Mounting and fixing device for steel plate wall

A technology of fixing device and steel plate wall, which is applied to building components, buildings, building structures, etc., can solve the problems of small welding width of stiffeners, poor stability effect, and reduced construction efficiency, so as to facilitate pouring construction and increase bonding. strength, and the effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

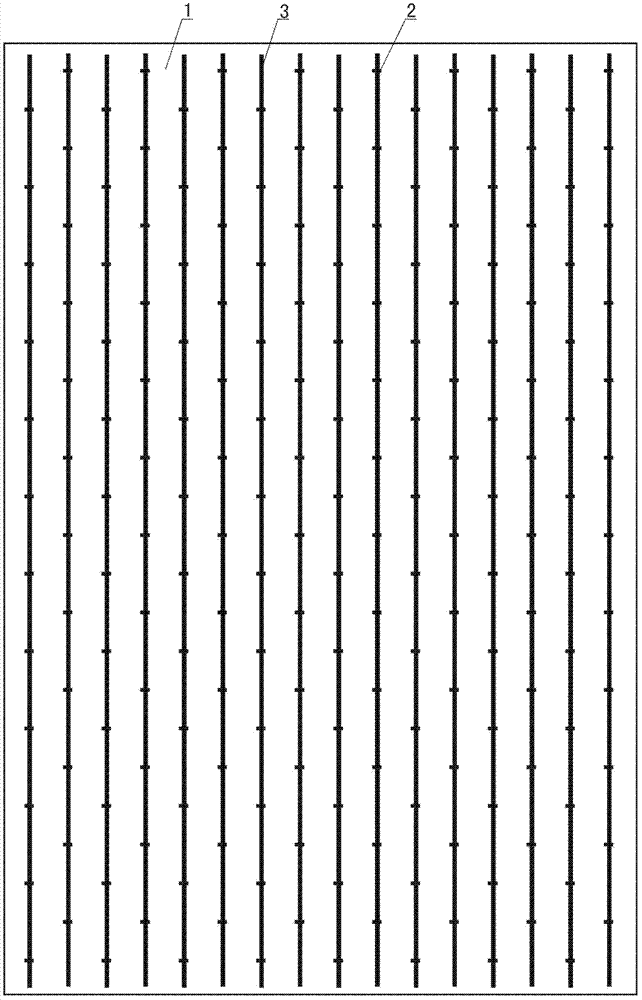

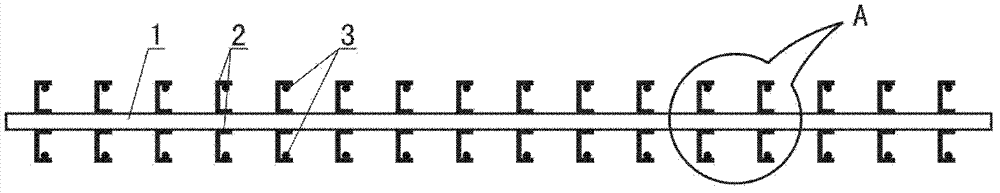

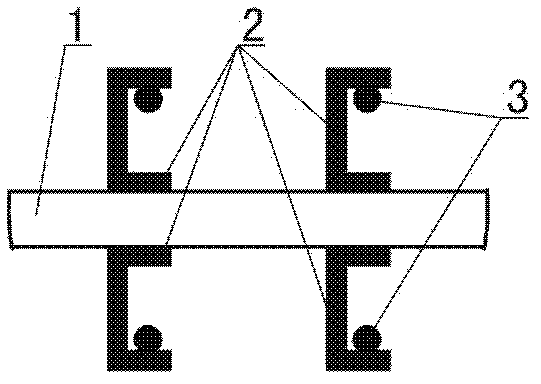

[0023] like figure 1 , figure 2 and image 3 As shown, the present invention comprises rectangular steel plate 1, 匚-shaped drag hook 2 and vertical reinforcing bar 3, with the major axis direction of steel plate 1 being the long side direction as the up and down direction, and the short axis direction of steel plate 1 being the broad side direction as the left and right direction, The front and rear two large planes of the steel plate 1 are respectively welded with a plurality of 匚-shaped pull hooks 2, and the adjacent 匚-shaped pull hooks 2 are welded and installed on the large plane of the steel plate 1 in a quincunx shape, and each 匚-shaped pull hook 2 is formed by itself The plane is perpendicular to the large plane of the steel plate 1, and the plane formed by each 匚-shaped drag hook 2 itself is parallel to the horizontal plane. On the last two large planes, a plurality of vertical steel bars 3 in the up and down direction are welded and installed respectively through t...

Embodiment 2

[0025] like Figure 4 , Figure 5 and Figure 6 As shown, if the steel plate has a large area and a large width in the minor axis direction, it is necessary to install the transverse reinforcement 4 by welding to avoid deformation of the steel plate 1 in the minor axis direction. This structure completely comprises the structure in embodiment 1, promptly comprises rectangular steel plate 1, 匚-shaped drag hook 2 and vertical reinforcing bar 3, and the connection structure between rectangular steel plate 1, 匚-shaped drag hook 2 and vertical reinforcing bar 3 is also identical with embodiment 1, the following structures are added on this basis: the front and rear two large planes of the steel plate 1 are respectively welded and installed with a plurality of horizontal steel bars 4 in the left and right directions through the 匚-shaped pull hook 2, and the multiple horizontal steel bars 4 are evenly tiled Installed on the large plane of the steel plate 1; the distance between adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com