Novel flow-channel plate-fin type heat exchanger

A heat exchanger and plate-fin technology, applied in the field of heat exchangers, can solve problems such as unfavorable transportation and installation, heavy weight, and bulky heat exchangers, and achieve enhanced turbulent dissipation rate, increased turbulent dissipation rate, and improved The effect of turbulence properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

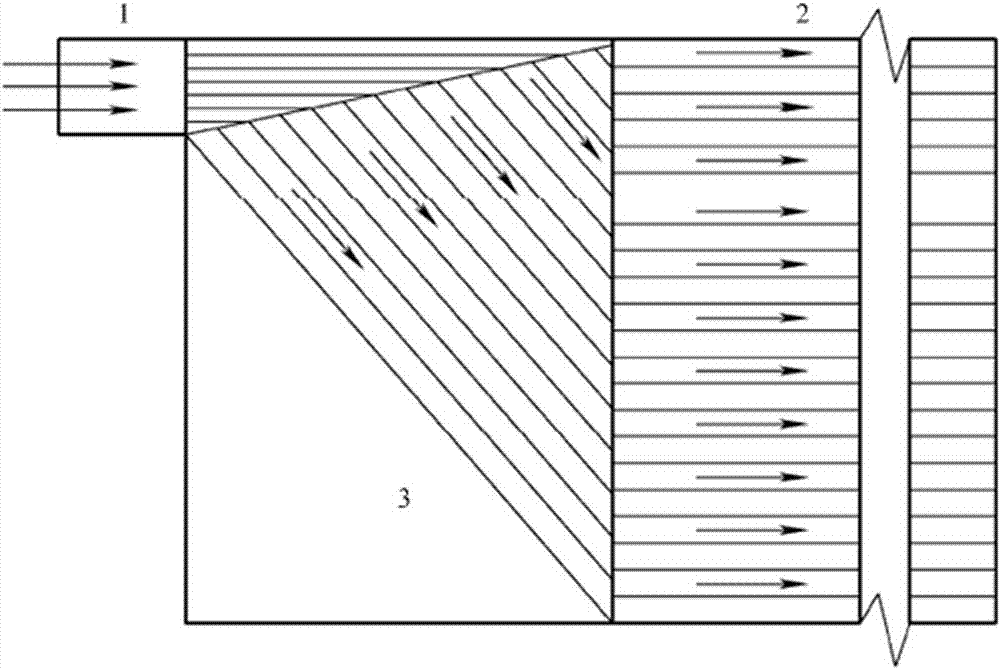

[0012] Preferably, the plate-fin heat exchanger unit mainly includes fins, baffles, deflectors, etc., and each unit is welded together by a vacuum brazing process, and the fluid flows in the flow channel formed by the fins.

[0013] exist figure 1 Among them, the plate-fin heat exchanger unit mainly includes fins, partitions, and deflectors. After each unit is welded together by vacuum brazing, the original fin type in the heat exchange section is replaced with a new type of fin. And there is no flow channel structure change in this heat exchange section.

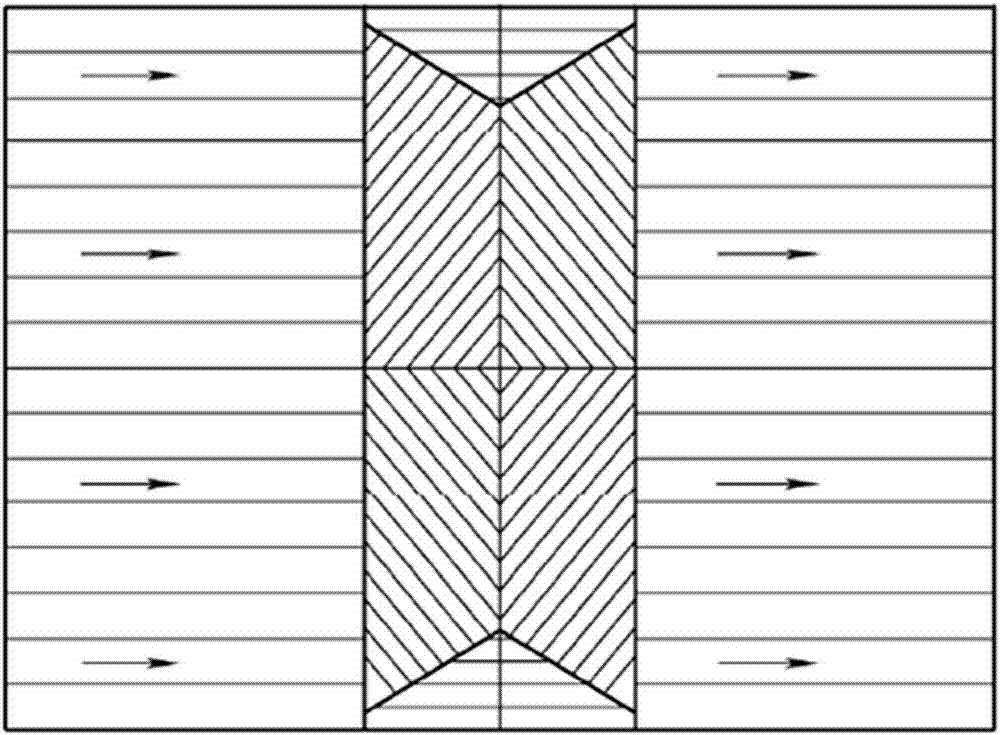

[0014] Preferably, on this basis, a new three-dimensional flow channel structure is adopted, such as figure 2 shown in .

[0015] exist figure 2 In the figure, the three-dimensional structure of the new flow channel is shown in the figure. In order to increase the turbulence performance of the fluid flow in the heat exchanger, extend the heat transfer distance, and improve the efficiency of the plate-fin heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com