Patents

Literature

47results about How to "High energy input" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additive manufacturing of metal alloys and metal alloy matrix composites

ActiveUS20180161874A1High strengthPrevent partial lowAdditive manufacturing apparatusTitanium carbideMetal alloyNucleation

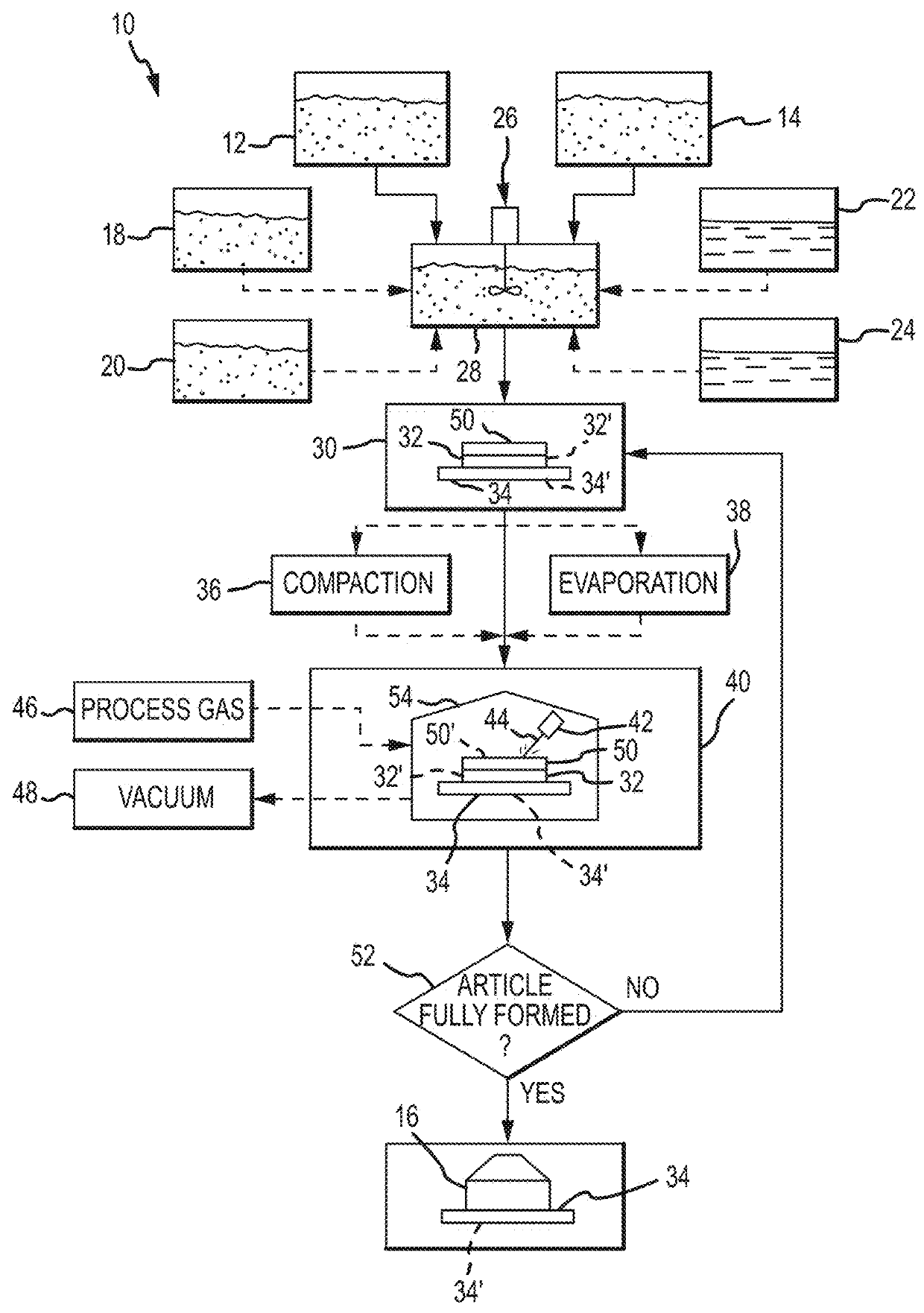

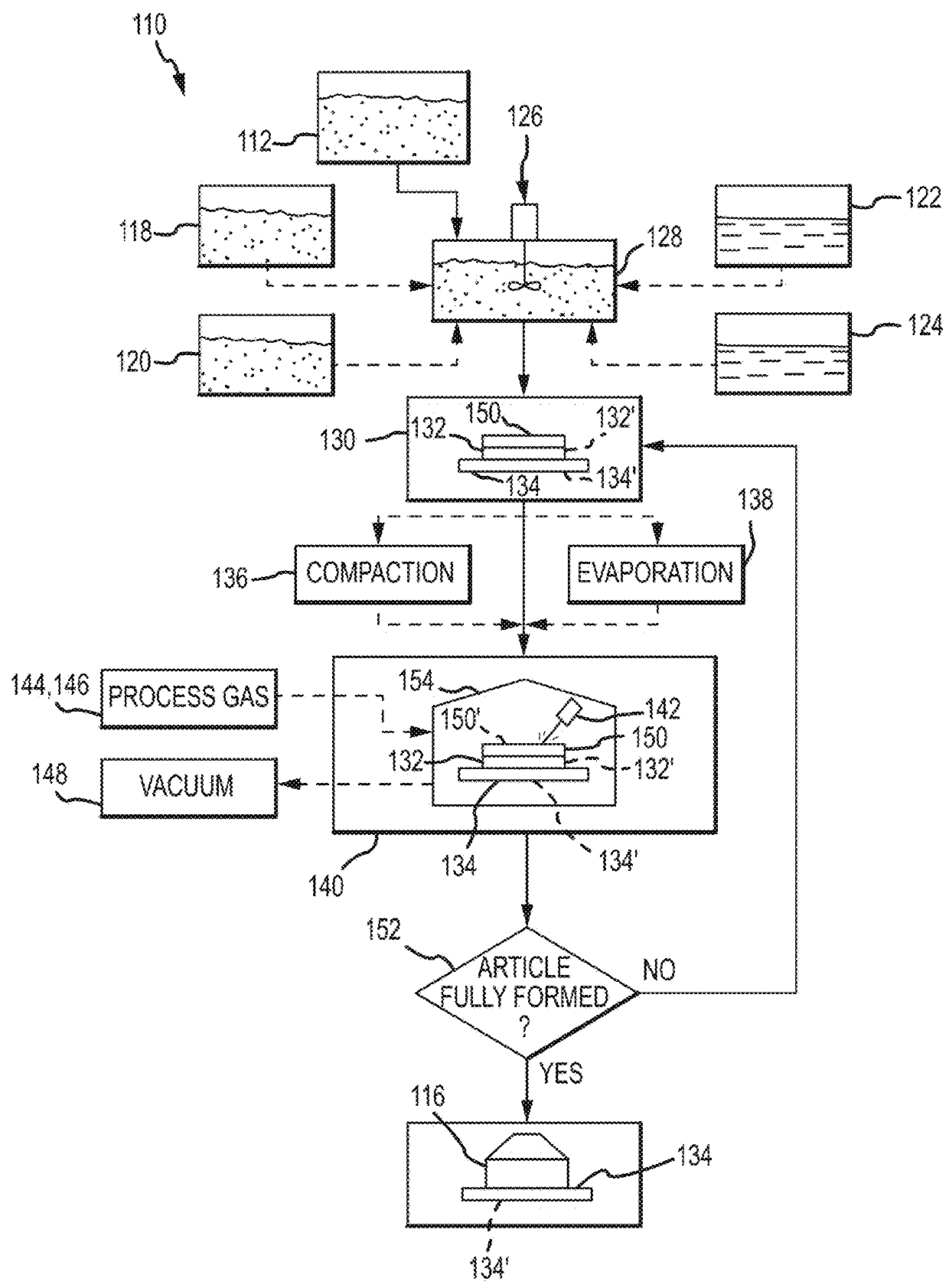

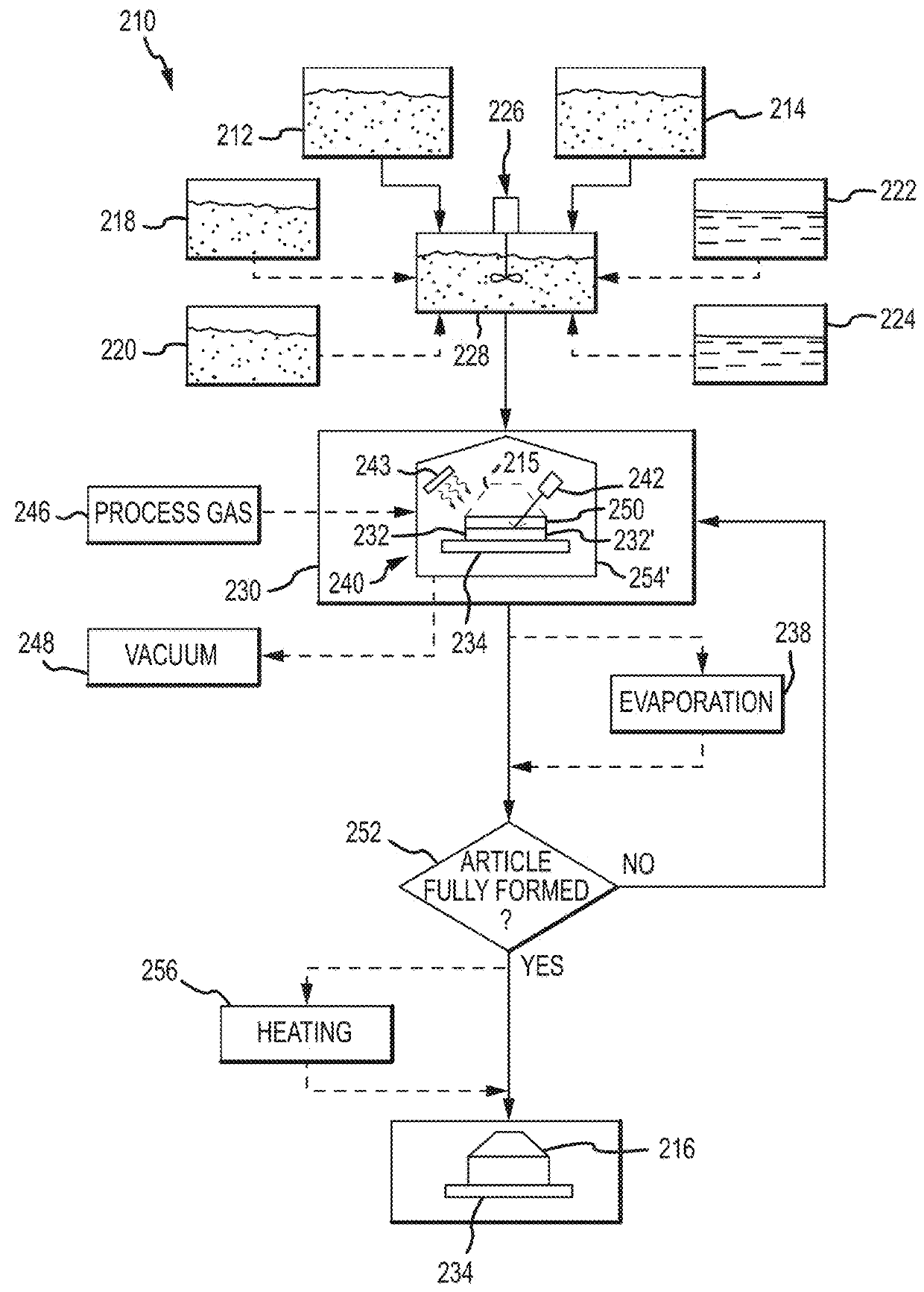

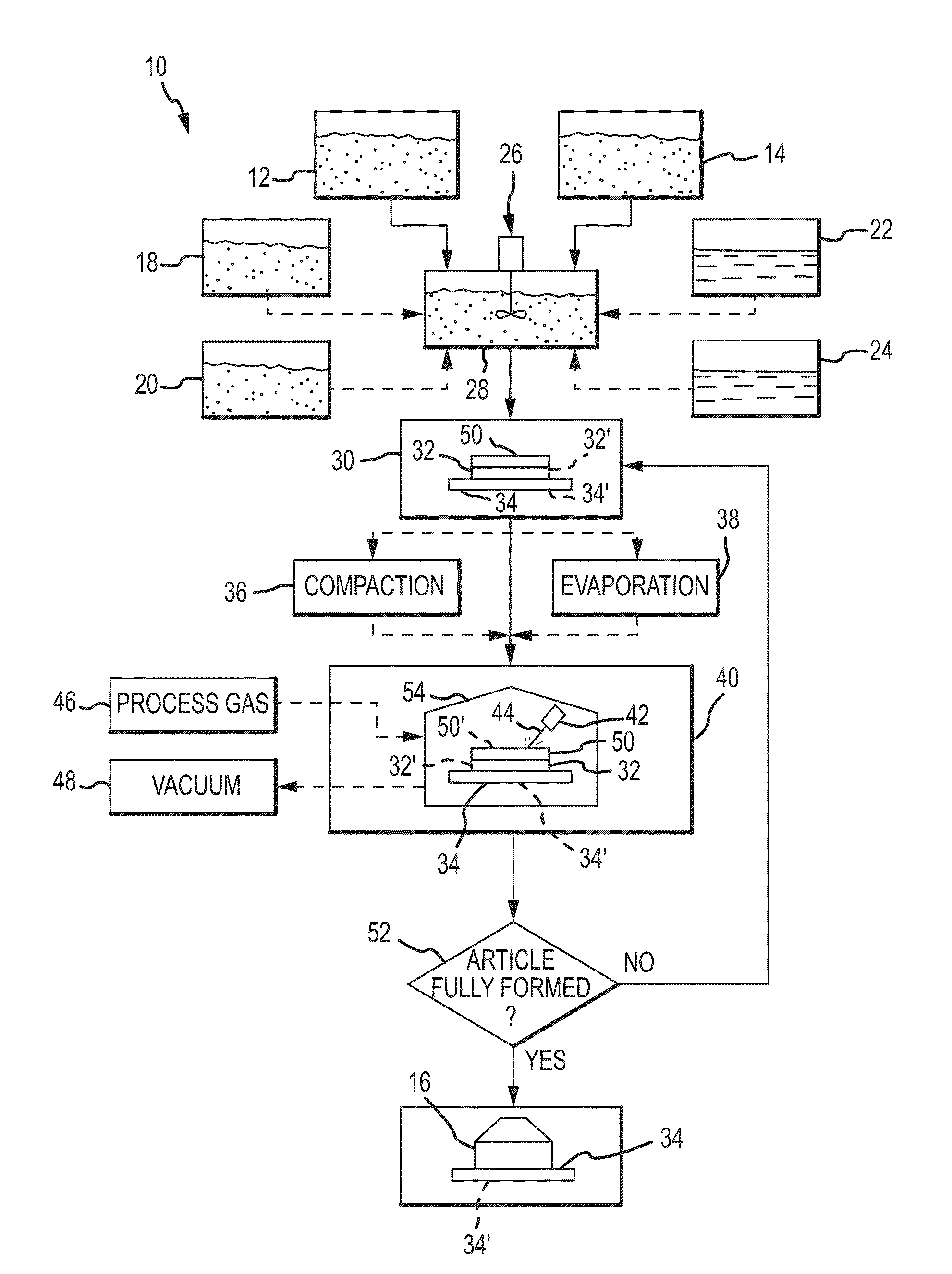

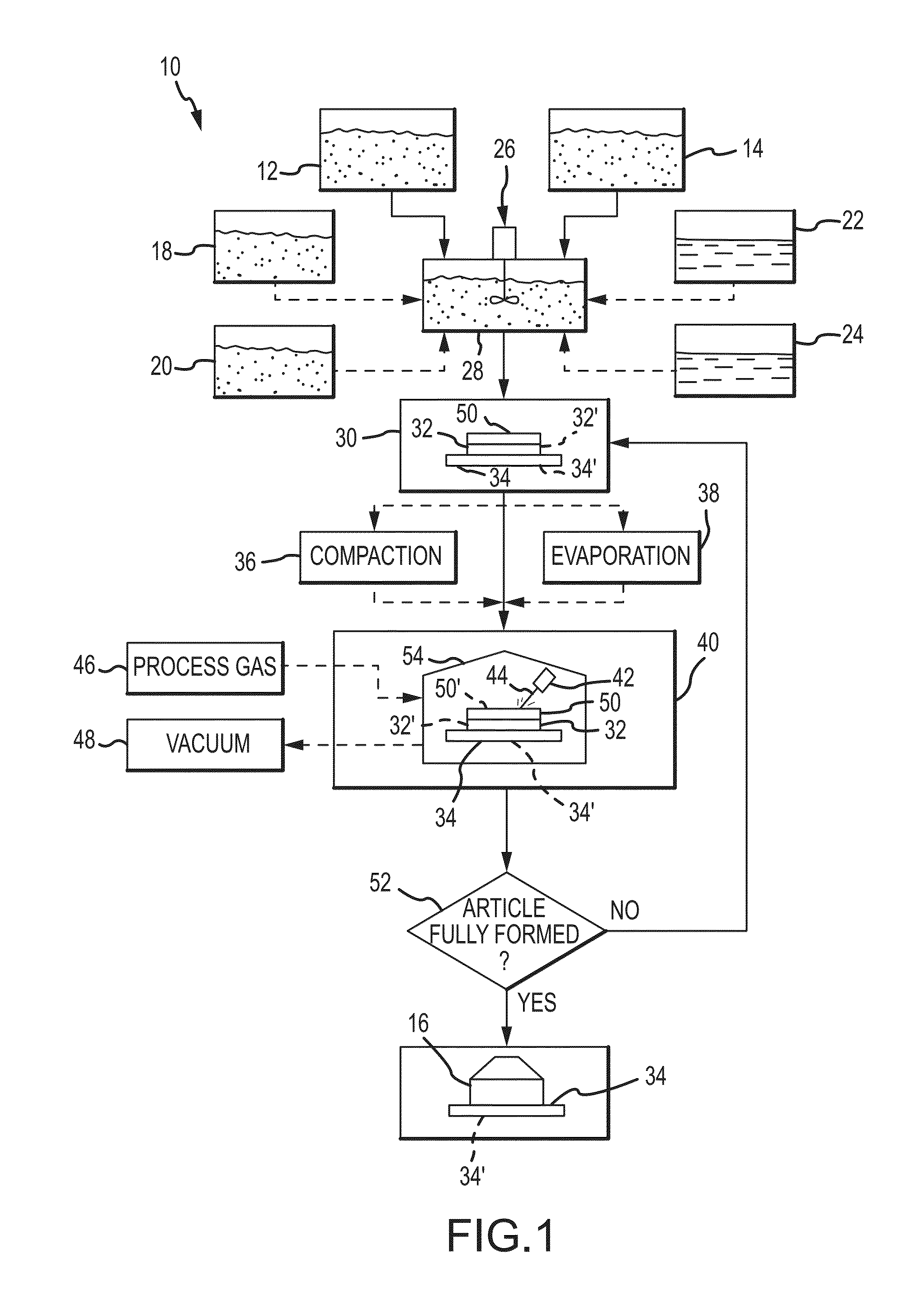

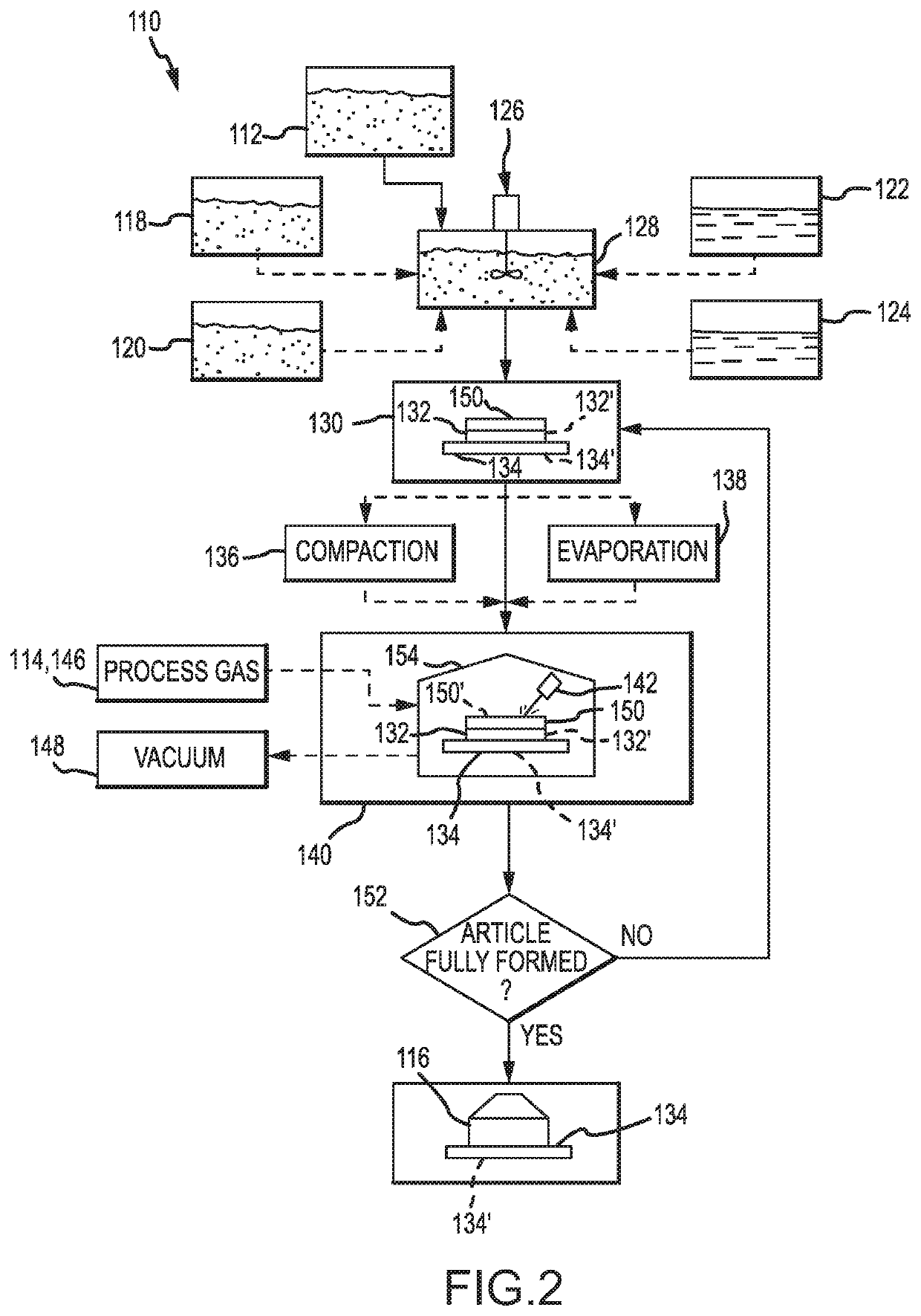

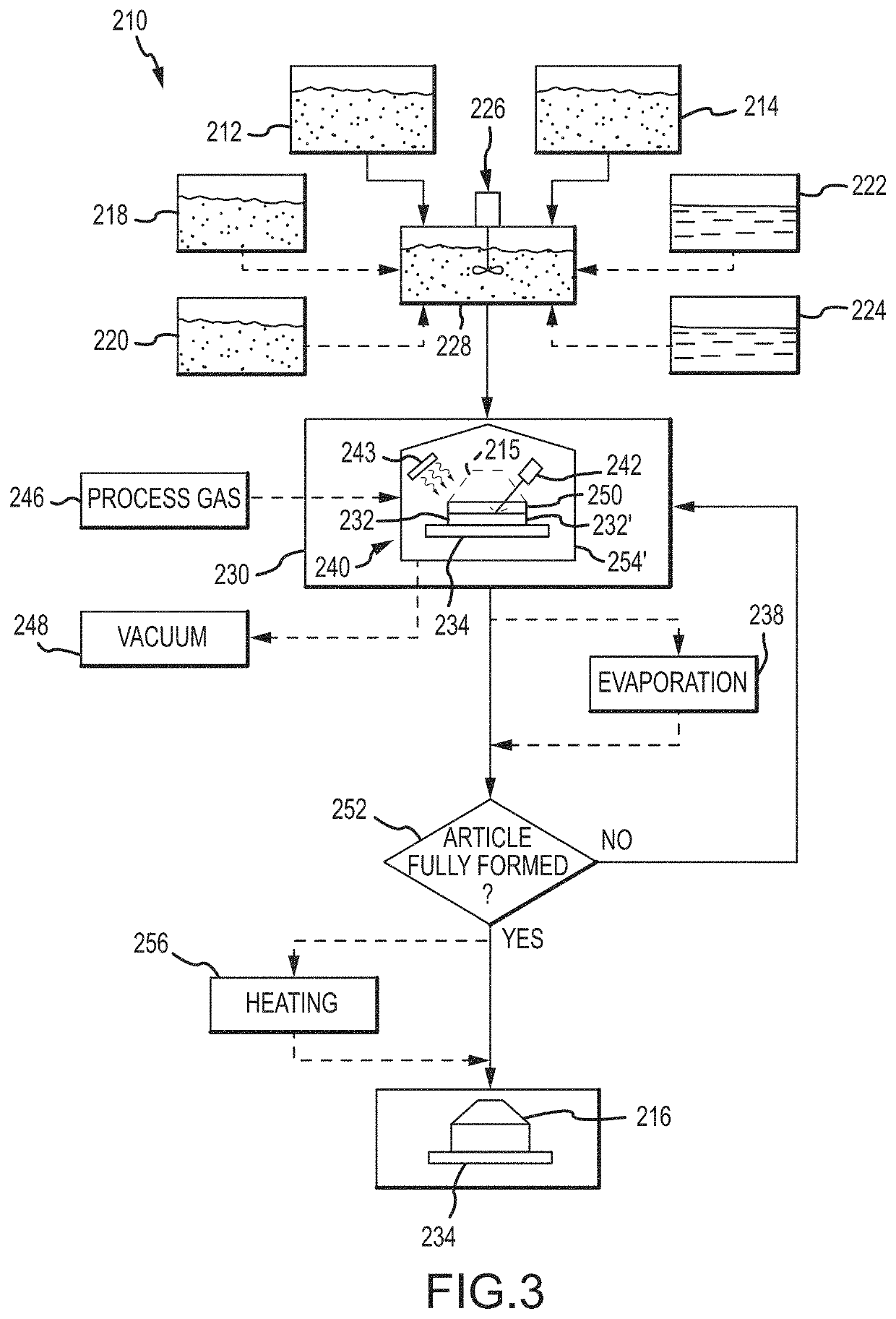

An additive manufacturing method of producing a metal alloy article may involve: Providing a supply of a metal alloy in powder form; providing a supply of a nucleant material, the nucleant material lowering the nucleation energy required to crystallize the metal alloy; blending the supply of metal alloy powder and nucleant material to form a blended mixture; forming the blended mixture into a first layer; subjecting at least a portion of the first layer to energy sufficient to raise the temperature of the first layer to at least the liquidus temperature of the metal alloy; allowing at least a portion of the first layer to cool to a temperature sufficient to allow the metal alloy to recrystallize; forming a second layer of the blended mixture on the first layer; and repeating the subjecting and allowing steps on the second layer to form an additional portion of the metal alloy article.

Owner:ELEMENTUM 3D INC

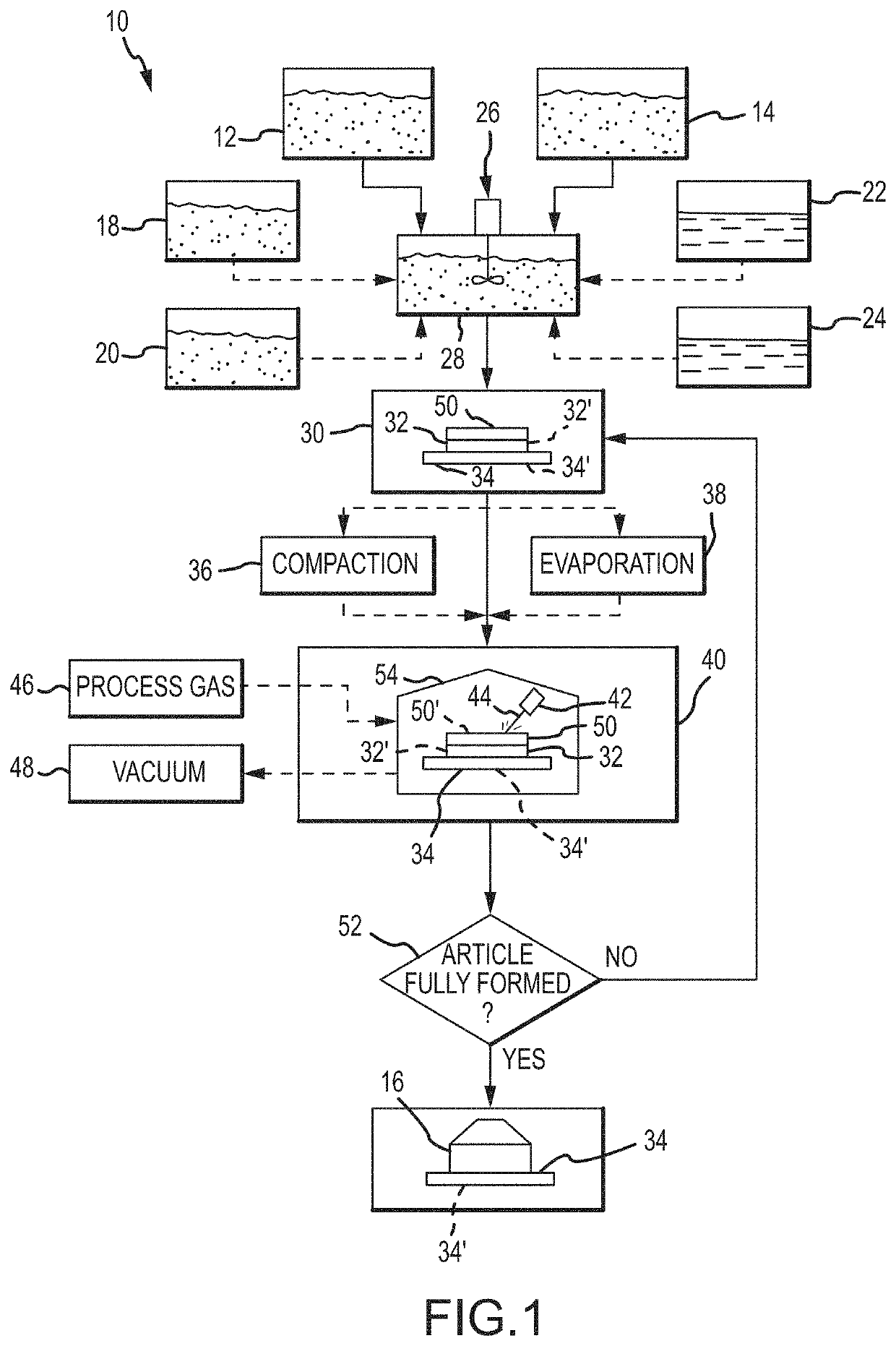

Reactive additive manufacturing

ActiveUS20160271878A1High quality partHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceReaction product

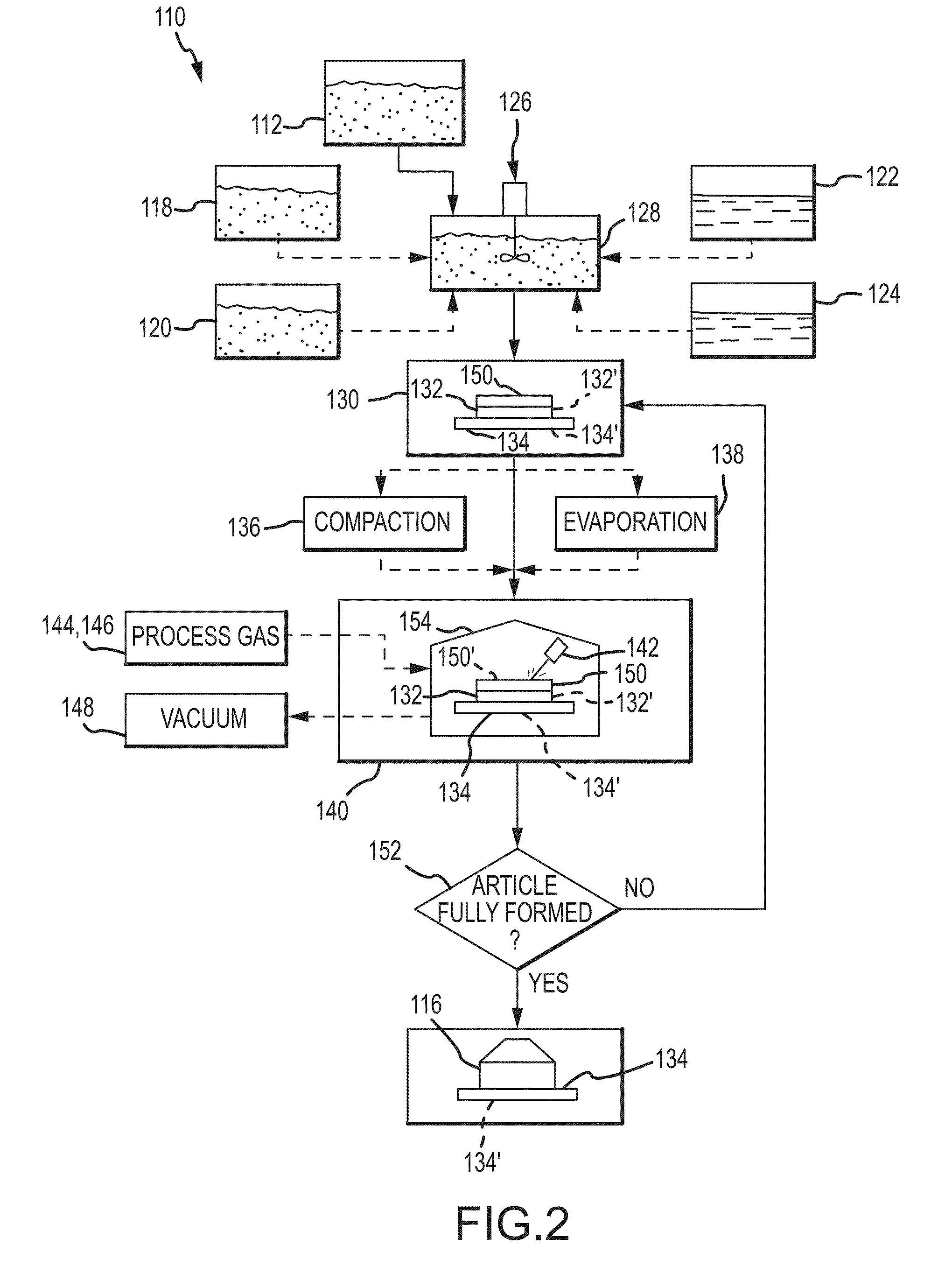

An additive manufacturing method may involve: Providing a first and a second material, the second material capable of reacting with the first material to form a reaction product; forming at least the first material into a first layer; subjecting at least a portion of the first layer to energy in the presence of the second material, the energy being sufficient to initiate a reaction between at least the first and second materials to form a portion of the article, the portion of the article comprising the reaction product; forming a second layer of at least the first material on the first layer; and subjecting at least a portion of the second layer to energy in the presence of the second material, the energy being sufficient to initiate a reaction between the first and second materials to form an additional portion of the article.

Owner:ELEMENTUM 3D INC

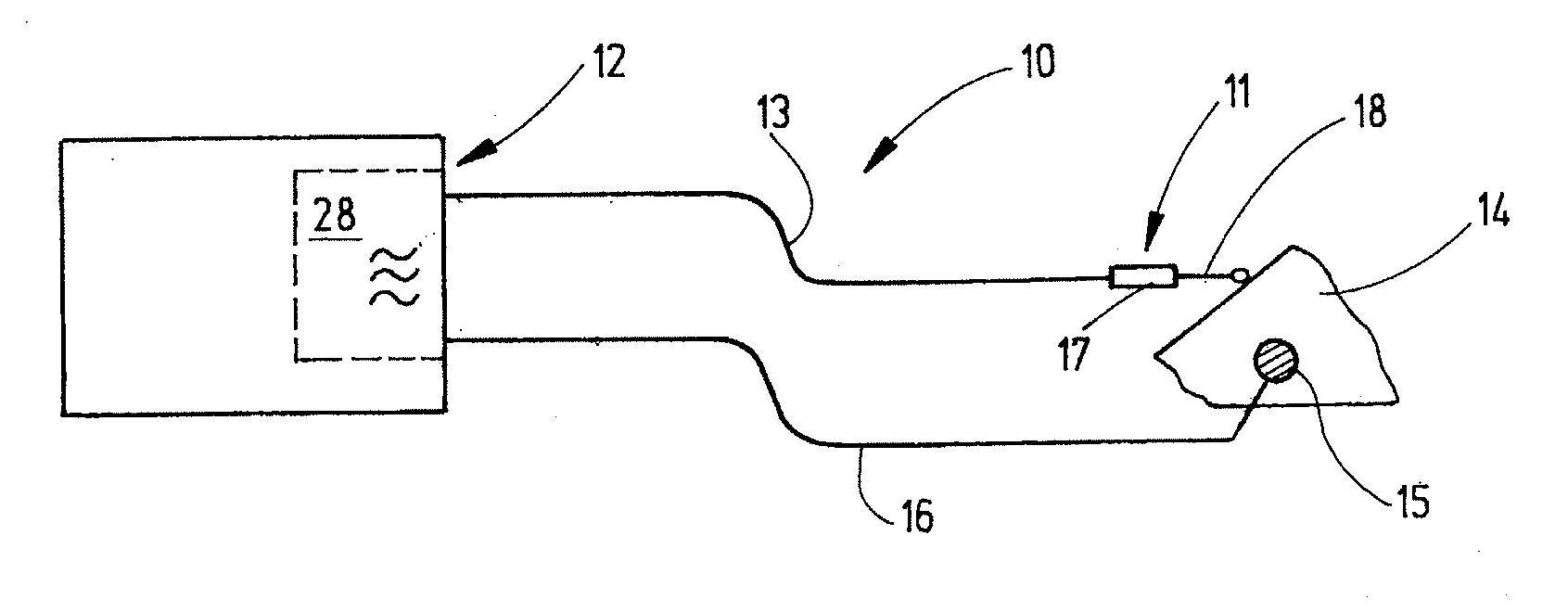

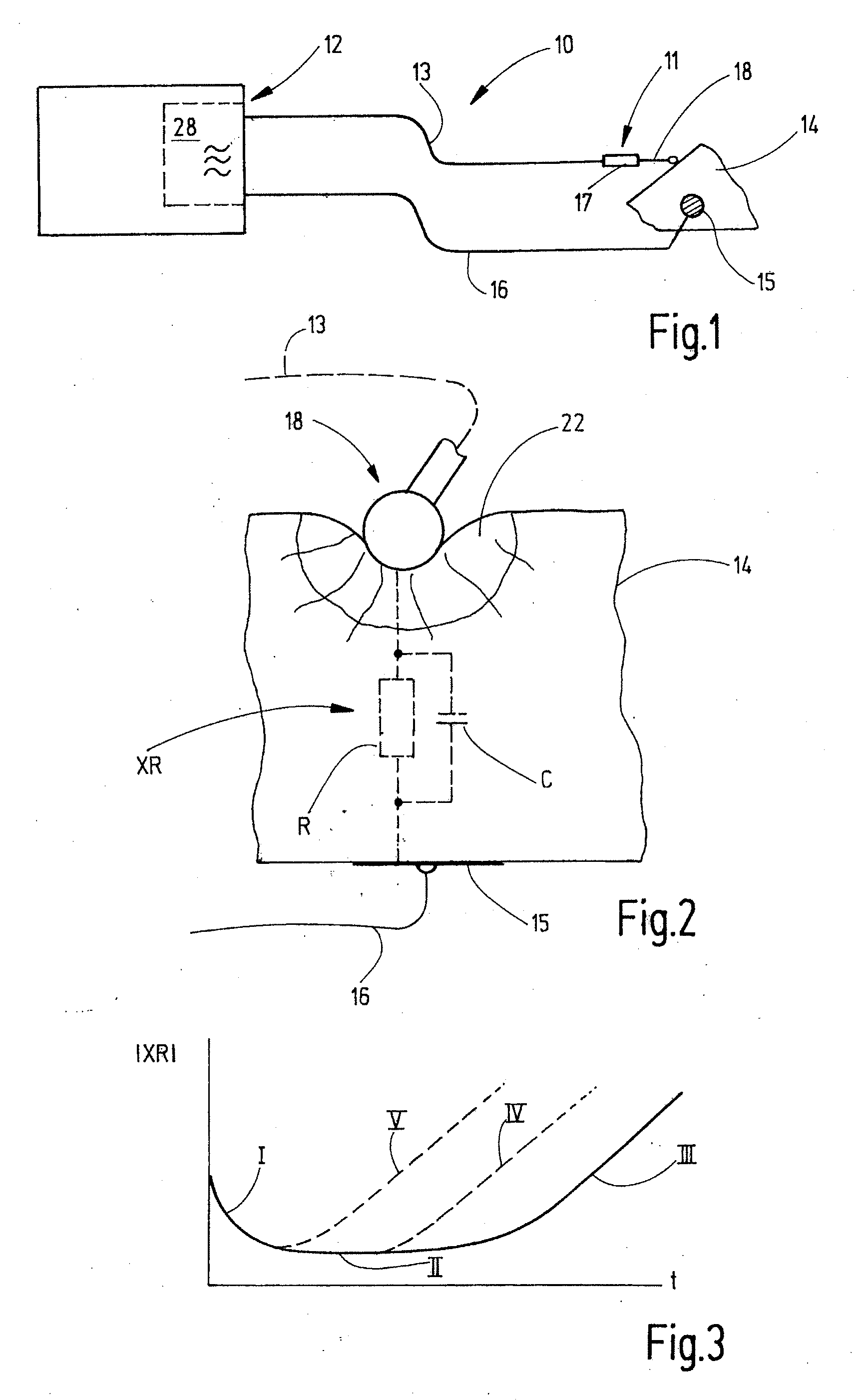

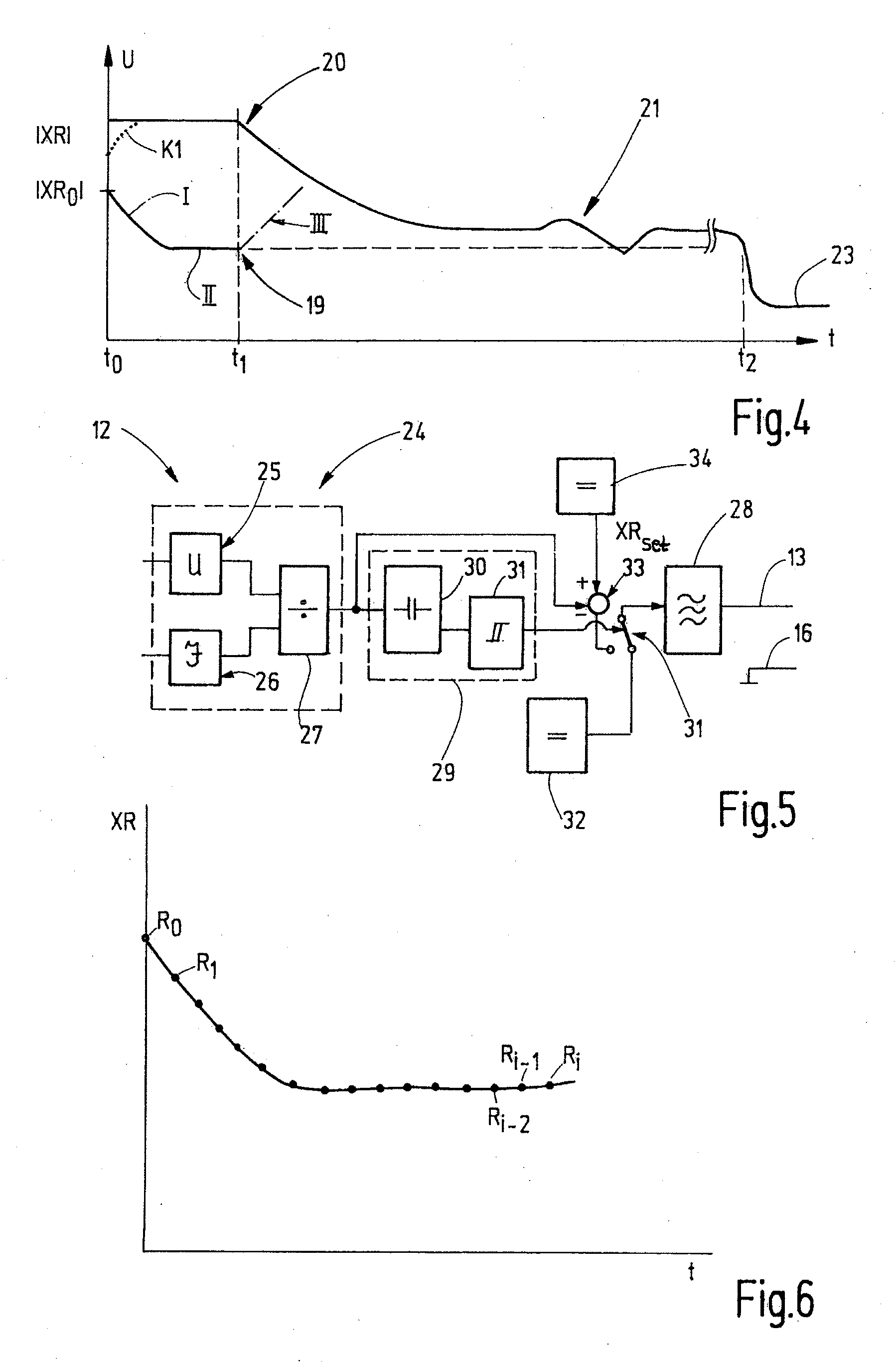

Method and device for optimized coagulation of biological tissue

ActiveUS20130006237A1High defined energy inputHigh quality rapid coagulationSurgical instruments for heatingElectrical resistance and conductanceUnit of time

Maximum HF current is initially introduced into tissue at a pre-specified maximum coagulation voltage. In this initial state, the tissue behaves in accordance with Ohm's law and can take up the maximum energy per unit of time. After the tissue has changed from an initial state to a state in which the tissue impedance or resistance is voltage-dependent, the HF parameters are selected such that the maximum possible energy input per unit of time is set.

Owner:ERBE ELEKTROMEDIZIN GMBH

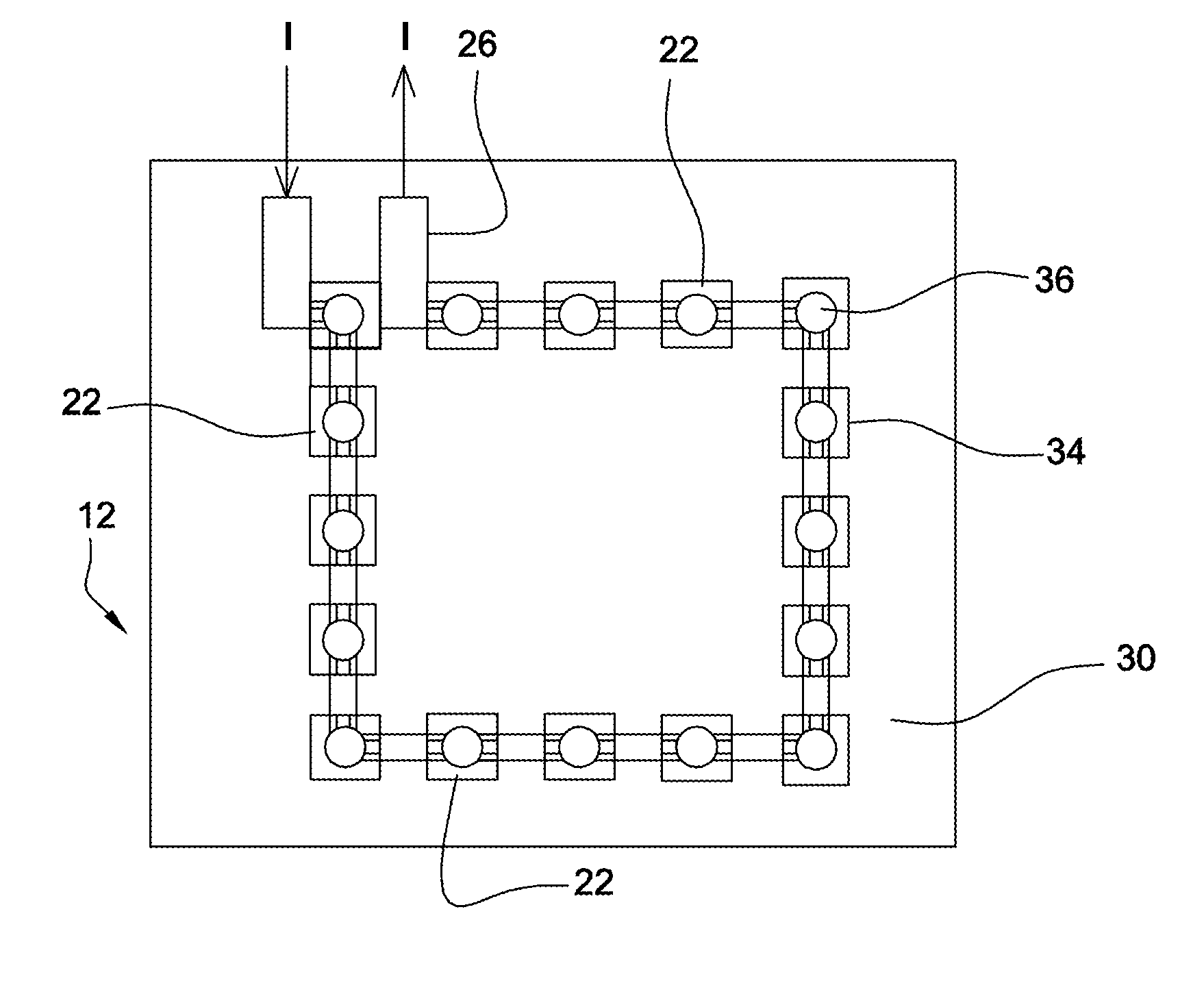

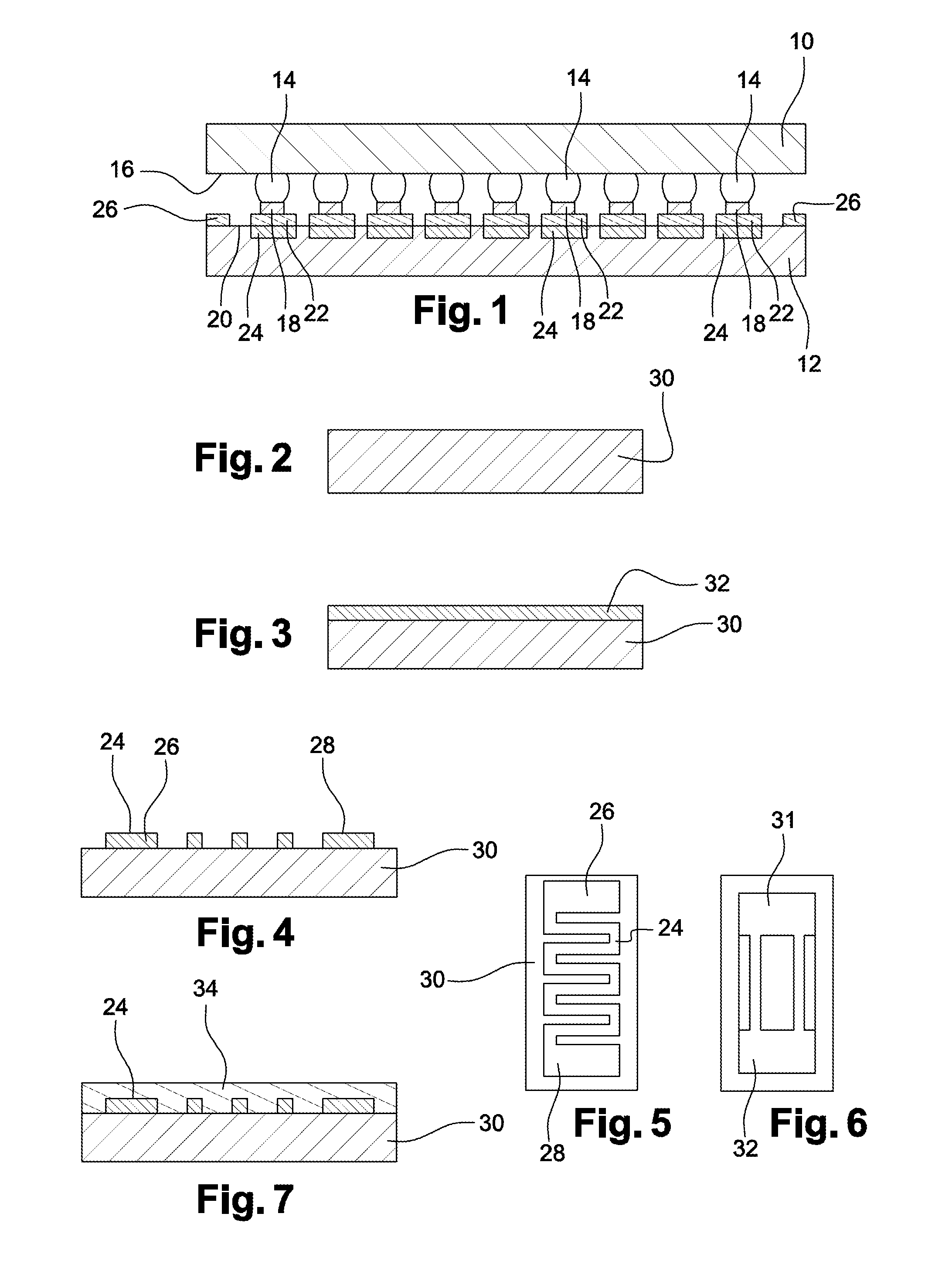

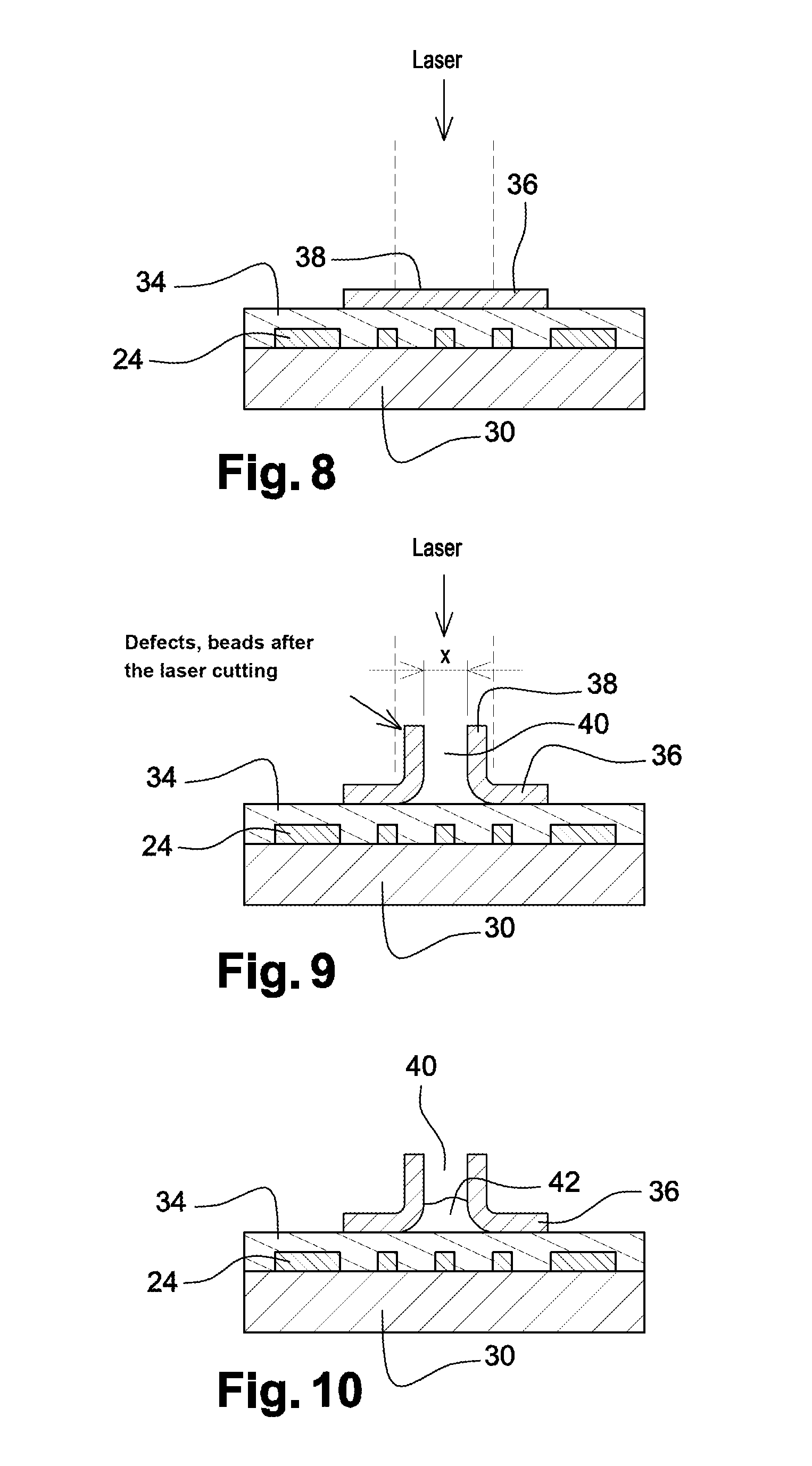

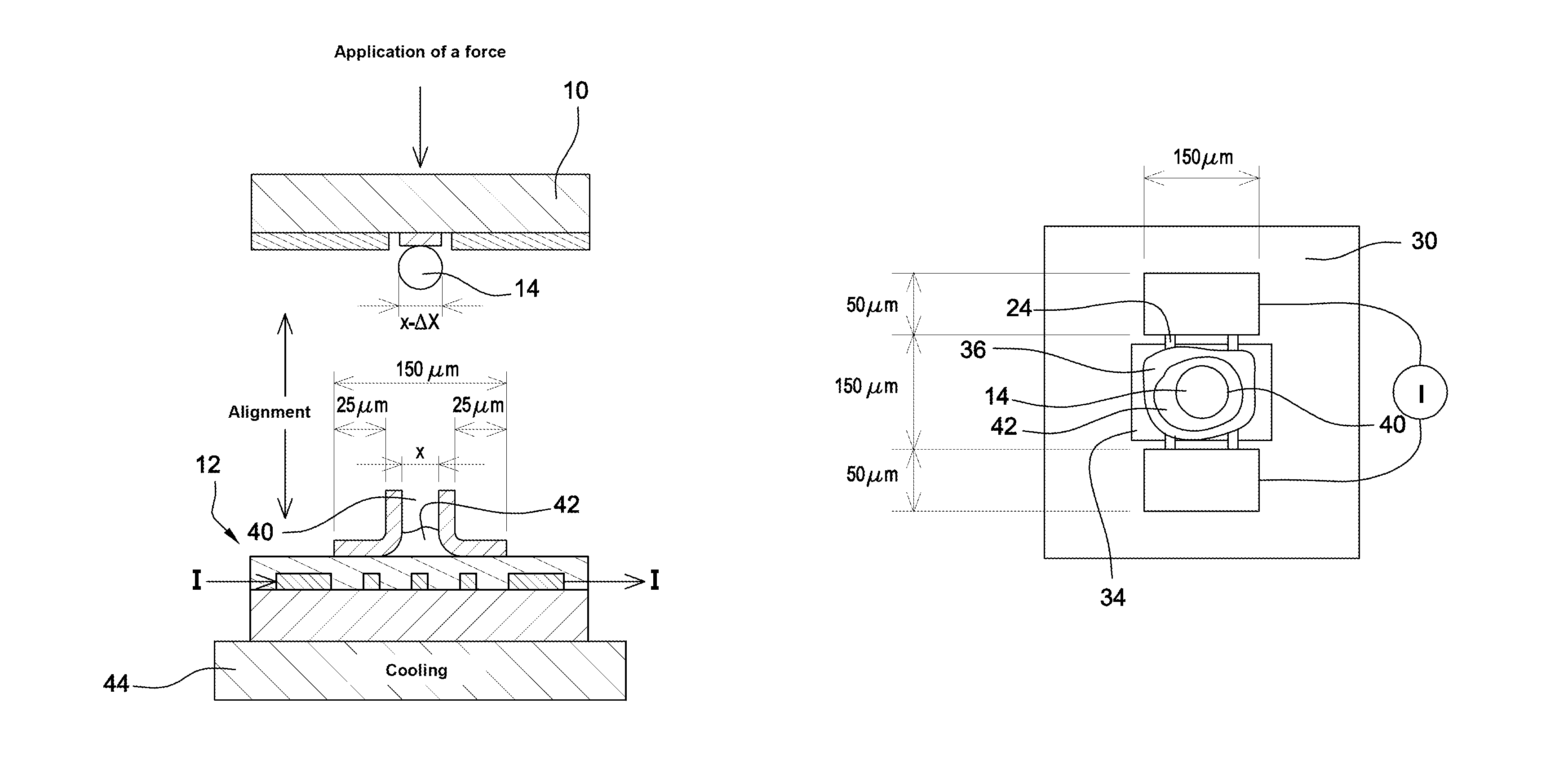

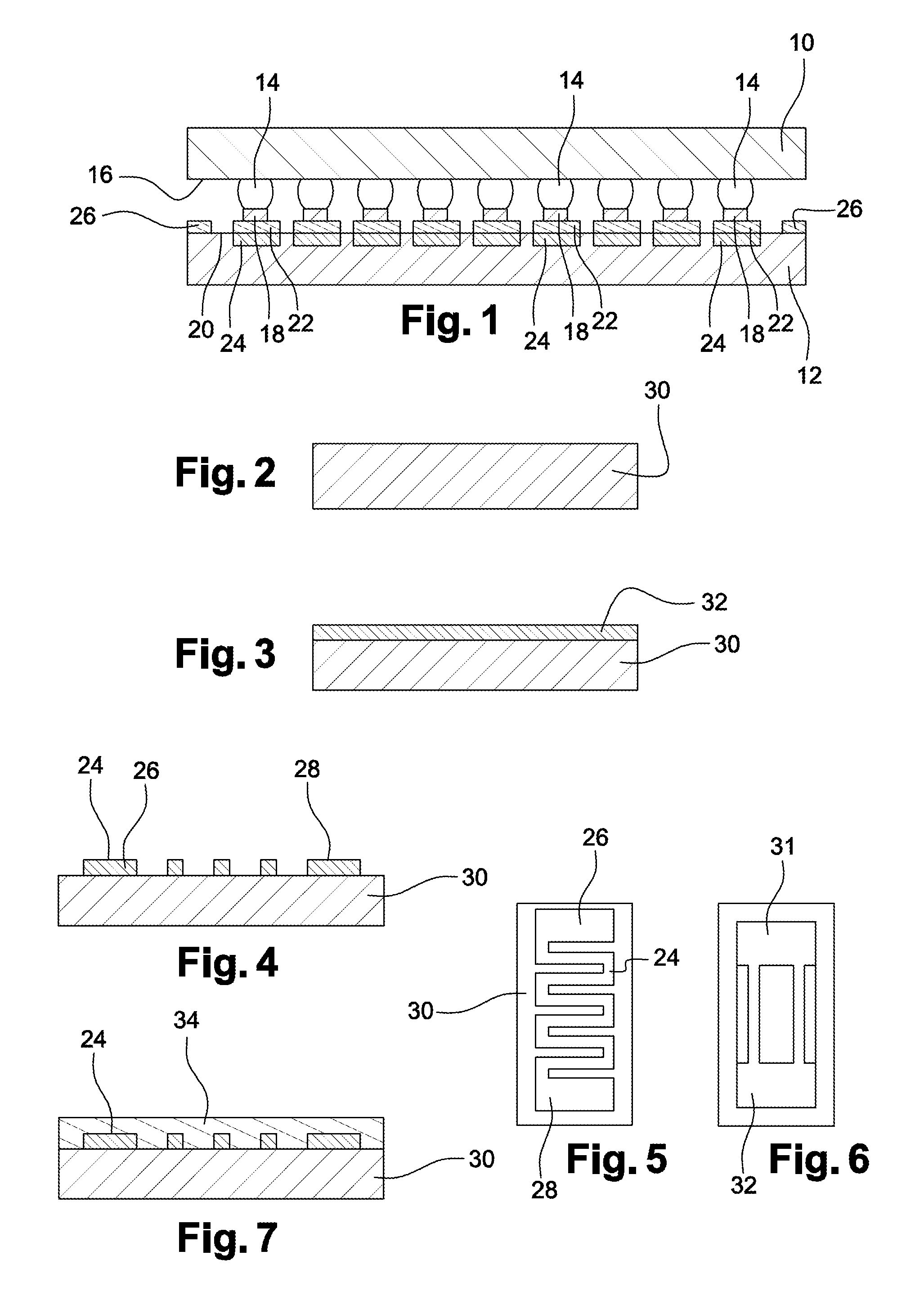

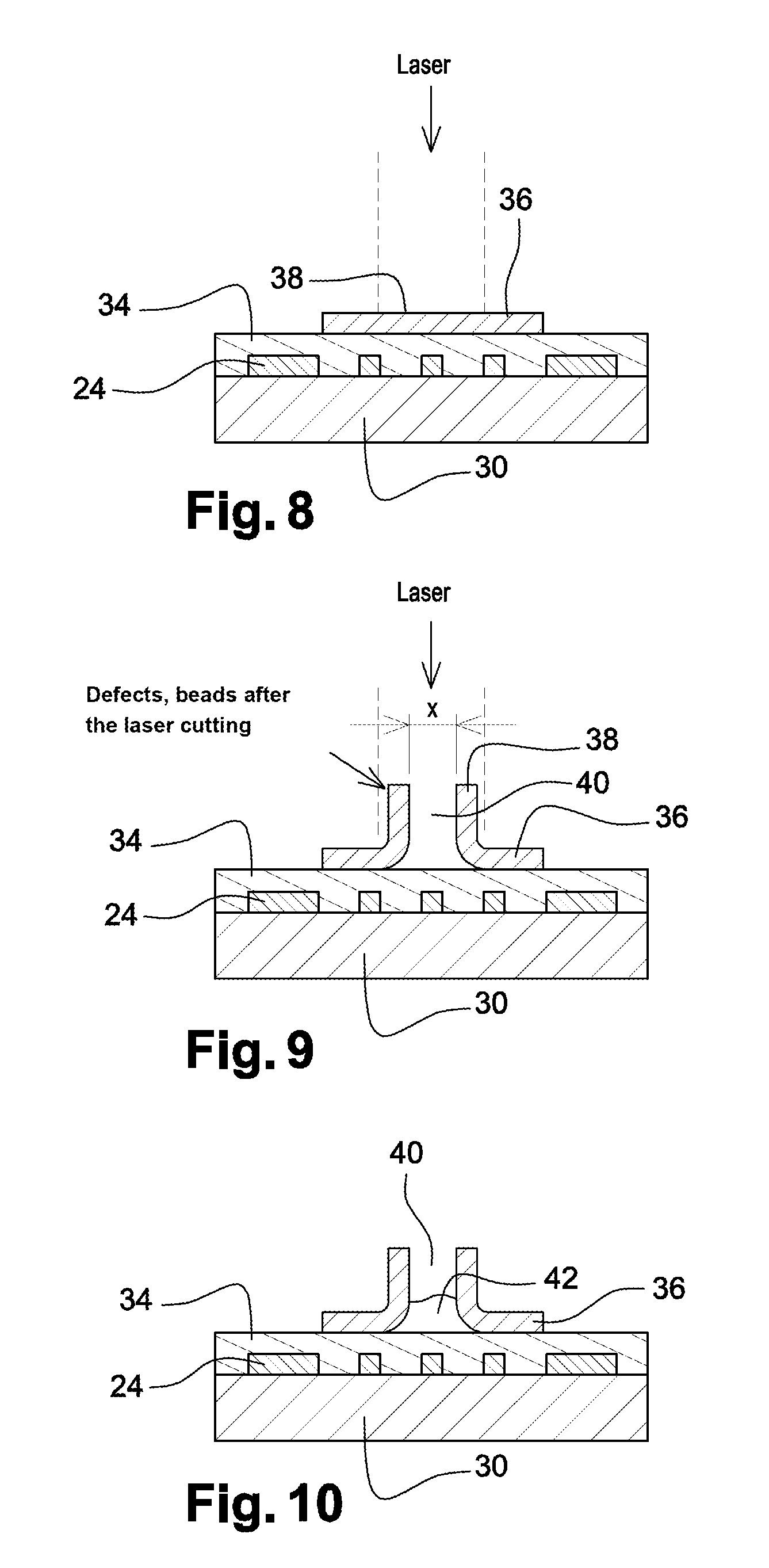

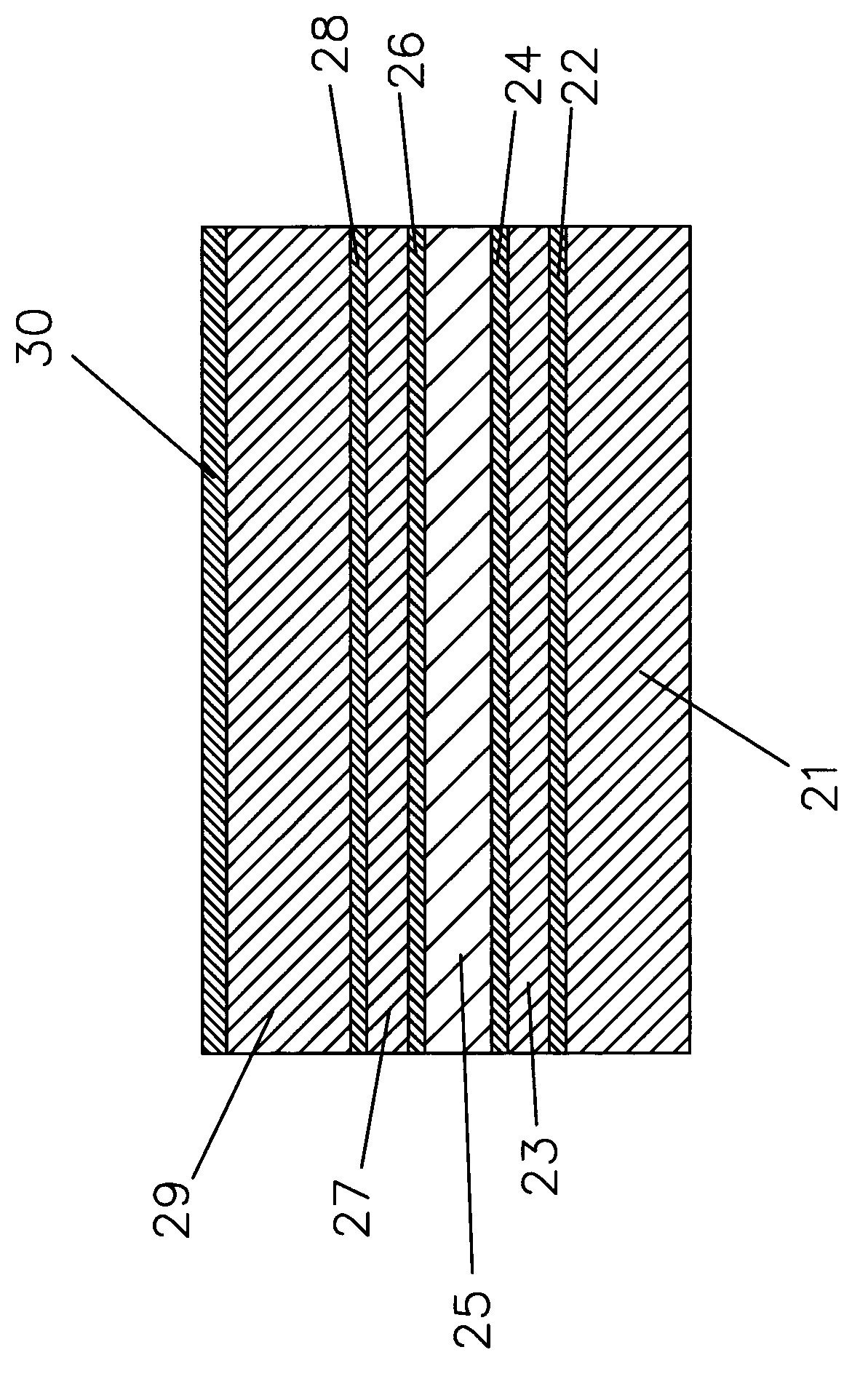

Flip-chip hybridization of microelectronic components by local heating of connecting elements

ActiveUS20140210076A1Limiting unwanted thermal effectHigh photonic energy inputSemiconductor/solid-state device detailsSolid-state devicesIndiumAlloy

A method of forming a hybridized device including forming a first component provided with metal bumps, and a second component provided with connection elements, attaching the bumps to the connection elements. The manufacturing of the second component includes forming, on a surface of a substrate, resistive elements at the locations provided for the connection elements; depositing an electric insulator layer at least on the resistive elements; and forming the connection elements, each comprising a metal well having an opening capable of receiving the corresponding metal bump of the first microelectronic component and at least partially filled with a fusible element, particularly indium or an alloy of tin and gold, or with a conductive ink, particularly based on silver or copper. Further, the attachment of the balls to the connection elements comprises applying an electric current through the resistive elements to heat the bumps.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

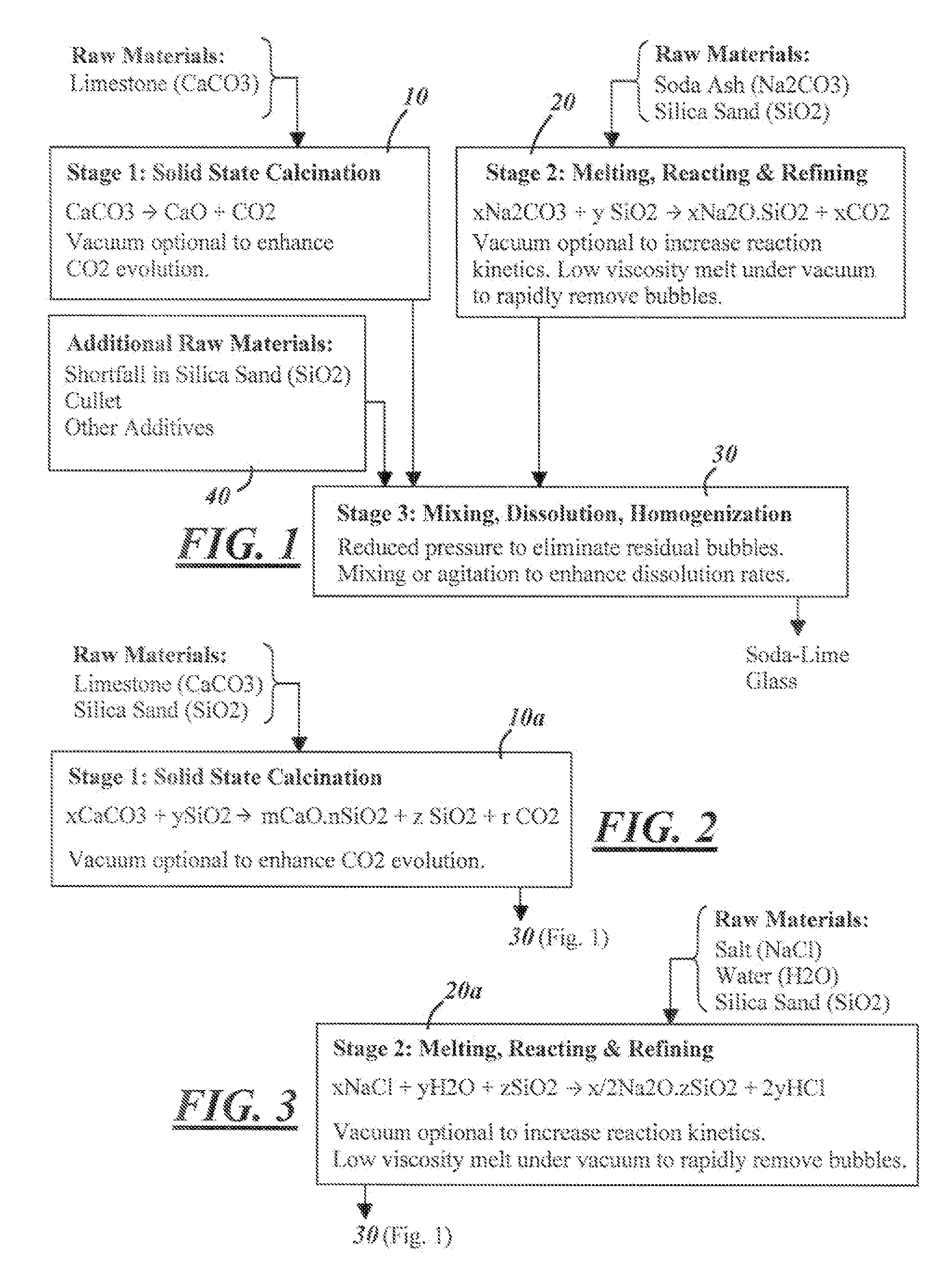

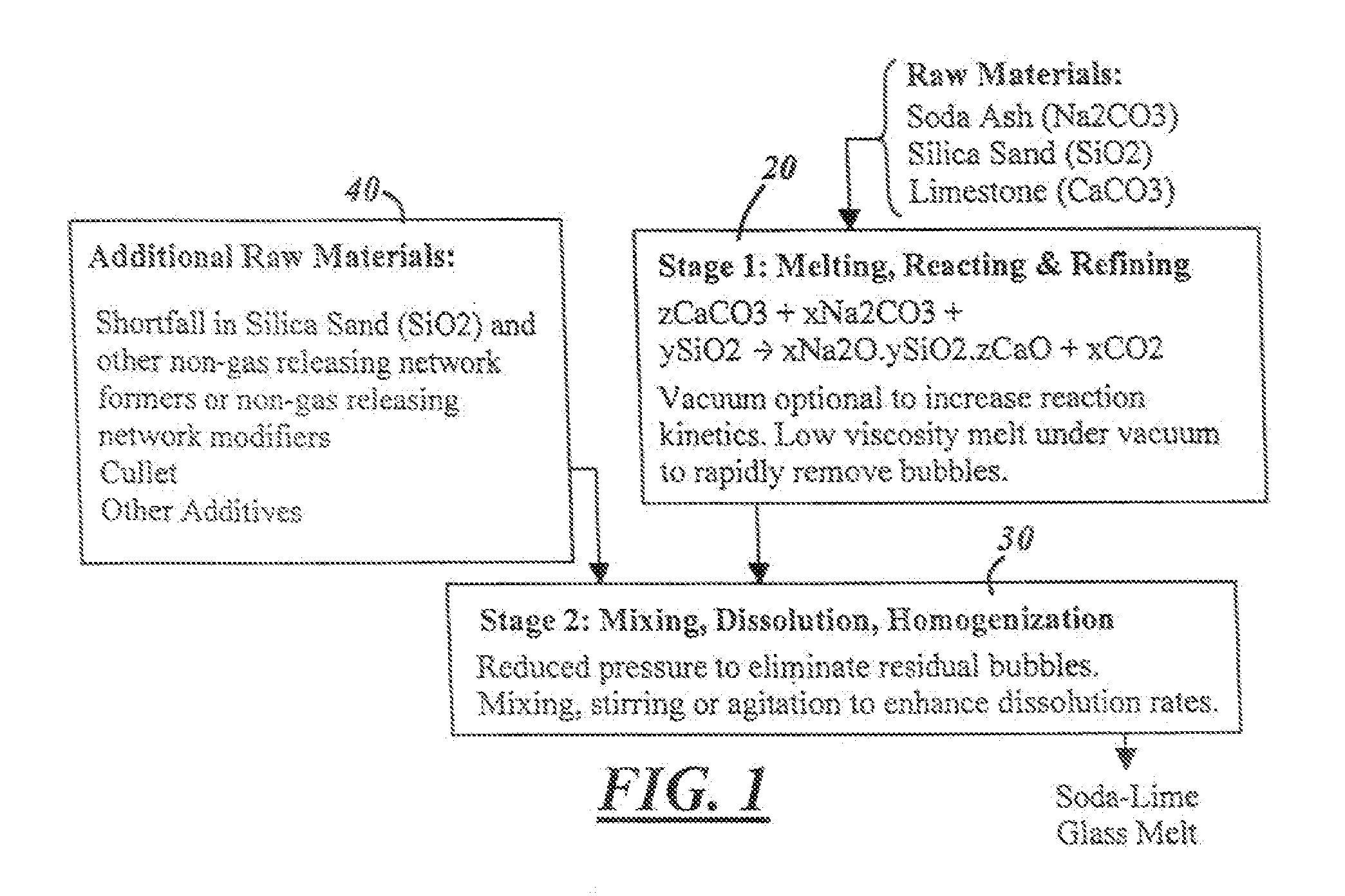

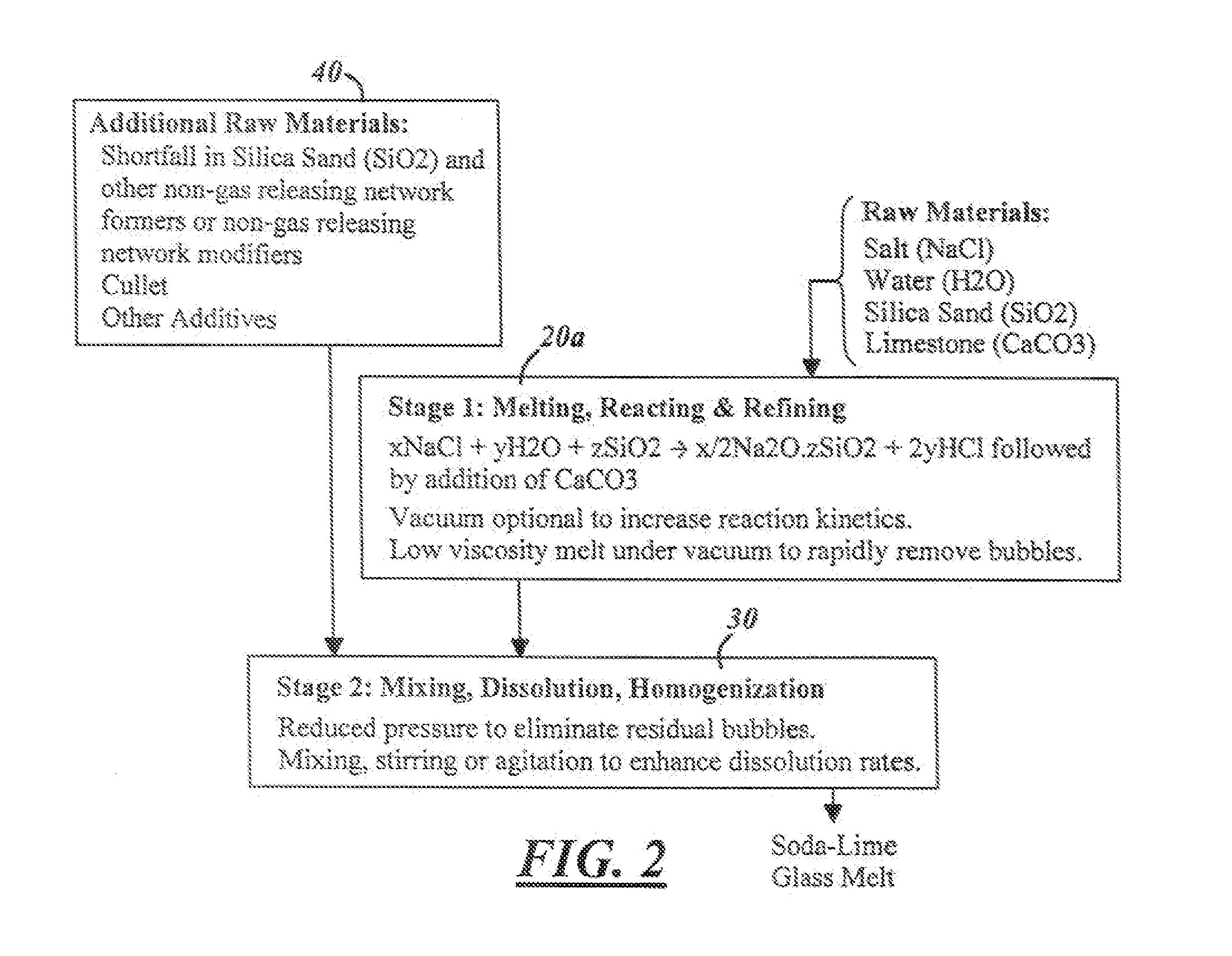

Process for Melting and Refining Soda-Lime Glass

ActiveUS20120216574A1High energy inputCharging furnaceGlass furnace apparatusSolid phasesSodium silicate

A process for making soda-lime glass includes calcinating calcium carbonate in solid phase and at elevated temperature to form calcium oxide and release gases such as carbon dioxide. Sodium silicate glass is formed separately in liquid phase while releasing gaseous reaction products. The calcium oxide and the sodium silicate glass intermediate products are mixed in liquid phase to form a soda-lime glass melt. Formation of sodium silicate glass as an intermediate product before mixing with the calcium oxide has the advantage of promoting release of gaseous reaction products in the sodium silicate due at least in part to the relatively low viscosity of the sodium silicate glass. The calcination step and / or the sodium silicate-forming step and / or the final mixing step can be carried out under reduced pressure further to promote release of gases and reduce bubble formation.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

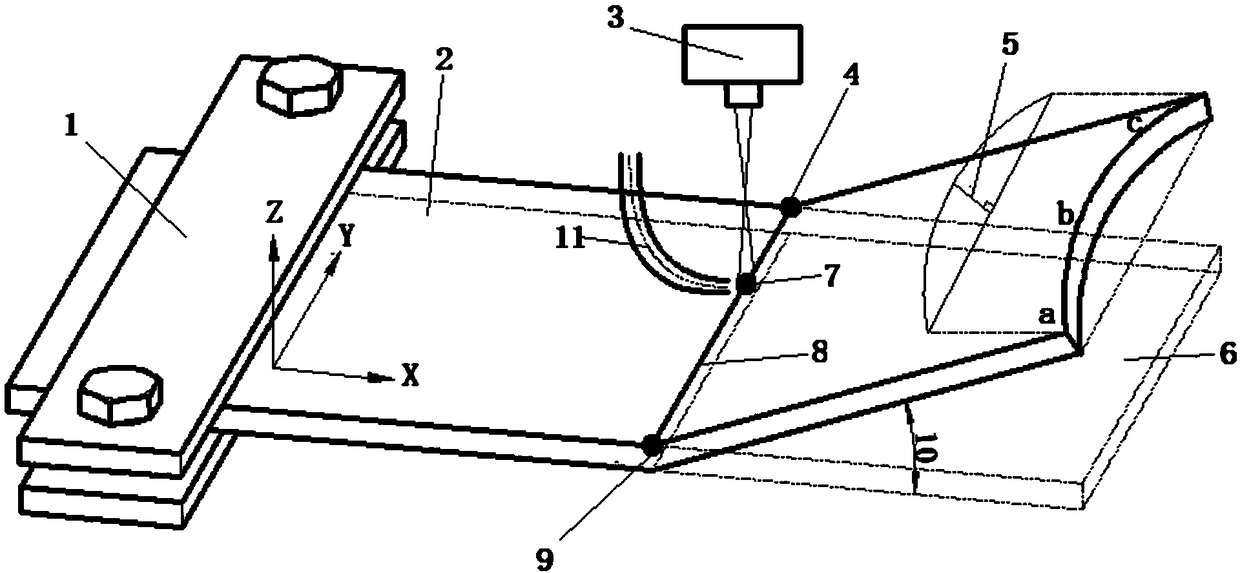

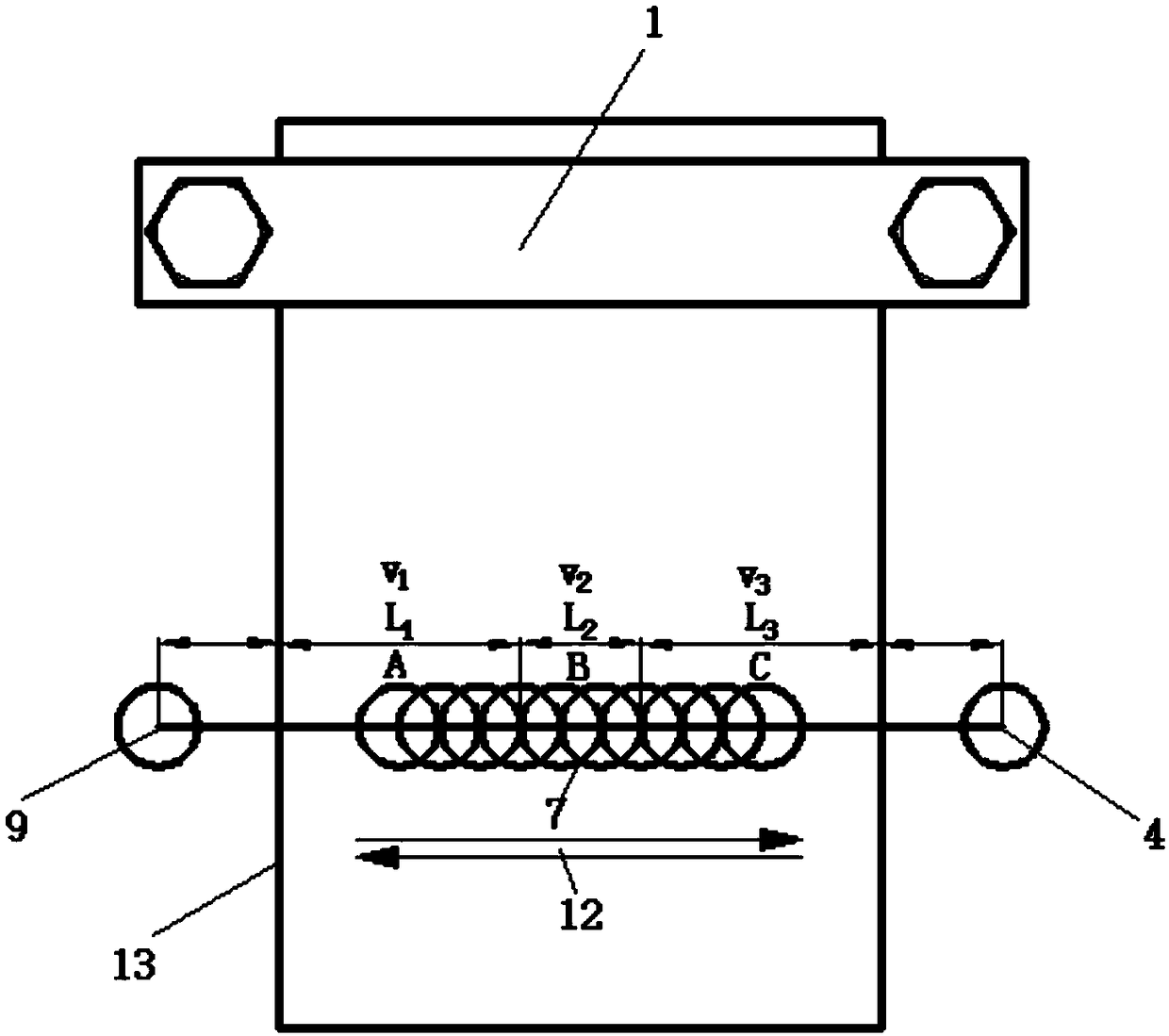

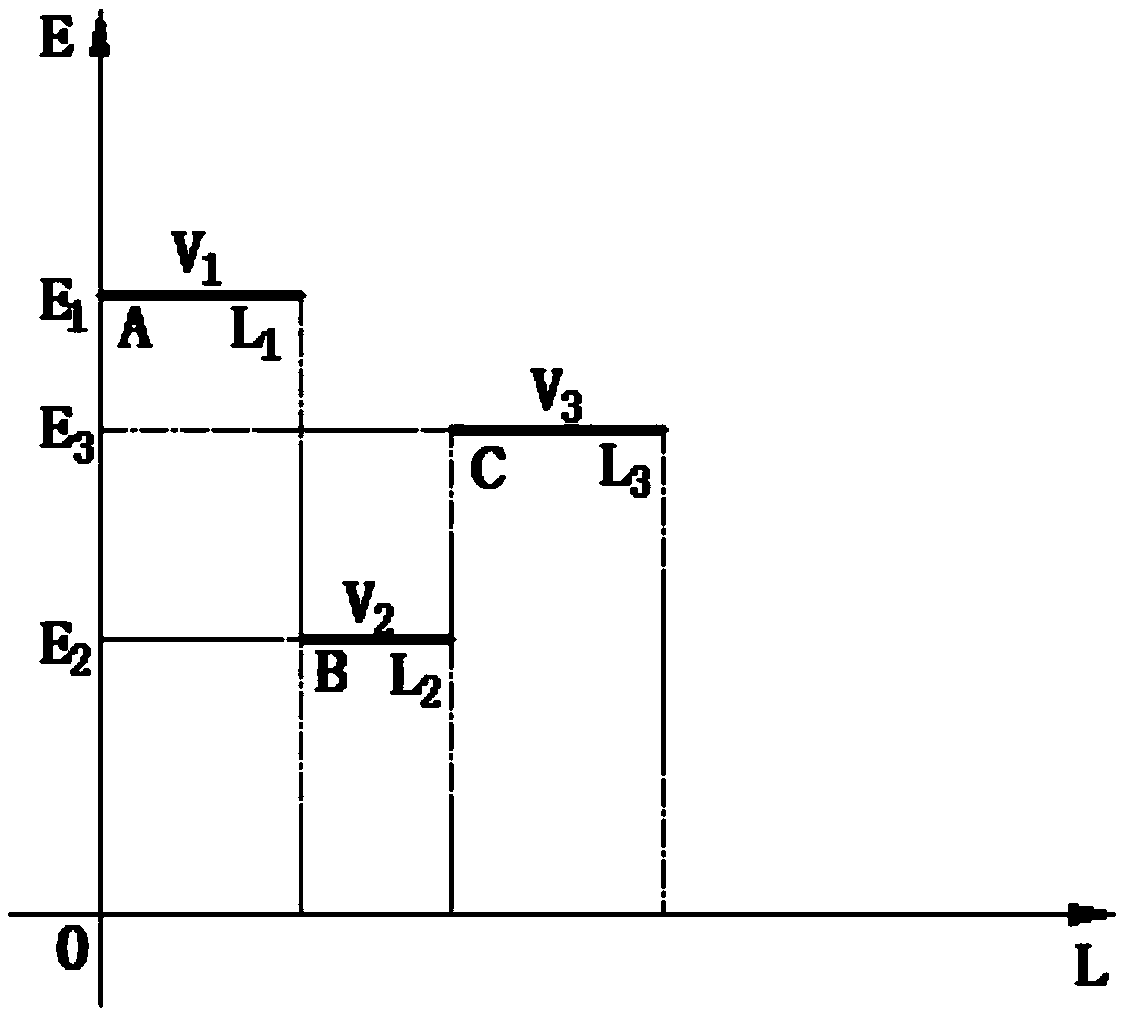

Energy regulation and control method for reducing bending amount of metal sheet laser bending forming

The invention belongs to the technical field of metal sheet laser bending forming, and relates to an energy regulation and control method for reducing the bending amount of a metal sheet laser bendingforming. In the invention, a method combining three-stage variable speed with local energy compensation is adopted for correcting a warping deformation, and the energy coarse adjustment is carried out by adopting a three-section variable speed mode to adopt a low speed to ensure higher energy input at the section position with small bending angle and high bending angle adopting high speed to ensure lower energy input; the energy compensation method comprises the following steps of: carrying out energy compensation on a segment position with small bending angle by scanning a local area with small bending angle for lesser times after the local energy compensation mode is processed; and the combination of the two aspects can effectively reduce the bending amount in the laser bending processof the metal sheet and meet the technical requirements. The method can be applied to the field of metal sheet forming with high angle precision required by laser non-die bending processing.

Owner:DALIAN UNIV OF TECH

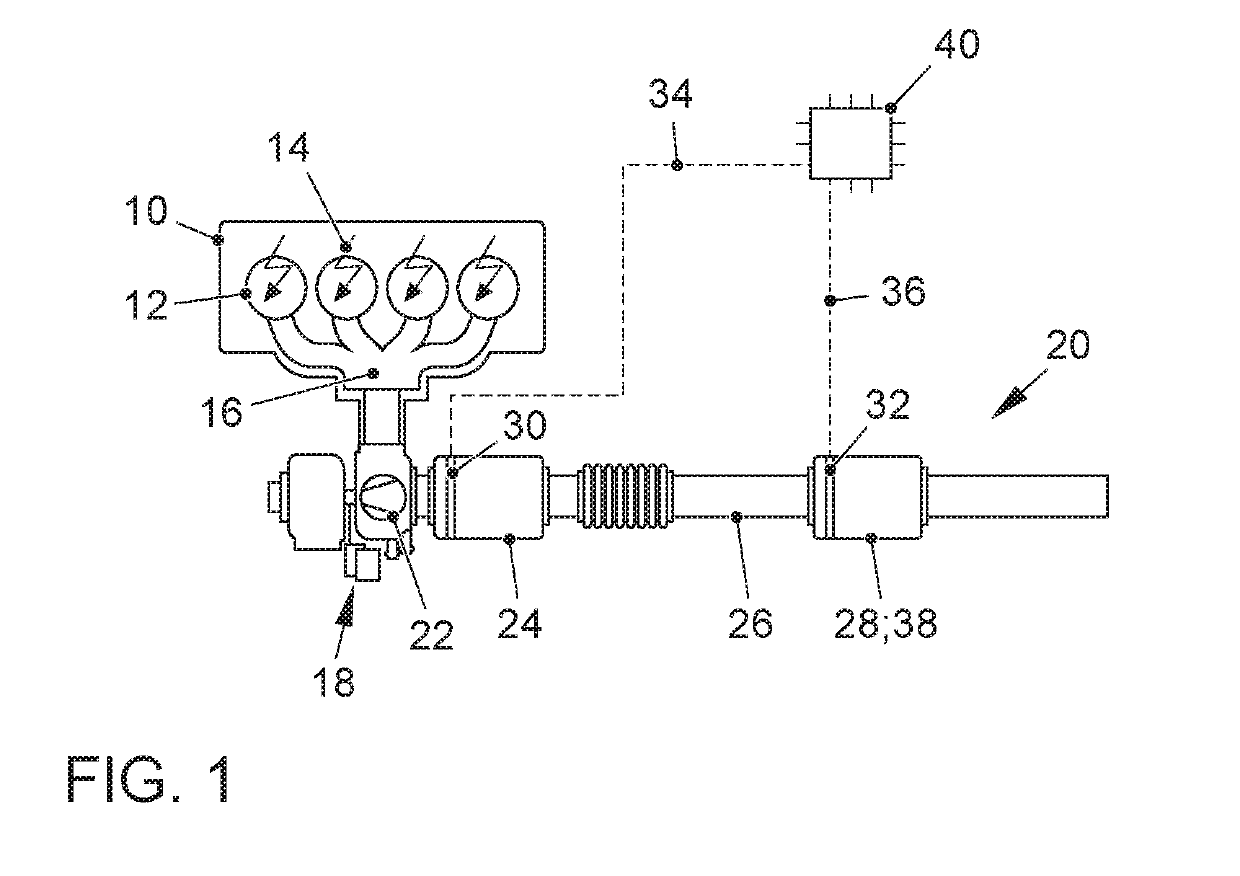

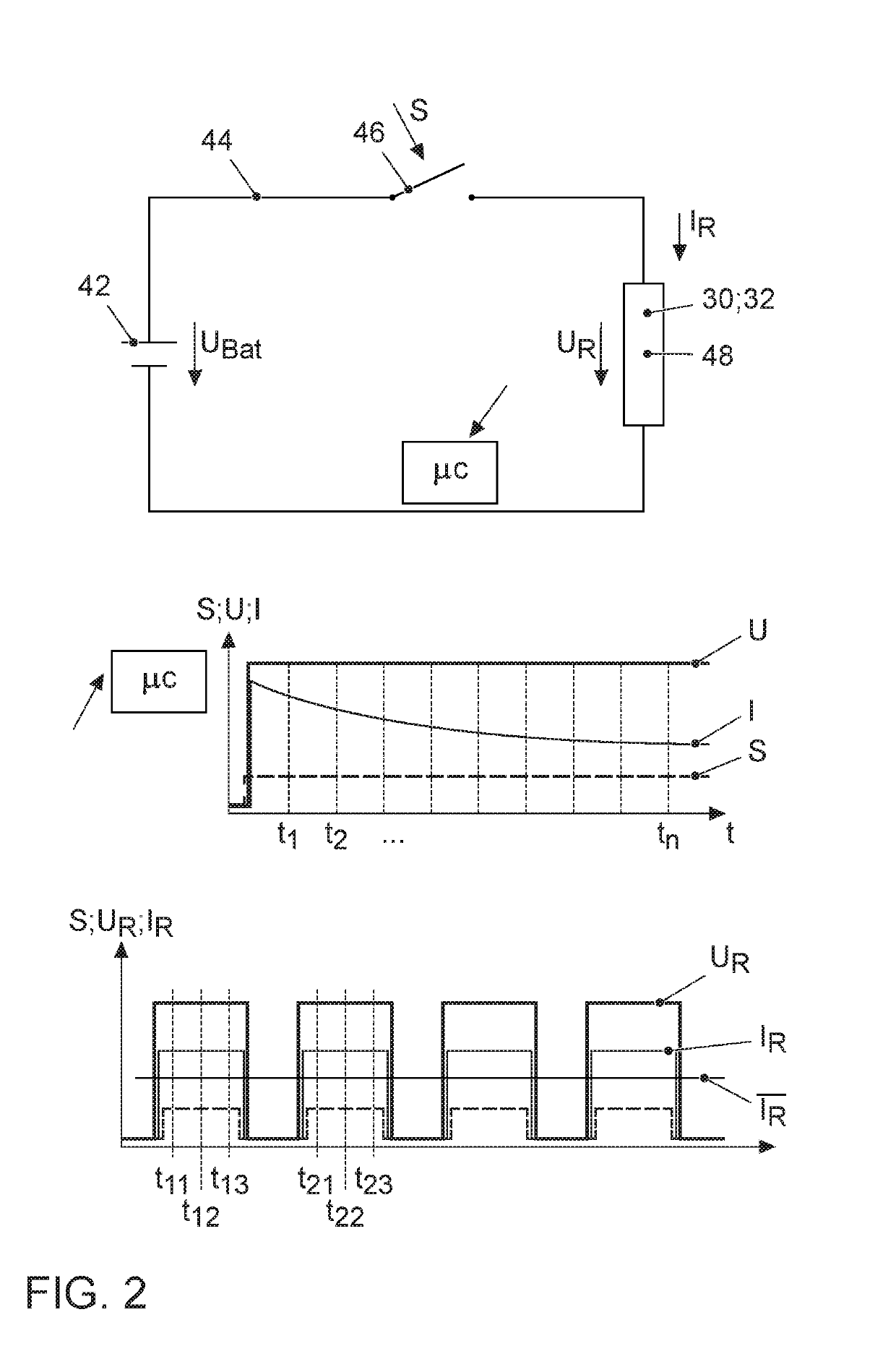

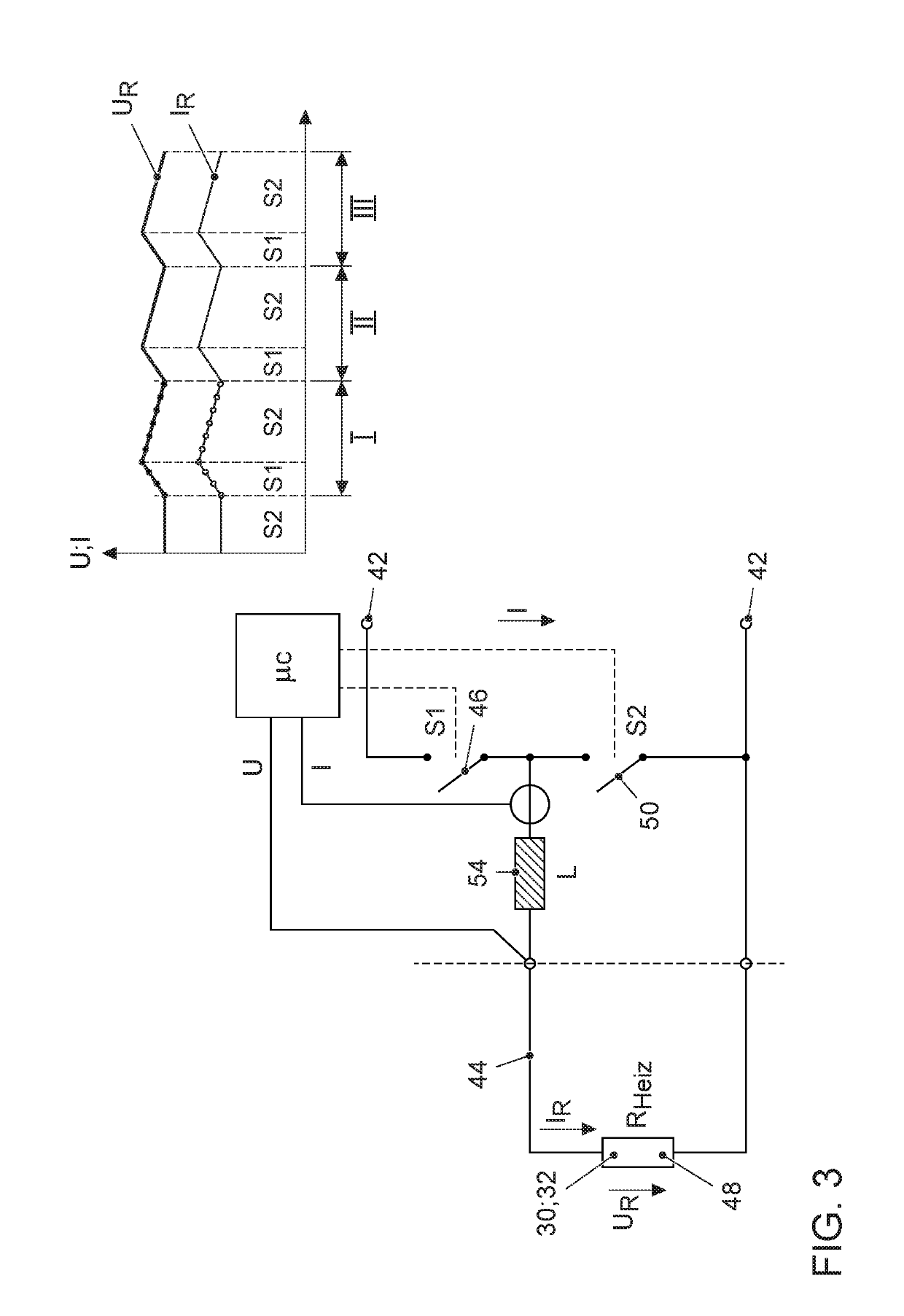

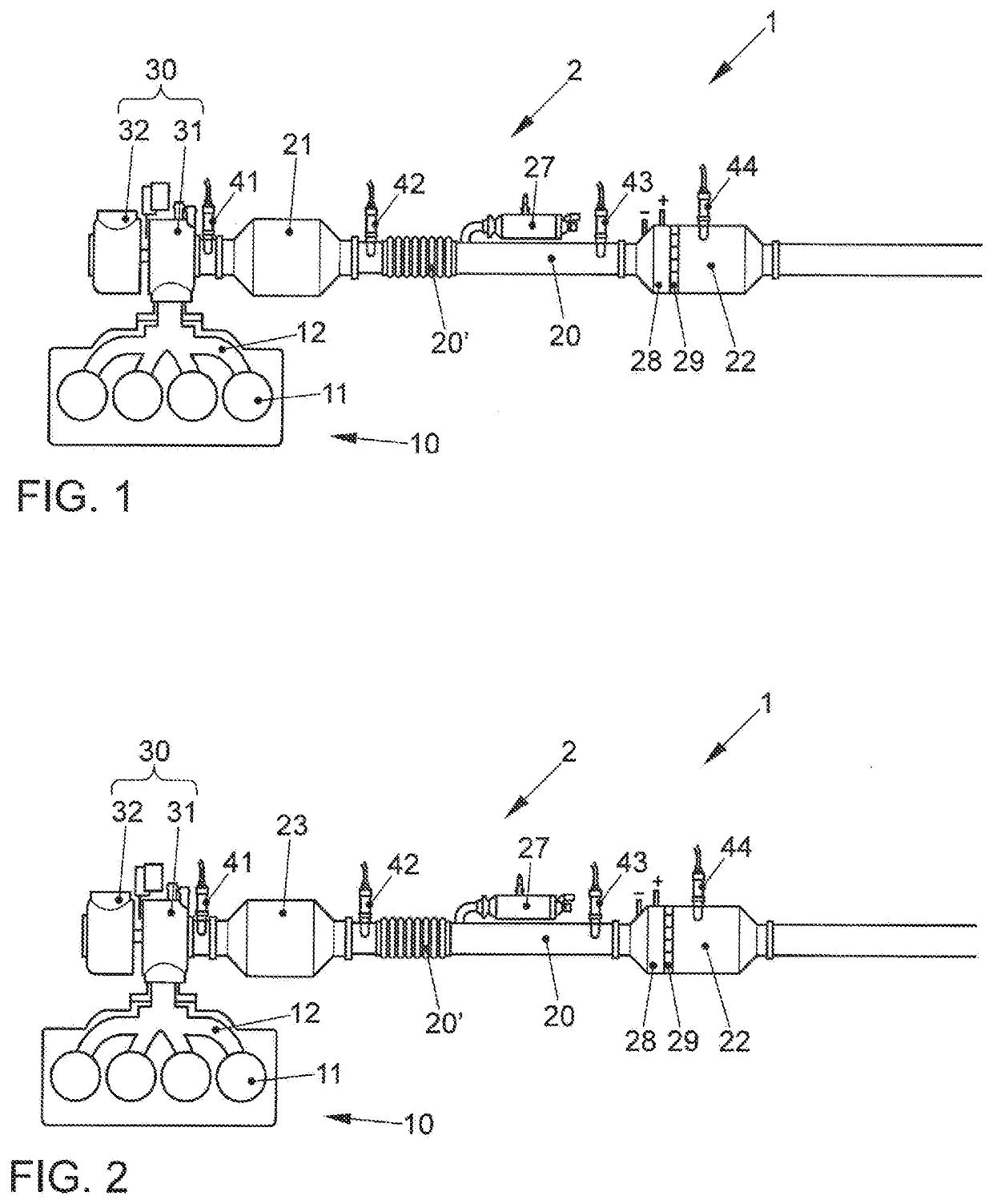

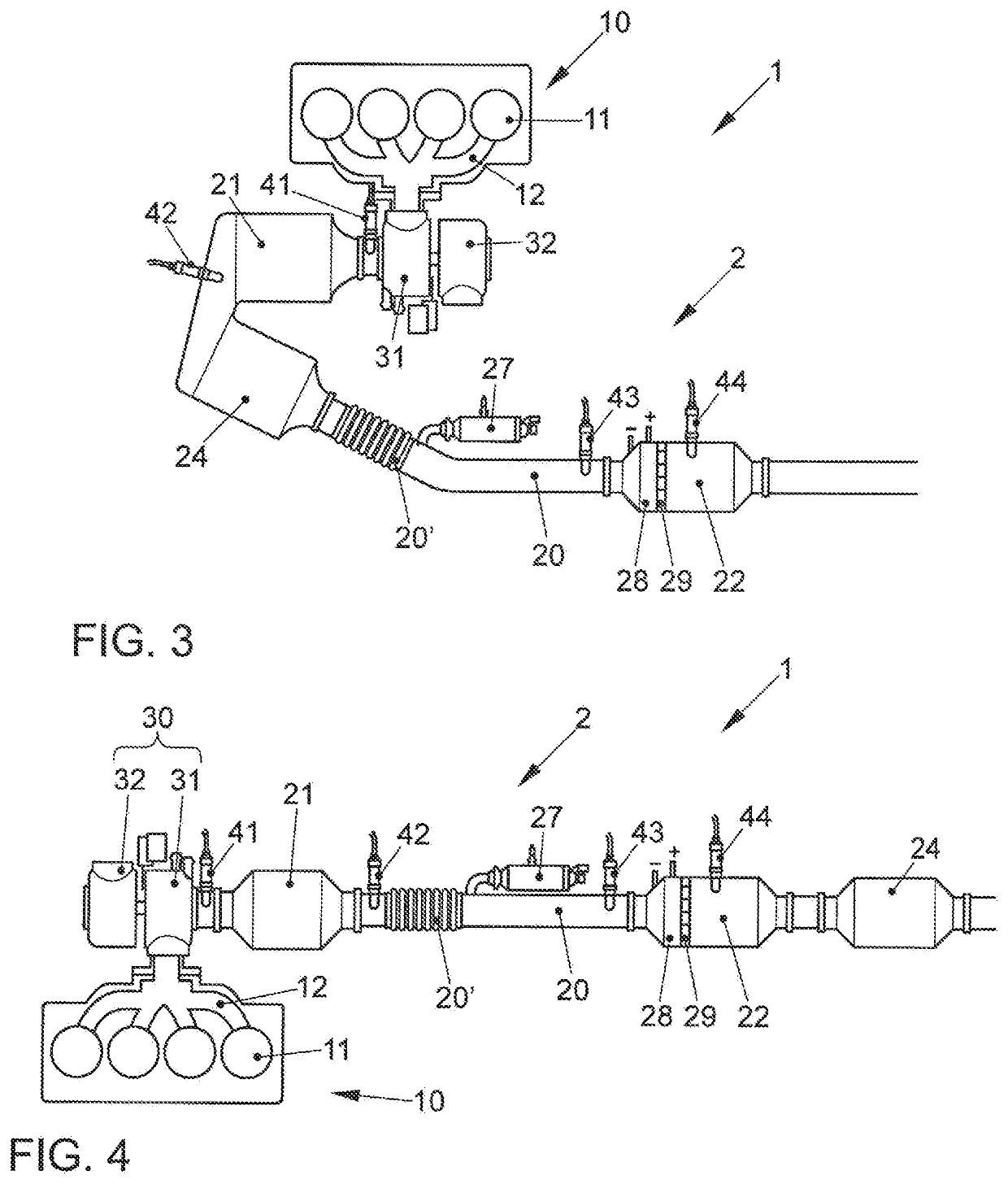

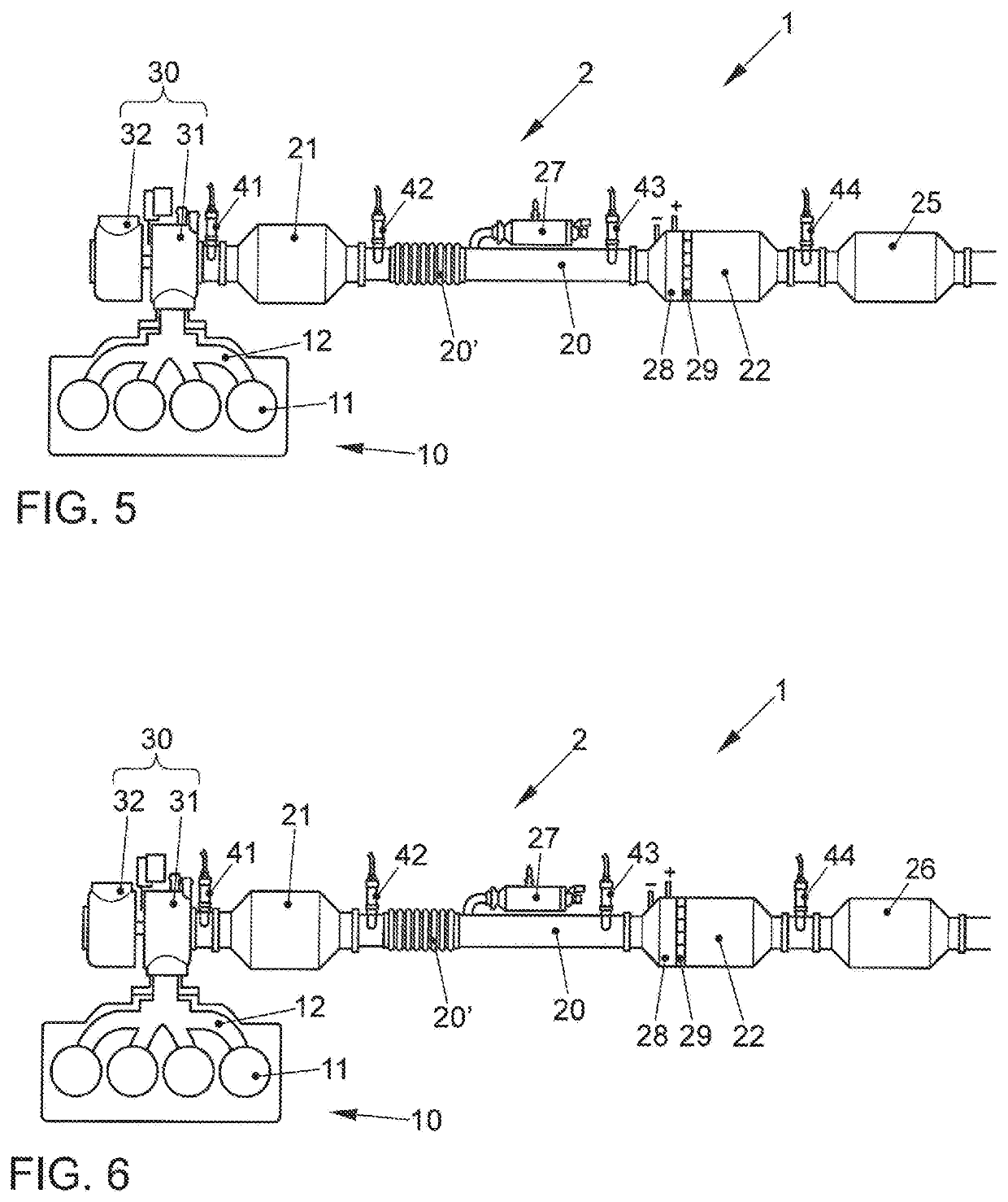

Method for determining the temperature of an electrically heatable catalytic converter

ActiveUS20190331015A1Improved determinationEfficient introductionInternal combustion piston enginesResistance/reactance/impedenceElectricityPower flow

A method for determining the temperature of an electrically heatable catalytic converter having an electric heating element that includes a heating resistor, the electrical resistance of which changes as a function of the component temperature of the electrically heatable catalytic converter. This resistance is determined from the current intensity and the voltage at the electrically heatable catalytic converter, and is used to determine the component temperature of the catalytic converter, based on a characteristic curve stored in the control unit. The energization of the heating resistor for determining the component temperature takes place in each case for only a short time in order to minimize the energy input into the heating resistor and thus avoid overheating of the heating resistor. In addition, by use of the short time interval, the aim is to minimize the energy requirements for determining the component temperature of the electrically heatable catalytic converter.

Owner:VOLKSWAGEN AG

Reactive additive manufacturing

ActiveUS10507638B2High strengthPrevent partial lowAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceReaction product

An additive manufacturing method may involve: Providing a first and a second material, the second material capable of reacting with the first material to form a reaction product; forming at least the first material into a first layer; subjecting at least a portion of the first layer to energy in the presence of the second material, the energy being sufficient to initiate a reaction between at least the first and second materials to form a portion of the article, the portion of the article comprising the reaction product; forming a second layer of at least the first material on the first layer; and subjecting at least a portion of the second layer to energy in the presence of the second material, the energy being sufficient to initiate a reaction between the first and second materials to form an additional portion of the article.

Owner:ELEMENTUM 3D INC

Method for making steel with electric arc furnace

InactiveUS6584137B1Increase ratingsReduce probabilityElectric discharge heatingIncreasing energy efficiencyElectric arc furnaceMaterials science

A method of making steel in an electric arc furnace is provided. The method comprises the steps of measuring electrical current in at least two phases of electrical power supplied to electrodes in the furnace during a campaign, establishing a setpoint current level and an input time interval, and switching between modes of inputting exothermic energy into the steel melt when at least two phases have measured current levels below the setpoint for the input time interval.

Owner:NUCOR CORP

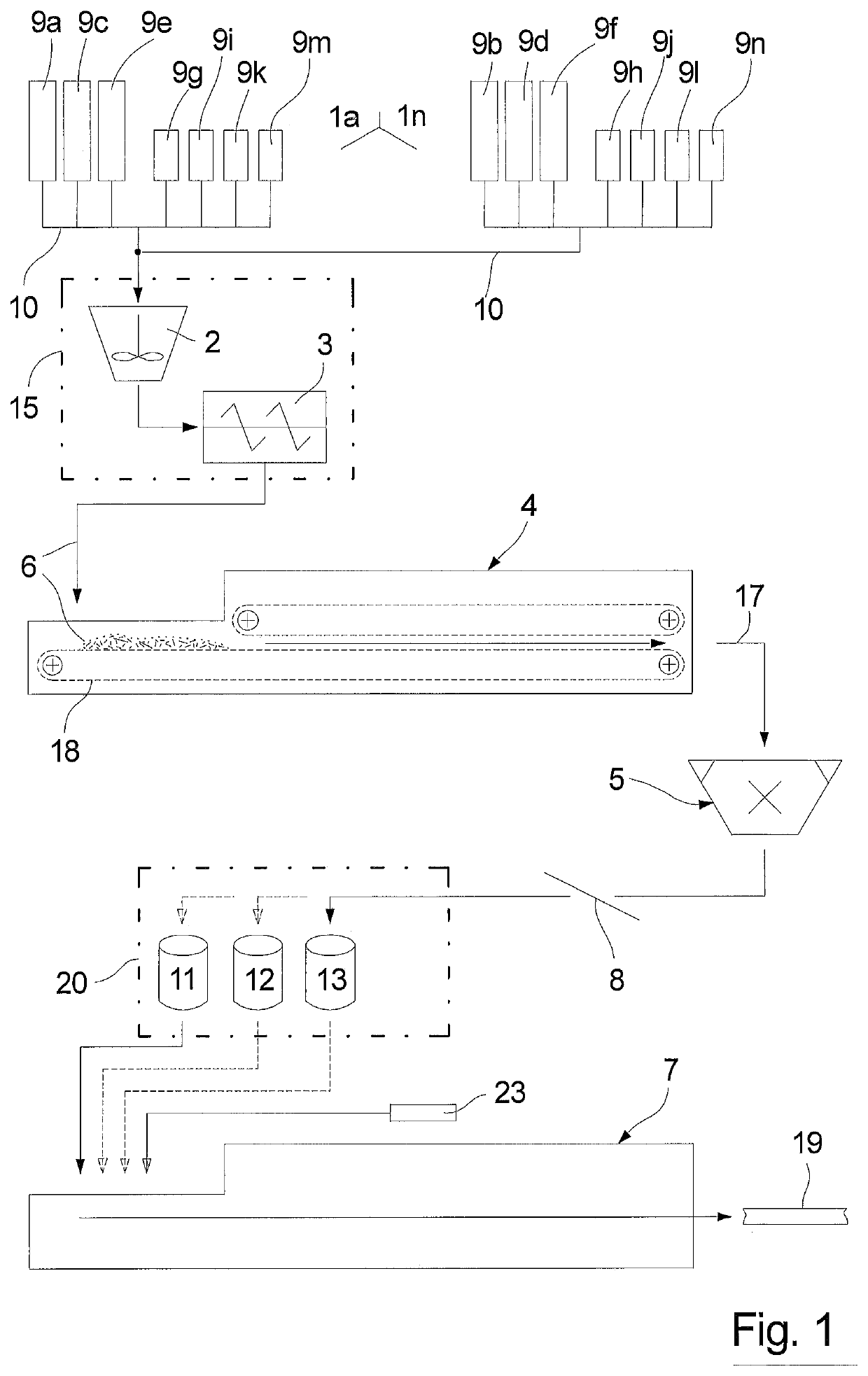

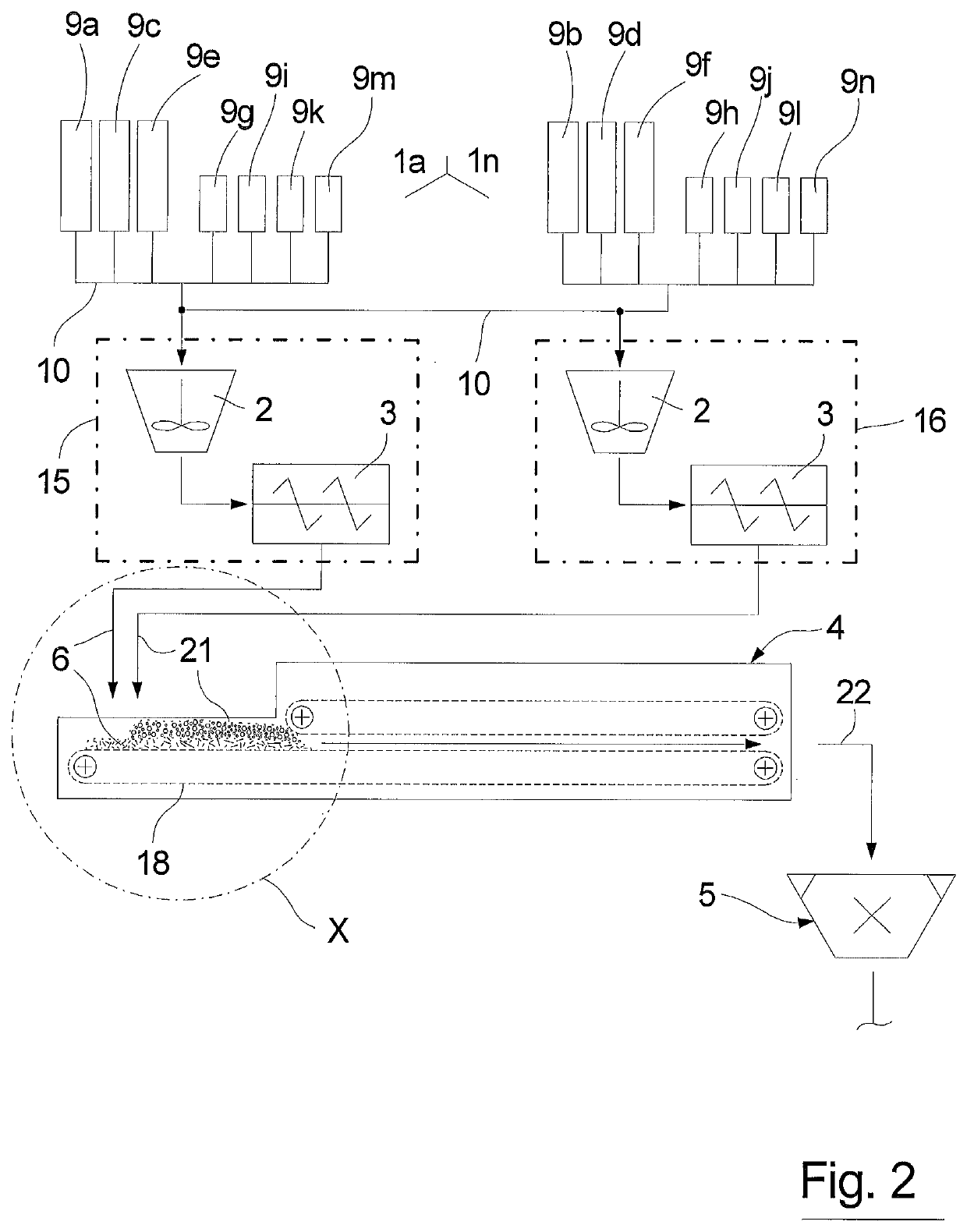

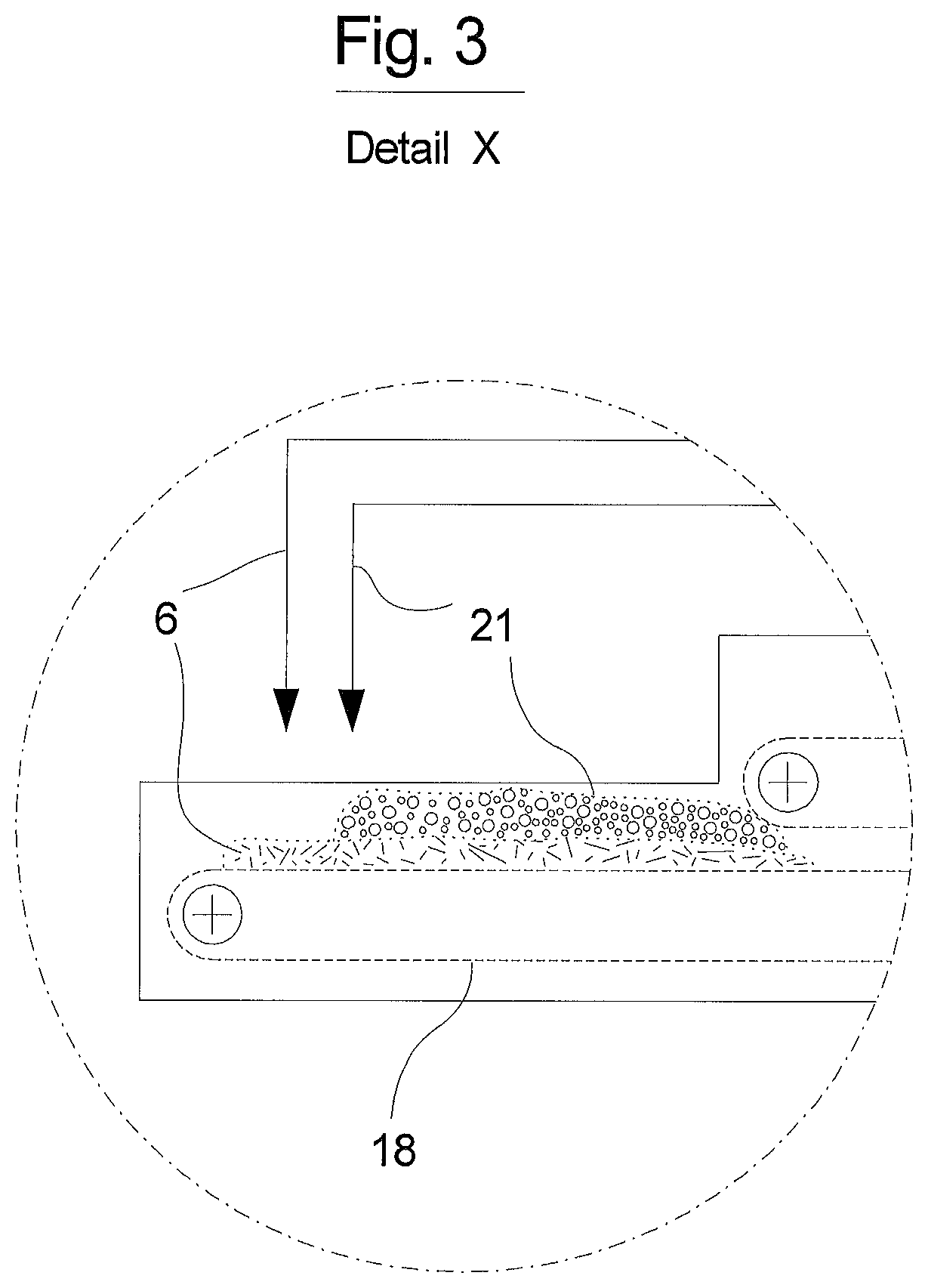

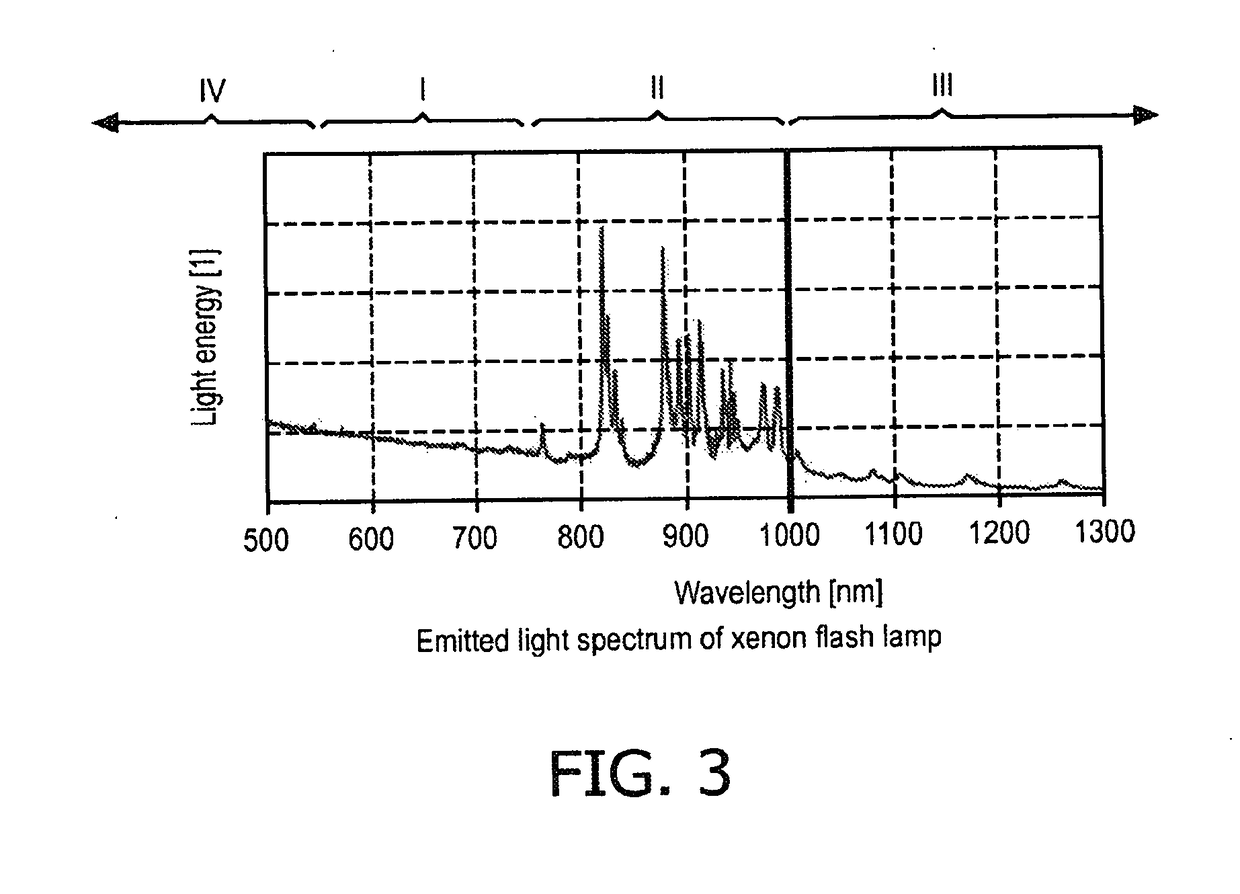

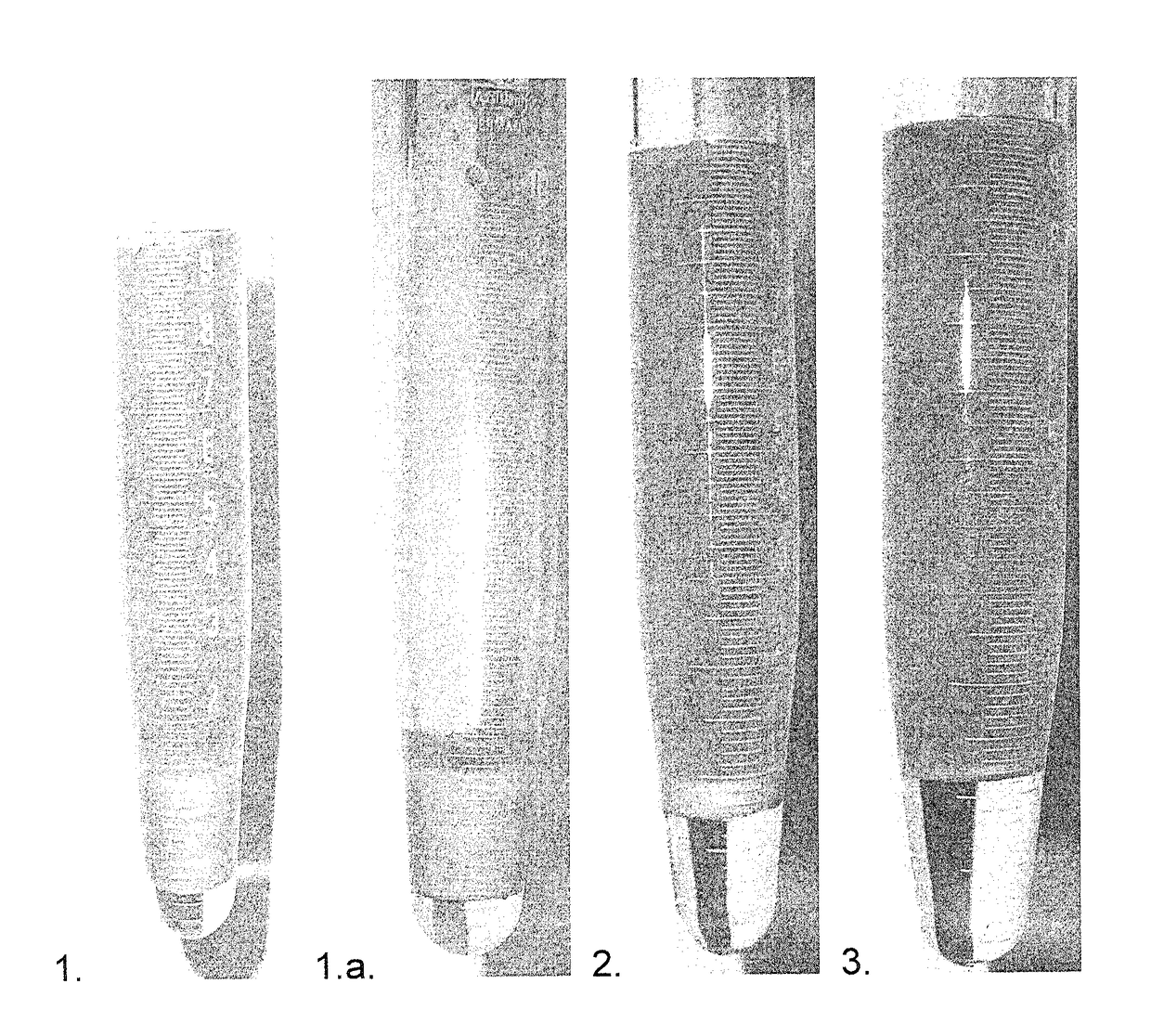

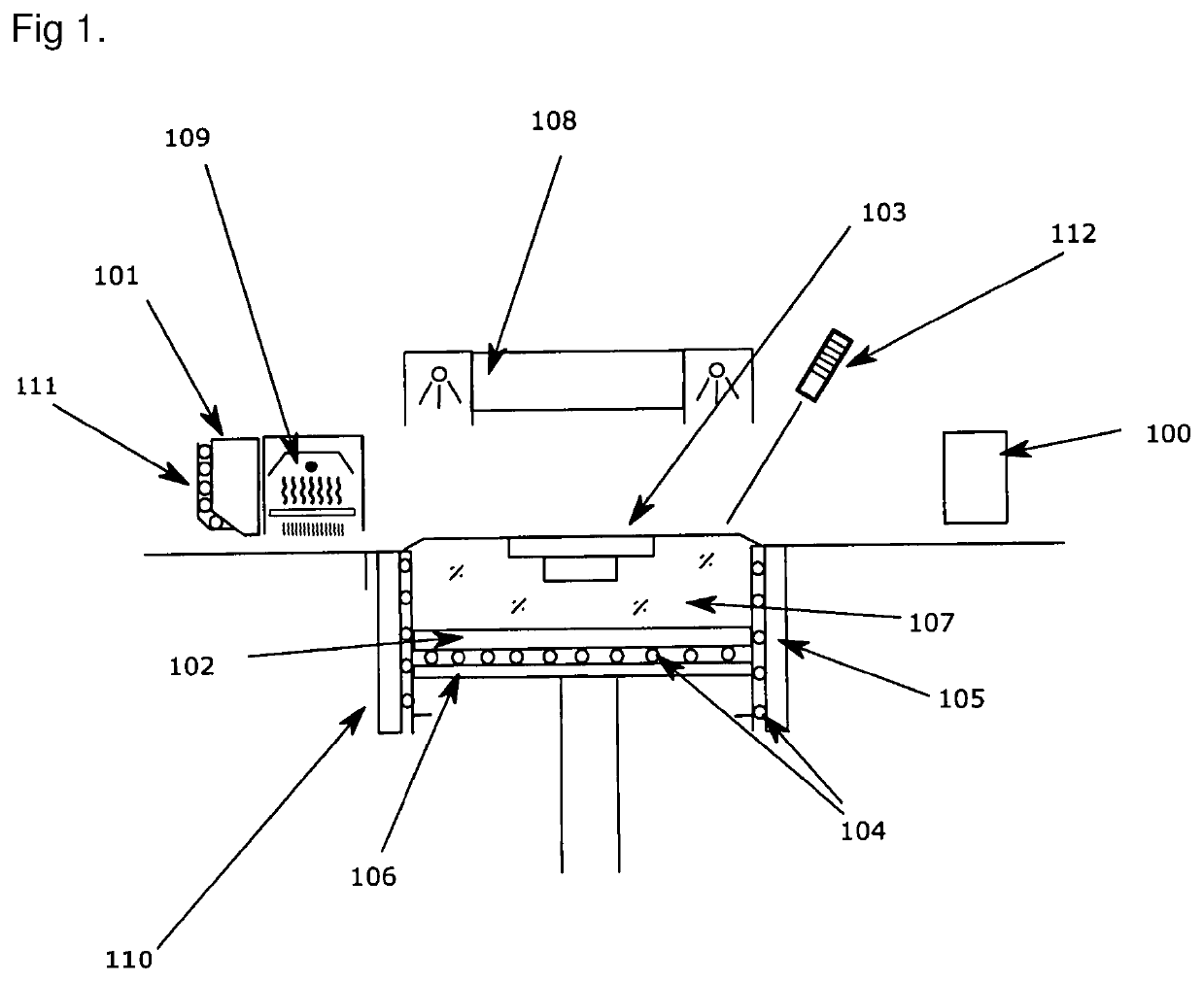

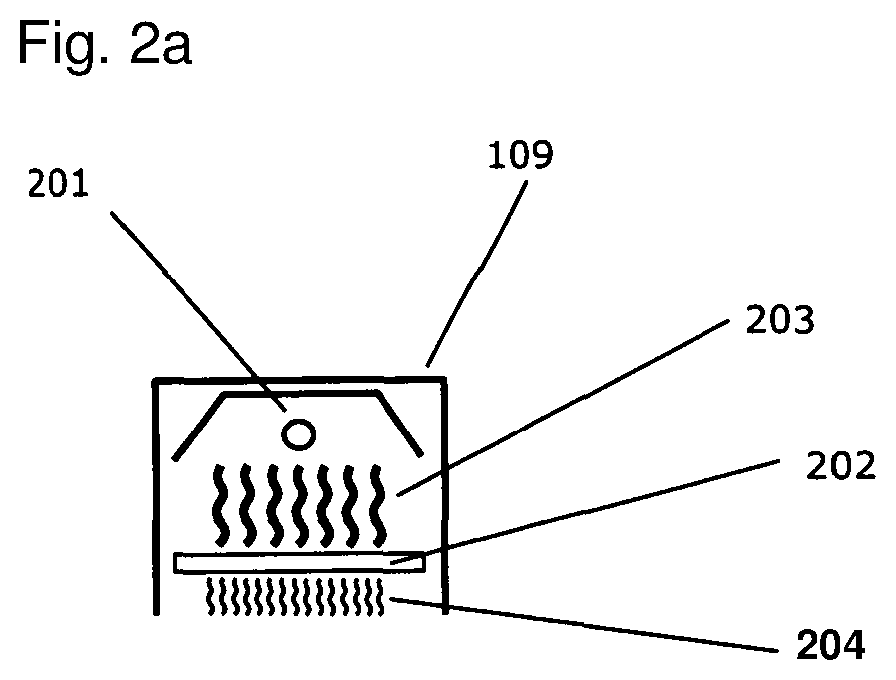

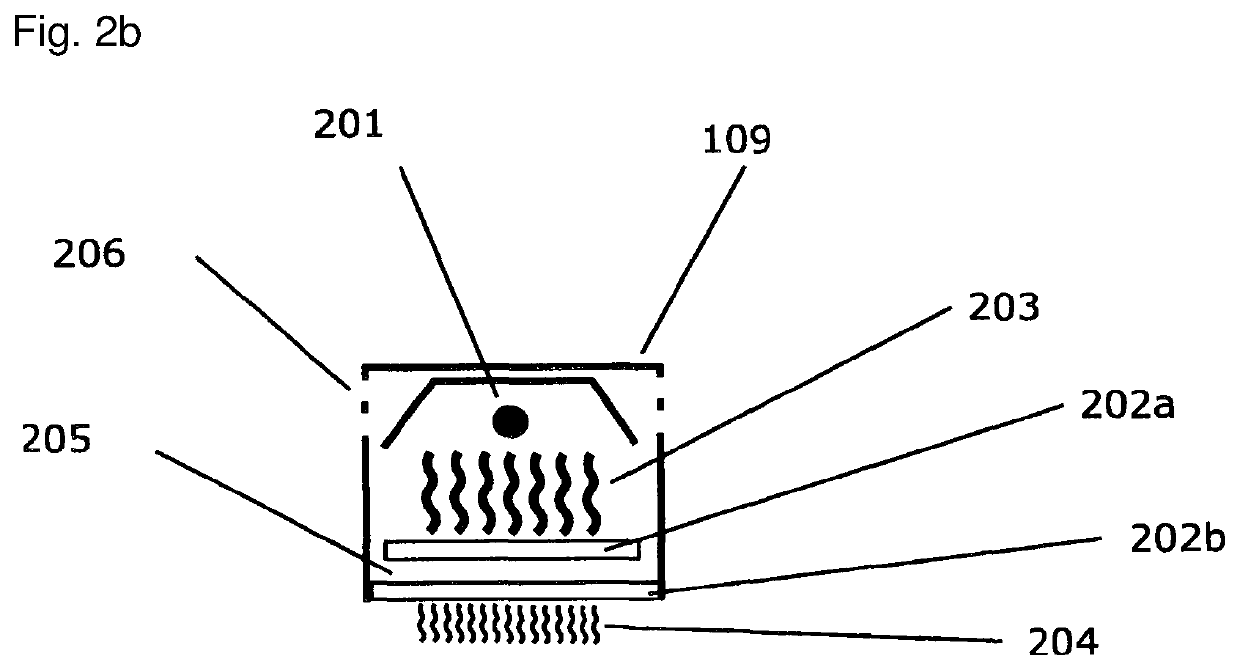

Process and apparatus for producing 3D moldings comprising a spectrum converter

ActiveUS20200130263A1Quality improvementNot to be sintered less reusableManufacturing platforms/substratesManufacturing heating elementsPhysicsSpectral conversion

A process and an apparatus for producing 3D moldings, wherein a spectrum converter is used. Said converter is defined as a means which absorbs a radiation, for example electromagnetic thermal radiation, and radiates or emits one or more defined wavelength ranges; the spectrum converter is here irradiated by an emitter of an electromagnetic thermal radiation (shortwave or longwave radiation), i.e. by a lamp or an emitter, for example an overhead emitter or a sintering unit, and then emits a defined electromagnetic thermal radiation

Owner:VOXELJET AG

Method for refining lipid phases, and use

ActiveUS20170135363A1High energy inputReduce solubilityFatty-oils/fats refiningEdible oils/fatsMineralogyColoring agents

The invention relates to a method for gently eliminating odorous substances and coloring agents from lipid phases. Said method is easy and inexpensive to carry out and and can be employed for purifying lipid phases of various origins.

Owner:DREI LILIEN PVG

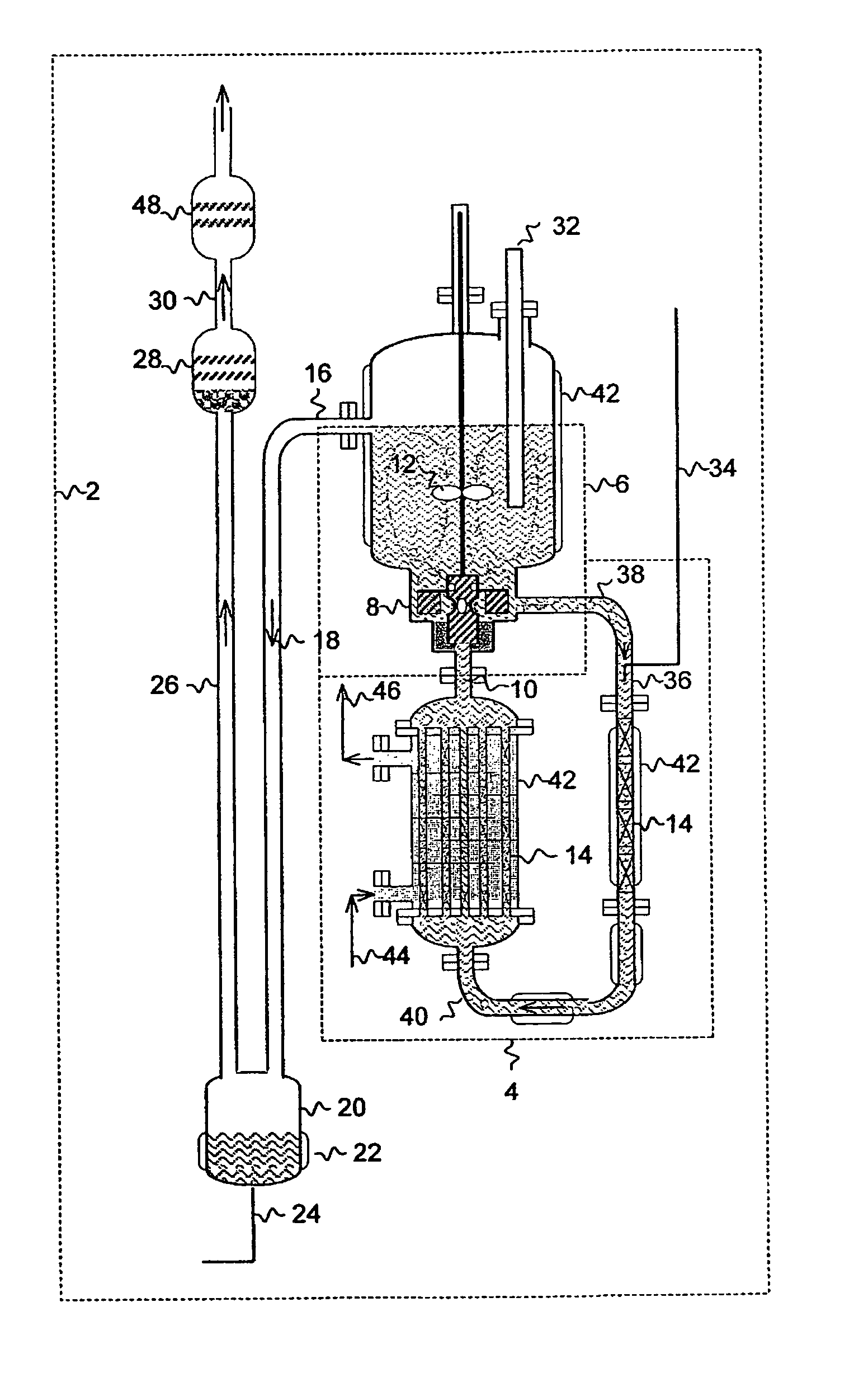

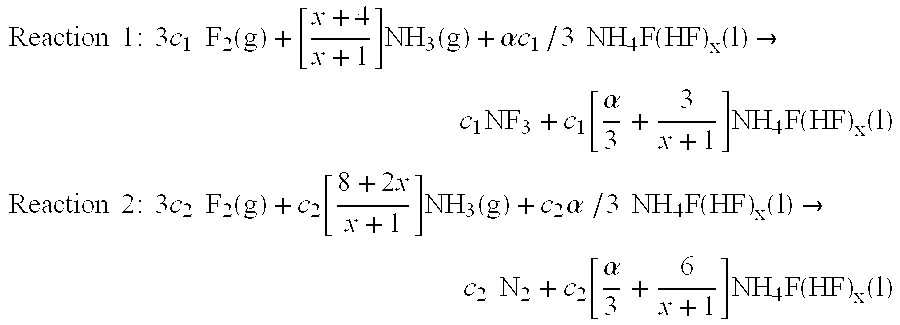

NF3 production reactor

InactiveUS7128885B2Reduce corrosionHigh energy inputCombination devicesFlow mixersBoron trifluorideHigh energy

A process for the production of nitrogen trifluoride by reacting fluorine gas and liquid ammonia acid fluoride in a first reaction zone having a relatively low energy input followed by treatment of the resulting reaction product in a second reaction zone having a relatively high energy input. The resulting crude nitrogen trifluoride product may be further treated with fluorine gas under elevated temperatures to improve yield of the desired product.

Owner:BOC GRP INC

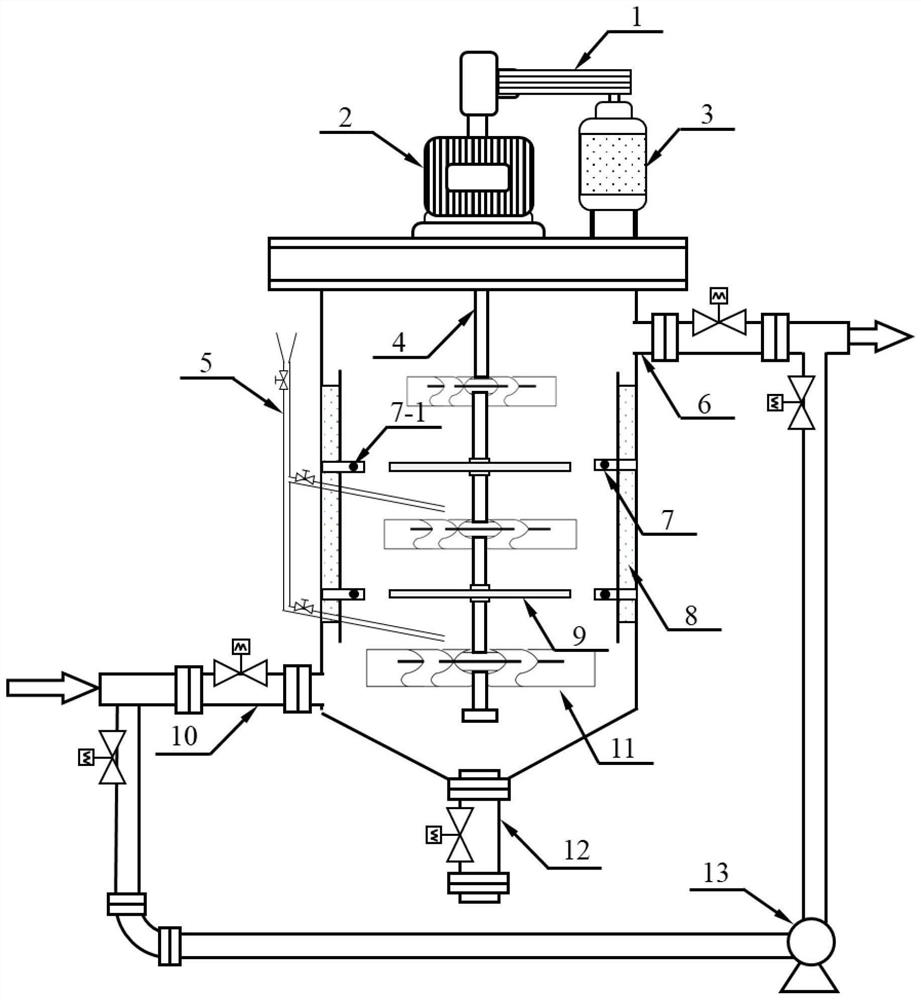

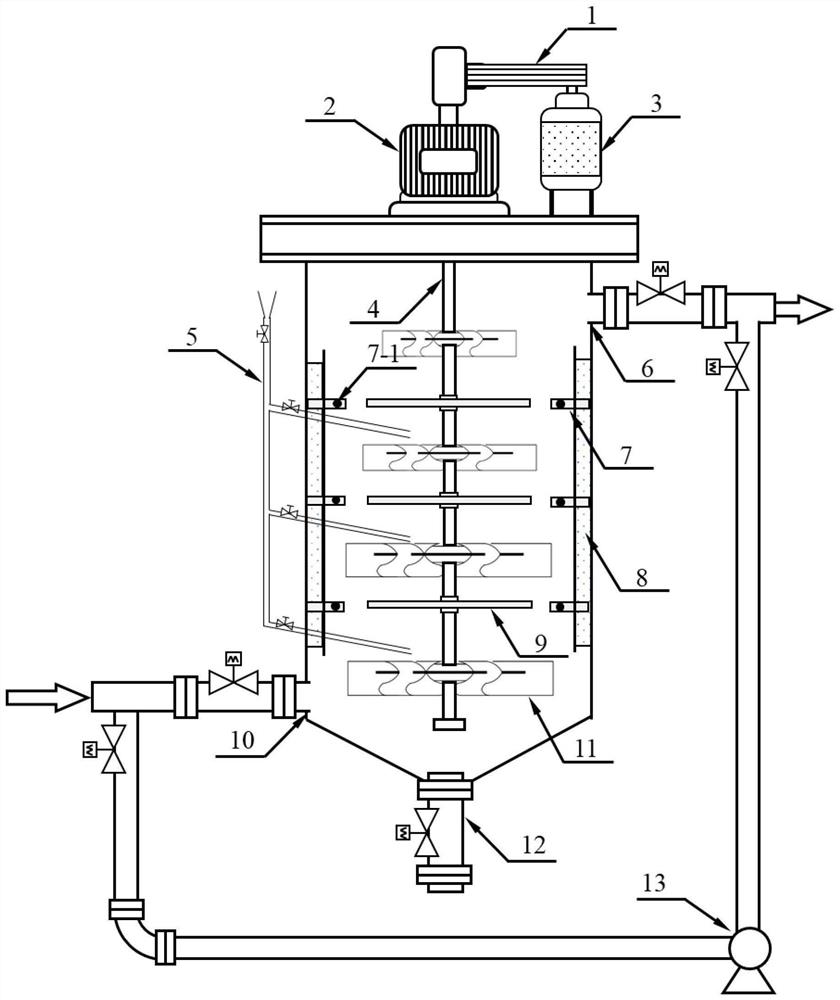

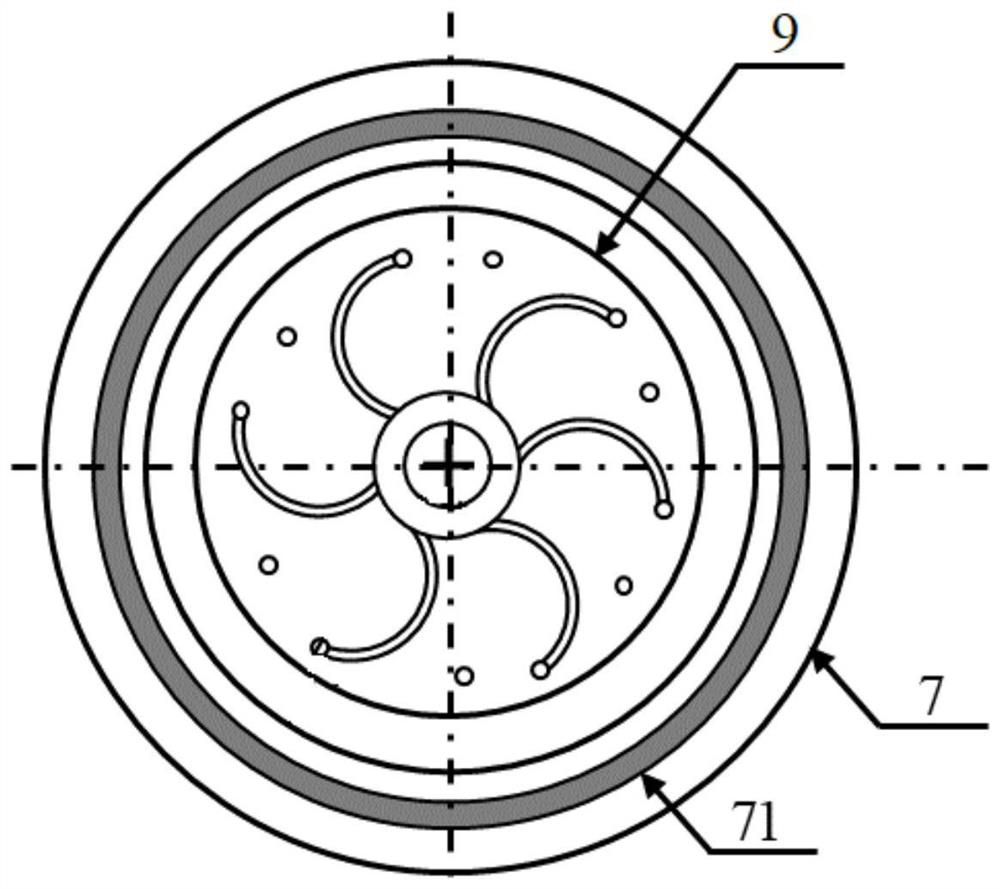

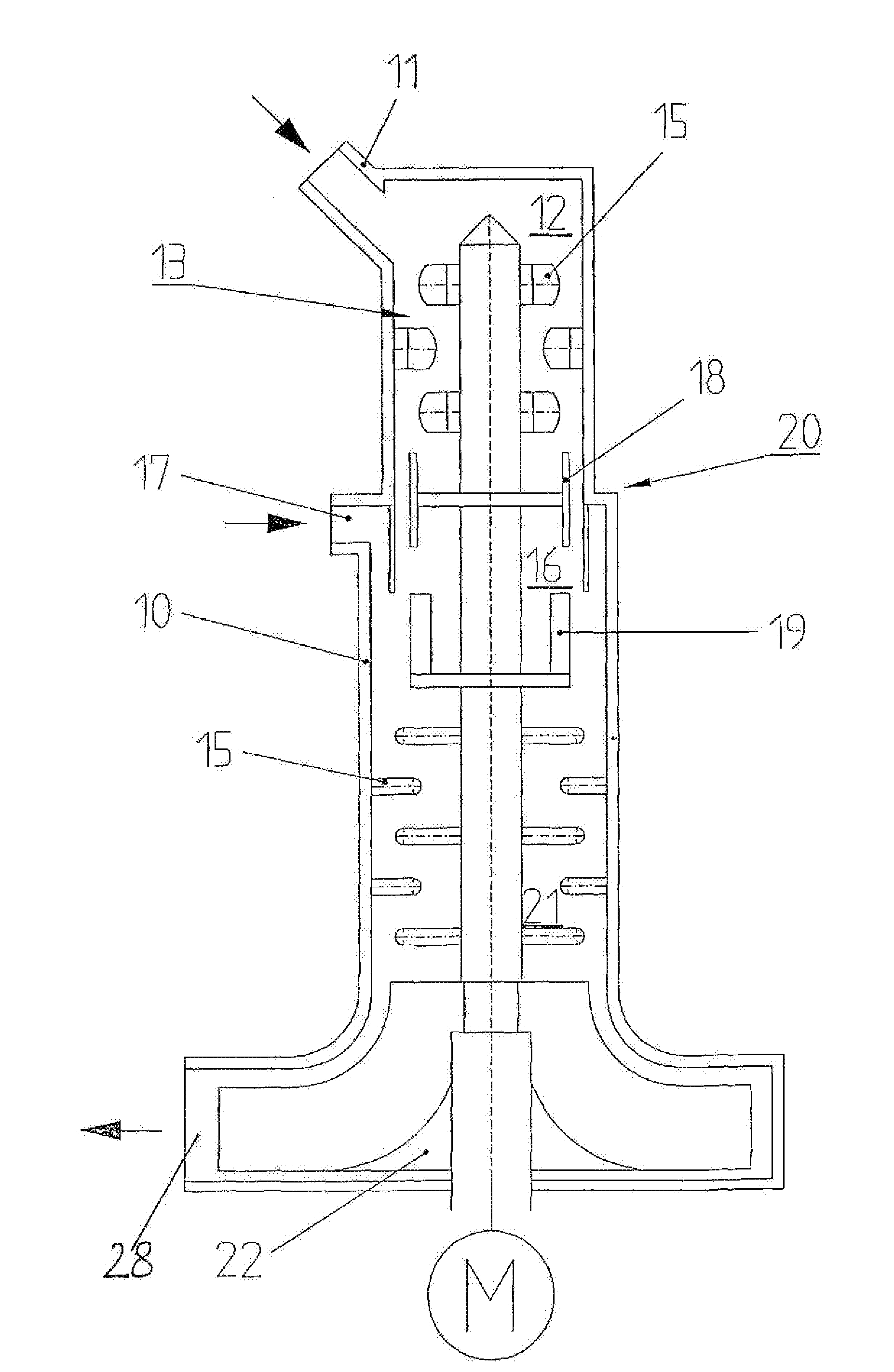

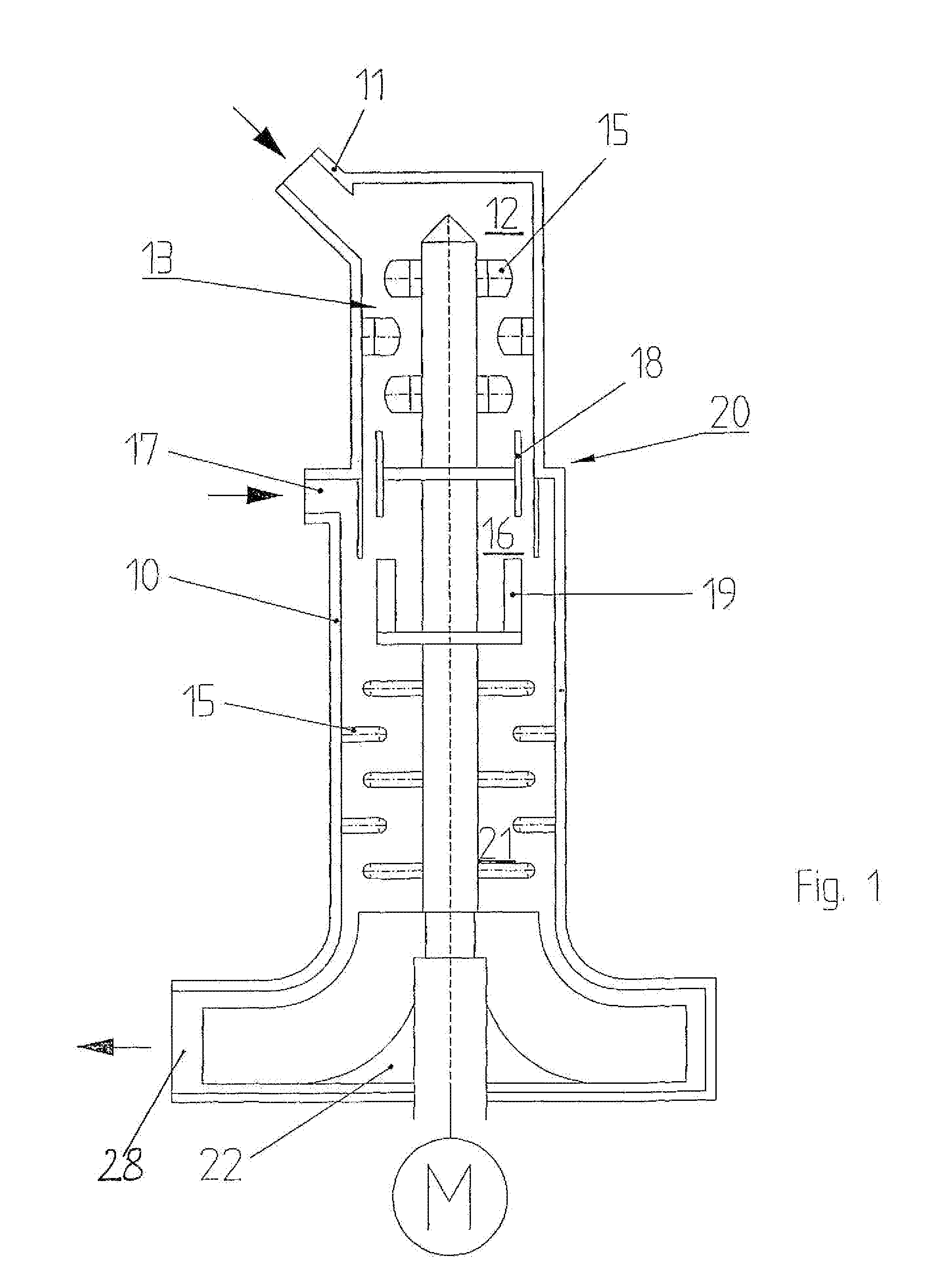

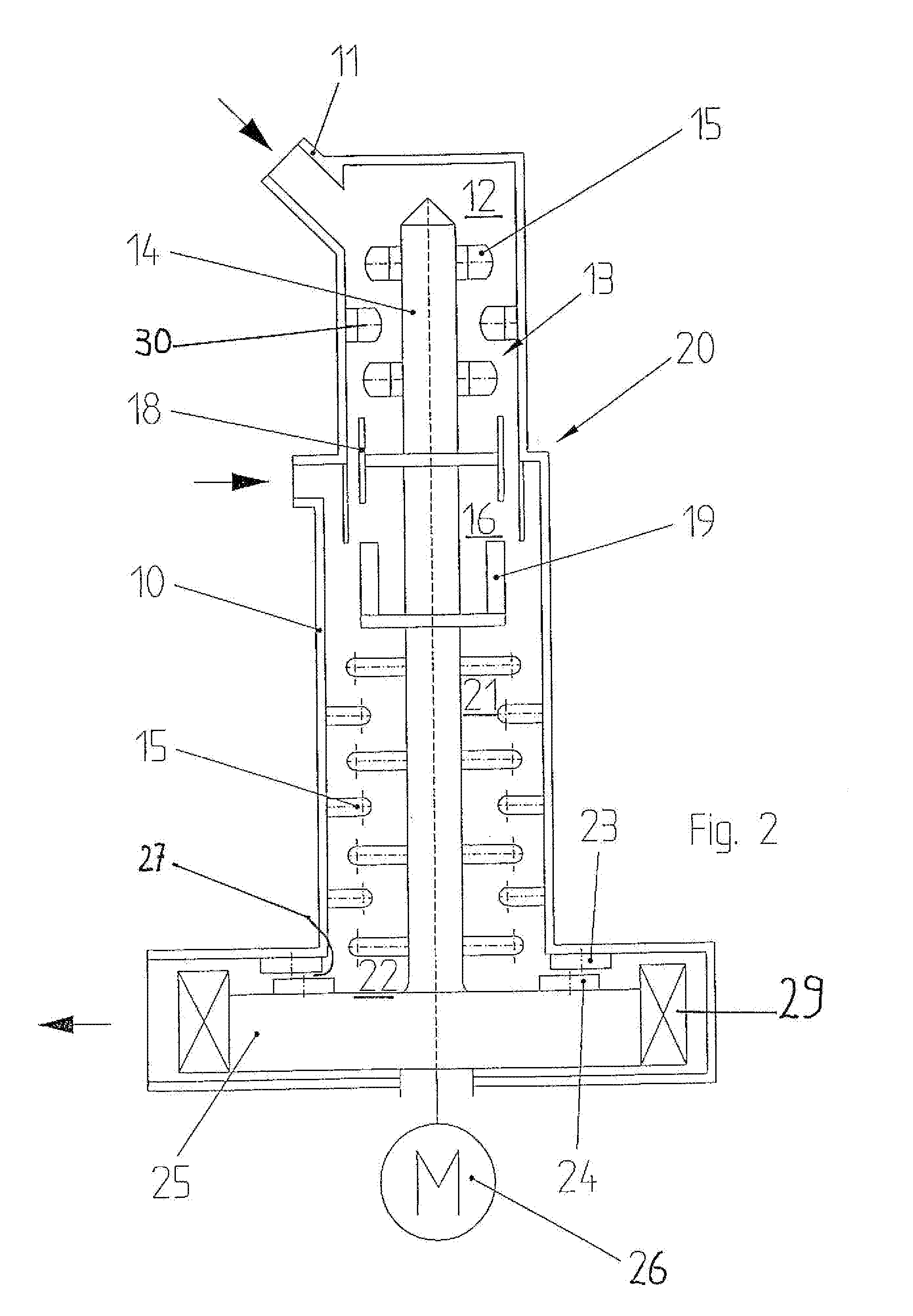

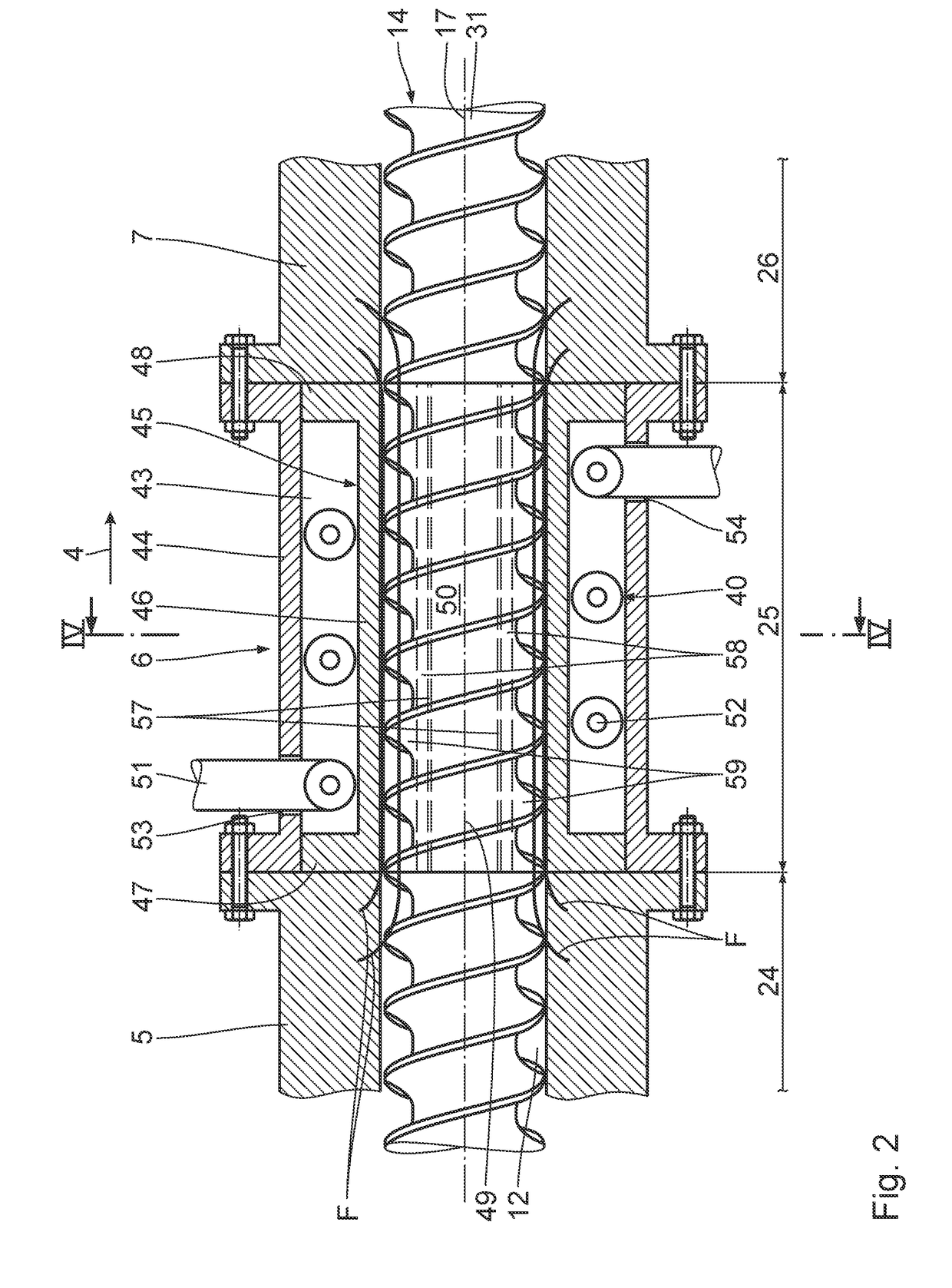

Multi-section stirring and circulating slurry mixing equipment and method

PendingCN113843051AIncreased turbulent dissipation rateImprove energy utilizationShaking/oscillating/vibrating mixersFlotationPhysicsProcess engineering

The invention relates to multi-section stirring and circulating slurry mixing equipment and method, belongs to the technical field of mineral flotation stirring slurry mixing, and solves the problem that slurry mixing equipment and method in the prior art are difficult to meet the requirements of high dispersion, high strengthening and efficient collision contact required by fine ore grains. The device comprises a slurry mixing barrel, wherein a flow guide disc paddle and stirring impellers are arranged in the slurry mixing barrel, the flow guide disc paddle divides the interior of the slurry mixing barrel into multiple sections of forced stirring slurry mixing areas from top to bottom, the stirring impellers are arranged in the forced stirring slurry mixing areas, and the radiuses of the stirring impellers in the forced stirring slurry mixing areas are arranged in a gradient mode. According to the invention, multi-section stirring circulation slurry mixing is adopted, the radius of the stirring impeller is arranged in a gradient manner, gradient input of energy is realized, and the slurry mixing effect is good.

Owner:CHINA UNIV OF MINING & TECH

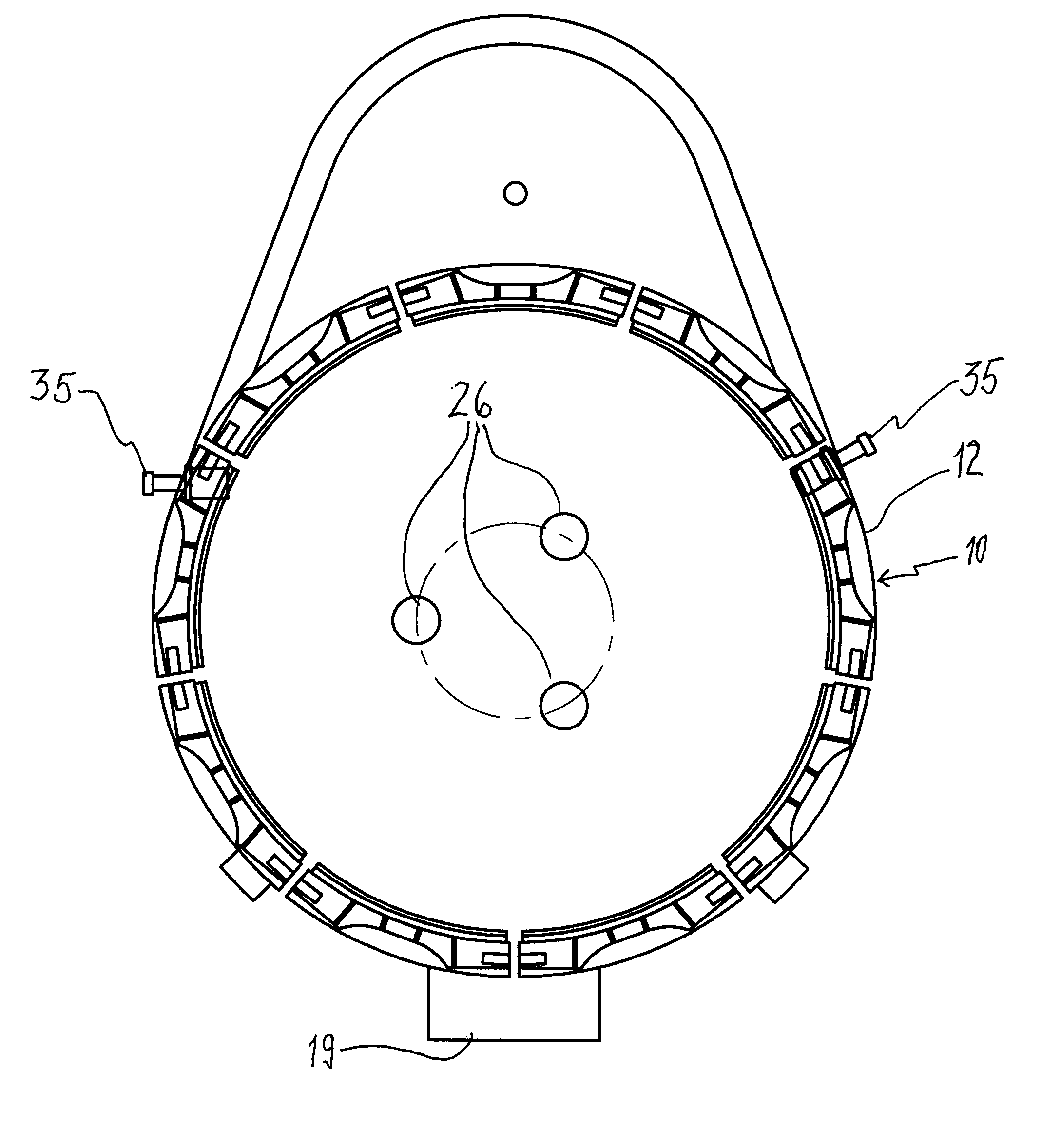

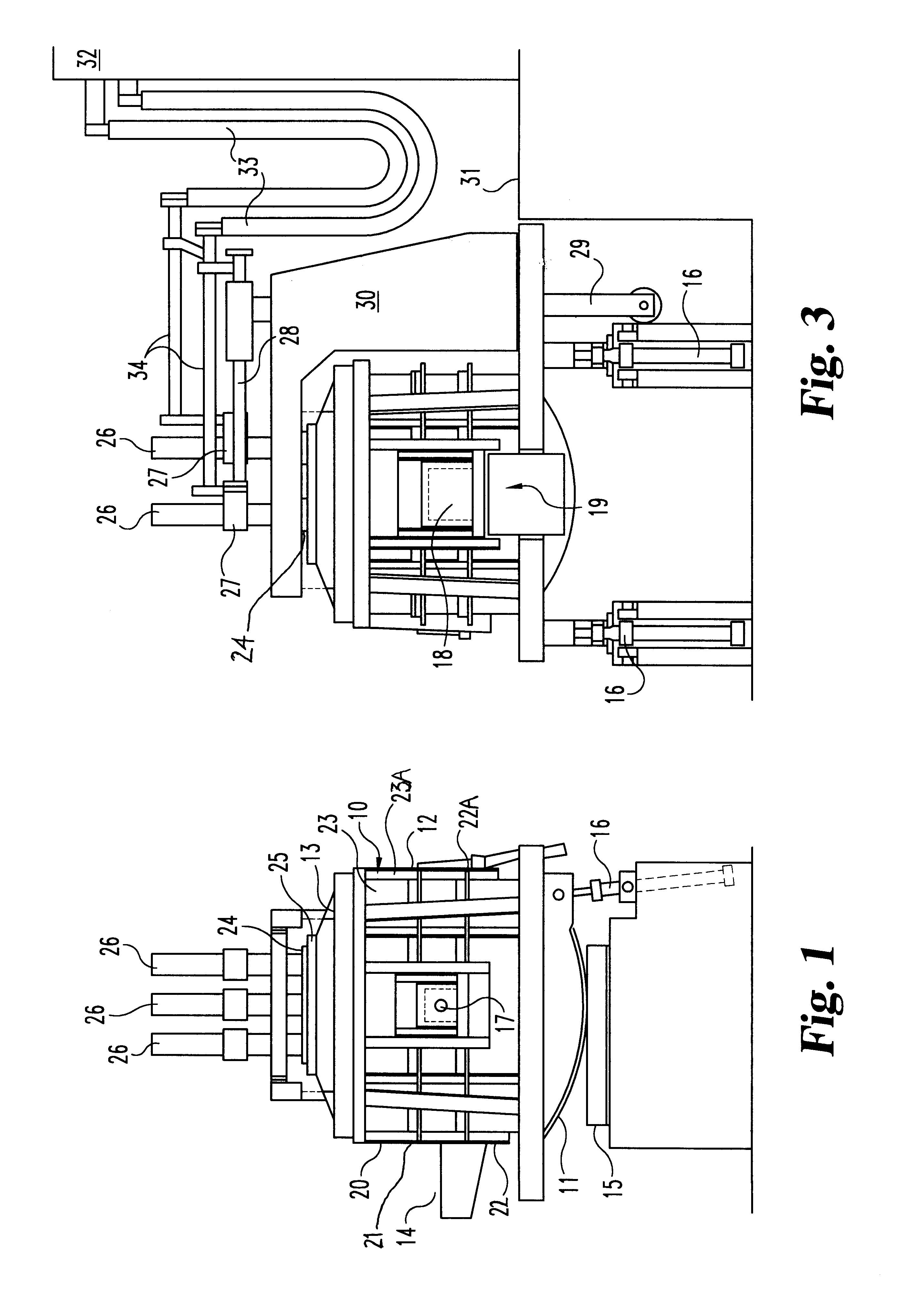

Method And Device For Recovering Ore

ActiveUS20090072057A1Promote wettingImprove homogeneityGrain treatmentsSortingEngineeringComminution

The invention relates to a method for the comminuting of natural or synthetic mineral products having a size of 10 nm to 30 mm, which are obtained from the upstream process in pre-comminuted form for example in a roller mill for inter-particle comminution, wherein these solids are further comminuted in a working process initially dry then wetted with liquid and in this liquid are comminuted so as to obtain a suspension that can be pumped, which suspension is subsequently ground to the desired final fineness by means of agitating mills.

Owner:NETZSCH FEINMAHL TECH GMBH

Exhaust system for an internal combustion engine and method for operating the same

PendingUS20200232359A1Increased content of CO and HCReducing particulate emissionExhaust apparatusDispersed particle separationExhaust gasExhaust fumes

An exhaust gas system for an internal combustion engine, comprising a first exhaust emission control device close to the engine and a second exhaust emission control device remote from the engine. The second exhaust emission control device is heatable by a combination of an upstream burner and an electric heating device. For heating the exhaust emission control devices after an engine start, the internal combustion engine is operated with at least one engine-internal measure for raising the exhaust gas temperature, and the burner and the electric heating device are activated at the same time or offset in time for heating the second exhaust emission control device. A mixed gas entering the second exhaust emission control device is set to a stoichiometric lambda value. The invention allows accelerated heating of the exhaust emission control devices, and thus, a reduction in starting emissions.

Owner:VOLKSWAGEN AG

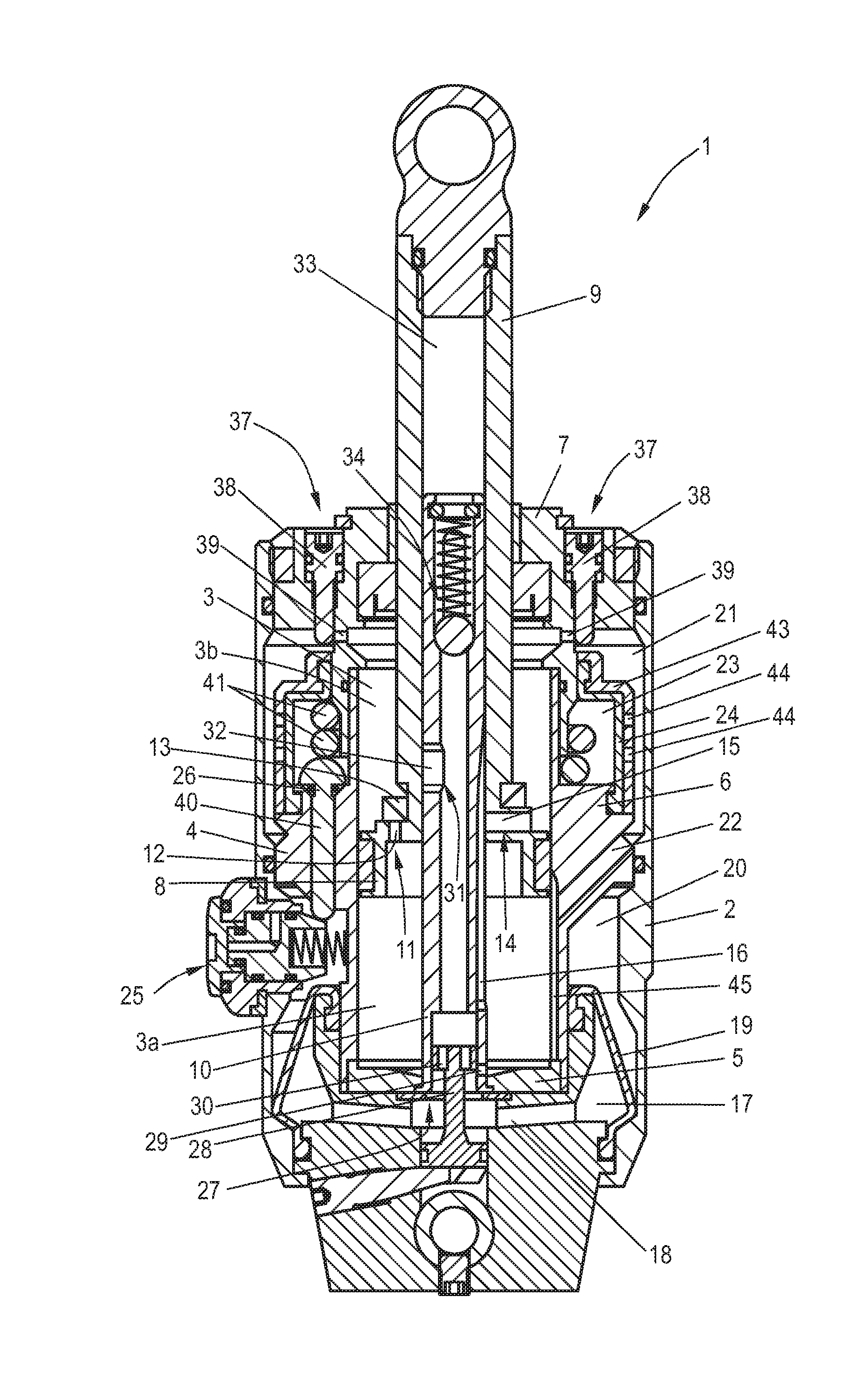

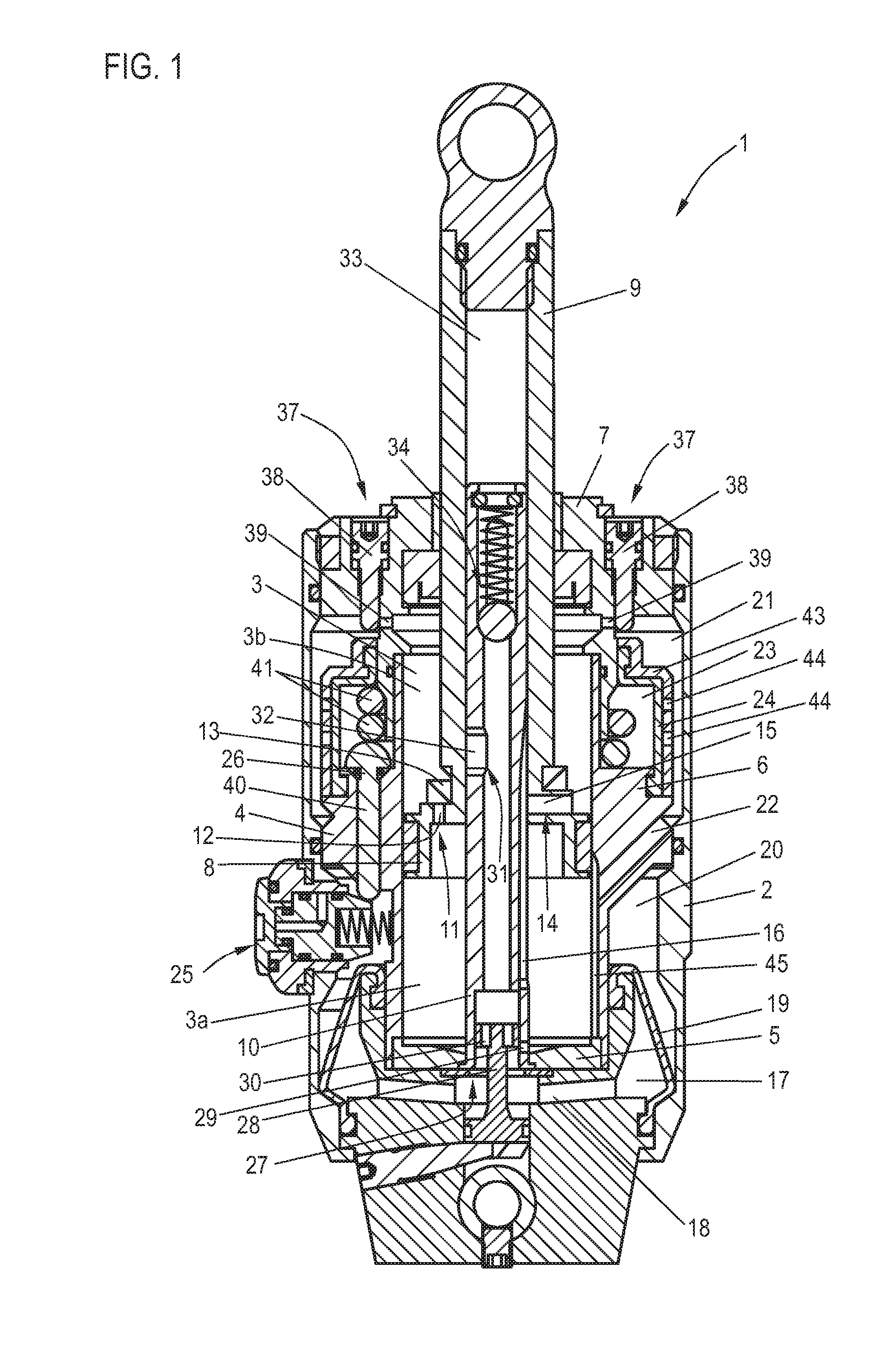

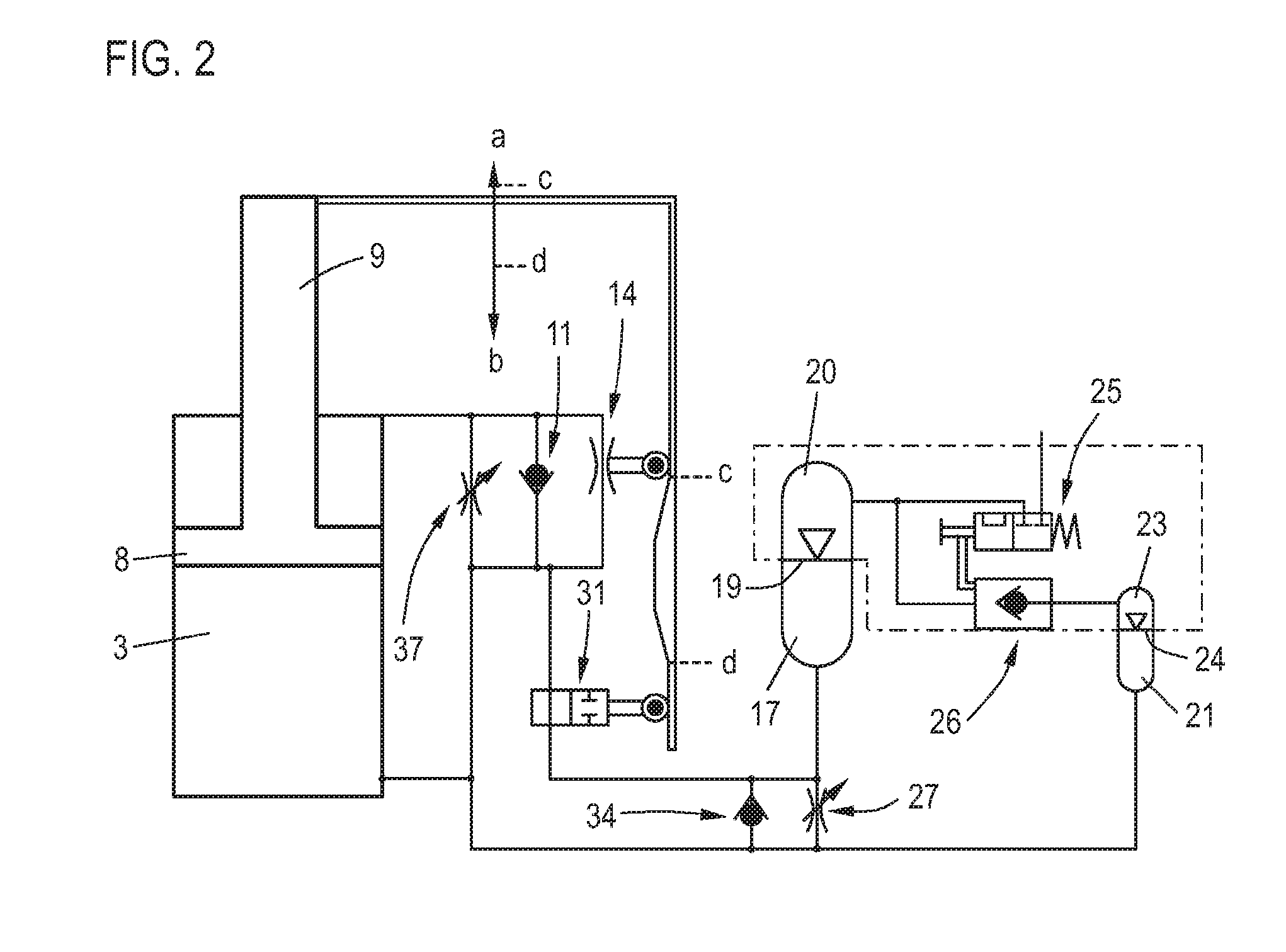

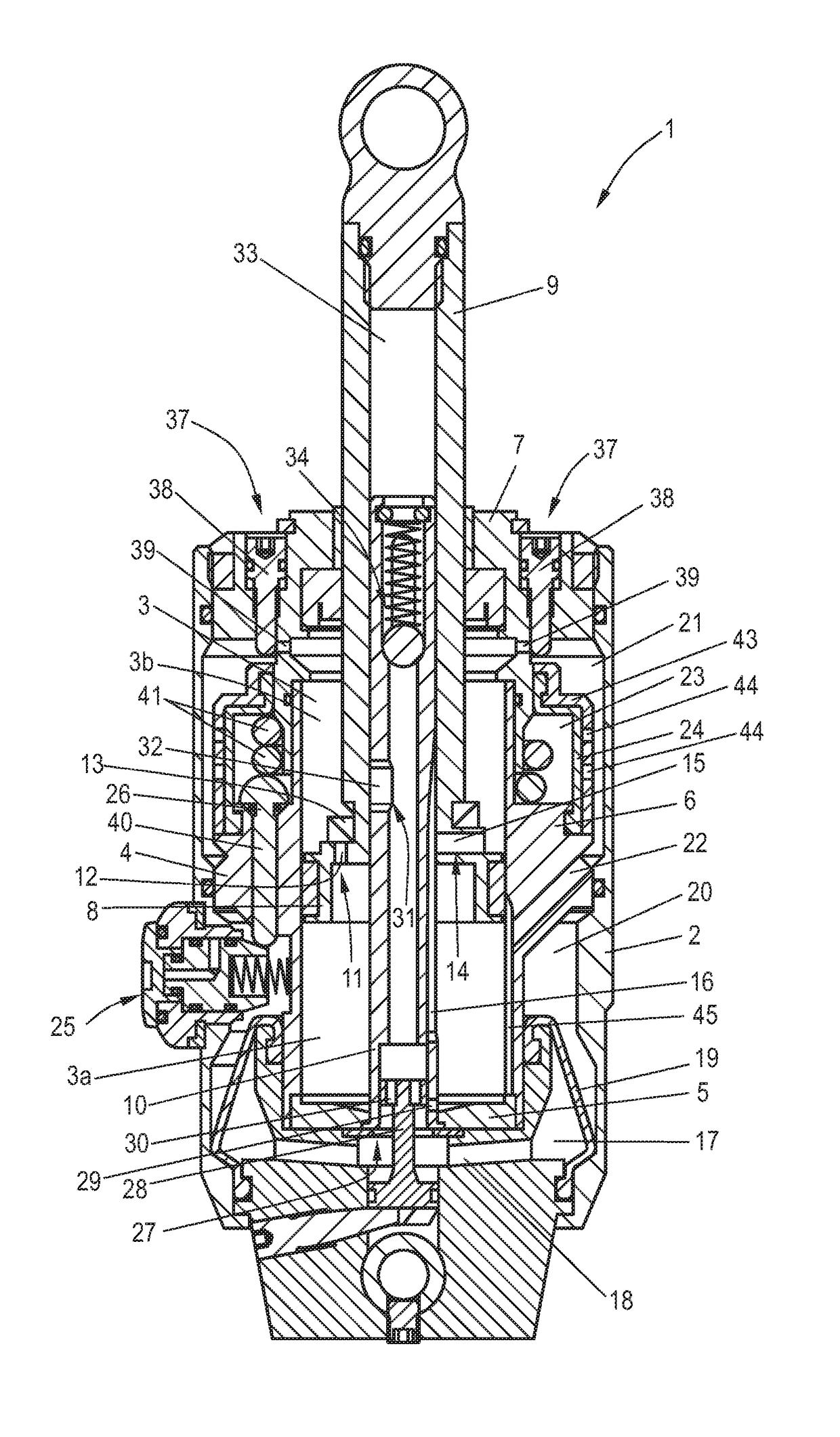

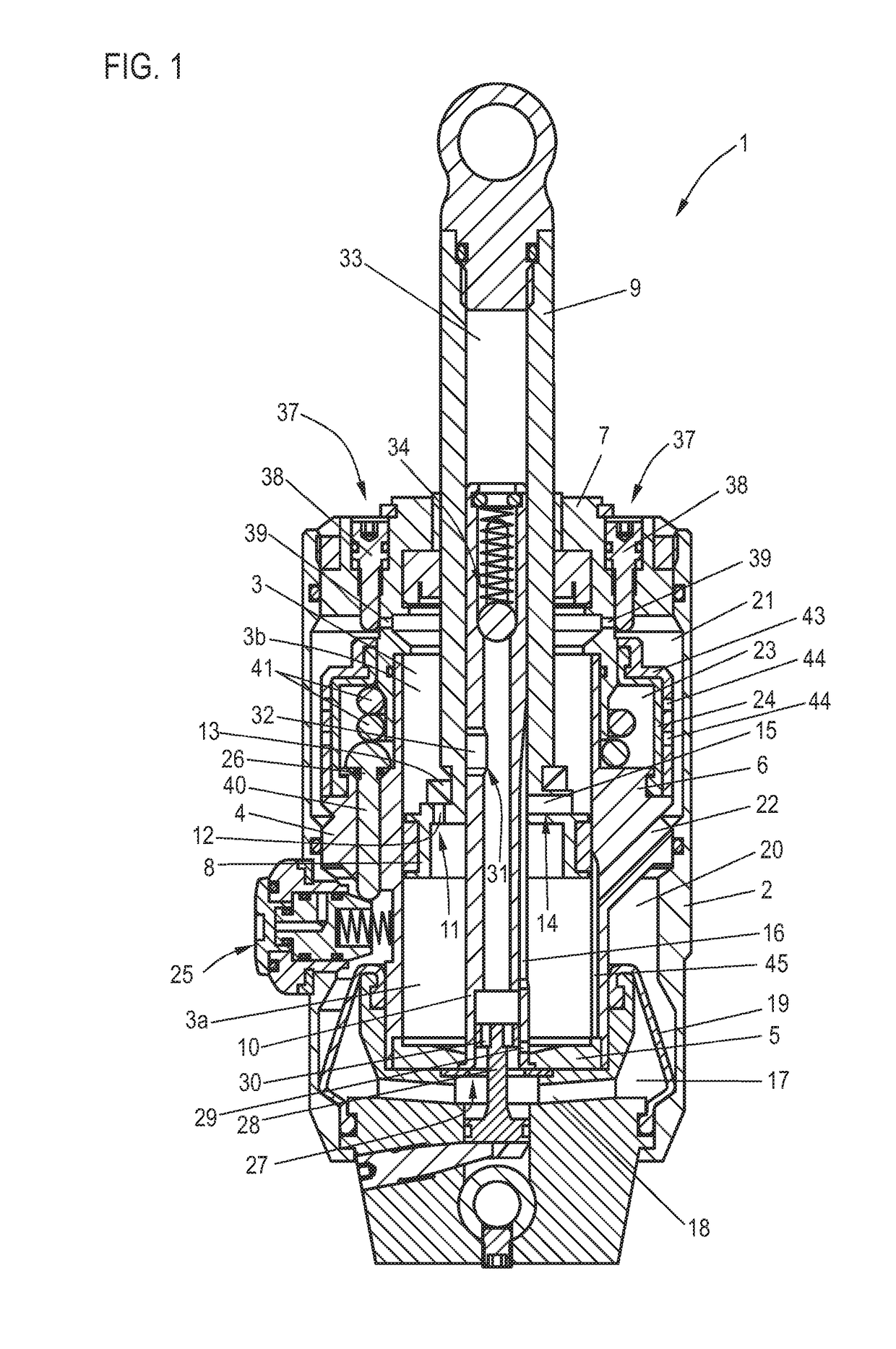

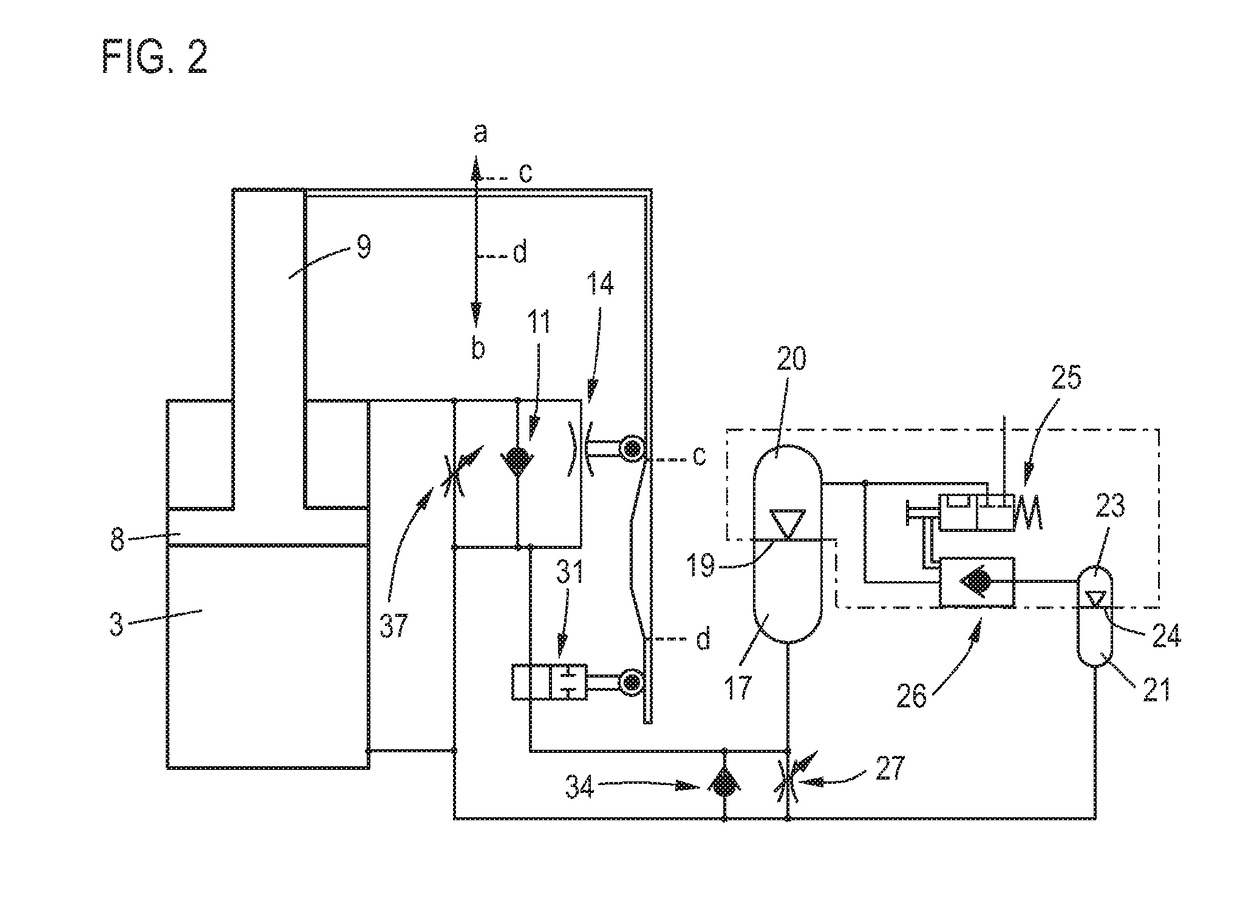

Hydraulic damping cylinder, in particular for a knee prosthesis

ActiveUS20160166410A1Greater the proportion of hydraulic fluidConvenient amountSpringsLiquid based dampersCompressible fluid flowKnee Joint

A hydraulic damping cylinder for a prosthetic knee joint, including a housing, a cylinder chamber in the housing and filled with a hydraulic fluid, and a piston arranged in the cylinder chamber and movable by a piston rod. In the housing there are provided at least two separate receiving chambers, which are of different size and are connected to the cylinder chamber by fluid ducts, for hydraulic fluid displaced from the cylinder chamber during a piston movement. The receiving chambers are each separated, by a diaphragm, from a compression chamber filled with a compressible fluid that forms an energy store. Upstream of the larger receiving chamber, there is connected a throttle device which forms a flow resistance for the hydraulic fluid flowing into the receiving chamber so that the hydraulic fluid can be distributed to the two receiving chambers in a manner dependent on speed of the piston movement.

Owner:OSSUR ICELAND EHF

Flip-chip hybridization of microelectronic components by local heating of connecting elements

InactiveUS9111924B2Limiting unwanted thermal effectHigh energy inputSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductancePower flow

A method of forming a hybridized device including forming a first component provided with metal bumps, and a second component provided with connection elements, attaching the bumps to the connection elements. The manufacturing of the second component includes forming, on a surface of a substrate, resistive elements at the locations provided for the connection elements; depositing an electric insulator layer at least on the resistive elements; and forming the connection elements, each comprising a metal well having an opening capable of receiving the corresponding metal bump of the first microelectronic component and at least partially filled with a fusible element, particularly indium or an alloy of tin and gold, or with a conductive ink, particularly based on silver or copper. Further, the attachment of the balls to the connection elements comprises applying an electric current through the resistive elements to heat the bumps.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

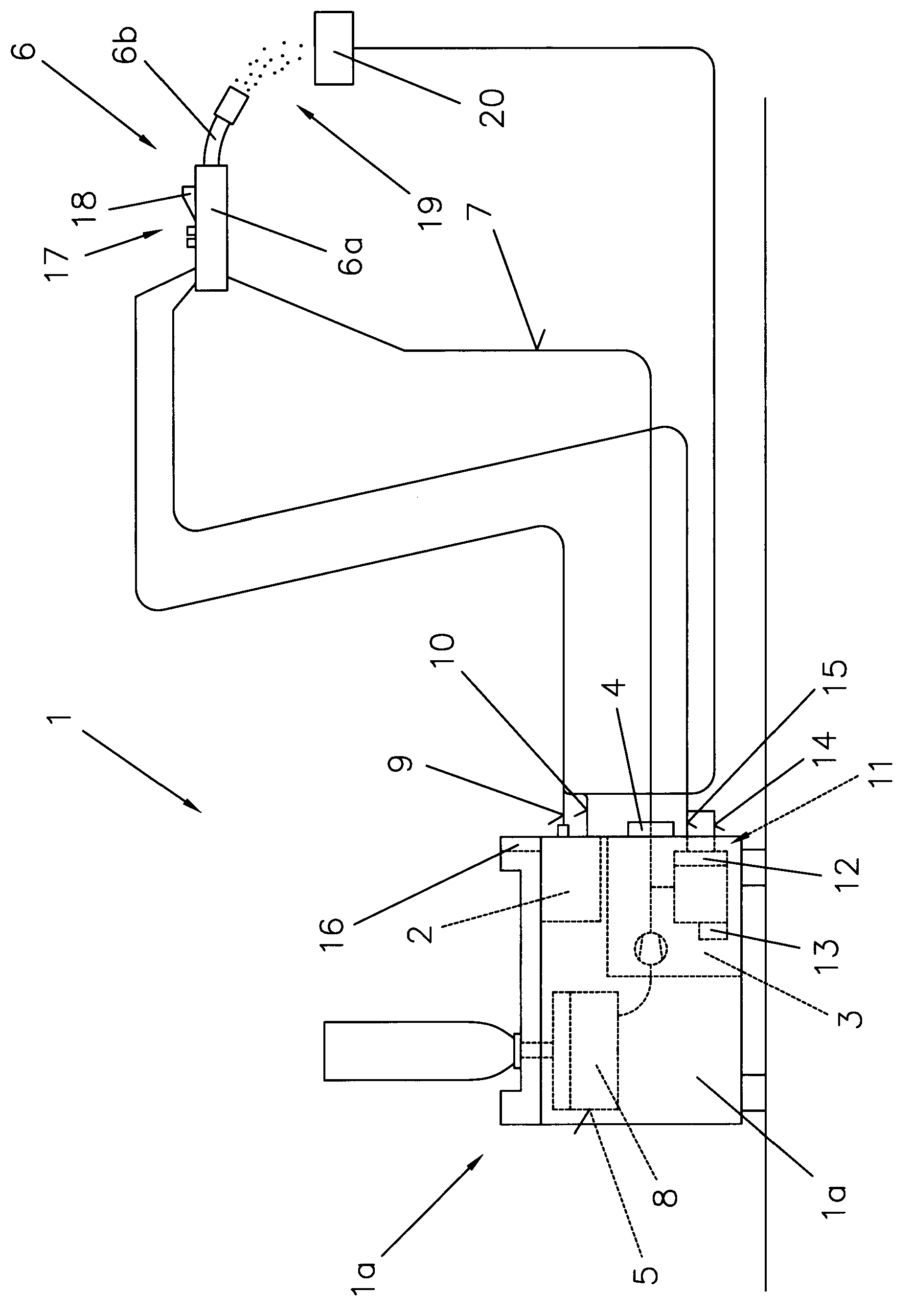

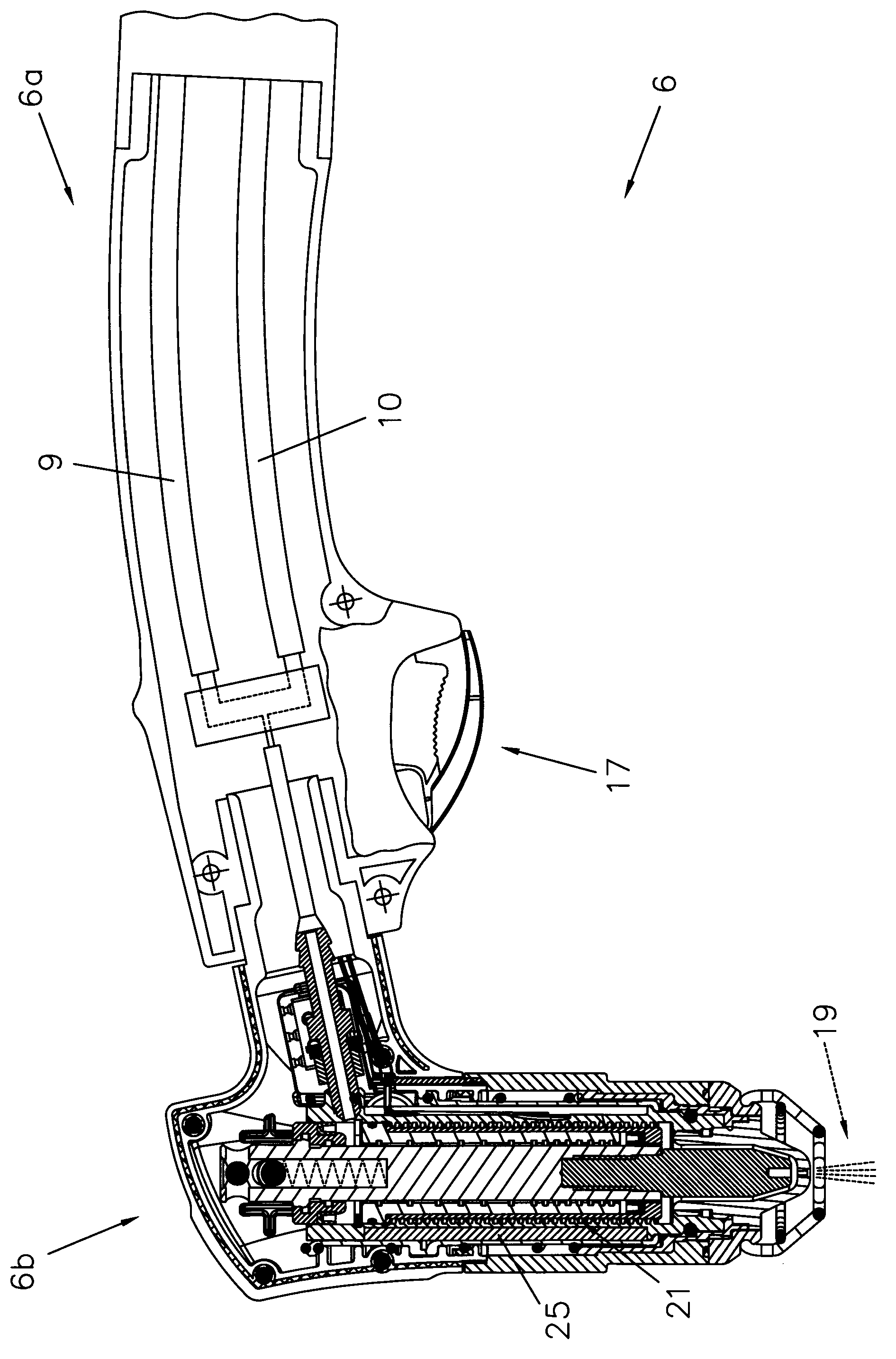

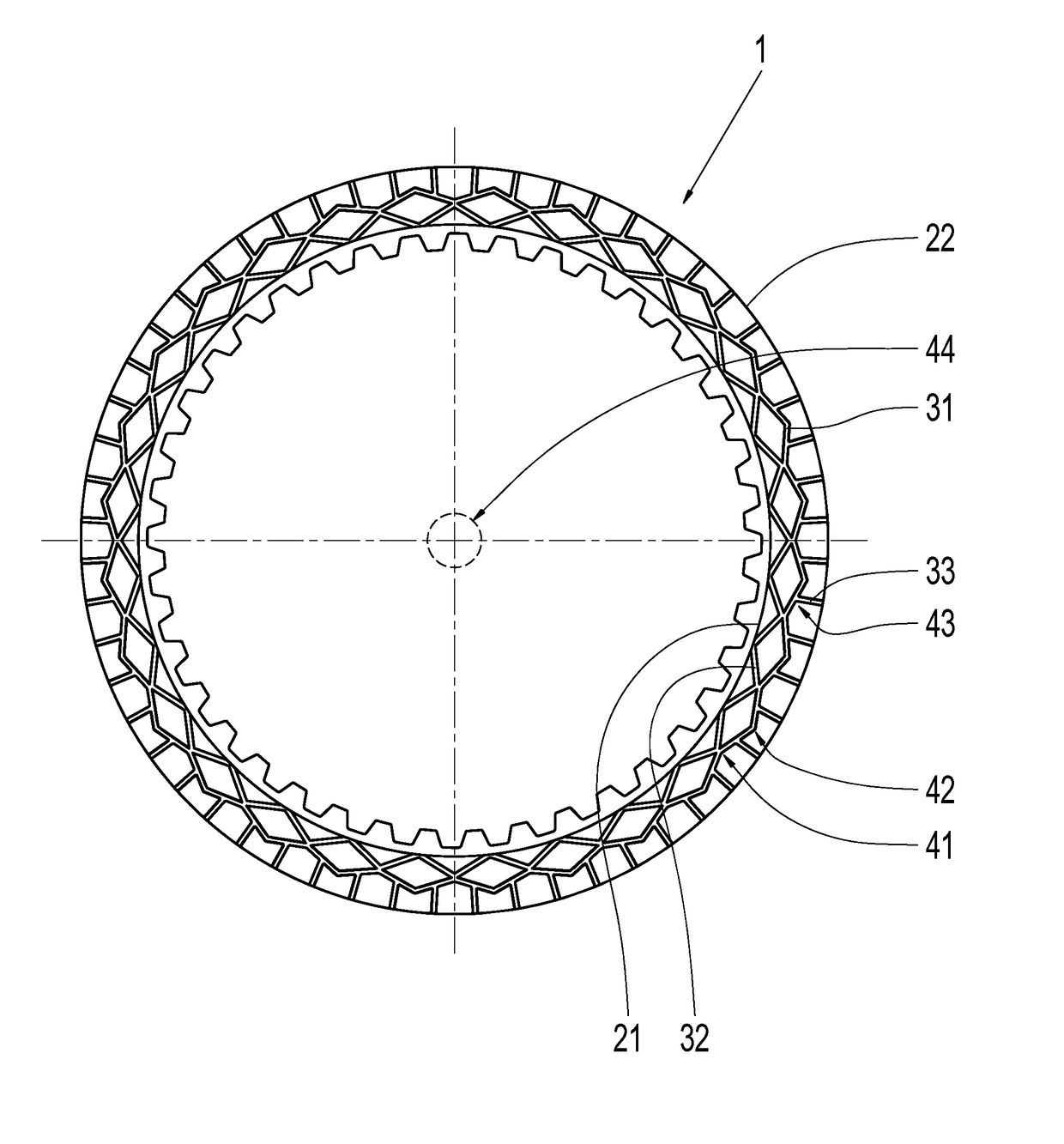

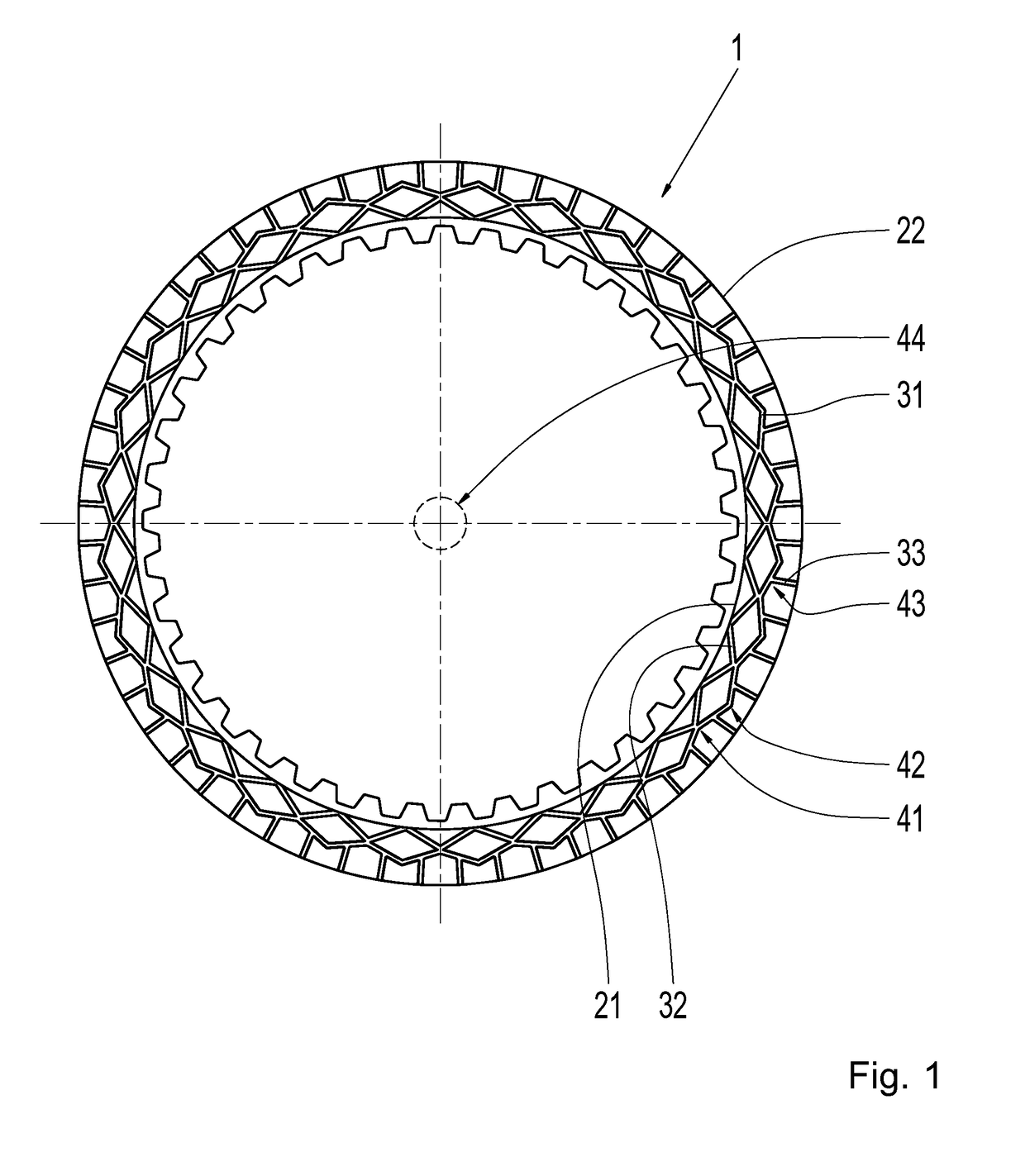

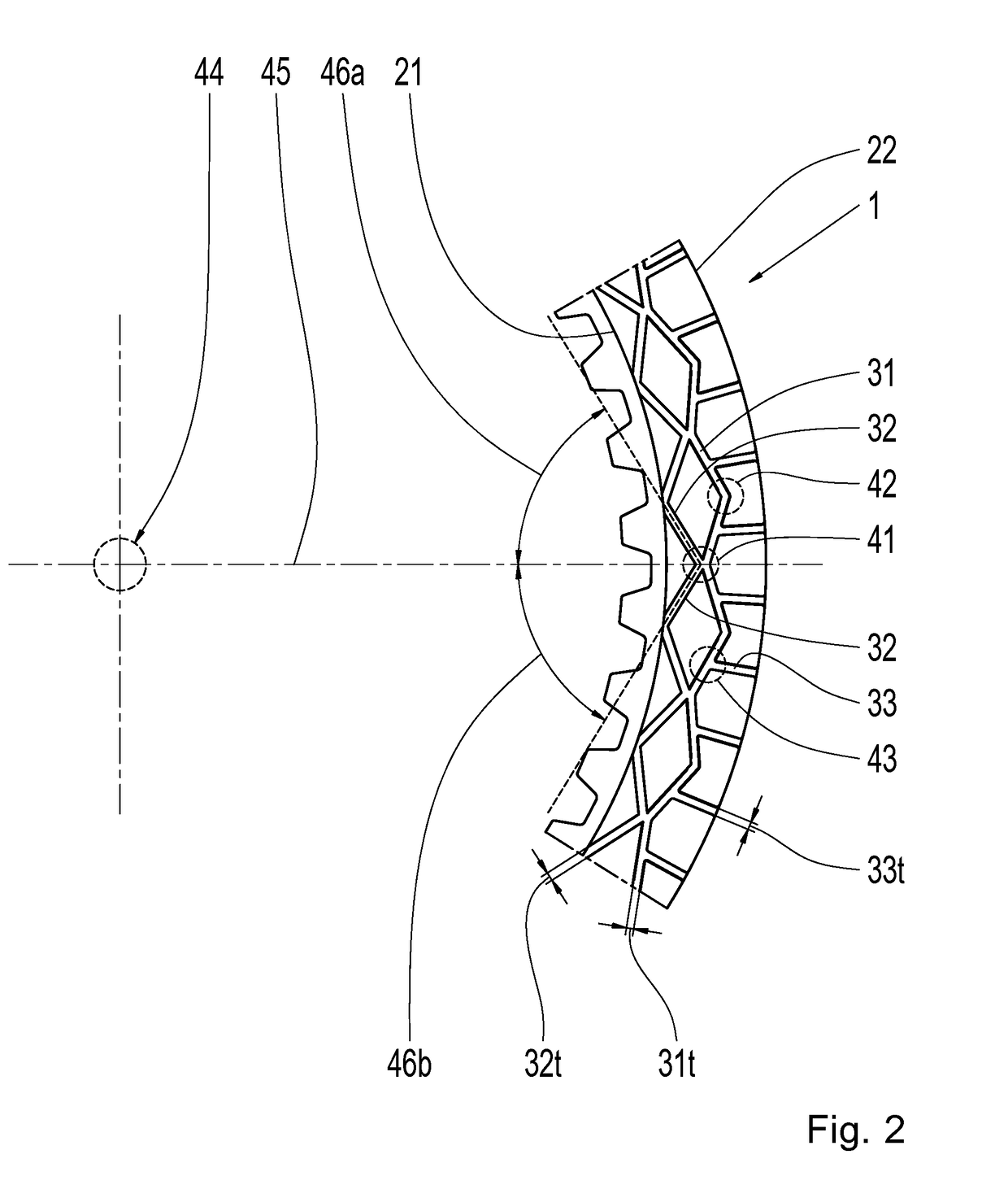

Heating element, steam cutting device, and burner of a power-enerating device

ActiveCN103262662APromote absorptionShorten the evaporation channelSteam generation heating methodsArc welding apparatusCombustorInduction heater

The invention relates to a heating element (25) for liquids to be vaporised as well as a burner (6) of a steam cutting device (1) and a burner (38) of a power-generating device, said element being designed as an induction heater (47) comprising one coil (25a). In order to improve vaporisation, the coil (25a) of the induction heater (47) is enclosed in a hybrid construction which is composed of a main part (31) with laterally extending webs (33), and which consists of an easily magnetisable material (35) and a thermally highly-conductive material, a covering element (32) consisting of nanocrystalline materials being arranged on said webs (33), and the easily magnetisable material (35) being designed to be installed on a thermally highly-conductive material (37) of a vaporiser (21).

Owner:FRONIUS INTERNATIONAL GMBH

Lamella for a Frictional Shift Element

InactiveUS20180328415A1High trafficLow flow resistanceFluid actuated clutchesFriction clutchesCentre of rotationEngineering

Owner:ZF FRIEDRICHSHAFEN AG

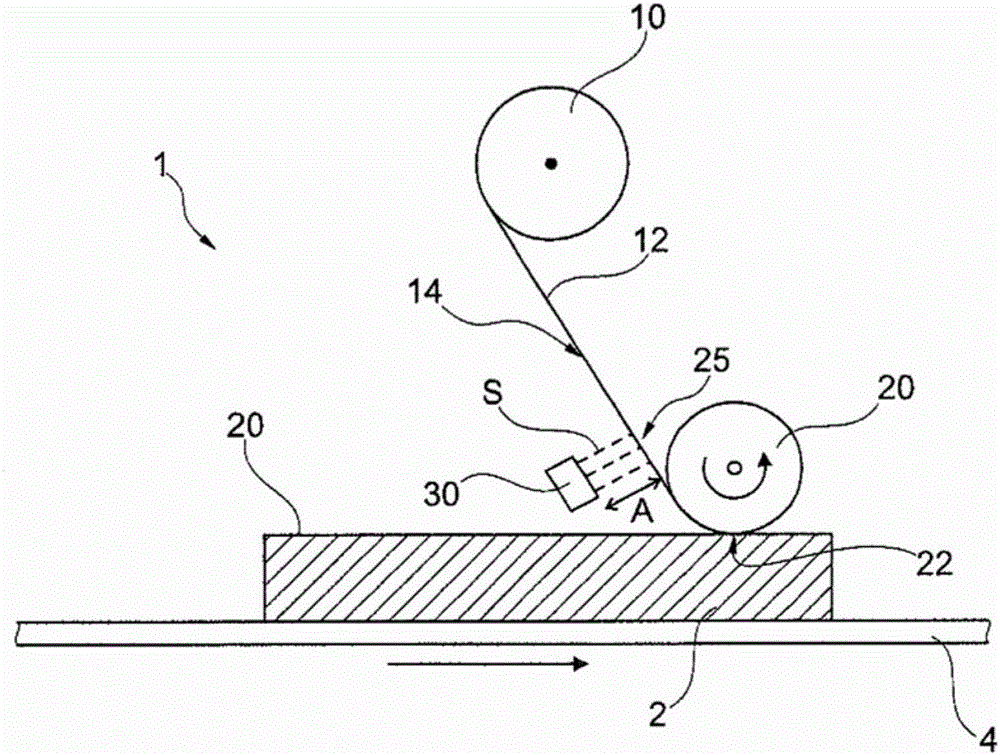

Method for applying a coating onto workpieces, and device for coating workpieces

ActiveCN105848855ASave active connection areaHigh energy inputOther plywood/veneer working apparatusBiological activationLight-emitting diode

The invention relates to a method for applying a coating, which preferably consists at least partly of plastic, onto workpieces, which preferably consist at least partly of wood, wood materials, plastic, or the like. The coating is activated or melted in a connection region, and the coating is connected to the workpiece by the connection region, said connection region being irradiated with incoherent radiation, in particular infrared radiation which is preferably dispensed by a light-emitting diode arrangement, for activation or melting purposes. The invention further relates to an arrangement for coating a workpiece in such a manner.

Owner:HOMAG HOLZBEARBEITUNGSSYST

Method and device for producing a thermoplastic granulate material

In the production of thermoplastic granulate material, after mixing the starting materials, it is common in the state of the art for these materials to be kneaded and compressed in extruders, with subsequent granulation. According to the invention, no extruder is used, rather the starting materials for the thermoplastic granulate material are supplied directly to a double belt press after the mixing. Subsequently, the generated web-type to sheet-type body is processed into a granulate material by means of grinding, or is used as a web-type, sheet-type, strip-type or film-type intermediate product for the production of a further intermediate product or end products.

Owner:IPCO GERMANY GMBH

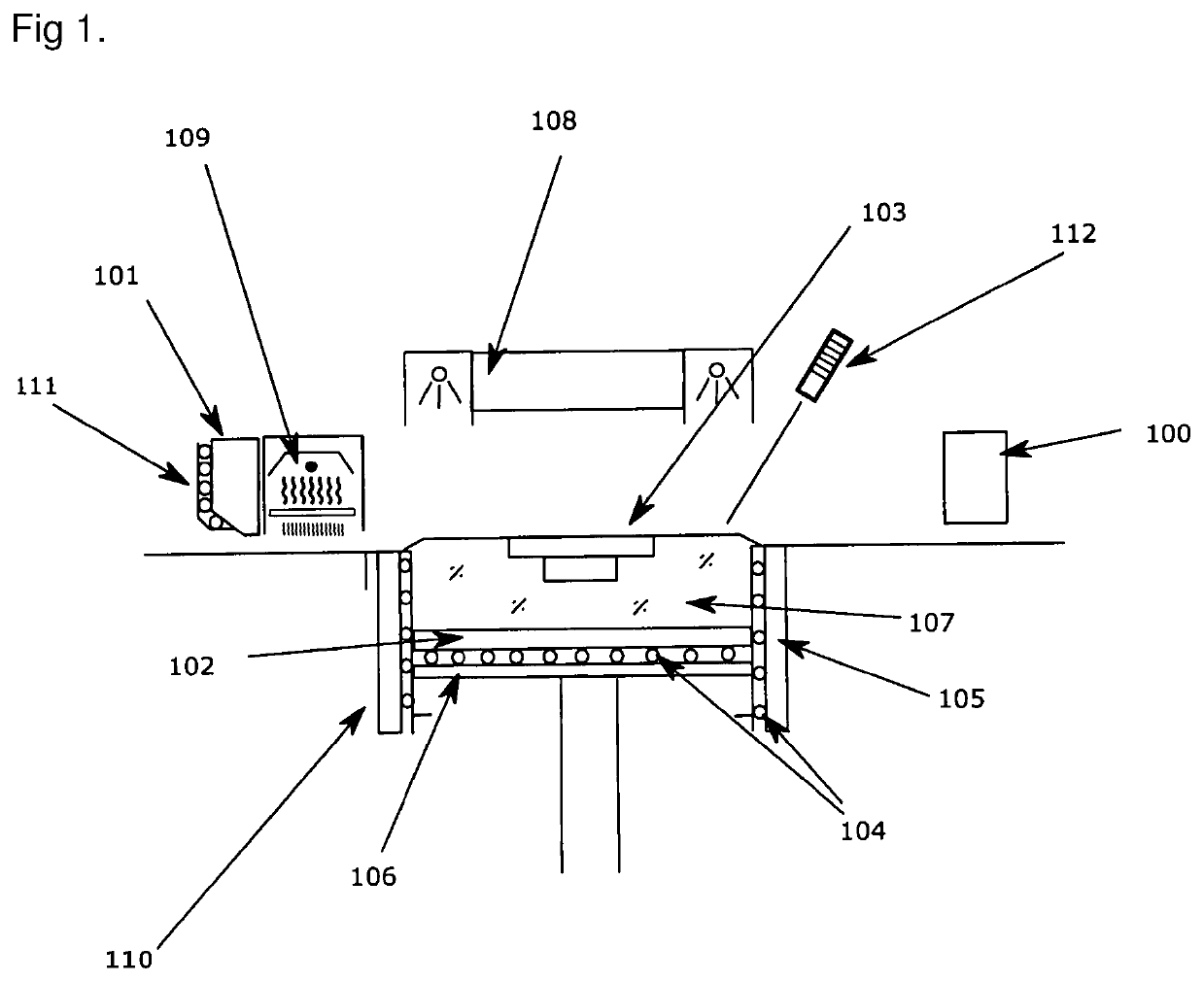

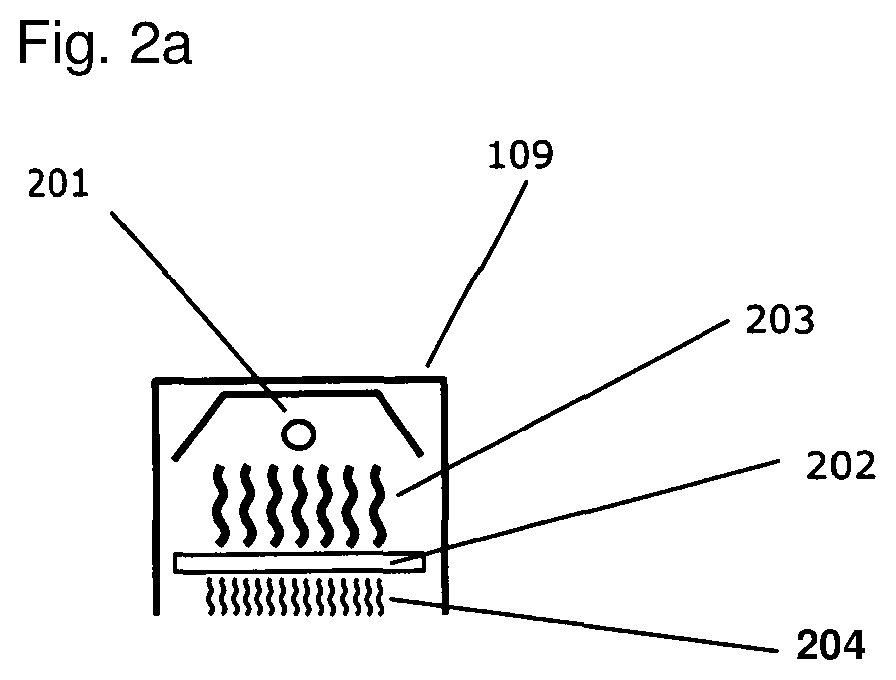

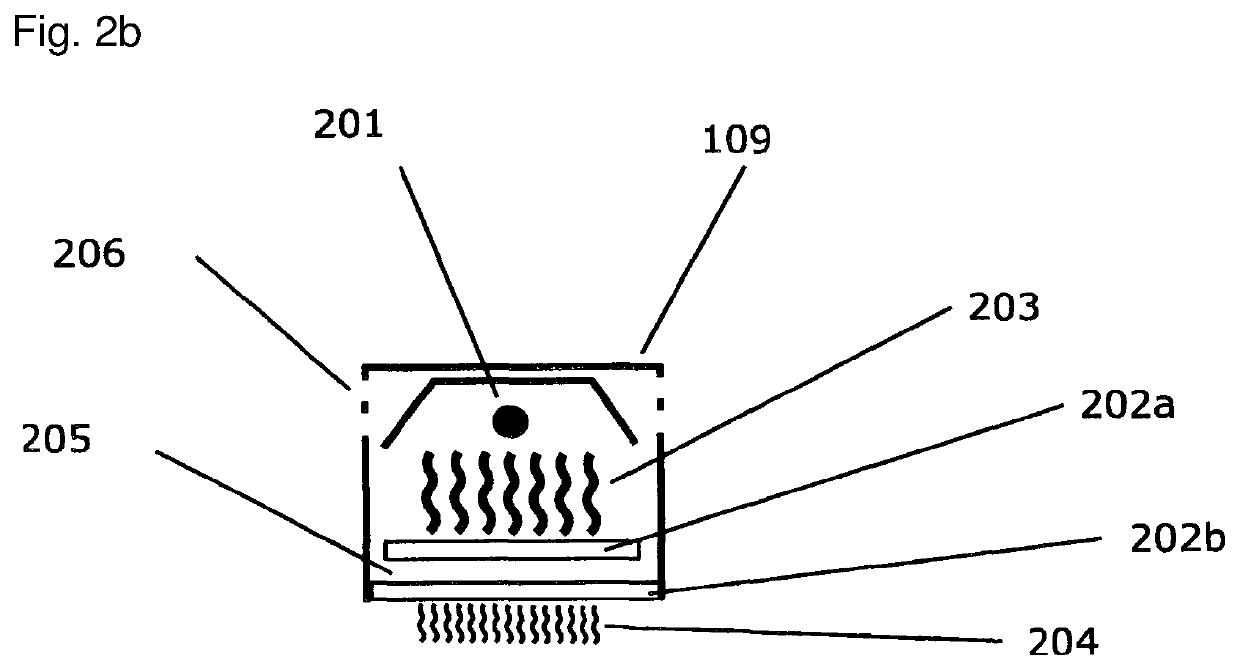

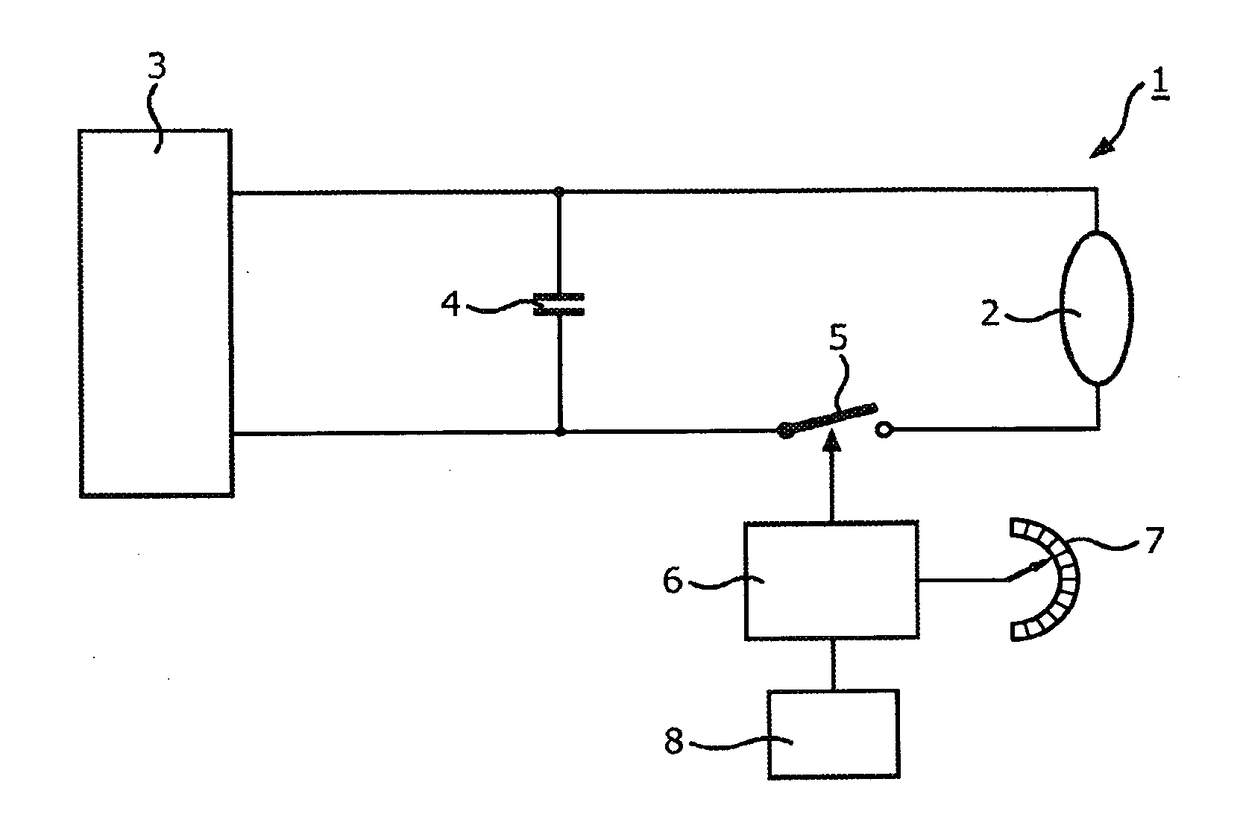

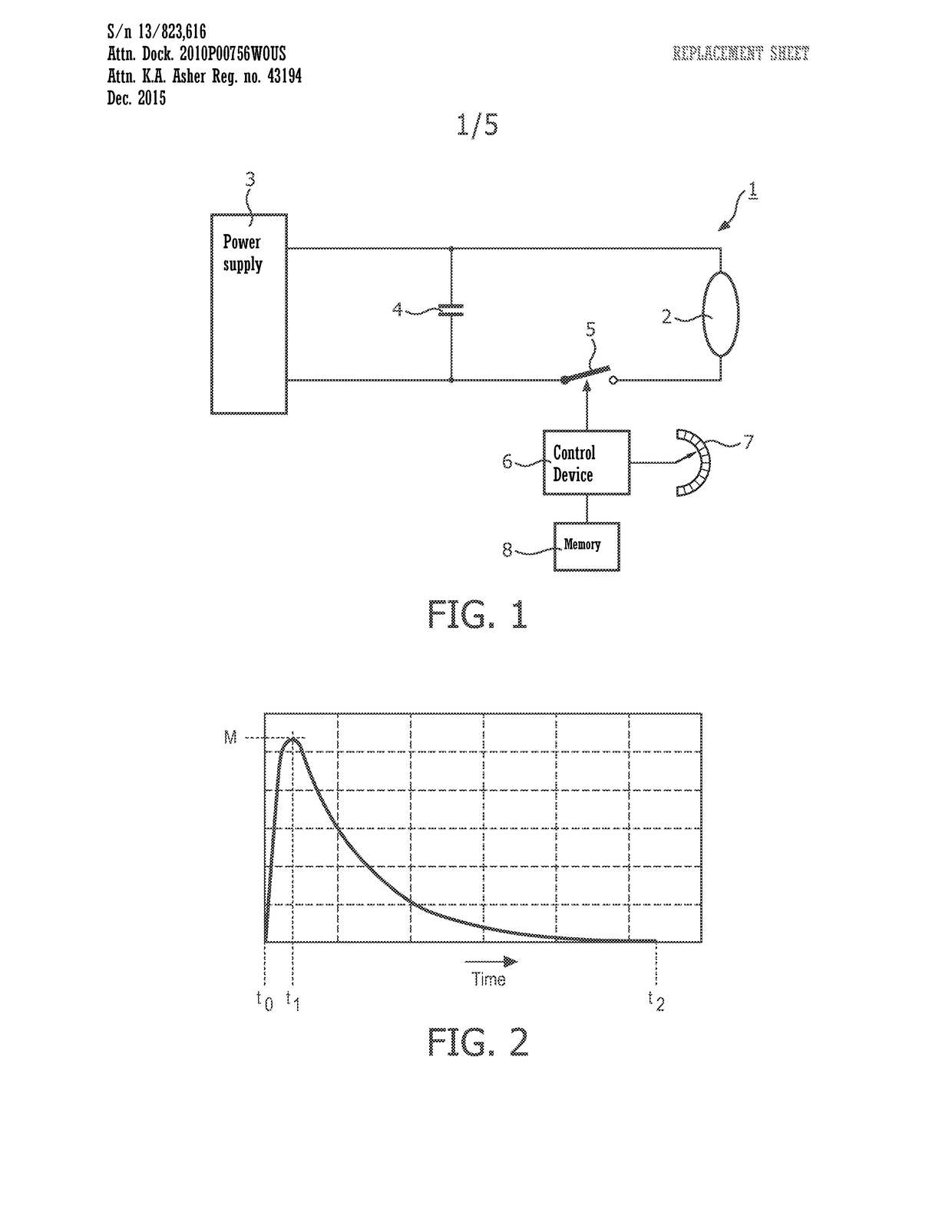

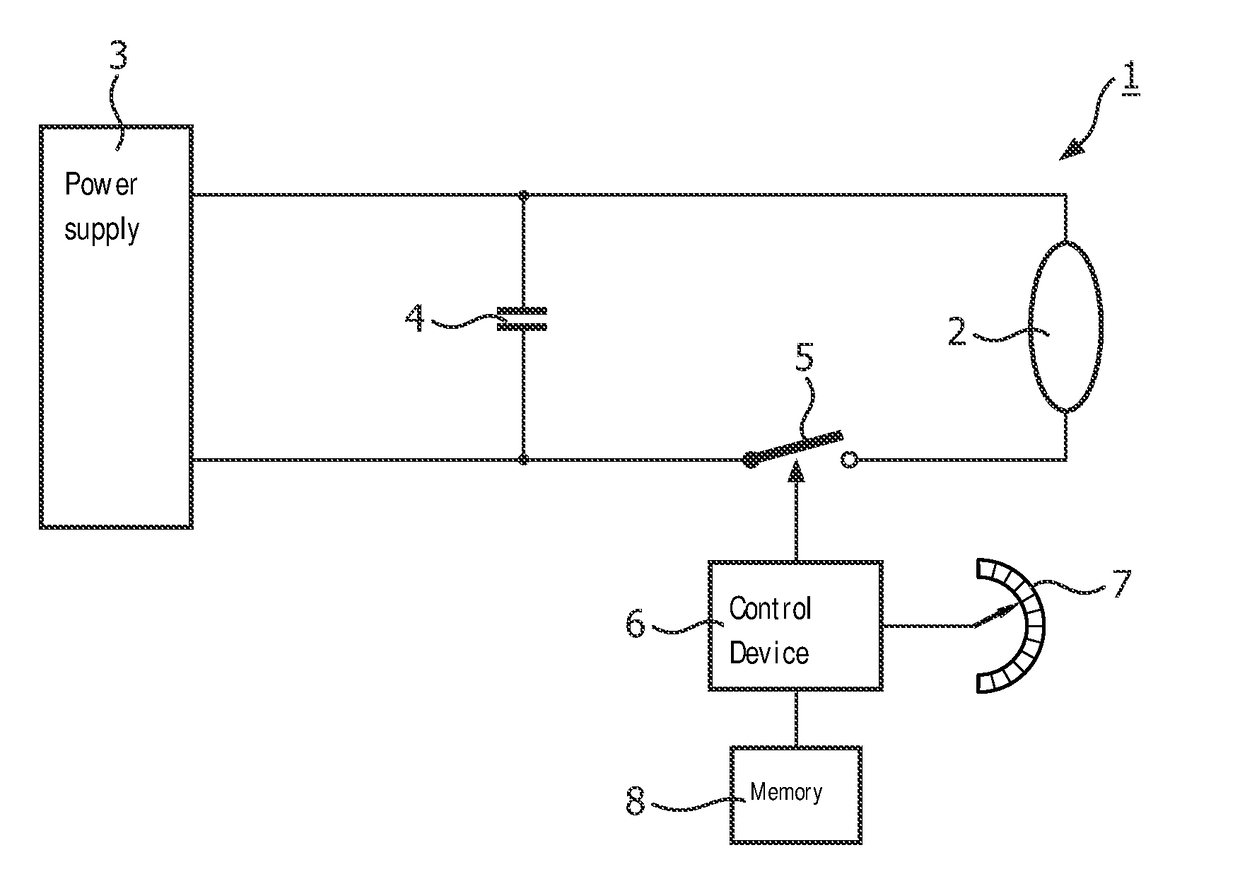

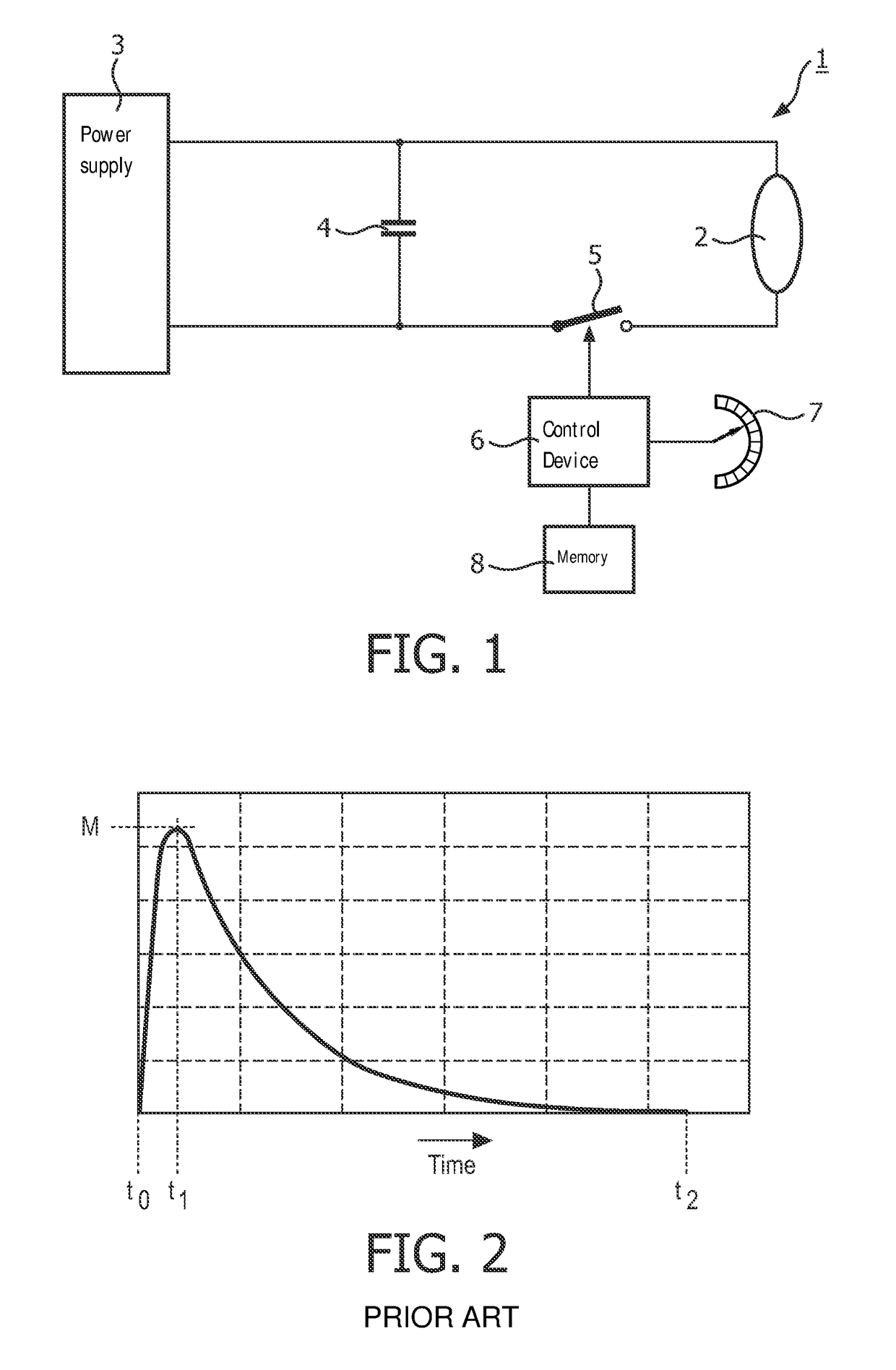

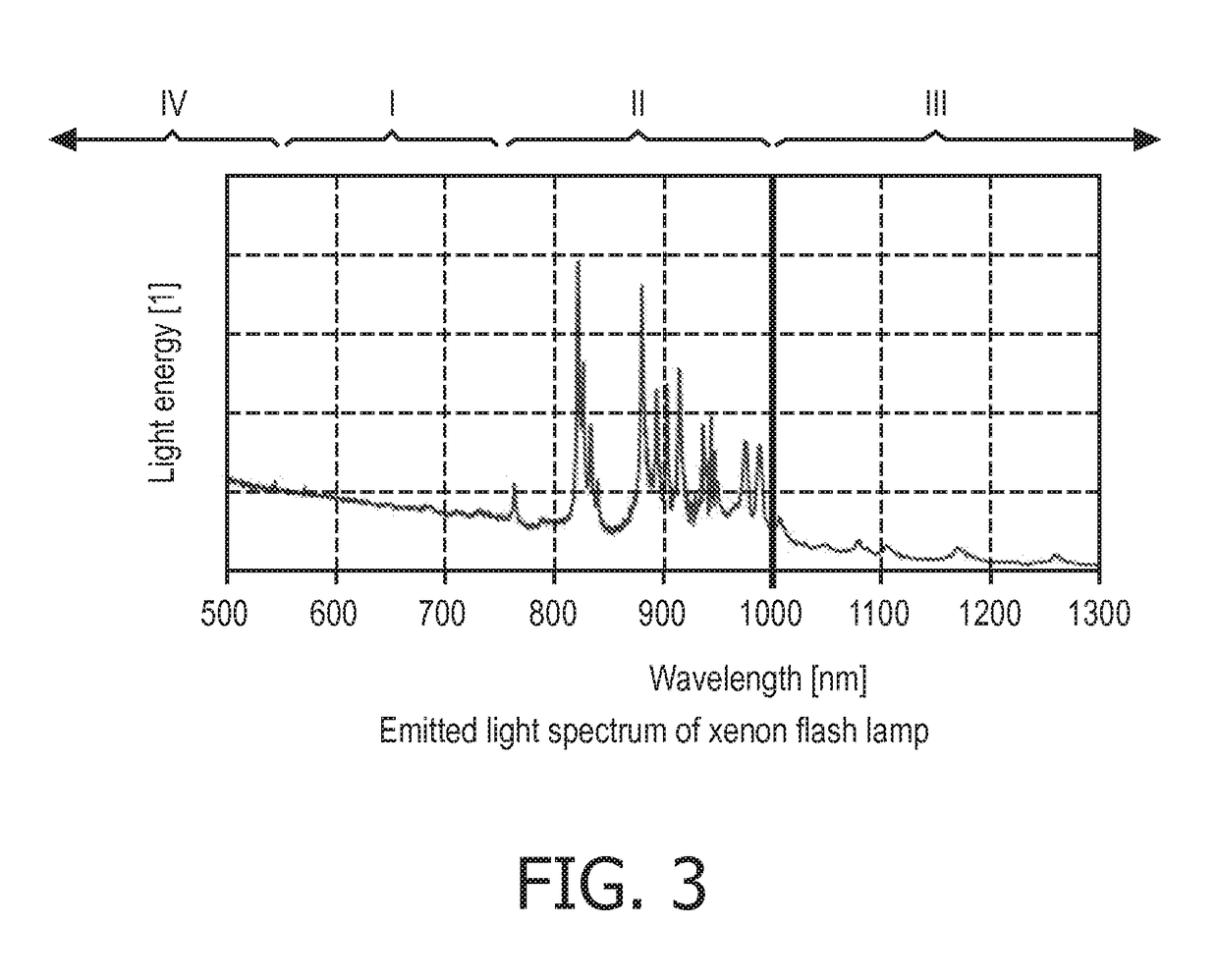

Skin treatment system

ActiveUS20170325888A1Efficient removalPrevent orElectrical apparatusElectric lighting sourcesSkin treatmentsEngineering

A method of operating a flashlamp in a skin treatment system comprises the steps of charging capacitor, discharging the capacitor through a flashlamp, and interrupting the discharge of the capacitor through the flashlamp at a predetermined time based on at least one condition caused by the discharge of the capacitor through the flashlamp.

Owner:KONINKLIJKE PHILIPS NV

Method for refining lipid phases, and use

ActiveUS9932540B2High energy inputReduce solubilityFatty-oils/fats refiningEdible oils/fatsBiochemical engineeringBiology

The invention relates to a method for gently eliminating odorous substances and coloring agents from lipid phases. Said method is easy and inexpensive to carry out and and can be employed for purifying lipid phases of various origins.

Owner:DREI LILIEN PVG

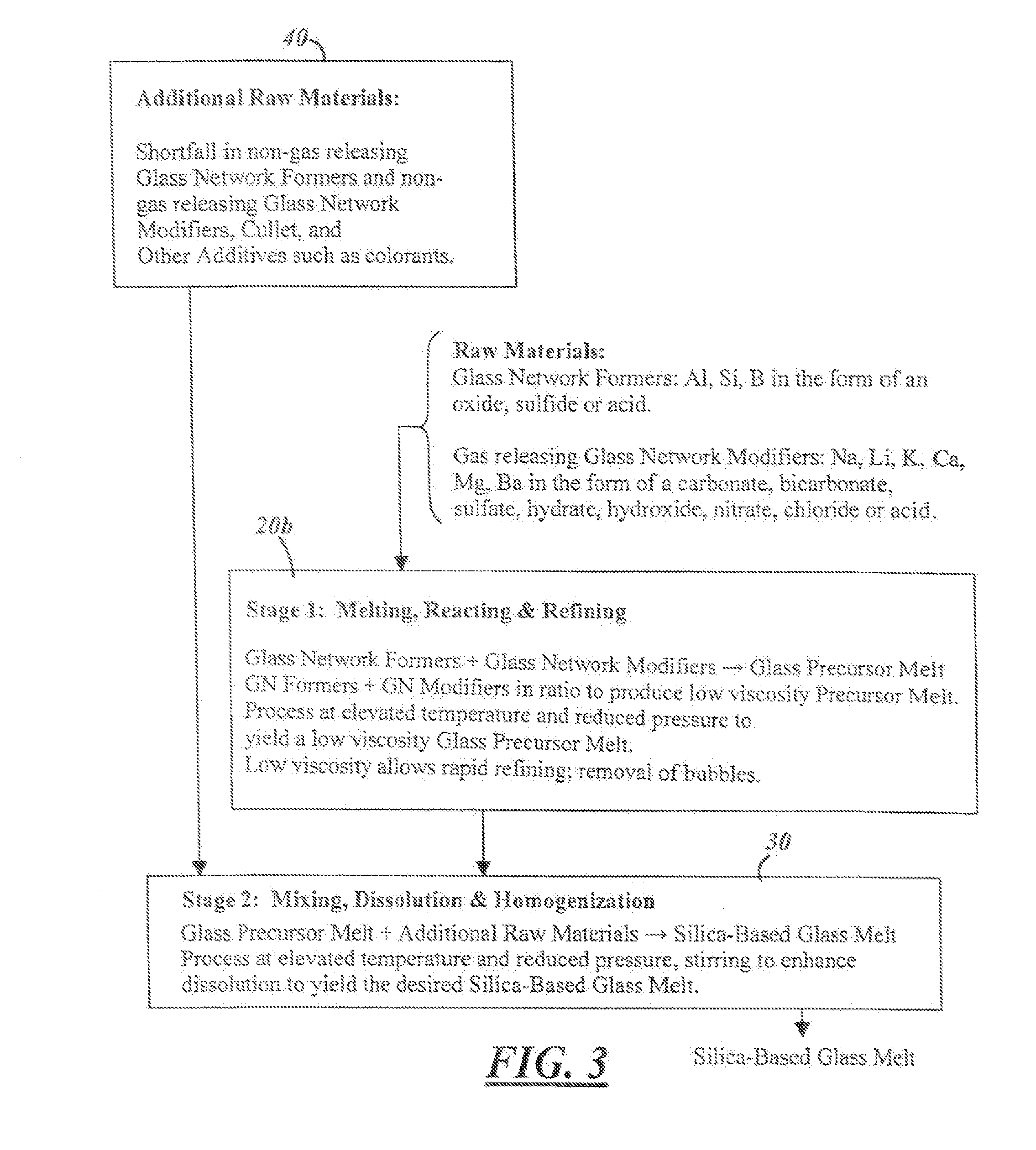

Process for Melting and Refining Silica-Based Glass

A process for making silica-based glass includes: (a) forming a glass precursor melt that includes glass network formers and glass network modifiers, the glass precursor melt being at a temperature in the range of 900 C to 1700 C and having a viscosity of not more than 3 Pa·s, and (b) refining the glass precursor melt. Either or both steps (a) and (b) can include stirring and / or be carried out under reduced pressure to enhance refining. The refined glass precursor melt preferably is mixed with additional materials including silica (SiO2) to form a silica-based glass melt.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

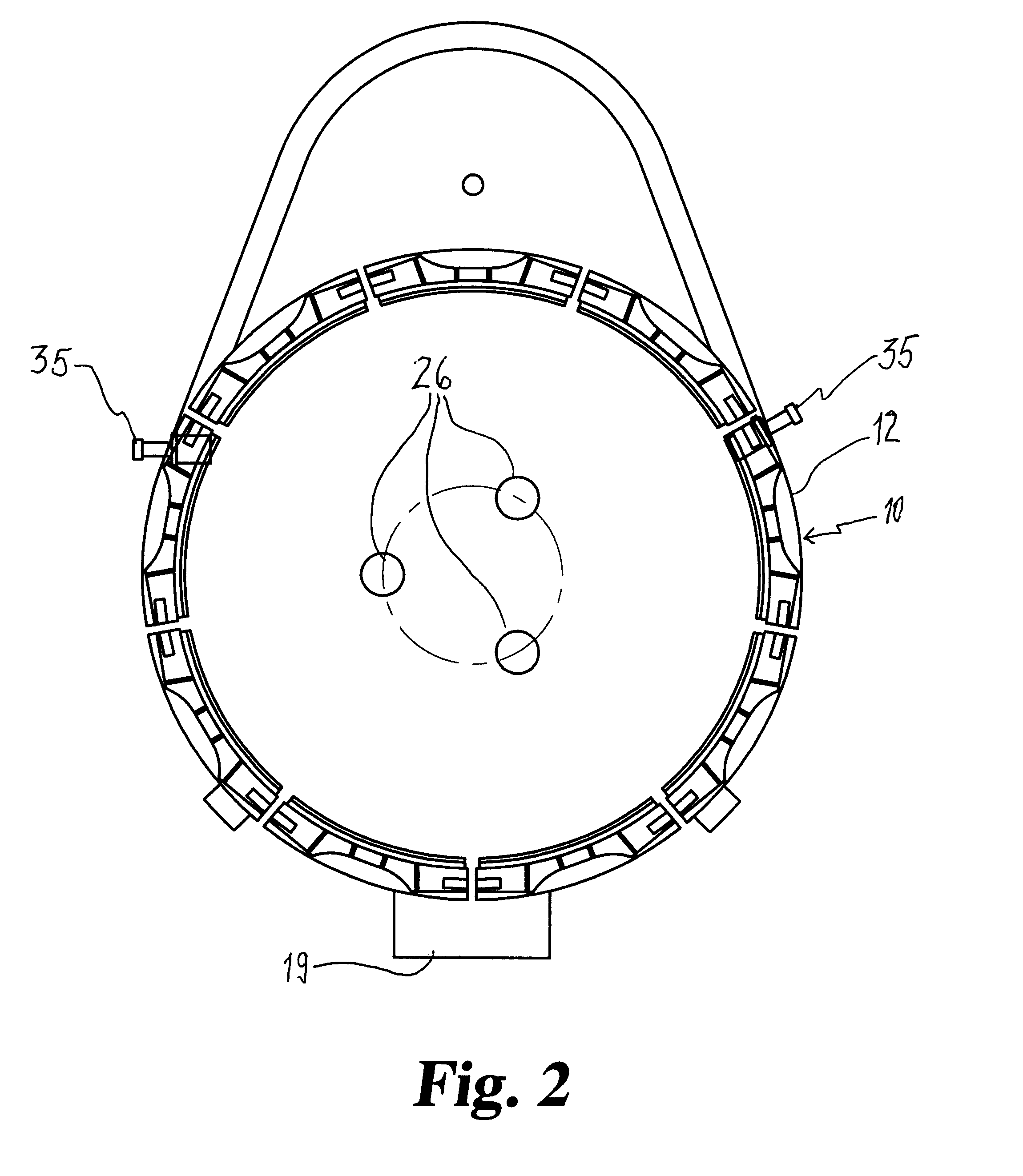

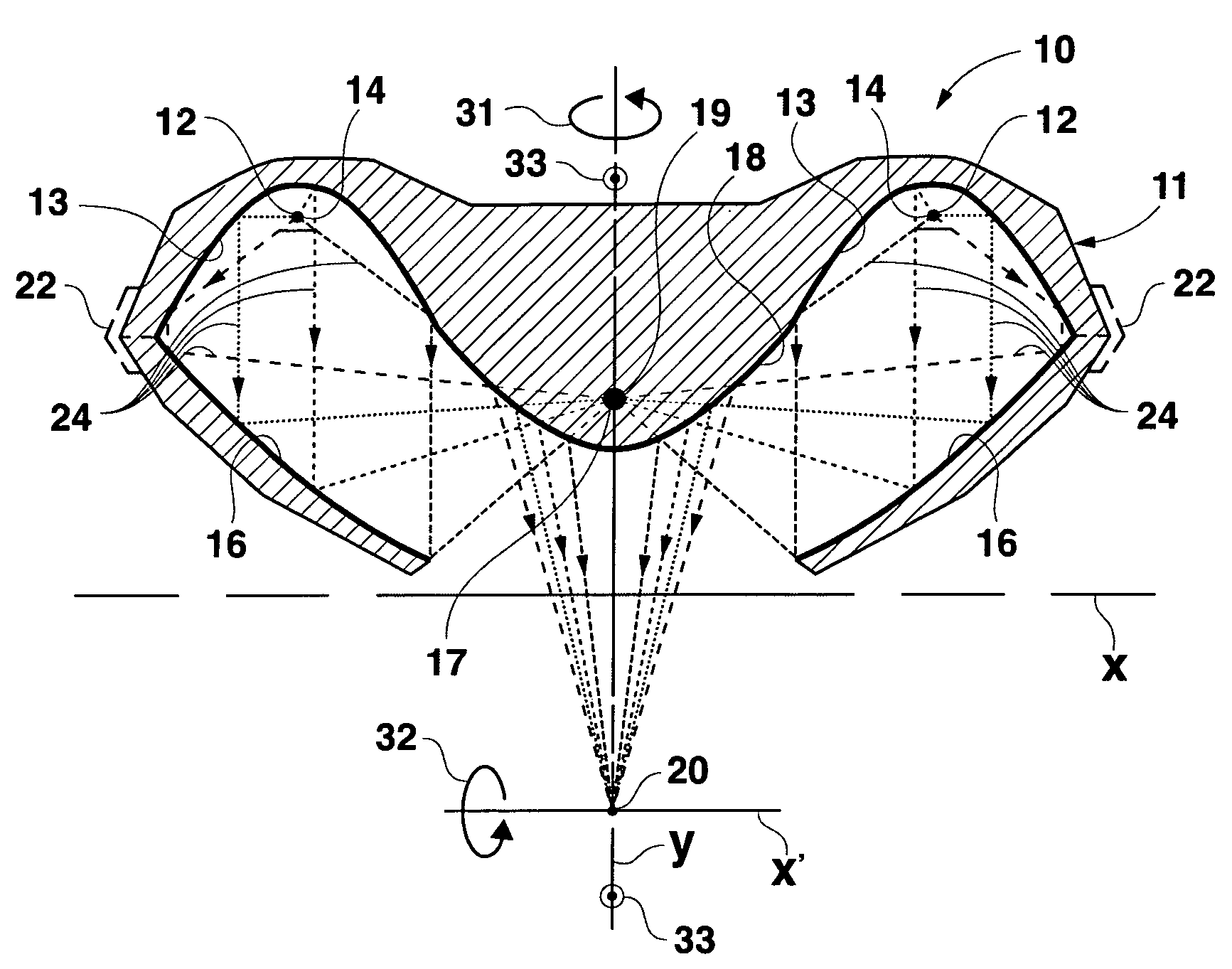

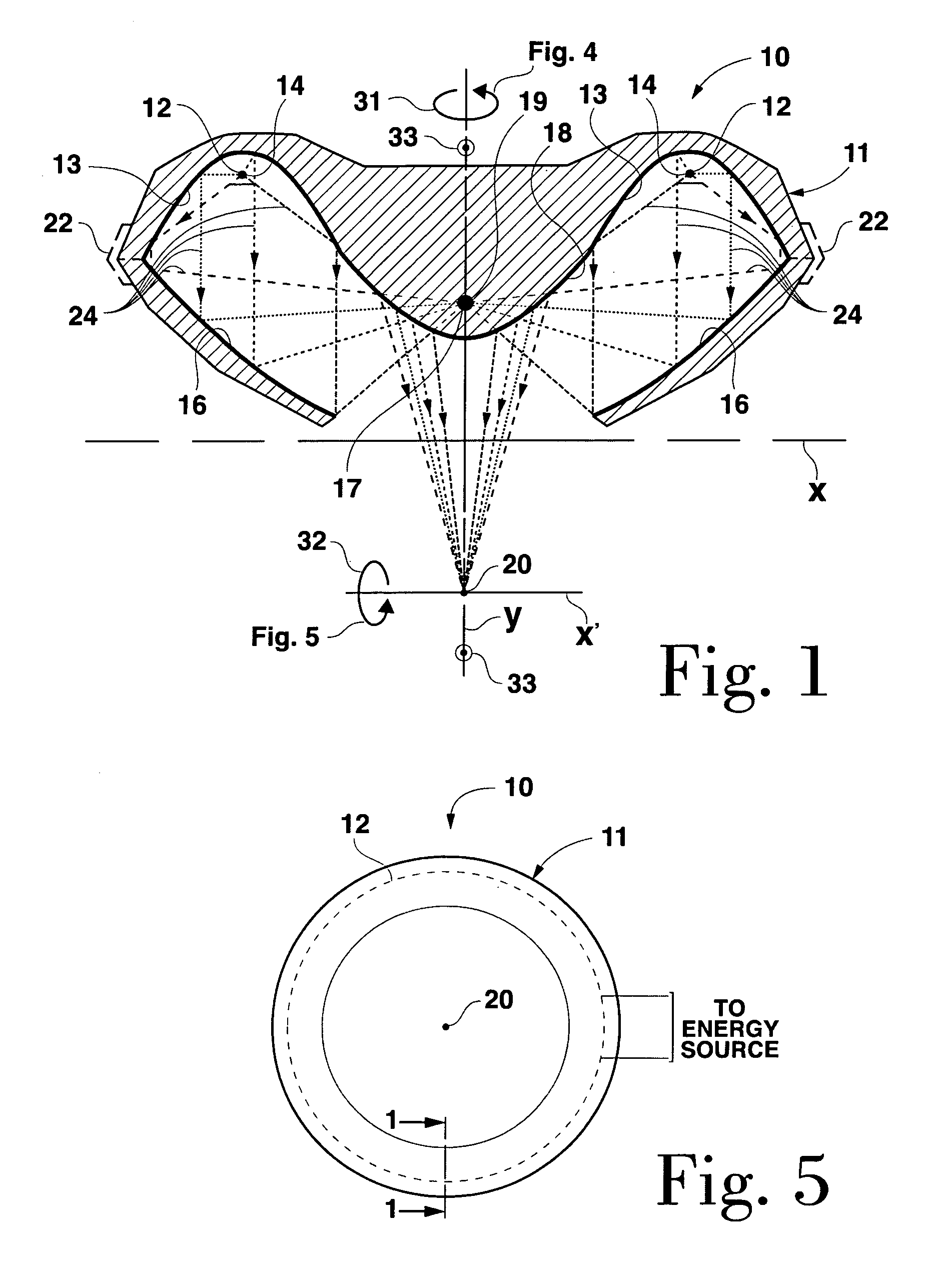

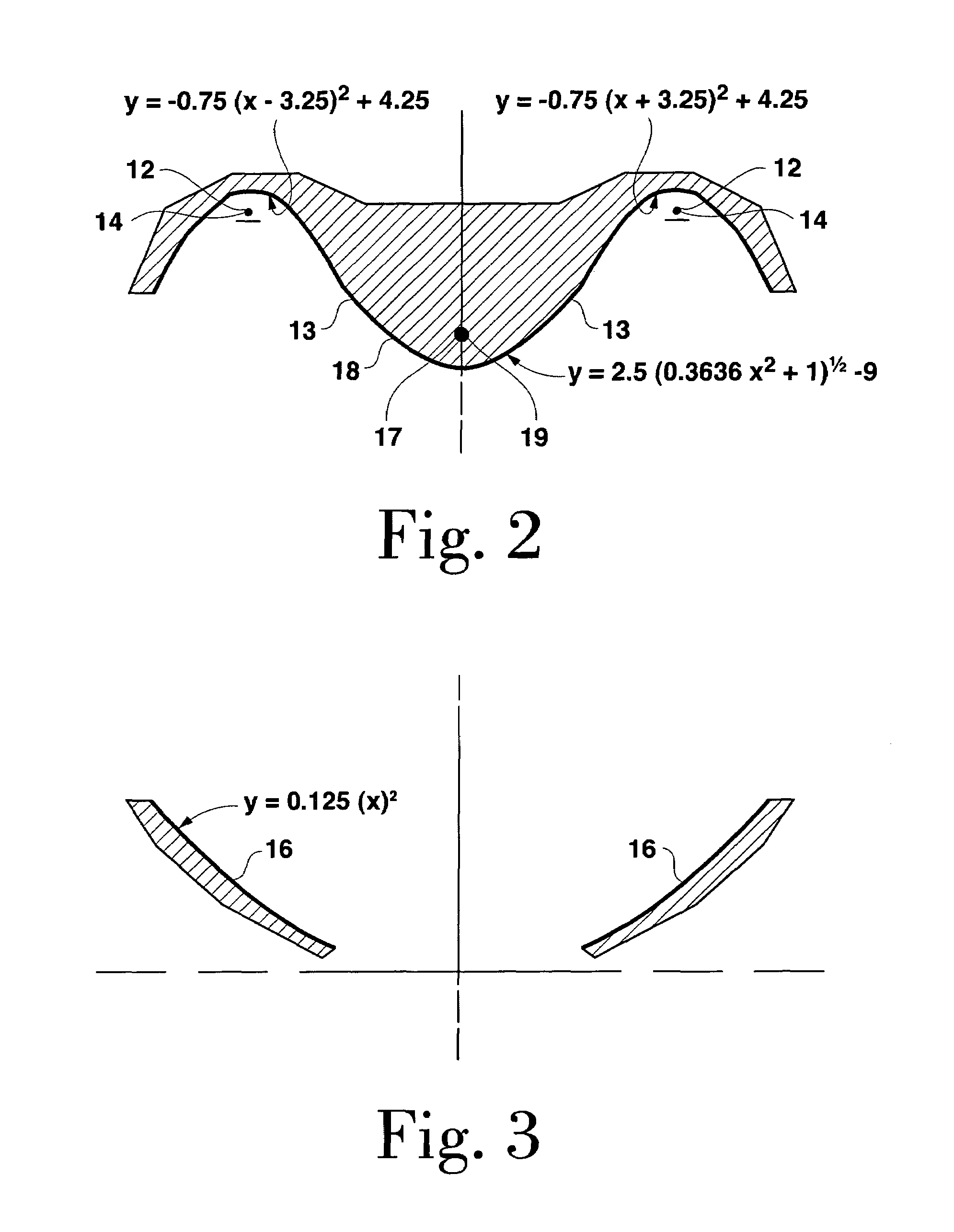

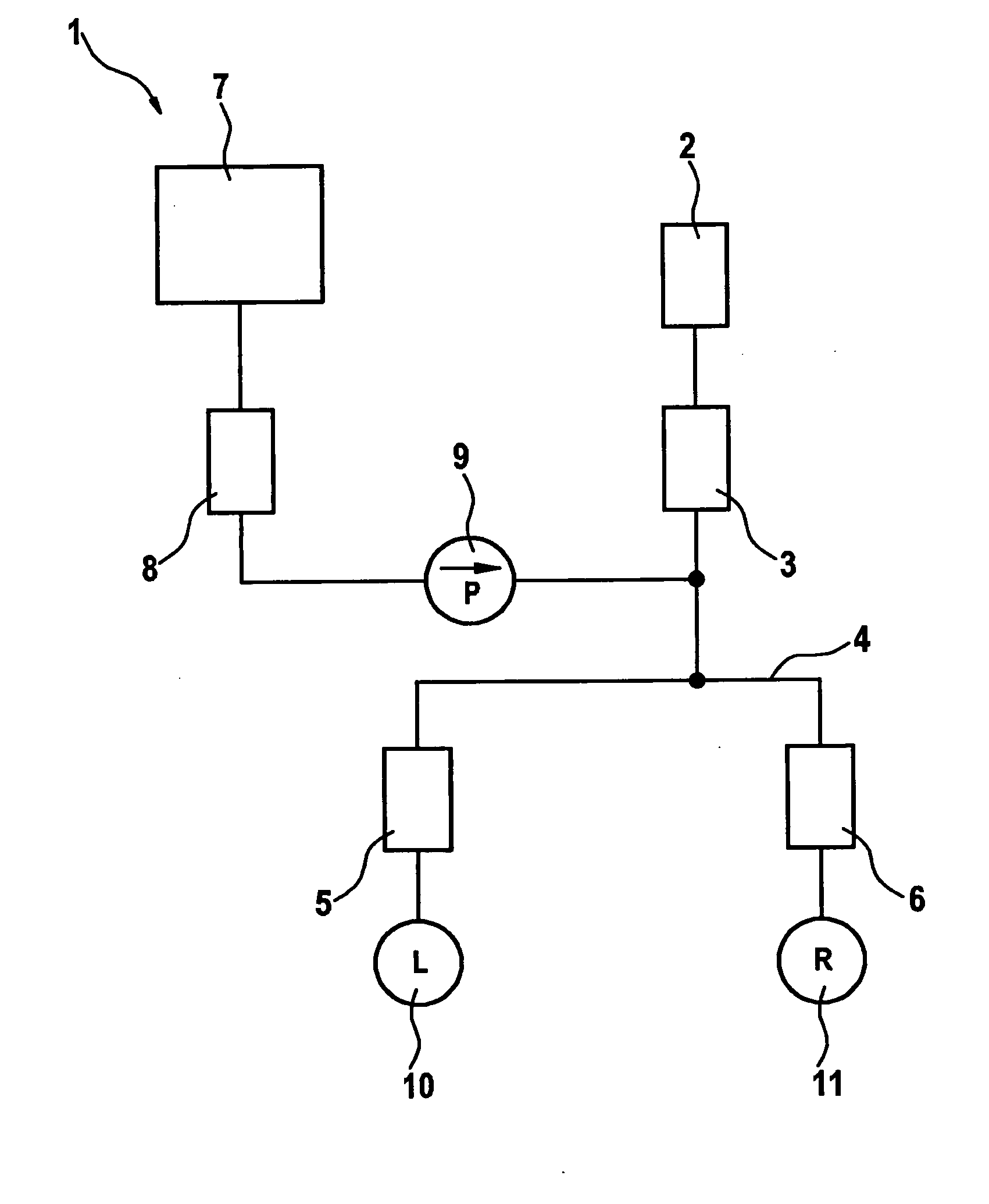

Energy concentrator system and method

InactiveUS7311677B1High energy inputIncrease efficiencyUltrasound therapyChiropractic devicesHigh concentrationRadiation

Reflective apparatus and method by which energy is radiated in divergent fashion from an elongated source and is reflected by a first parabolic reflector as a paraxial beam, focused by a second parabolic reflector onto a hyperbolic reflector and reflectively concentrated by the hyperbolic reflector at a focus at a distance from the source. The system also shields the point from extraneous radiation that would not be concentrated at the point. In one exemplary application, electromagnetic energy radiated from a point or linear source is focused by the multiple reflector system to a very high concentration at a point, for example, within an organism such as a human or animal body.

Owner:FIELDS JOHN G +1

Process and apparatus for producing 3D moldings comprising a spectrum converter

ActiveUS11279087B2Quality improvementNot to be sintered less reusableManufacturing platforms/substratesManufacturing heating elementsConvertersFrequency spectrum

A process and an apparatus for producing 3D moldings, wherein a spectrum converter is used. Said converter is defined as a means which absorbs a radiation, for example electromagnetic thermal radiation, and radiates or emits one or more defined wavelength ranges; the spectrum converter is here irradiated by an emitter of an electromagnetic thermal radiation (shortwave or longwave radiation), i.e. by a lamp or an emitter, for example an overhead emitter or a sintering unit, and then emits a defined electromagnetic thermal radiation.

Owner:VOXELJET AG

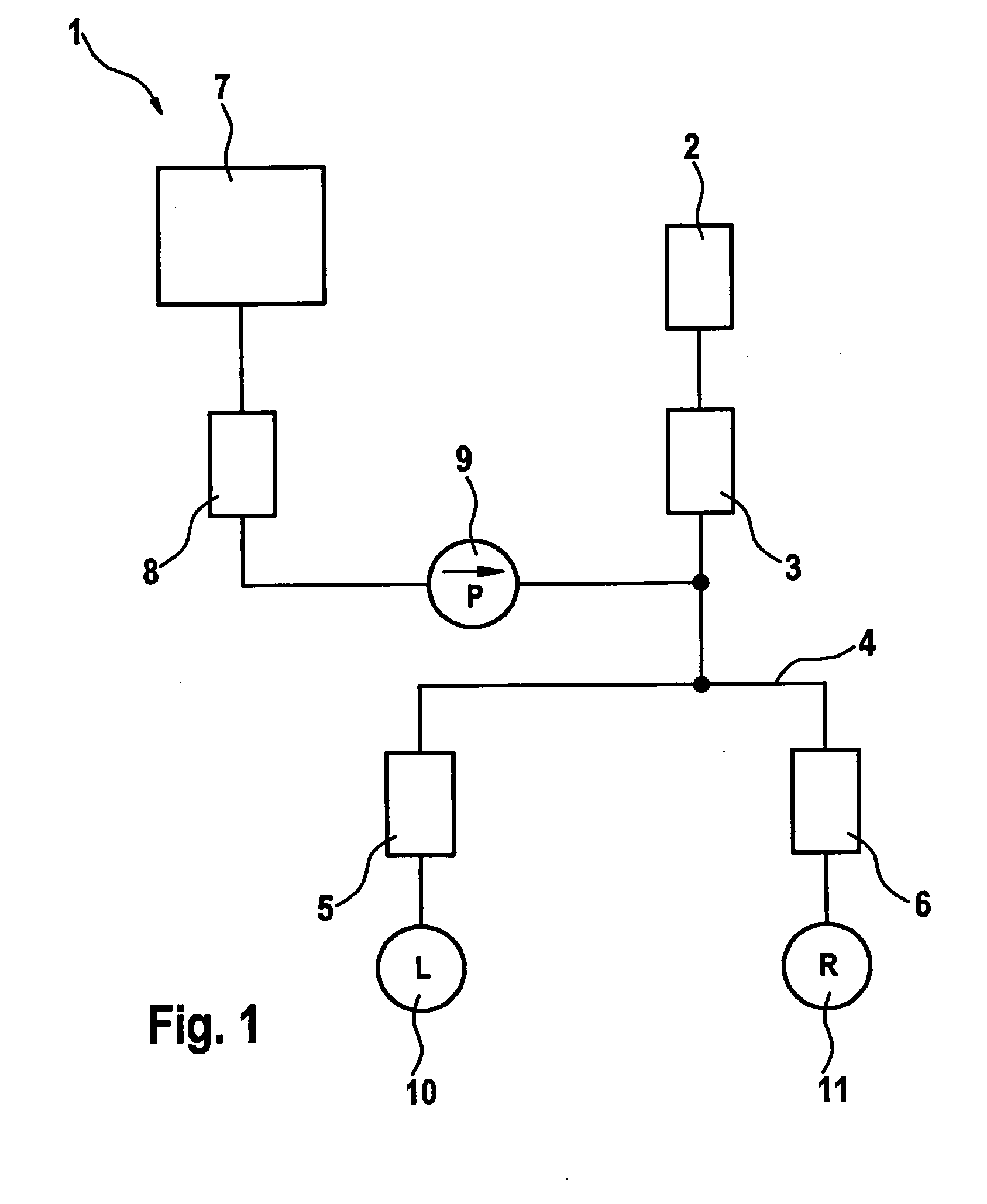

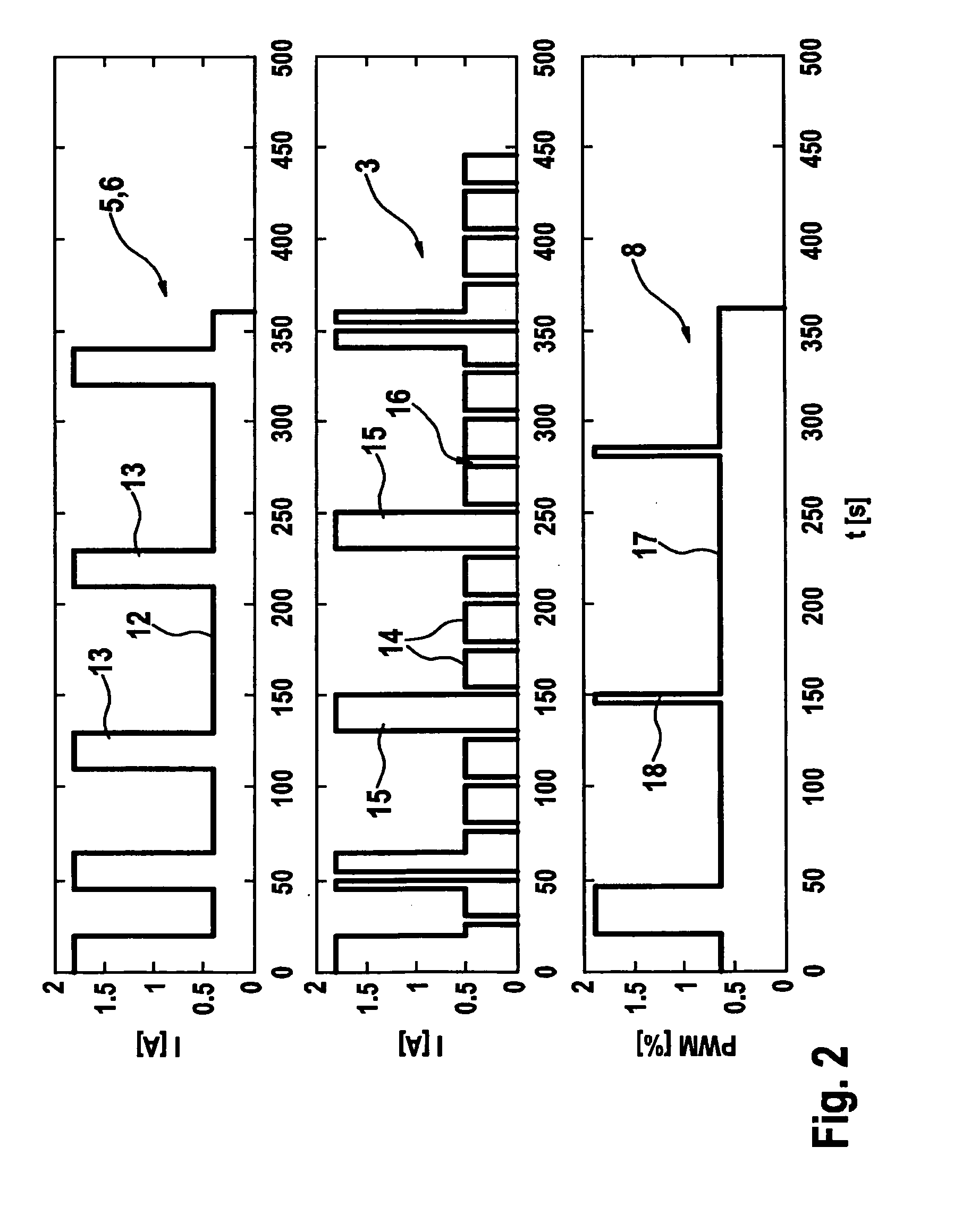

Method for operating an hydraulic brake system in a motovehicle

InactiveUS20110266270A1Simple and efficient mannerLow noise developmentElectric heatingServometer circuitsMobile vehicleHydraulic fluid

In a method for operating an hydraulic brake system in a vehicle, which has at least two electrically actuable hydraulic valves, the hydraulic valves are energized at a different current intensity at least intermittently in order to heat the hydraulic fluid during a heating period.

Owner:ROBERT BOSCH GMBH

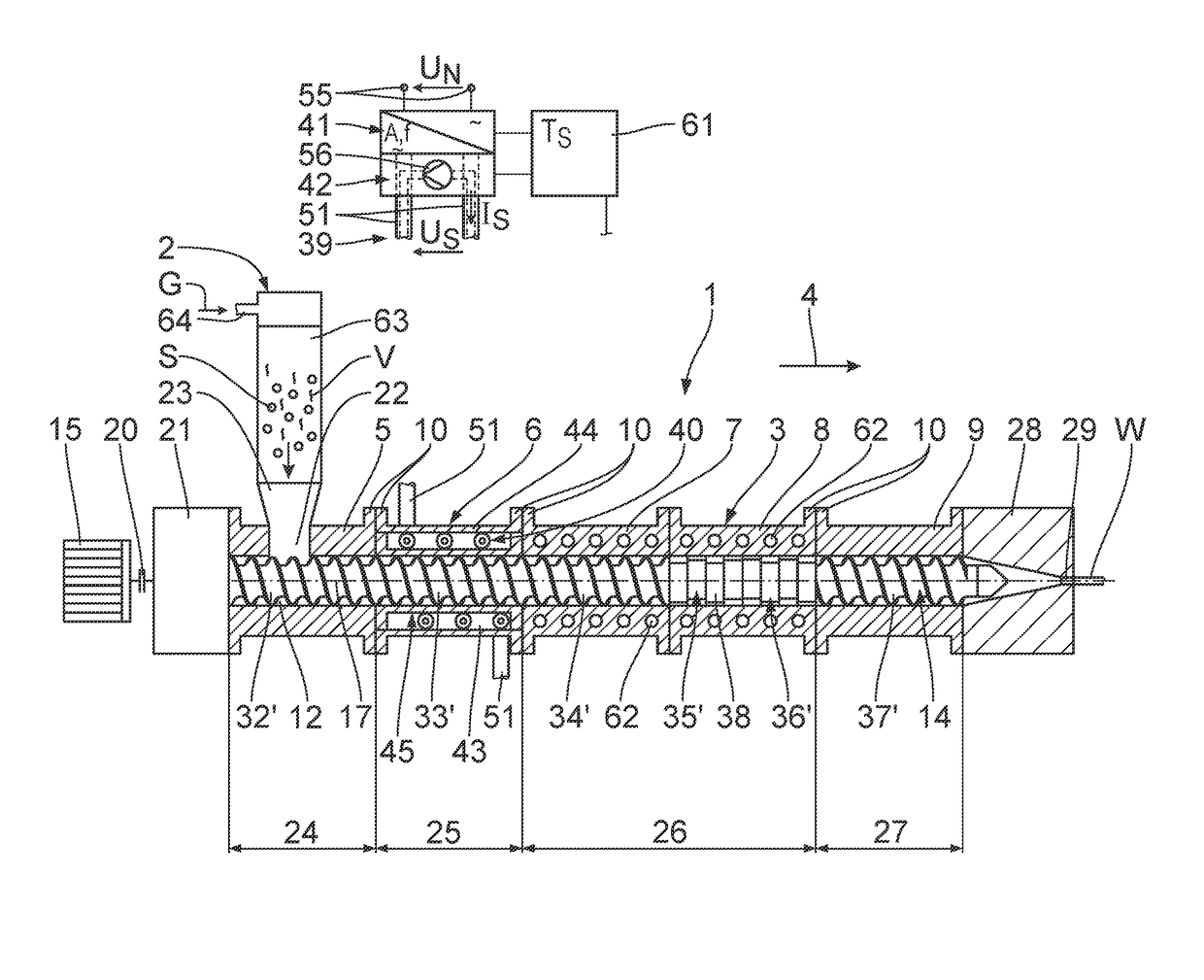

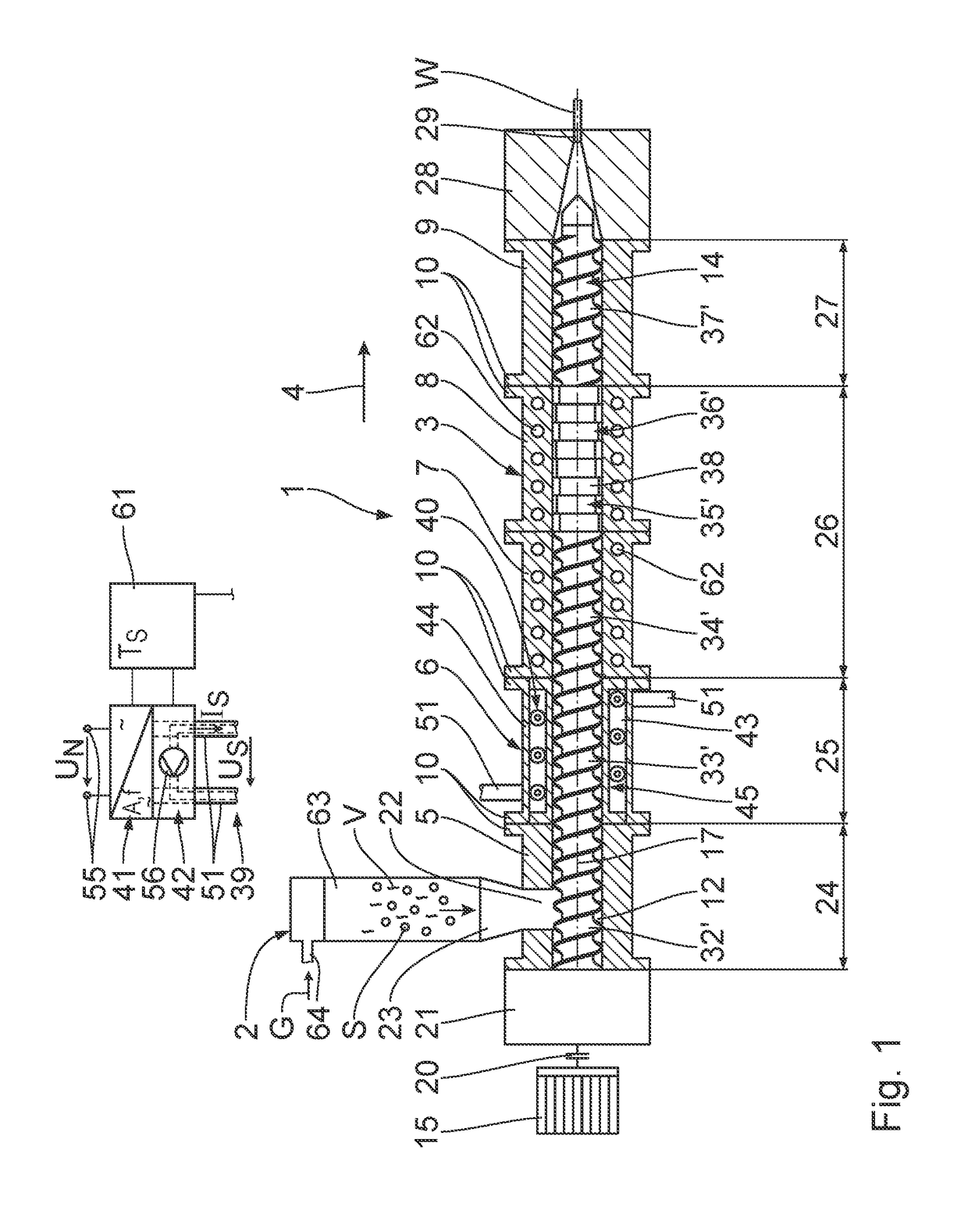

Method and apparatus for producing a mixture of a metallic matrix material and an additive

In a method for producing a mixture of a metallic matrix material and an additive, a metallic bulk material is molten in a multi-shaft screw machine in a heating zone thereof by means of an inductive heating device to form a metal matrix material. As the at least one housing portion of the housing of the multi-shaft screw machine is made of a non-magnetic and electrically non-conductive material at least partly in the heating zone, a high and efficient energy input for melting the metallic bulk material is achievable in a simple manner. The additive for producing the mixture is admixed to the metallic matrix material by means of treatment element shafts of the multi-shaft screw machine.

Owner:COPERION

Hydraulic damping cylinder, in particular for a knee prosthesis

ActiveUS9757253B2Greater the proportion of hydraulic fluidConvenient amountSpringsLiquid based dampersKnee JointHydraulic fluid

A hydraulic damping cylinder for a prosthetic knee joint, including a housing, a cylinder chamber in the housing and filled with a hydraulic fluid, and a piston arranged in the cylinder chamber and movable by a piston rod. In the housing there are provided at least two separate receiving chambers, which are of different size and are connected to the cylinder chamber by fluid ducts, for hydraulic fluid displaced from the cylinder chamber during a piston movement. The receiving chambers are each separated, by a diaphragm, from a compression chamber filled with a compressible fluid that forms an energy store. Upstream of the larger receiving chamber, there is connected a throttle device which forms a flow resistance for the hydraulic fluid flowing into the receiving chamber so that the hydraulic fluid can be distributed to the two receiving chambers in a manner dependent on speed of the piston movement.

Owner:OSSUR ICELAND EHF

Skin treatment system

ActiveUS9724160B2Efficient removalPrevent orElectrical apparatusElectric lighting sourcesSkin treatmentsPower flow

A method of operating a flashlamp (2) in a skin treatment system (1) comprises the steps of establishing a conductive path between the flashlamp (2) and a charged capacitor (4) causing a free discharge within the flashlamp, and interrupting said conductive path so as to cut off the current through the lamp when the current density drops below a predetermined current density threshold level (Ix) or when the energy applied to the skin reaches a certain maximum (EM).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com