Hull section non-allowance healing accuracy control process

A technology of precision control and hull, applied in ship parts, ship construction, ships, etc., can solve the problems of prolonged construction period and low enterprise efficiency, and achieve the effect of shortening construction period, increasing enterprise efficiency and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

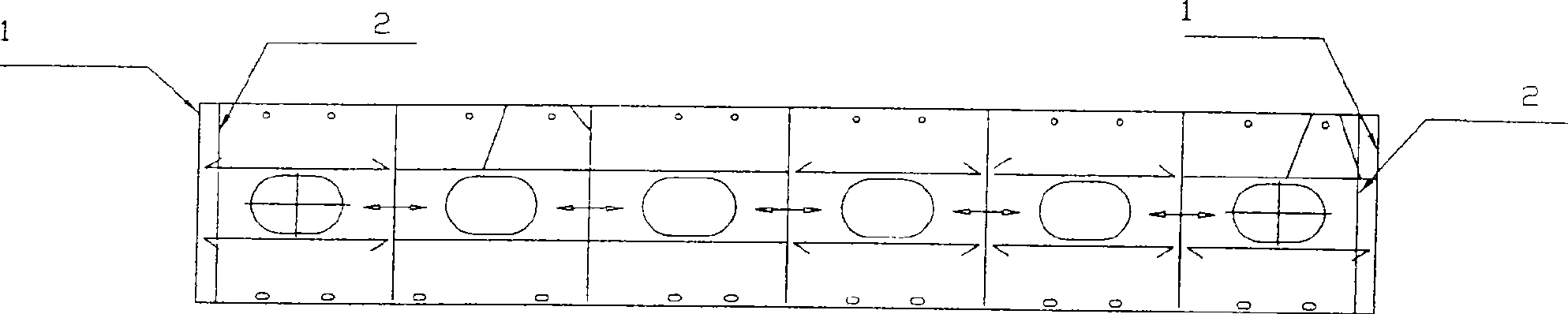

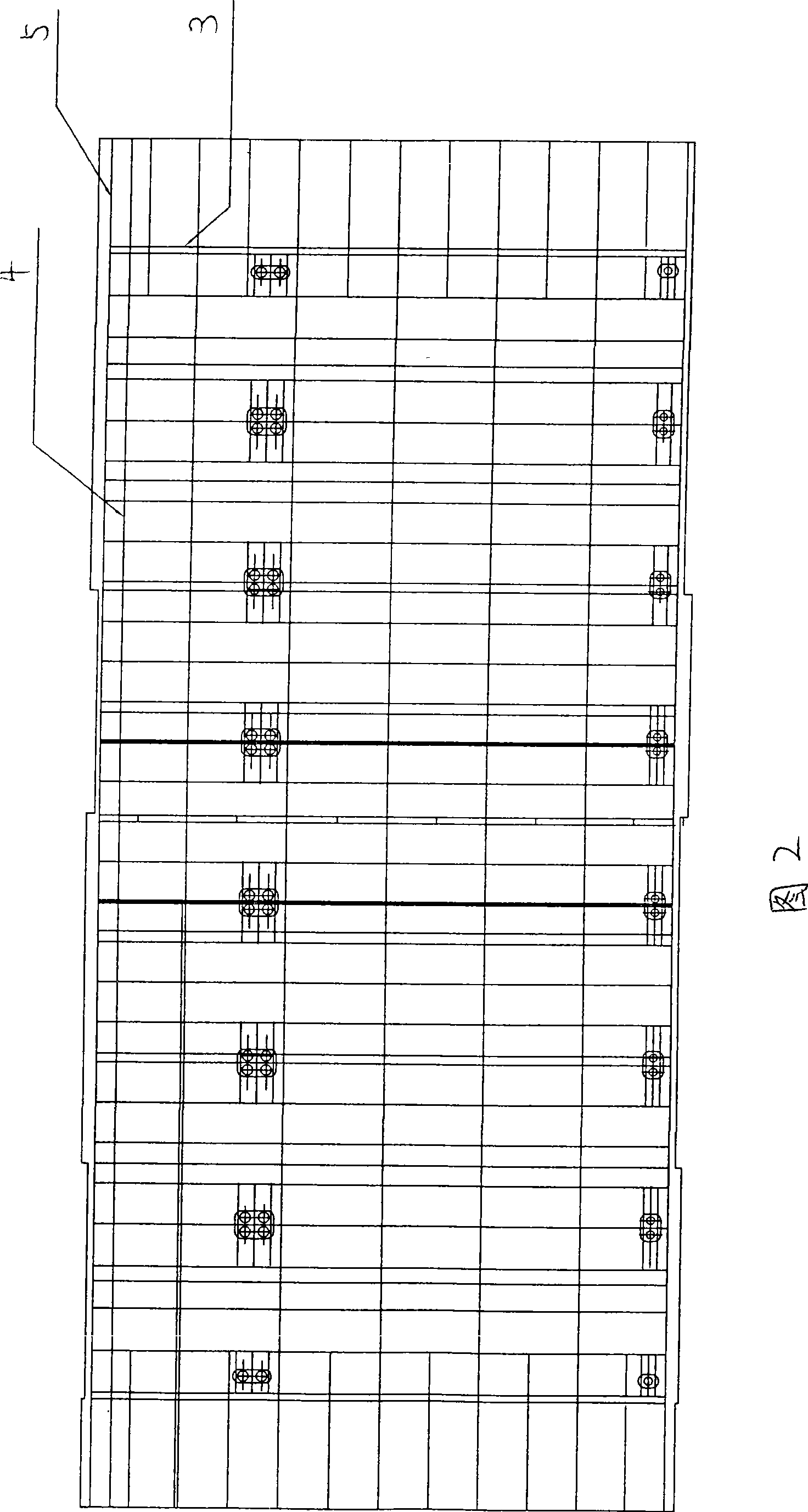

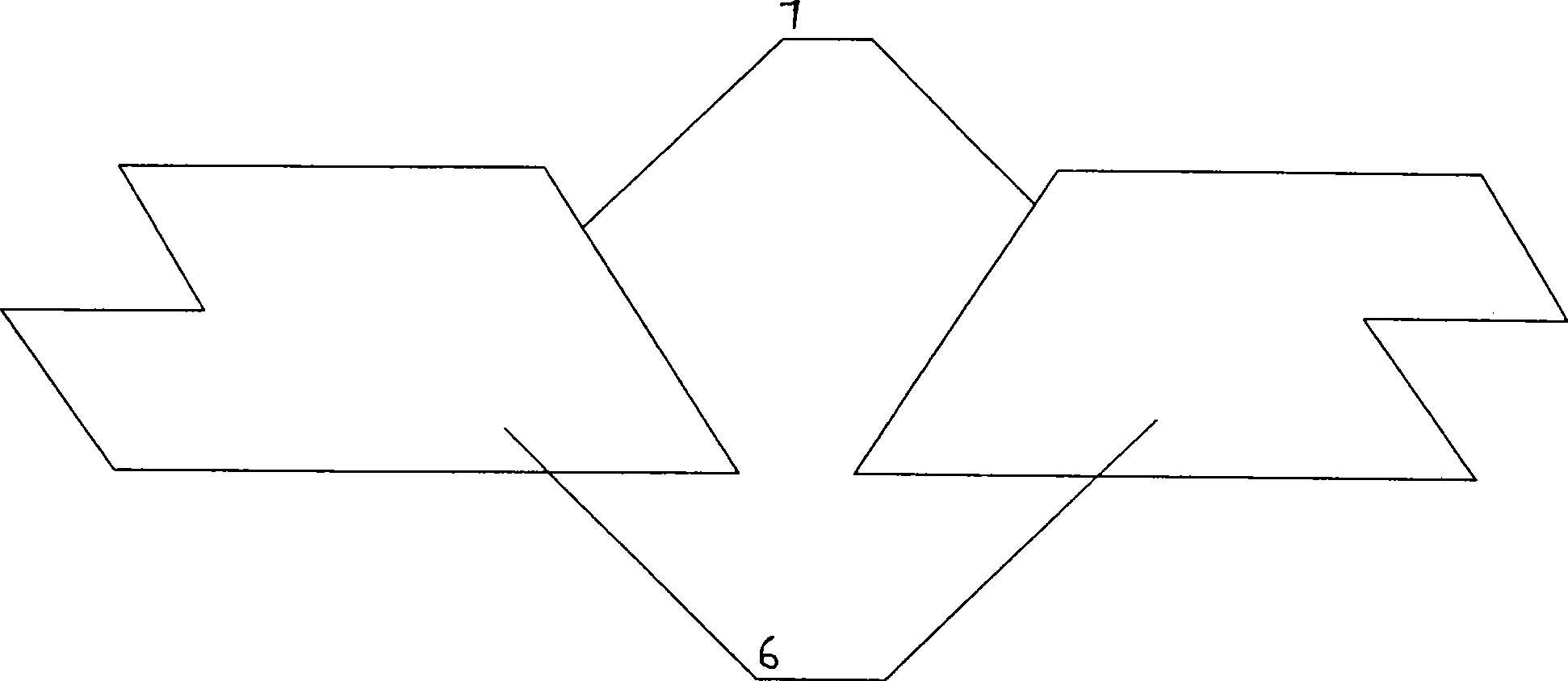

[0019] See attached figure 1 -twenty three;

[0020] The precision control process of closing the hull section without margin: includes the following steps:

[0021] (1) At the beginning of construction, each section of the hull is in a reversed state, with the inner bottom decking on the bottom and the ship's bottom deck on the top; draw the structural line 1 on the inner bottom decking and draw the margin cutting line 2 at both ends at the same time. Take 200mm from the end inward as the cross inspection line, put on the foreign punch, and do a good job of marking and film protection; the segmental allowance cutting line 2 will not be cut for the time being, and will be cut after re-measurement and adjustment after turning over. The segmental structure gap is controlled within 0-2mm; to reduce stress concentration and deformation;

[0022] (2) When starting to build the hull section, the welding of the section structure should be strictly in accordance with the relevant re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com