Hybrid controlled damping structure construction method

A technology of mixed control and construction method, applied in the direction of earthquake resistance, building components, building structure, etc., can solve the problems of unsatisfactory, high earthquake resistance requirements, increase the construction cost of the structure, etc., and achieve the effect of flexible space layout and reduced construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

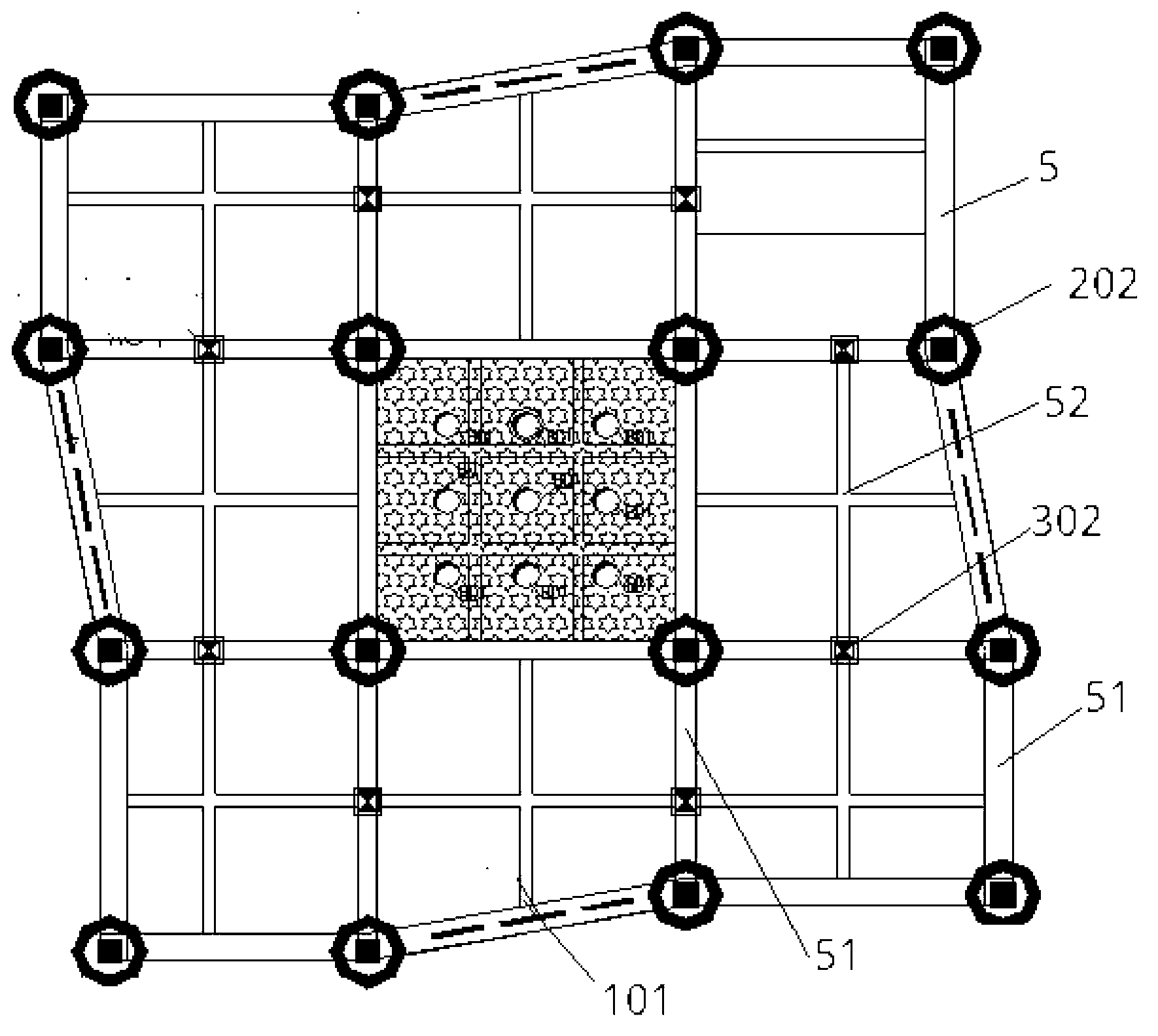

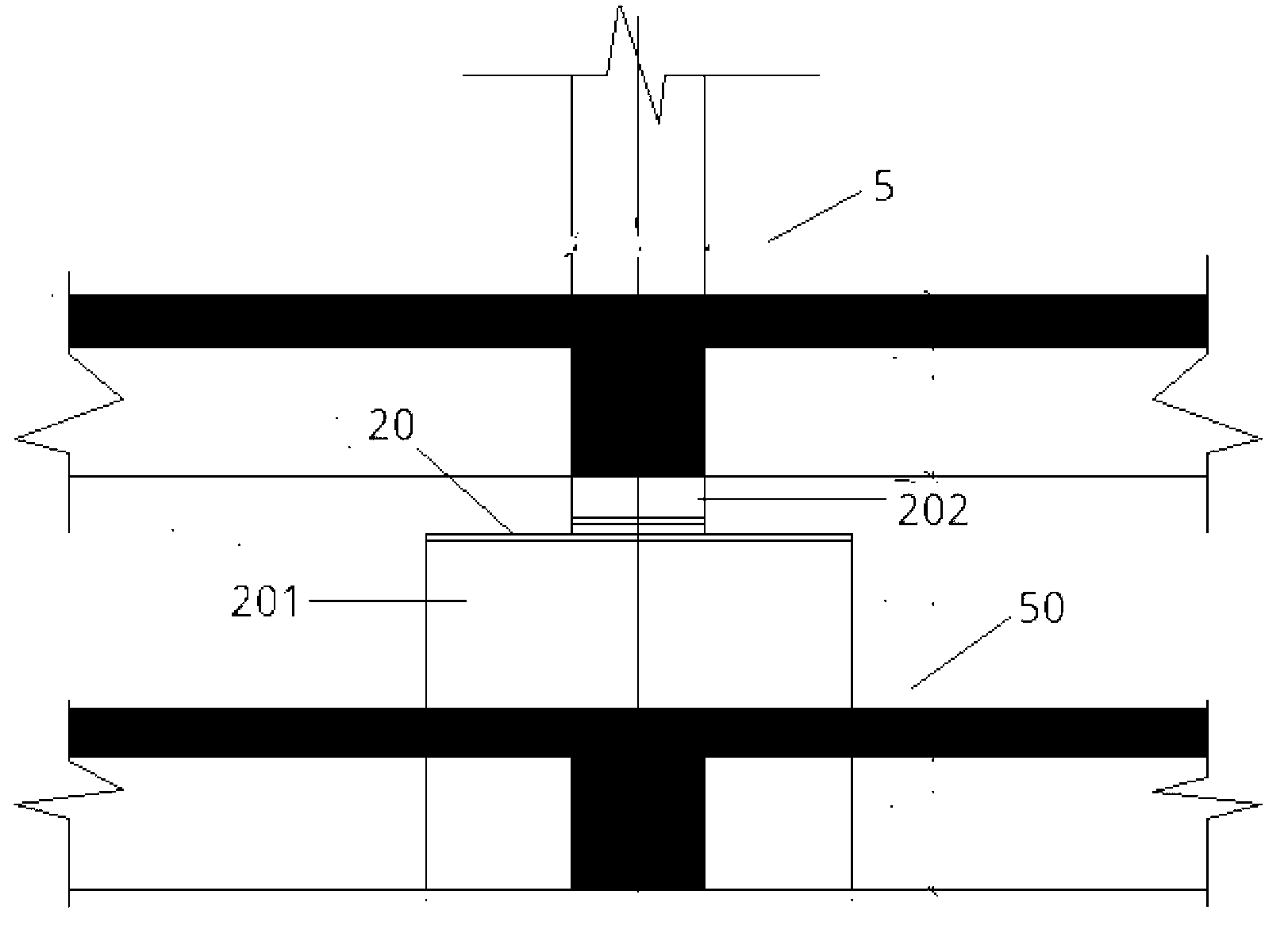

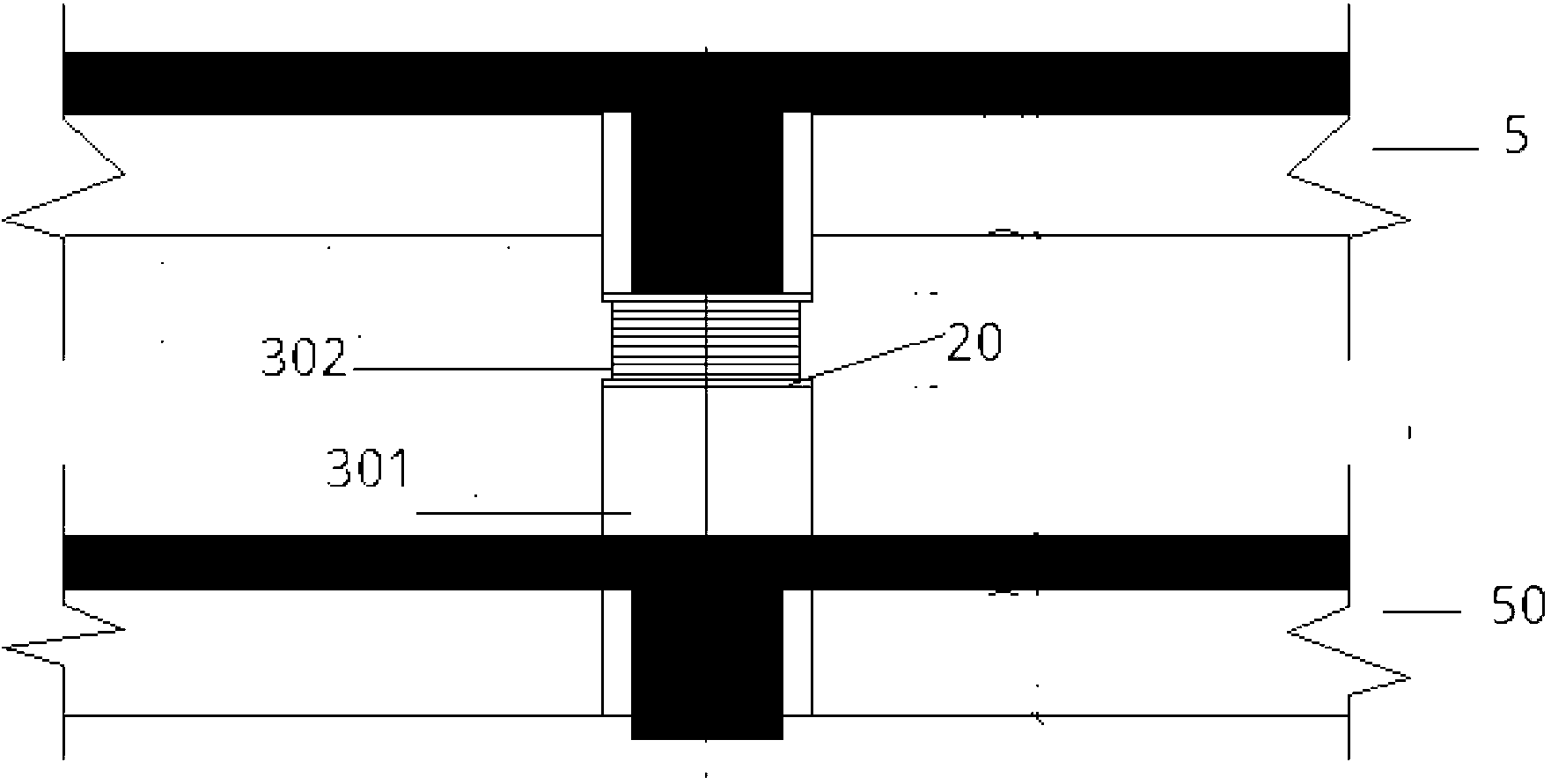

[0043] Figure 1 to Figure 10 Shown is the hybrid control shock absorbing structure of the present invention, which includes a shock absorbing frame consisting of an upper frame 5 and a lower frame 50, both of which are composed of a main frame 51 and a sub frame 52 , the main frame includes several main frame beams, and several main frame beams are vertically and horizontally intersected. For the sub-frame beams arranged crosswise, frame columns are provided below the intersections of the frame beams of the above-mentioned main frame and sub-frames, and flat sliding bearings are provided between the frame columns at the intersections of the vertical and horizontal main frame beams of the upper frame and the lower frame, Laminated rubber bearings are arranged between the lower frame column and the lower frame at the cross intersection of the sub-frame beams of the upper frame. The laminated rubber bearing 302 or the flat plate sliding bearing 202 is installed on the square co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com