Composite shear connection piece of steel-concrete structure and manufacturing and installing method thereof

A technology of concrete structure and installation method, applied in the direction of load-bearing elongated structural components, structural elements, building components, etc. The effect of strong lifting ability and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

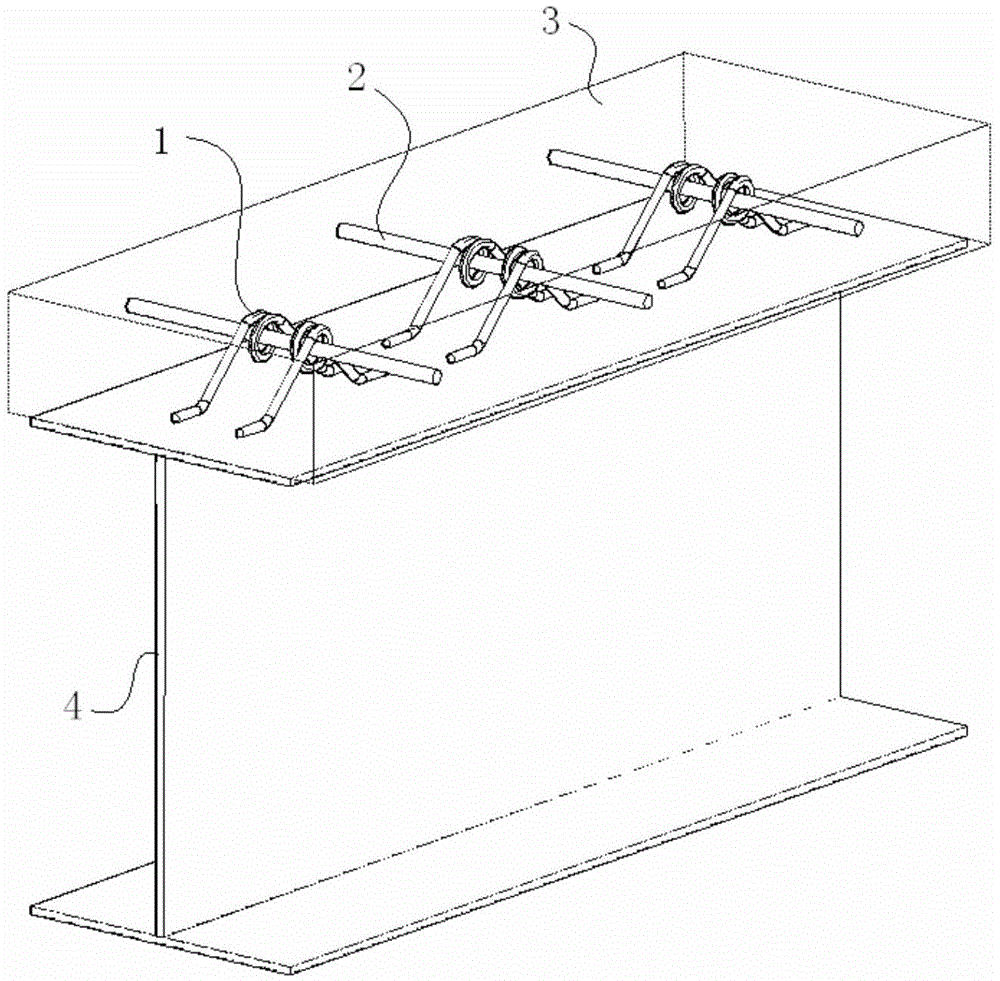

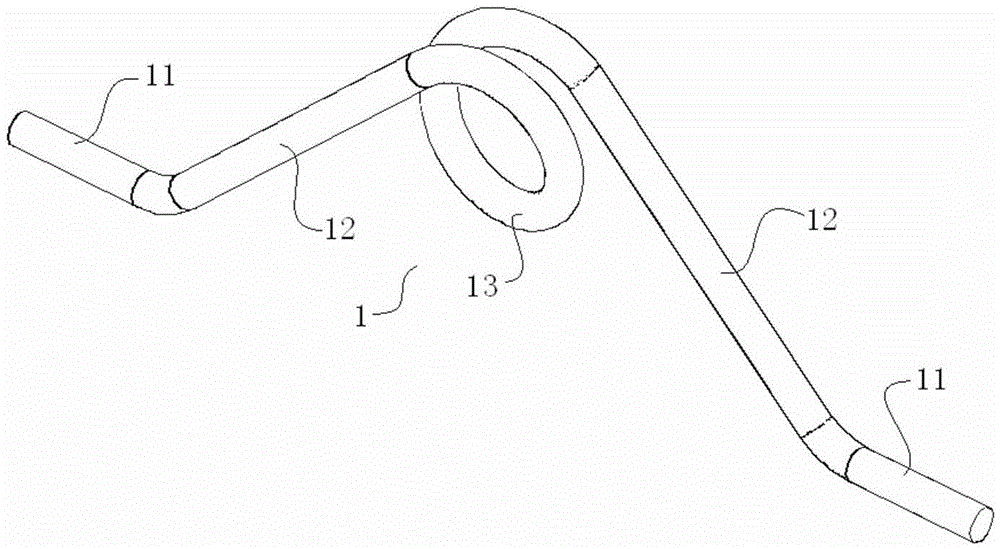

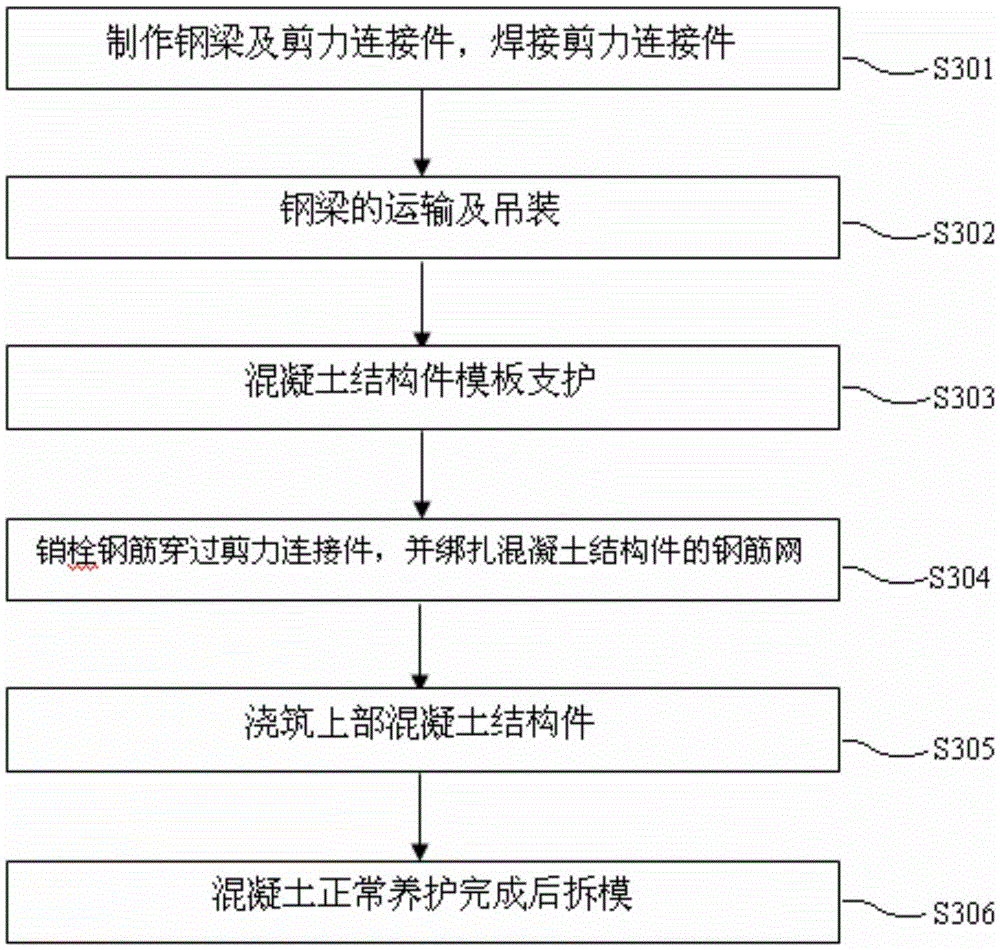

[0039] Such as figure 1 and figure 2 As shown, the composite shear connector of the embodiment of the present invention includes a shear connector 1 bent by a steel bar and a pin bolt steel bar 2 passing through the round hole of the connector, and the shear connector 1 bent by a steel bar is composed of The two groups are respectively provided with the straight section 11 and the bent section 12, and the spiral ring 13 connected at the intersection of the bent section; the straight sections 11 located at both ends of the shear connector are arranged horizontally, In order to carry out double-sided welding and fixed connection with the upper flange steel plate of the lower section steel beam 3, one end of the two groups of curved sections 12 is connected with the straight section 12 by a circular arc transition, and the other end is respectively the starting position and key point of the spiral ring 13 The location is tangentially connected. When steel bars are used to bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com