Arching method for stiff skeleton concrete arch bridge

A stiff skeleton and concrete technology, which is applied in arch bridges, erection/assembly bridges, bridges, etc., can solve the problems of increased construction difficulty, long construction period, and many joints in the arch ring, so as to improve the overall performance and mechanical properties, and single-shot The effect of increasing the amount of concrete pouring and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1, as shown in the figure:

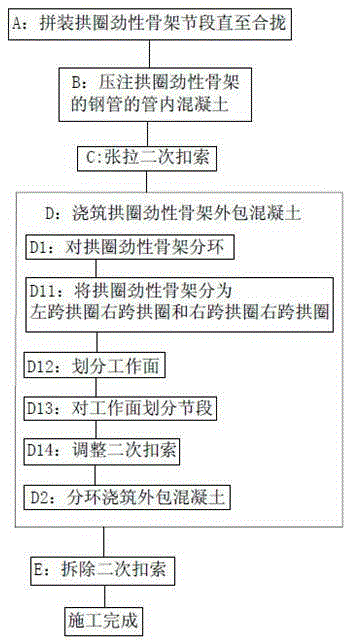

[0065] A method for forming an arch of a rigid skeleton concrete arch bridge is characterized in that it comprises the following steps in sequence:

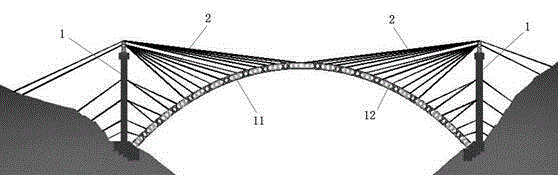

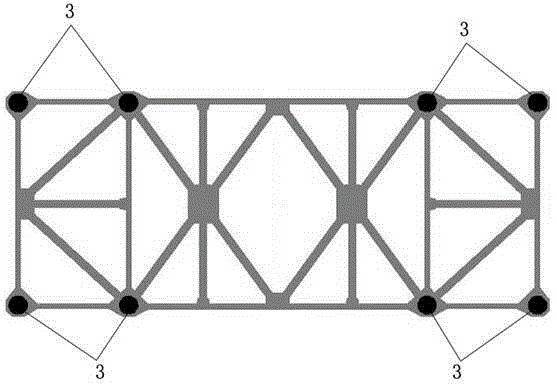

[0066] A: Assemble the arch ring stiff skeleton segment until it is closed: the arch ring stiff skeleton segment is a steel pipe 3 truss segment, use the junction pier 1 on both sides of the arch ring as a buckle tower, and hoist the arch ring stiff skeleton segment At the same time, the first buckle cable 2 of the arch ring is stretched, assembled piece by piece from the arch foot until it is closed, and the stiff skeleton of the arch ring is obtained;

[0067] B: Injection of the concrete in the steel pipe 3 with the stiff skeleton of the arch ring: remove the buckle cable 2 once, and then inject the concrete in the pipe of the steel pipe 3 with the stiff skeleton of the arch ring;

[0068]C: tensioning the secondary buckle cable 4: in step B, after the concrete in the steel pipe ...

Embodiment 2

[0075] Embodiment 2, as shown in the figure,

[0076] As in the arching method of the stiff skeleton concrete arch bridge described in Example 1, in the step C, before carrying out the 4 tensioning of the second fastening cable, the stiff skeleton of the arch ring is first subjected to influence line loading, and the control section is determined. The position most sensitive to stress changes is taken as the loading point, and then the secondary buckle cable 4 is stretched at the loading point;

[0077] In the step C, the secondary buckle cable 4 is stretched before pouring the outsourcing concrete, so that the stiff skeleton of the arch ring deforms in the opposite direction to that which should be deformed in the subsequent loading.

[0078] In the technical field of bridge construction, in the construction of the arch ring, the control section is mostly at the arch foot. In the above-mentioned scheme of this embodiment, the most sensitive to the stress change of the control...

Embodiment 3

[0080] Embodiment 3, as shown in the figure,

[0081] The arching method of the stiff skeleton concrete arch bridge as described in embodiment 2,

[0082] In the step D, pouring the arch ring stiff skeleton outsourcing concrete includes the following steps in sequence:

[0083] D1: Separation of the stiff skeleton of the arch ring: along the section of the stiff skeleton of the arch ring, it is divided into side box bottom plate 5, middle box bottom plate 6, lower web 7, upper web 8, side box top plate 9 and middle box top plate 10;

[0084] D2: Sub-ring pouring of outsourcing concrete: pouring of outsourcing concrete according to the sub-ring division of step D1, the pouring sequence is: side box bottom plate 5, lower web 7, upper web 8, side box top plate 9, middle box bottom plate 6 and middle Box roof 10;

[0085] In the step D, a step D11 is also provided between the steps D1 and D2,

[0086] Step D11: Divide the arch ring stiff skeleton into left-span arch ring stiff ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com