Multi-section stirring and circulating slurry mixing equipment and method

A slurry mixing and equipment technology, applied in chemical instruments and methods, mixers, flotation, etc., can solve the problems of high dispersion, high strengthening, and efficient collision contact of fine ore particles, which can improve energy utilization, strengthen The effect of mixing pulp and avoiding the effect of flotation entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

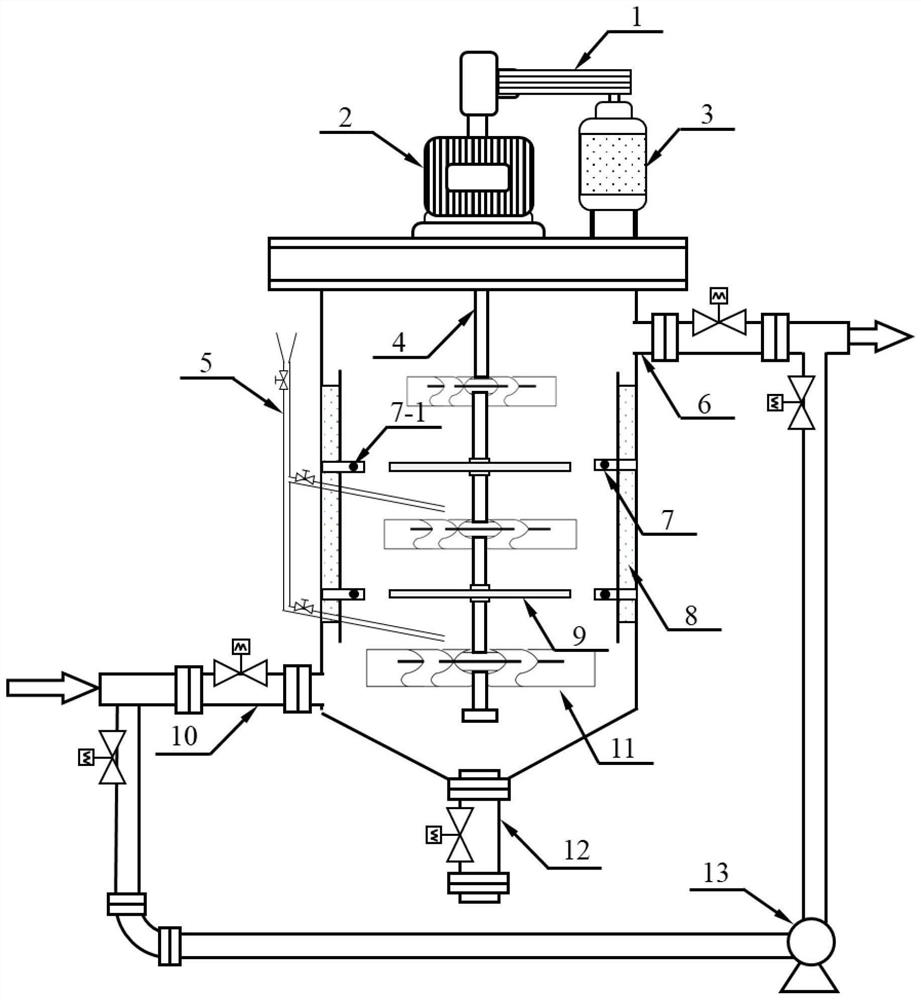

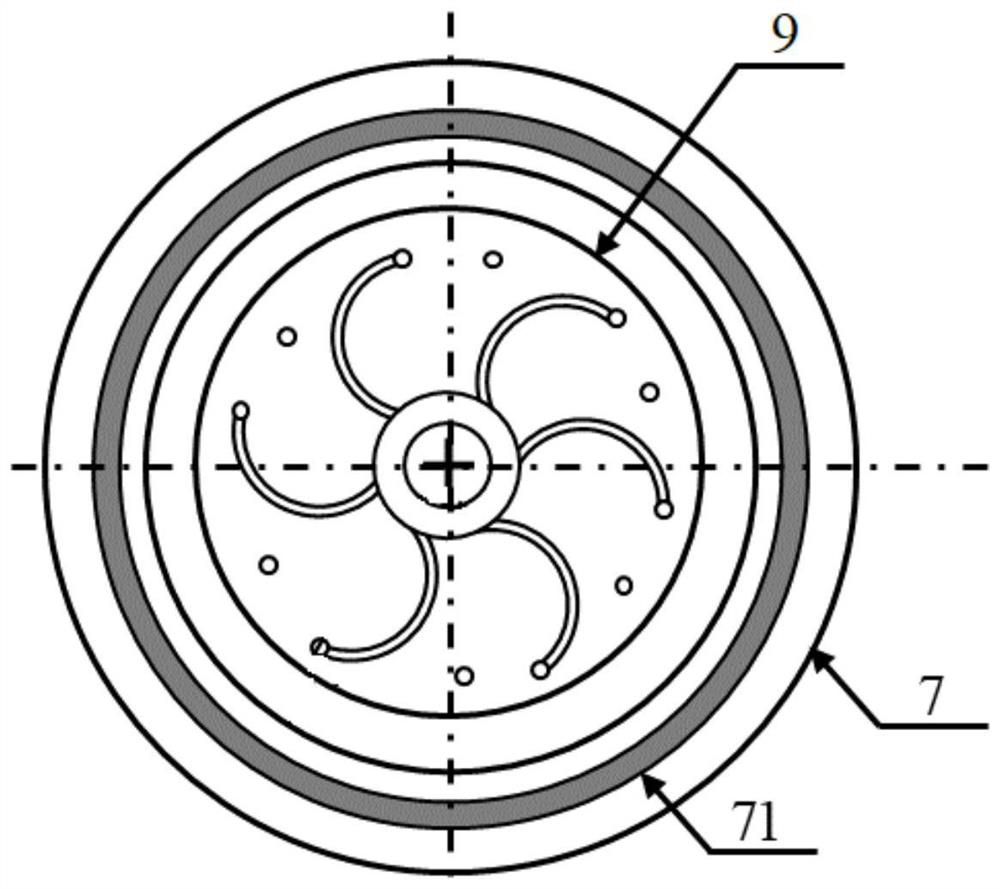

[0044] A specific embodiment of the present invention, such as figure 1 As shown, a multi-stage stirring cycle pulping equipment is disclosed, including a pulping bucket, a diversion disc paddle 9 and a stirring impeller 11 are arranged in the pulping bucket, and the diversion disc paddle 9 moves the inside of the pulping bucket from top to bottom. The lower section is divided into multiple sections of forced stirring and pulping areas, and the stirring impellers 11 are arranged in the forced stirring and pulping areas, and the radius of the stirring impellers 11 in each forced stirring and pulping area is set in a gradient manner.

[0045] Compared with the prior art, the multi-stage forced stirring circulation slurry mixing equipment based on energy regulation provided by this embodiment has a stirring impeller with a gradient radius in the mixing slurry tank to control the stepwise input of energy in the mixing process and improve the mixing process. The energy utilization ...

Embodiment 2

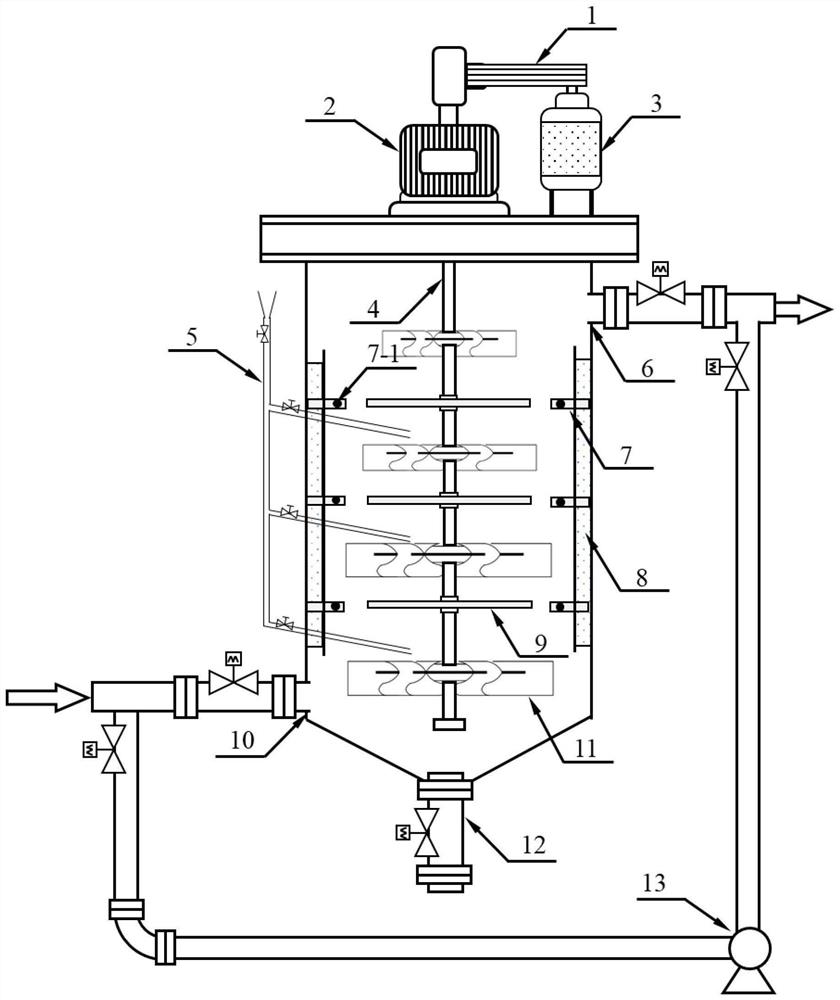

[0063] A specific embodiment of the present invention, such as Figure 5 As shown, a multi-stage stirring cycle pulping equipment is disclosed. The difference from Embodiment 1 is that the height and / or radius of the stirring impeller 11 and the guide disk paddle 9 in the pulping tank increase sequentially from top to bottom, The gap between the annular baffle 7 and the guide disc paddle 9 decreases from top to bottom.

[0064] In this embodiment, the passage time of the pulp decreases from bottom to top with the size of the gap, and the gap between the bottom annular baffle plate 7 and the diversion disc pulp 9 is small, resulting in a high degree of turbulence dissipation, and prolonging the passage time of the pulp at the same time. It is beneficial to improve the effect of forced shear mixing, strengthen the erasure of fine mud on the particle surface and the dispersion of chemicals, especially suitable for materials with a large content of fine mud. Other structures and ...

Embodiment 3

[0066] A specific embodiment of the present invention, such as Image 6 As shown, a multi-stage stirring cycle pulping equipment is disclosed. The difference from Embodiment 1 is that the height and / or radius of the stirring impeller 11 and the guide disk paddle 9 in the pulping tank increase sequentially from top to bottom, The gap between the annular baffle 7 and the guide disc paddle 9 is consistent from top to bottom, that is, the radius of the inner ring of the annular baffle 7 increases sequentially from top to bottom.

[0067] In this embodiment, the pulping intensity is kept in a gradient setting, and the pulp passing time is kept equal from top to bottom. On the basis of ensuring the pulping effect, the pulping amount per unit time of the equipment is increased, and it is suitable for ordinary mines with less fine mud content. material type. Other structures and beneficial effects are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com