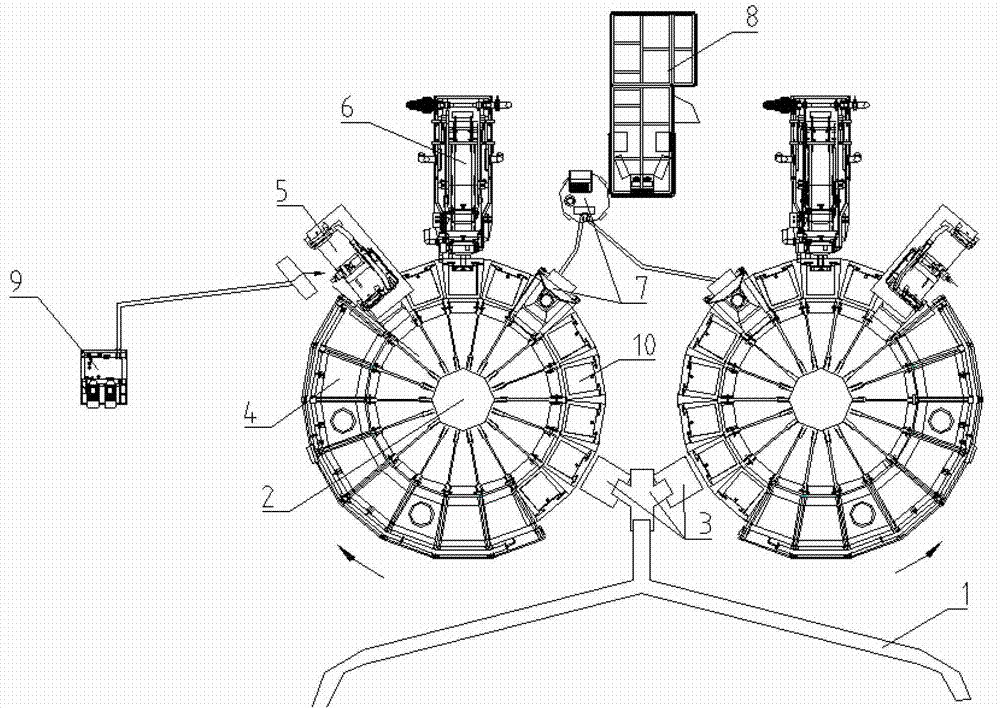

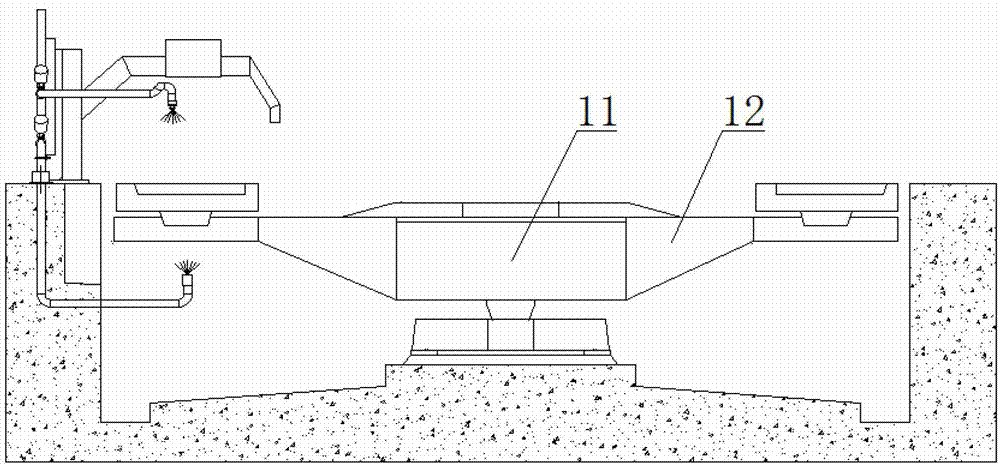

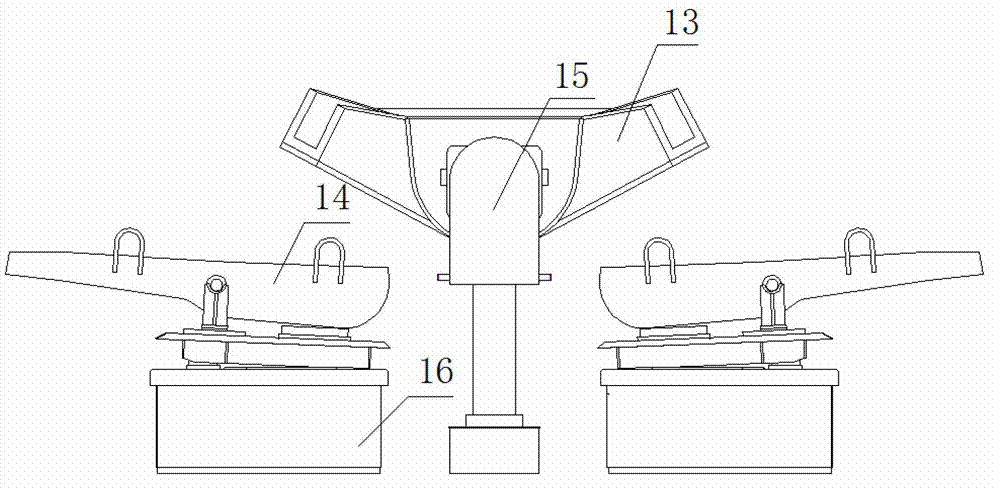

[0037] like figure 1 As shown, the center-driven double-mode disc casting machine of the present invention includes a chute 1, a casting disc 2, a quantitative casting system 3, a spraying system 4, a waste anode hanger 5, a hoist and a water tank system 6, a spraying System 7, control room 8 and hydraulic system 9; the dual-mode casting disc 2 is fixedly installed on the concrete foundation, the quantitative casting system 3 is distributed between the dual-mode casting discs, along the direction of disc rotation, the quantitative casting system 3 The spray system 4 in the front is placed above the eight empty molds 10 of the casting disc, the waste anode hanger 5 is placed on the outer side of the casting disc following the spray system 4, and the lifter and water tank system 6 are placed next to the waste anode hanger 5 On the outer side of the casting disc, the spraying system 7 is placed on the outer side of the casting disc following the lifting machine and the water tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com