Component for tubular well precipitation construction in elevator foundation pit or sump and construction method

A construction method and sump technology, which are applied in infrastructure engineering, construction, etc., can solve the problems of long time consumption, hidden danger of water backflow, buried underground, etc., achieve good economic and social benefits, improve strength and durability Sex, the effect of small impact on the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to describe the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

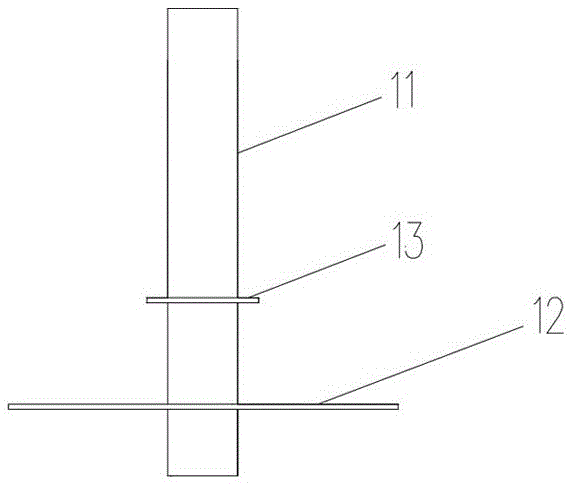

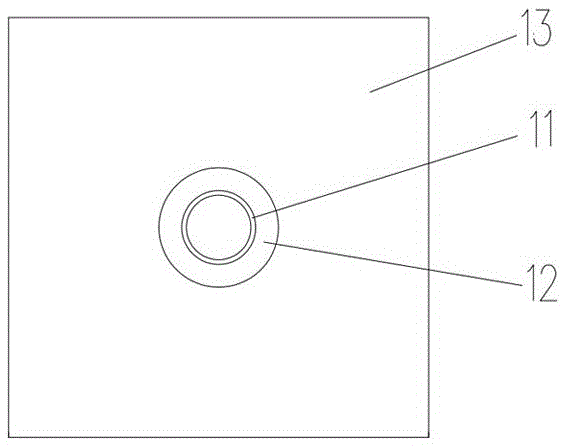

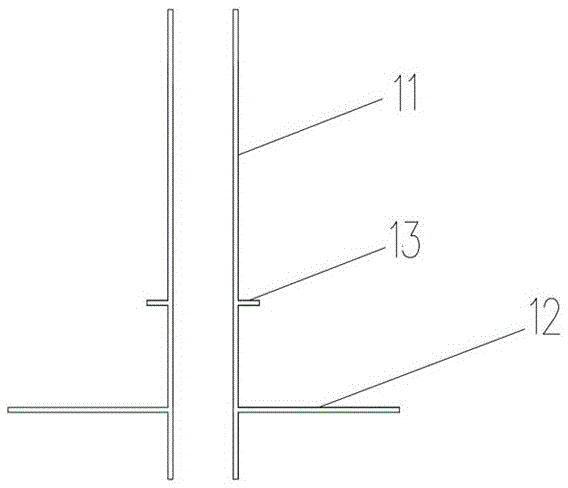

[0041] A component 1 for the dewatering construction of a tube well in an elevator foundation pit or sump pit, see Figure 1-3 , including a hollow casing 11, the lower part of the casing 11 is perpendicular to the casing 11 and is provided with a horizontal support plate 12, the casing 11 is provided with a cornice 13 above the support plate 12, and the casing 11 runs through the cornice 13 and the support plate 12 , the eaves 13 and the support plate 12 are fixed and seamlessly connected with the casing 11; the lower part of the casing 11, which is located below the support plate 12, is used to insert into the tube well, and the support plate 12 is used to support the casing 11 on a horizontal frame placed outside the tube well mouth .

[0042] Wherein, the casing 11 is a sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com