Mining large electromotor coupler dismounting device

A dismantling device and motor technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in dismantling motor couplings, narrow surrounding space, and large coupling volume, etc. High efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

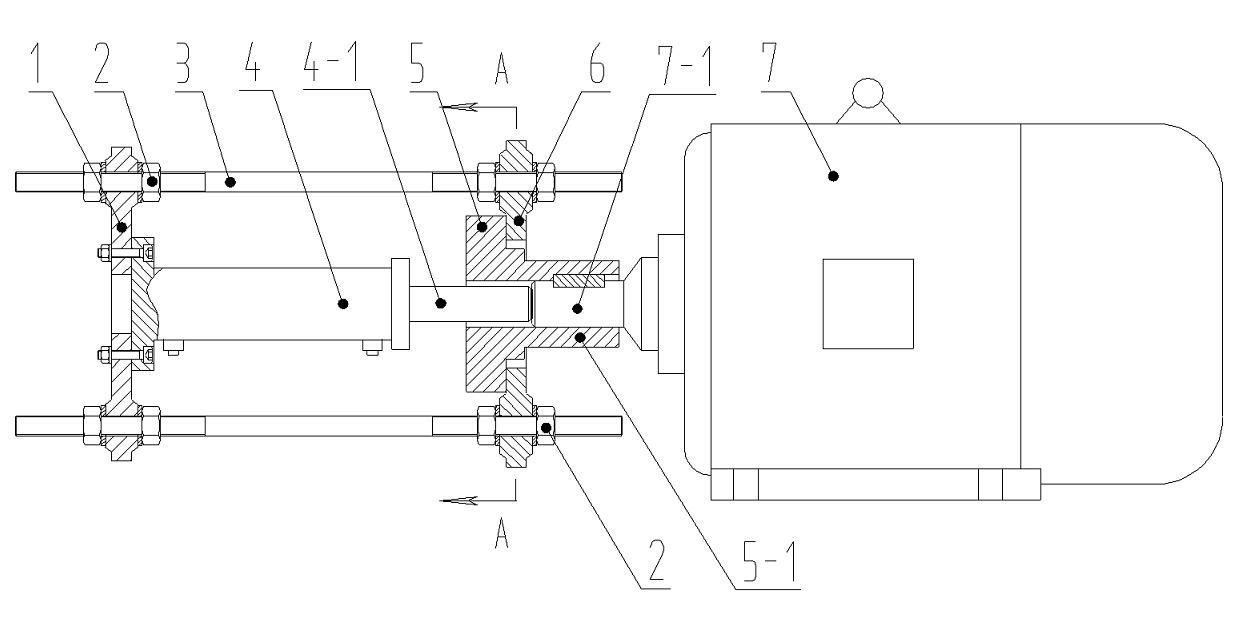

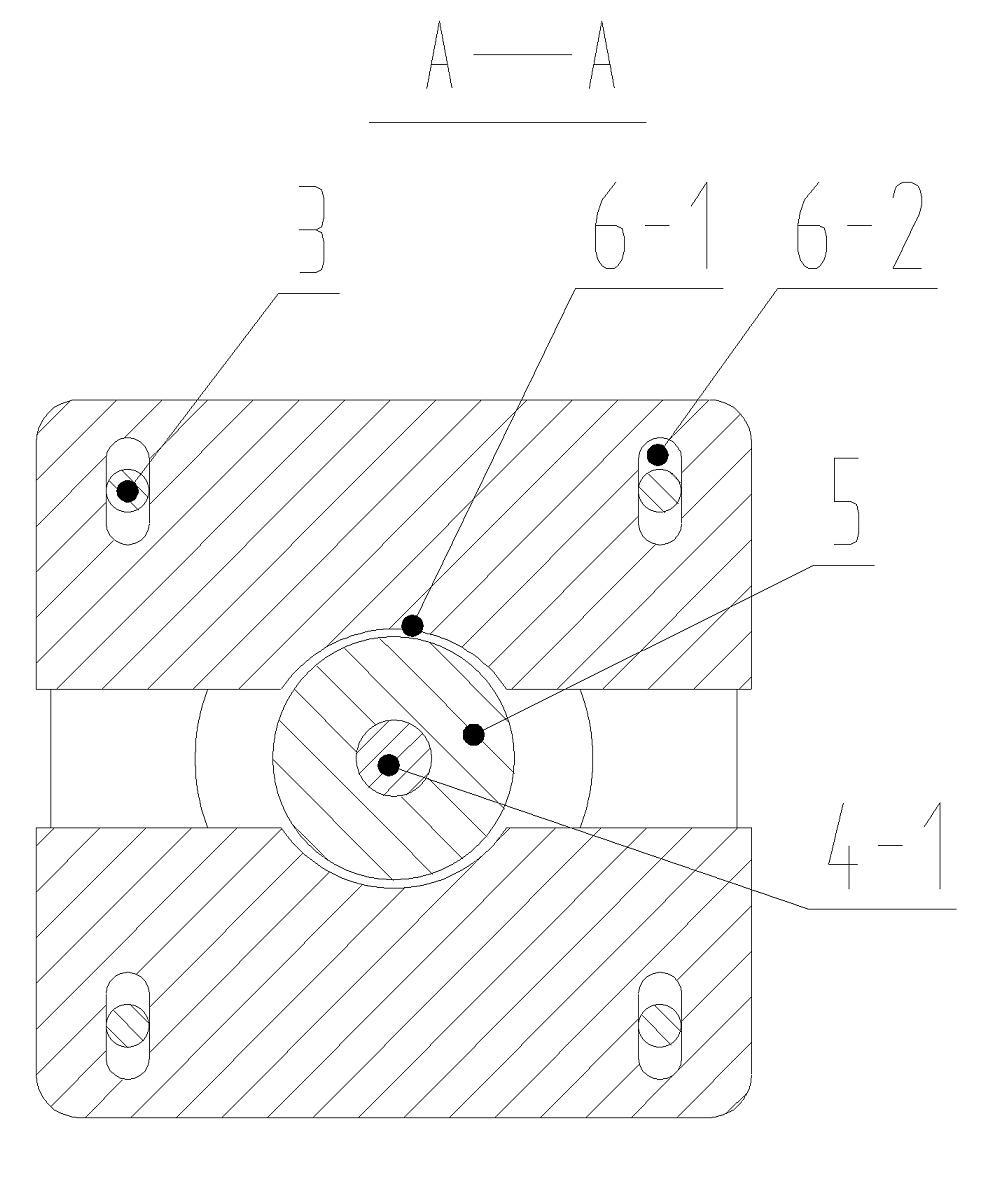

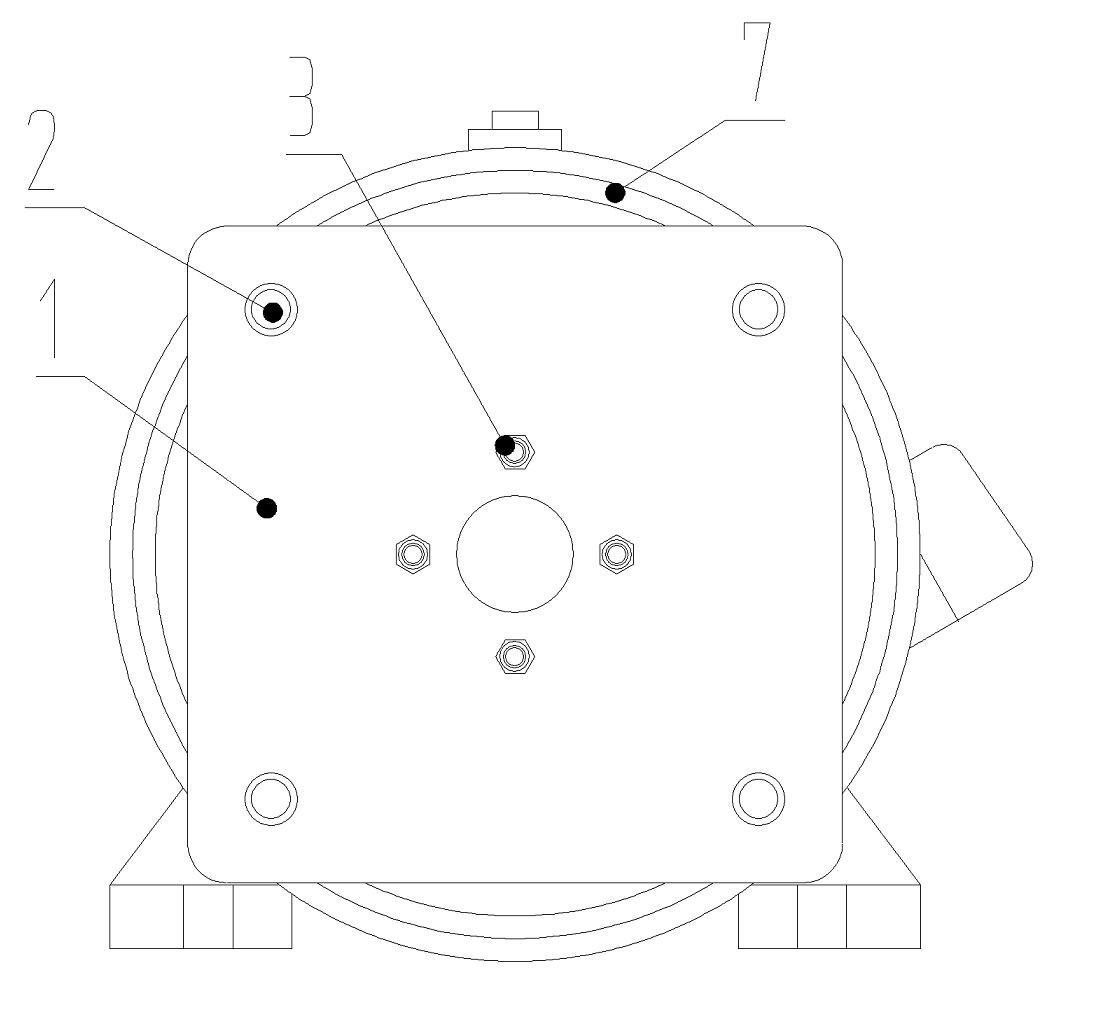

[0017] Such as figure 1 , 2 , Shown in 3: a large-scale electric motor coupling dismounting device for mining, characterized in that: the device is composed of a bracket, a hydraulic cylinder 4 and a clamp 6; the bracket is composed of a mounting plate 1 and a stud bolt 3, Four round holes are made on the described installation version 1, and the described stud bolts 3 are four, and one end of the stud bolts 3 is inserted in the round holes of the installation version 1, and fixed with the adjusting nut 2; There are two clamping plates 6, the inner sides of which are made with arc-shaped grooves 6-1, and the other end of the stud bolt 3 is inserted in the hole of the clamping plate 6, and fixed with the adjusting nut 2; the cylinder body of the hydraulic cylinder 4 Fastened vertically to the inside of mounting plate 1.

[0018] A long hole 6-2 is made at the junction of the clamping plate 6 and the stud bolt 3 . The arc-shaped diameter of the arc-shaped groove 6-1 is larger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com