Patents

Literature

85results about How to "Reduce shear rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gelled hydrocarbon compositions and methods for use thereof

InactiveUS6849581B1Improve stabilityAvoid stabilityOrganic detergent compounding agentsSurface-active detergent compositionsOrganic baseOrganic fluid

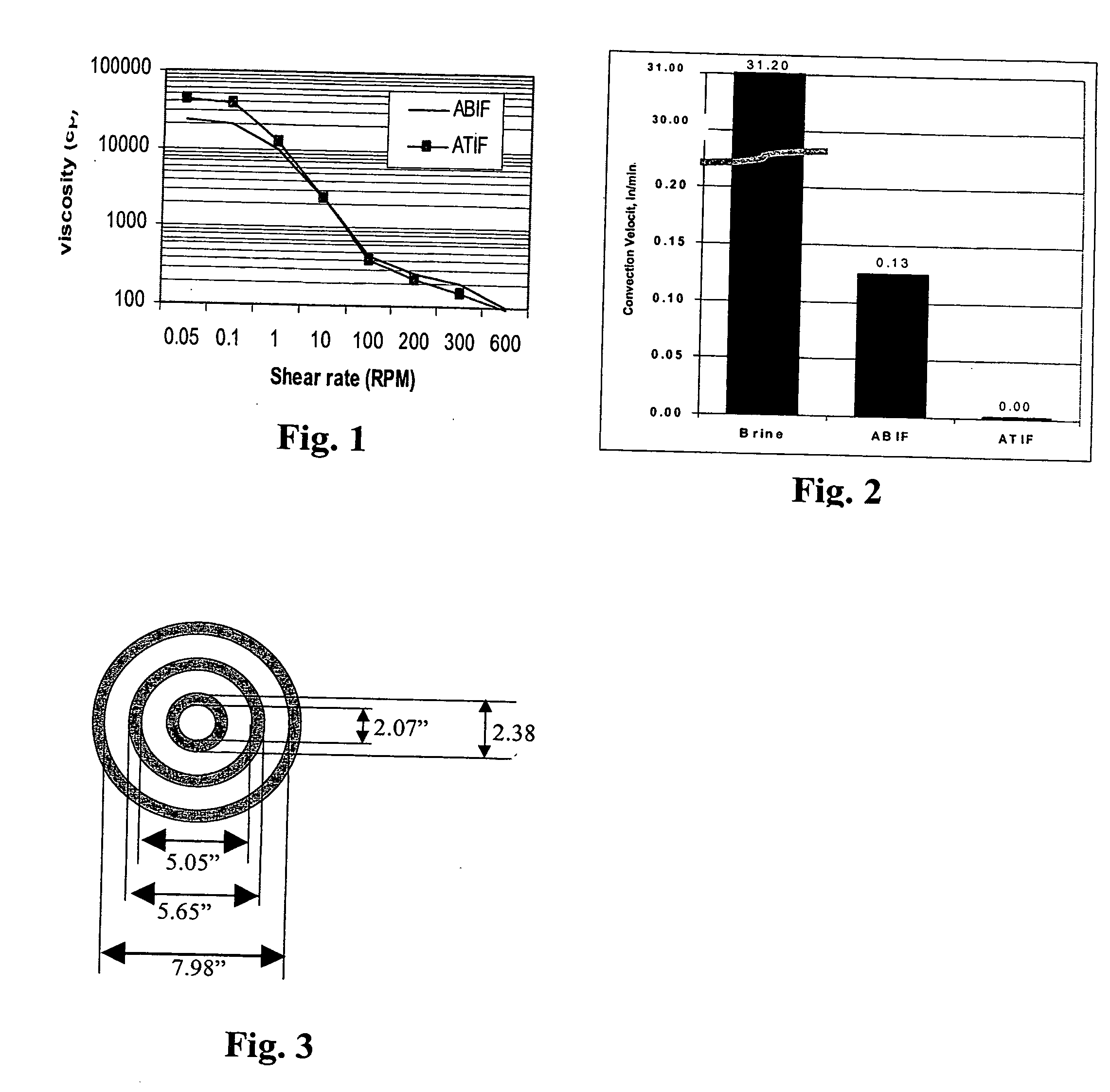

Gelled organic compositions and methods for using same. The gelled compositions may be liquid organic fluids, such as gelled liquid hydrocarbons, formed from a mixture of an organic-base fluid, a carboxylic acid, and one or more metal source compounds, such as a metal salt of carboxylic acid. The gelled compositions may be used in variety of applications including, but not limited to, oil field, pipeline and processing facility applications.

Owner:BJ SERVICES LLC +1

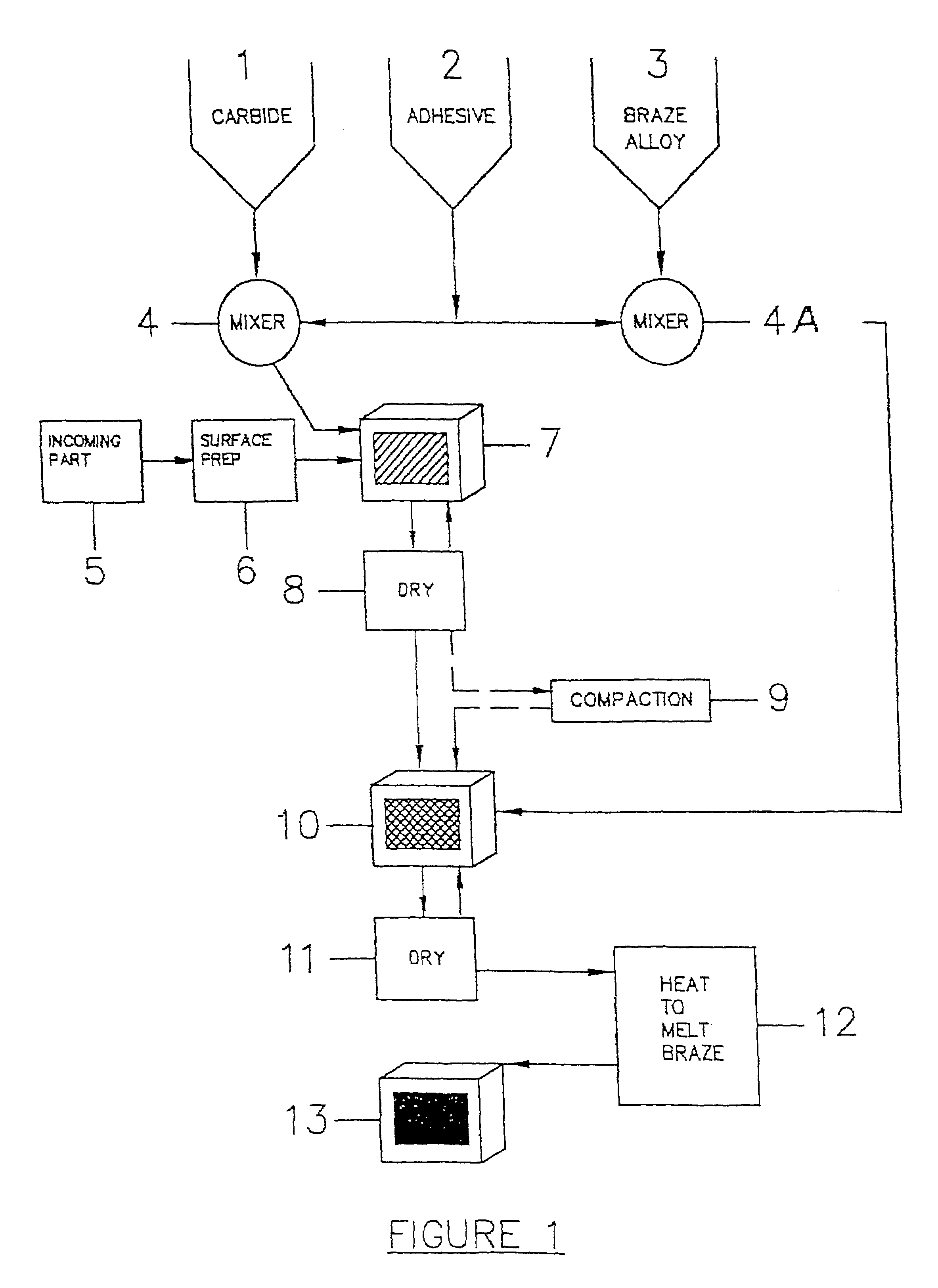

Process for making wear-resistant coatings

InactiveUS7262240B1Readily be sprayed onto substrateHigh viscosityAnti-corrosive paintsMetallic material coating processesCross-linkWear resistant

A paint system and process are disclosed for hardfacing metal surfaces. In one embodiment of the process, a paint including a dispersion of hard particles is first applied as a coating to a surface. Next, a paint including a dispersion of a braze alloy is applied over the layer of hard particles. The surface is then heated to cause the braze alloy to melt and infiltrate into the hard particles thereby bonding them to the metallic surface. In another embodiment, a first layer of adhesive is applied, and a hardfacing powder is applied onto the adhesive. Then a second layer if adhesive is applied, and a braze alloy powder is applied onto the second adhesive. Then the material is heated as in the first embodiment. In another embodiment, paint containing hard particles is coated onto the substrate, and an acid-containing cross-linked copolymer in the paint is then neutralized to increase the viscosity of the paint to prevent running.

Owner:KENNAMETAL INC

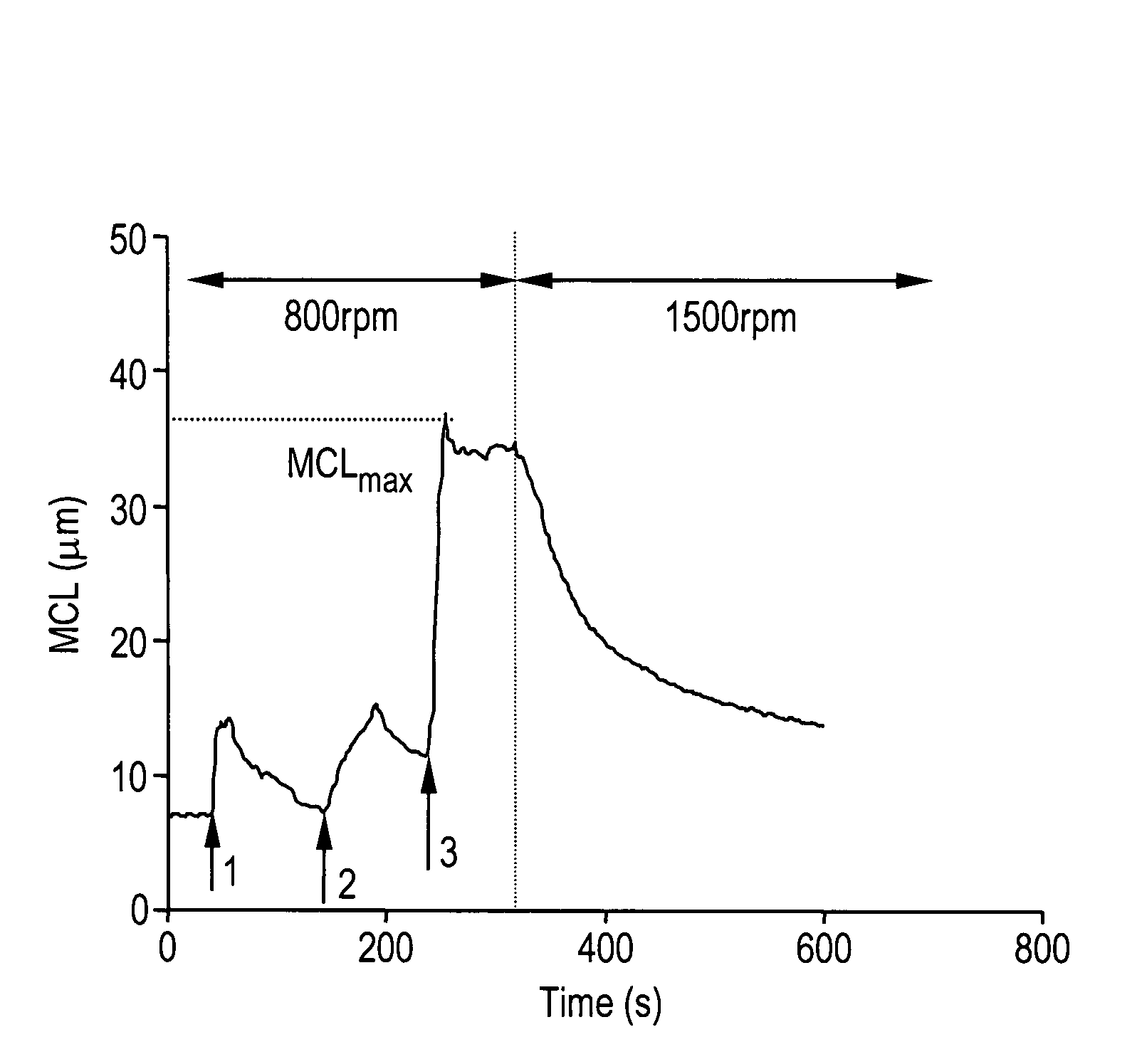

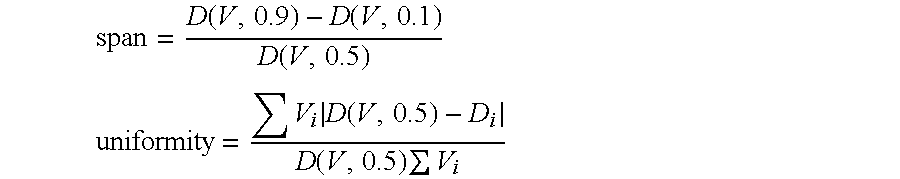

Controllable filler prefloculation using a dual polymer system

ActiveUS8172983B2Reduce molecular weightLess viscousNatural cellulose pulp/paperSpecial paperPolymer scienceAqueous dispersion

A method of preparing a stable dispersion of flocculated filler particles for use in papermaking processes comprises sequential addition of high and low molecular weight flocculating agents to an aqueous dispersion of filler particles followed by shearing of the resultant filler flocs to the desired particle size resulting in shear resistant filler flocs with a defined and controllable size distribution.

Owner:ECOLAB USA INC

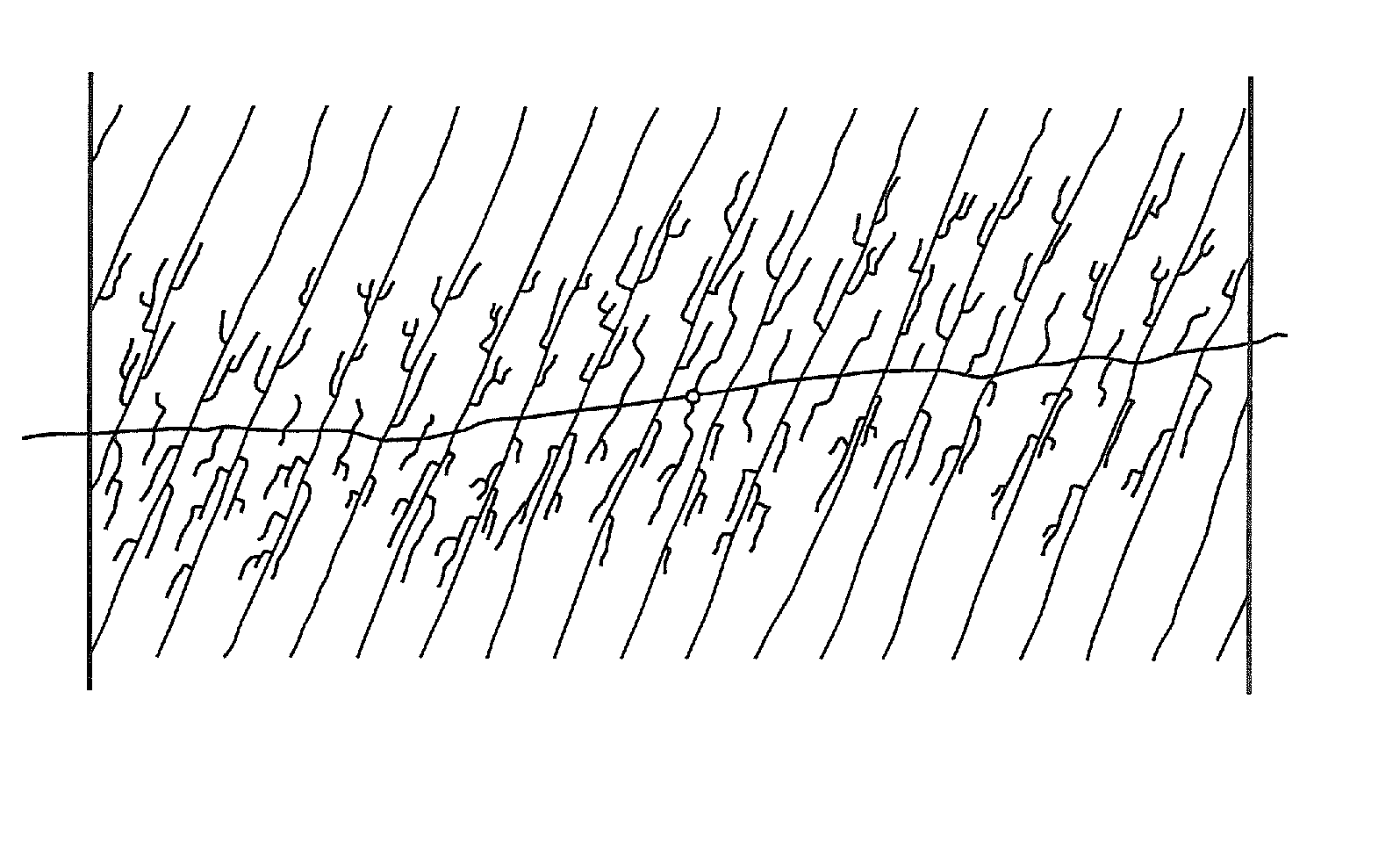

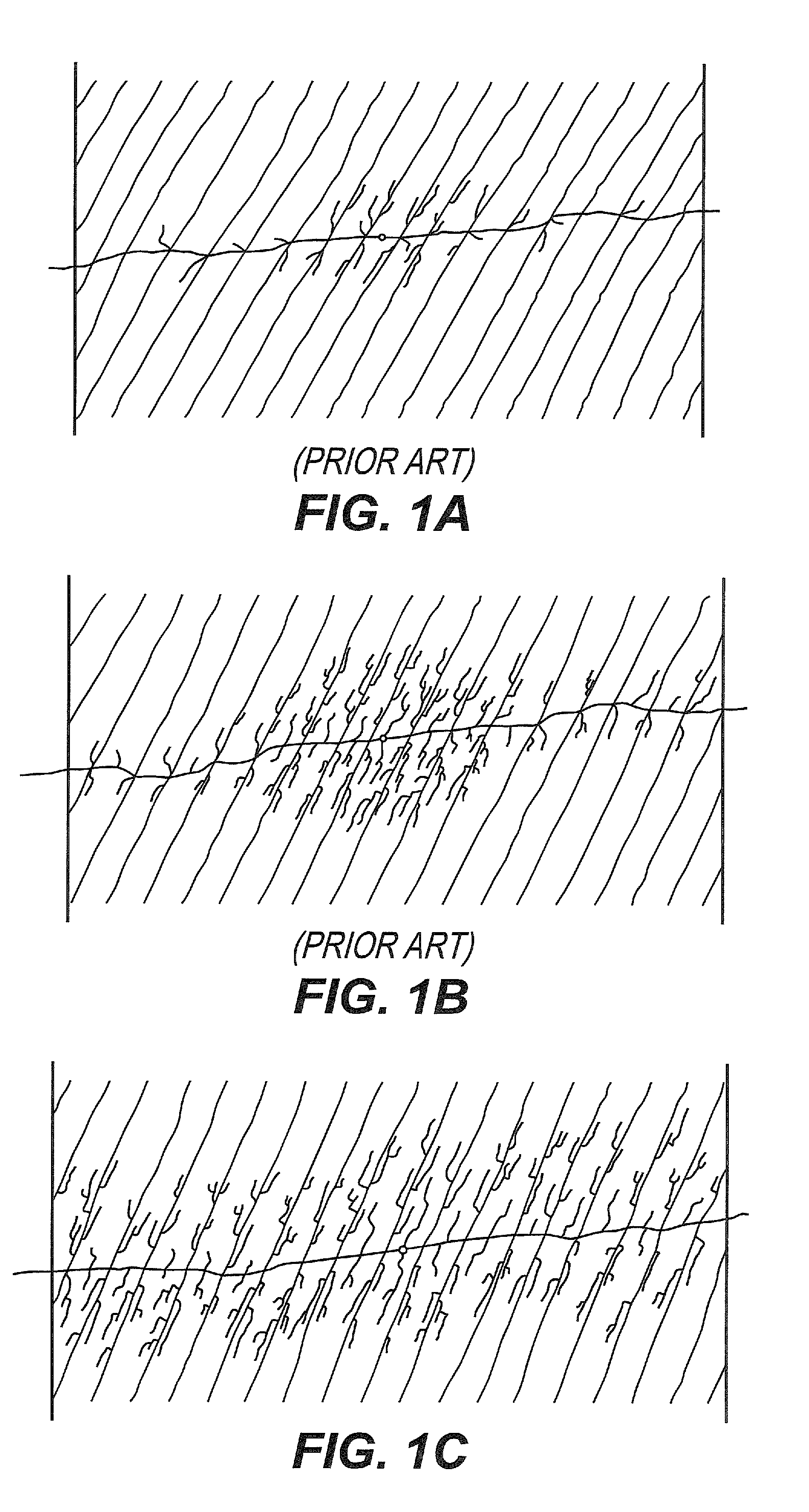

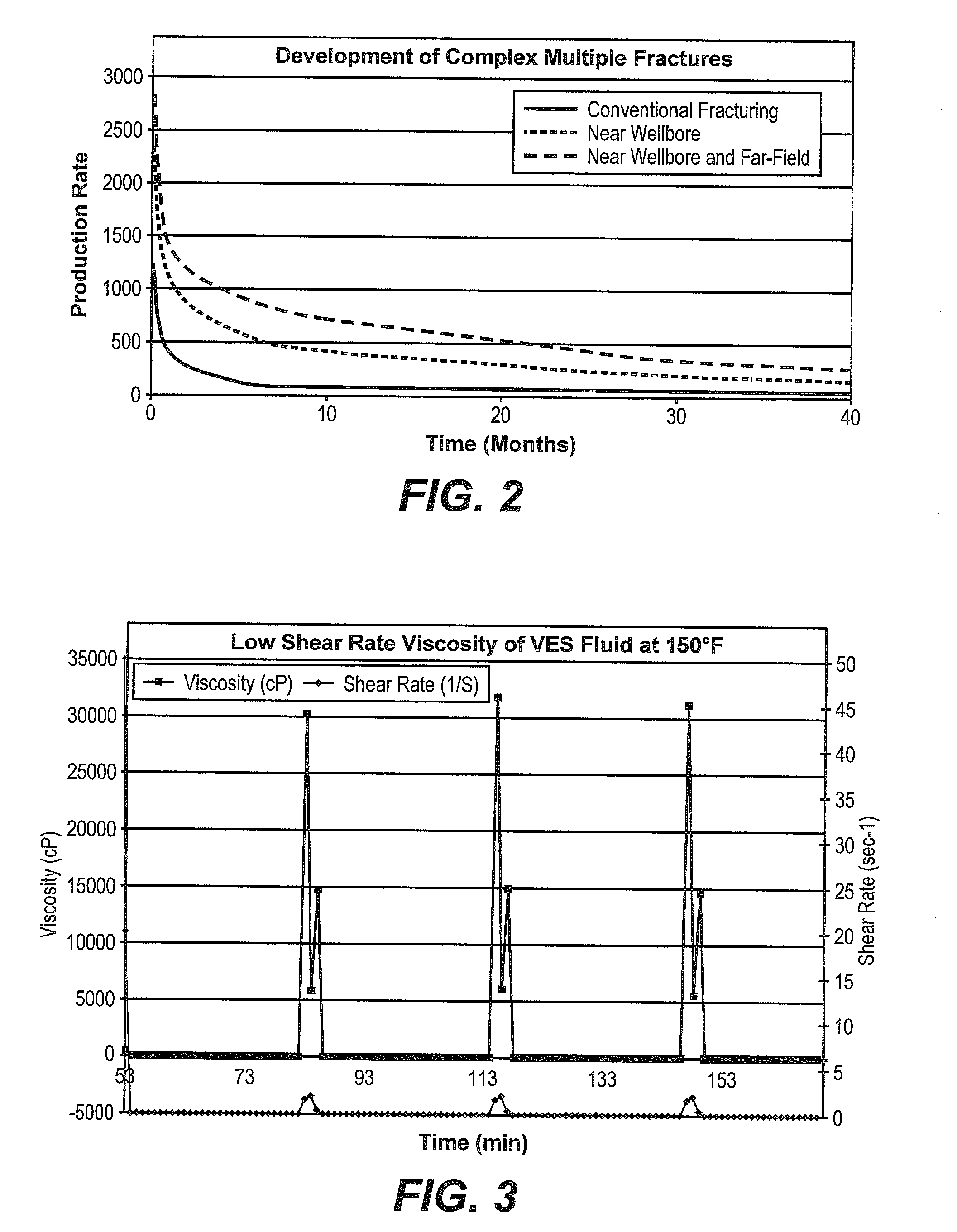

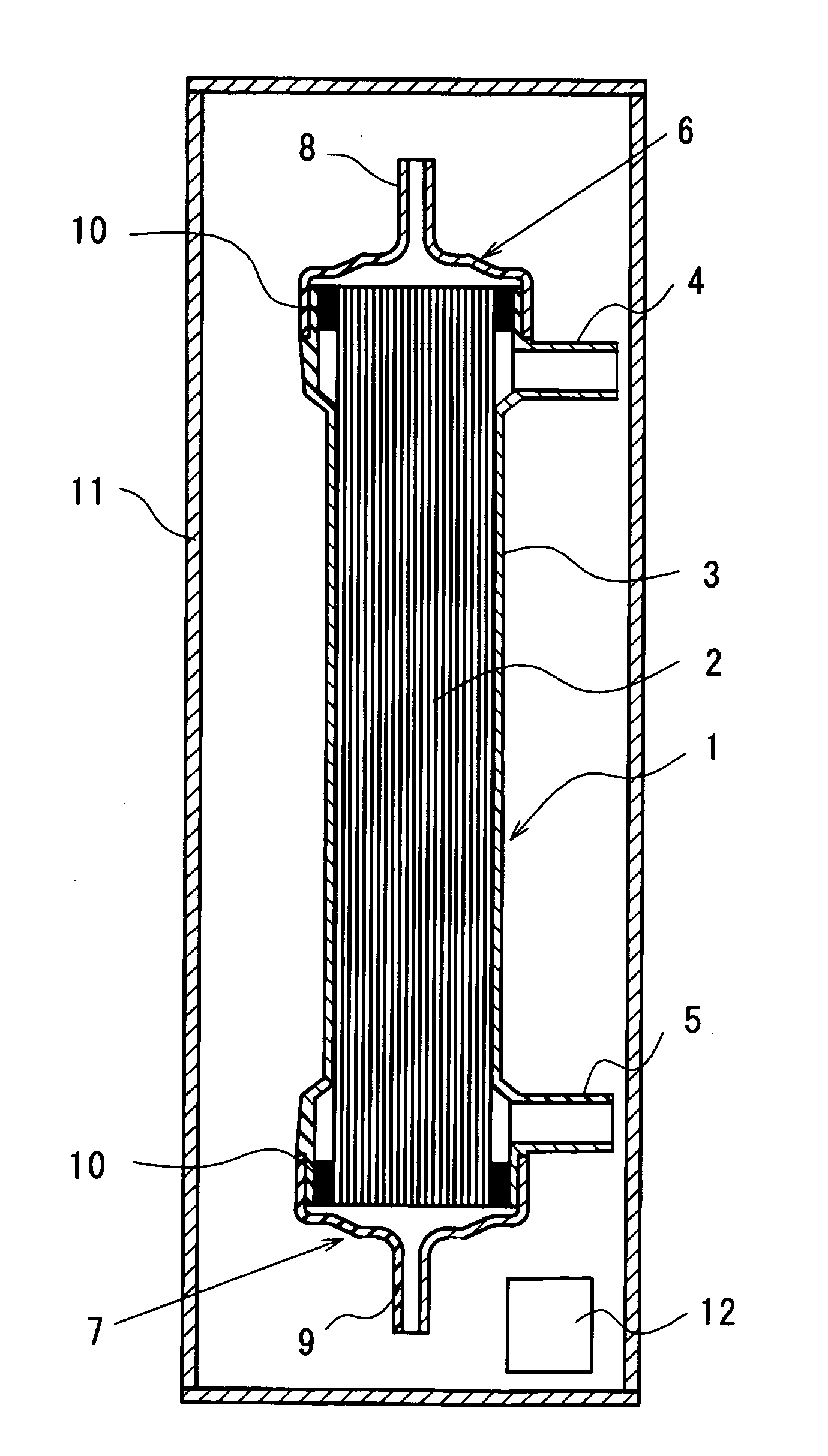

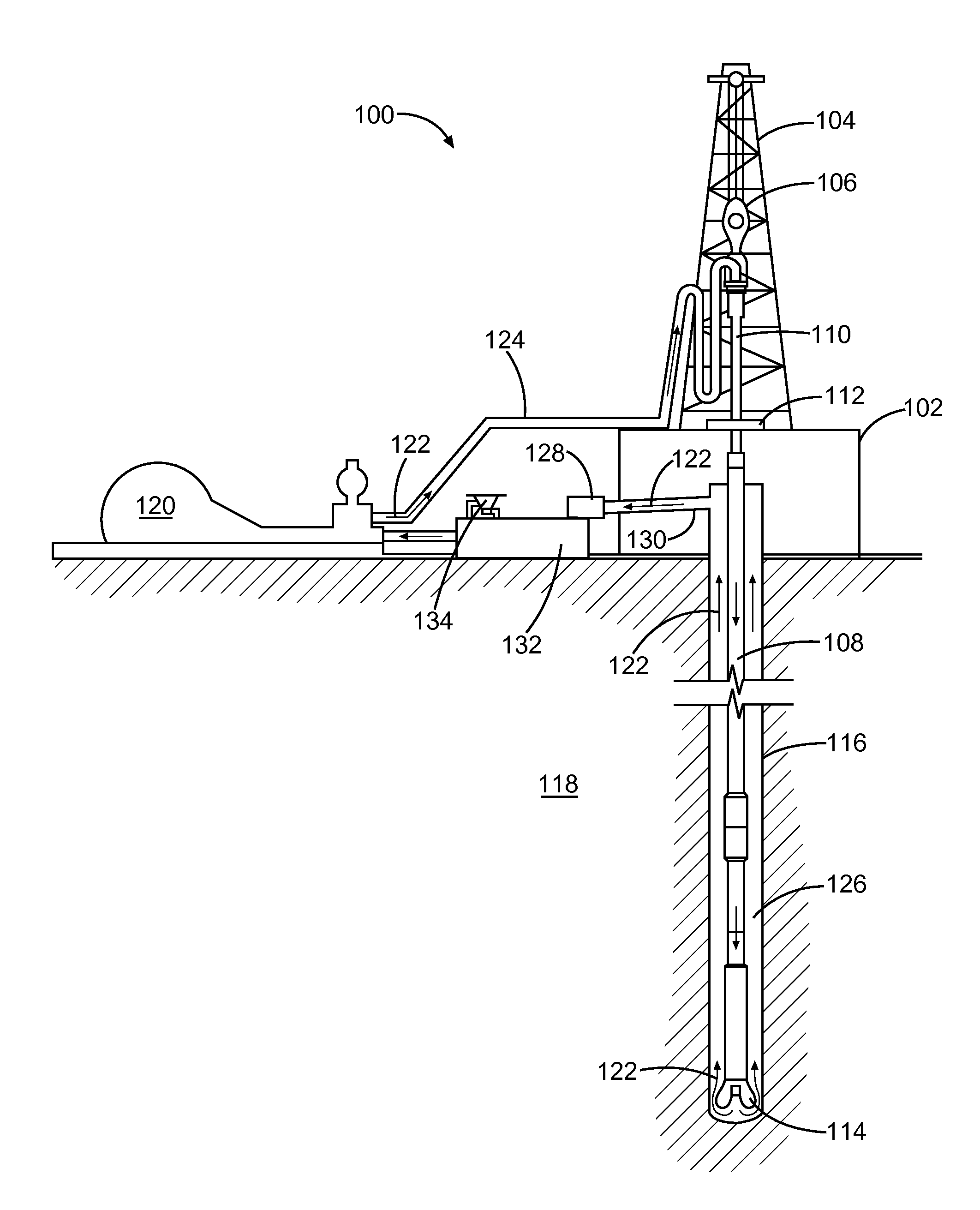

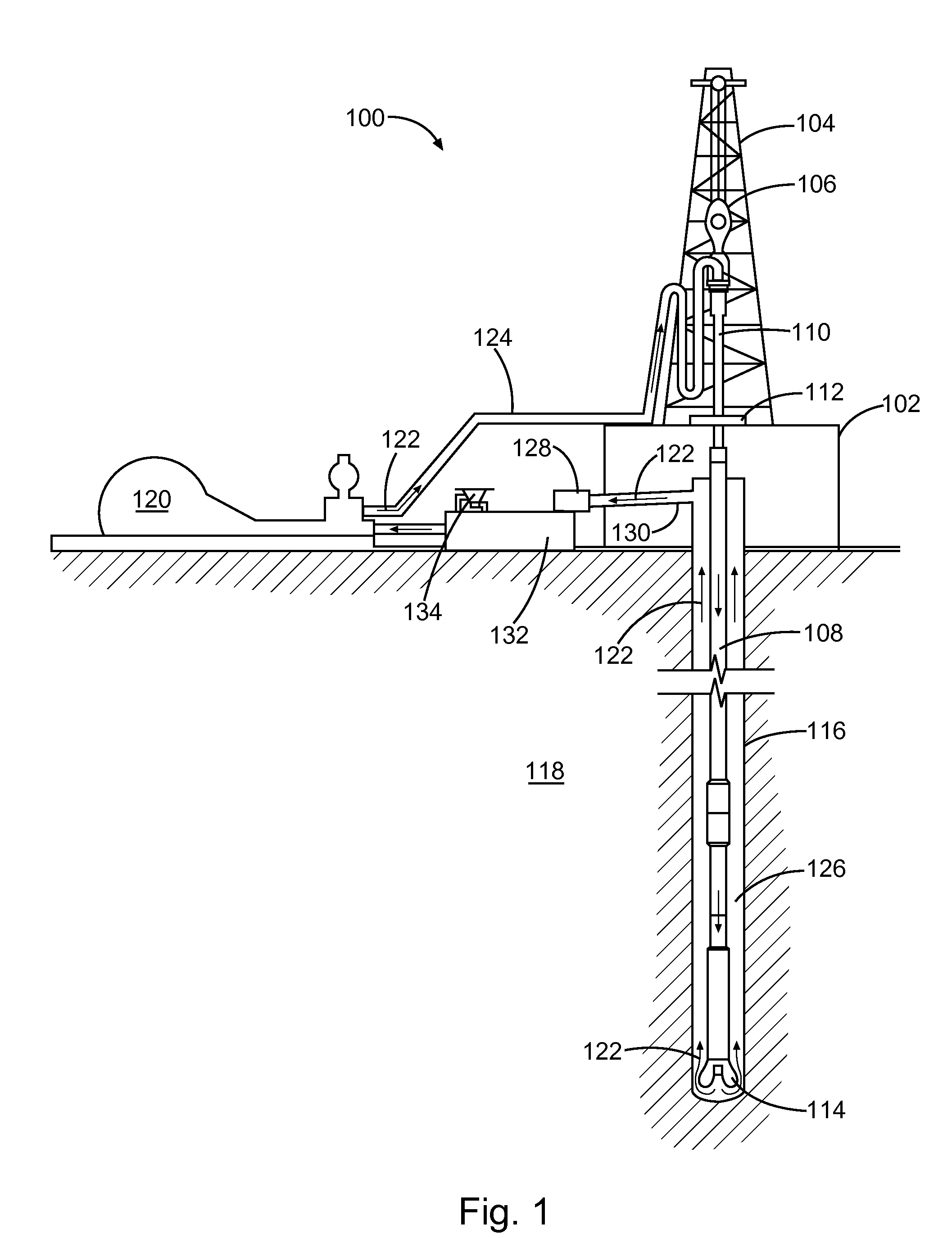

Method of Increasing the Permeability of a Subterranean Formation by Creating a Multiple Fracture Network

InactiveUS20140014338A1Wider distribution fracturing patternIncrease shearFluid removalDrilling compositionGeomorphologyFracturing fluid

The stimulated rock volume (SRV) of a subterranean formation may be increased by pumping viscous fracturing fluid into the formation in a first stage to create or enlarge a primary fracture, decreasing the pumping in order for the fluid to increase in viscosity within the primary fracture, and then continuing to pump viscous fluid into the formation in a second stage. The fluid pumped into the second stage is diverted away from the primary fracture and a secondary fracture is created. The directional orientation of the secondary fracture is distinct from the directional orientation of the primary fracture. The fluid of the first stage may contain a viscosifying polymer or viscoelastic surfactant or may be slickwater.

Owner:BAKER HUGHES INC

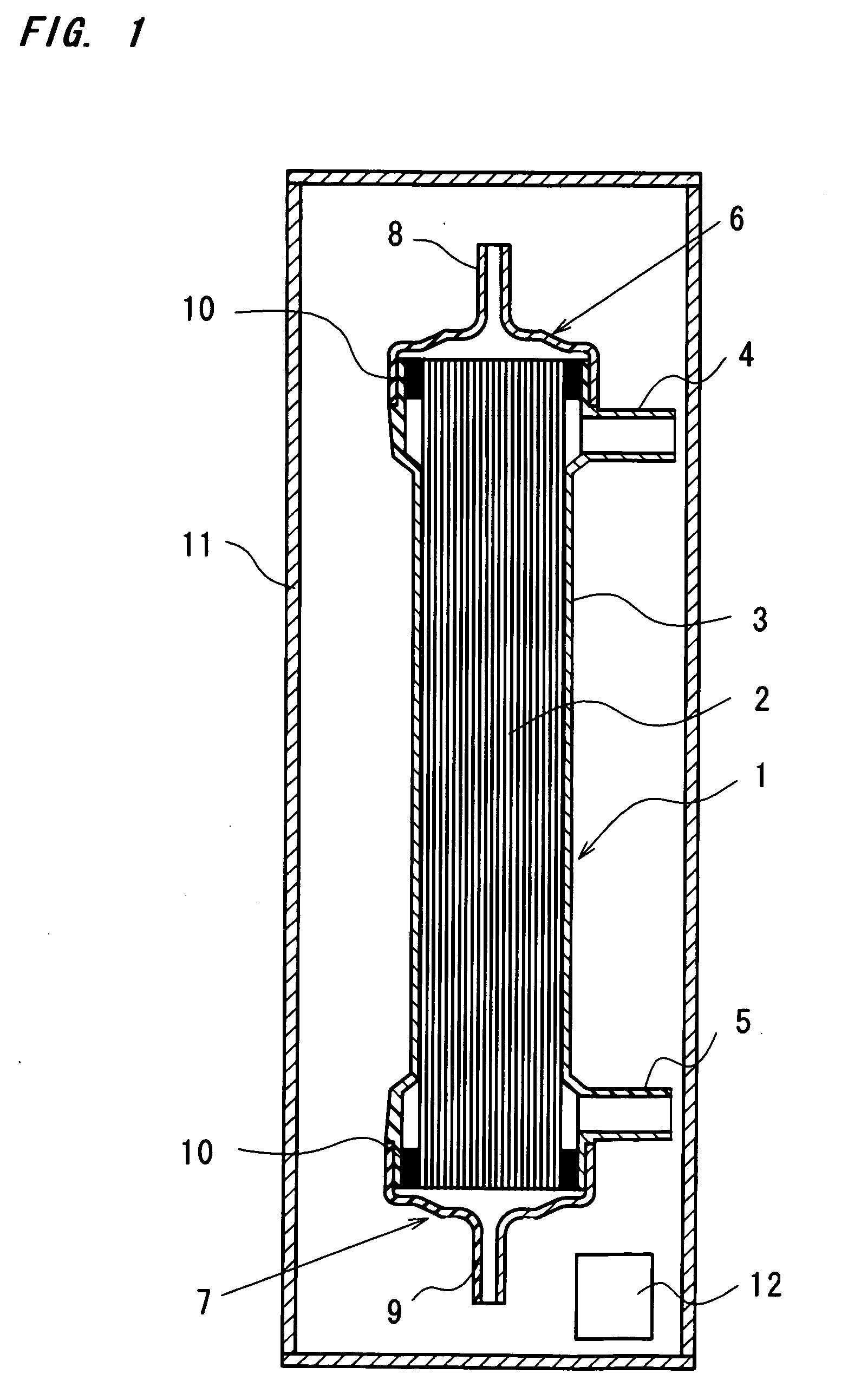

Hollow fiber blood-processing device and method for packaging and sterilizing such devices

ActiveUS20050063859A1Minimize damageIncreased pressure lossSemi-permeable membranesDialysis systemsFiberHollow fibre

A hollow fiber blood-processing device comprises a bundle of hollow fibers and is sealed in a gas-impermeable container together with a deoxidizer of a water-releasing type and radiation sterilized. The blood processing device is produced by a method comprising the steps of sealing a hollow fiber blood-processing device in a gas-impermeable container together with a deoxidizer of a water-releasing type, and radiation sterilizing the blood-processing device held in the sealed gas-impermeable container.

Owner:NIPRO CORP

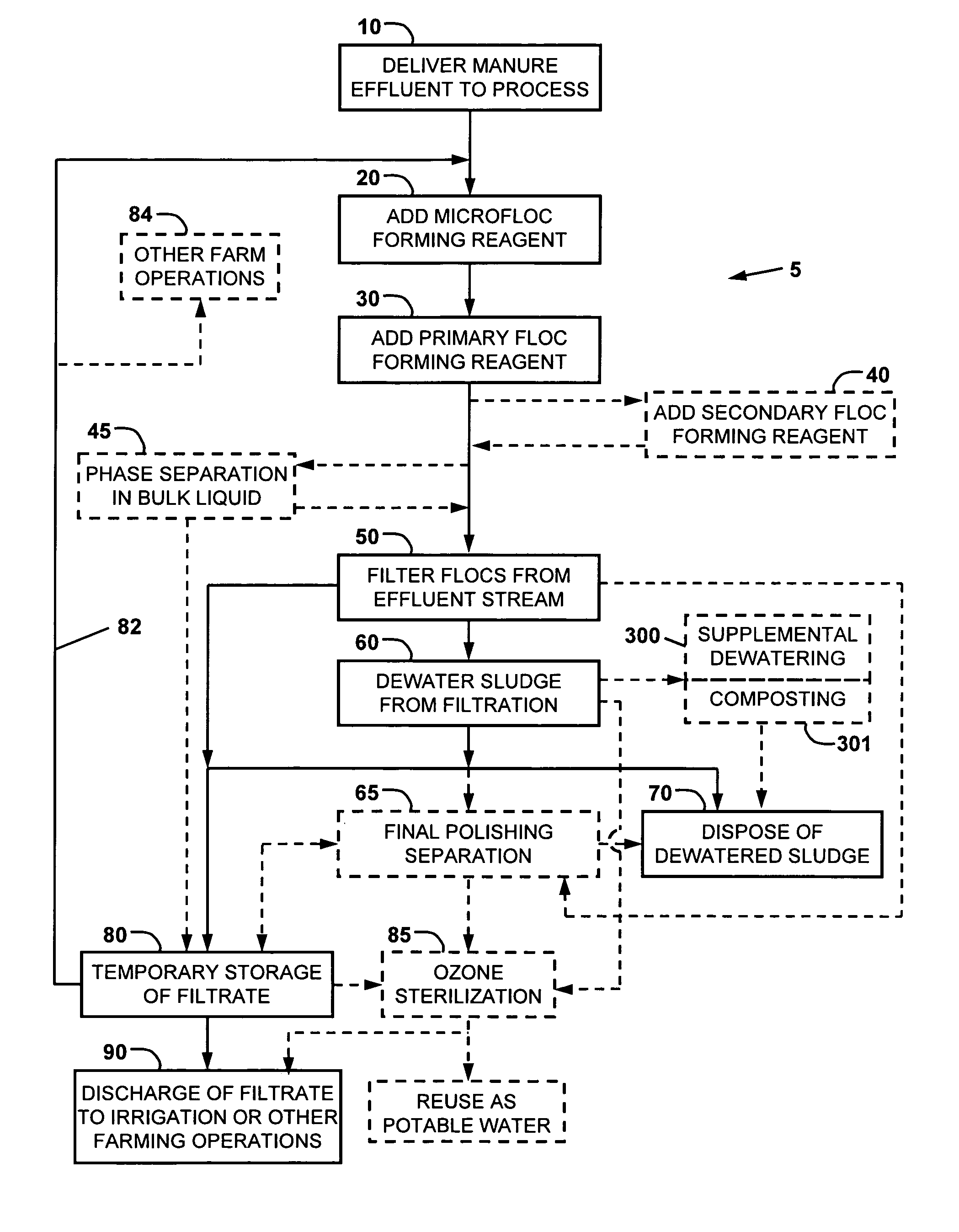

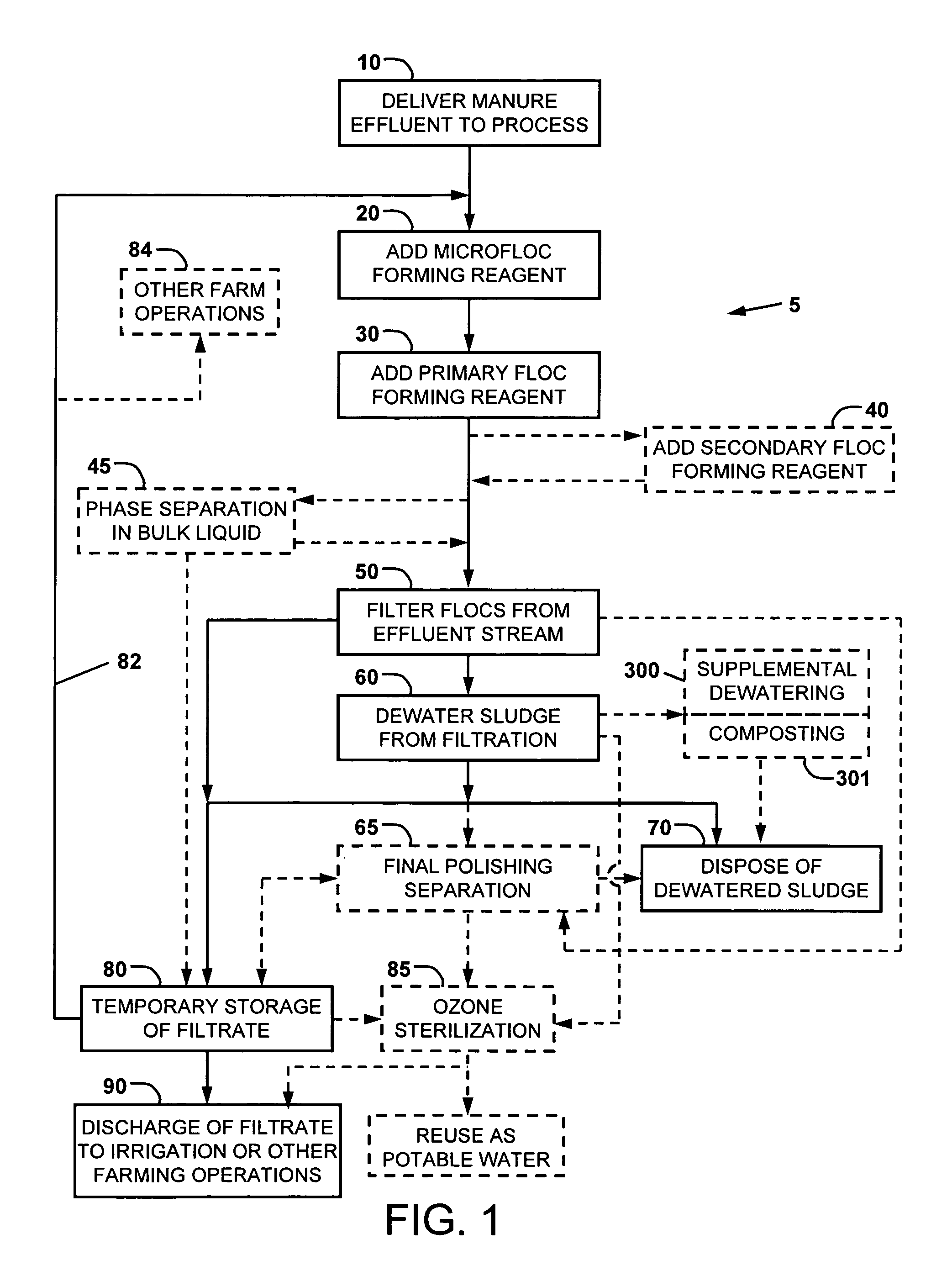

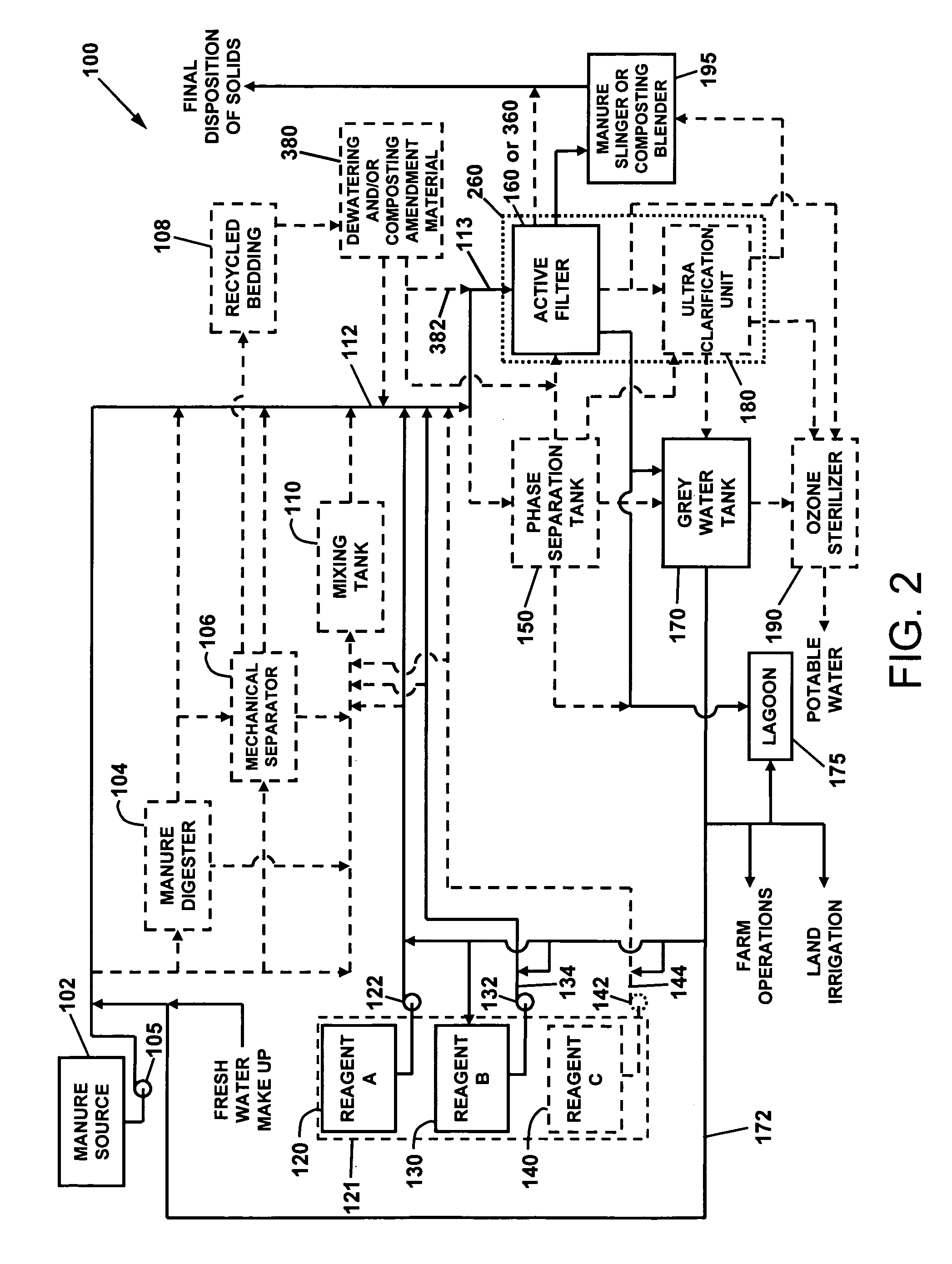

Method for treatment of agricultural waste

InactiveUS7972517B1Improved filtrate clarityReduce shipping costsSludge treatment by de-watering/drying/thickeningExcrement fertilisersLiquid wasteFeces

A method for treating a portion of liquid waste manure comprising adding a first reagent to the portion in a first vessel to cause the formation of waste manure flocs of a first size; adding a second reagent to liquid portion to cause growth of the waste manure flocs of the first size into separable waste manure flocs; adding optionally a third reagent to the portion of liquid containing waste manure flocs to cause further growth of the separable waste manure flocs; separating the liquid volume containing separable waste manure flocs into a waste manure sludge and a first filtrate; and dewatering the waste manure sludge in a filtration system comprising a first filter including a first housing, a first displaceable filter medium, and a first displacement actuator disposed between the first housing and the first displaceable filter medium.

Owner:INNOVATIVE ENVIRONMENTAL PRODS

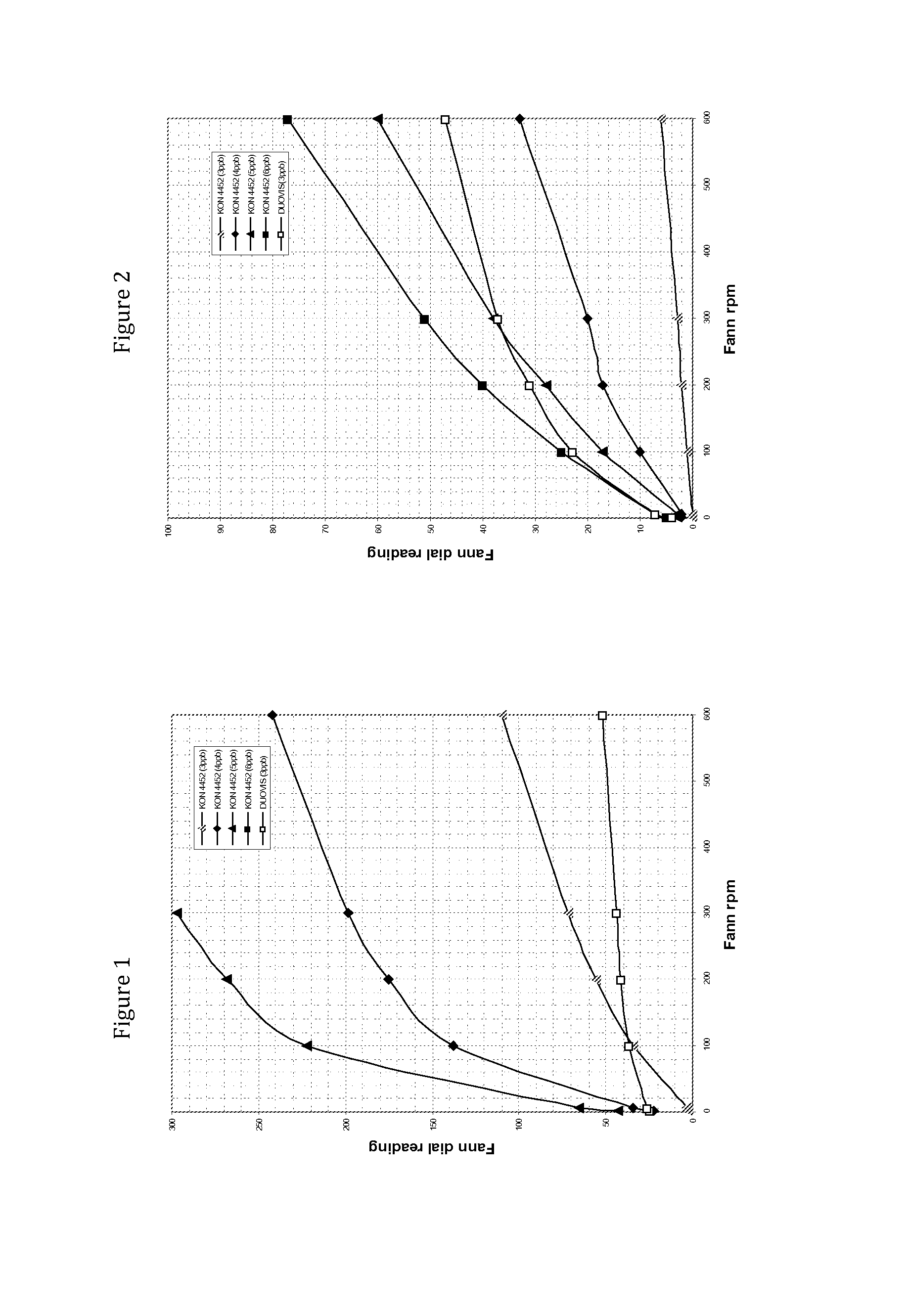

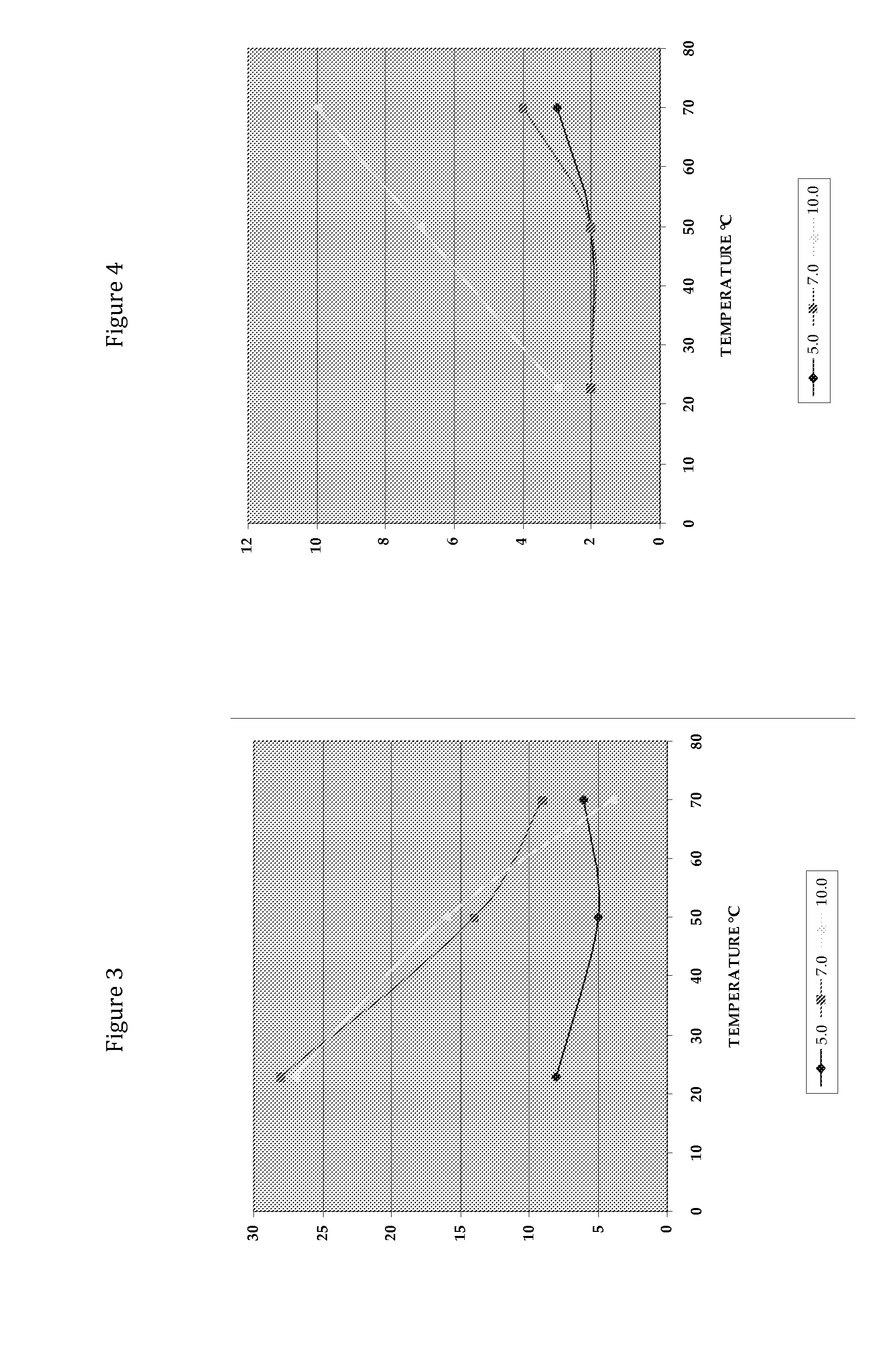

Wellbore fluid

InactiveUS20150021027A1Increase ratingsExhibits a synergistic rheological performanceFluid removalFlushingGlucomannanPetroleum engineering

The present invention provides a wellbore fluid, such as a drilling, completion or workover fluid, said wellbore fluid comprising a glucomannan additive. Further provided is a method of forming a gel plug from the wellbore fluid, a method of modifying the properties of a wellbore fluid, a method of drilling a subterranean hole with such a fluid and the use of glucomannan in wellbore fluids.

Owner:M I DRILLING FLUIDS U K LTD

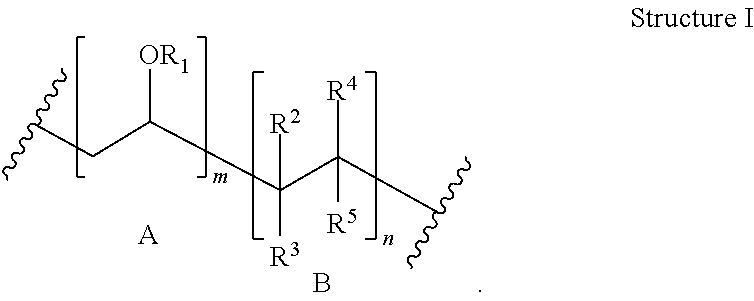

Drilling fluid composition including viscosifier and method of using the same

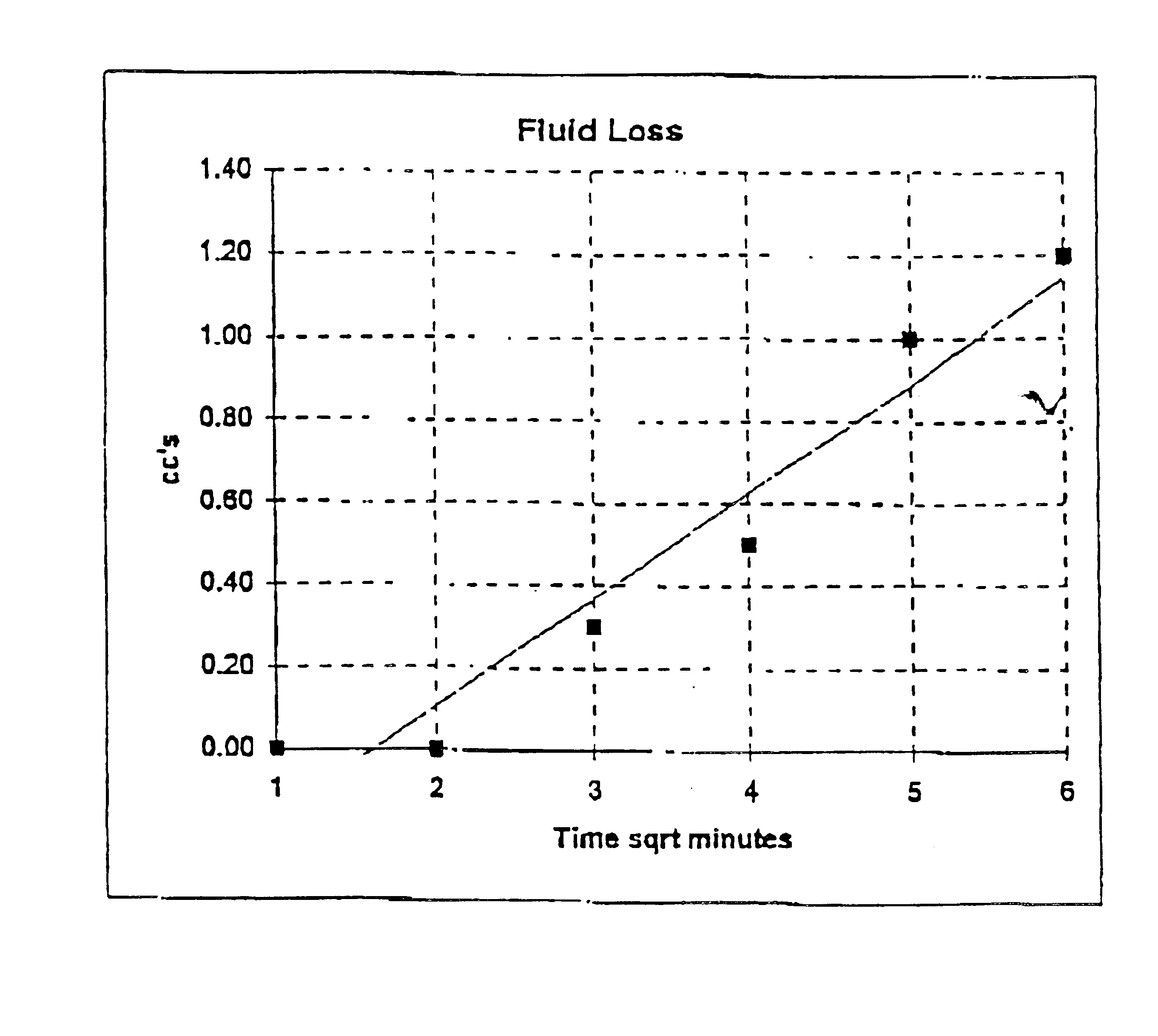

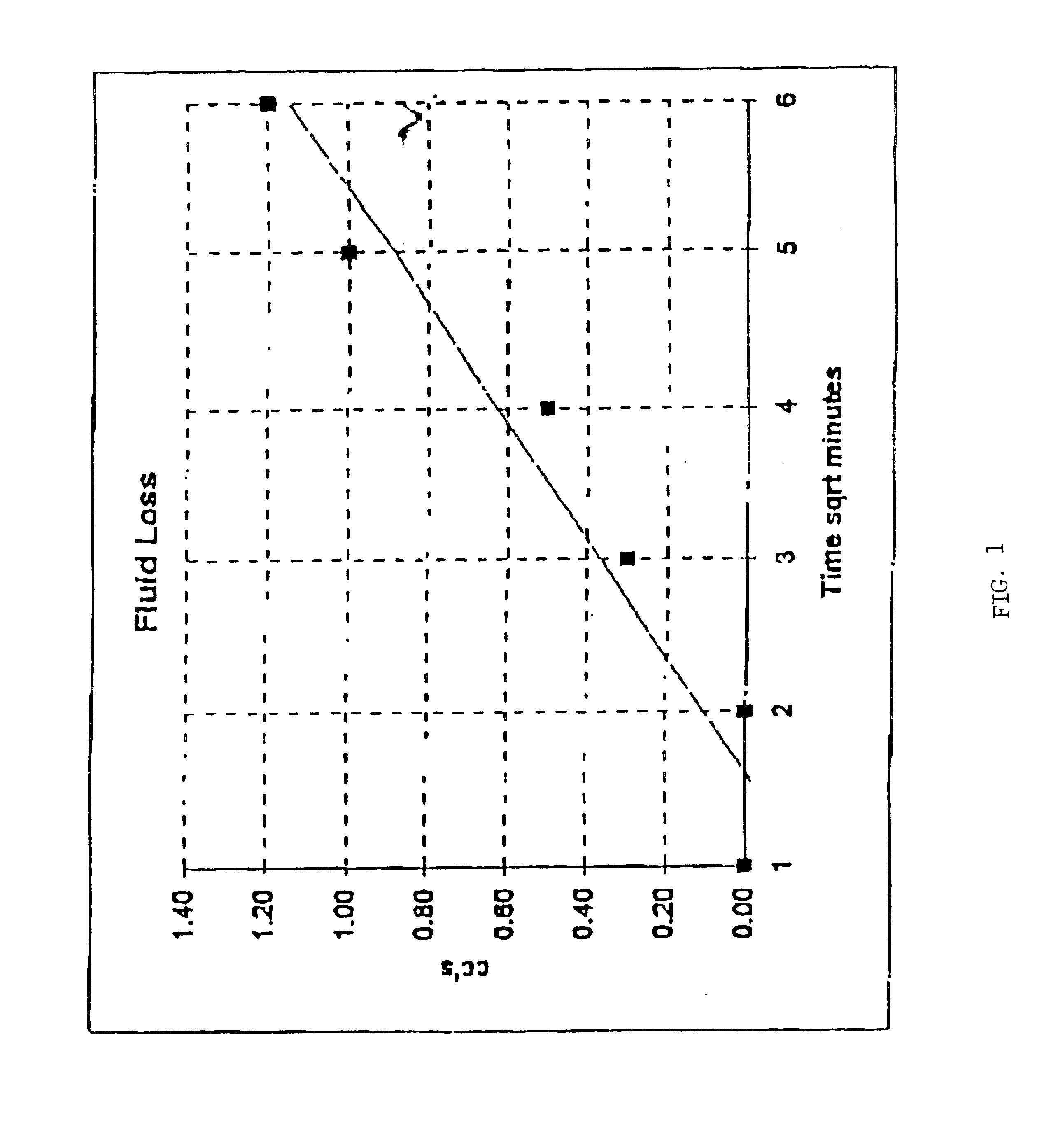

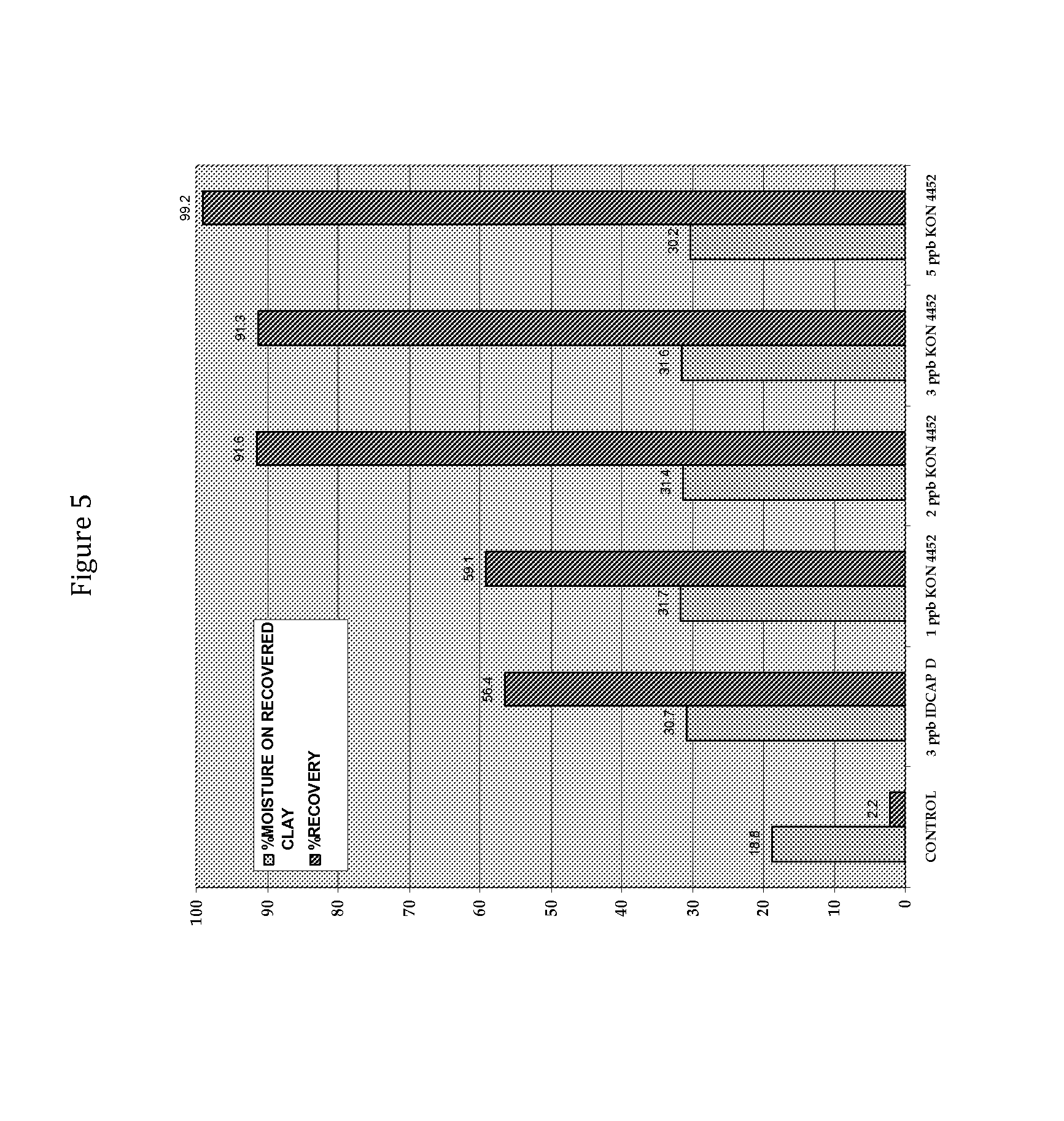

ActiveUS20160122613A1High viscosityGood fluid loss controlDrilling rodsFluid removalFluid compositionCopolymer

The present invention relates to drilling fluid compositions and methods of using the same. In various embodiments, the present invention provides a method of treating a subterranean formation including obtaining or providing a drilling fluid composition including a viscosifier including at least one of a poly(vinyl alcohol) copolymer, a crosslinked poly(vinyl alcohol), and a crosslinked poly(vinyl alcohol) copolymer. The method also includes placing the composition in a subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

Concrete admixture and pre-mixed and water-permeable concrete using concrete admixture

The invention relates to a pre-mixed and water-permeable concrete admixture and water-permeable concrete. The pre-mixed and water-permeable concrete admixture is formed by mixing of the following components in percentage by weight: 10-20% of a water reducing component, 1-5% of a hydration regulating and controlling component, 0.1-1.0% of a viscosity regulating component, 0.5-5% of a water evaporation inhibiting component, 0.5-3% of a thixotropic agent component, and the balance of water. The pre-mixed and water-permeable concrete admixture provided in the invention can effectively improve work conditions of the water-permeable concrete, greatly improve the cohesiveness and the uniformity of slurry wrapping aggregate surfaces, and can effectively prolong the operable time of the water-permeable concrete, meet the requirements of pre-mixing production, long-distance transportation and long-time construction of the water-permeable concrete, and improve the control of production and construction quality of the water-permeable concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

Topical ointment and method for making and using same

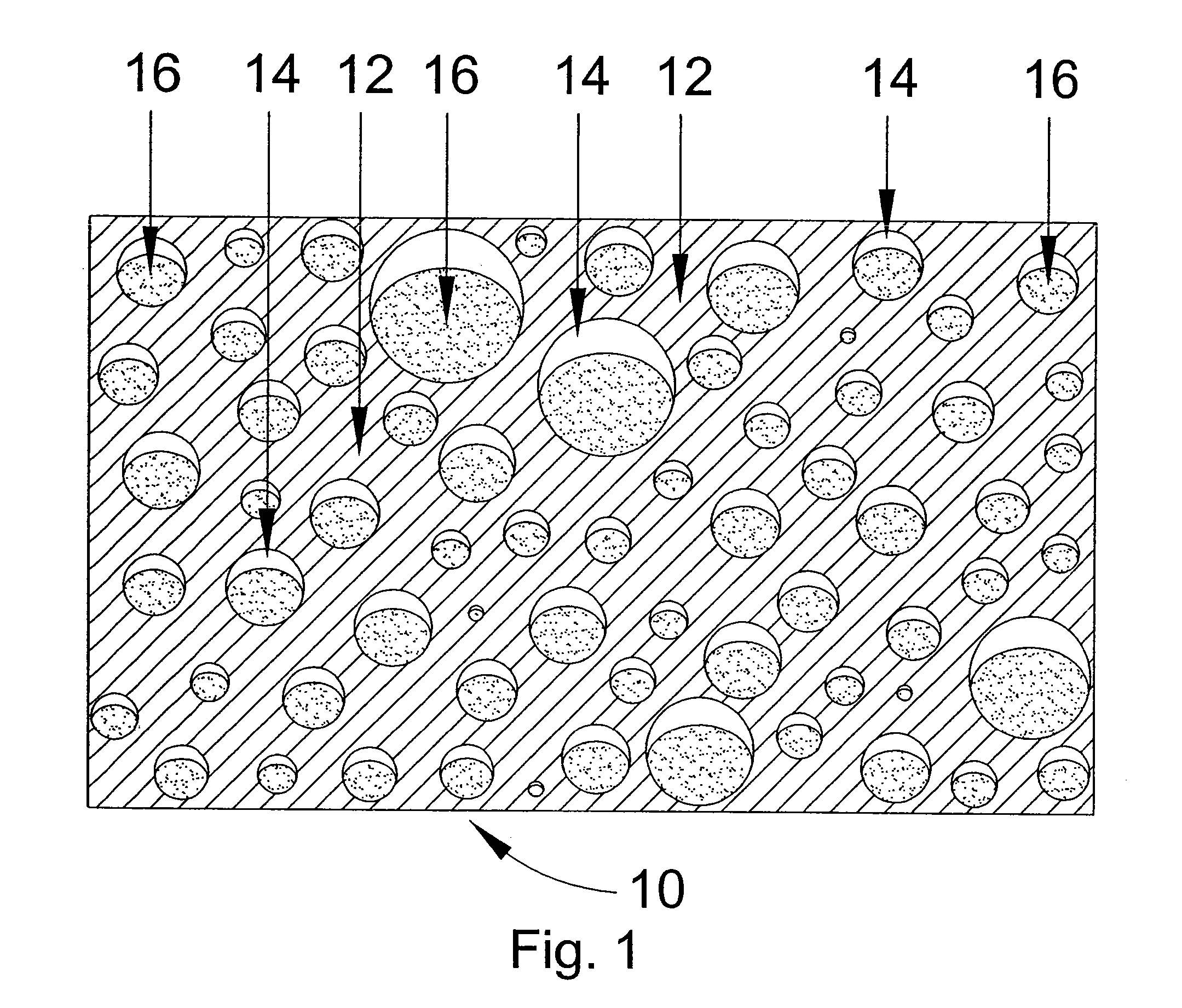

InactiveUS20070026025A1Reduce shear rateIncrease shear ratePowder deliveryCosmetic preparationsMicrobubblesMedicine

A topical ointment comprises a base material of plasticized hydrocarbon gel and methylcellulose in which are dispersed a plurality of microbubbles containing liquid. The microbubbles containing liquid are encapsulated by the base material to form microencapsulations which are dispersed in the base material to form a hydrogel. Application of the topical ointment to a body area provides for the moisturizing and the slow delivery of the liquid in the microencapsulations to the applied area. Body heat melts the base material and the contents of the microencapsulations are thereby released.

Owner:AQUEGEL COSMETICS

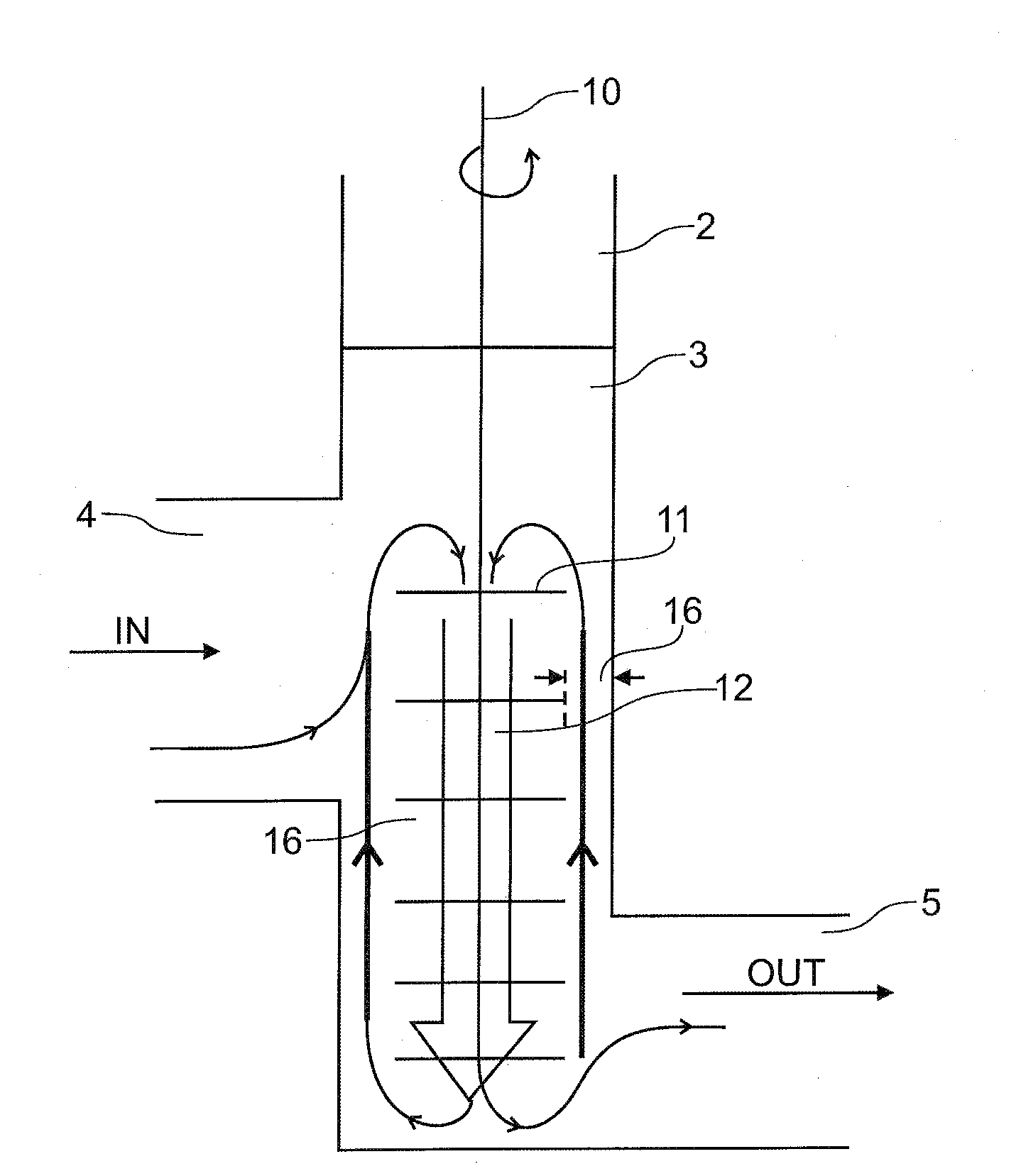

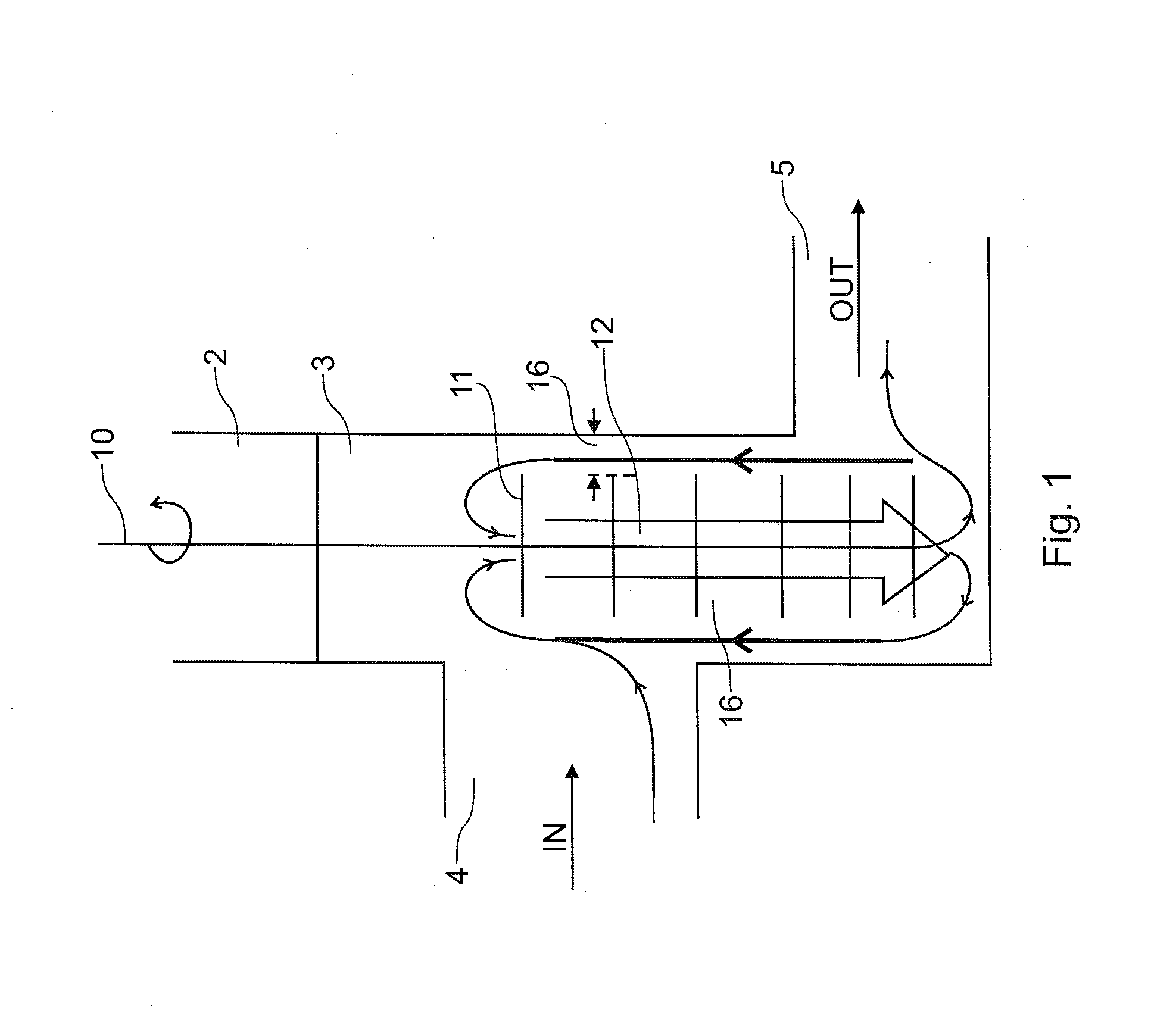

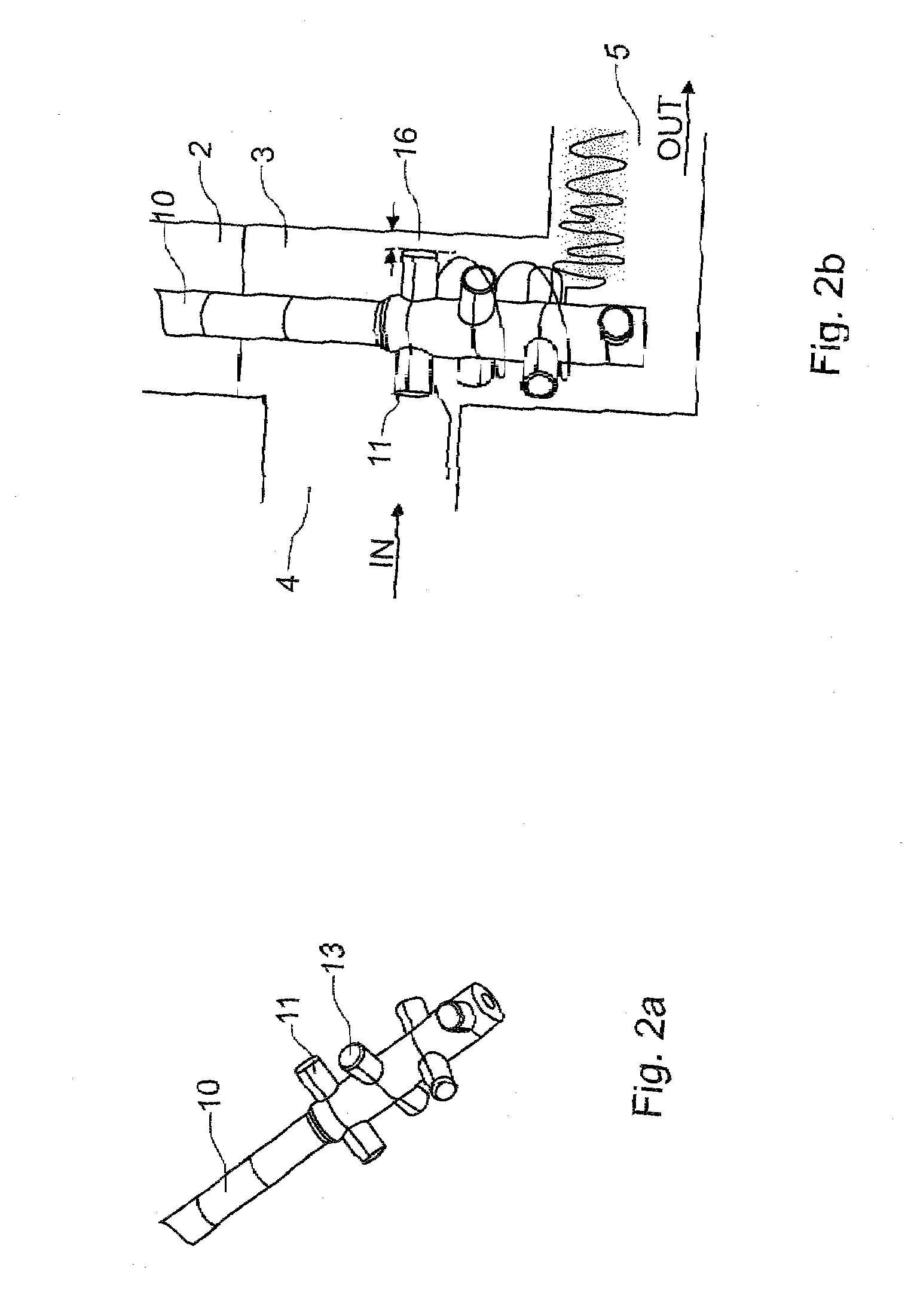

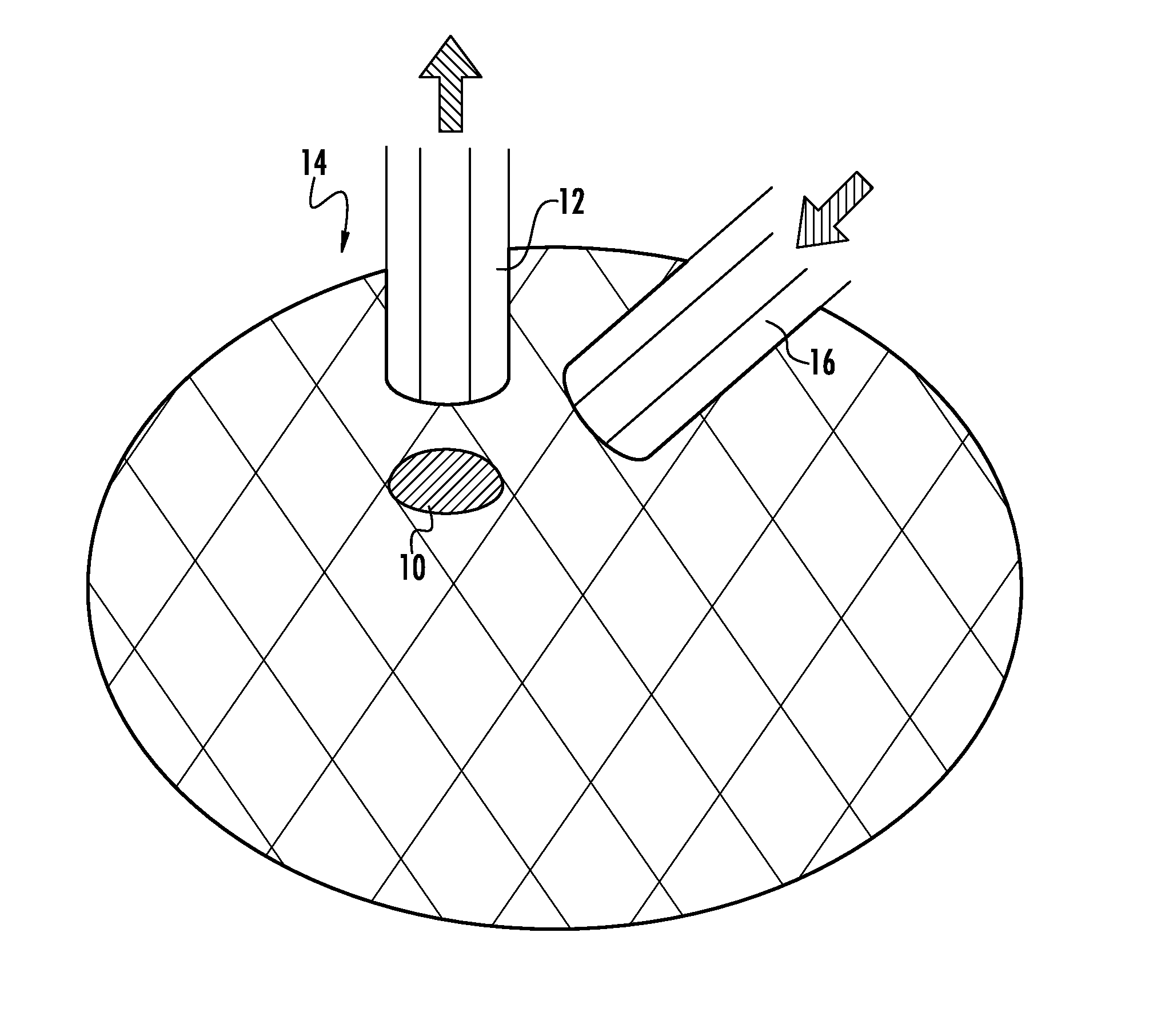

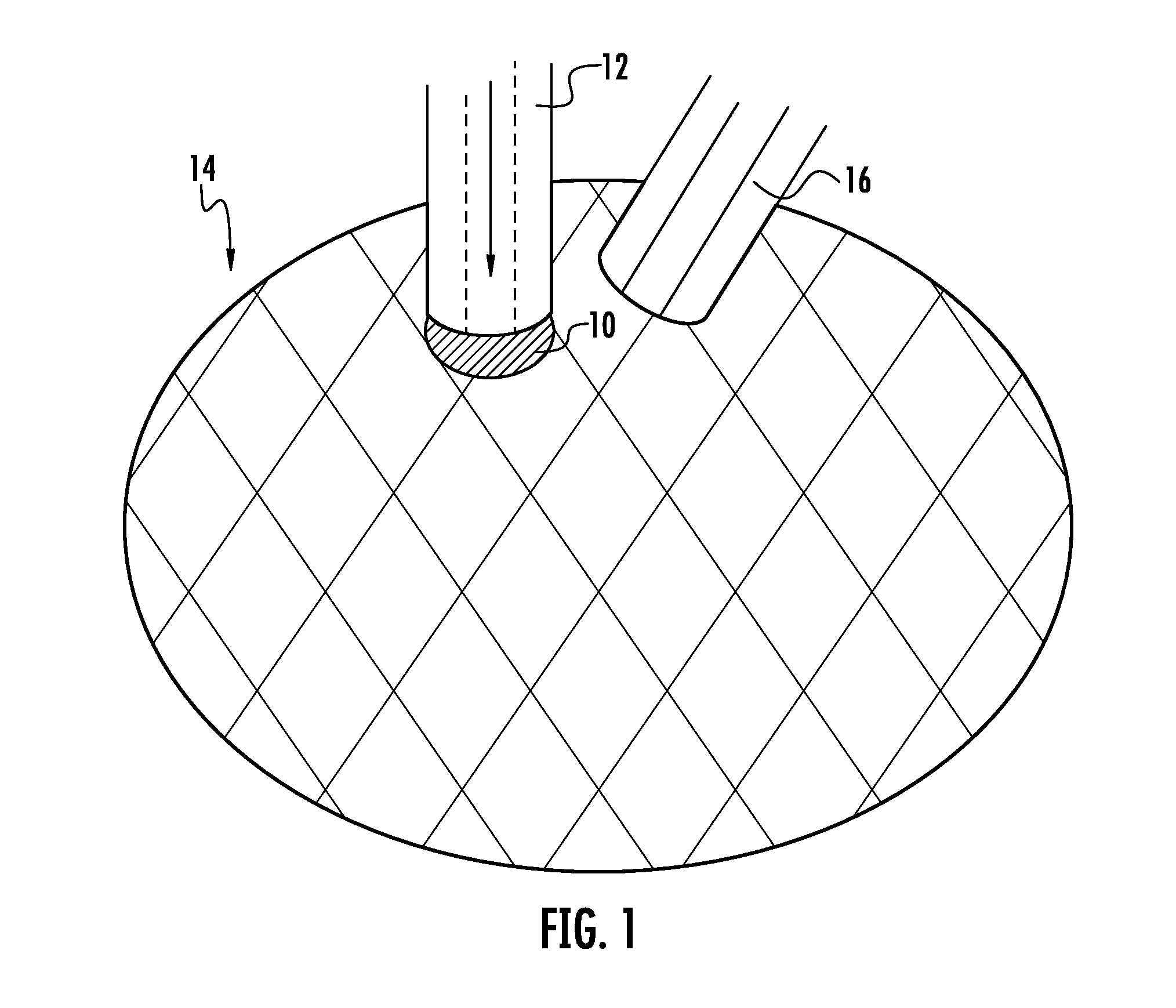

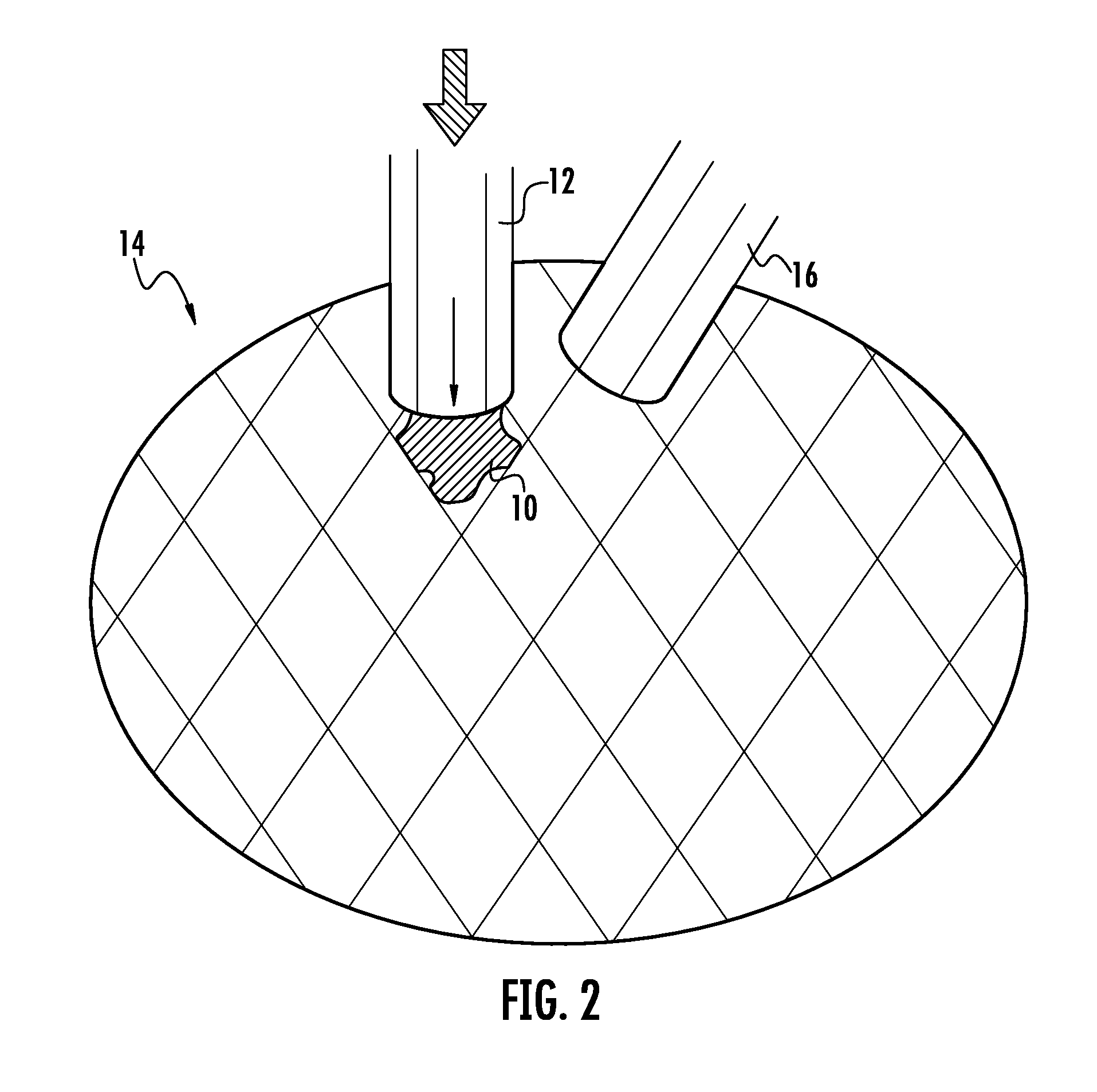

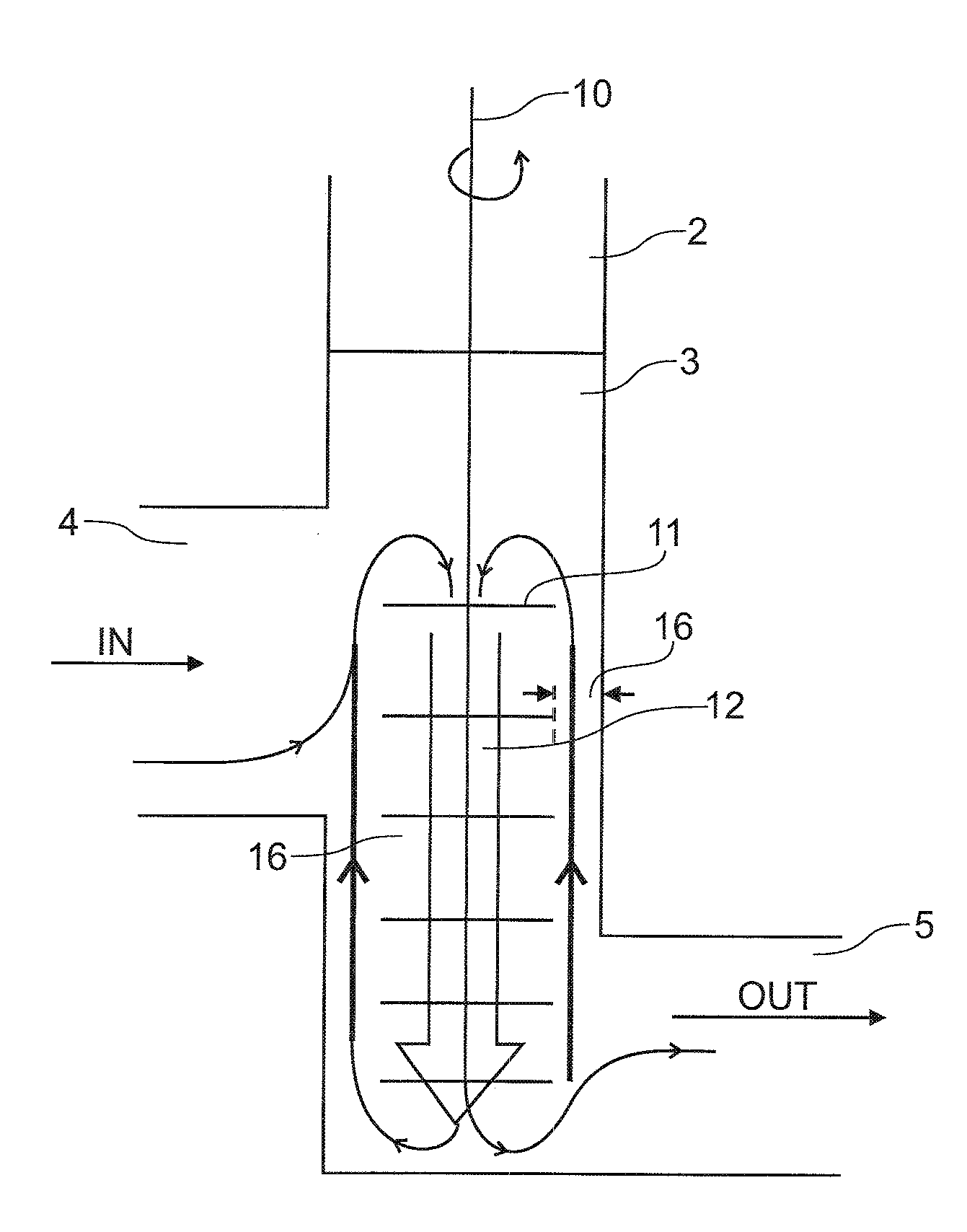

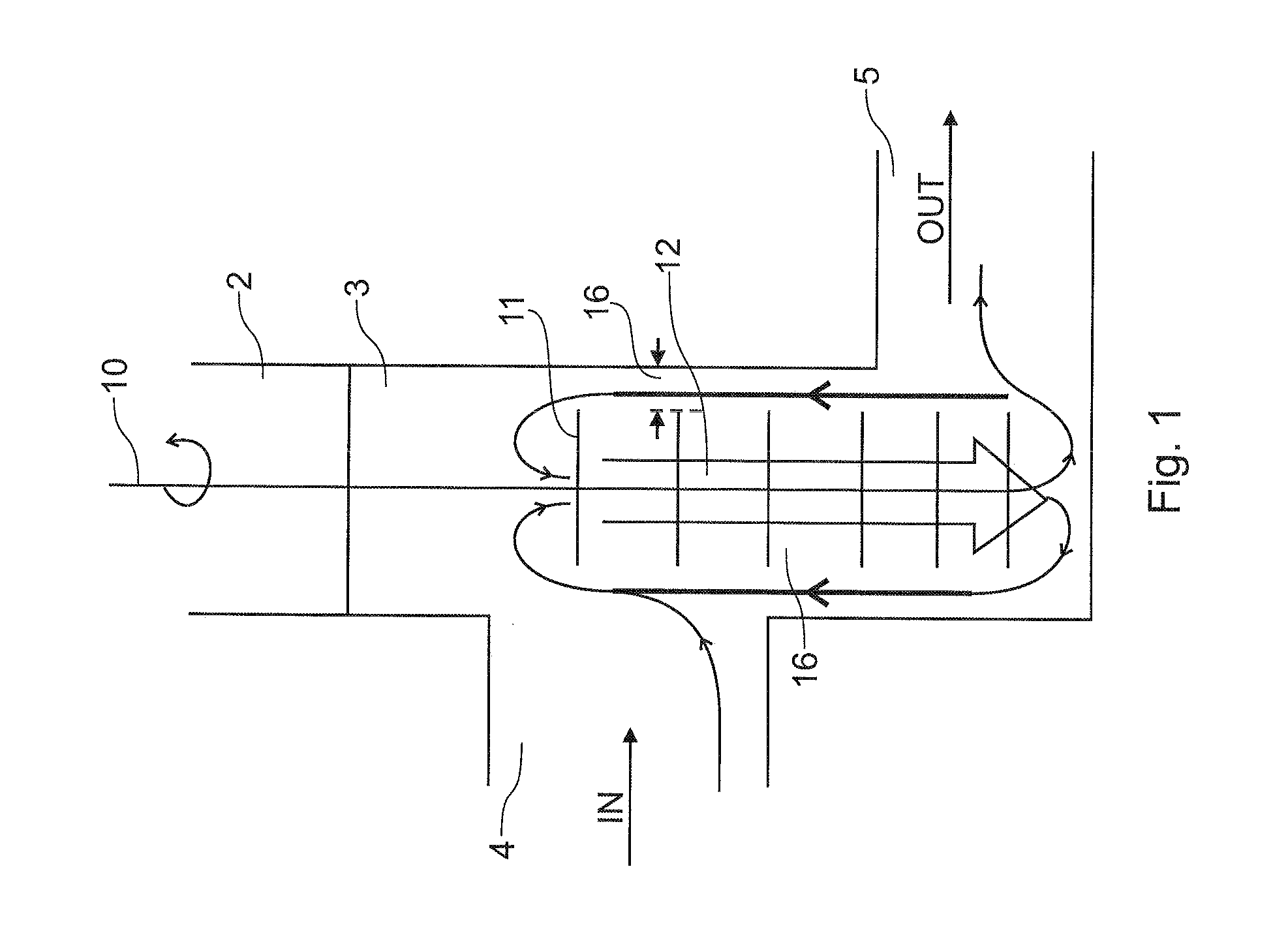

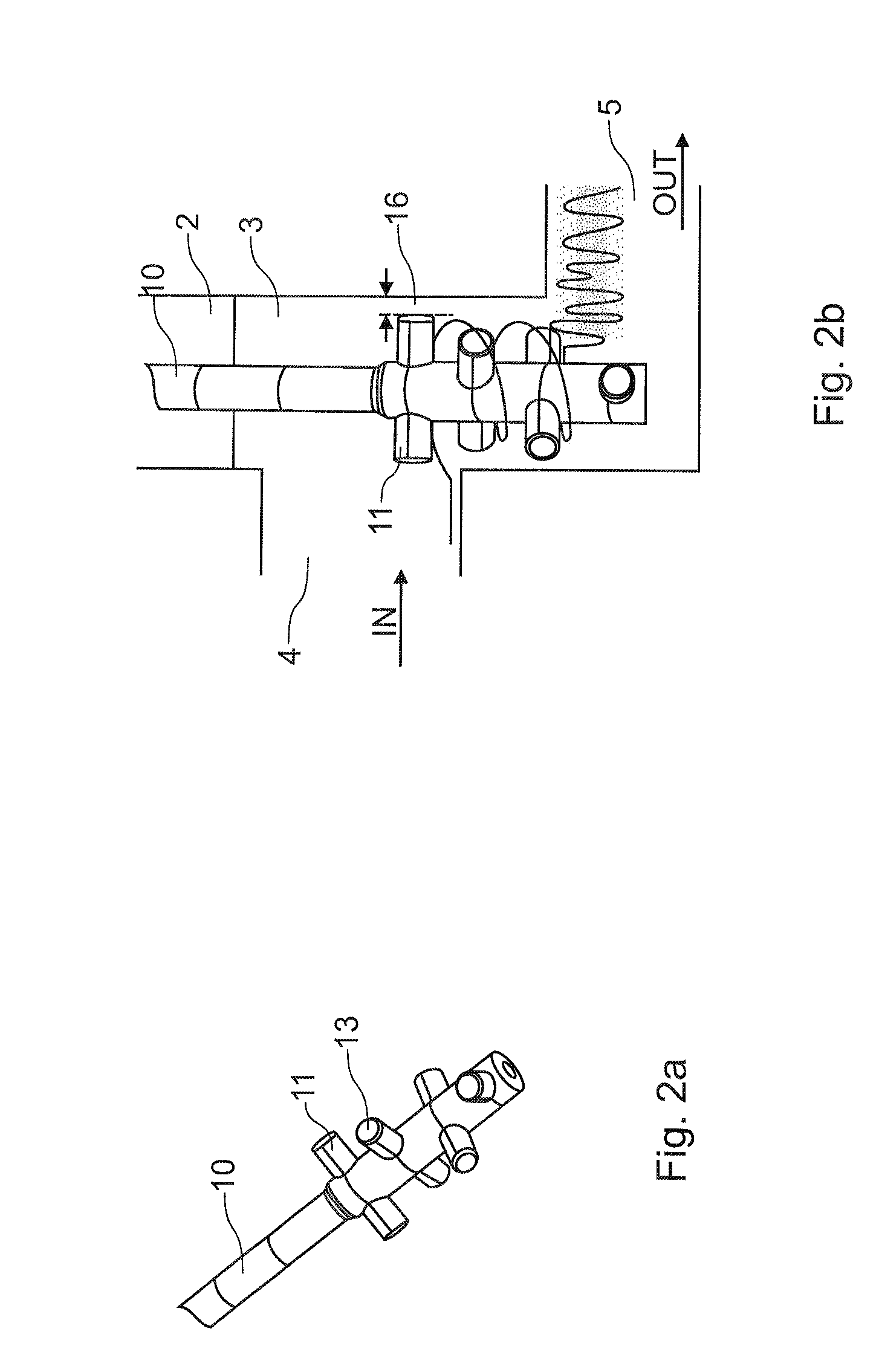

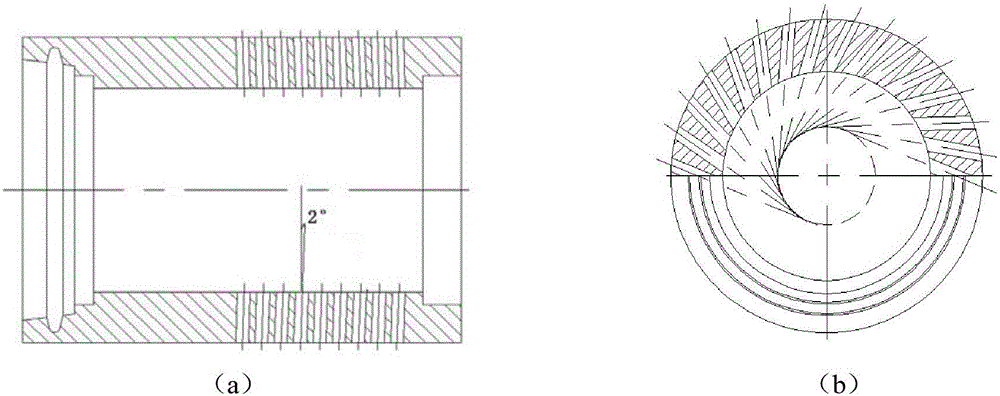

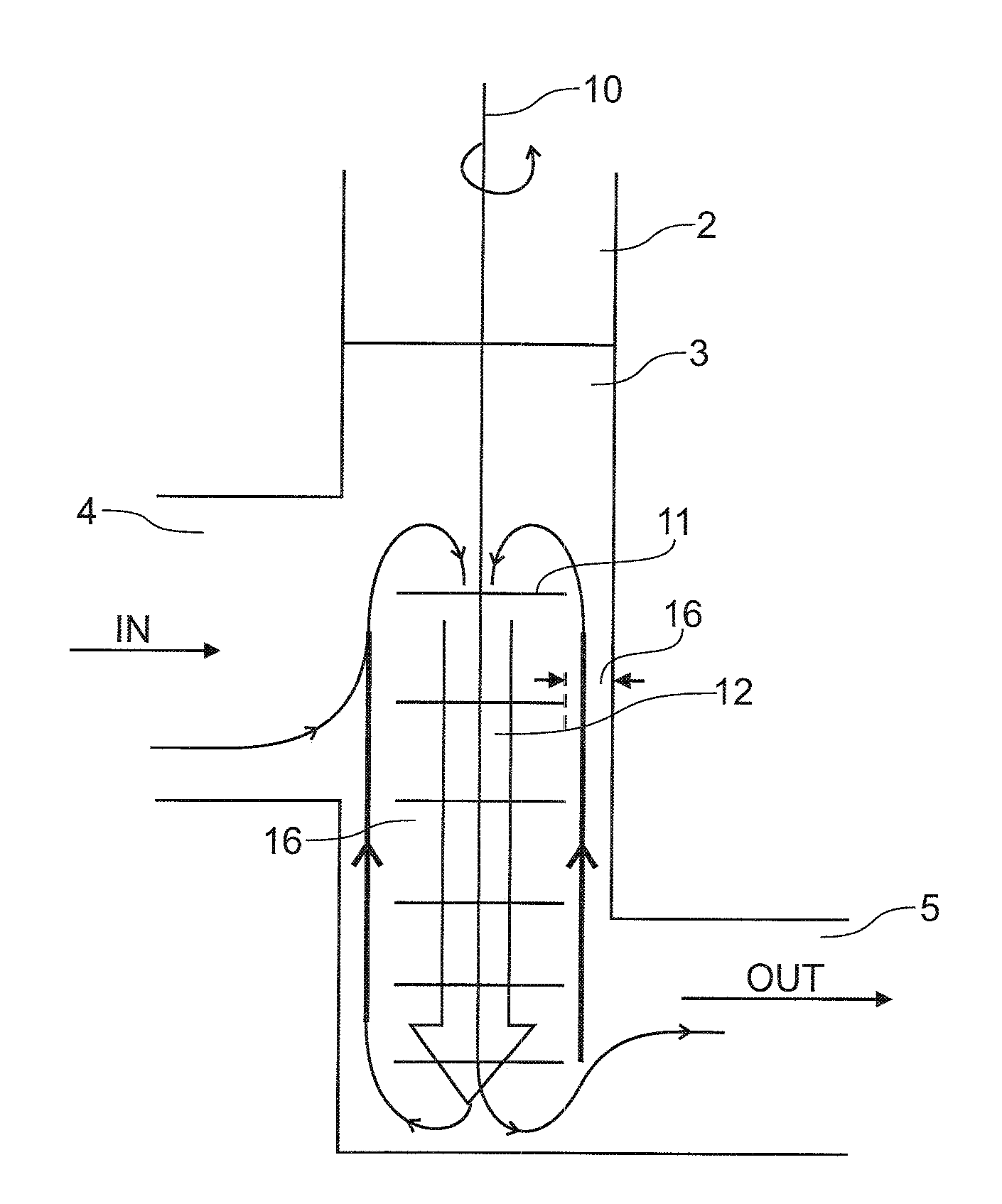

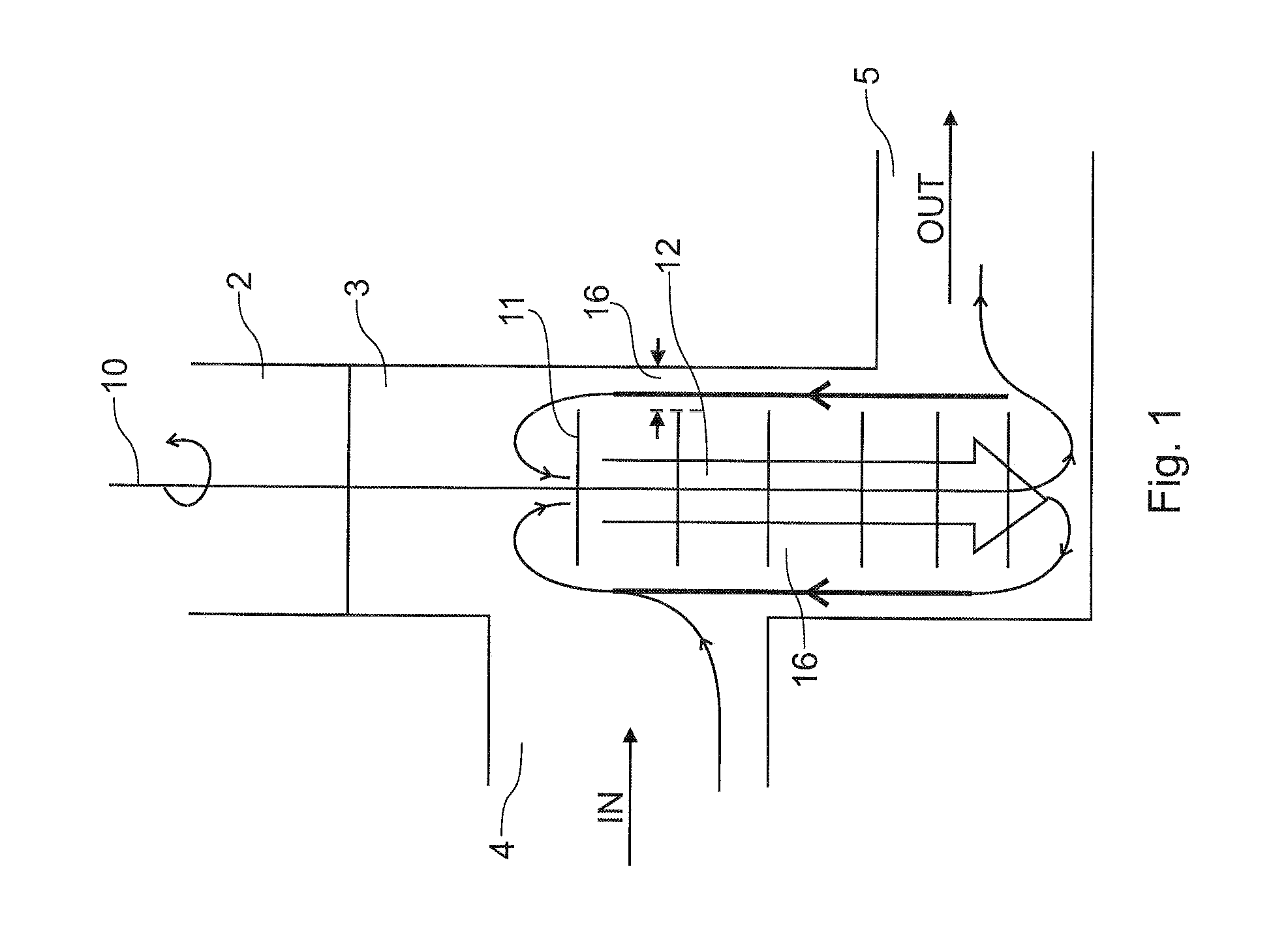

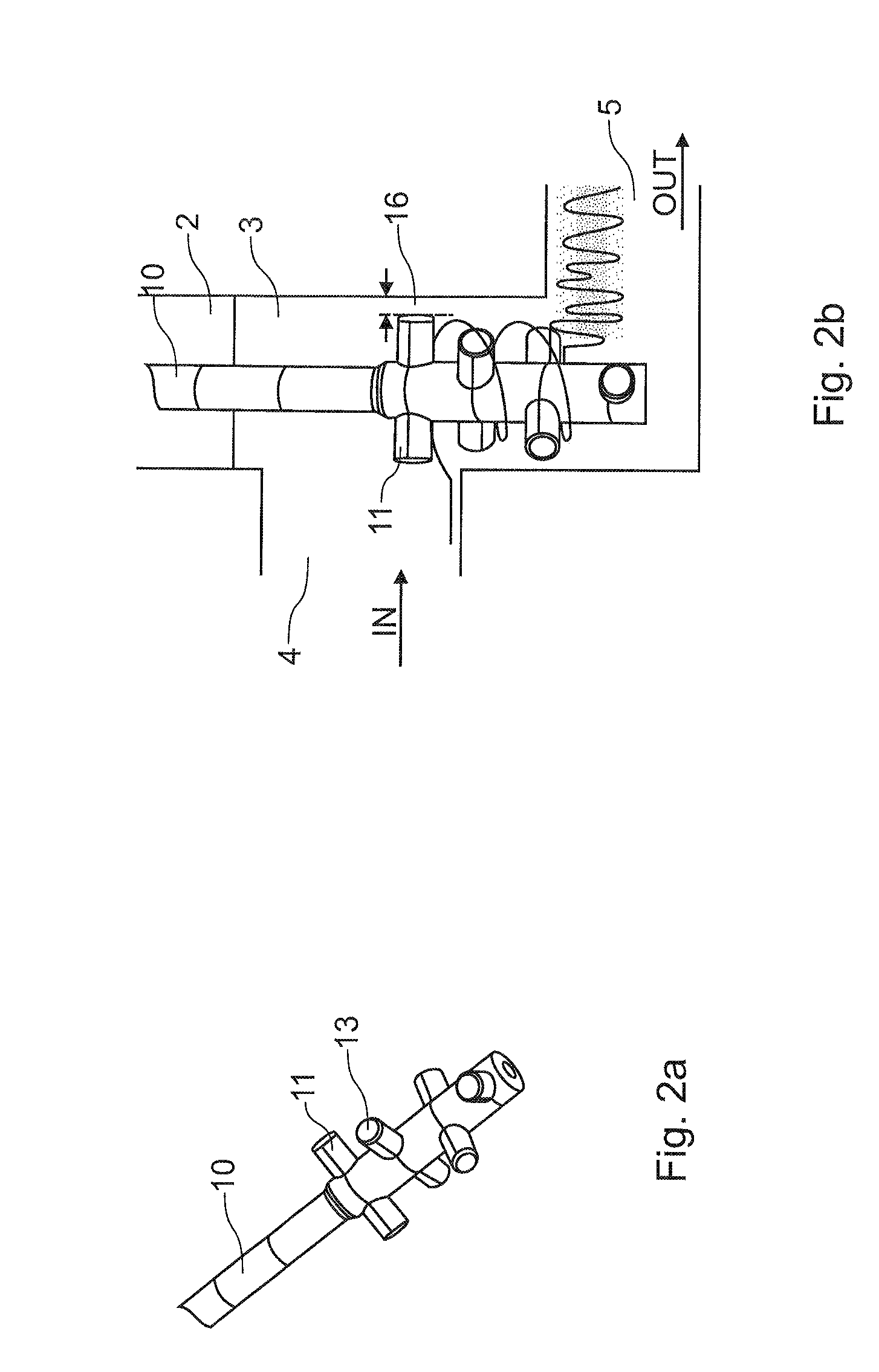

Method and device for homogenizing glass melt

ActiveUS20080148780A1Efficient HomogenizationEasy to adjustRotary stirring mixersGlass furnace apparatusEngineeringMechanical engineering

The invention relates to a method and to a device for homogenizing a glass melt in a melt receptacle, wherein at least one stirring device (10, 11) is disposed in the melt receptacle, which comprises a stirrer shaft (10) and a plurality of stirrer blades (11), and wherein a gap (16) is formed between a wall region of the melt receptacle (2) and the stirrer blades (11).According to the invention, the respective stirring device causes an axial feed action in an inner stirring region (12) between the stirrer shaft (10) and the stirrer blades (11) in order to feed the melt in the stirring region along the stirrer shaft (10). A melt flow brought about by the axial feed action seals the gap (16) against direct passage of the melt.According to the invention, a very high gap width can be achieved, thus preventing the abrasion of materials in the region of the marginal gap. This also reduces the complexity required for adjusting the device. According to the invention, a high level of homogenization can be achieved regardless of the entry point of the inhomogeneities.

Owner:SCHOTT AG

Compatibilized polymer processing additives

ActiveUS8178479B2Impart desired physical characteristicImprove economyBiocideOrganic chemistryPolymer scienceMaterials science

Owner:STRATSYS INC

Method and system for automating sample preparation for microfluidic cryo tem

ActiveUS20110238225A1More volumeReduce shear rateMaterial analysis using wave/particle radiationElectric discharge tubesSmall sampleShear rate

A method and system is provided for automatically preparing transmission electron microscopy (TEM) samples for examination by depositing extremely small samples onto a grid without need for a blotting step. A sample liquid droplet is formed at the end of a capillary, wherein a portion of the liquid is transferred to the TEM sample grid by contact. The excess volume in the liquid droplet is then retracted by an adjacent capillary. After a predetermined time interval, the retraction capillary is moved toward the drop of the sample to remove the excess volume. As compared to a conventional machine, where the blotting procedure can deform the structure of the molecule of interest, the present invention utilizes a very low shear rate for removal of the excess sample fluid.

Owner:BOARD OF GOVERNORS FOR HIGHER EDUCATION STATE OF RHODE ISLAND & PROVIDENCE PLANTATIONS

Method and device for homogenizing glass melt

ActiveUS20110083474A1Efficient HomogenizationEasy to adjustGlass furnace apparatusRotary stirring mixersEngineeringMechanical engineering

The invention relates to a method and to a device for homogenizing a glass melt in a melt receptacle, wherein at least one stirring device (10, 11) is disposed in the melt receptacle, which comprises a stirrer shaft (10) and a plurality of stirrer blades (11), and wherein a gap (16) is formed between a wall region of the melt receptacle (2) and the stirrer blades (11).According to the invention, the respective stirring device causes an axial feed action in an inner stirring region (12) between the stirrer shaft (10) and the stirrer blades (11) in order to feed the melt in the stirring region along the stirrer shaft (10). A melt flow brought about by the axial feed action seals the gap (16) against direct passage of the melt.According to the invention, a very high gap width can be achieved, thus preventing the abrasion of materials in the region of the marginal gap. This also reduces the complexity required for adjusting the device. According to the invention, a high level of homogenization can be achieved regardless of the entry point of the inhomogeneities.

Owner:SCHOTT AG

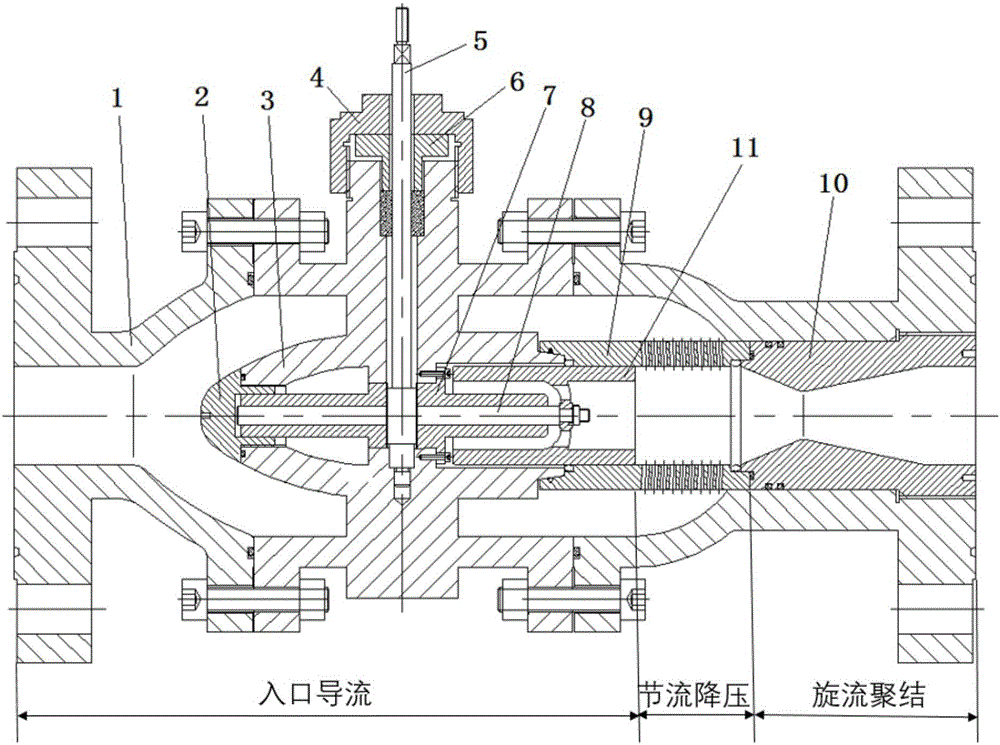

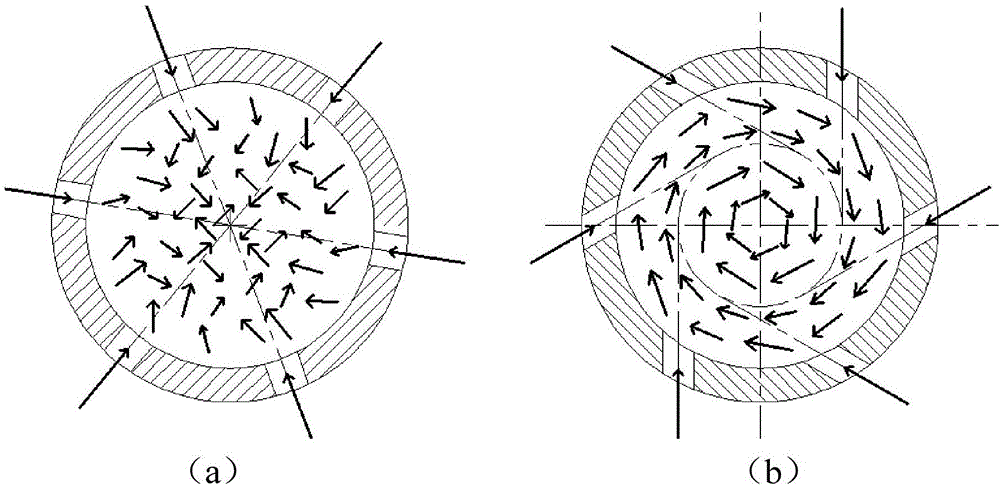

Low shearing plunger type throttling valve used for oil production gathering and transporting

InactiveCN106439137AEnhance swirl effectReduce random vortex motionEqualizing valvesSafety valvesBase functionOil water

The invention discloses a low shearing plunger type throttling valve used for oil production gathering and transporting. Based on a rotational flow agglomeration and unit mass energy dissipation rate control technology, orifices of a valve cage are designed to be in the tangential direction, a rotational flow chamber which is converged firstly and expanded afterwards is connected behind the orifices, the basic function of flow and pressure adjustment can be achieved on the plunger type throttling valve, meanwhile, the velocity gradient and the turbulence energy dissipation rate in a flow field are reduced, the shearing force of the orifices for fluid is reduced, the liquid drop breaking degree is lowered, and the subsequent oil water separation difficulty is lowered.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

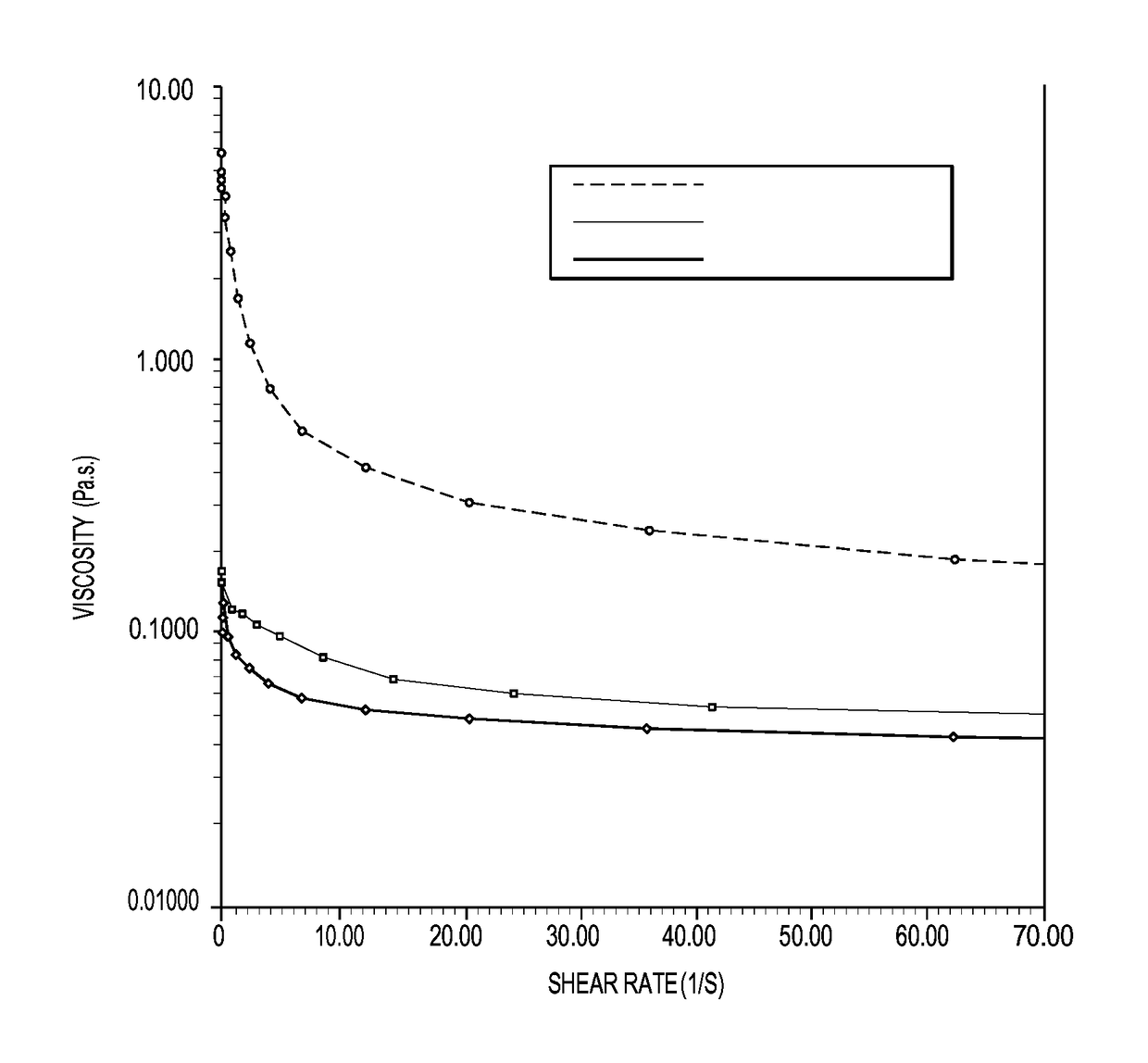

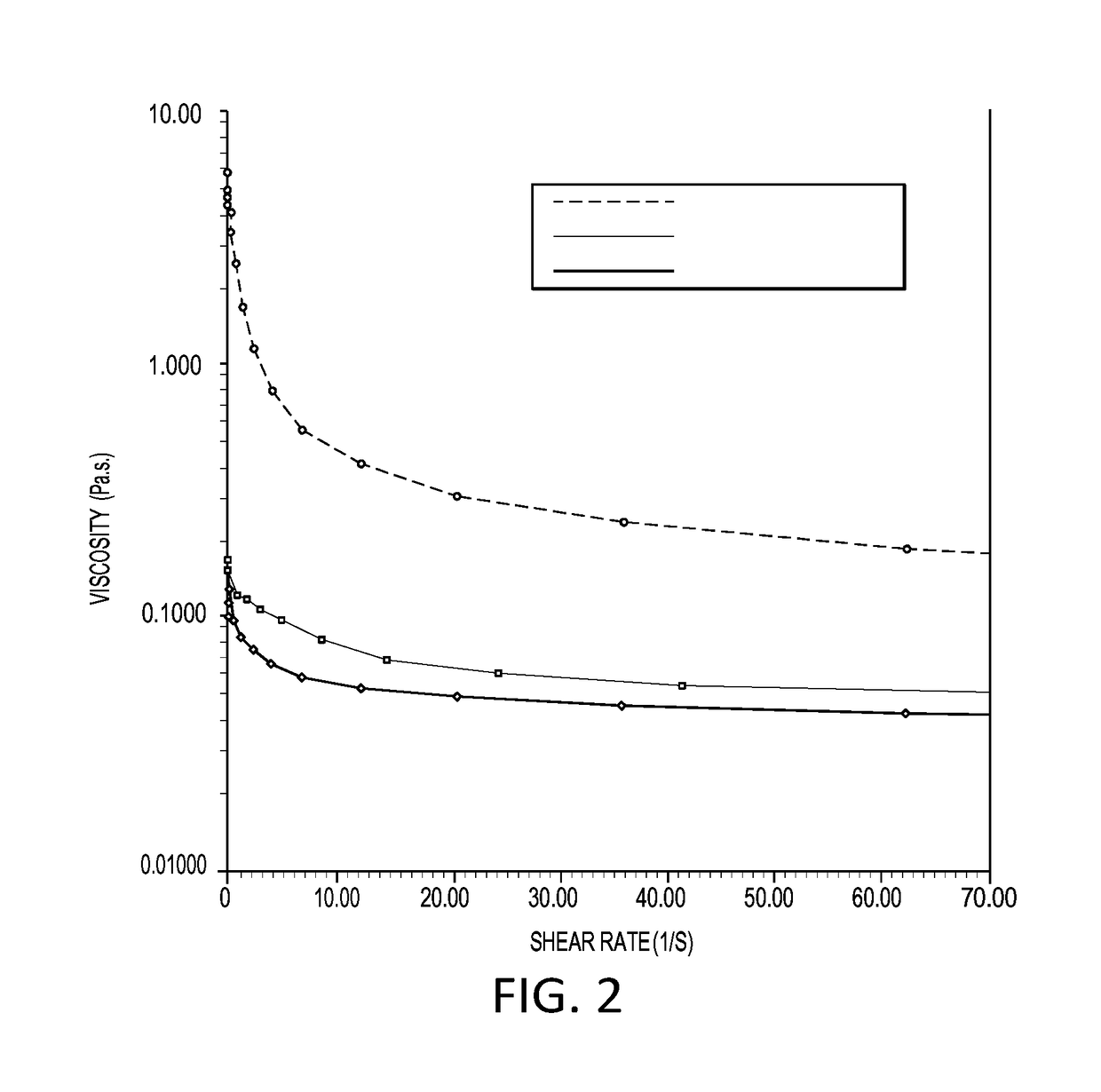

Salt-tolerant, thermally-stable rheology modifiers

ActiveUS10023782B2Improve rheologyReduce shear rateFluid removalDrilling compositionDispersion polymerizationLong chain

A salt-tolerant, thermally-stable rheology modifier and, in particular, a rheology modifier for applications in oilfield well-bore fluids. In accordance with one aspect, the rheology modifier comprises a terpolymer of acrylamide, 2-acrylamido-2-methyl-propanesulfonic acid (AMPS) and a long-chain alkyl acrylate wherein the terpolymer is prepared by dispersion polymerization.

Owner:ISP INVESTMENTS LLC

Insoluble sulfur pre-dispersed rubber masterbatch and preparation method thereof

The invention discloses an insoluble sulfur pre-dispersed rubber masterbatch and a preparation method thereof. The preparation method comprises the following steps of: adding EVA (Ethylene-Vinyl Acetate) and a dispersing agent to a insoluble sulfur masterbatch composite formed by taking an ethylene-propylene diene copolymer and styrene butadiene rubber as colloids, and plasticating at 95-105 DEG C for 15-16 minutes; when the mooney viscosity reaches 23-26 and the surface temperature of plasticated rubber is 18-20 DEG C, adding insoluble sulfur IS7020 and naphthenic oil, and controlling the temperature at 59-63 DEG C; respectively knifing left and right for 4-6 times and 3-4 minutes every time, rolling for 4-6 times and the total time of 1-2 minutes, and tabletting and granulating to prepare the insoluble sulfur IS60-75 rubber masterbatch. Compared with the traditional product technology, the insoluble sulfur pre-dispersed rubber masterbatch disclosed by the invention has the advantage that raw materials of 38 micrometers are all sieved, is not adhered at room temperature without dust flying, can ensure the activity of IS by being pre-dispersed by using a rubber carrier, has very good compatibility with different rubbers, still has lower viscosity and low shearing rate at lower mixing temperature and is easy to disperse and automatically metered. According to the invention, the mixing speed is accelerated, and good dispersion and distribution can be realized within a short time.

Owner:朝阳明宇化工有限公司

Fluoropolymer processing aid modified drip irrigation belt

InactiveCN102746551AReduce shear rateReduce dosageClimate change adaptationWatering devicesPolymer scienceProcedure Agents

The invention relates to a fluoropolymer processing aid modified drip irrigation belt, comprising the following ingredients: 10-90 weight parts of polyethylene resin, 0.2-3 weight parts of fluoropolymer processing aid, and 1-6 weight parts of anti-aging master batch. According to the invention, by fully utilizing the characteristics of good flexibility, strength, and extrusion processing property of the polyethylene resin and combining the fluoropolymer processing aid, the problems of low proportion of added polyethylene reworked materials, high cost, low pressure resistance, and unstable production process in existing drip irrigation belts are solved. The invention can be widely applied in agriculture, forestry and fruit industry, green lawn and the like, and has good social and economic benefit.

Owner:XINJIANG TIANYE GRP +1

Method of using water-superabsorbent polymer in production tubing and pipes

InactiveUS20070167542A1Low viscosityEasy to pumpCosmetic preparationsDrilling rodsSuperabsorbent polymerHeat losses

A thermal insulating packer fluid contains at least one water superabsorbent polymer and optionally water and / or brine, and a viscosifying polymer. The composition is capable of inhibiting unwanted heat loss from production tubing or uncontrolled heat transfer to outer annuli. The viscosity of the composition is sufficient to reduce the convection flow velocity within the annulus.

Owner:BAKER HUGHES INC

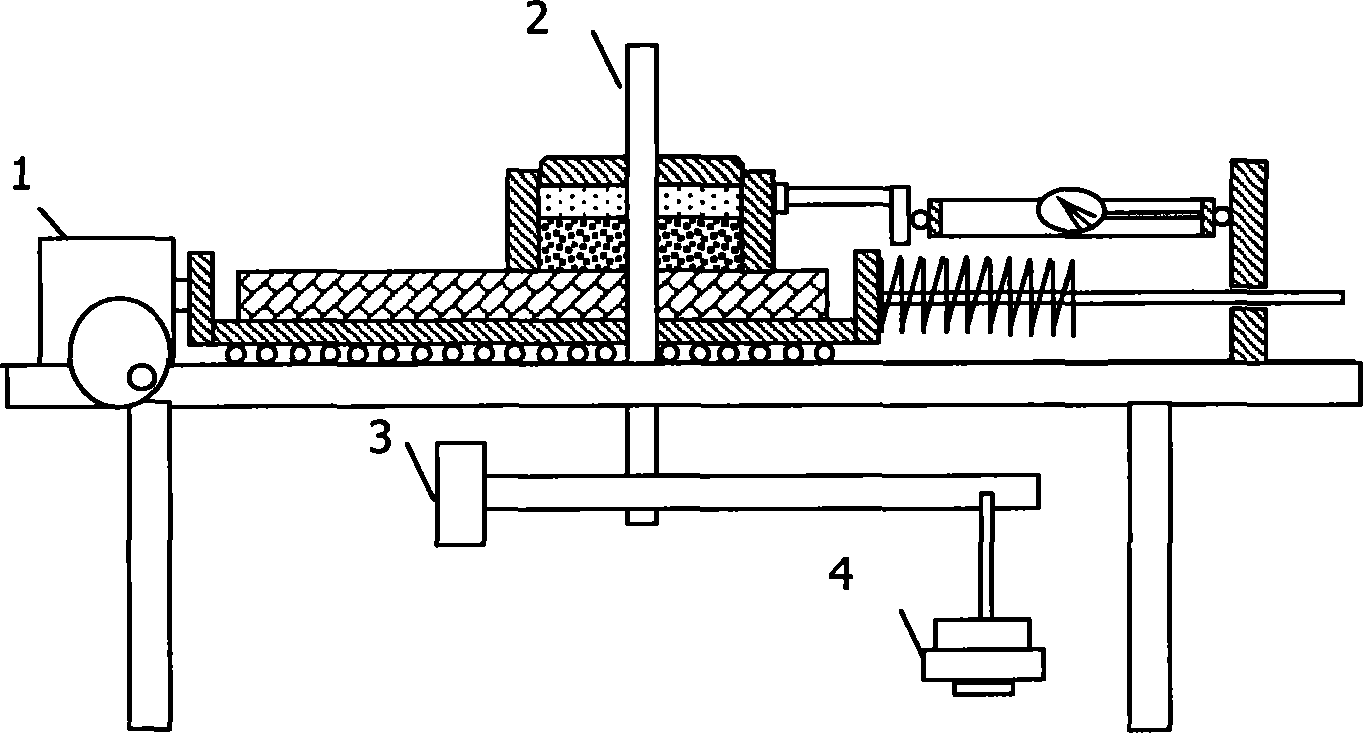

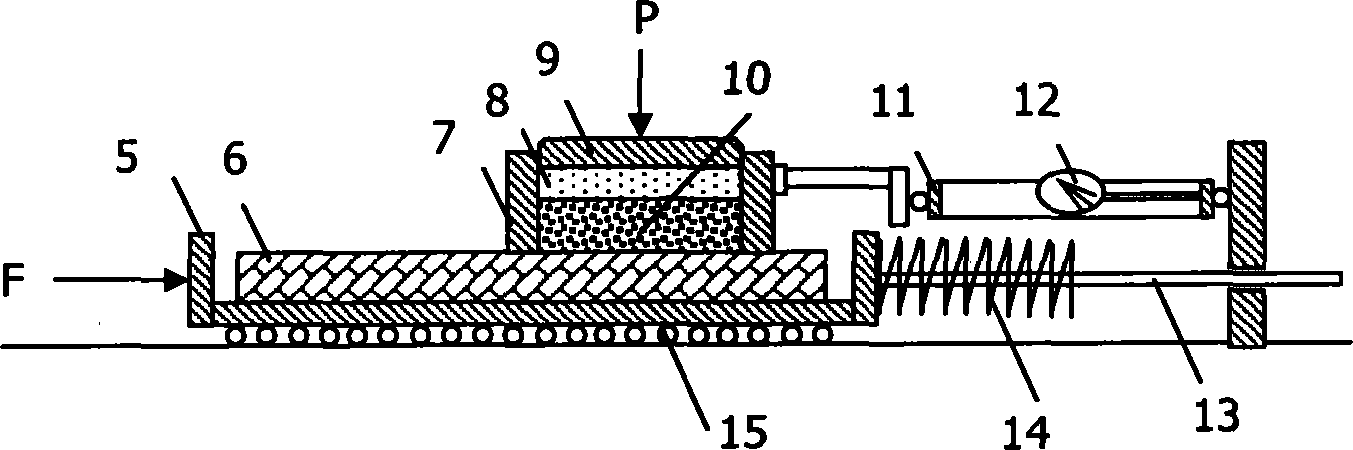

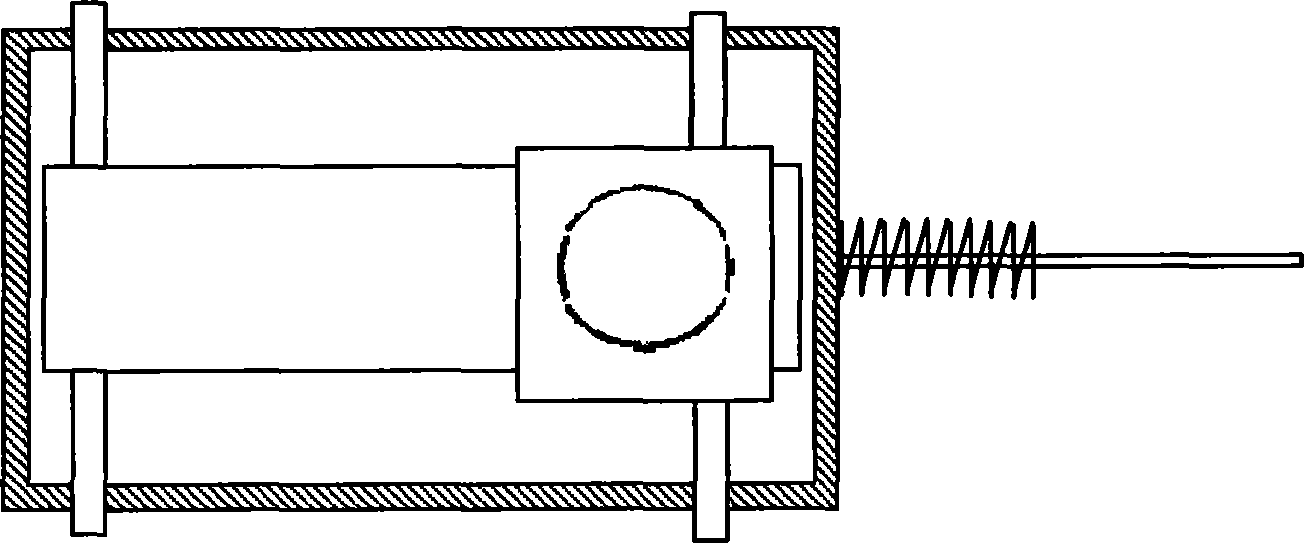

Pile soil sliding friction testing method

InactiveCN104345028AReduce shear rateThe contact area does not changeUsing mechanical meansMaterial analysisStatic frictionEngineering

The invention relates to a testing method for simulating the static friction and the sliding friction of pile soil. On the basis of a direct shearing instrument of soil, necessary improvement is made for simulating the sliding friction of pile soil, and a special pile soil sliding friction testing instrument is designed, so that the static friction and the sliding friction of pile soil can be tested under different bearing stratum conditions, and the static friction and the sliding friction of pile soil can be relatively well measured under different testing conditions. By using a special shearing box, the situation that the contact area is changed in an ordinary shearing process is effectively avoided; as springs for simulating a soil body are additionally arranged, the shearing speed is increased, and the measurement on the friction of pile soil with a bearing stratum and without a bearing stratum can be relatively well completed.

Owner:SUN YAT SEN UNIV

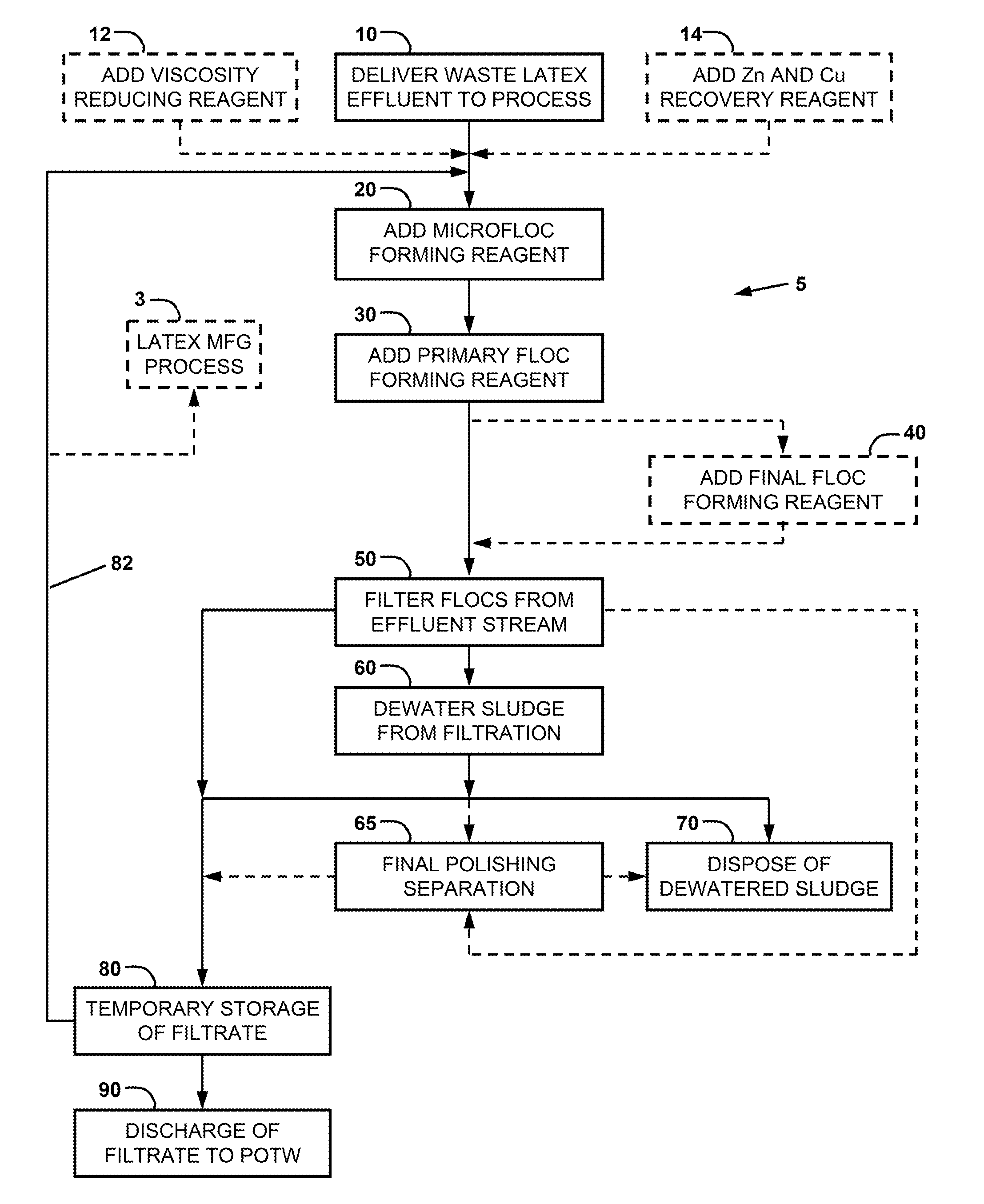

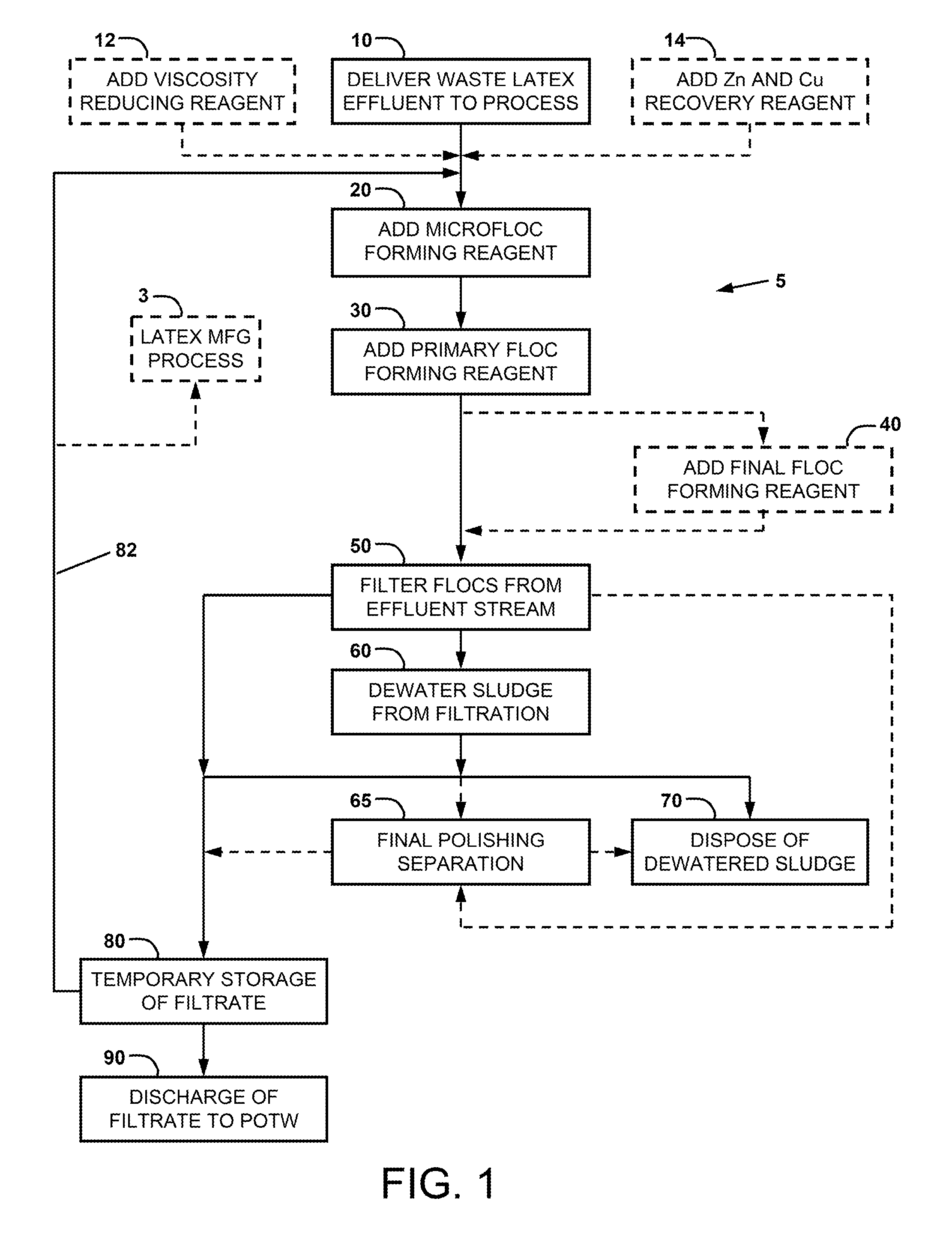

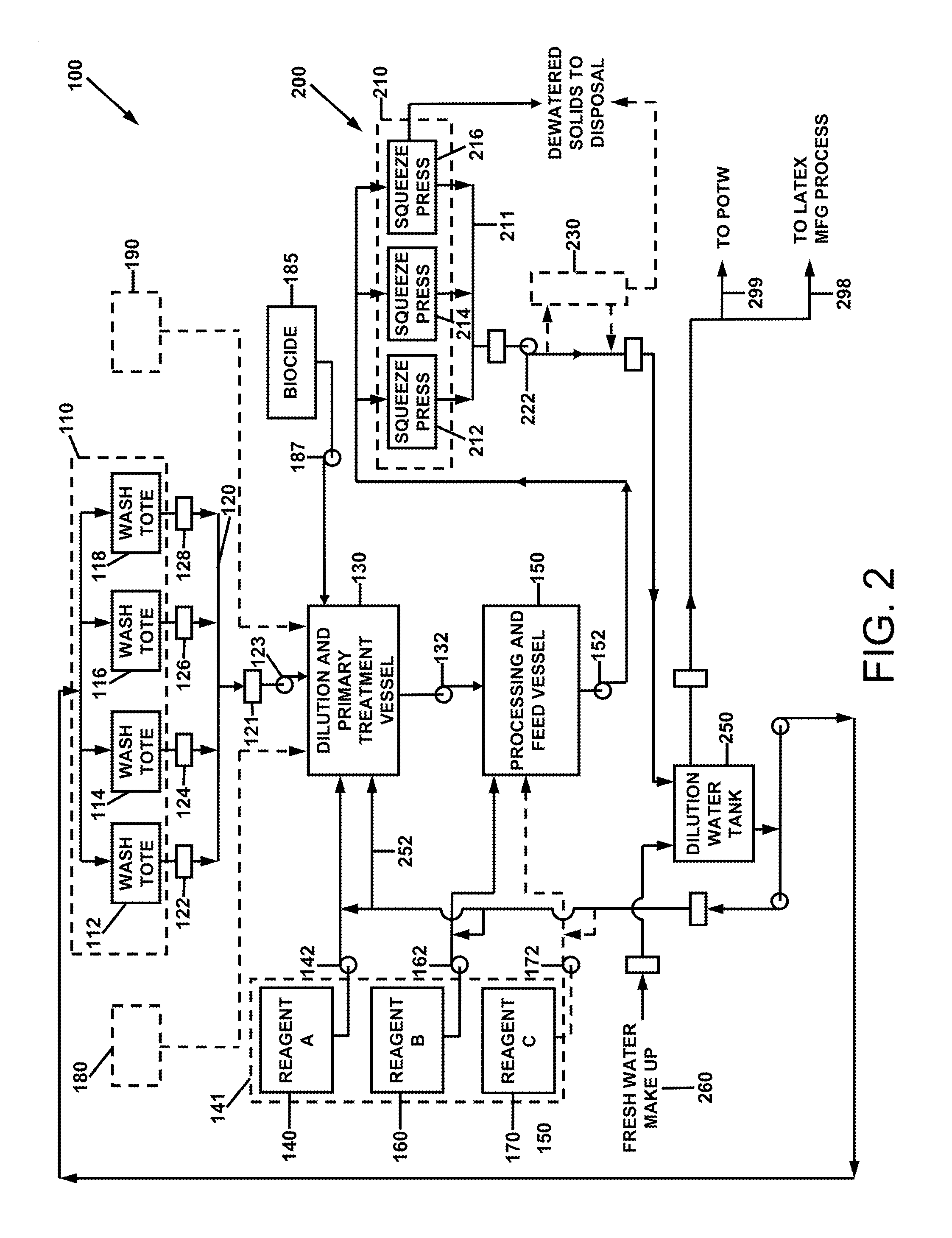

Method for treatment of waste latex

InactiveUS7967988B1More effective dewatering of the sludgeDifficult and impossible to separateTreatment involving filtrationSolid sorbent liquid separationSludgeFiltration

A method and a apparatus for treating a liquid volume containing latex waste, the method comprising providing a treatment apparatus comprising at least a first vessel, and a filtration system in liquid communication with the first vessel; delivering a portion of the liquid containing waste latex to the first vessel; adding a first reagent to the portion of liquid containing waste latex to cause the formation of waste latex flocs of a first size; adding a second reagent to the portion of liquid containing waste latex to cause growth of the waste latex flocs of the first size into separable waste latex flocs; separating the separable waste latex flocs within the filtration system into a waste latex sludge and a first filtrate; and dewatering the waste latex sludge to produce a waste latex solid and a second filtrate. The filtrates may be reusable in a latex manufacturing process.

Owner:INNOVATIVE ENVIRONMENTAL PRODS

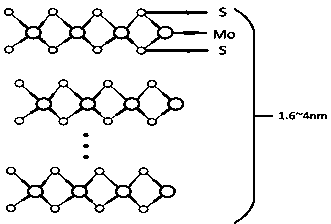

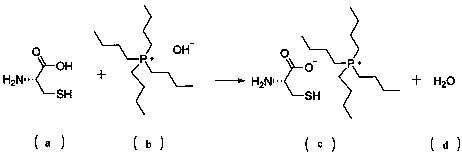

High-loading two-dimensional molybdenum disulfide-binary ionic liquid composite lubricating membrane and preparation method thereof

The invention discloses a high-loading two-dimensional molybdenum disulfide-binary ionic liquid composite lubricating membrane and a preparation method thereof. Two-dimensional molybdenum disulfide isuniformly dispersed in cysteine / cystine tetrabutyl phosphonium salt binary ionic liquid to form uniform and stable suspension, and the surface of a metal substrate is uniformly coated with the suspension. According to the preparation method, the two-dimensional molybdenum disulfide and the binary ionic liquid are combined, the two-dimensional molybdenum disulfide has a layered structure, the ionic liquid has a low shearing rate characteristic, the surface loading capacity of the composite lubricating membrane containing sulphur element formed by the synergistic reaction of the two-dimensionalmolybdenum disulfide and the ionic liquid can be improved, and the friction reducing and resisting performance and self lubricating performance of the surface are enhanced. Compared with a traditional ion lubricant and a molybdenum disulfide solid lubricant, the friction wearing coefficient and loading capacity of the metal substrate and the surface of the metal substrate can be improved.

Owner:XIANGTAN UNIV

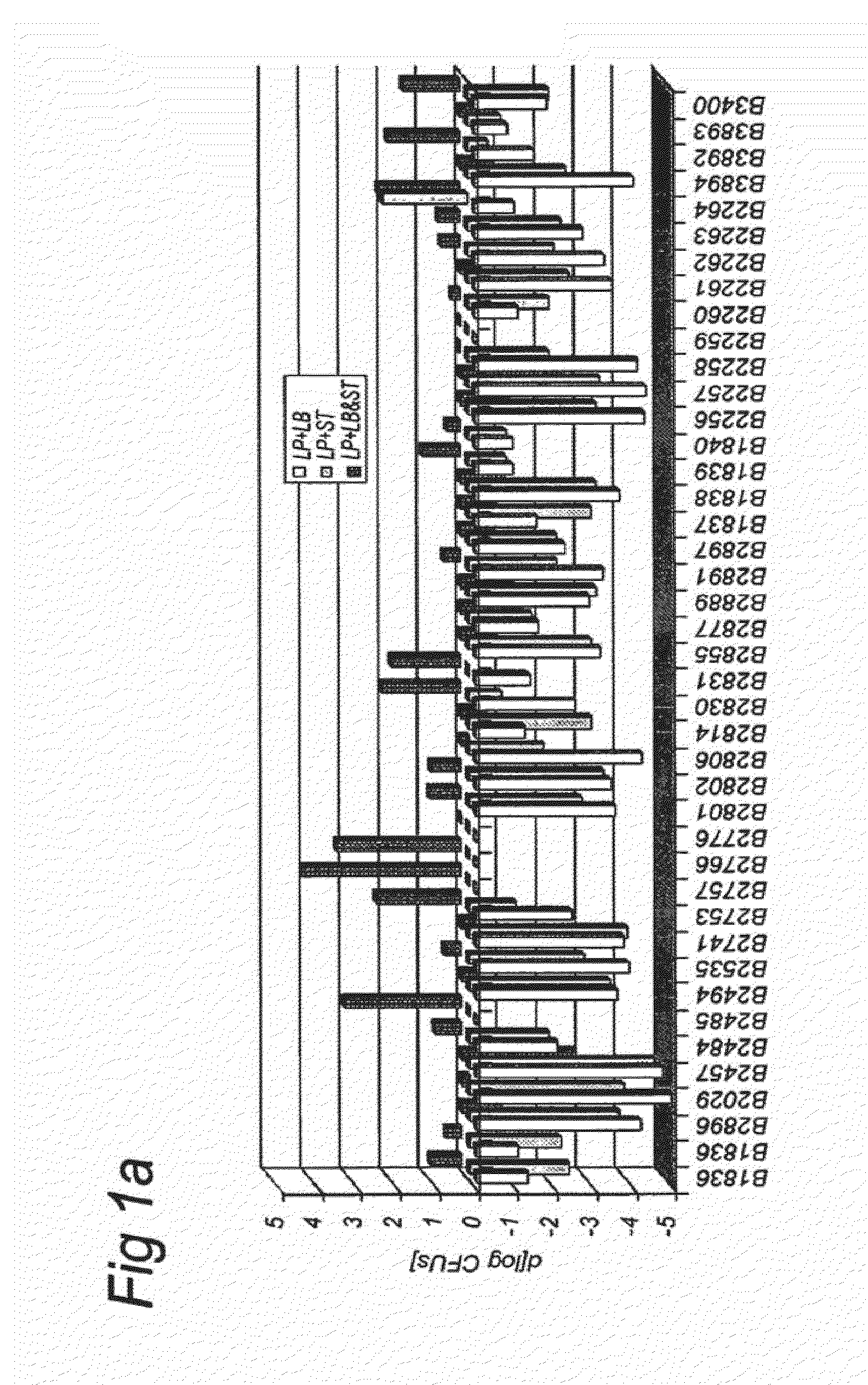

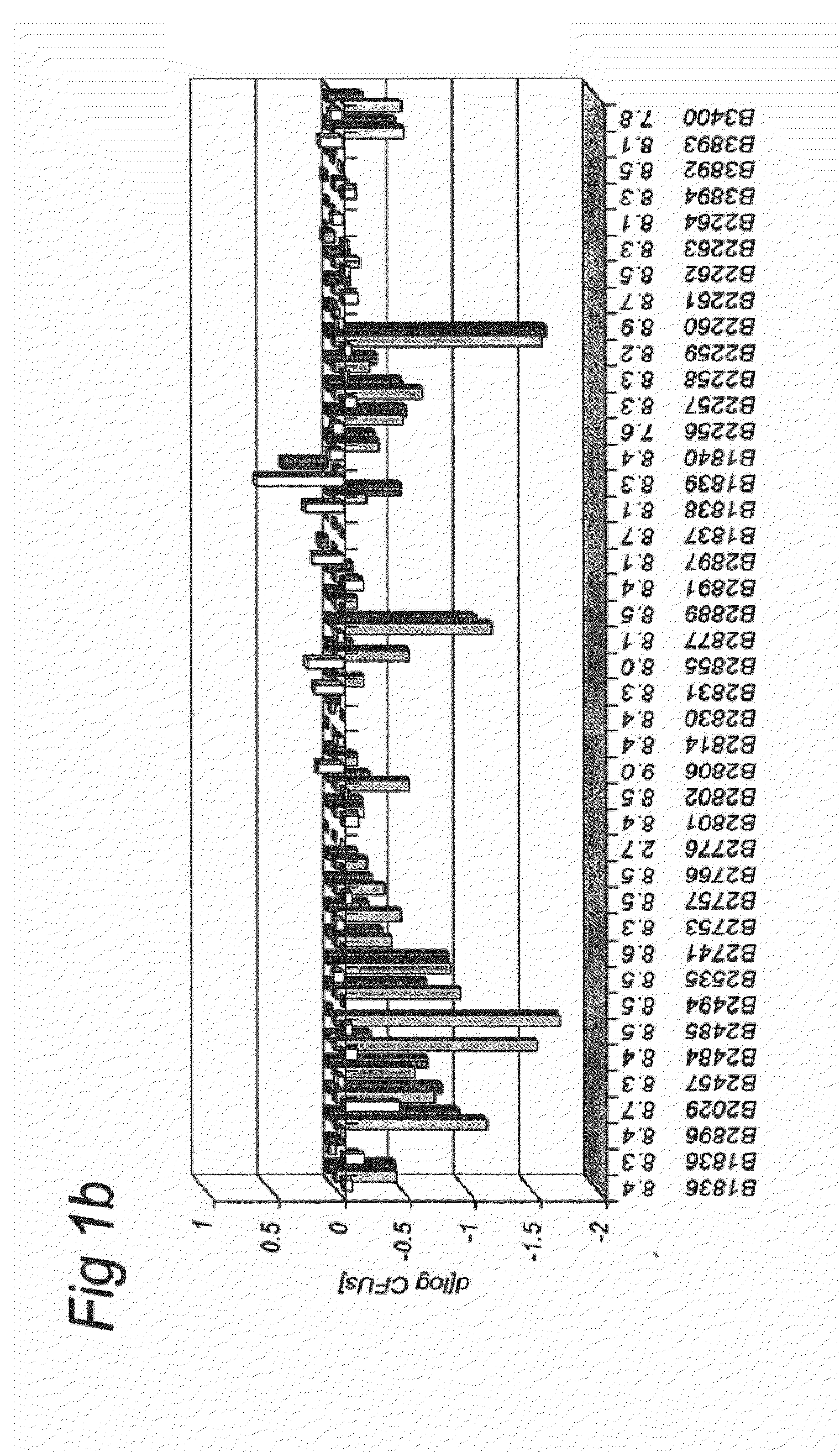

Soy milk fermentation

Owner:DSM IP ASSETS BV

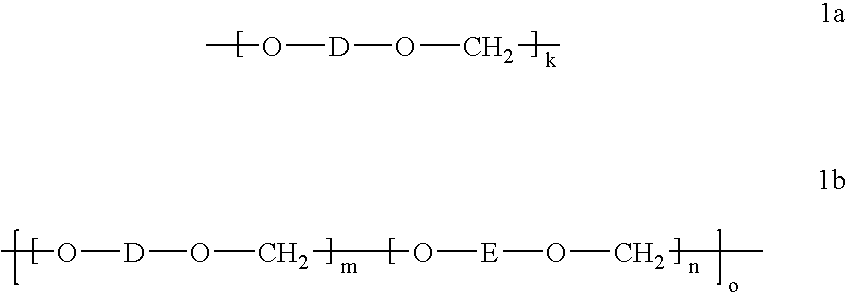

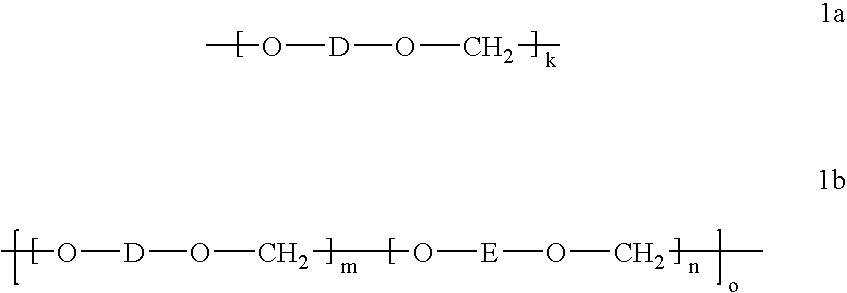

Branched polyformals and copolyformals their preparation and use

InactiveUS20050049389A1Reduce shear rateIncrease shear rateCeramic shaping apparatusMountingsStructural unitWater uptake

A branched (co)polyformal is disclosed. The (co)polyformal contains structural units conforming to at least one the general formulae (1a) and (1b) wherein each of -E- and -D- independently of one another denote an aromatic radical having 6 to 40 C atoms, k is 1 to 4,000, o is 1 to 4,000, m is z / o and n is (o-z) / o, where z is 0 to o. The branched (co)polyformal is characterized by its reduced water uptake and improved hydrolytic stability. Also disclosed are processes for its preparation and use in the production of molded articles.

Owner:BAYER MATERIALSCIENCE AG

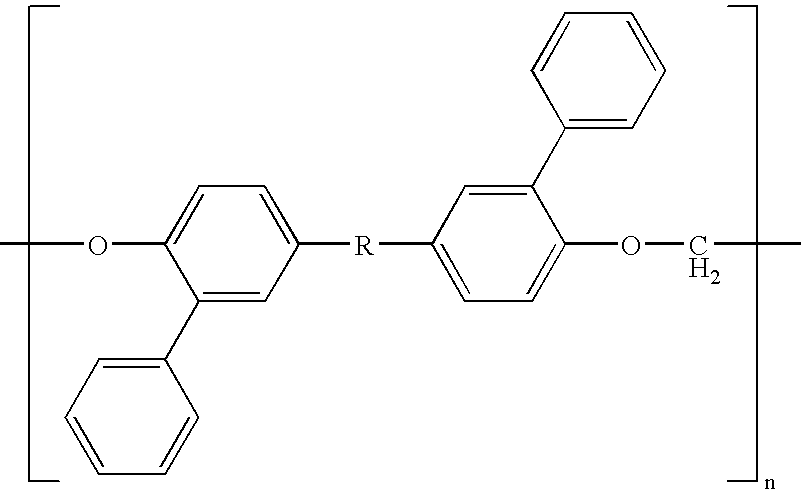

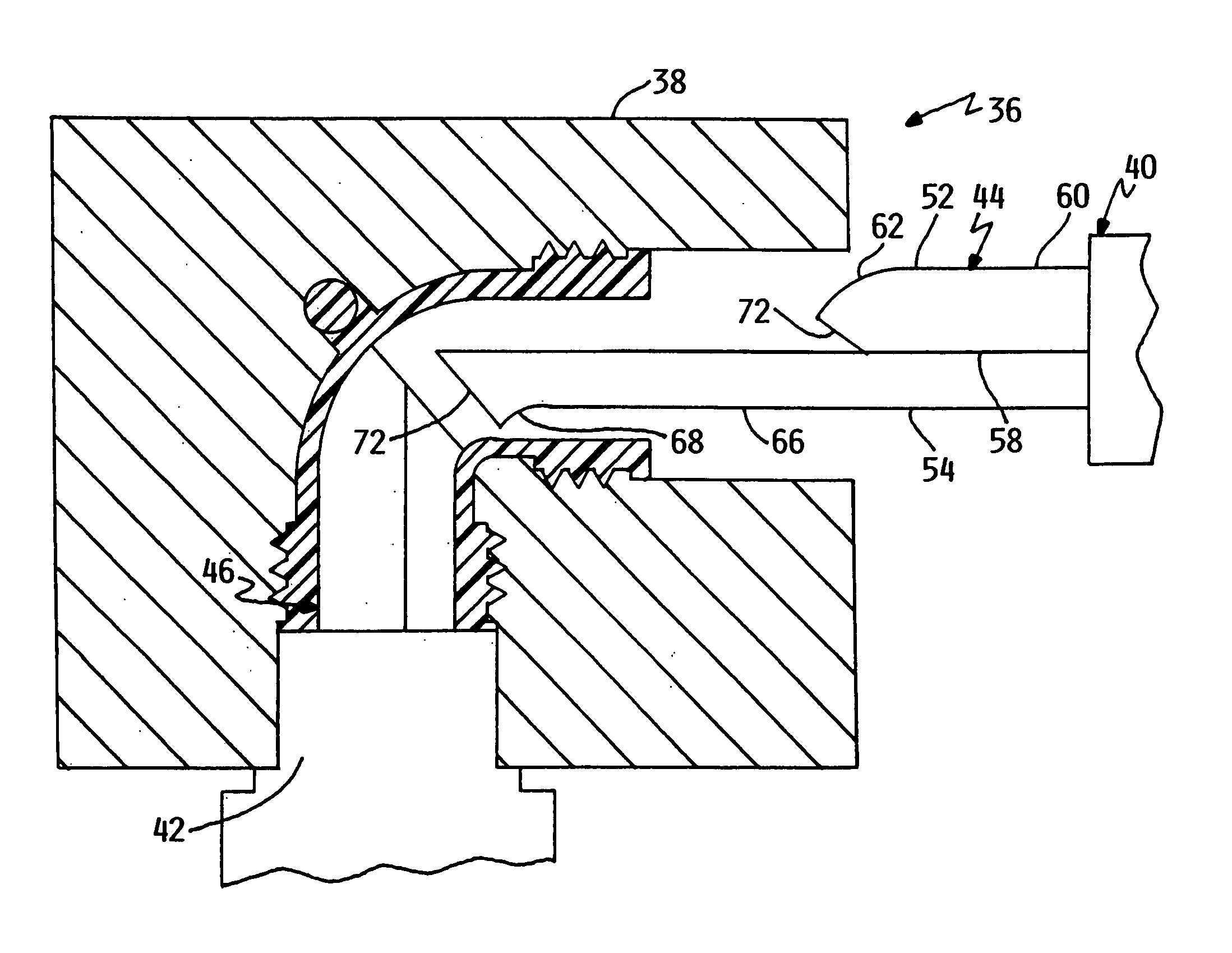

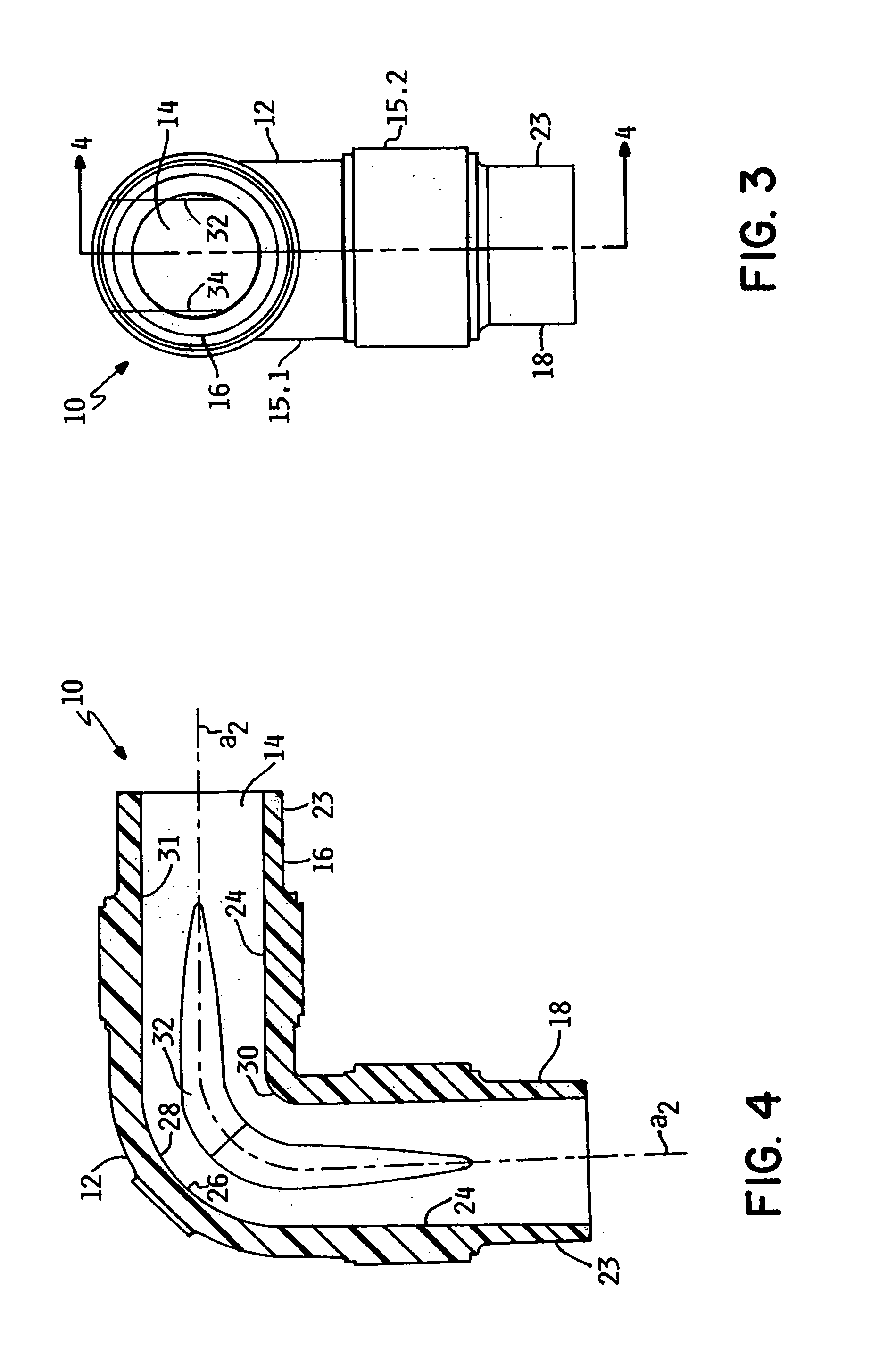

Process and apparatus for molding polymer fittings

InactiveUS7160497B2Improves fluid dynamic of fluidReduce shear rateDischarging arrangementMouldsEngineeringFluoropolymer

A method and apparatus for producing molded fluoropolymer sweep elbows with straight ends while minimizing distortion of the fitting. The invention includes a mold for creating the sweep fittings of the invention. The mold includes a mold cavity block and internal coring. The internal coring includes two symmetrical cores that shut off at a 45° miter. Each of the symmetrical cores is divided into two parts, an outside sweep core and an inside sweep core. The outside sweep core and the inside sweep core are divided on a straight plane running the length of the core. The outside sweep core molds half of the straight lumen and the greater curvature at the outside sweep surface of the bend. The inside sweep core molds the other half of the straight bore and the lesser curvature of the inside or undercut portion of the bend.

Owner:ENTEGRIS INC

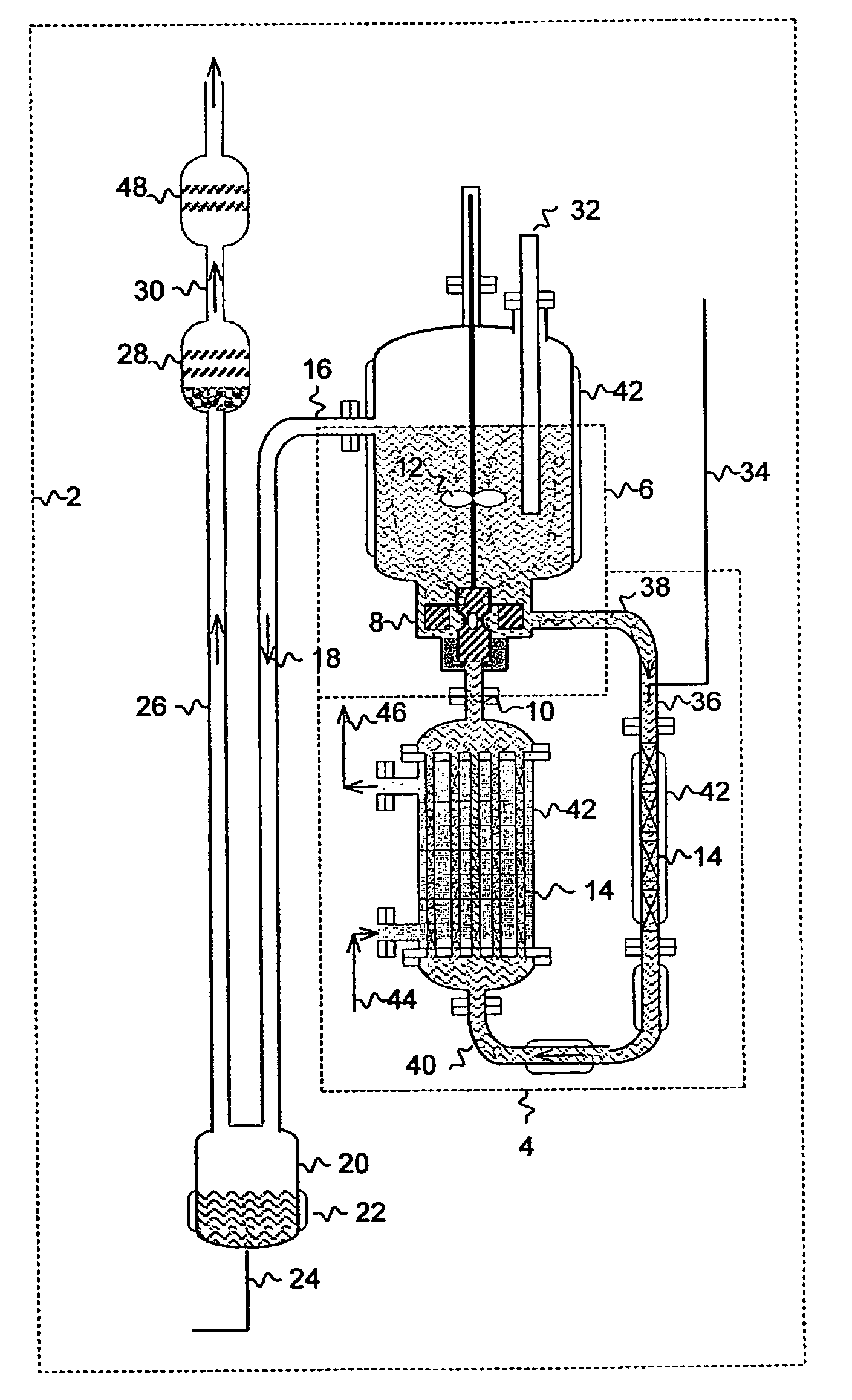

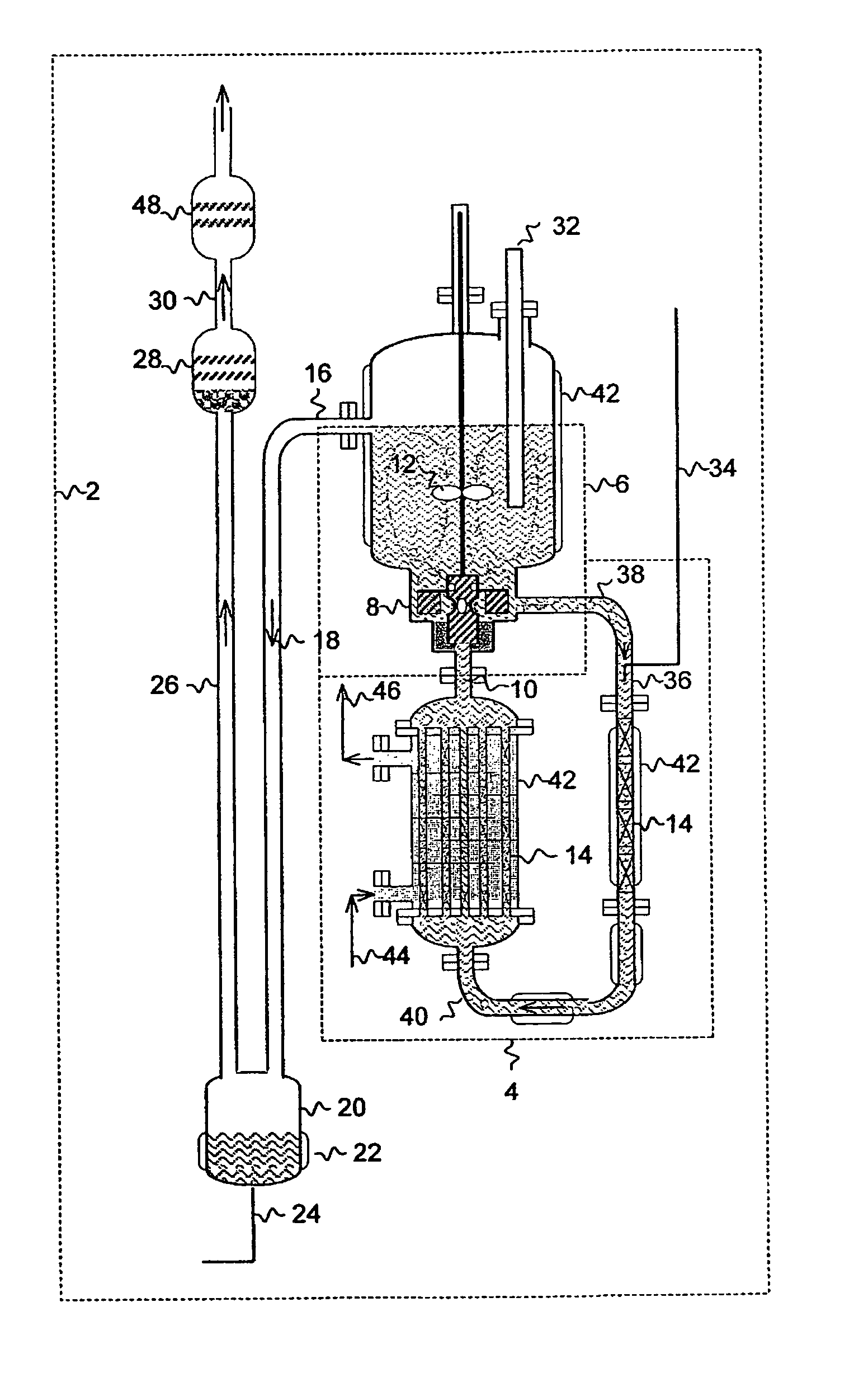

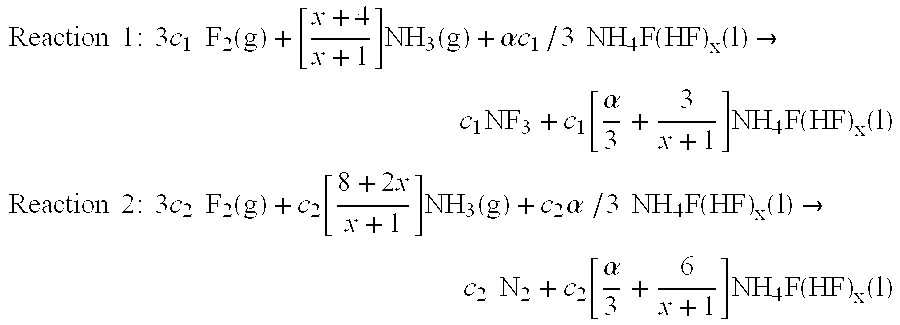

NF3 production reactor

InactiveUS7128885B2Reduce corrosionHigh energy inputCombination devicesFlow mixersBoron trifluorideHigh energy

A process for the production of nitrogen trifluoride by reacting fluorine gas and liquid ammonia acid fluoride in a first reaction zone having a relatively low energy input followed by treatment of the resulting reaction product in a second reaction zone having a relatively high energy input. The resulting crude nitrogen trifluoride product may be further treated with fluorine gas under elevated temperatures to improve yield of the desired product.

Owner:BOC GRP INC

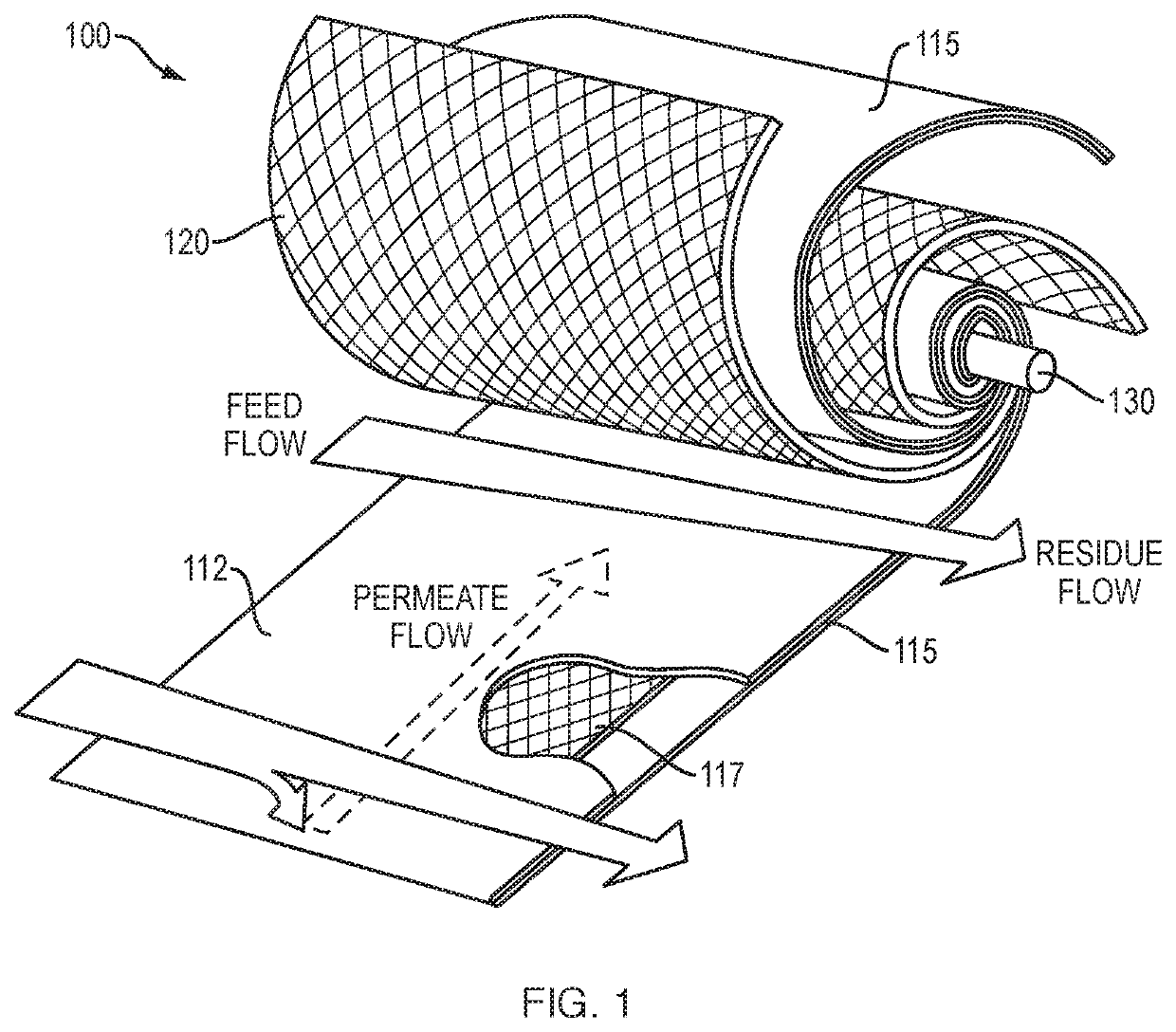

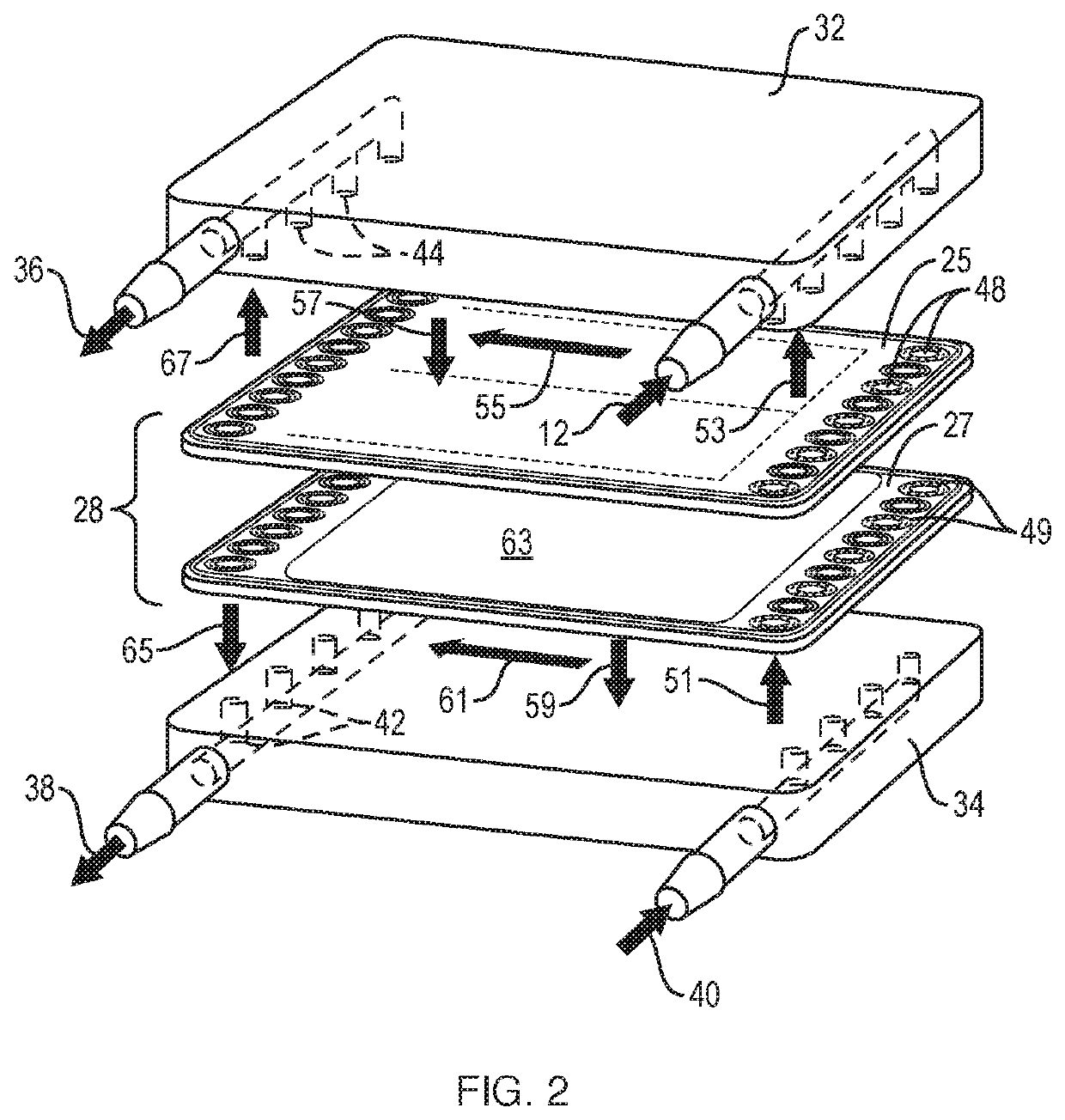

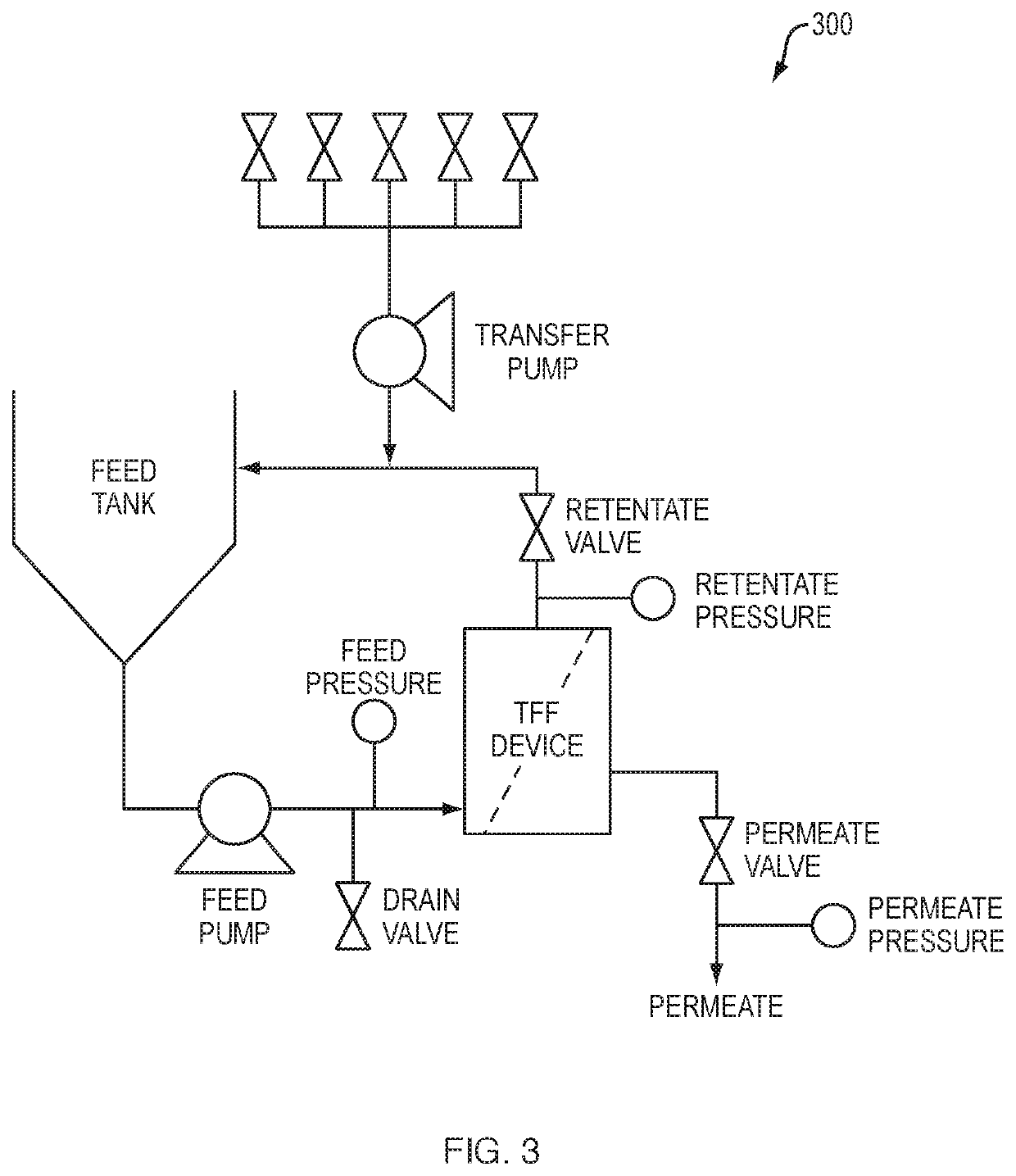

Tangential flow filtration device for perfusion applications

InactiveUS20200139303A1Easy to sieveReduce shear rateBioreactor/fermenter combinationsMembranesFiberSurgery

Filter elements (20, 100) for perfusion systems and methods are provided. A filter element sheet includes a microporous membrane (63, 112) having a mean pore size of at least about 0.65 μm and a feed spacer (25, 120) comprising woven fibers and having an open area of at least about 35%. The filter element sheet can be arranged within a filter element, for example, in a spiral-wound format or in a cassette format. A perfusion system includes at least one filter element and a pump configured to control flow of a liquid feed through the at least one filter element.

Owner:MILLIPORE CORP

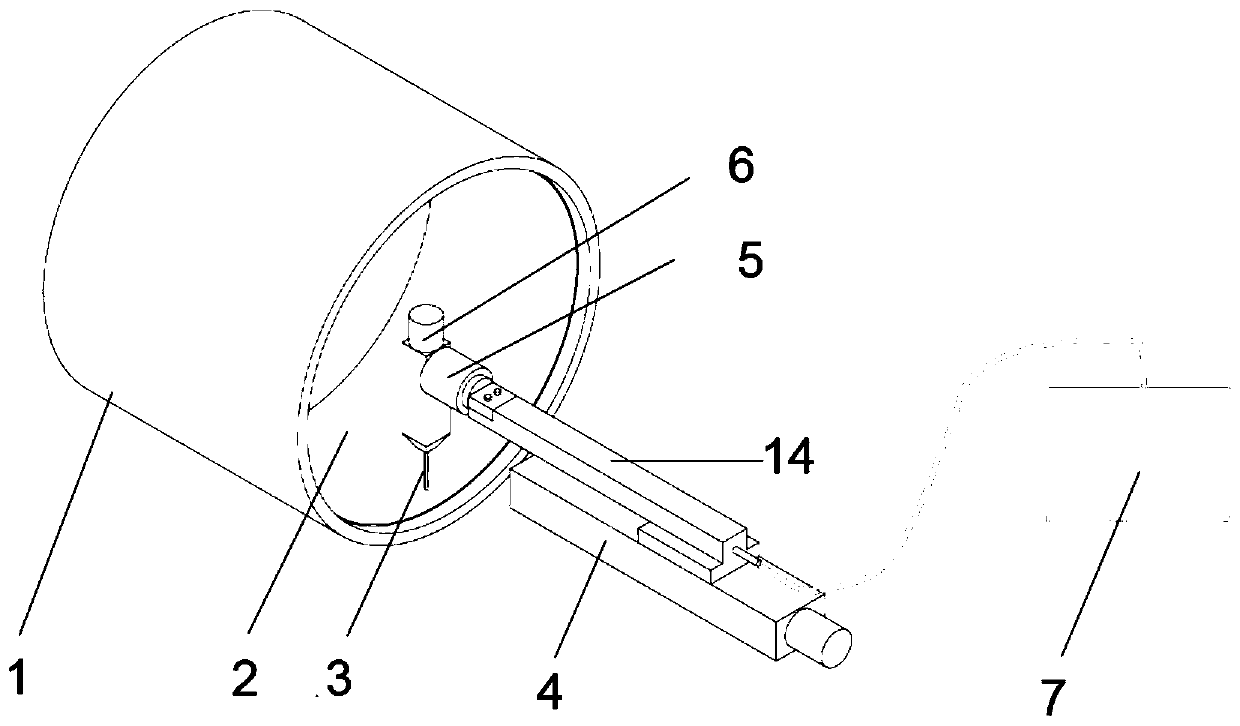

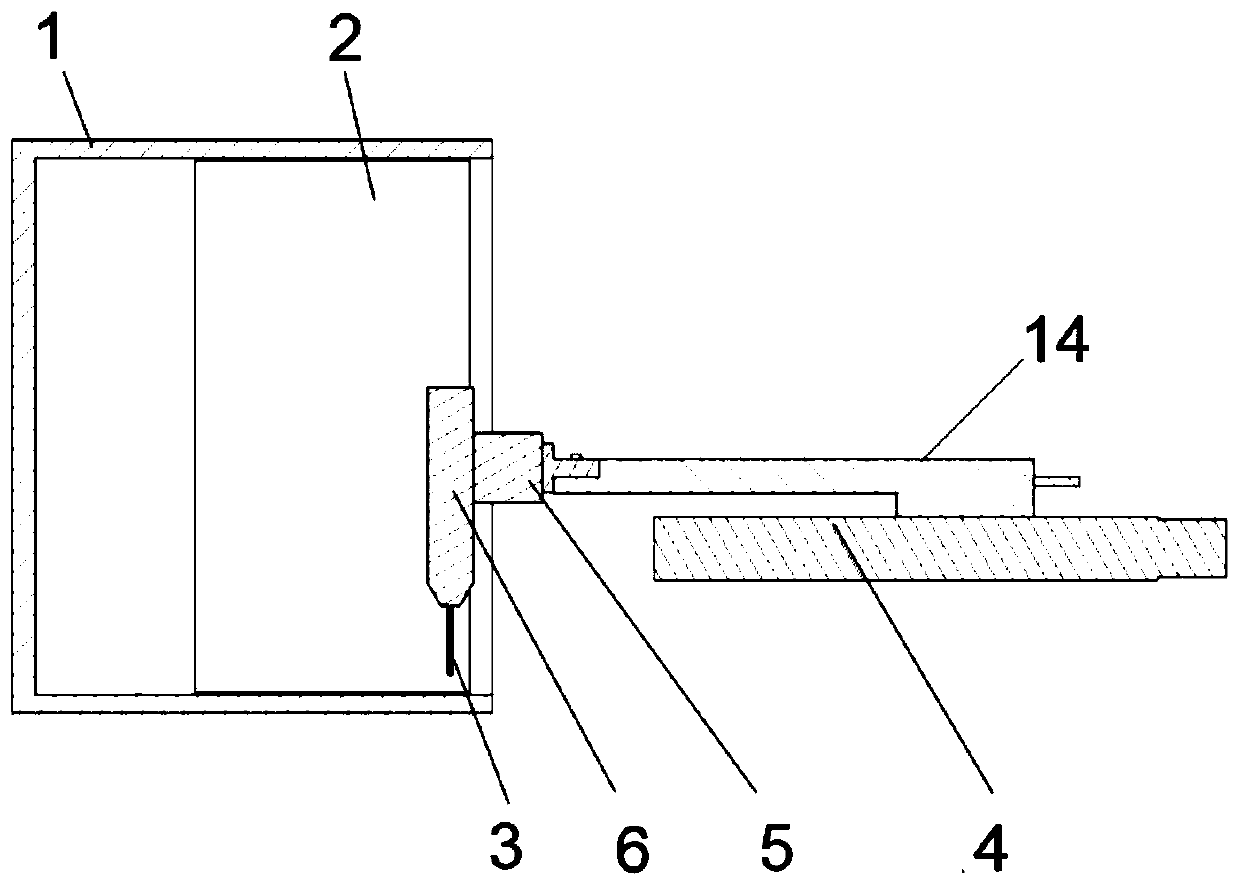

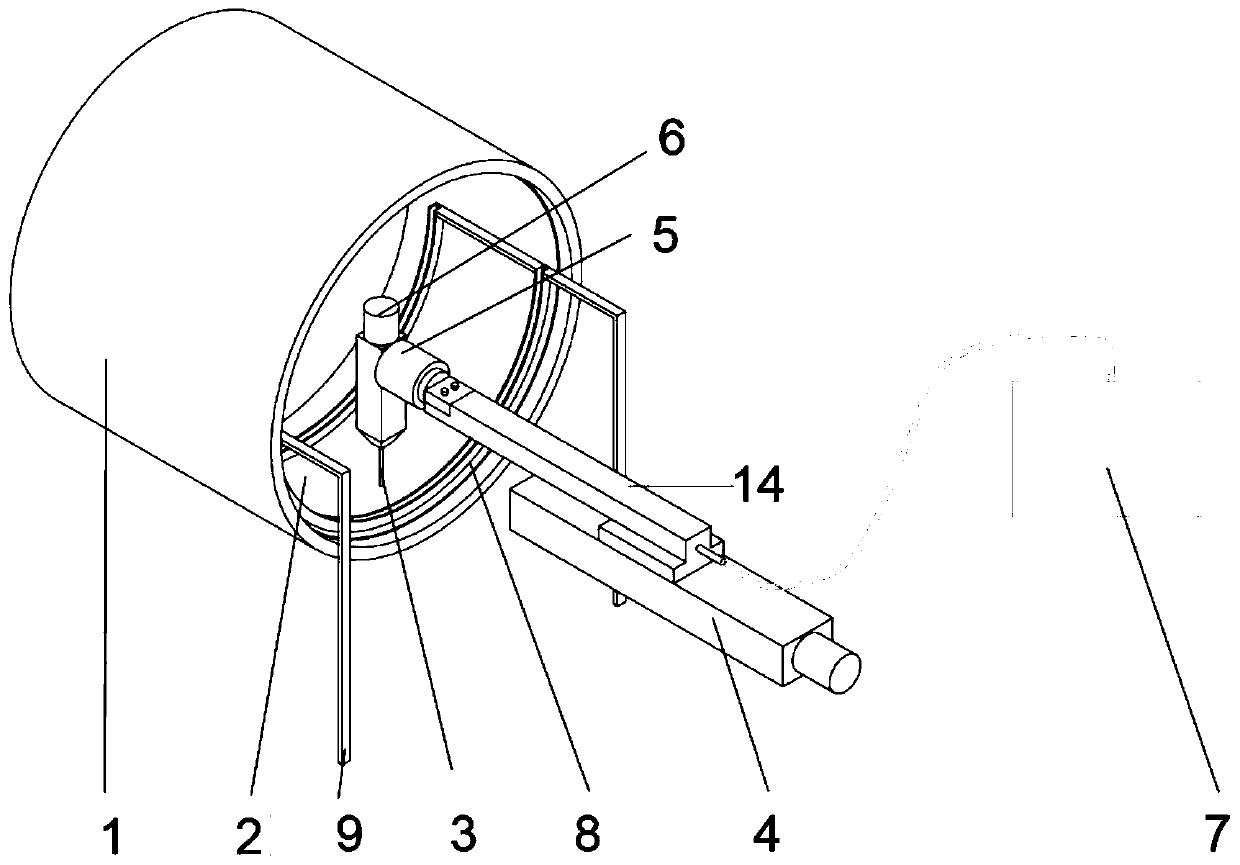

Film forming liquid injection device for centrifugal film preparation

PendingCN110394933AReduce shear ratePrevents direct fall into the film-forming areaCoatingsRotational axisBiomedical engineering

The invention relates to the field of thin film materials and device manufacturing, in particular to a film forming liquid injection device for centrifugal film preparation equipment. The device comprises a rotating drum, a film forming base body, a needle head, a device for moving the needle head in the direction of a rotating axis of the drum, a needle injection angle adjusting device, a needlehead stretching and retracting device and a film forming liquid pressurization assembly, the film forming base body is arranged on the inner surface of the rotating drum, a sliding rod I is arranged on the device for moving the needle head in the direction of the rotating axis of the drum, the sliding rod I is in sliding fit with the device for moving the needle head in the direction of the rotating axis of the drum, one end of the needle injection angle adjusting device is arranged at the tail end of the sliding rod I, the needle head stretching and retracting device is arranged at the otherend of the needle head injection angle adjusting device, a needle head is arranged on the needle head stretching and retracting device, and the needle head is connected with the film forming liquid pressurization assembly through a pipeline. The film forming liquid injection device is mainly used for injecting the film forming liquid of different substances into the surface of the rotating base body in the form of a liquid column so as to realize accurate control and preparation of a thin film structure.

Owner:深圳烯材科技有限公司

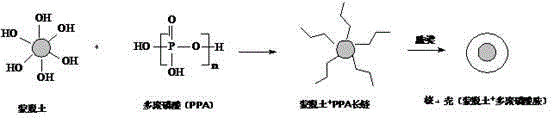

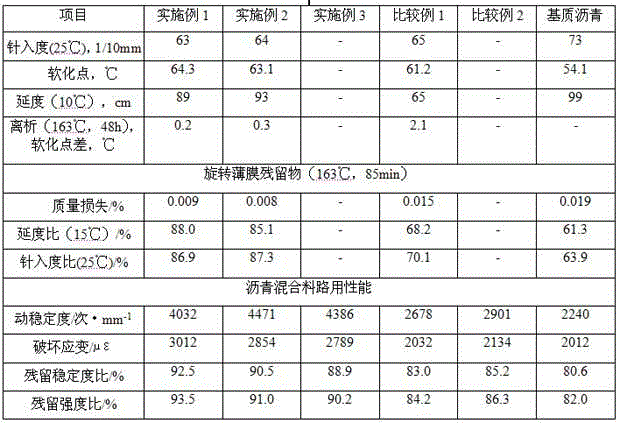

Modified asphalt mixture and preparation method thereof

ActiveCN105585279AImproved rheological properties and anti-aging propertiesHigh hardnessSolid waste managementAmmonium polyphosphateAsphalt

The invention provides a modified asphalt mixture which includes 100 parts of a mineral aggregate, 3-6 parts of asphalt, and 0.05-1 part of organized montmorillonoid. The organized montmorillonoid is an organized montmorillonoid road asphalt modifier having a core-shell structure and being prepared in a manner of modifying the surface of micron-scale montmorillonite granules and coating the micron-scale montmorillonite granules by ammonium polyphosphate with montmorillonoid, polyphosphoric acid and amine compounds as raw materials, wherein the core-shell structure improves the dispersibility and uniformity of the montmorillonite inorganic powder granules in asphalt and greatly improves the rheological property and anti-aging performance of the asphalt. The modified asphalt mixture has excellent anti-rutting performance, low-temperature anti-cracking performance and anti-aging performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for homogenizing glass melt

ActiveUS8347652B2Efficient HomogenizationEasy to adjustRotary stirring mixersGlass furnace apparatusMechanical engineeringPhysics

The invention relates to a device for homogenizing a glass melt in a melt receptacle, wherein at least one stirring device is disposed in a melt receptacle, which comprises a stirrer shaft and a plurality of stirrer blades, and wherein a gap (16) is formed between a wall region of the melt receptacle and the stirrer blades. According to the invention, the respective stirring device causes an axial feed action in an inner stirring region between the stirrer shaft and the stirrer blades in order to feed the melt in the stirring region along the stirrer shaft. A melt flow brought about by the axial feed action seals the gap against direct passage of the melt. According to the invention, a very high gap width can be achieved, thus preventing the abrasion of materials in the region of the marginal gap. This also reduces the complexity required for adjusting the device. According to the invention, a high level of homogenization can be achieved regardless of the entry point of the inhomogeneities.

Owner:SCHOTT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com