Modified asphalt mixture and preparation method thereof

A modified asphalt and mixture technology, applied in the field of asphalt mixture, can solve problems such as difficult formation of exfoliated montmorillonite structure, improve rheological properties, anti-aging performance, better compatibility, and convenient application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

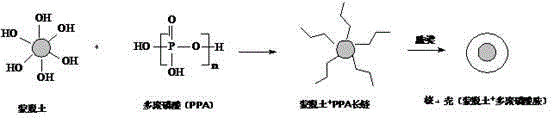

Method used

Image

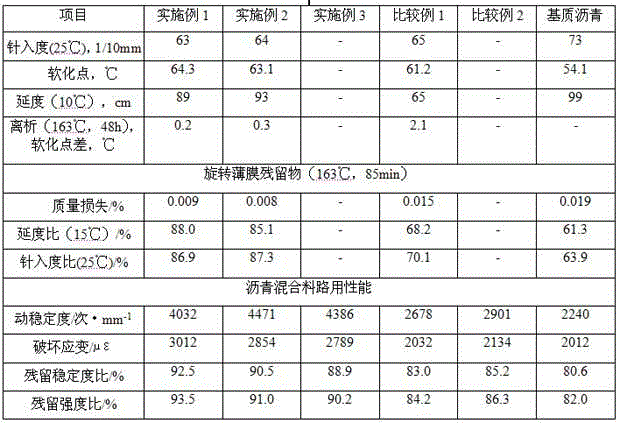

Examples

Embodiment 1

[0044] The modified asphalt mixture of this embodiment is made of the following raw materials: 100 kg of mineral aggregate, 3.5 kg of asphalt, 0.1 kg of organic montmorillonite, and the asphalt is ordinary 70# asphalt.

[0045] Organic montmorillonite was prepared as follows:

[0046] Under the condition of high-speed stirring (1500r / min), quickly add montmorillonite to polyphosphoric acid ethanol solution, keep stirring for 20min, and filter with suction. Add the filter cake to the dodecylamine ethanol solution, stir for 1 h after the addition is complete, and filter with suction. After washing and vacuum drying, the organic montmorillonite with good particle dispersion, fluffy and no grinding is finally obtained. The weight content of each substance is as follows: montmorillonite: 25%; polyphosphoric acid: 25%; dodecylamine: 50%.

[0047] The preparation method of modified asphalt mixture in the present embodiment is:

[0048] (1) The organic montmorillonite was added to ...

Embodiment 2

[0052] The modified asphalt mixture of this embodiment is made of the following raw materials: 100 kg of mineral aggregate, 5 kg of asphalt, 0.5 kg of organic montmorillonite, and the asphalt is ordinary 70# asphalt.

[0053] Preparation of organic montmorillonite:

[0054] Under the condition of high-speed stirring (1500r / min), quickly add montmorillonite to polyphosphoric acid ethanol solution, keep stirring for 20min, and filter with suction. Add the filter cake to the cetylamine ethanol solution, stir for 1 hour after the addition is complete, and filter with suction. After washing and vacuum drying, the organic montmorillonite with good particle dispersion, fluffy and no grinding is finally obtained. The weight content of each substance is as follows: montmorillonite: 20%; polyphosphoric acid: 40%; cetylamine: 40%.

[0055] The preparation method of modified asphalt mixture in the present embodiment is:

[0056] (1) The organic montmorillonite was added to the asphalt at...

Embodiment 3

[0061] The modified asphalt mixture of this embodiment is made of the following raw materials: 100 kg of mineral aggregate, 4 kg of asphalt, 1 kg of organic montmorillonite, and the asphalt is ordinary 70# asphalt.

[0062] Preparation of organic montmorillonite:

[0063] Under the condition of high-speed stirring (1500r / min), quickly add montmorillonite to polyphosphoric acid ethanol solution, keep stirring for 20min, and filter with suction. Add the filter cake to the stearylamine ethanol solution, stir for 1 hour after the addition is complete, and filter with suction. After washing and vacuum drying, the organic montmorillonite with good particle dispersion, fluffy and no grinding is finally obtained. The weight content of each substance is as follows: montmorillonite: 15%; polyphosphoric acid: 35%; octadecylamine: 50%.

[0064] The preparation method of modified asphalt mixture in the present embodiment is:

[0065] (1) Heat the aggregate in the mineral material to 180...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com