Patents

Literature

41results about How to "Convenient pouring construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Concrete admixture and pre-mixed and water-permeable concrete using concrete admixture

The invention relates to a pre-mixed and water-permeable concrete admixture and water-permeable concrete. The pre-mixed and water-permeable concrete admixture is formed by mixing of the following components in percentage by weight: 10-20% of a water reducing component, 1-5% of a hydration regulating and controlling component, 0.1-1.0% of a viscosity regulating component, 0.5-5% of a water evaporation inhibiting component, 0.5-3% of a thixotropic agent component, and the balance of water. The pre-mixed and water-permeable concrete admixture provided in the invention can effectively improve work conditions of the water-permeable concrete, greatly improve the cohesiveness and the uniformity of slurry wrapping aggregate surfaces, and can effectively prolong the operable time of the water-permeable concrete, meet the requirements of pre-mixing production, long-distance transportation and long-time construction of the water-permeable concrete, and improve the control of production and construction quality of the water-permeable concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

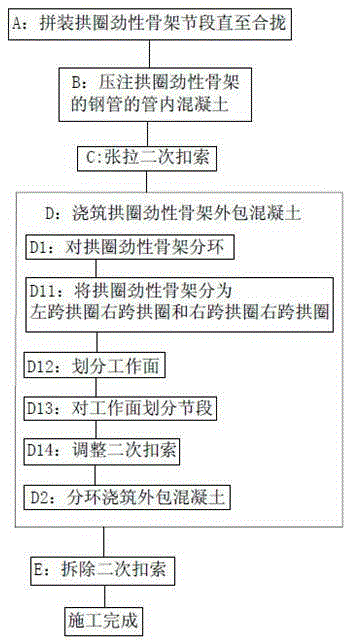

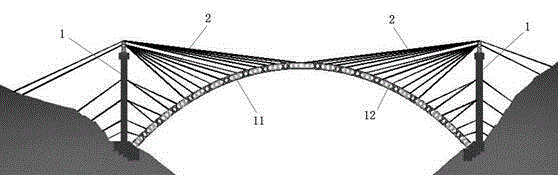

Arching method for stiff skeleton concrete arch bridge

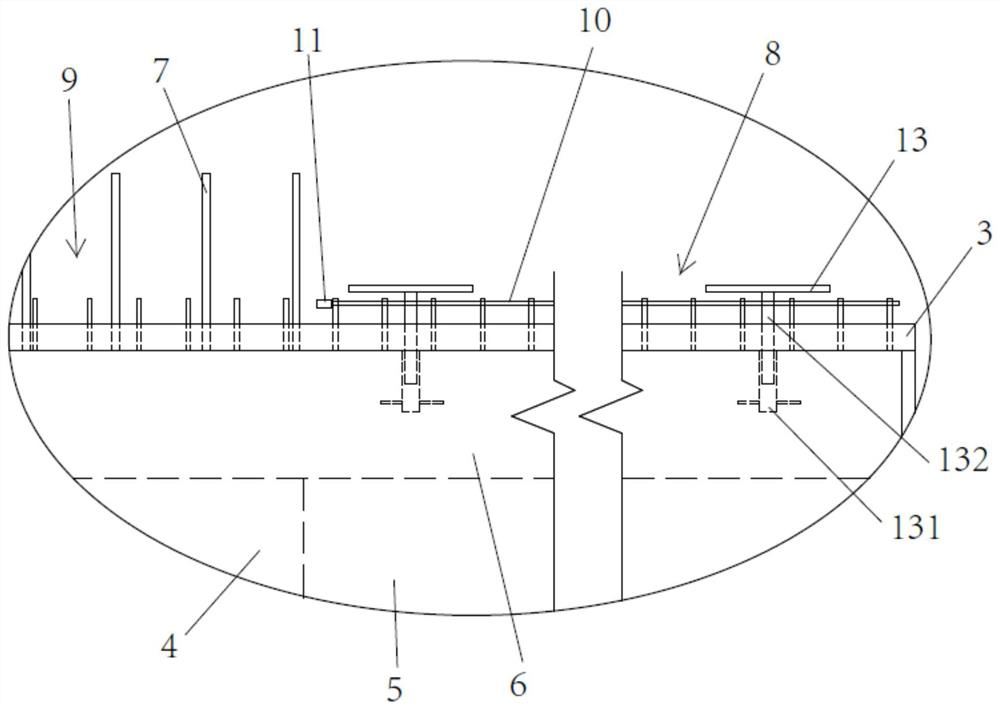

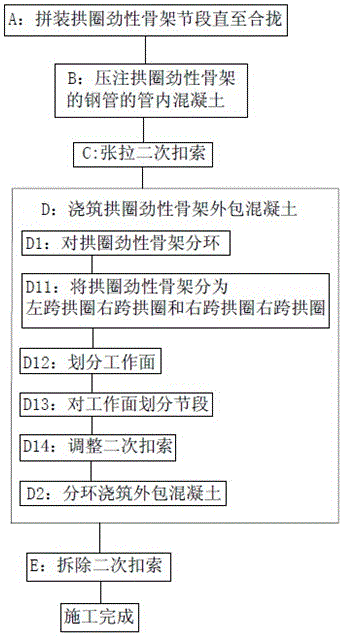

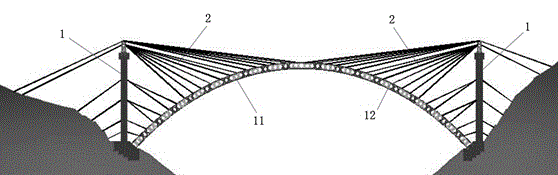

ActiveCN105350442AReduce construction costsReduce construction difficultyBridge erection/assemblyArch-type bridgeBridge engineeringArchitectural engineering

The invention belongs to the technical field of bridge engineering, and particularly relates to an arching method for a stiff skeleton concrete arch bridge. The arching method sequentially includes the following steps that A, segments of an arch ring stiff skeleton are spliced till the segments are folded; B, concrete in steel pipes of the arch ring stiff skeleton is pressed and poured; C, secondary fastening cables are tensioned; D, outer wrapped concrete of the arch ring stiff skeleton is poured; and E, the secondary fastening cables are detached. According to the arching method, due to tensioning of the secondary fastening cables, in the outer wrapping pouring process, no other supporting components need to be arranged for supporting the arch ring stiff skeleton; firstly, the construction cost is reduced, and the construction difficulty is lowered; meanwhile, due to the fact that the fastening cables are used for tensioning the arch ring stiff skeleton, the occupied space is smaller than that of other supporting manners during connection of the fastening cables and an arch ring; and blocking in the following concrete pouring process is reduced, and following concrete pouring construction is further facilitated.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

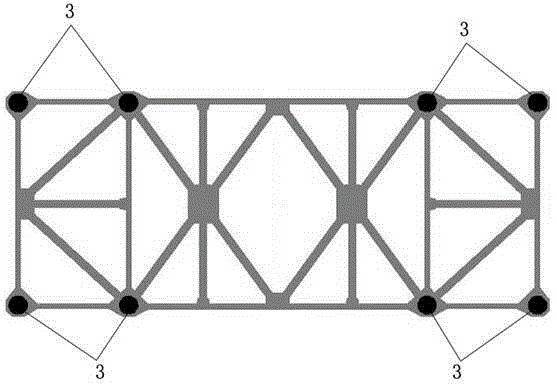

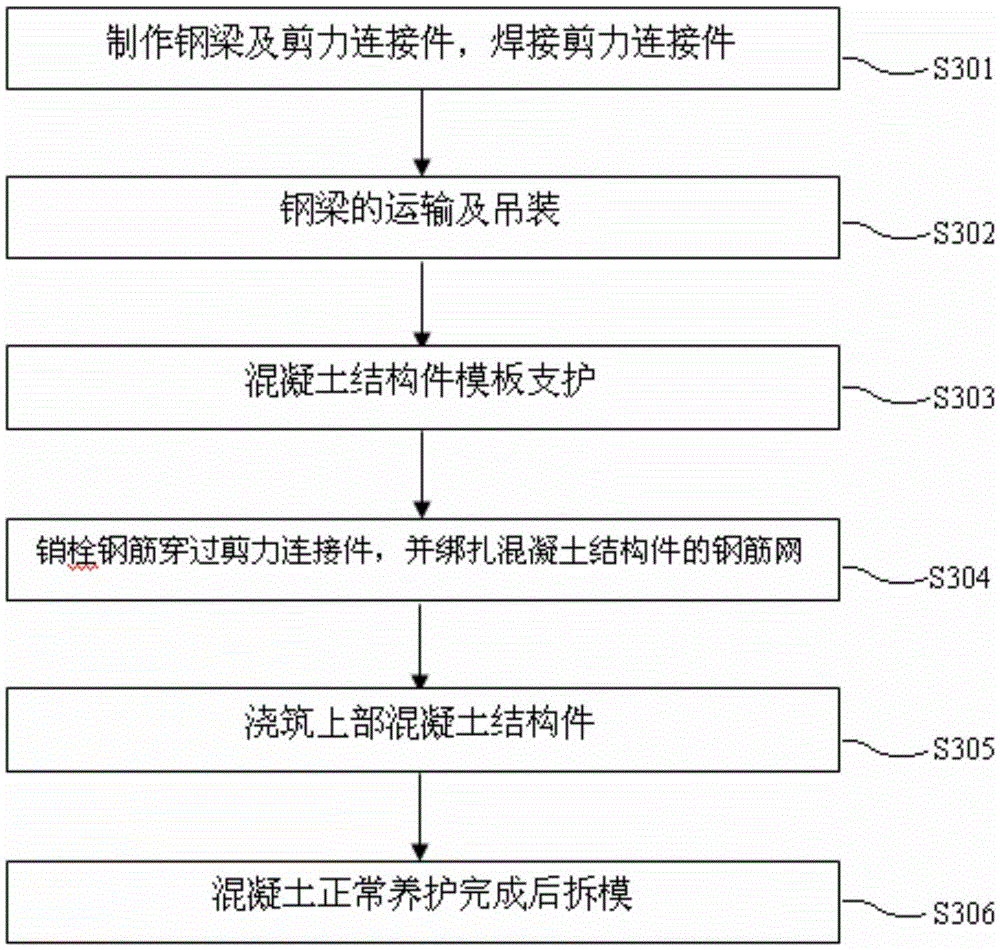

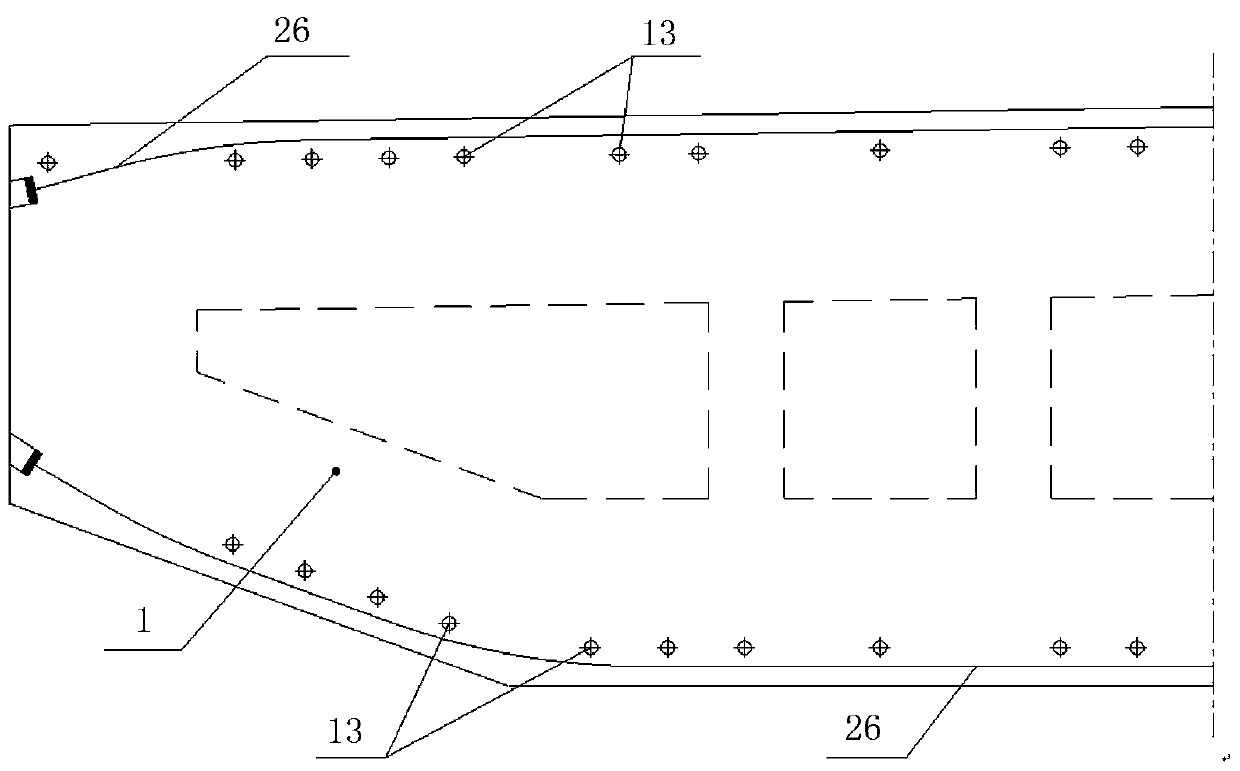

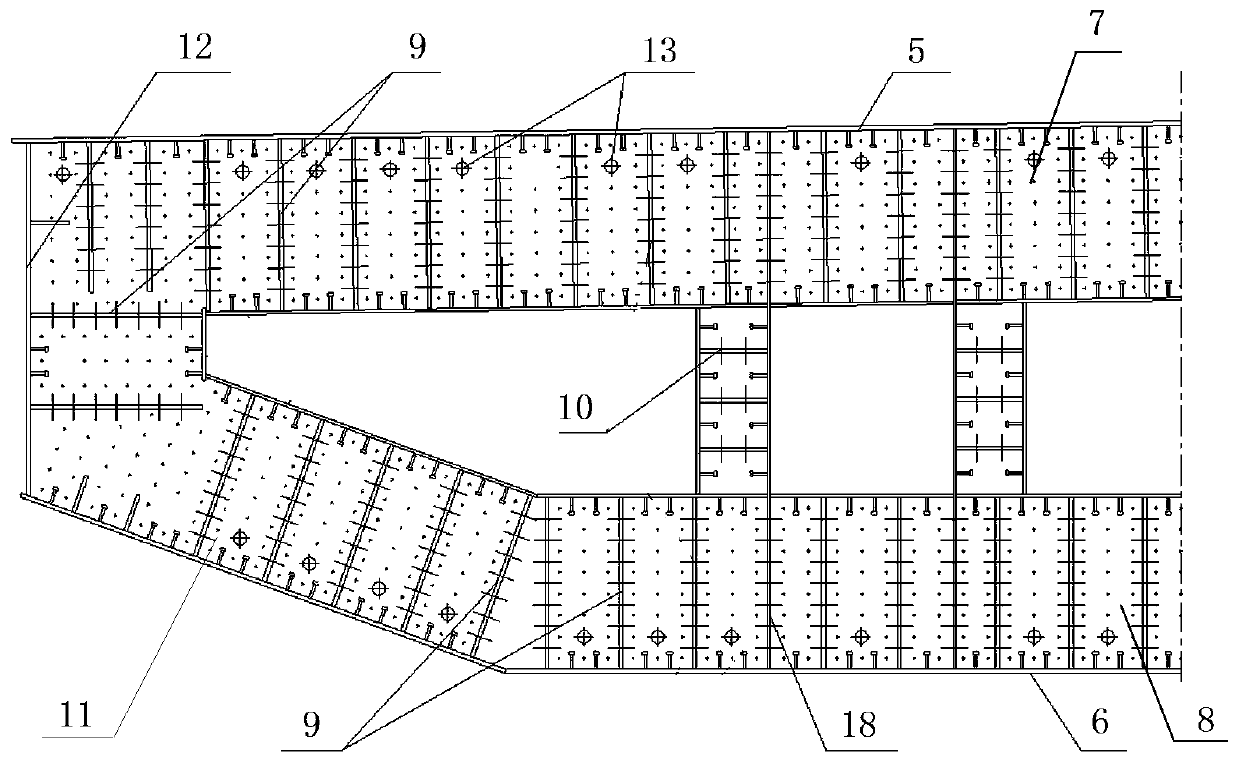

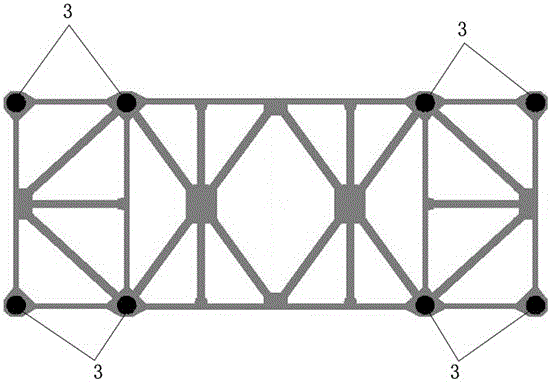

Composite shear connection piece of steel-concrete structure and manufacturing and installing method thereof

ActiveCN105569271AIncreased shear strengthIncrease stiffnessLoad-supporting elementsBuilding reinforcementsFloor slabEngineering

The invention discloses a composite shear connection piece of a steel-concrete structure and a manufacturing and installing method thereof. The composite shear connection piece comprises shear connection piece bodies bent by reinforcing steel bars and bolt pin reinforcing steel bars penetrating through the shear connection piece bodies. The specific manufacturing and installing method includes the steps that steel beams are manufactured, and shear connection piece bodies are bent and welded; the steel beams are transported and lifted; concrete floor formworks are supported; the bolt pin reinforcing steel bars penetrate through the shear connection piece bodies, and the bolt pin reinforcing steel bars and the shear connection piece bodies are jointly bound to form a reinforcing steel bar mesh of concrete structure pieces; the formworks are disassembled after concrete pouring and normal maintenance are completed. According to the composite shear connection piece, as the shear connection piece bodies and the structural steel beams are welded and fixedly connected, and then a whole is formed through the bolt pin reinforcing steel bars penetrating through the shear connection piece bodies and the concrete structure pieces cast in place, the shearing strength and the rigidity of the steel-concrete composite structure are greatly improved, synergetic stressing between concrete plates and the steel beams is effectively achieved, and the composite shear connection piece has the advantages that the structure is simple, processing is easy and convenient, cost is low, construction cost is reduced, the site installing speed is high, and welding quality is guaranteed.

Owner:CENT SOUTH UNIV

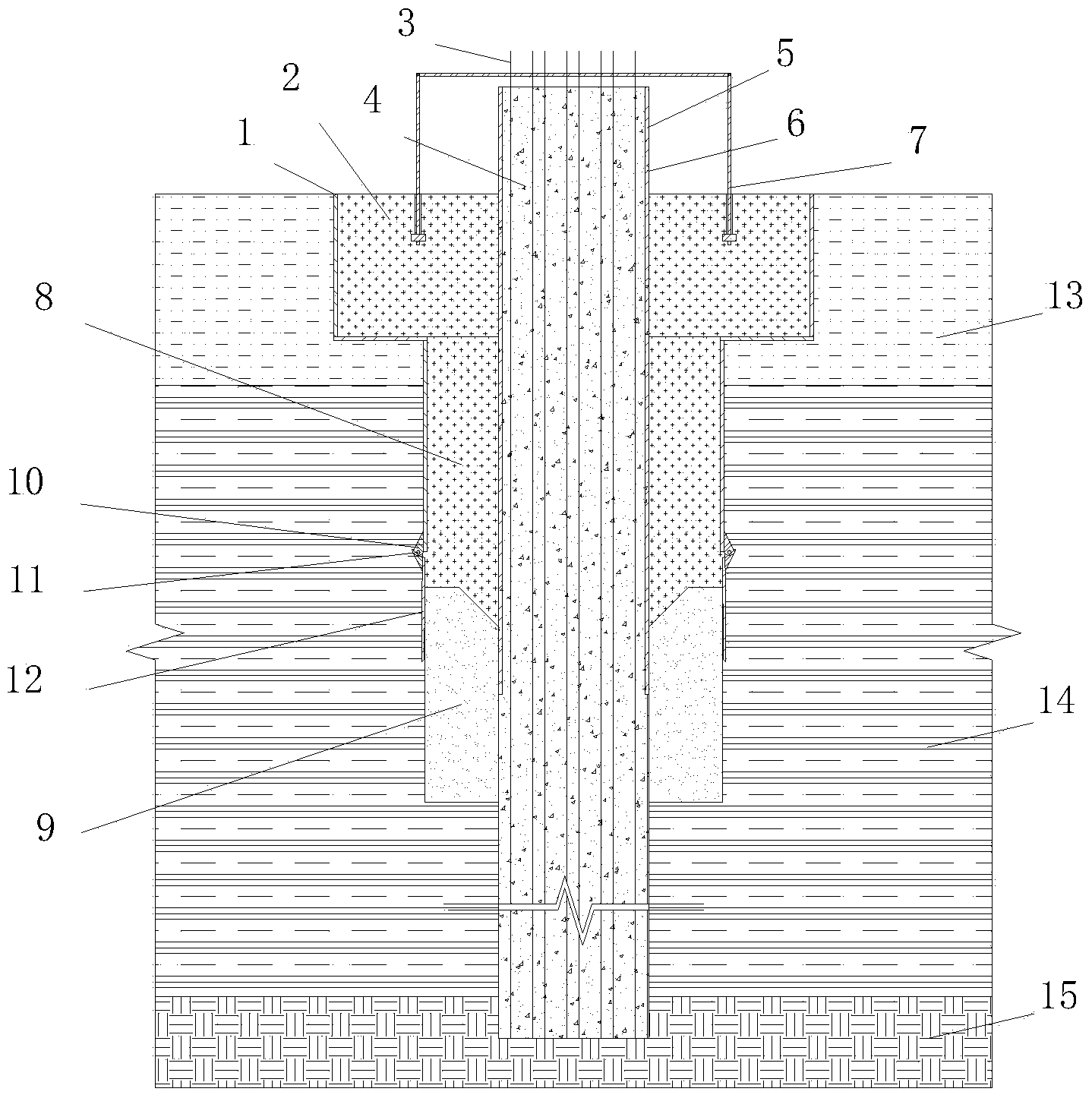

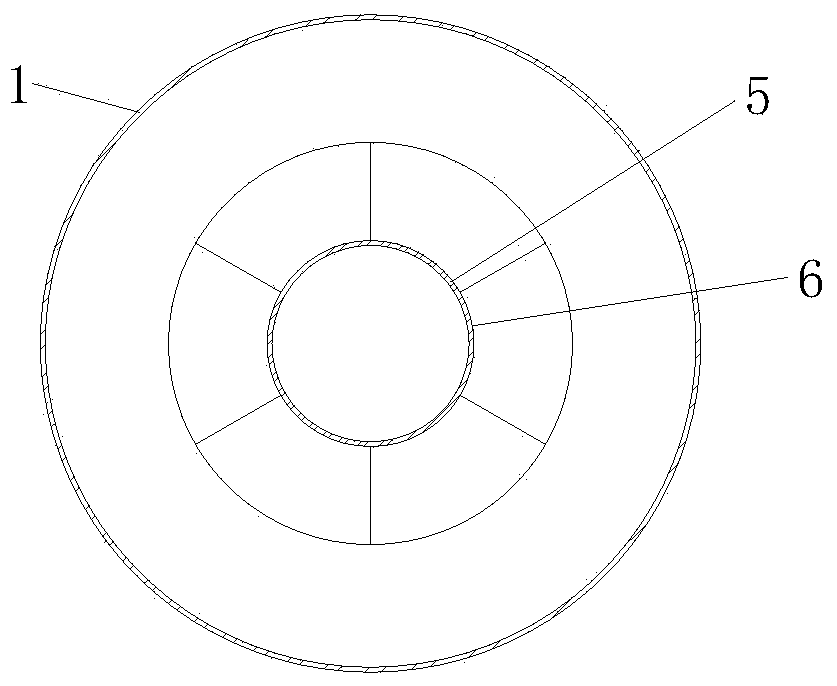

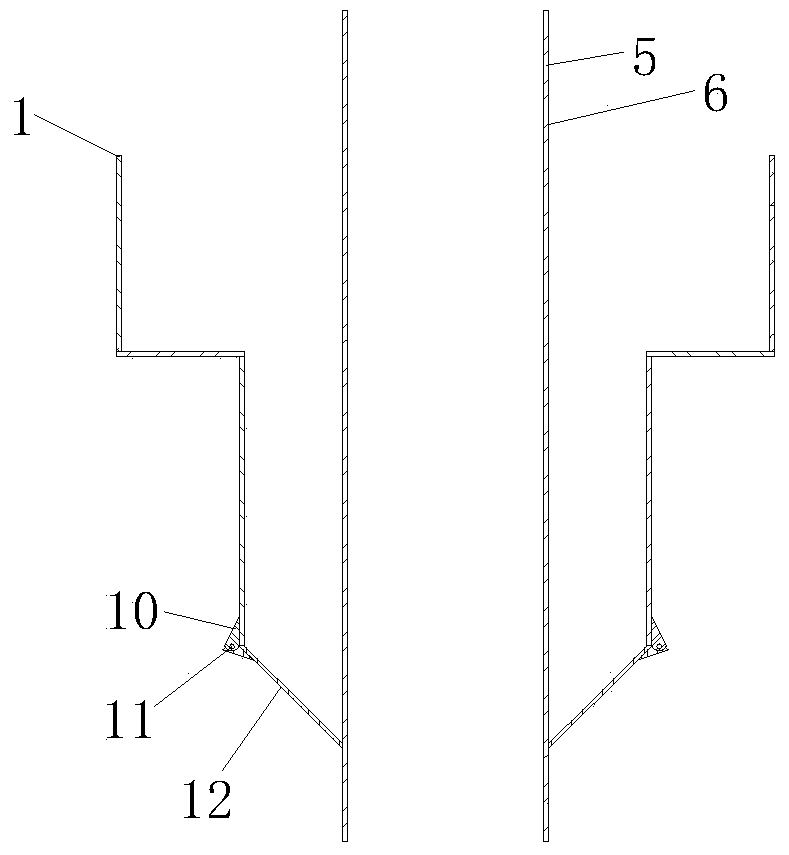

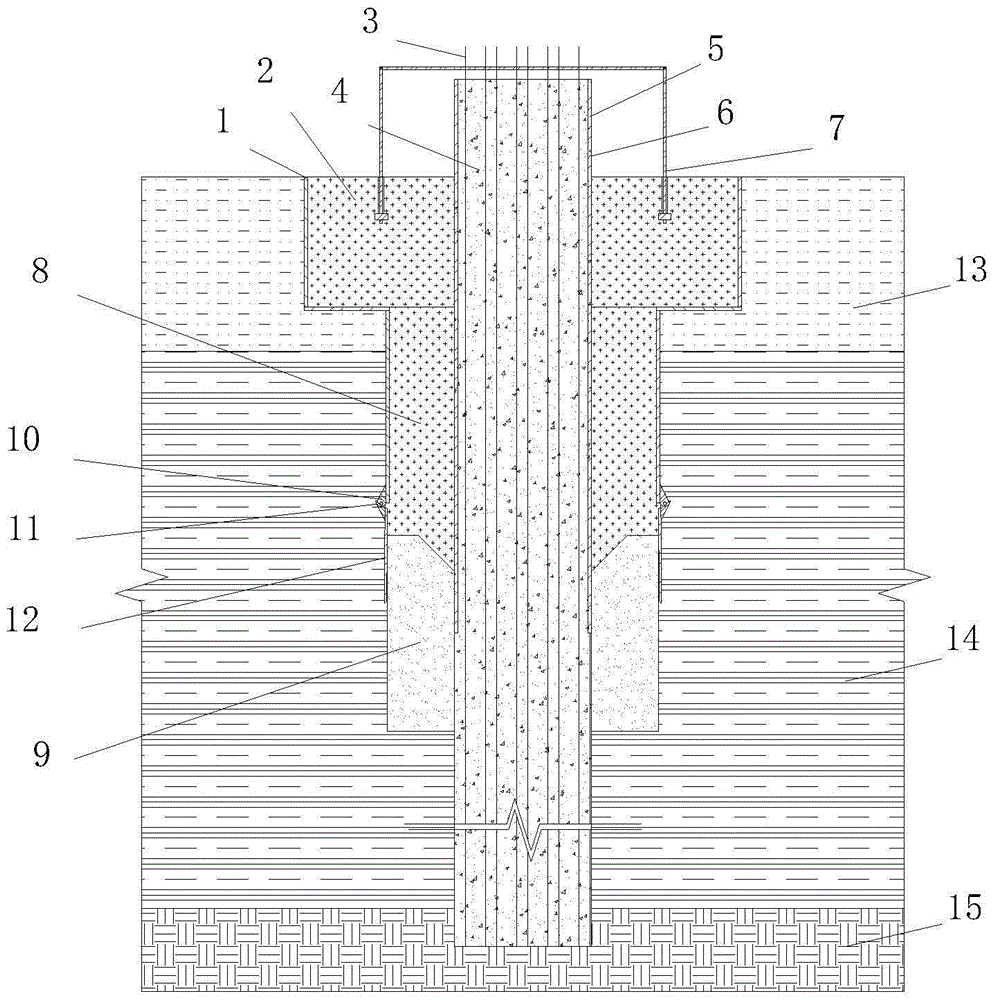

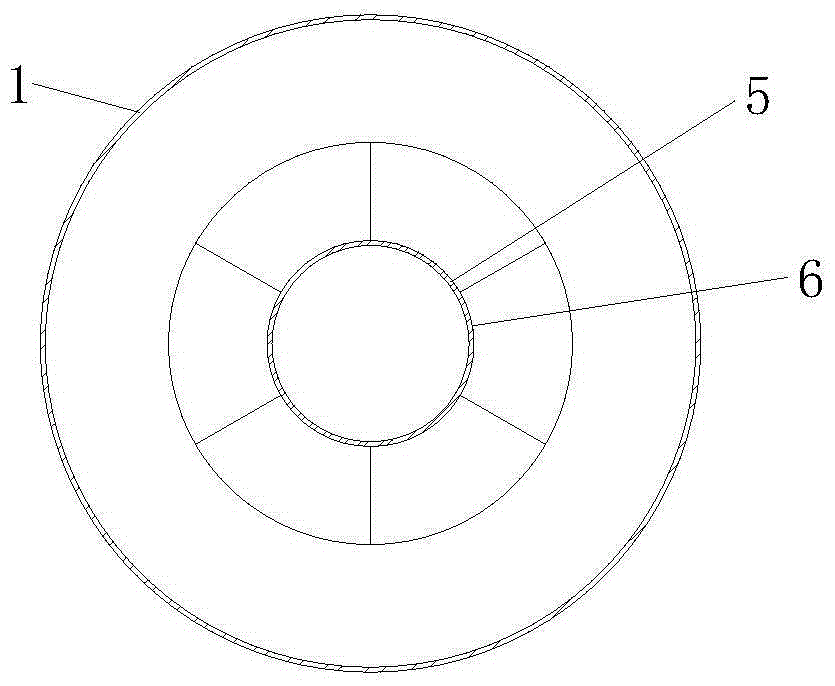

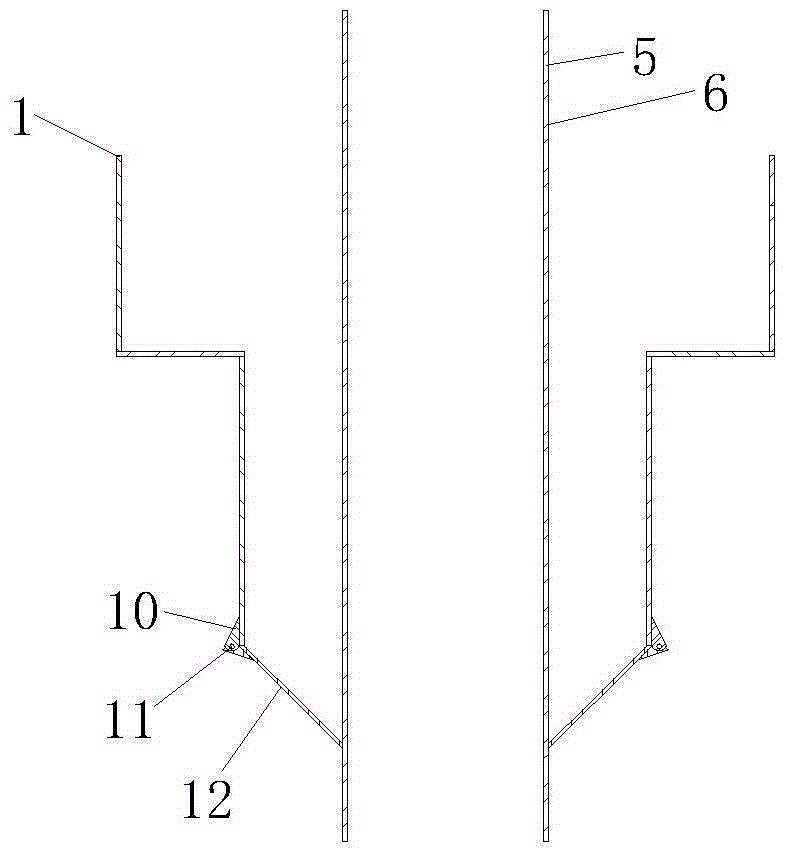

Structure for preventing perforation and slurry leakage of cast-in-situ bored pile in water and construction method of structure

ActiveCN104358252AReduce construction costsAvoid difficult extractionBulkheads/pilesRebarReinforced concrete

The invention relates to a structure for preventing perforation and slurry leakage of a cast-in-situ bored pile in water and a construction method of the structure. An outer protecting cylinder is arranged at the periphery of a reinforced concrete cast-in-situ bored pile, an activated material slurry fixed protecting disk and an activated material slurry fixed protecting wall are arranged between the reinforced concrete cast-in-situ bored pile and the outer protecting cylinder from top to bottom, and a cement soil water stop protecting wall is arranged below the activated material slurry fixed protecting wall; the diameter of the activated material slurry fixed protecting disk is greater than that of the activated material slurry fixed protecting wall and that of the cement soil water stop protecting wall; a reinforcement cage positioning embedded part is arranged in the middle of the activated material slurry fixed protecting disk; the reinforced concrete cast-in-situ bored pile is formed by placing a reinforcement cage in an inner protecting cylinder and then pouring concrete. The protecting cylinder structure is high in stability, good in environmental protection and lower in cost, is capable of effectively preventing the perforation and the slurry leakage of the cast-in-situ bored pile in the water, and has better technical and economical benefits.

Owner:德州市公路工程总公司

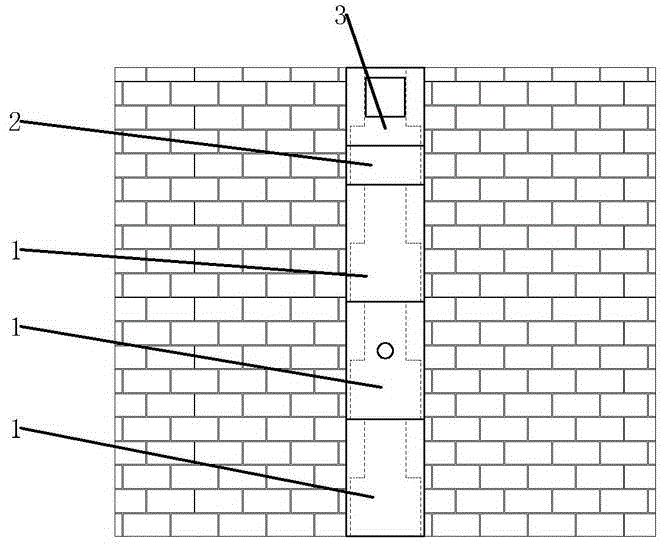

Concrete supporting replacement structure and method for performing defective concrete replacement applying concrete supporting replacement structure

PendingCN110397305AReduced support areaIncrease the work areaBuilding repairsDeformation monitoringJoist

The invention belongs to the technical field of defective concrete reinforcing and relates to a concrete supporting replacement structure and a method for performing defective concrete replacement applying the concrete supporting replacement structure. The concrete supporting replacement structure comprises a plurality of combined supporting racks and horizontal connection parts for connecting thecombined supporting racks together. The defective concrete replacement method comprises the steps that stepA, holing is performed in specified positions; stepB, top horizontal beams and bottom horizontal beams are installed; stepC, beam supporting brackets are installed; stepD, bracket vertical columns are installed; stepE, the horizontal connection parts are installed; stepF, concrete is chiselled away; stepG, a template is supported and arranged; stepH, concrete pouring is performed; stepI, the template is removed; stepJ, deformation monitoring is performed; and stepK, the supporting replacement structure is removed. By means of the concrete supporting replacement structure and the method for performing the defective concrete replacement applying the concrete supporting replacement structure, in-situ concrete structural replacement can be performed under the premise of not damaging or changing the building structural appearance, and the defective concrete structural safety problem is solved.

Owner:CONSTR DEV OF CHINA CONSTR SIXTH ENG DIV +1

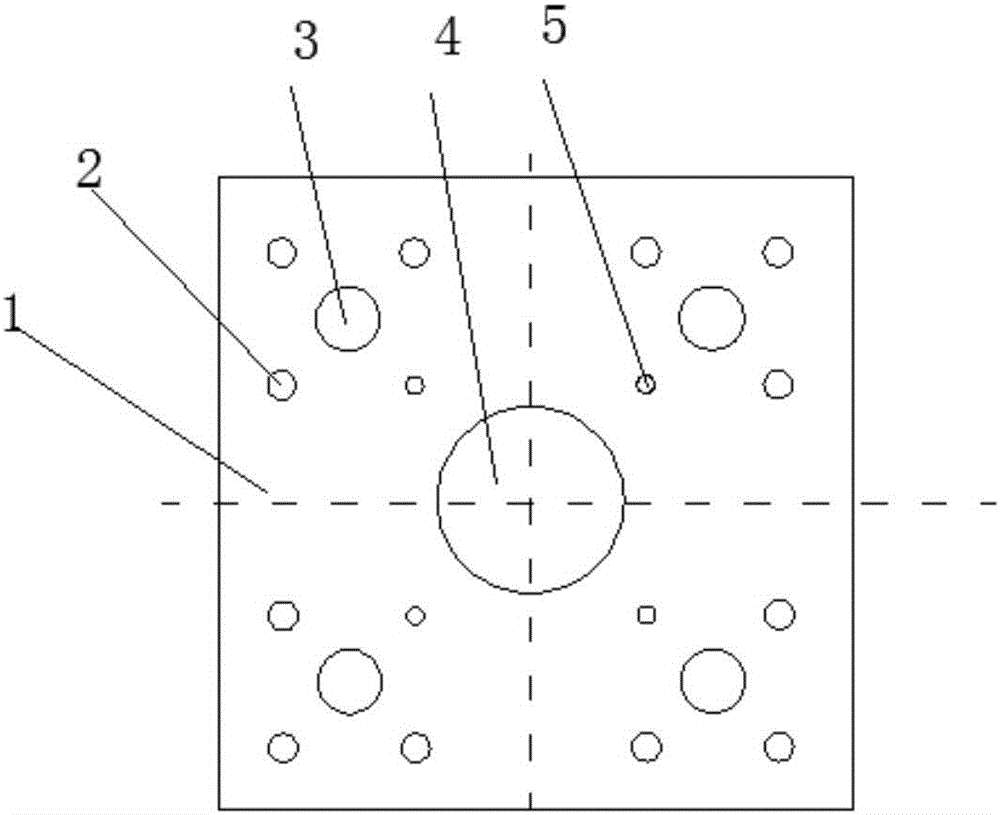

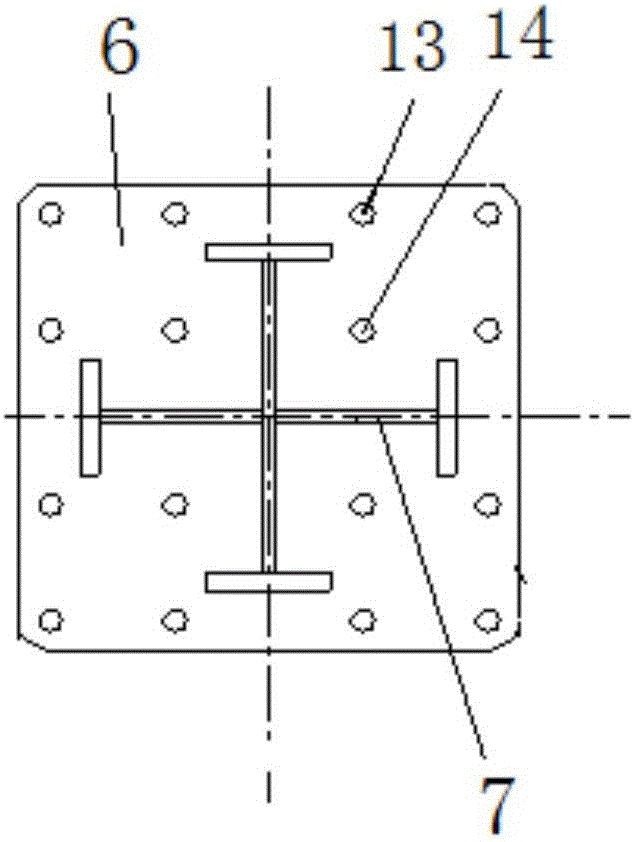

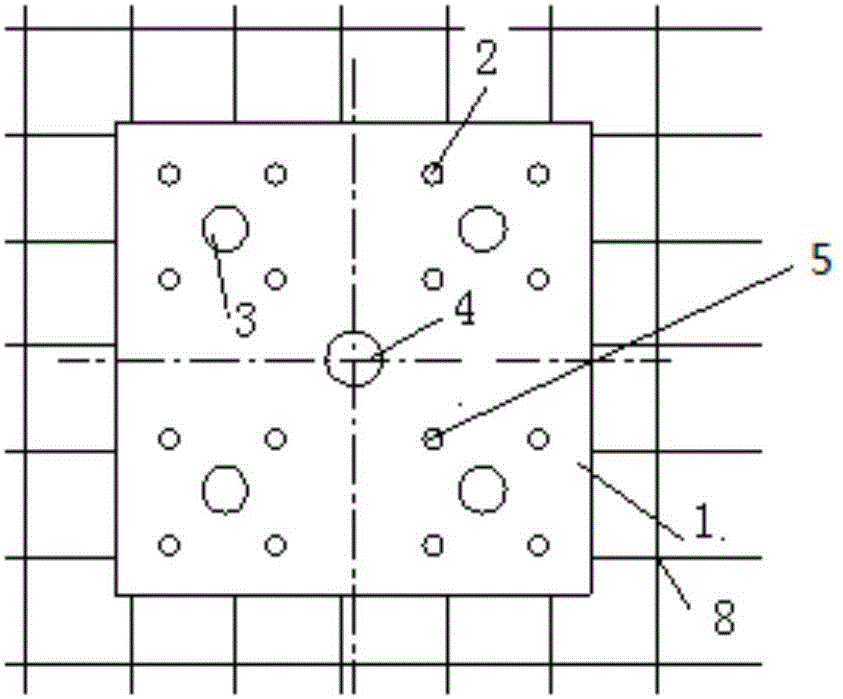

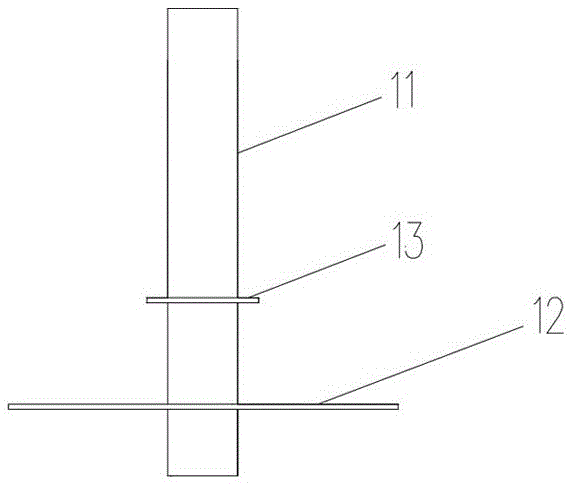

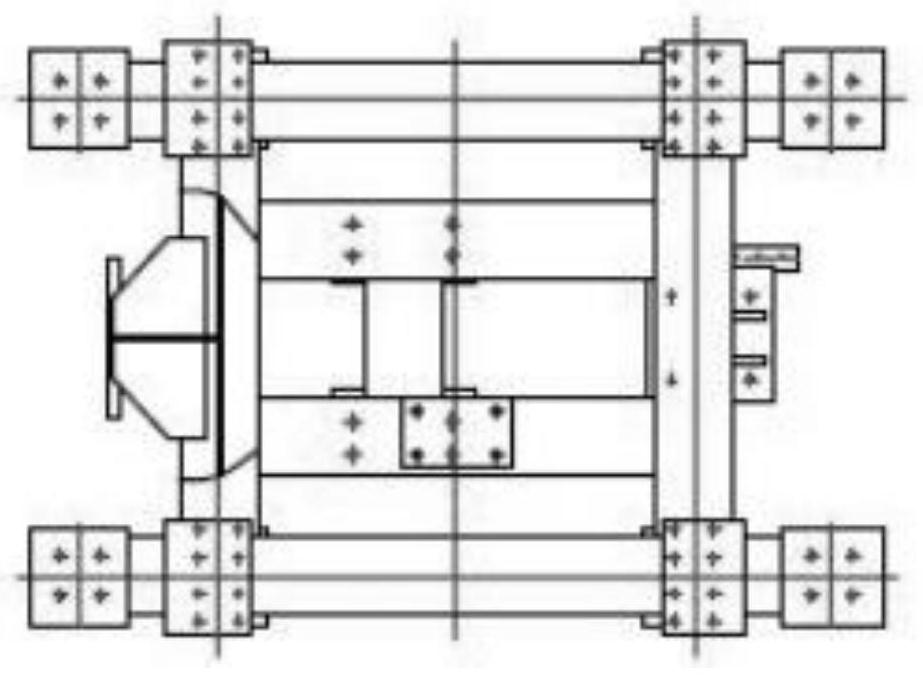

Locating template for stiff steel column and construction method employing template

ActiveCN106223541AImprove installation efficiencyImprove construction qualityStrutsPillarsSteel columnsRebar

The invention provides a locating template for a stiff steel column. The locating template comprises a flat plate, wherein the outer edge of the flat plate and vertical reinforcing bars arranged around the outer side of the stiff steel column are arranged correspondingly, the flat plate is provided with a plurality of ground bolt locating holes, a ventilating hole is formed in the center of the flat plate, and the flat plate is further provided with a plurality of inner-side vertical reinforcing bar locating holes and a plurality of pouring holes. The locating template provided by the invention is applied to ground bolts and the vertical reinforcing bars of the stiff steel column, and the ground bolt locating holes formed in the flat plate are used for locating specific positions of the ground bolts and mutual spacing thereof; the inner-side vertical reinforcing bar locating holes formed in the flat plate are used for locating specific positions of inner-side vertical reinforcing bars and mutual spacing thereof; outer-side vertical reinforcing bars are prevented from inward displacement through widening the peripheral dimension of the flat plate.

Owner:MCC TIANGONG GROUP

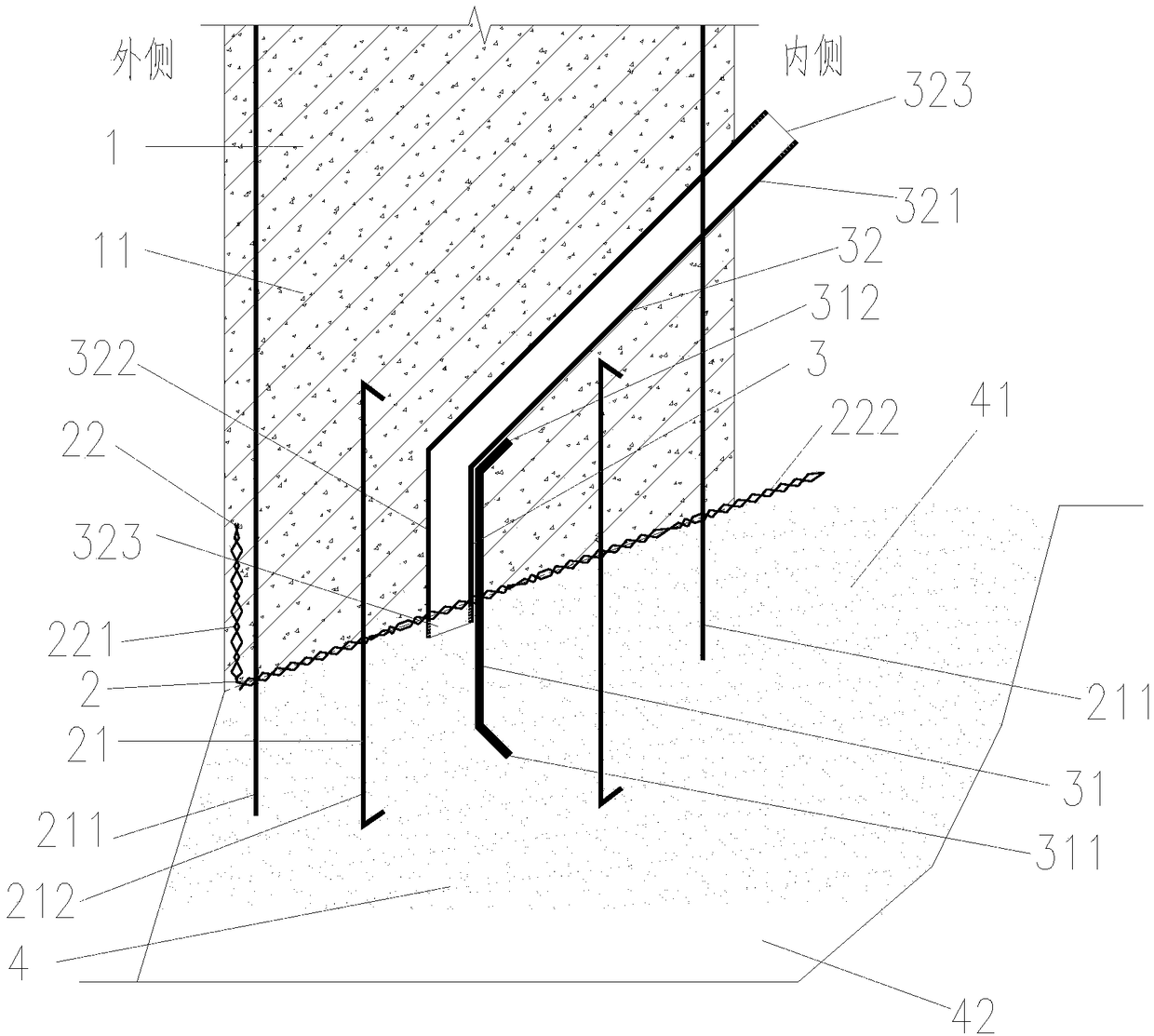

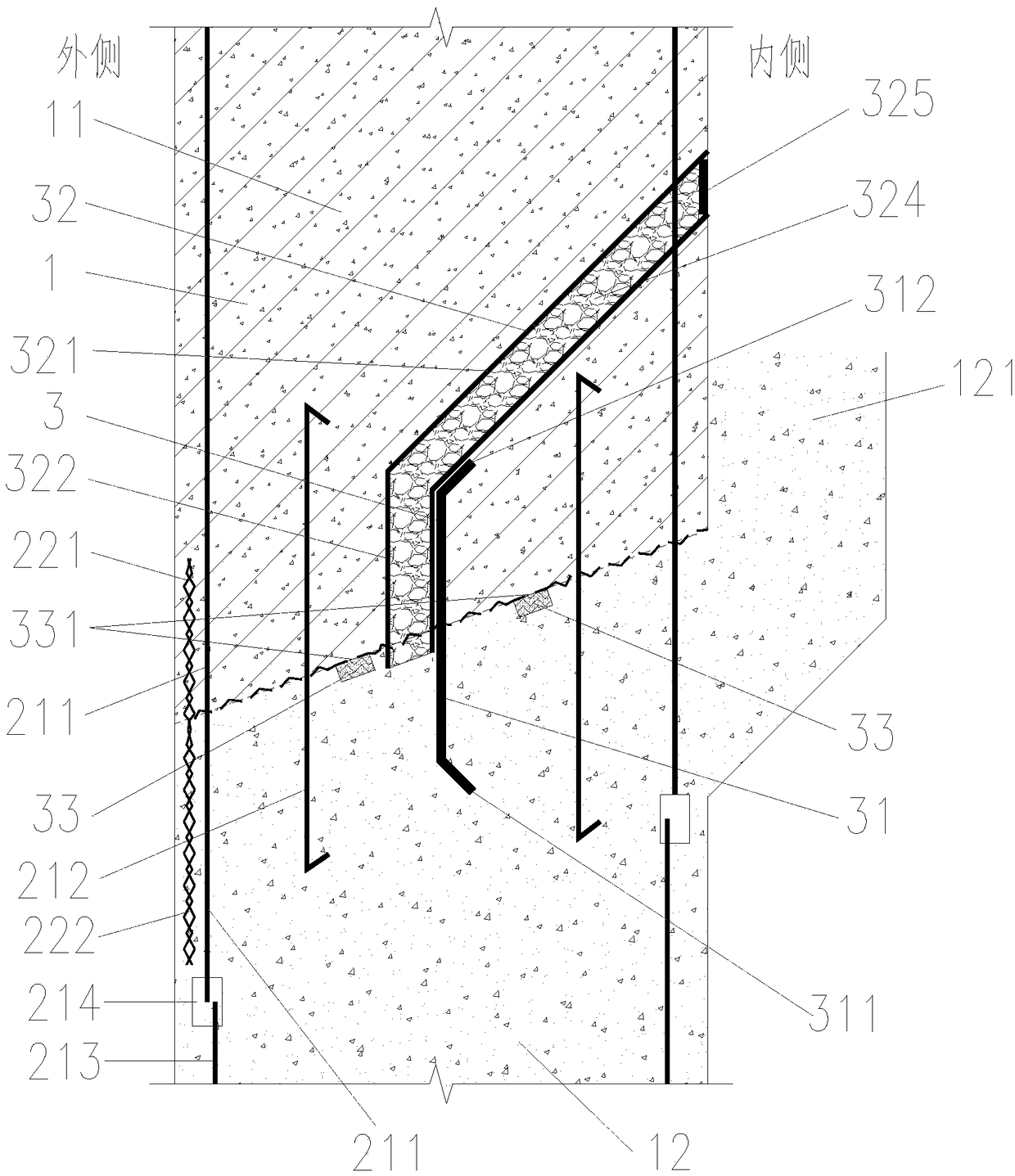

Construction joint structure of deep foundation pit inverted construction

The invention relates to a construction joint structure of deep foundation pit inverted construction. The construction joint structure comprises an upper wall segment, a lower wall segment, a connecting assembly and an impermeable assembly. The bottom surface of the upper wall segment is tightly attached to the top surface of the lower wall segment. The bottom of the upper wall segment and the upper portion of the lower wall segment have the same gradient. The connecting assembly comprises vertical joint bars. The impermeable assembly comprises a waterproof steel plate, water-expandable rubberstrips and an air exhaust pipe. The water-expandable rubber strips are arranged at the bottom of the upper wall segment. Parts of the vertical joint bars, the waterproof steel plate and the air exhaust pipe are buried in the upper wall segment, and the other parts are buried in the lower wall segment. The underground structure adopts multiple impermeable anti-cracking structure measures, the construction joint waterproof effect and construction quality of layer-by-layer inverted construction of the underground structure are effectively guaranteed, the construction joint structure has the advantages of high adaptability, simple technology, high mechanical degree, short construction period, safety and reliability, and a good waterproof anti-cracking effect is particularly achieved on inverted construction of complex underground deep foundation pit structures similar to large swirl pools.

Owner:WISDRI ENG & RES INC LTD

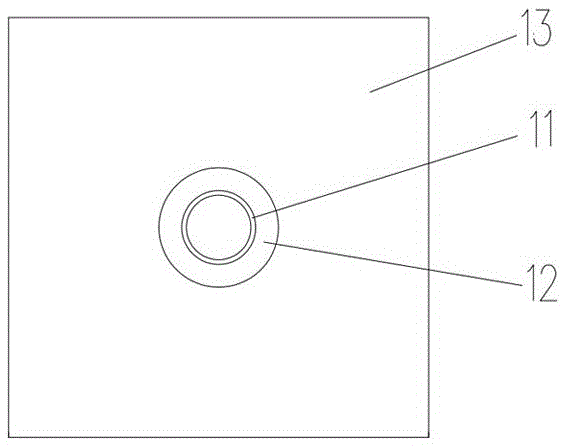

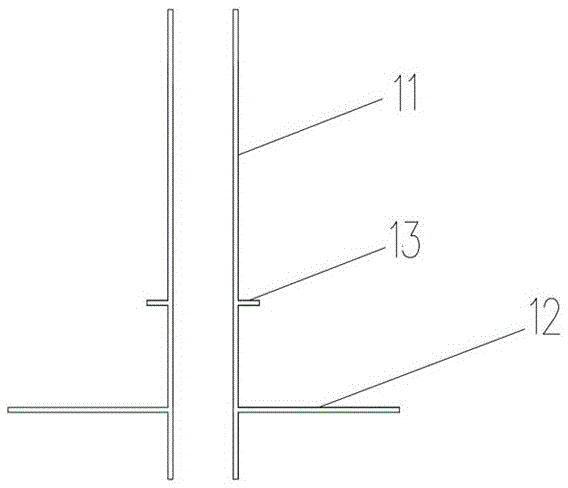

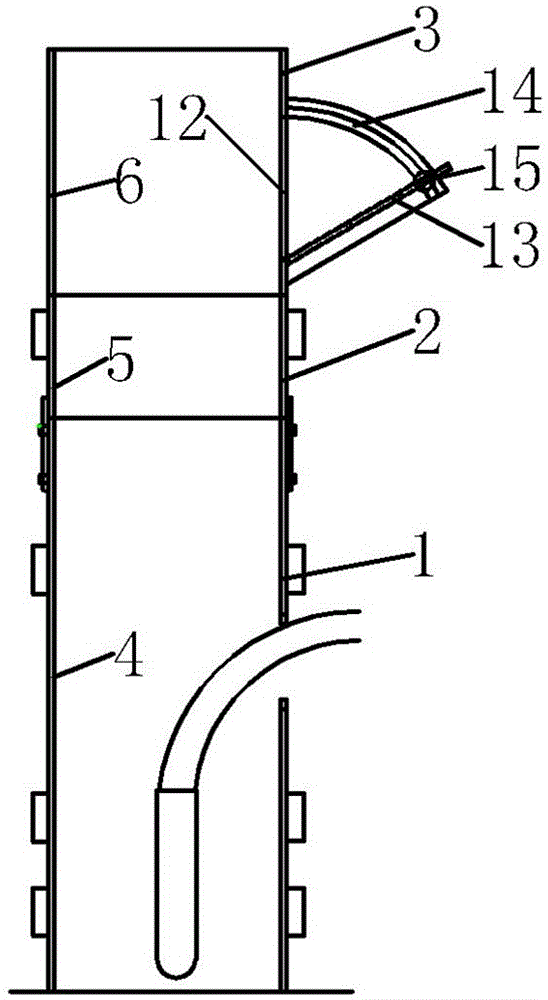

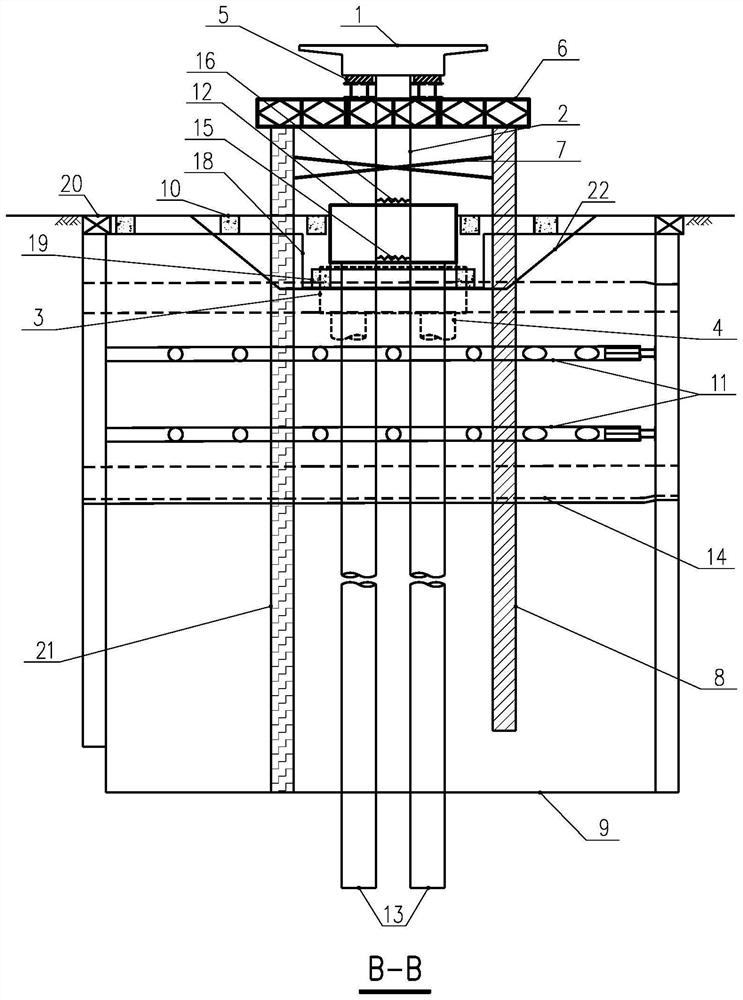

Component for tubular well precipitation construction in elevator foundation pit or sump and construction method

InactiveCN105484277AEasy constructionGuarantee the waterproof quality of constructionFoundation engineeringBasementEaves

The invention relates to the technical field of basement building construction, in particular to the technical field of high-water-level elevator foundation pit or sump construction, and particularly discloses a component for tubular well precipitation construction in an elevator foundation pit or sump. The component comprises a hollow sleeve, wherein a horizontal support plate, perpendicular to the sleeve, is arranged at the lower part of the sleeve, the sleeve is provided with an eave board above the support plate, the sleeve penetrates through the eave board and the support plate, and the eave board and the support plate are fixed with and in seamless connection with the sleeve; and the part, below the support plate, of the lower part of the sleeve is inserted into a tubular well, and the support plate is horizontally erected outside the opening of the tubular well and used for supporting the sleeve. The invention further discloses a construction method. The construction method comprises the following steps of tubular well precipitation, earth excavation, component mounting, cushion layer construction, water-proof layer construction, foundation raft concrete pouring, earth backfilling, tubular well blocking and the like. By applying the component and the construction method, the construction of the cushion layer, the water-proof layer and the foundation raft of the elevator foundation pit or sump can be conveniently carried out, the construction water-proof quality can be ensured, the construction efficiency can be improved, and the construction cycle can be shortened.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Integral type building construction assembly technique

InactiveCN105587117AAccelerateControl construction qualityFloorsForms/shuttering/falseworksRebarSteel columns

The invention discloses an integral type building construction assembly technique. The integral type building construction assembly technique is characterized in that: a base is arranged on the bottom of a column template; an adjustable support pillar is arranged at one side of the column template; angle steel is arranged on the upper part of the support pillar; a superposed beam is arranged on the angle steel; a hole is formed in the superposed beam; a steel column is inserted into the hole; a square timber is arranged on the steel column; a prefabricated ribbed prestressed concrete superposed plate are arranged on the square timber; the columns, the beam, and plate steel bars are lapped according to a design demand; a prefabricated concrete superposed beam template is arranged; and then the columns, the beam, and the plates are poured into a whole. The integral type building construction assembly technique can increase the whole speed of building assembly and construction, facilitates construction quality control, and can ensure construction safety.

Owner:HARBIN TAOYI ADVERTISING DECORATION ENG

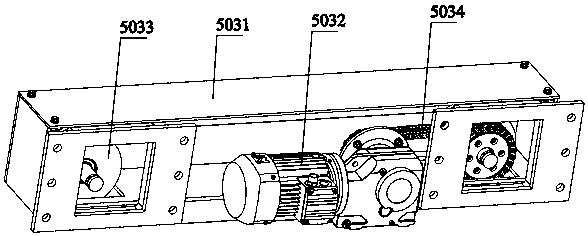

Lining pouring method for telescopic moulding bed and used for integral pouring for lining of molten steel tank

InactiveCN112643017AImprove securityExtended service lifeMelt-holding vesselsCeramic shaping apparatusRelative displacementElectric machine

The invention discloses a lining pouring method for a telescopic moulding bed and used for integral pouring for a lining of a molten steel tank, and relates to the technical field of construction methods for castables of molten steel tanks. According to the lining pouring method for the telescopic moulding bed and used for integral pouring for the lining of the molten steel tank, a frame and a shell body of the molding bed are integrally connected and have different functions, the relative displacement of the frame and the shell body is realized by using the thrust of an electric cylinder, and the purpose of accurate centering is achieved; the shell body of the moulding bed is divided into two parts, that is, a telescopic door and the shell body, the telescopic door is moved through the thrust of an electric push rod, the working diameter of the shell body of the moulding bed is changed, and a shaping pouring function and a demoulding function for the moulding bed are realized; and attached vibration motors which are arranged in a layered and staggered manner are adopted, so that uniform and independent vibration of all parts of the moulding bed is ensured, and the compactness of a castable is realized.

Owner:MAANSHAN IRON & STEEL CO LTD

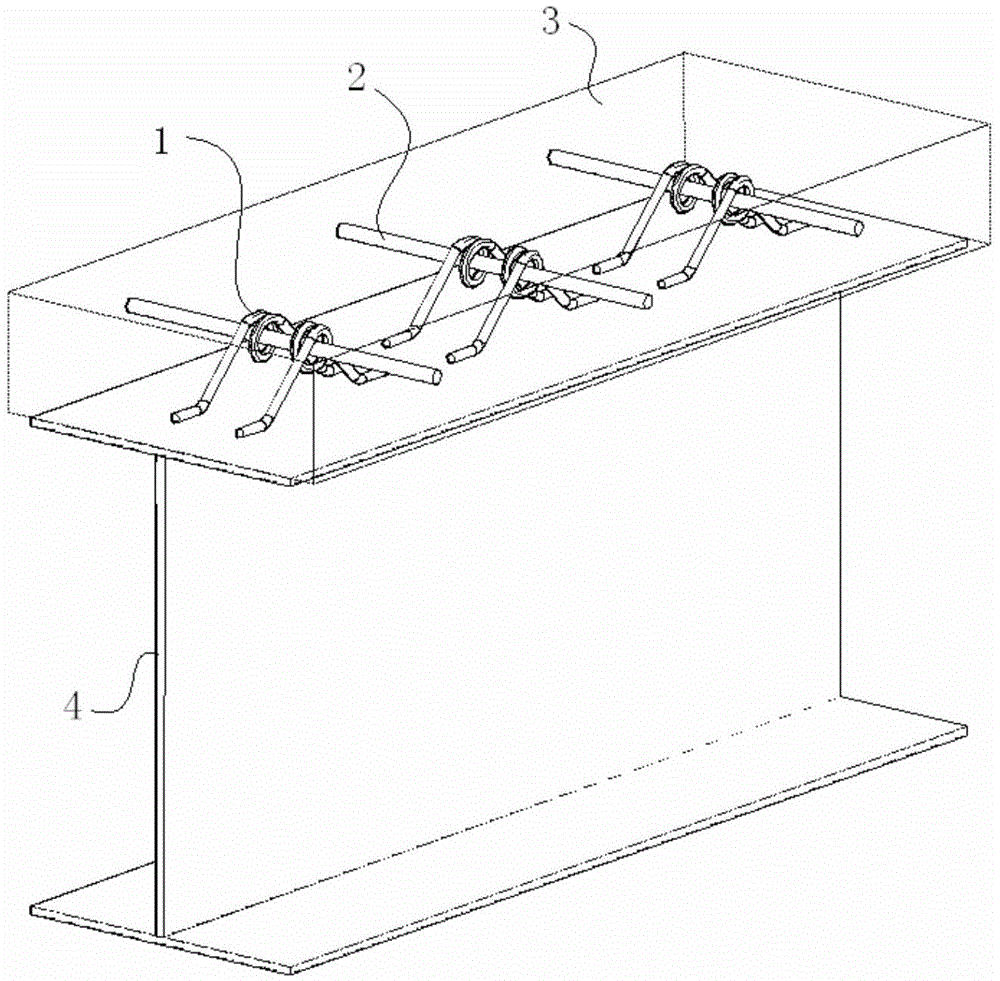

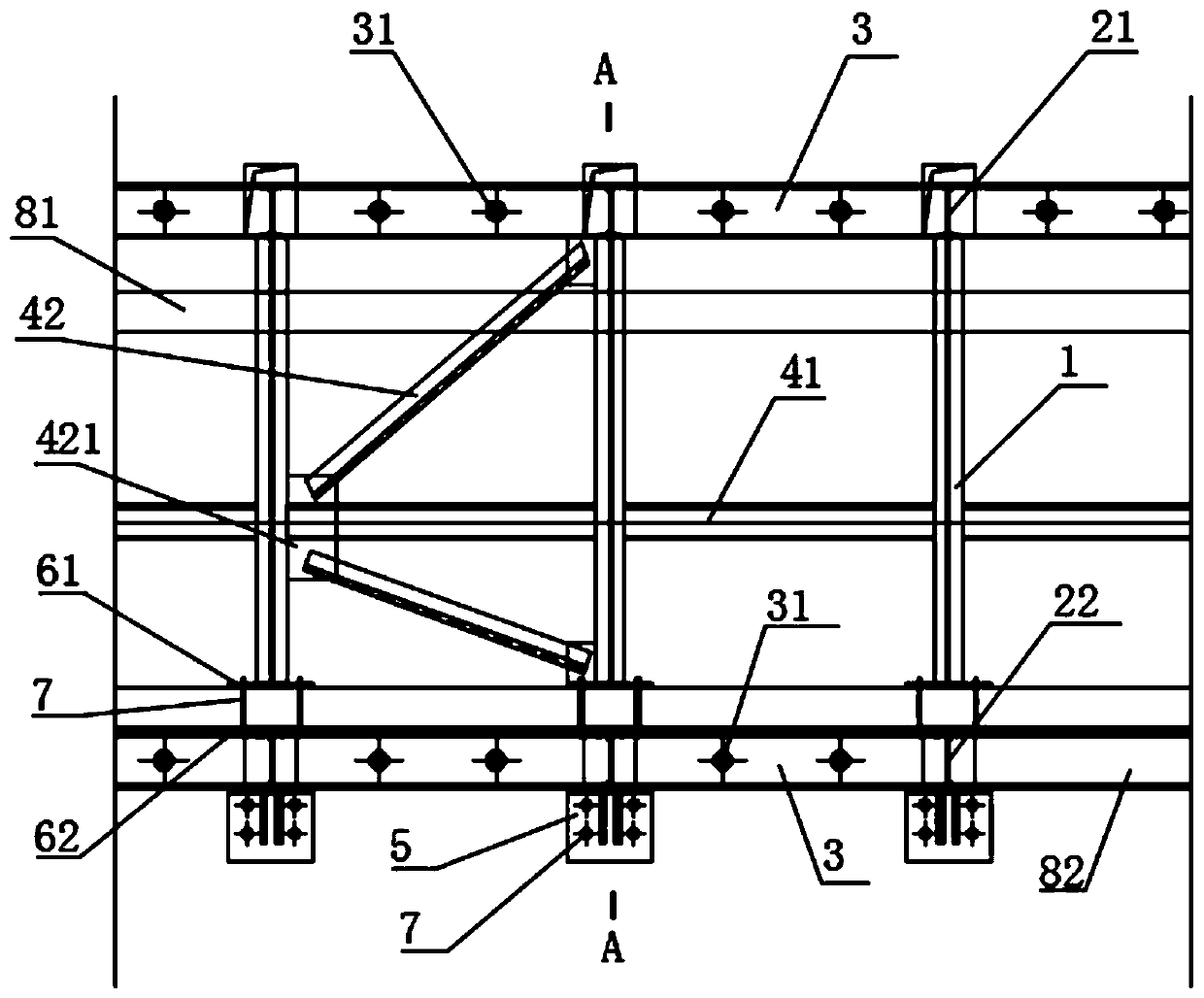

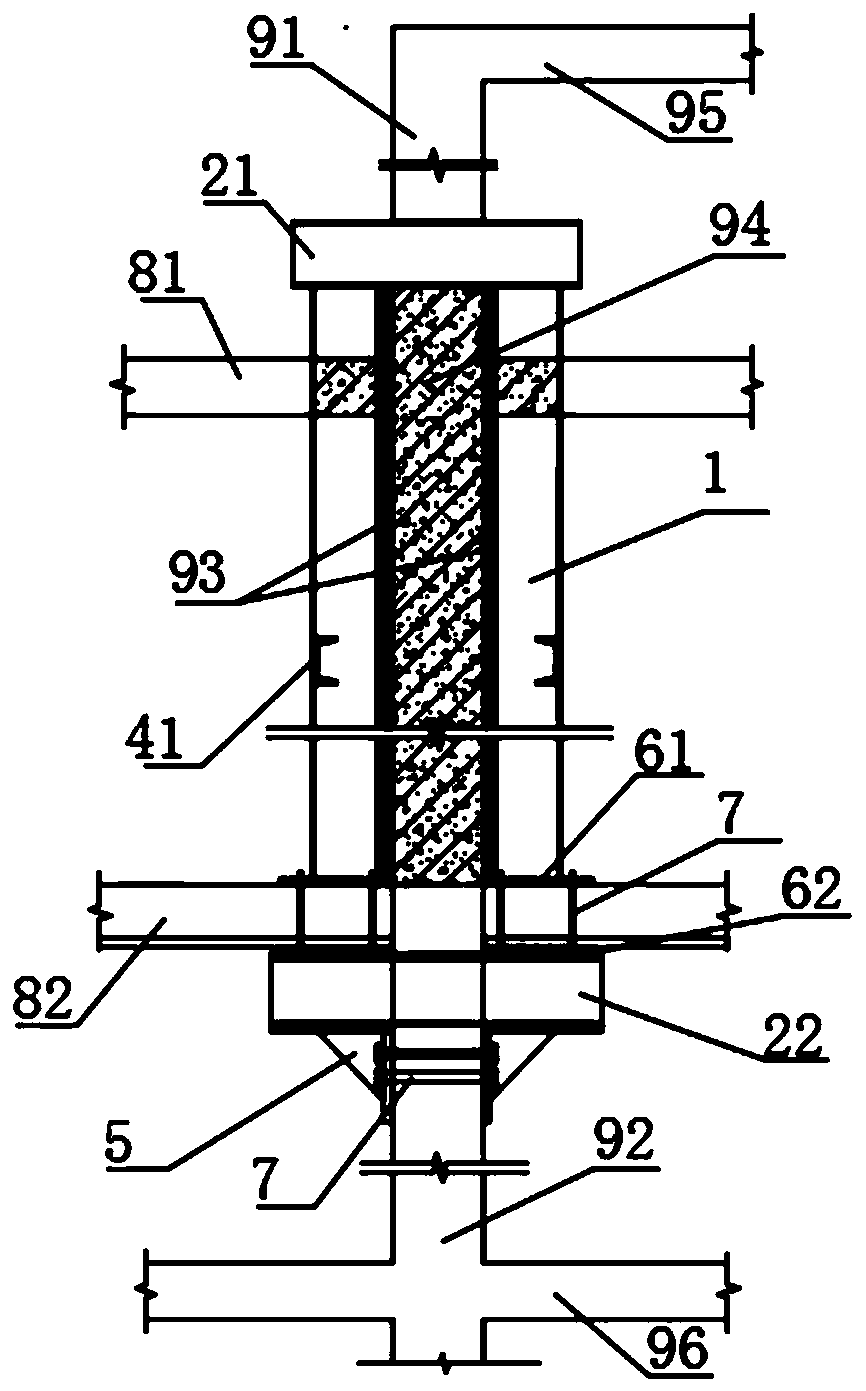

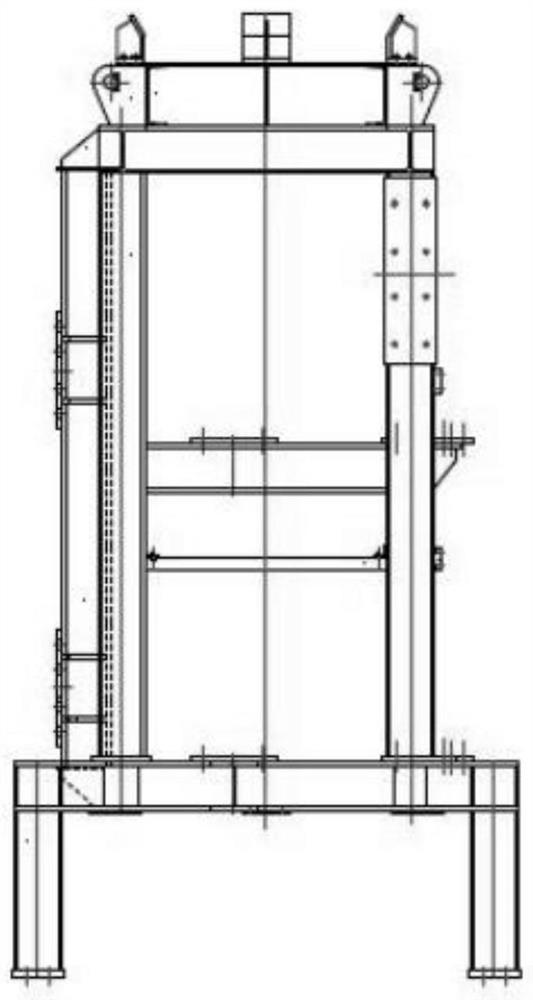

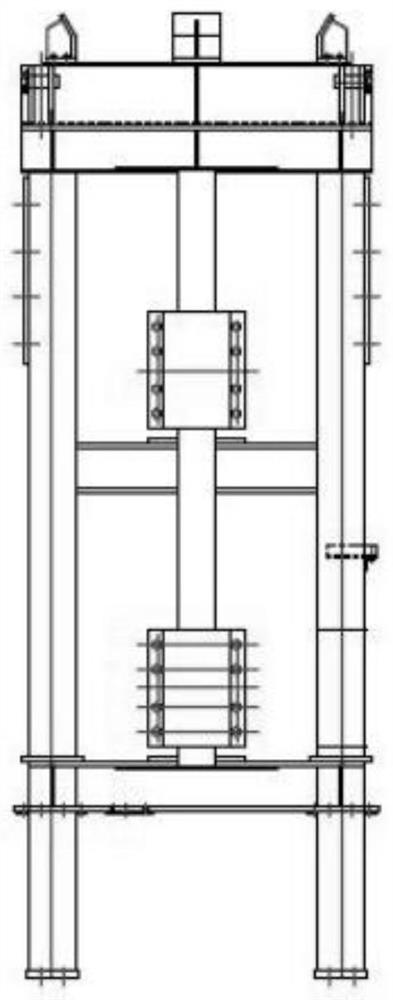

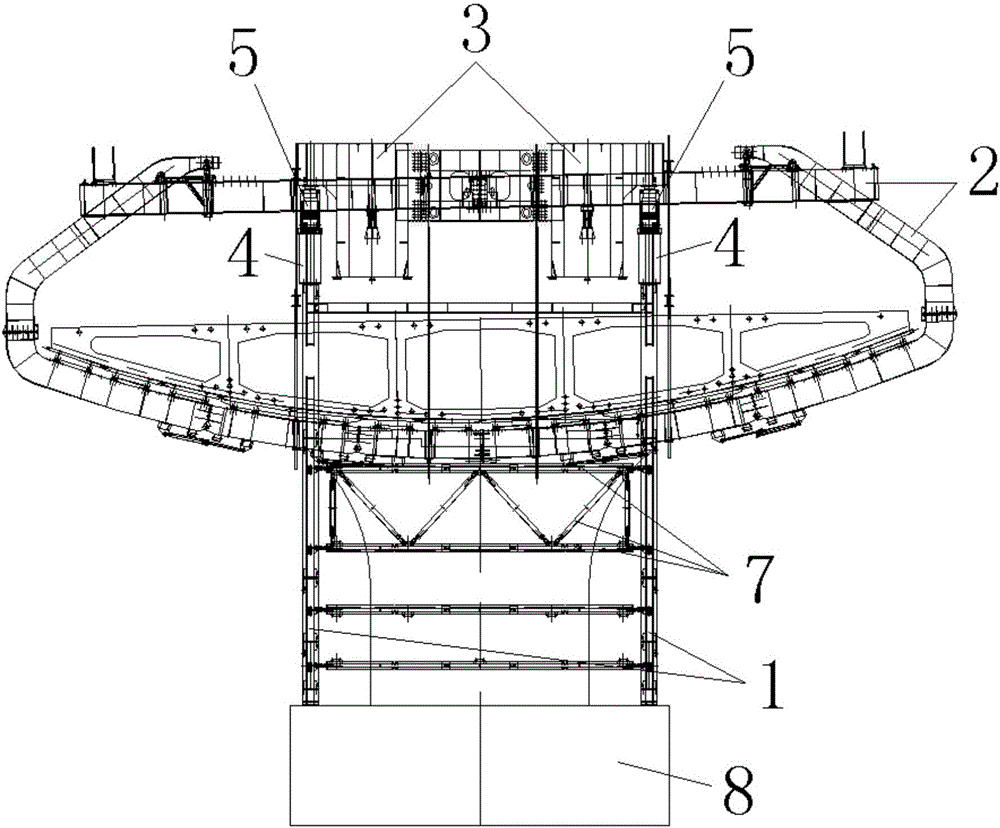

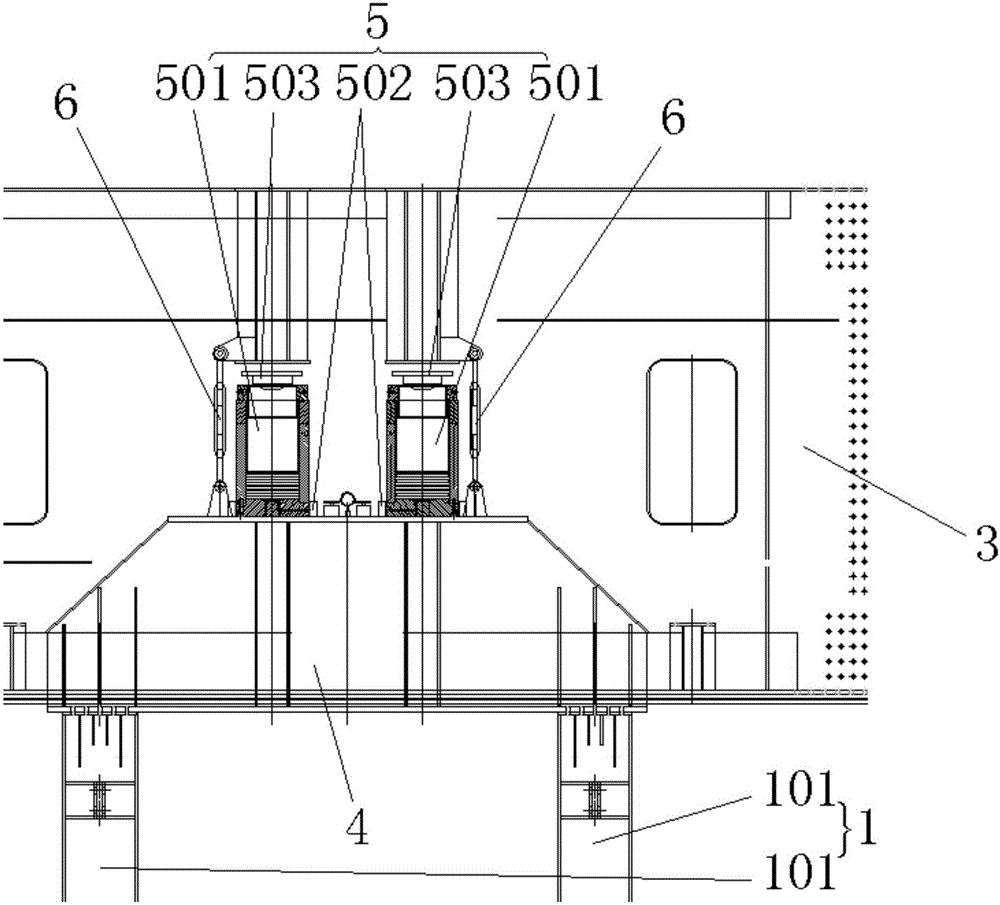

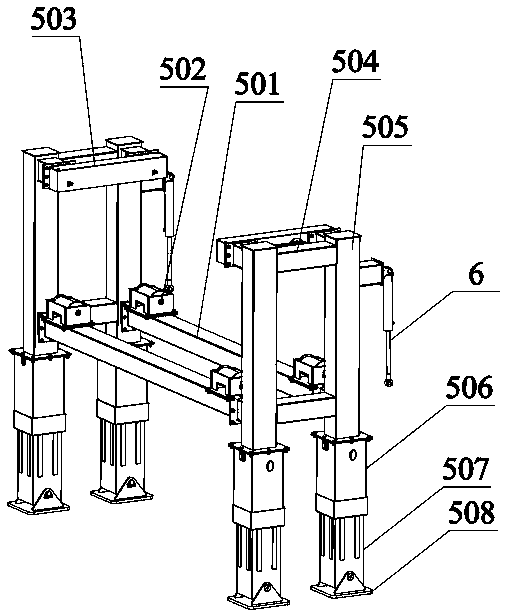

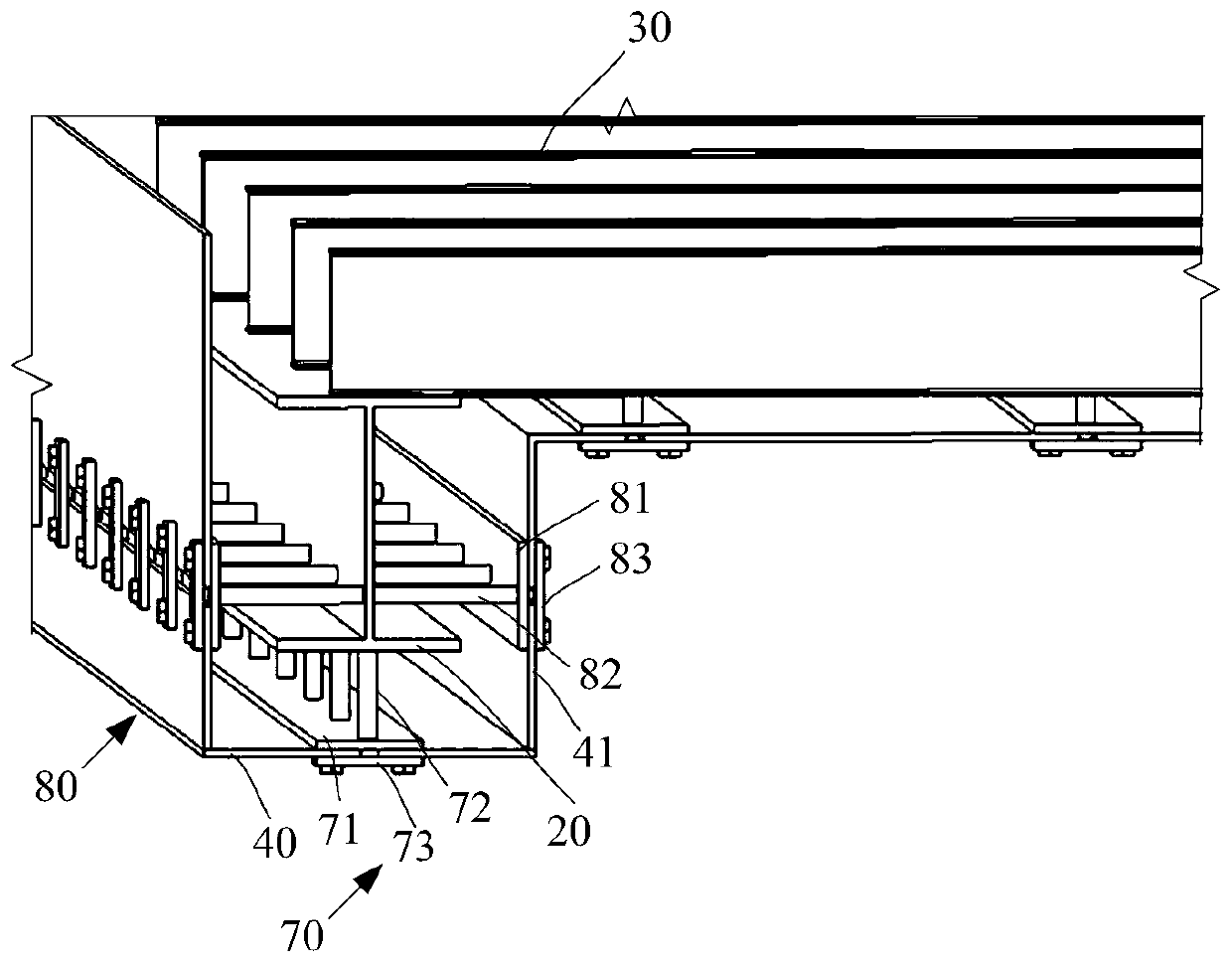

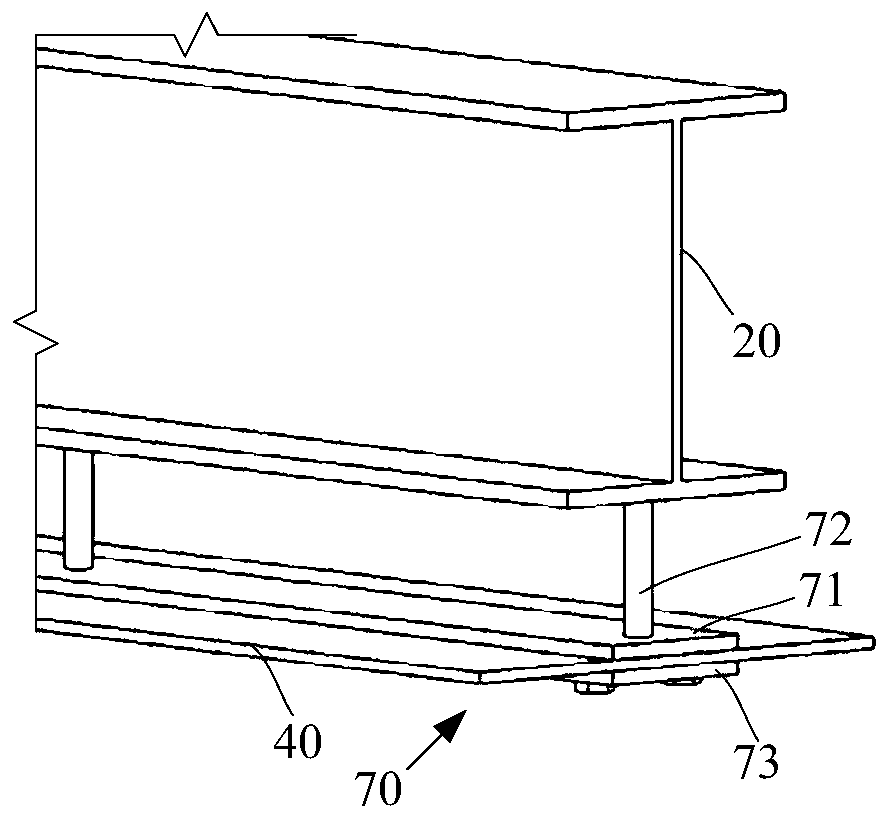

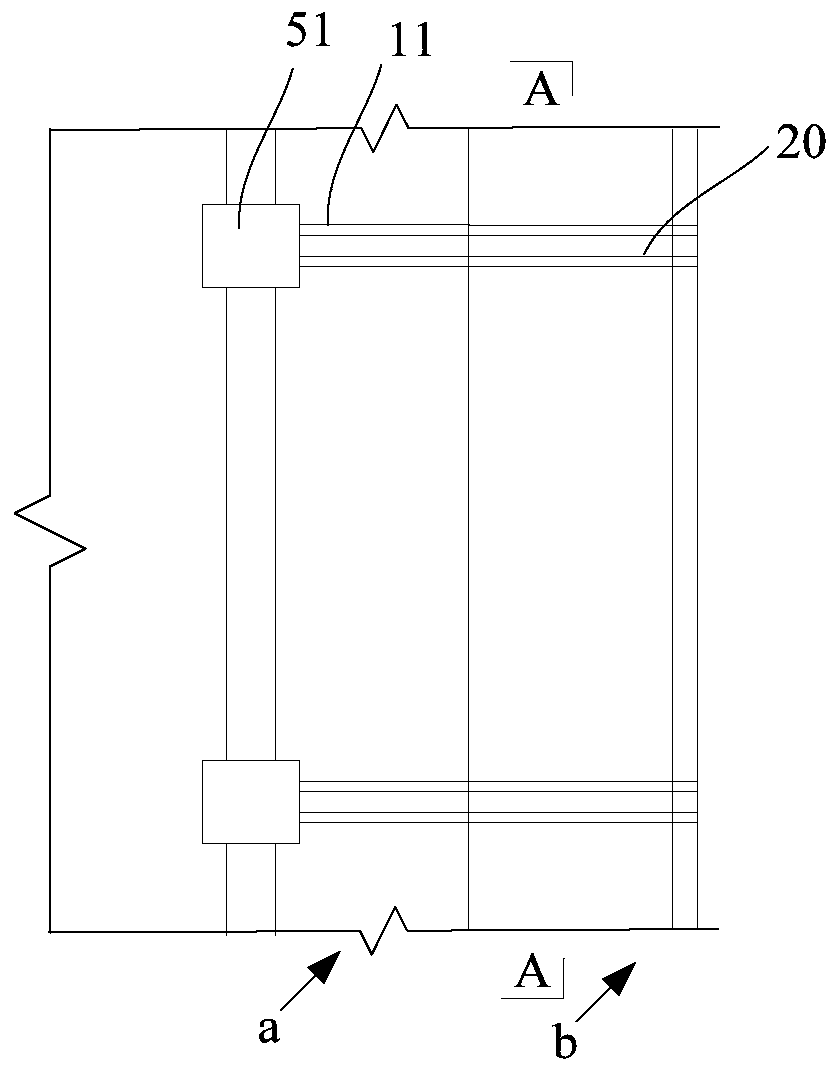

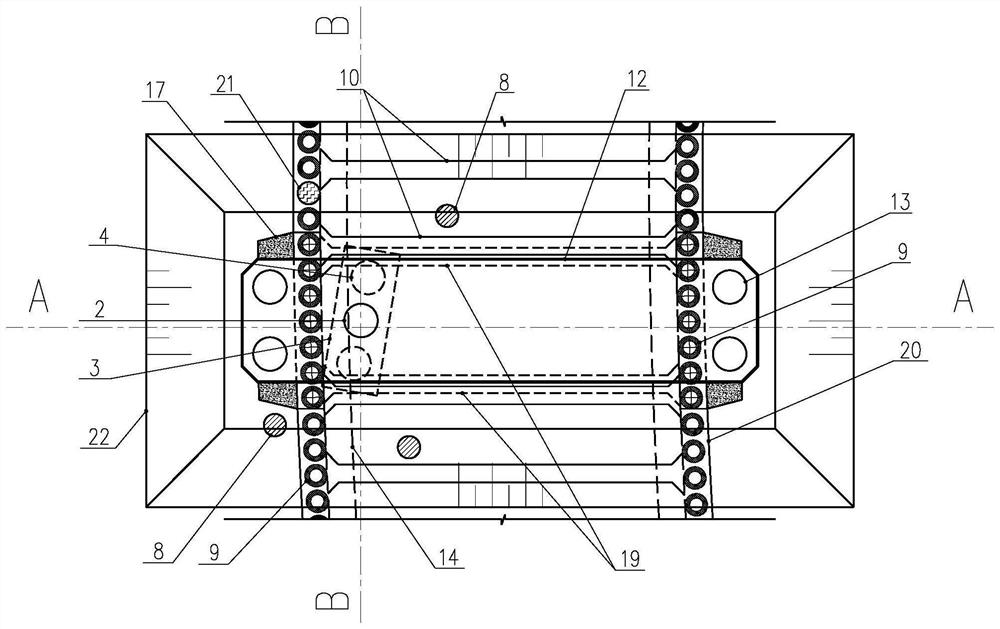

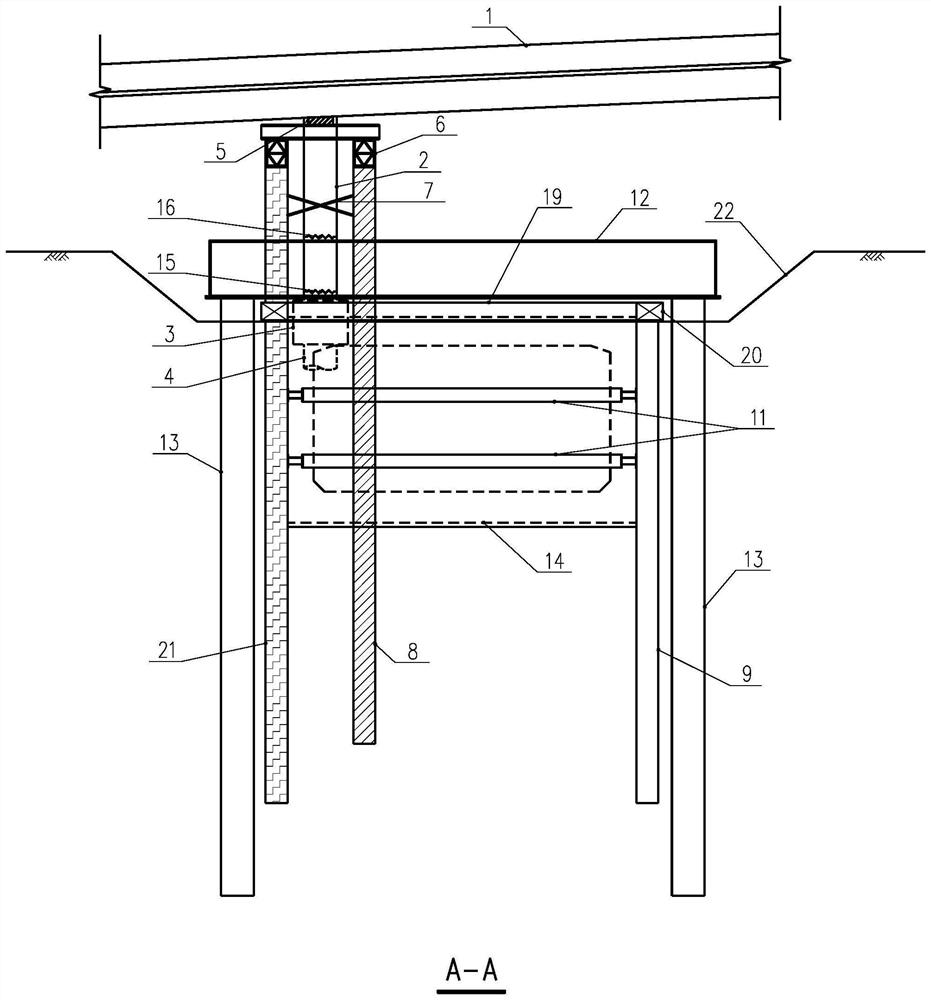

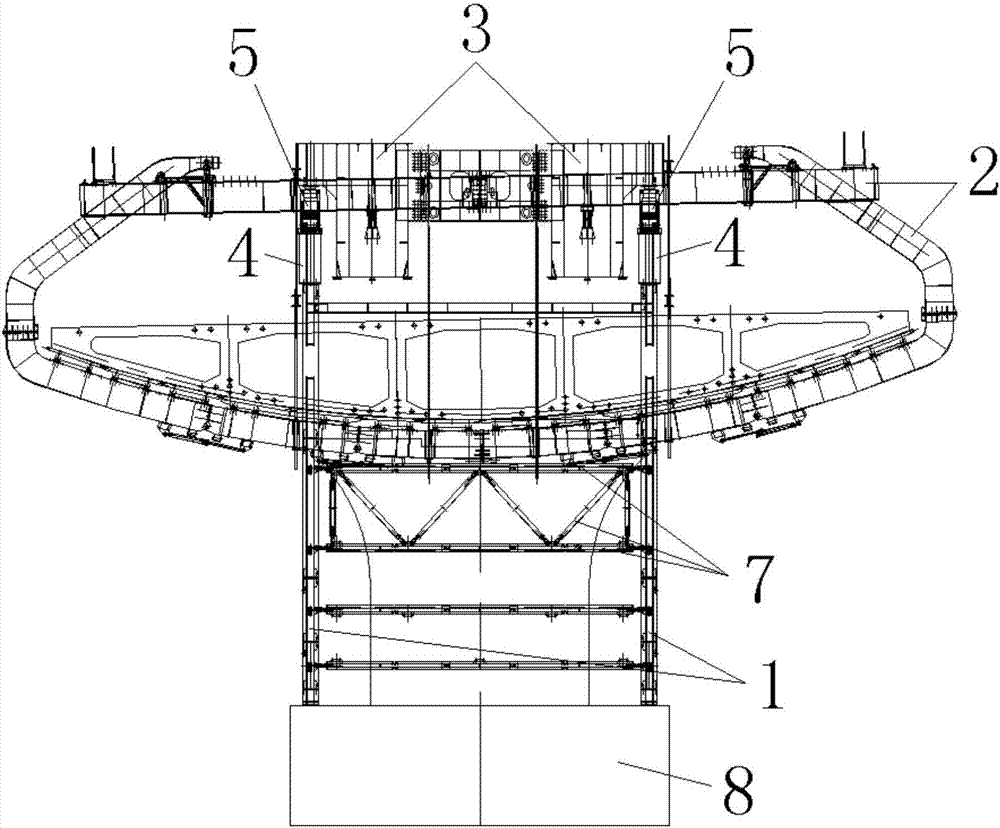

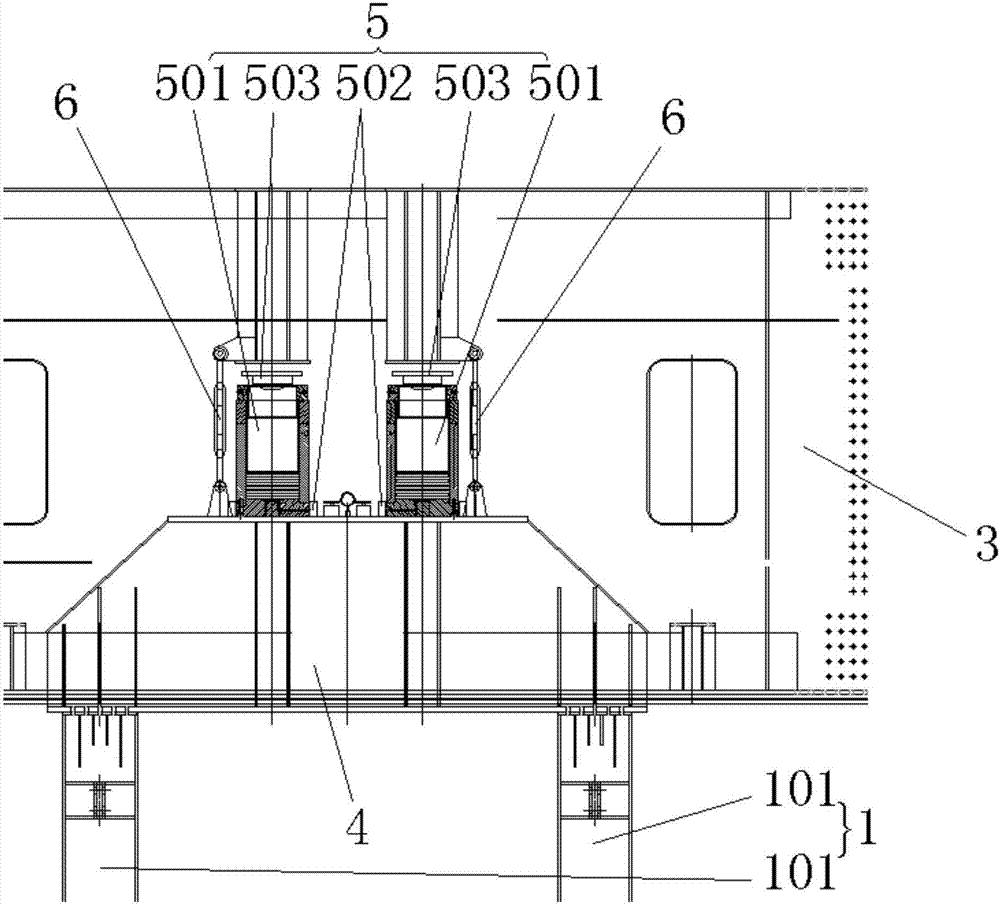

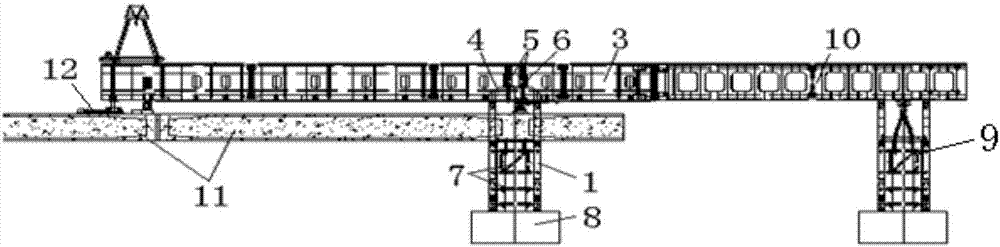

Jack balancing device used for movable formwork and movable formwork

ActiveCN106192772AConvenient pouring constructionReduce the problem of unbalanced load of support force caused by disturbanceBridge erection/assemblyJackscrewEngineering

Owner:CCFEB CIVIL ENG

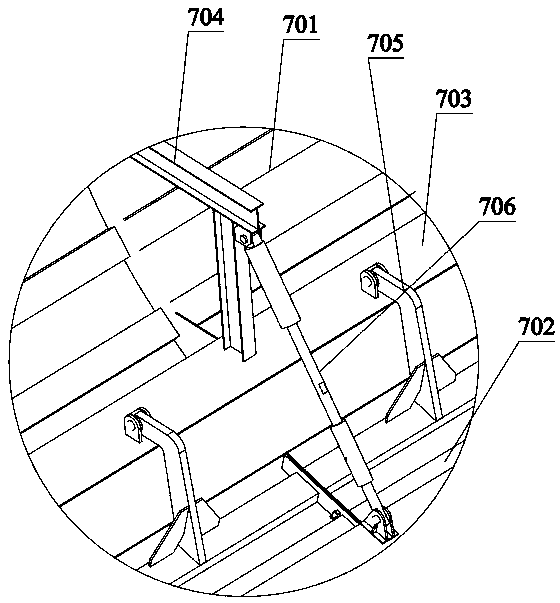

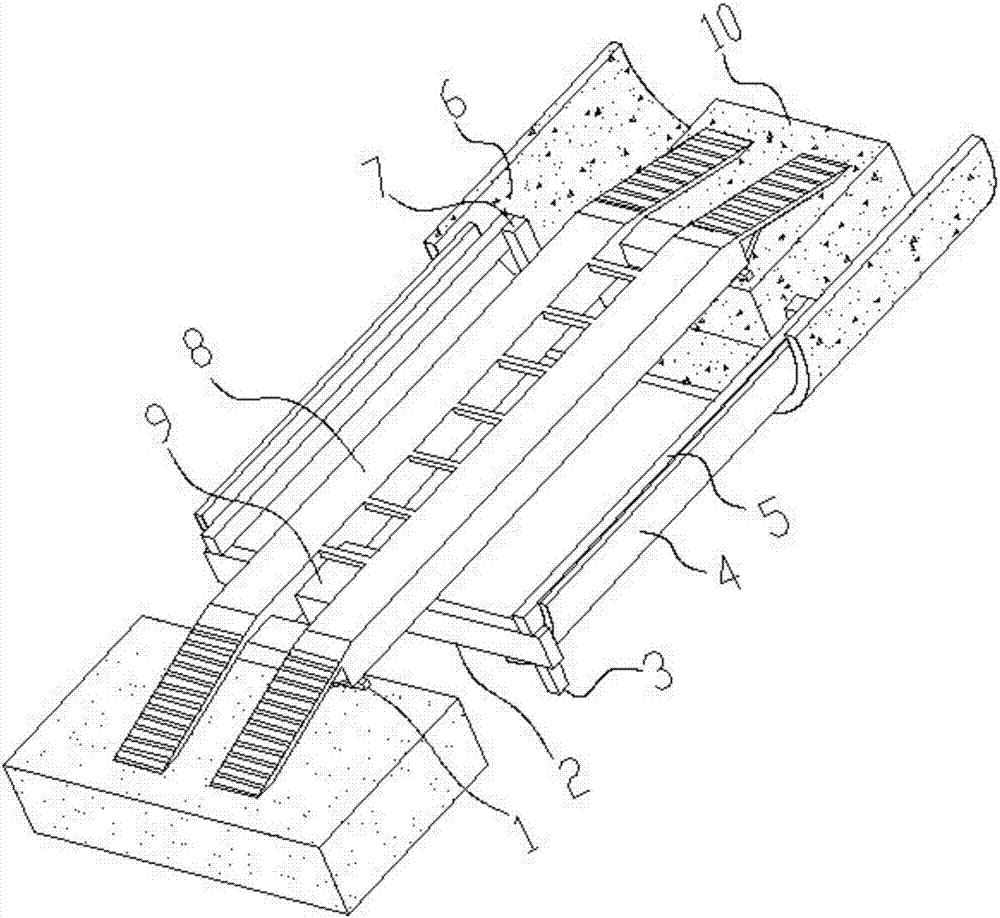

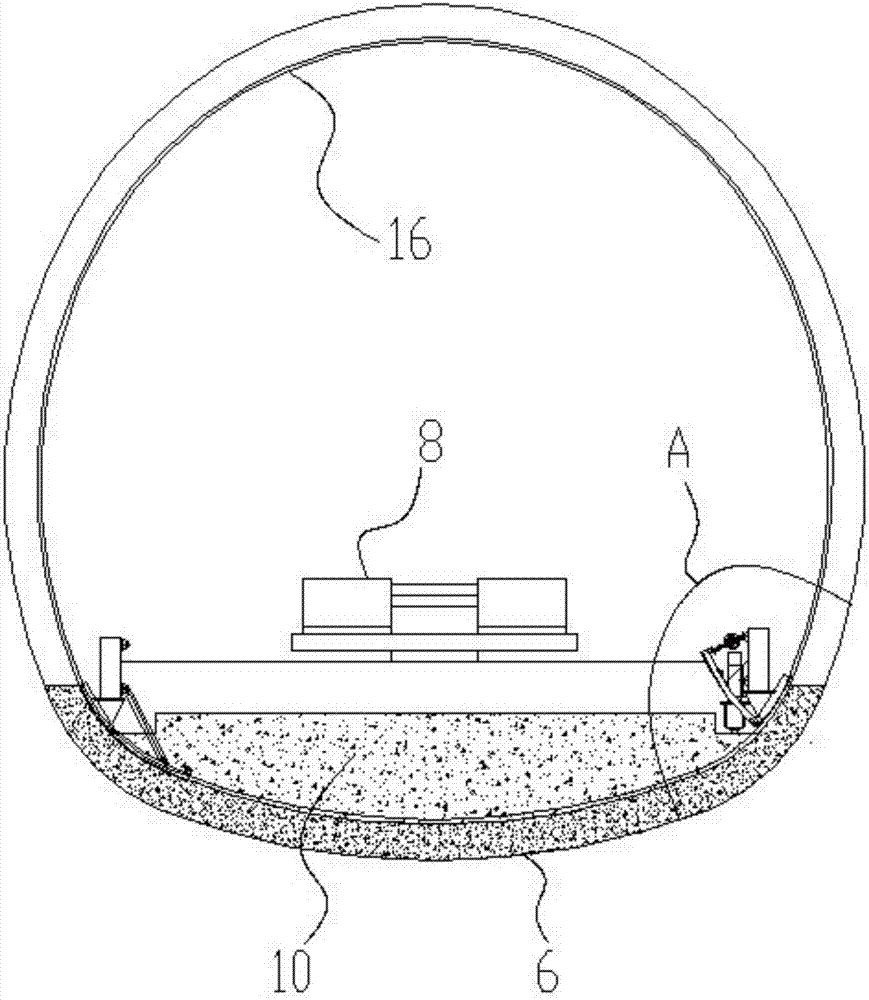

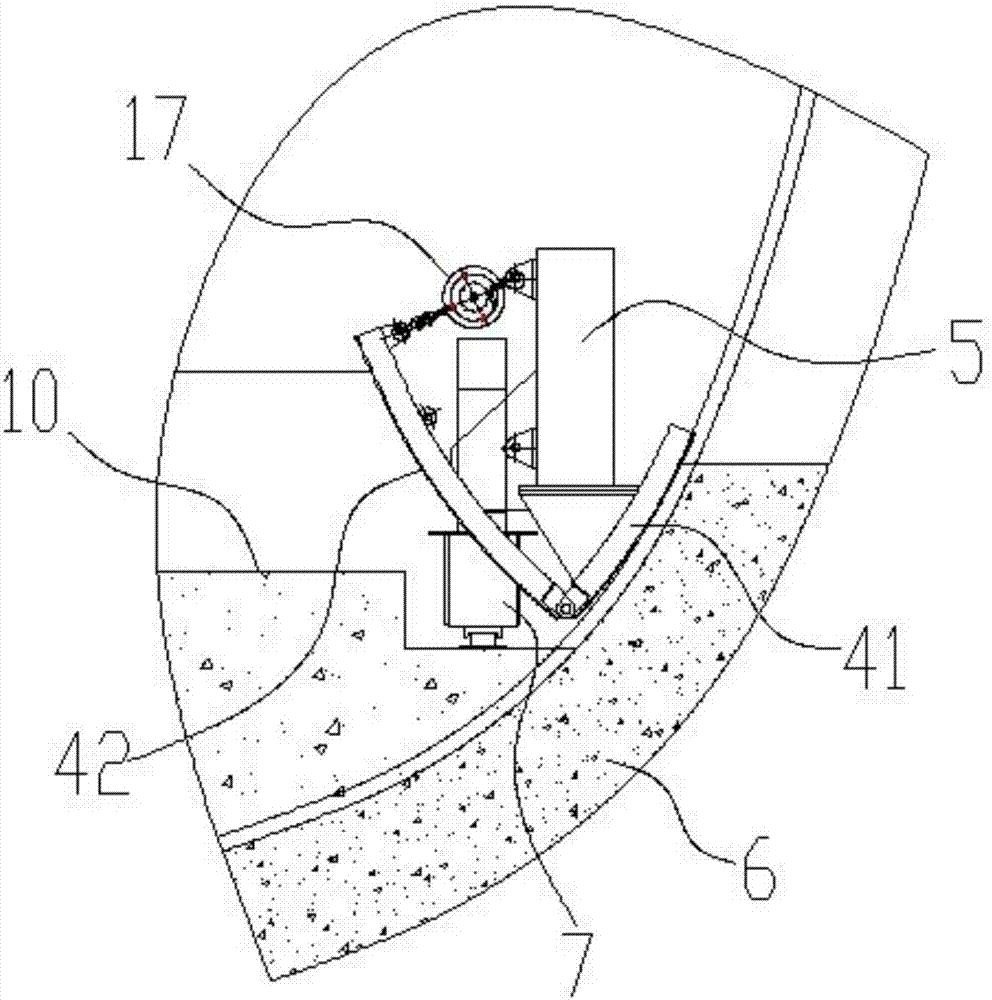

Self-propelled trestle trolley for inverted arch trestle trolley

InactiveCN111535148ASave assemblySave demolitionUnderground chambersTravelling bridgesArchitectural engineeringStructural engineering

The invention provides a self-propelled trestle trolley for an inverted arch trestle trolley. After an inverted arch formwork system is installed at a time, the inverted arch formwork system can be dragged by a trestle trolley to achieve inverted arch operation construction of a whole tunnel with the same section, formwork assembling and disassembling are omitted, full-automatic mechanical controlmoving and positioning are adopted, labor intensity of workers is greatly reduced, labor cost is saved, and construction efficiency and construction quality are improved; and meanwhile, the invertedarch formwork system is detachably connected with the trestle trolley, a separation mode is simple, the inverted arch formwork can be ensured not to interfere with construction of other procedures inthe procedures of inverted arch excavation, wire-tie and the like, and control is flexible and convenient.

Owner:李军

Steel-concrete combination segment structure equipped with cells and used for long-span self-anchored suspension bridge

PendingCN110835884AImprove mechanical performanceAdapt to structural needsSuspension bridgeBridge structural detailsStress concentrationConcrete beams

The invention discloses a steel-concrete combination segment structure equipped with cells and used for a long-span self-anchored suspension bridge. A variable-height stiffening segment is provided with a bottom plate. The steel-concrete combination segment structure sequentially comprises a concrete cross beam segment, a steel cell segment, a steel beam stiffening variable-height segment and a steel beam stiffening constant-height segment. The steel-concrete combination segment structure has the beneficial effects of reasonable design, simple structure, and convenient and efficient construction. The steel-concrete combination segment structure also has the beneficial effects of optimizing the stress performance of a steel-concrete combination segment, adapting to structural needs of the long-span self-anchored suspension bridge, enlarging a combination surface of a combination part by virtue of the structure with the cells, forming multi-directional restraints on filled concrete, enhancing the combination of a steel beam and a concrete beam, improving the stress condition on the concrete at the combination part, bringing the functions of connectors into full play by virtue of theconstruction mode of rear pressure-bearing plates, enabling the force transmission to be clear and definite, achieving relatively small stress concentration at the combination surface, enabling the concrete of the cells and a main beam to form a continuous structure, facilitating concrete pouring construction, and enabling the concrete at the roots of the connectors to be not prone to disintegration.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

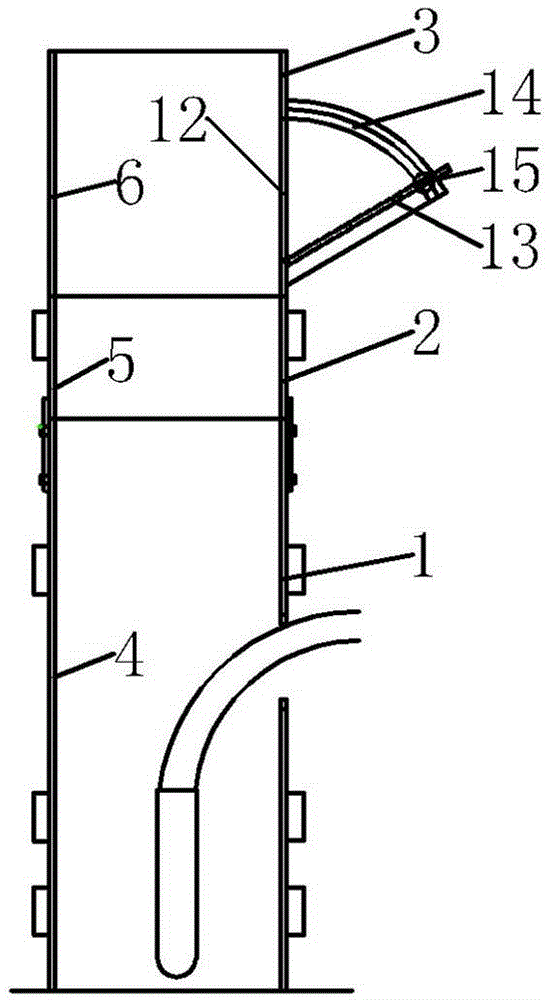

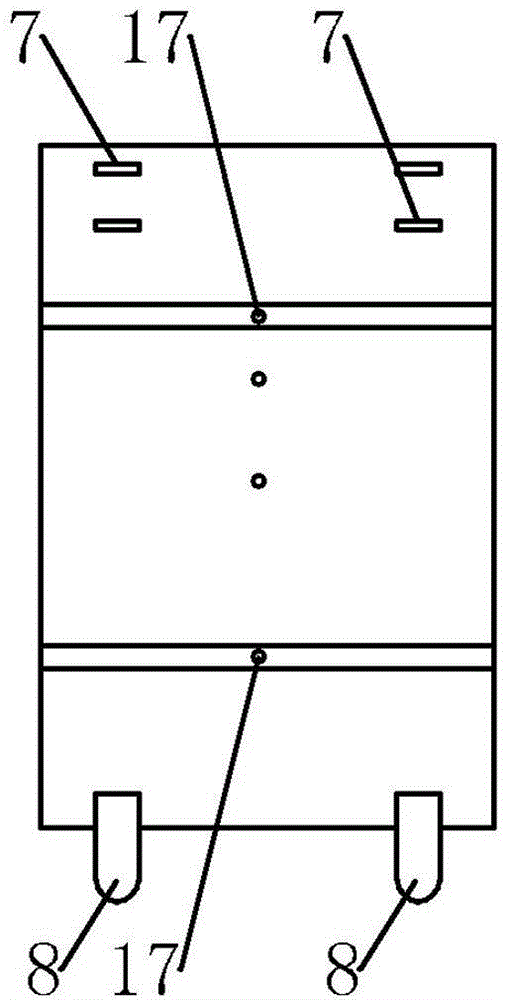

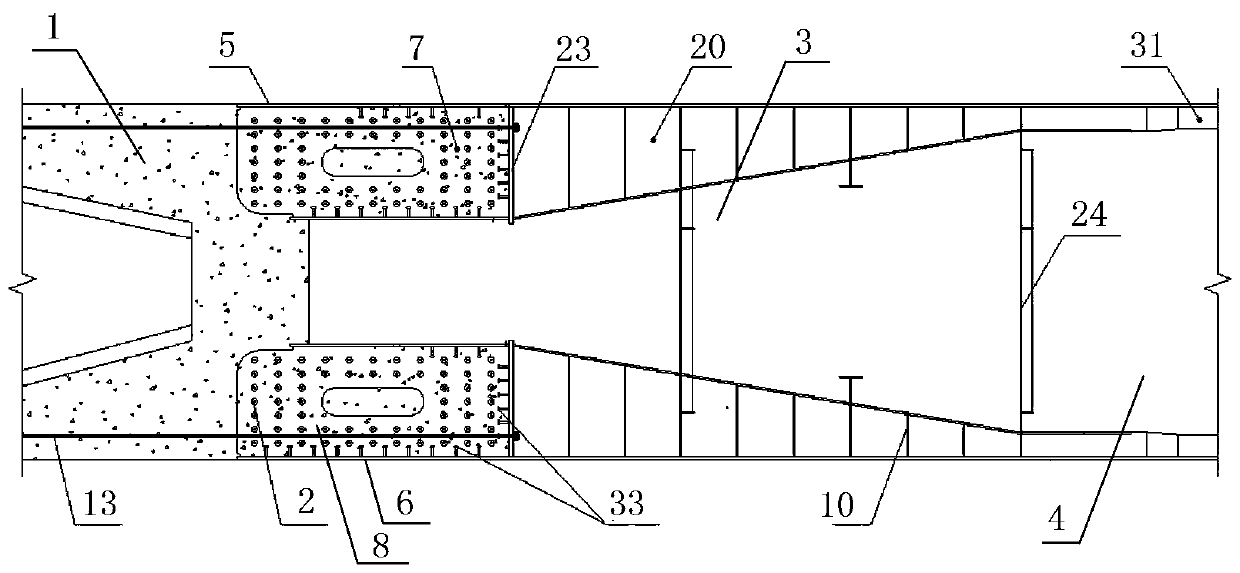

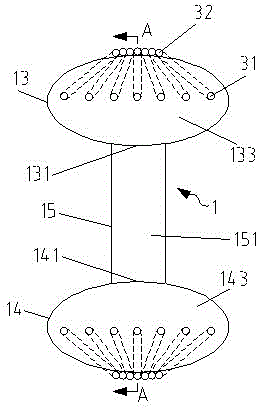

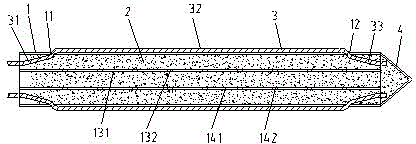

Cast-in-place externally prestressed concrete-filled steel pipe pile and construction method thereof and support pile wall

ActiveCN104099923AConvenient pouring constructionReduce shipping costsBulkheads/pilesSteel tubeEngineering

The invention discloses a cast-in-place externally prestressed concrete-filled steel pipe pile, which comprises a steel pipe, a concrete layer cast-in-place in the steel pipe and multiple prestressed tendons arranged on the steel pipe, wherein the prestressed tendons are arranged along the direction of the axis of the steel pipe, and comprise top sections, middle sections and bottom sections; the middle sections are positioned outside the steel pipe; the top sections and the bottom sections penetrate through the wall of the steel pipe and enter into the steel pipe; the upper end of the steel pipe is opened, and the bottom end of the steel pipe is provided with a sealed structure. The invention also provides a construction method of the concrete-filled steel pipe pile and a support pile wall with the concrete-filled steel pipe pile. In the way, the external prestressing technology is adopted by the cast-in-place externally prestressed concrete-filled steel pipe pile, a pile body can be restrained better, the tensile resistance is provided, and deformation of the support pile wall in the excavation process of a foundation pit is effectively limited; in addition, field fabrication can be performed, transport costs are reduced, on the premise of guaranteeing safety and reliability of a foundation pit support, the cost is reduced, the construction period is shortened, and construction is convenient.

Owner:JIANGSU DINGDA BUILDING NEW TECH +1

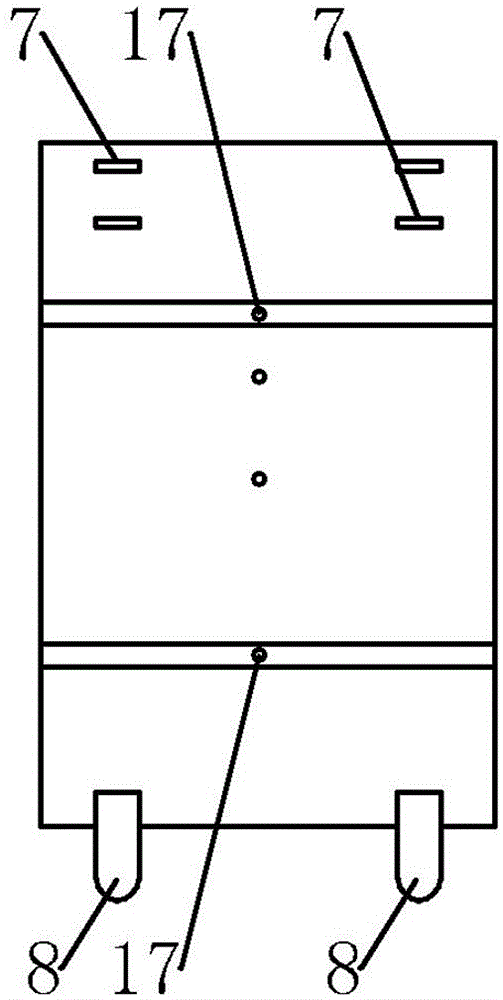

Structural column steel formwork

ActiveCN104831923BEasy to installReduce labor costsForms/shuttering/falseworksArchitectural engineeringBuilding construction

Owner:郑增豪

A kind of concrete admixture and a kind of ready-mixed permeable concrete using it

The invention relates to a pre-mixed and water-permeable concrete admixture and water-permeable concrete. The pre-mixed and water-permeable concrete admixture is formed by mixing of the following components in percentage by weight: 10-20% of a water reducing component, 1-5% of a hydration regulating and controlling component, 0.1-1.0% of a viscosity regulating component, 0.5-5% of a water evaporation inhibiting component, 0.5-3% of a thixotropic agent component, and the balance of water. The pre-mixed and water-permeable concrete admixture provided in the invention can effectively improve work conditions of the water-permeable concrete, greatly improve the cohesiveness and the uniformity of slurry wrapping aggregate surfaces, and can effectively prolong the operable time of the water-permeable concrete, meet the requirements of pre-mixing production, long-distance transportation and long-time construction of the water-permeable concrete, and improve the control of production and construction quality of the water-permeable concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

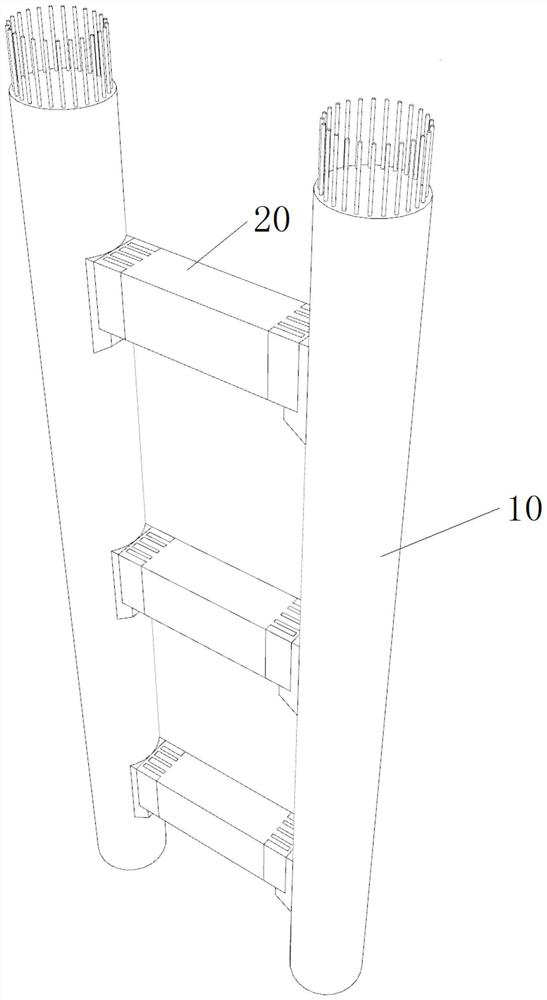

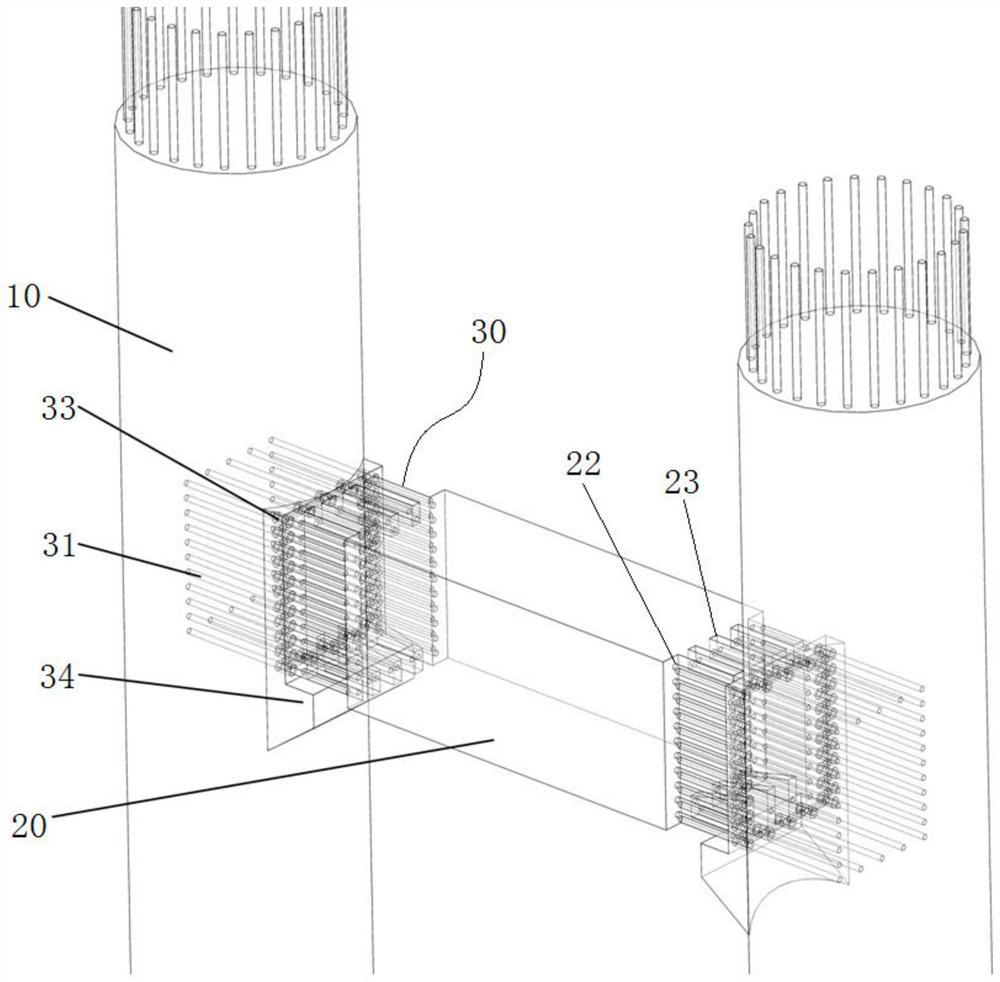

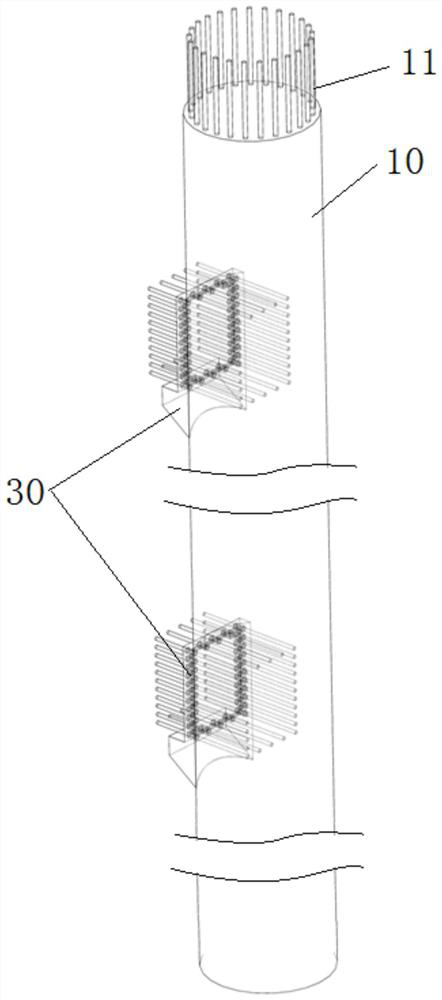

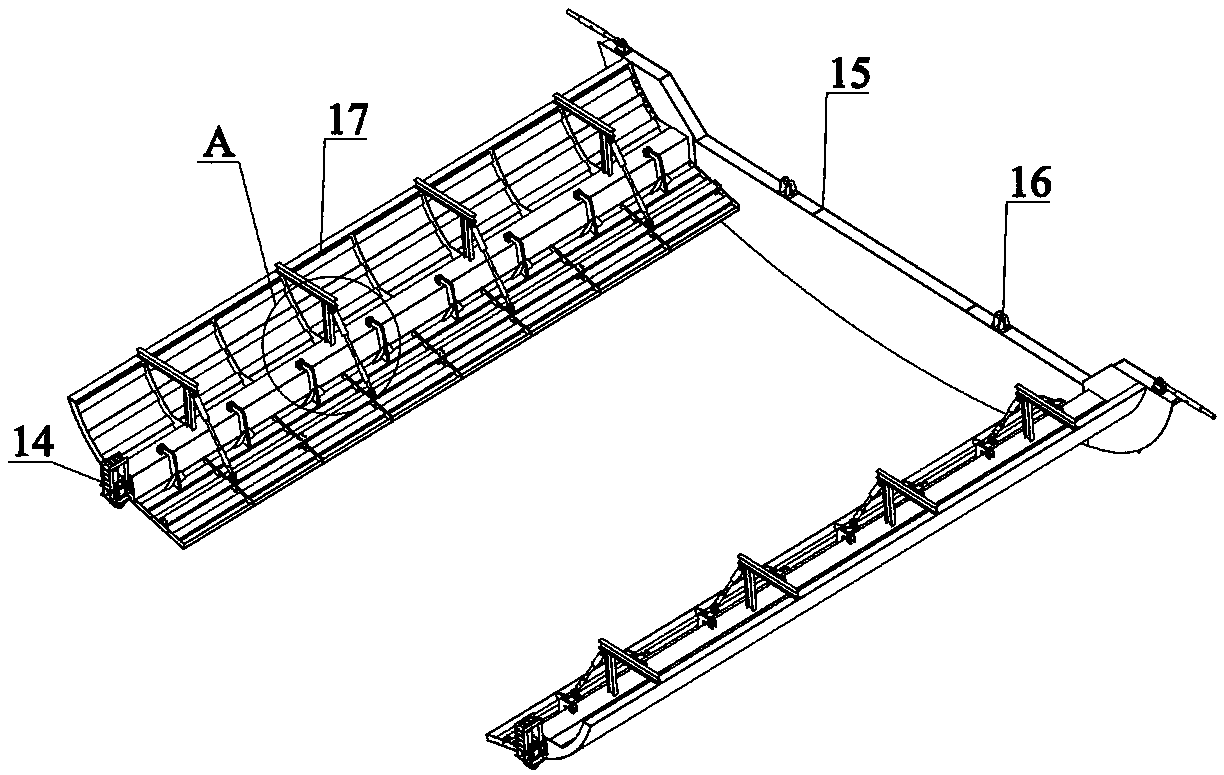

Prefabricated bridge pier and construction method thereof

PendingCN113668370AShort construction periodImprove structural strengthBridge structural detailsBridge erection/assemblyPierColumn structure

The invention relates to the field of buildings, and provides a prefabricated assembly type pier and a construction method thereof. The pier comprises a plurality of pier columns arranged at intervals in the first direction; prefabricated straining beams arranged between two adjacent pier columns in the plurality of pier columns; and connecting pieces arranged at the joints of the pier columns and the prefabricated straining beams; wherein at least part of the connecting pieces and the pier columns are integrally formed in a pouring mode, the prefabricated straining beams are provided with assembling ends, and the assembling ends are fixedly connected with the connecting pieces. The prefabricated assembly type pier has the advantages that the connecting pieces and the pier columns are integrally formed in a pouring mode, then the connecting pieces are connected with the prefabricated straining beams, and the assembling of the prefabricated straining beams and the pier columns is achieved. In the construction process, the pier columns can be continuously constructed, the construction period is short, the pier columns are not provided with splicing sections, and the pier column structure strength is high.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

Formwork system for inverted arch trestle trolley

ActiveCN111535835AConvenient pouring constructionFast demoulding speedUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention provides a formwork system for an inverted arch trestle trolley. According to the formwork system for the inverted arch trestle trolley, the inverted arch formwork is formed by hinging afixed inverted arch formwork body and a movable inverted arch formwork body, when movable inverted arch faces located on the two sides of an inverted arch layer need to be demolded, demolding can beachieved by controlling the movable inverted arch formwork body to be turned over, and the demolding speed can be increased; meanwhile, when an inverted arch formwork system does not need to be used,the movable inverted arch formwork can be overturned and contracted, so that pouring construction of filling layer concrete is facilitated, and operation is quite convenient; moreover, the formwork system composed of the inverted arch formwork system and a central ditch formwork can be driven by other traction mechanisms to achieve inverted arch operation construction of the whole tunnel with thesame section after one-time installation is completed, assembly and disassembly of the formworks are omitted, the labor intensity of workers is greatly relieved, the labor cost is saved, and the construction efficiency and the construction quality are improved.

Owner:李军

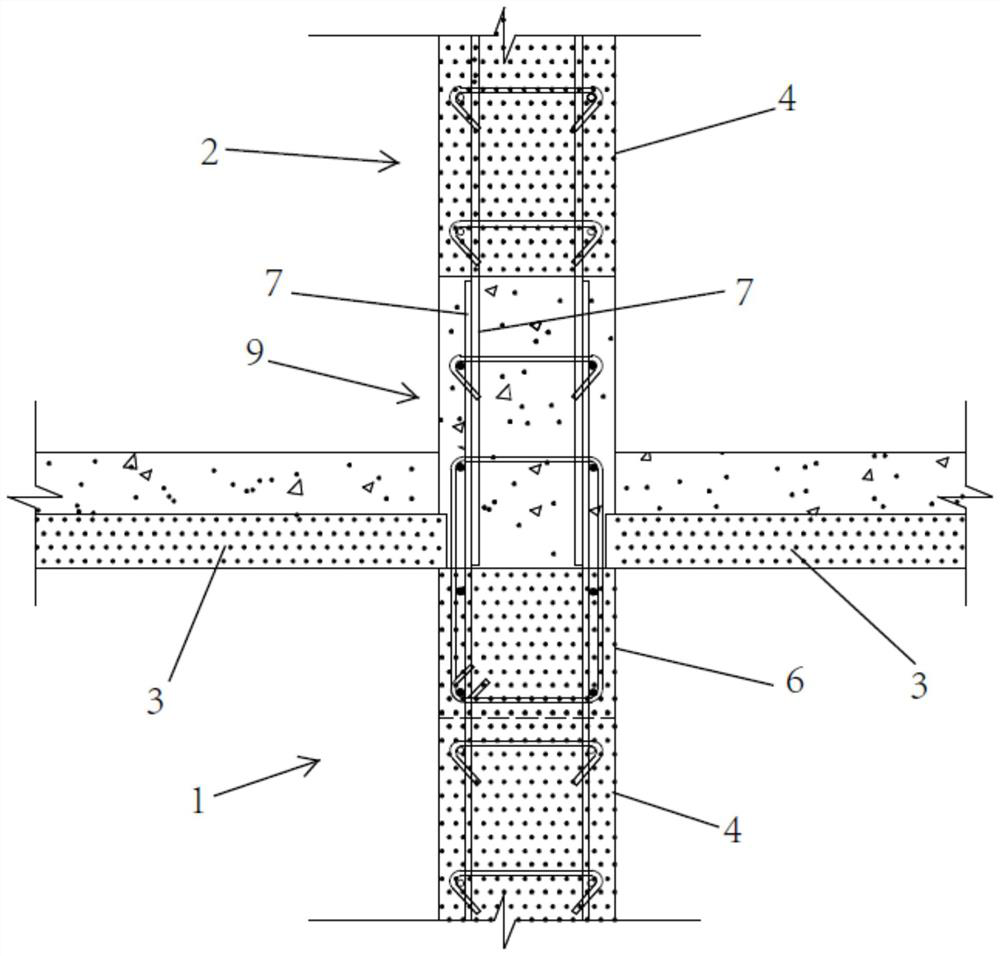

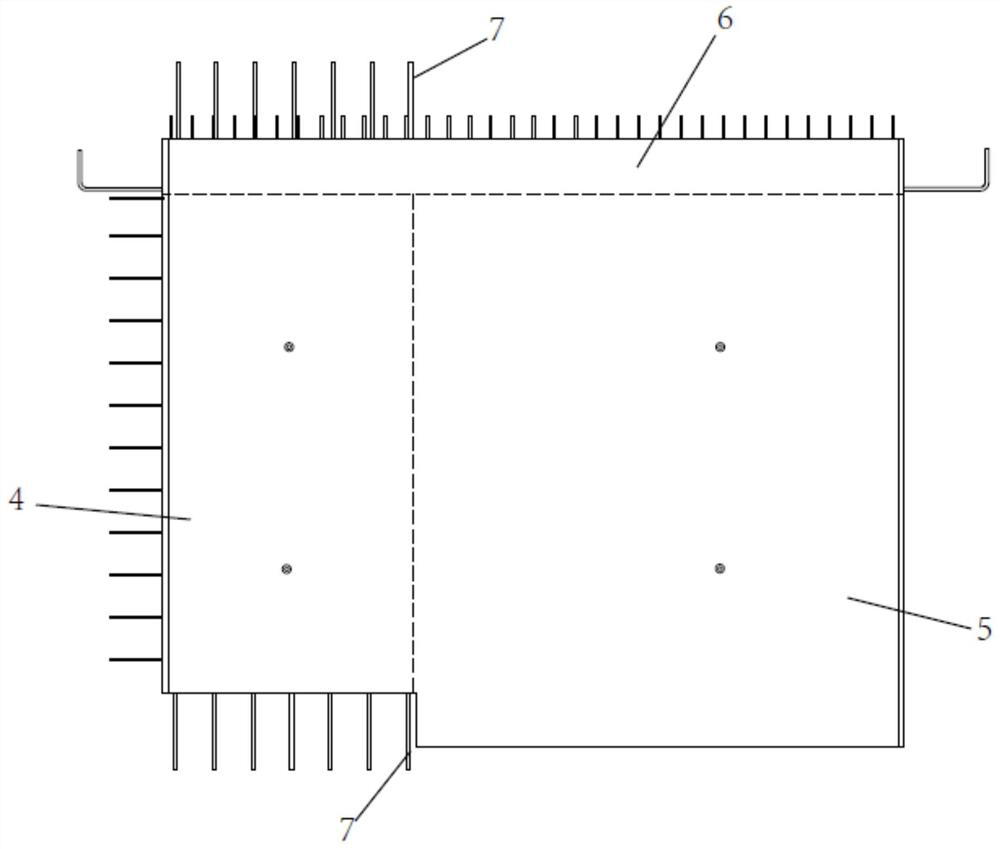

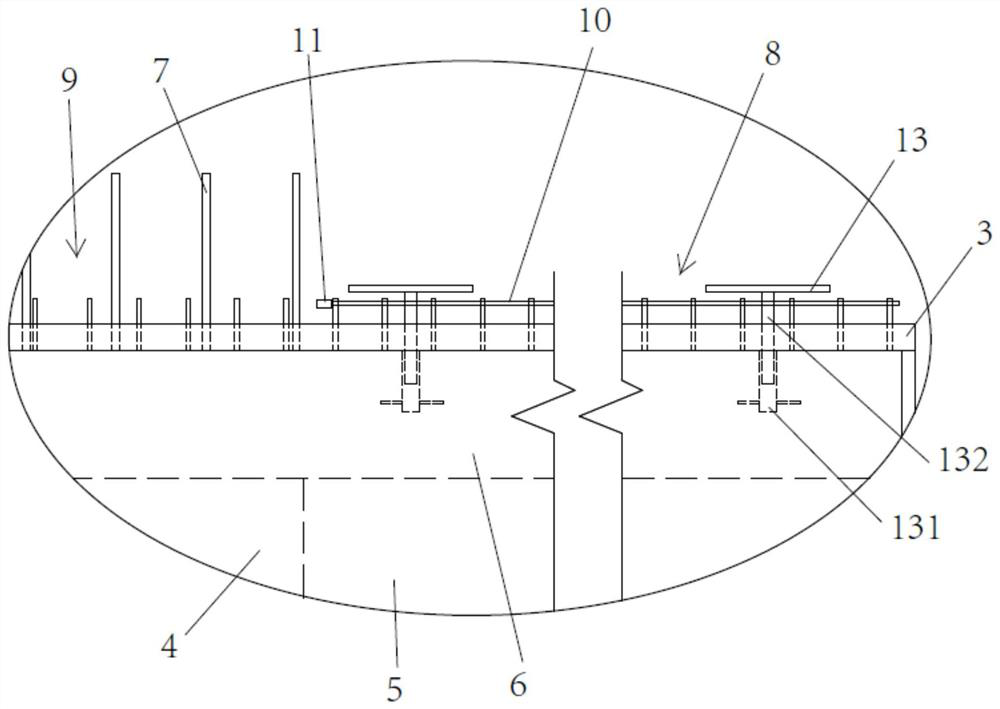

Construction method of interlayer connection joints of combined prefabricated concrete walls

ActiveCN113006321AImprove connection installation qualityConvenient pouring constructionWallsFloorsArchitectural engineeringPrecast concrete

The invention discloses a construction method of interlayer connection joints of combined prefabricated concrete walls. The construction method comprises the steps that the two combined walls and laminated slab prefabricated bottom plates on the two sides are assembled in a matched mode and poured to form the interlayer connection joints, each combined wall comprises a shear wall, a light filling wall and a laminated beam prefabricated bottom beam which are integrally prefabricated, and the bottom of each shear wall is provided with a retraction part and matched with the corresponding light filling wall to form a step structure; during construction, the tops of the laminated beam prefabricated bottom beams corresponding to the light filling walls are poured and serve as first supporting connection parts, then the upper-layer combined wall is hoisted to the position overlapped with the upper portion of the lower-layer combined wall, the bottoms of the light filling walls of the upper-layer combined wall are placed on the first supporting connection parts, then stabilizing is conducted through oblique supporting, and pouring is conducted through second post-poured concrete after the perpendicularity is adjusted; and finally, the light filling walls and the first supporting connection parts are subjected to joint filling, and construction is completed. According to the construction method, the construction sequence is reasonable, the process is convenient, fast and efficient, and the joint connection quality is easy to control.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT +1

Arching method of stiff skeleton concrete arch bridge

ActiveCN105350442BReduce construction costsReduce construction difficultyBridge erection/assemblyArch-type bridgeBridge engineeringSteel tube

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

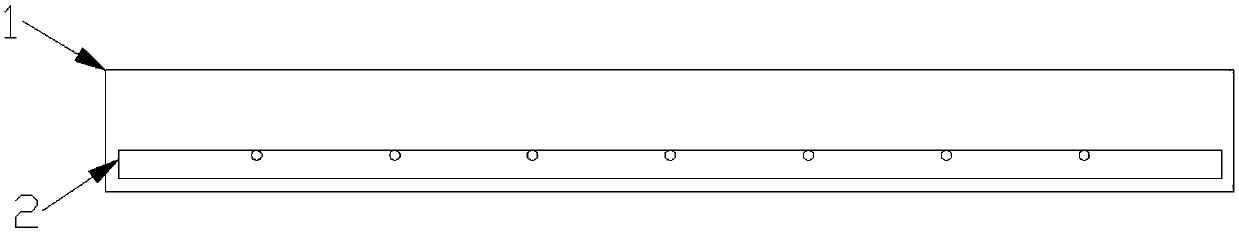

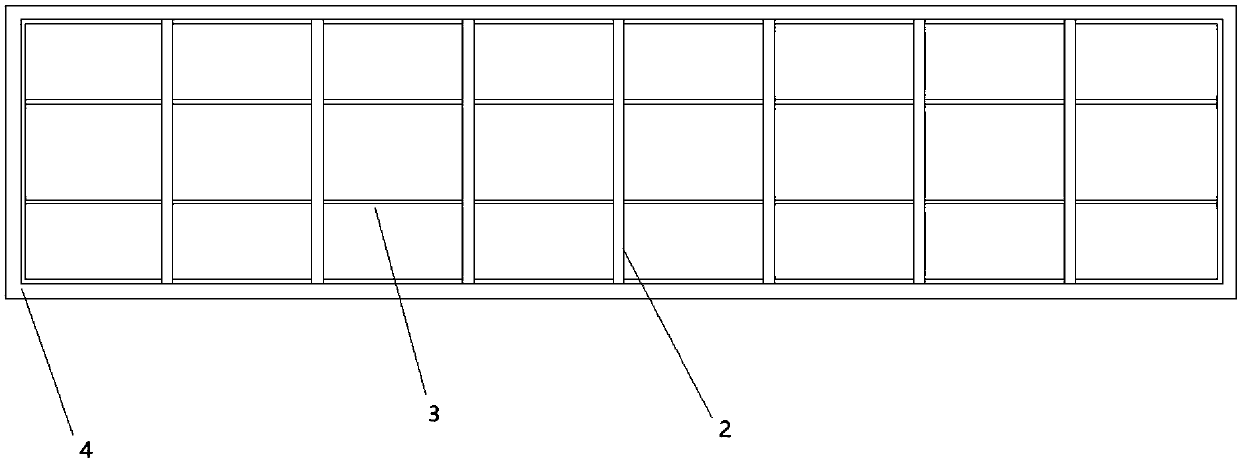

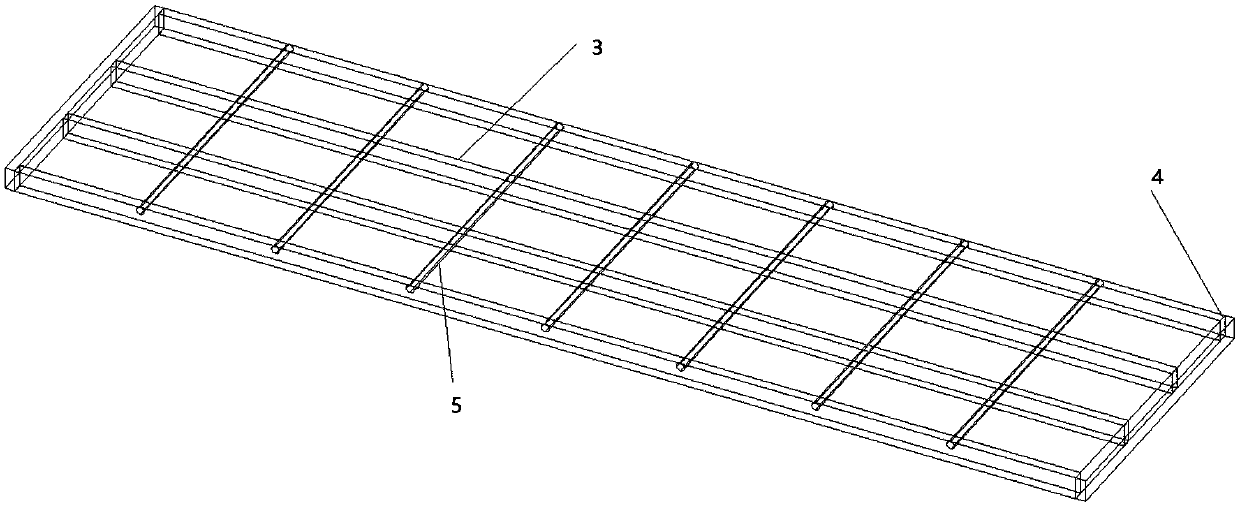

Assembly type concrete plate

InactiveCN109577127AReduce thicknessReduce quality problemsSingle unit pavingsCross connectionMechanical property

The invention relates to the technical field of concrete plates, in particular to an assembly type concrete plate. The assembly type concrete plate disclosed by the invention comprises a steel grid mesh and concrete, wherein the steel grid mesh is poured with the concrete to form the assembly type concrete plate; the steel grid mesh comprises first profile steel and second profile steel; multiplepieces of first profile steel and multiple pieces of second profile steel are connected in a crossed mode to form the steel grid mesh; and the first profile steel is longitudinal flat steel, and the second profile steel is transverse flat steel, transverse round steel or transverse twisted square steel. When the concrete plate obtains the same bearing force, the thickness and quality of the concrete plate can be reduced; when a steel ratio of the steel grid mesh is consistent with that of a reinforcing mesh, the steel grid mesh can reduce number of first profile steel and longitudinal flat steel of a frame body by regulating a geometric dimension of the first profile file and the cross section of the longitudinal flat steel of the frame body, so that spacing among the stress steel is increased, pouring construction of concrete is facilitated, and construction efficiency and mechanical properties of the concrete plate are improved.

Owner:GUANGDONG UNIV OF TECH

Formwork device for cantilever structure construction and construction method thereof

ActiveCN110409820AConvenient pouring constructionSolve the problem of no rooting pointForms/shuttering/falseworksPre embeddingCantilever

The invention relates to a formwork device for cantilever structure construction and a construction method thereof. The device comprises at least one pair of supporting rods arranged oppositely, convex extending sections, a plurality of connecting rods, first connecting members and second connecting members; each convex extending section is formed in the manner that one end is embedded in a pouredmain body structure and the other end convexly extends out of the poured main body structure and is located in a to-be-constructed cantilever structure; the opposite two ends of each connecting rod are fixed to the convex extending sections of the corresponding supporting rods; and the first connecting members are transversely fixed on the supporting rods and the bottom surfaces of the connectingrods, and transverse first slots where bottom molds are inserted are formed in the opposite two sides of each first connecting member. According to the formwork device, the supporting rods are pre-embedded in the main structure to serve as subsequent main stress members. The connecting rods and the supporting rods are used as the stress members for transversely hoisting templates so that pouringcan be carried out on the templates to form the cantilever structure.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Open cut tunnel and bridge combined underpinning integrated construction method

PendingCN114718104AWill not affect normal useImprove deformation resistanceClimate change adaptationBridge erection/assemblyArchitectural engineeringRail transit

The invention provides an open cut tunnel and bridge underpinning combined integrated construction method, belongs to the technical field of rail transit deep foundation pit engineering, and aims to meet the requirements of rapid construction of an underpass tunnel and normal passage of an upper bridge at the same time. The method comprises the steps that firstly, supporting piles, underpinning piles and fender posts are constructed; 2, the jacking holding force of the auxiliary pier is set, and the stand column is hooped; thirdly, slope excavation is conducted till the underpinning bearing platform bottom is reached, stand columns are cut off, and old bearing platforms and old pile foundations which conflict with the tunnel structure and the first horizontal supports at the upper end and the lower end are chiseled away; fourthly, water cutting is conducted on stand columns, a top ring beam and first horizontal supports at the upper end and the lower end are constructed, and then an underpinning bearing platform is constructed; fifthly, after the underpinning bearing platform reaches the design strength, the auxiliary piers are dismantled, the bearing piles are pulled out, and pile bodies on the upper portions of the shared fender posts are cut off to the elevation of the top ring beam; sixthly, foundation pit earth excavation is conducted layer by layer, and supports below the first horizontal supports at the upper end and the lower end are poured and erected; and seventhly, after excavation is conducted to the base, a tunnel structure is built back, the horizontal supports are dismantled, and construction is completed.

Owner:SHANGHAI CONSTRUCTION GROUP

The Structure and Construction Method of Preventing Perforation and Grout Leakage of Bored Pile in Water

ActiveCN104358252BReduce construction costsConvenient pouring constructionBulkheads/pilesReinforced concreteEconomic benefits

The invention relates to a structure for preventing perforated grout leakage of bored piles in water and a construction method thereof. An outer casing is arranged on the periphery of the reinforced concrete bored piles, and an outer casing is arranged between the reinforced concrete bored piles and the outer casing from top to bottom. The active material slurry-solid protection plate and the active material slurry-solid protection wall are provided with a cement-soil water-stop retaining wall under the active material slurry-solid protection wall; the diameter of the active material slurry-solid protection plate is larger than the active material slurry-solid protection wall and the cement-soil water-stop protection wall; A reinforcement cage is arranged in the middle of the active material slurry reinforcement plate to position the embedded parts; the reinforced concrete bored pile is formed by placing a reinforcement cage in the inner casing and then pouring concrete. The casing of the invention has good structural stability, good environmental protection and relatively low manufacturing cost, can effectively prevent perforated grout leakage of bored piles in water, and has good technical and economic benefits.

Owner:德达交通建设发展集团有限公司

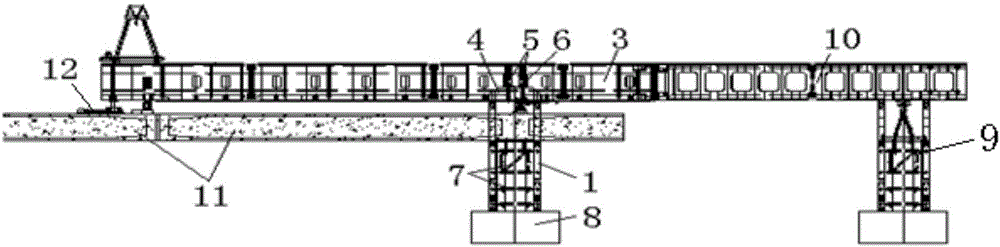

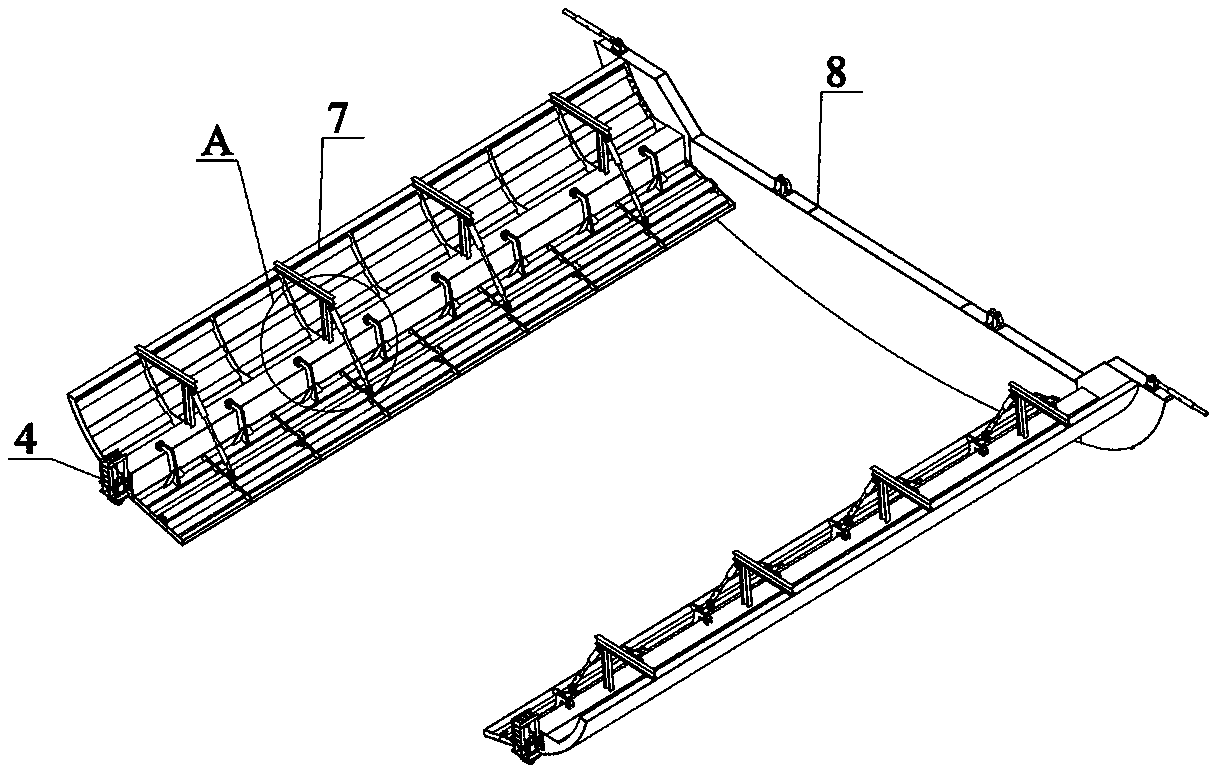

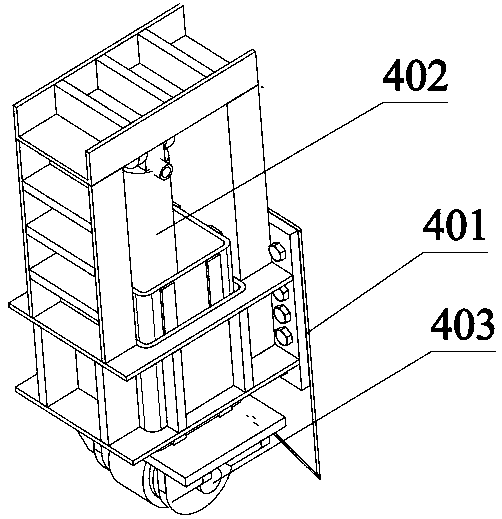

Automatic hydraulic inverted trestle trolley and its construction method

ActiveCN105649654BReduce labor intensityReduce labor costsUnderground chambersTravelling bridgesBogieRebar

The invention discloses an automatic hydraulic inverted arch trestle trolley which comprises a trestle system and inverted arch mold frame systems, wherein a trestle bogie is arranged on the trestle system, and is connected with the inverted arch mold frame systems; each inverted arch mold frame system comprises an inverted arch mold longitudinal beam and an arc inverted arch template group; each arc inverted arch template group comprises a fixed inverted arch template and a movable inverted arch template; a stretching mechanism is arranged between each movable inverted arch template and the corresponding inverted arch mold longitudinal beam; lifting supporting legs are arranged at the bottom of an inverted arch template transversal beam; an inverted arch travelling mechanism capable of stretching up and down is arranged at the bottom of the tail end of each inverted arch mold longitudinal beam; transversal moving mechanisms are arranged at the two ends of the trestle system in the longitudinal direction; trestle travelling wheels are arranged at the tail ends of the trestle system. A trolley construction method comprises the following steps: moving trestle in position, excavating inverted arch, binding steel bars, demolding the inverted arches, moving molds in position, and molding and pouring. According to the invention, quick inverted arch operation conduction of a whole tunnel on the same fracture surface can be realized, assembly and disassembly of the templates are avoided, the labor intensity of workers is greatly reduced, and the construction efficiency and the construction quality are improved.

Owner:HUNAN WUXIN MACHINERY

Jack balance device and mobile formwork for mobile formwork

ActiveCN106192772BConvenient pouring constructionReduce the problem of unbalanced load of support force caused by disturbanceBridge erection/assemblyEngineeringBuilding construction

The invention discloses a jack balance device for a mobile formwork, which comprises a plurality of balance beams arranged parallel to the longitudinal axis of the main beam of the mobile formwork, and the plurality of balance beams are respectively erected on the middle legs of the mobile formwork at the positions On the outrigger units on both sides of the main beam, a balance mechanism for stably applying a vertical force and controlling force deviation is provided between the balance beam and the main beam. The balance mechanism can control the force deviation of the reaction force fed back by the main girder while applying the vertical force, reducing the problem of unbalanced support force caused by the disturbance of the main girder itself. The middle leg can balance the force, In order to ensure the safety of the overall equipment and construction quality.

Owner:CCFEB CIVIL ENG

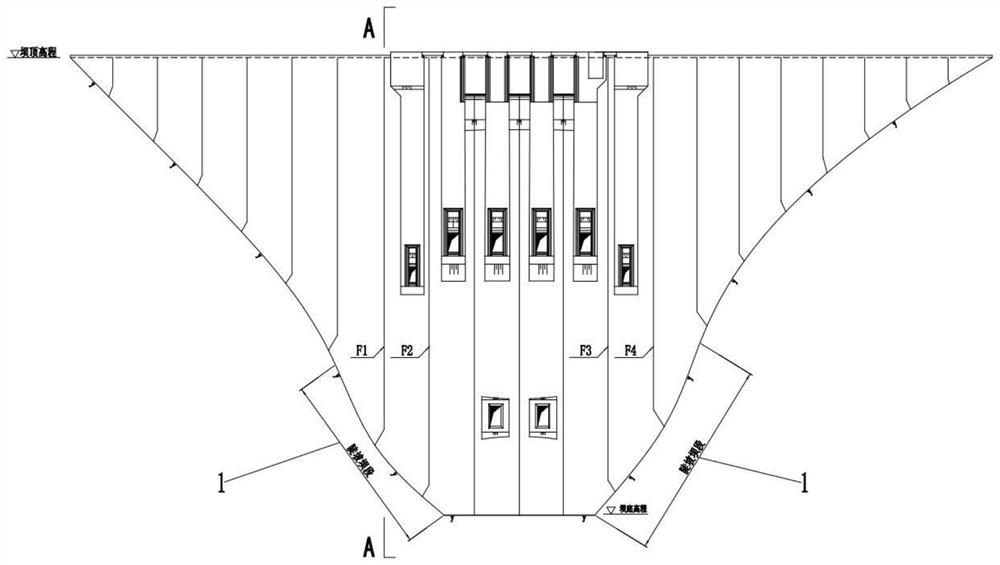

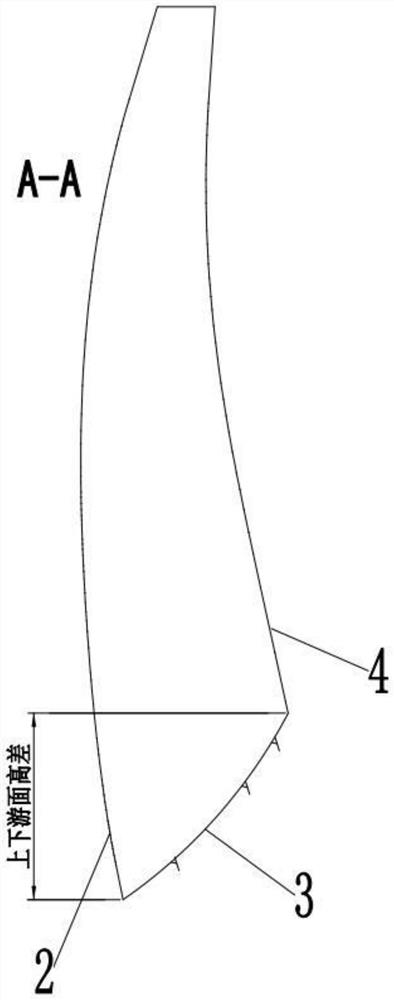

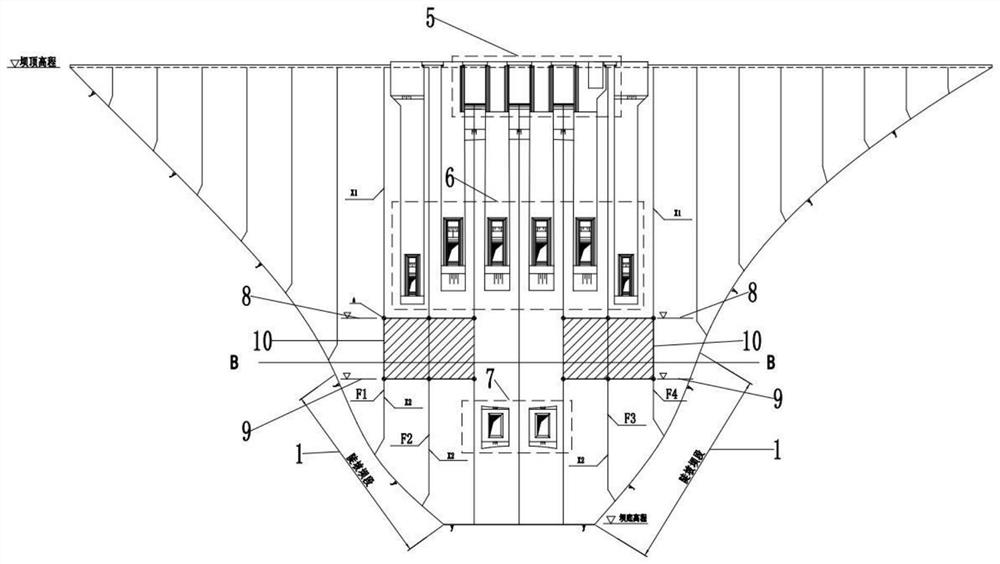

Design method for transverse joint of arch dam of abrupt slope dam section

PendingCN114239113AConvenient pouring constructionImprove stress distributionGeometric CADDesign optimisation/simulationStructural engineeringArch dam

The abrupt slope dam section arch dam transverse joint design method comprises the following steps that (1) the joint position is determined, specifically, the basic position of transverse joint arrangement of an abrupt slope dam section is determined according to the standard requirement of an arch dam in combination with the size of a dam body flood discharge hole and the structural arrangement of holes in the dam; calculating coordinates of an intersection point of each seam and the dam axis according to the dam axis curvilinear equation and the parting length; (2) selecting a transverse joint transition interval of the abrupt slope dam section; (3) determining the arrangement of the transverse joints above the first control elevation; (4) determining the arrangement of a transverse joint below a second control elevation; and (5) determining the arrangement of a transition joint between the first control elevation and the second control elevation. According to the abrupt slope dam section arch dam transverse joint design method, pouring construction of the abrupt slope dam section and the transverse joint face is facilitated, and stress distribution of a triangular body of the abrupt slope dam section is improved.

Owner:YELLOW RIVER ENG CONSULTING

A construction method for interlayer connection nodes of combined prefabricated concrete walls

ActiveCN113006321BImprove connection installation qualityConvenient pouring constructionWallsFloorsArchitectural engineeringPrecast concrete

The invention discloses a construction method for interlayer connection nodes of a combined prefabricated concrete wall, which comprises two combined walls and prefabricated bottom plates of laminated plates on both sides which are assembled and poured together, and the combined wall includes an integrated prefabricated shear The prefabricated bottom beam of force wall, lightweight infill wall and composite beam, the bottom of the shear wall is provided with an indentation and cooperates with the light infill wall to form a stepped structure; during construction, the composite beam corresponding to the light infill wall is prefabricated first The top is poured and used as the first supporting connection, and then the upper combined wall is hoisted to a position above and overlapping with the lower combined wall, and the bottom of the lightweight infill wall of the upper combined wall is placed on the first supporting connection Then use oblique supports for stabilization, adjust the verticality and use the second post-cast concrete for pouring; finally fill the joint between the lightweight filling wall and the first support to complete the construction. The construction sequence of the invention is reasonable, the process is convenient and efficient, and the node connection quality is easy to control.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT +1

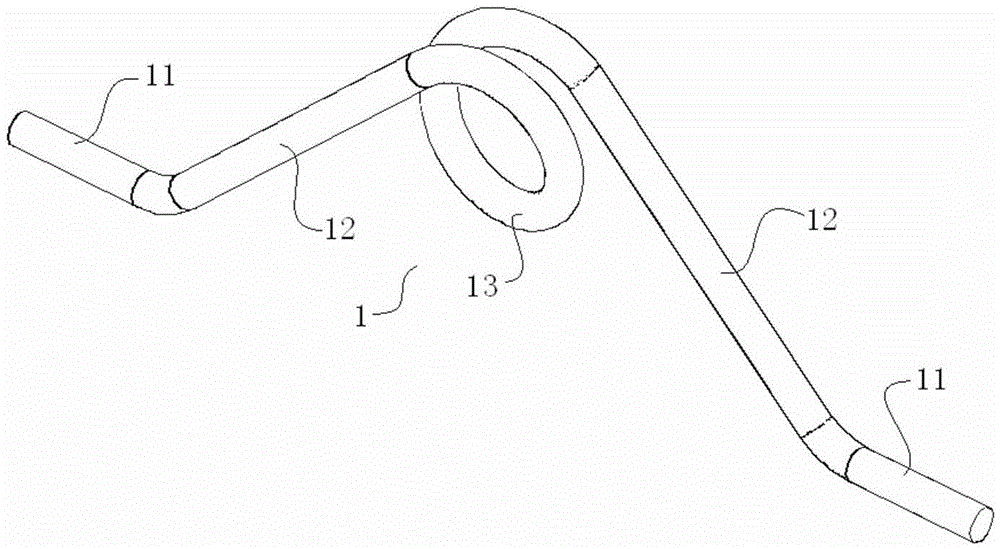

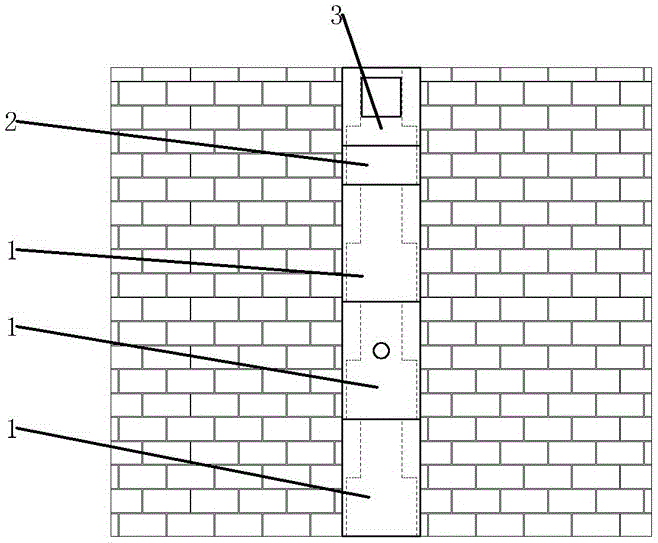

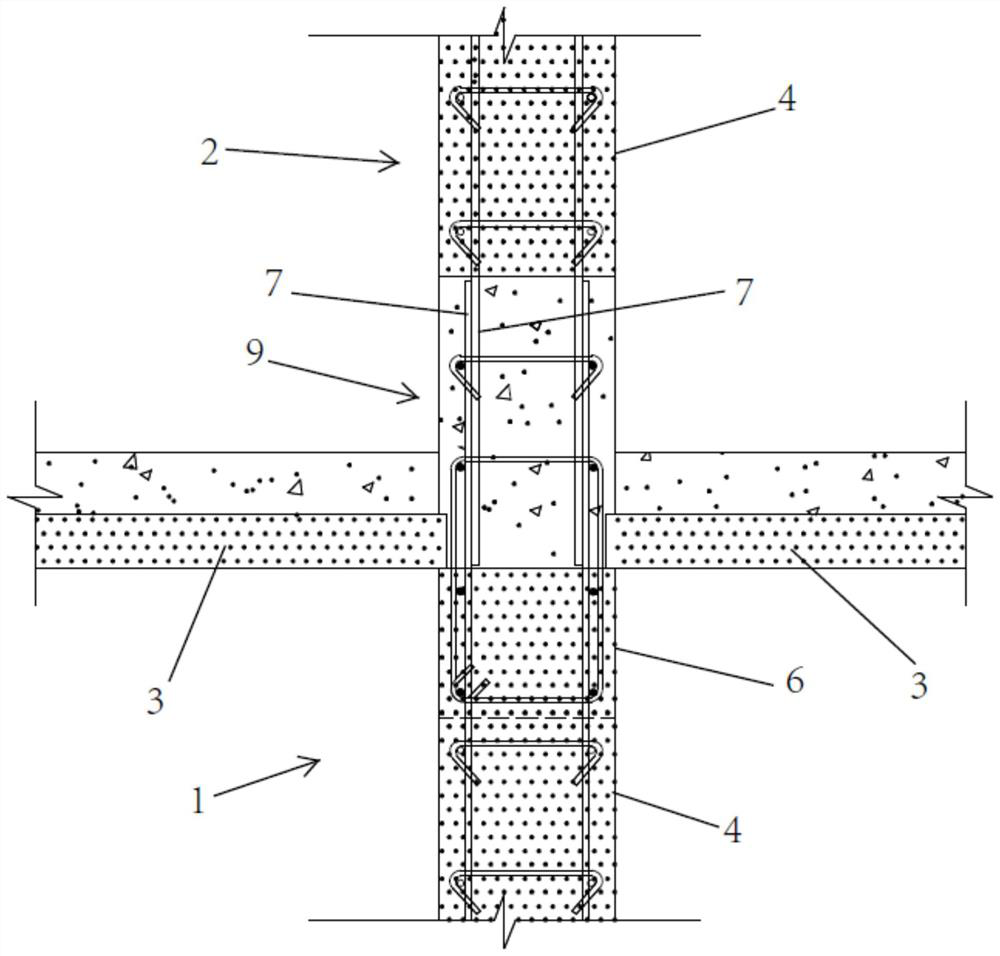

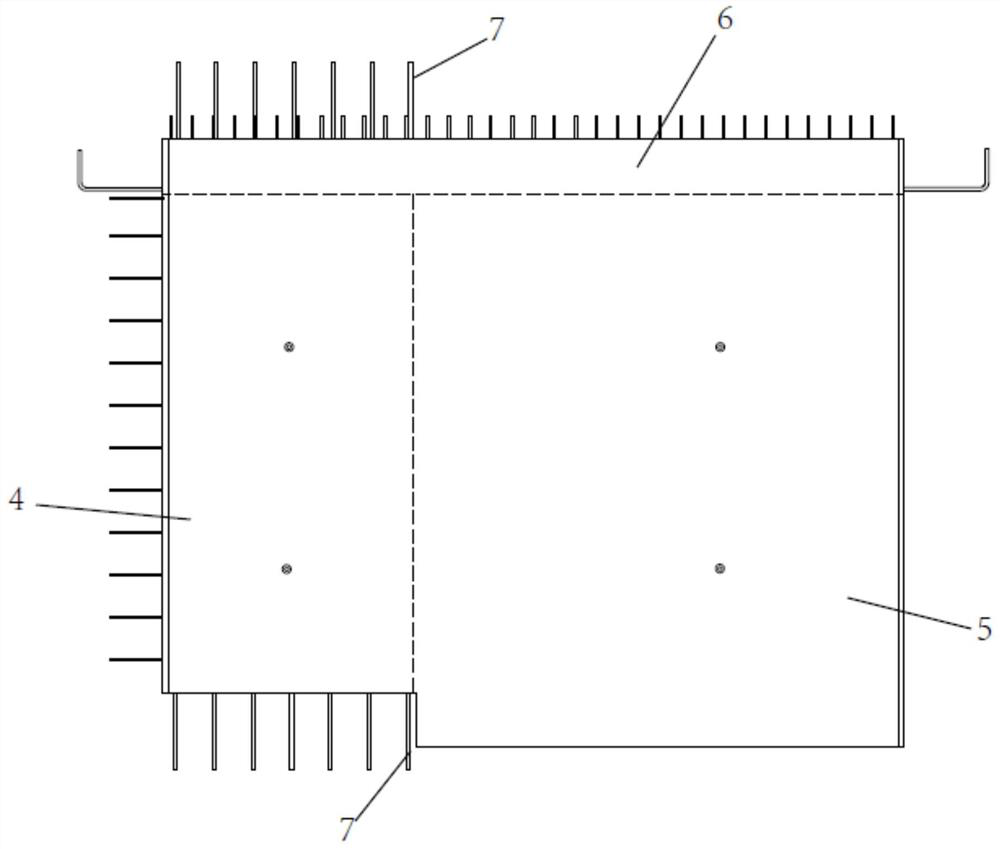

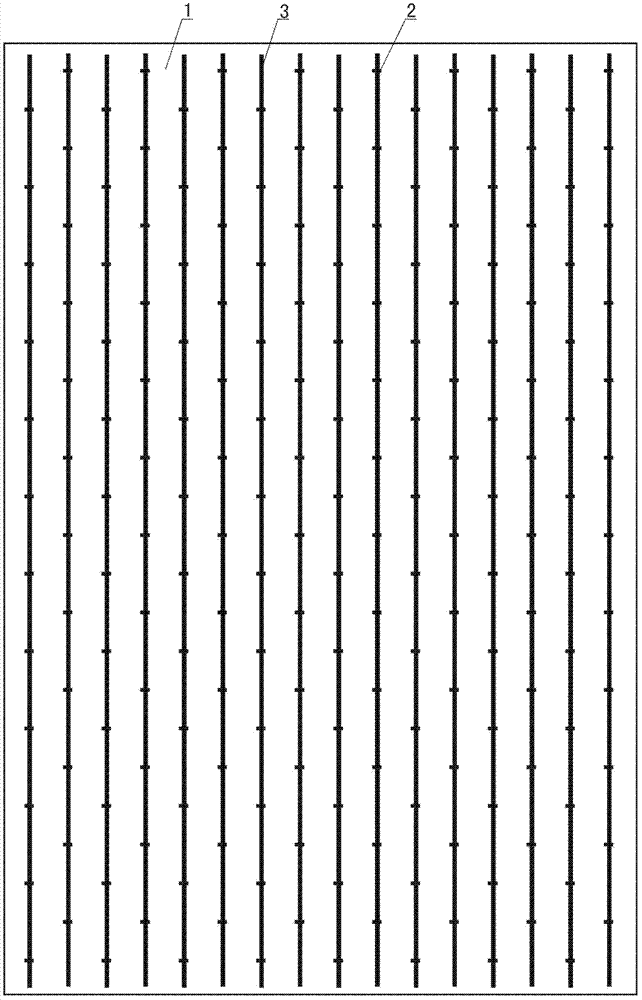

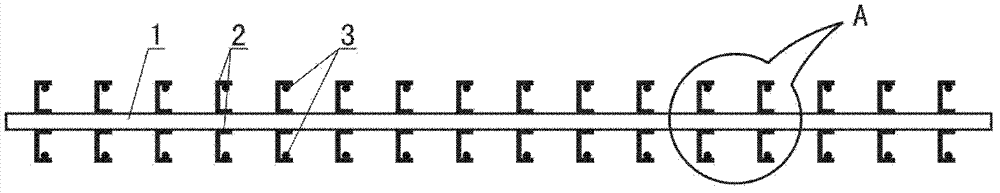

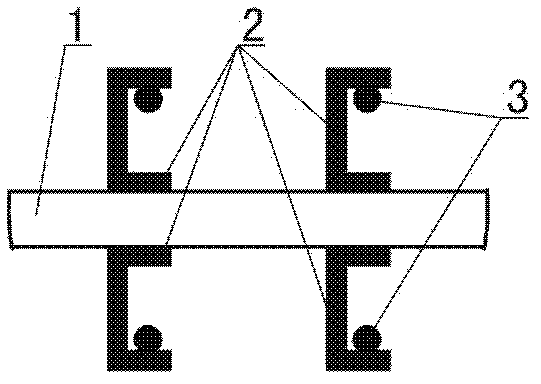

Mounting and fixing device for steel plate wall

InactiveCN103362249AControl thicknessImprove construction qualityBuilding componentsSheet steelLong axis

The invention discloses a mounting and fixing device for a steel plate wall. The mounting and fixing device comprises a steel plate, wherein the long axis direction of the steel plate is perpendicular to the short axis direction of the steel plate; a plurality of pull hooks are respectively welded on a front large plane and a back large plane of the steel plate by taking the long axis direction of the steel plate as a longitudinal direction and the short axis direction of the steel plate as a transverse direction; a plane formed by each pull hook is perpendicular to the large planes of the steel plate; a plurality of longitudinal upright steel bars are welded on the front large plane and the back large plane of the steel plate respectively through the pull hooks and are uniformly and flatly arranged on the large planes of the steel plate. According to the mounting and fixing device, the pull hooks are welded on the two planes of the steel plate, and the upright steel bars are connected with one another through the pull hooks, so that the steel plate, the pull hooks and the upright steel bars form a whole; and therefore, the integrated rigidity is improved, the stability of the steel plate wall can be guaranteed, and the steel plate wall can not deform; the pull hooks can also improve the bonding strength between the steel plate wall and concrete, so that casting construction is facilitated; the pull hooks can also replace studs, so that steel materials are saved, and the working efficiency is improved.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com