Patents

Literature

41results about How to "Strong reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

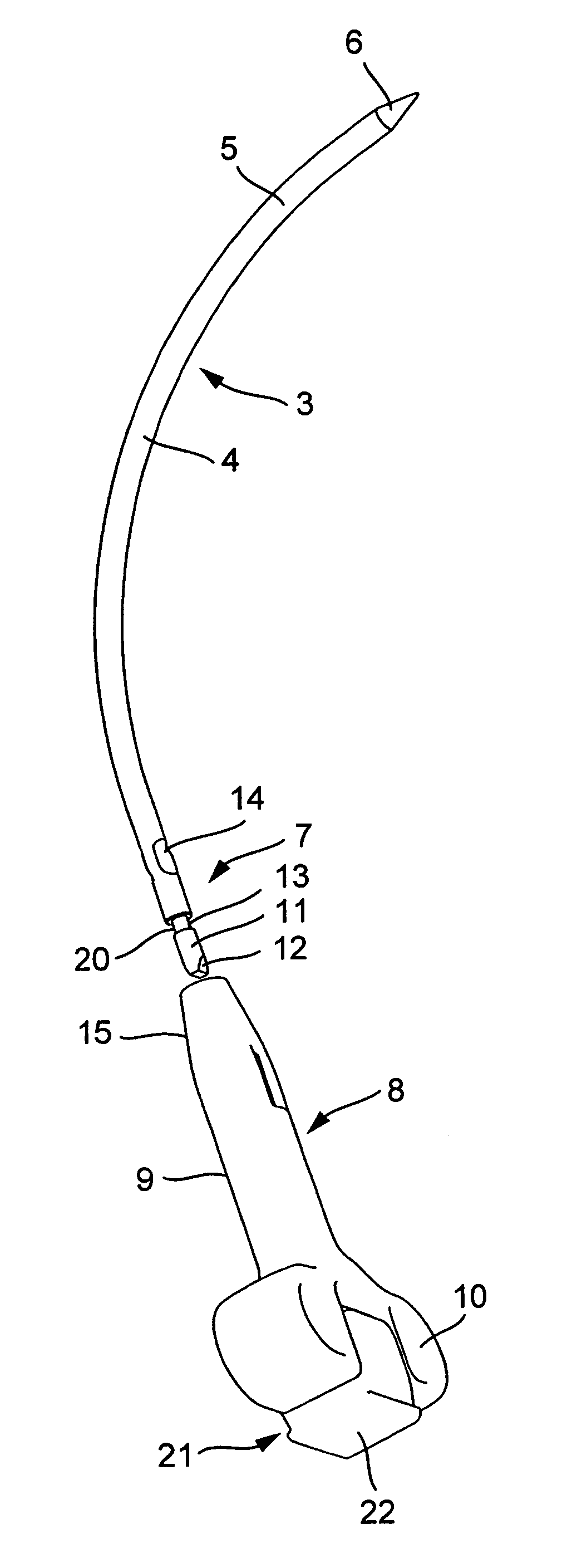

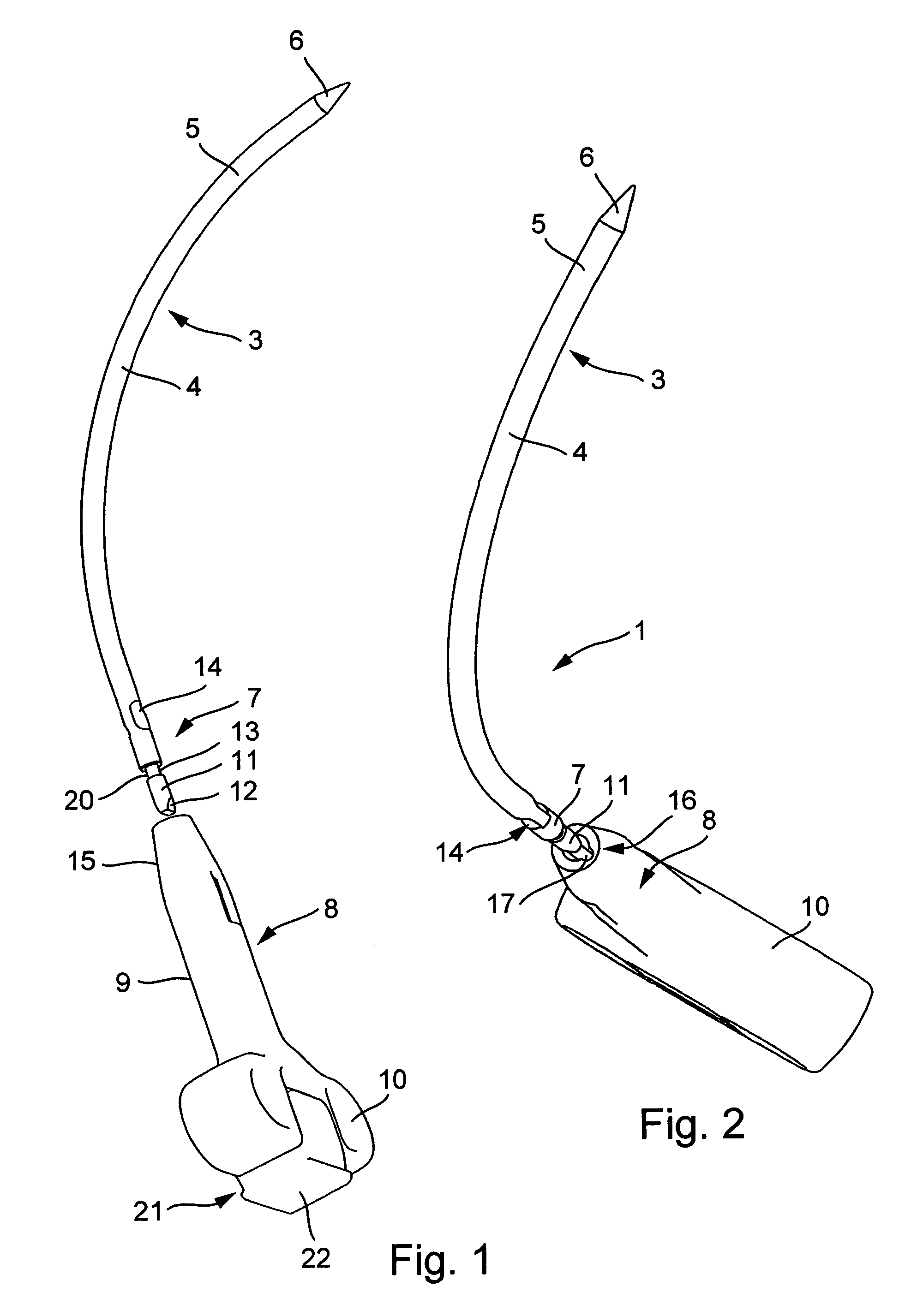

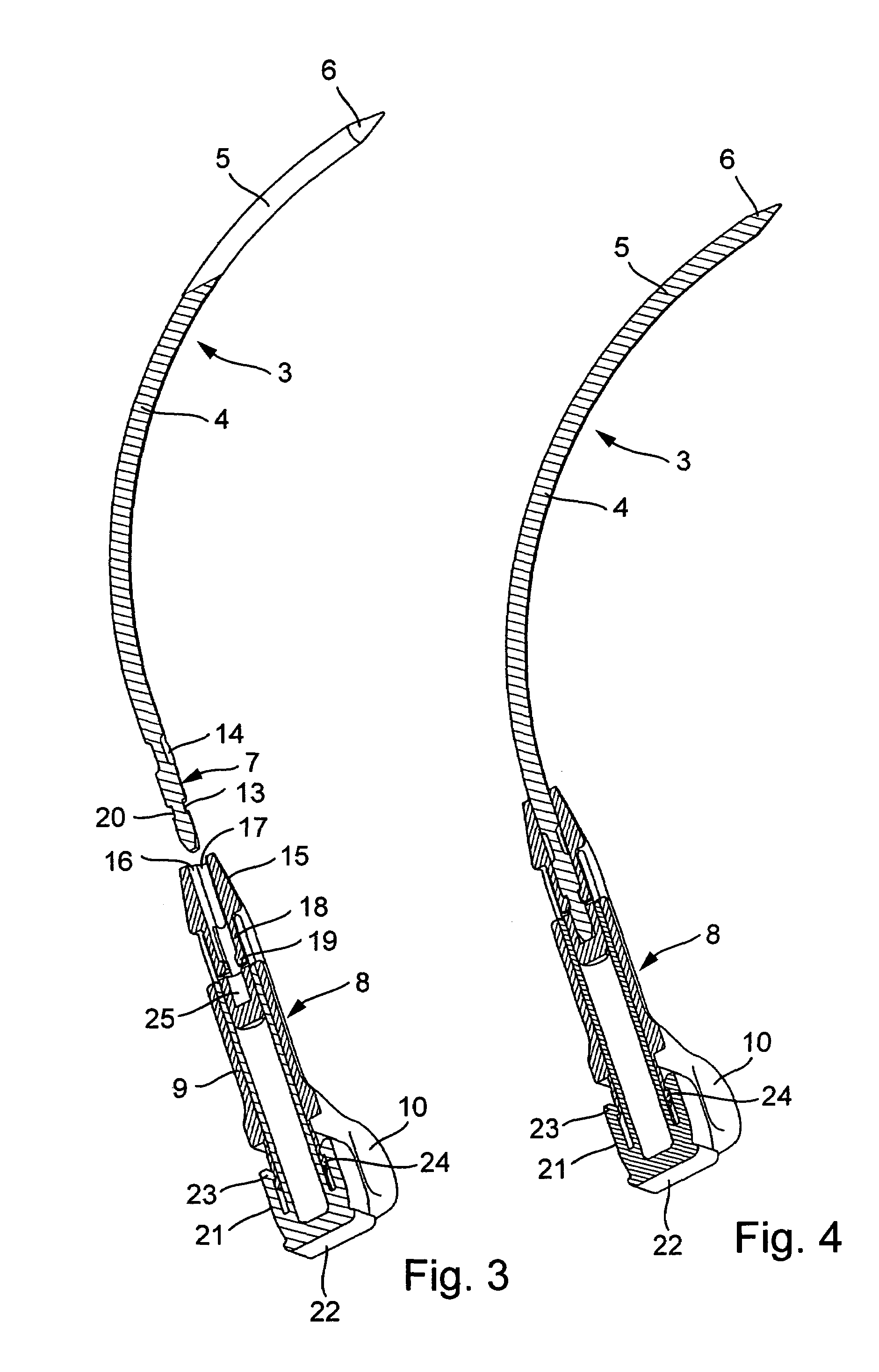

Incontinence strip for treating urinary incontinence

InactiveUS7351196B2Avoid tearingModify its flexibilitySuture equipmentsAnti-incontinence devicesUrinary incontinence

The invention relates to a an incontinence strap (66) for treating urinary incontinence, in particular, urinary incontinence in females, that is configured such that it is flexible.

Owner:AESCULAP AG

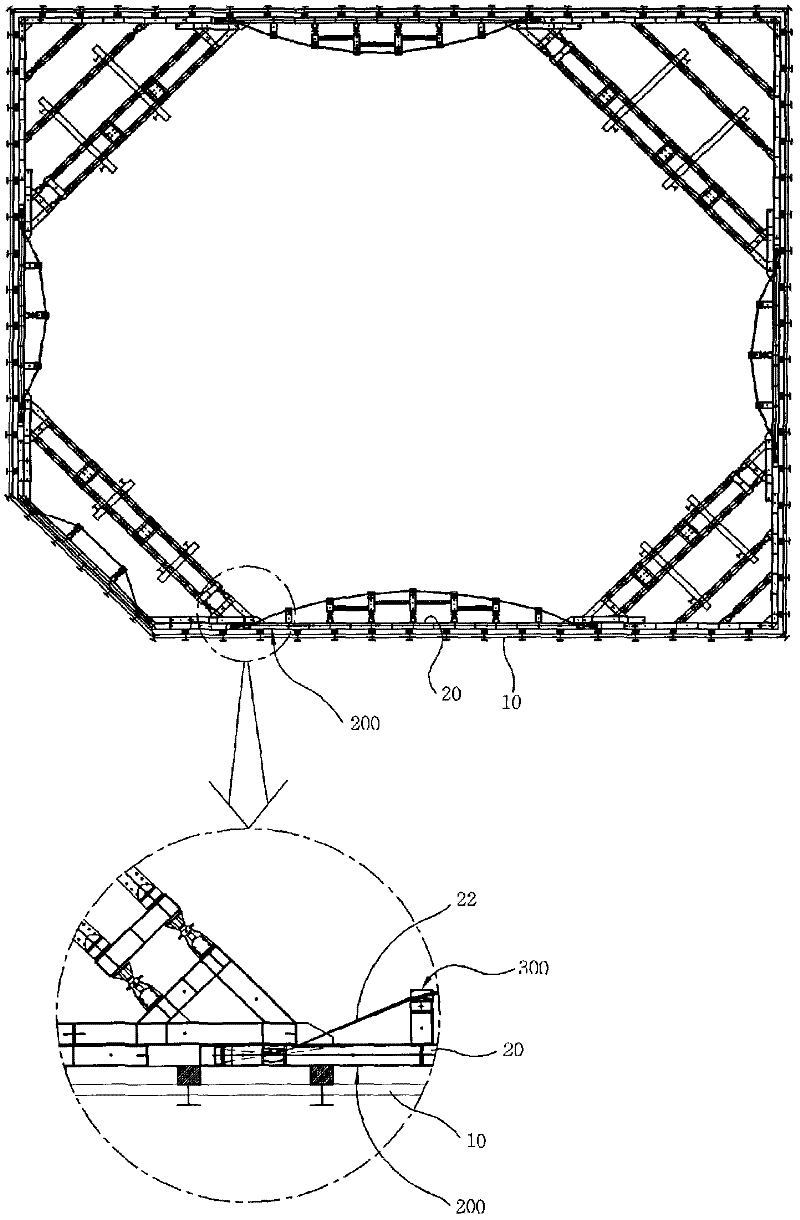

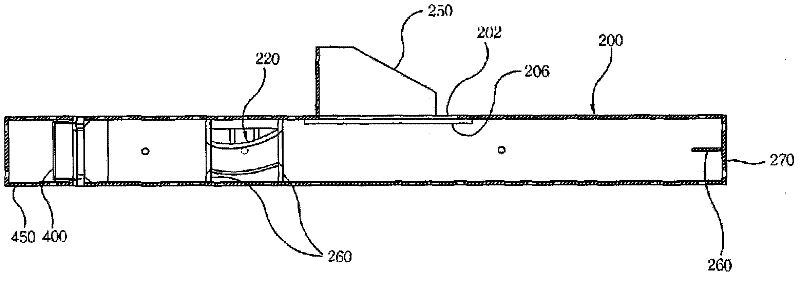

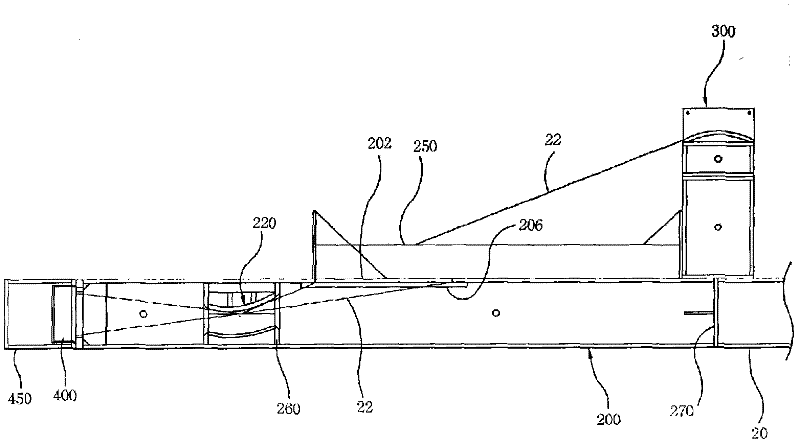

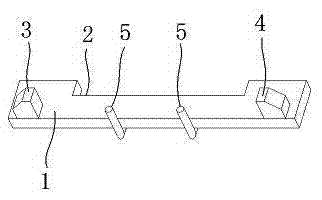

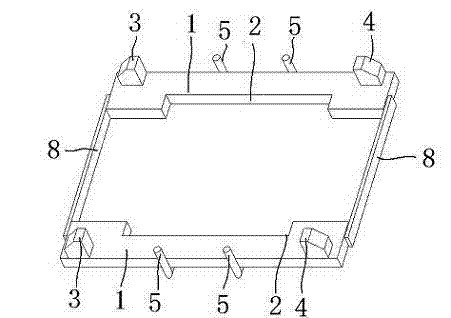

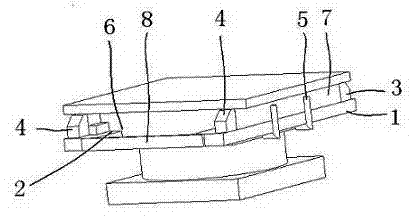

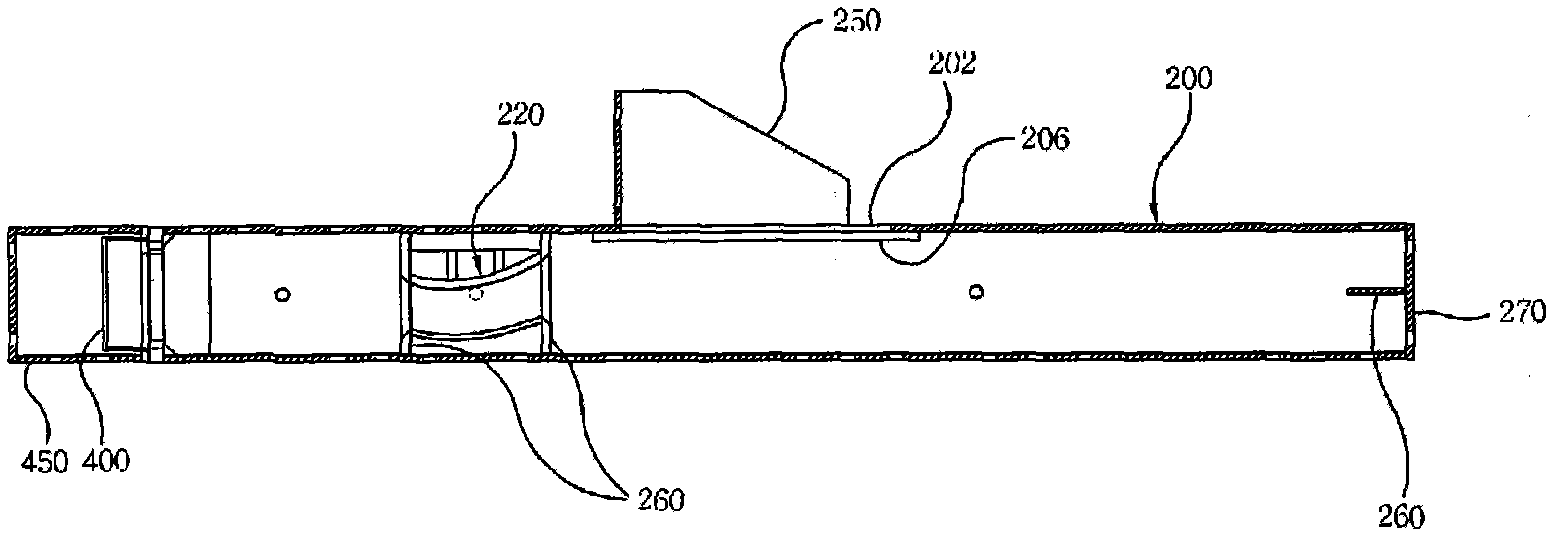

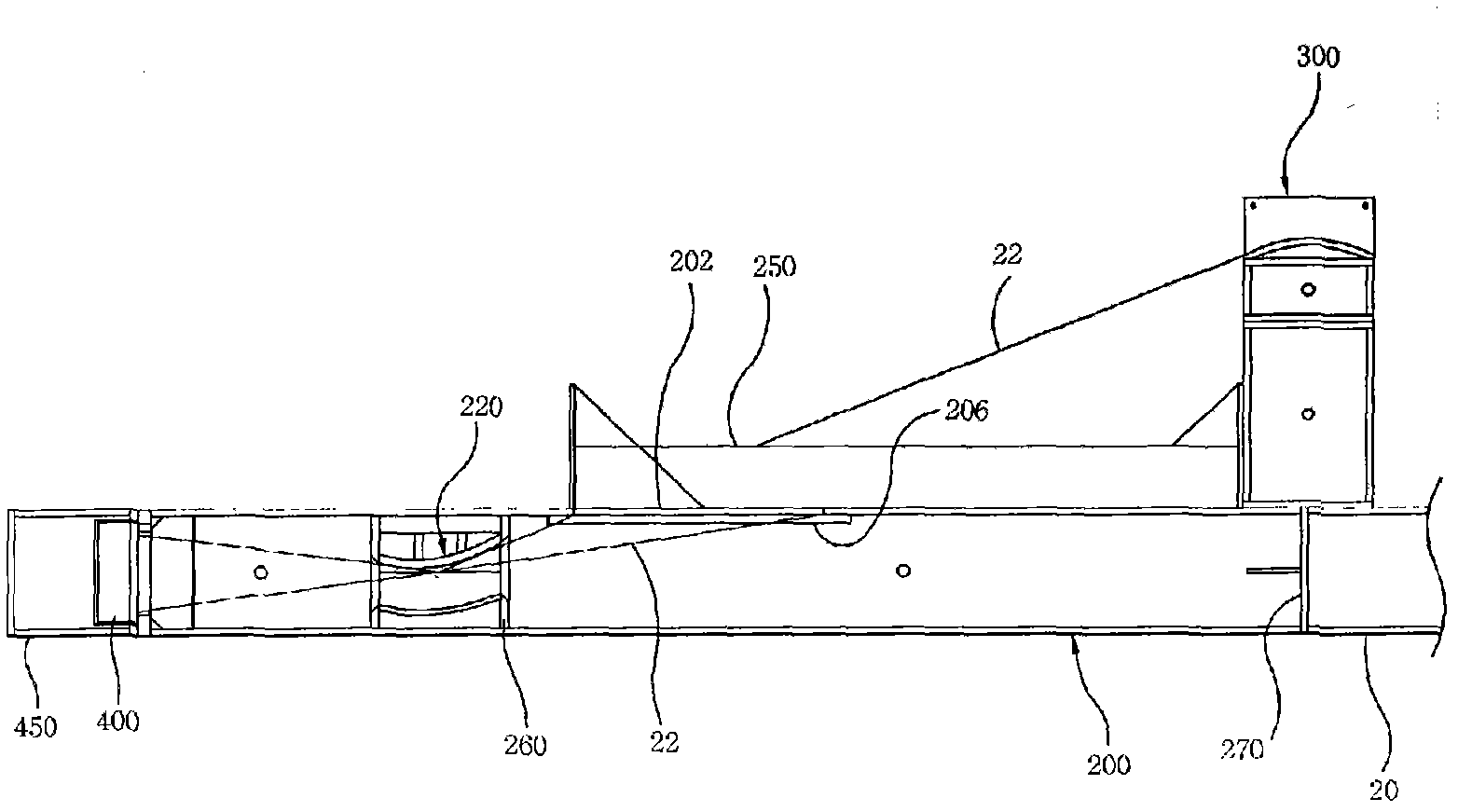

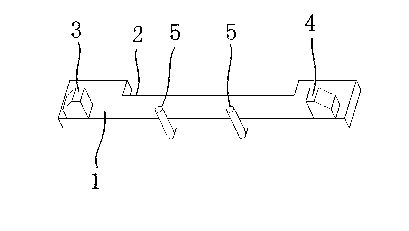

Apparatus for fixing steel wire of wale

The present invention provides an apparatus for fixing a steel wire of a wale, which comprises the following components: a fixing body which is cross-beam-shaped, wherein a first end of the fixing body is combined with one end of a prestressed wale, the fixing body is provided with a coupling hole and penetration of one end of the steel wire of the wale through the coupling hole is allowed; an arrester which projects from a front surface of the fixing body for improving shearing force resistance of the fixing body; a guiding plate which has a preset curvature and is integrated with an inner surface of the fixing body for guiding the steel wire to be inserted into the fixing body; and a cushion block which is provided at a second end of the fixing body and fixes the end of the steel wire of the wale.

Owner:SUPPORTEC CO LTD

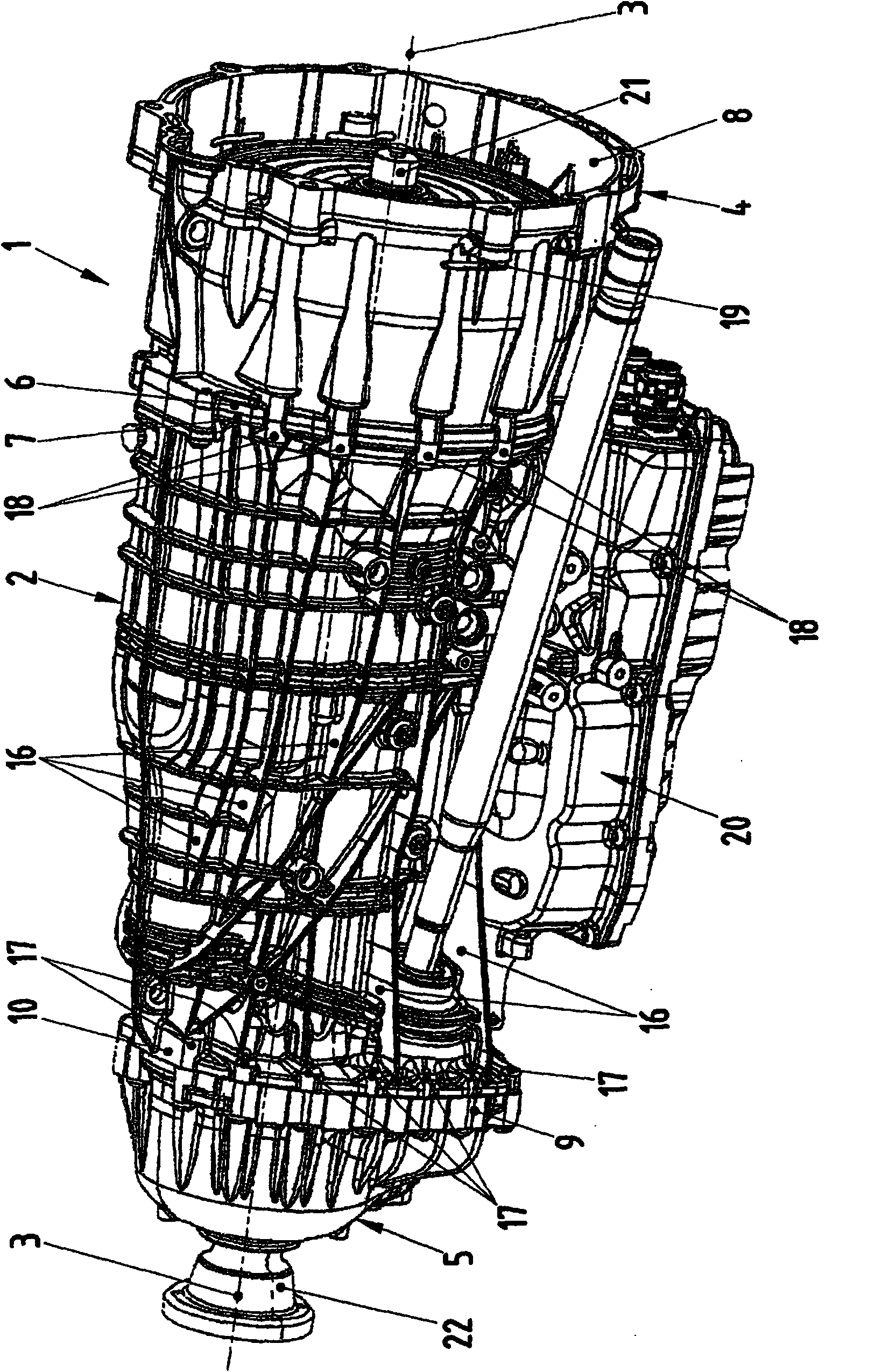

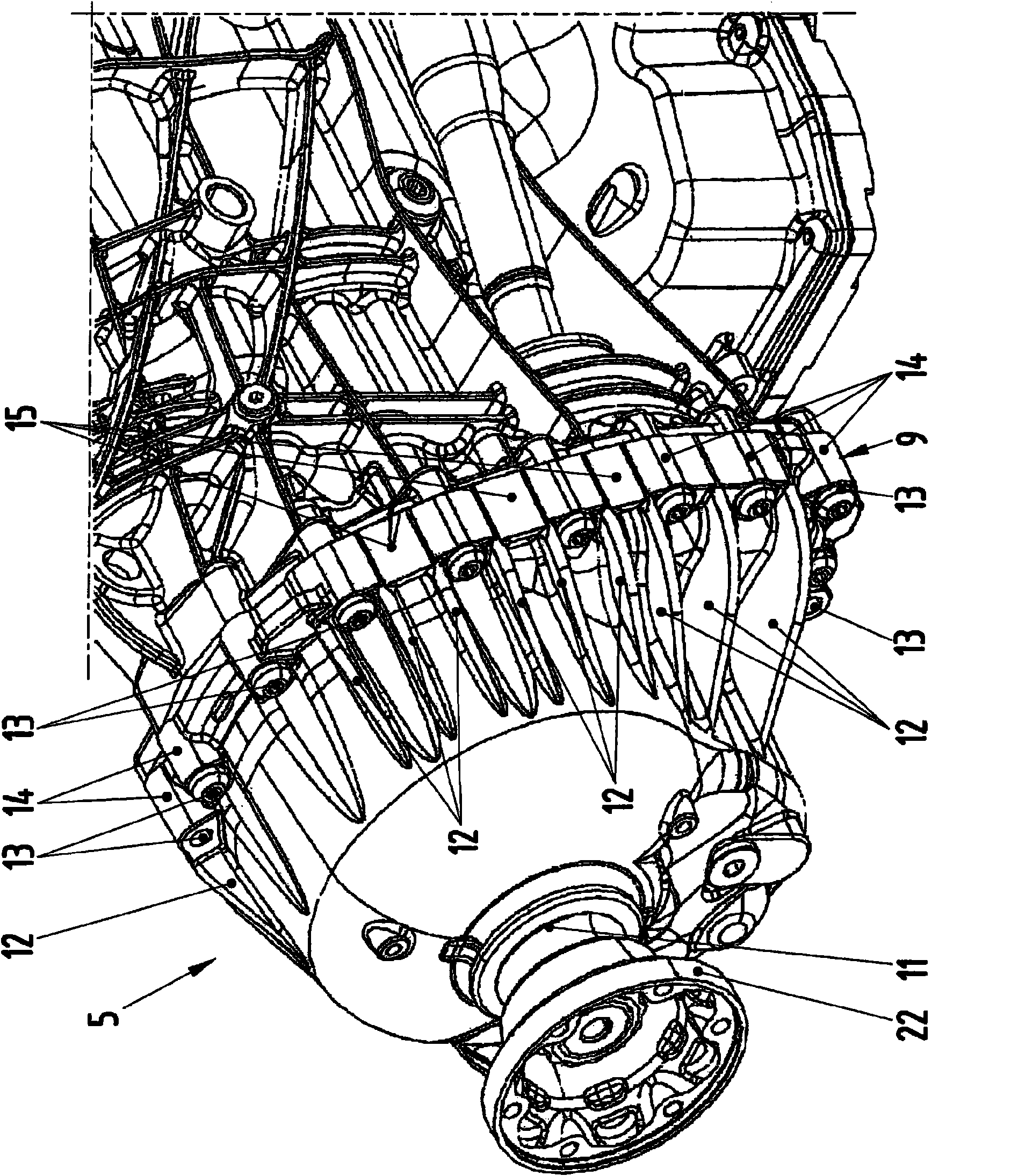

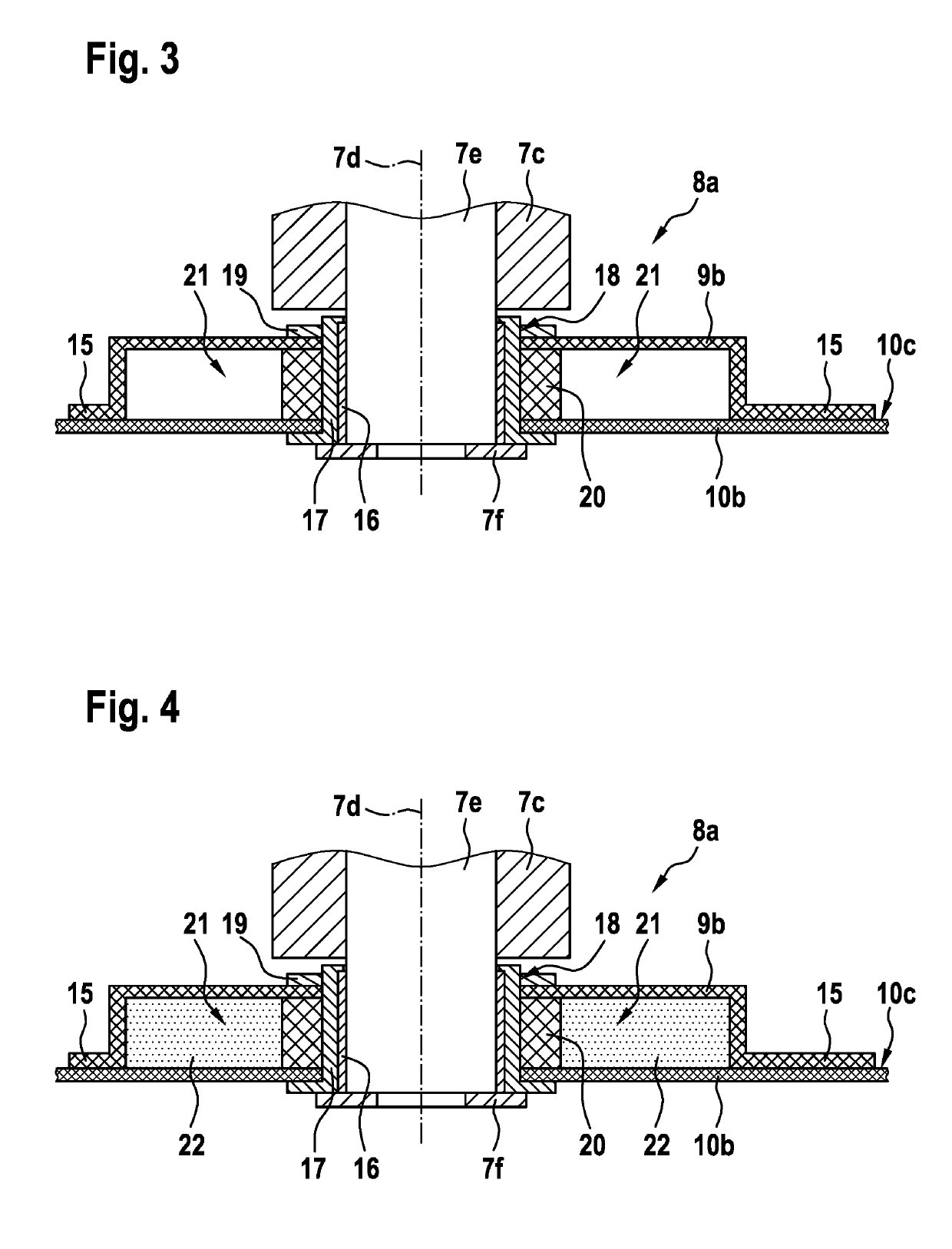

Housing used for vehicle transmission

InactiveCN101566222AEasy to passAvoid breakingGearboxesGearing detailsInternal combustion engineFlange

The invention relates to a housing used for transmission of motor vehicle, especially car. The housing has: a main housing used for receiving the transmission; and a transmission cover used for receiving the torque-converter of the transmission and / or the clutch of the transmission. One end of the transmission cover is connected on the main housing by a flange, the other end can be connected on the cylinder of the internal combustion engine of the vehicle by a flange; if the flange of the end cover is equipped with longitudinal ribs, the end cover is connected onto the main housing by the flange, and the longitudinal ribs are arranged on both sides of the screw holes; and if the flange of the end cover is provided with bump bridges, the bump bridges can connect the adjacent longitudinal ribs between the adjacent screw holes to each other in circumference direction; thereby, the failure properties of the transmission housing can be improved.

Owner:DR ING H C F PORSCHE AG

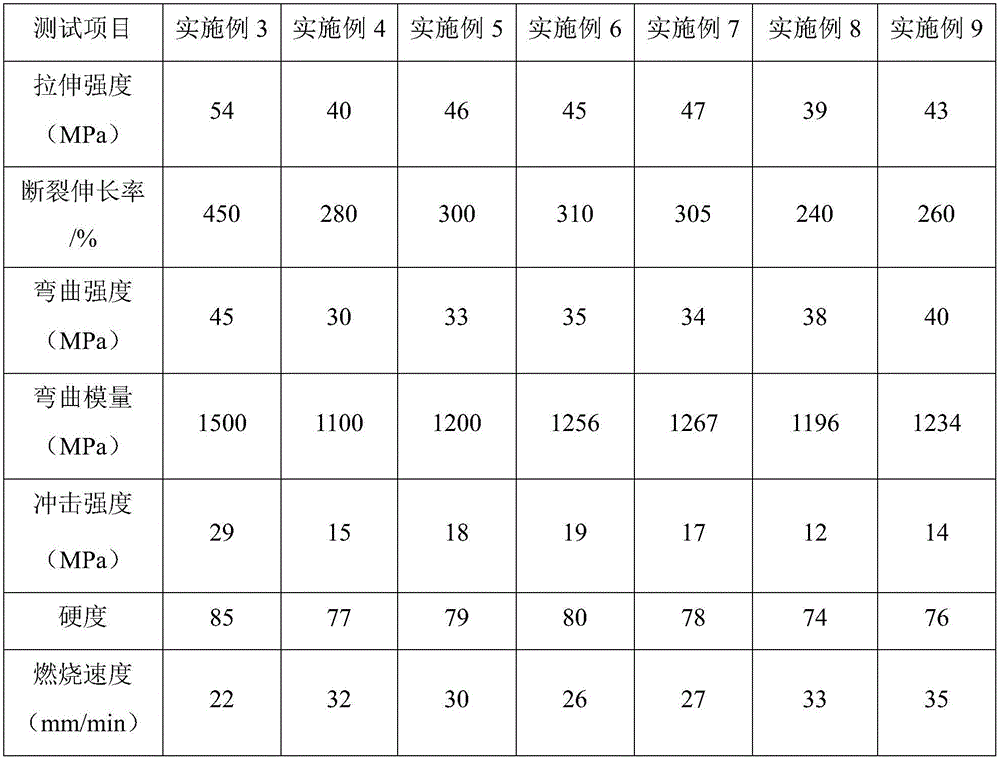

Polypropylene/montmorillonite nanometer composite material preparation method

The invention discloses a polypropylene / montmorillonite nanometer composite material preparation method, which comprises: 1, montmorillonite pre-treatment: carrying out three different pre-treatments on three equal montmorillonite to finally obtain pre-treated composite montmorillonite; 2, montmorillonite modification: uniformly dividing the pre-treated composite montmorillonite into two equal parts and respectively carrying out two different modification treatments to obtain modified composite montmorillonite; 3, polypropylene modification: mixing polypropylene, a grafting monomer and an initiator by using a high-speed stirrer, and carrying out melting blending with a twin-screw extruder to obtain modified polypropylene; and 4, polypropylene / montmorillonite nanometer composite material preparation. According to the present invention, the obtained polypropylene / montmorillonite nanometer composite material has excellent mechanical properties such as tension performance, bending performance, impact resistance and the like, can meet diversified requirements of people, and has broad market prospects.

Owner:GUANGXI TEACHERS EDUCATION UNIV

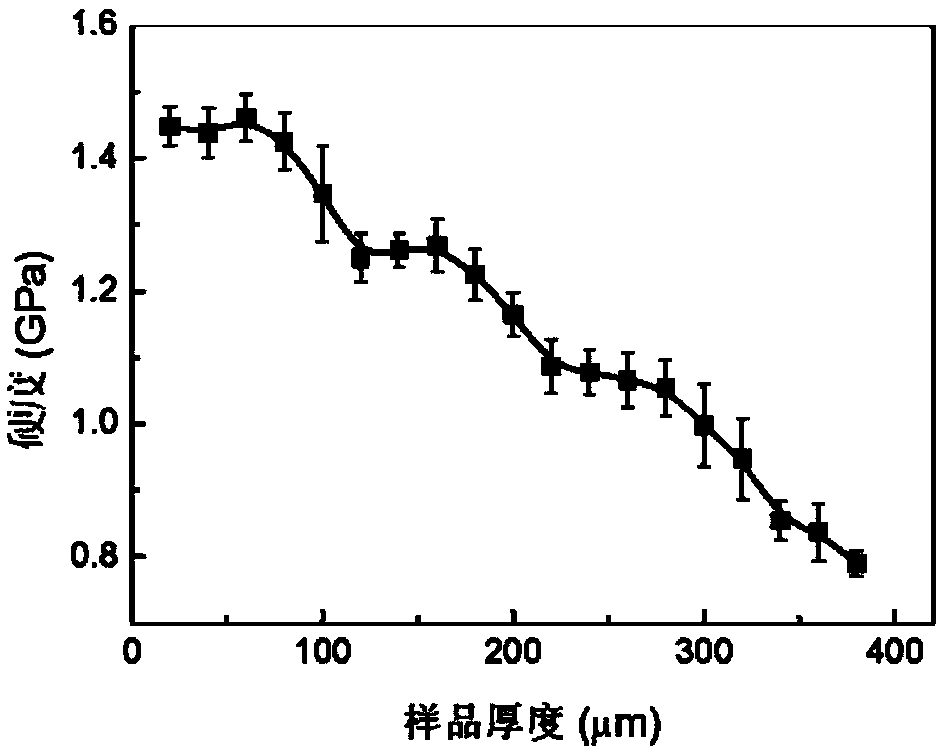

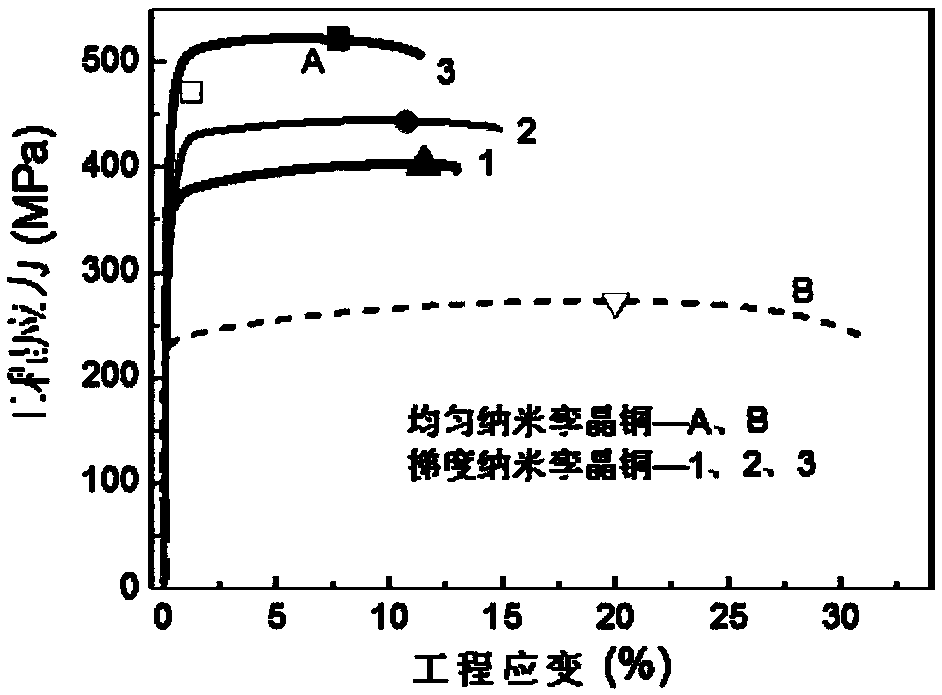

Method of improving mechanical property of material by changing metal material gradient nano twin-crystal structure

ActiveCN108677213AUnique microstructureUnique Strengthening MechanismCellsPhotography auxillary processesCrystal twinningNano structuring

The invention discloses a method of improving a mechanical property of a material by changing a metal material gradient nano twin-crystal structure, and belongs to the technical field of nano-structure metal materials. According to the method, the mechanical property of the material improved by utilizing the inherent law of the microstructure and the mechanical property of the metal material the metal material is provided with the gradient nano twin-crystal structure, and the law of the microstructure and the mechanical property of the metal material refers to regulating the mechanical property of the metal material by changing the gradient size of the nano-twin crystal structure. According to the method, two strengthening methods of nano-twin crystal strengthening and the gradient structure are integrated so that the mechanical property of the metal material can be remarkably improved; and for a gradient nano-twin crystal structure pure copper material prepared by utilizing a electrolytic deposition preparation technology, the yield strength highly reaches 481 + / - 15 MPa, the tensile strength is highly up to 520 + / - 12 MPa, meanwhile, the uniform elongation rate can reach 7 + / - 0.5%, and the elongation at break can reach 11.7 + / - 1.3%%.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method for composite material of nano-concave-convex stick stone/silicon dioxide

InactiveCN101367960AGood reinforcing effectChange surface propertiesSODIUM SILICATE SOLNSilicon dioxide

The invention discloses a method for preparing nano attapulgite / silicon dioxide composite materials. Firstly, attapulgite is added into de-ionized water to prepare suspension liquid containing 2-20 percent of solid; secondly, sodium silicate solution (mass concentration: 5-30 percent) and acid solution (mass concentration: 3-30 percent) are prepared; finally, the achieved nano attapulgite / silicon dioxide composite materials are filtered, the soluble salt is repeatedly washed by de-ionized water, dried and porphyrized. On the precondition that the clavated structure of the nano attapulgite is not damaged, the method adopts chemical precipitation to generate nano granular silicon dioxide in situ in the nano attapulgite dispersed liquid, and a spherical-clavated composite reinforcing material is prepared, thereby, the surface properties of the attapulgite is changed, the brightness of the nano attapulgite is improved, and the field of attapulgite minerals deep-processing and comprehensive utilization is expanded; the preparation process is simple and the production cost is relatively low.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

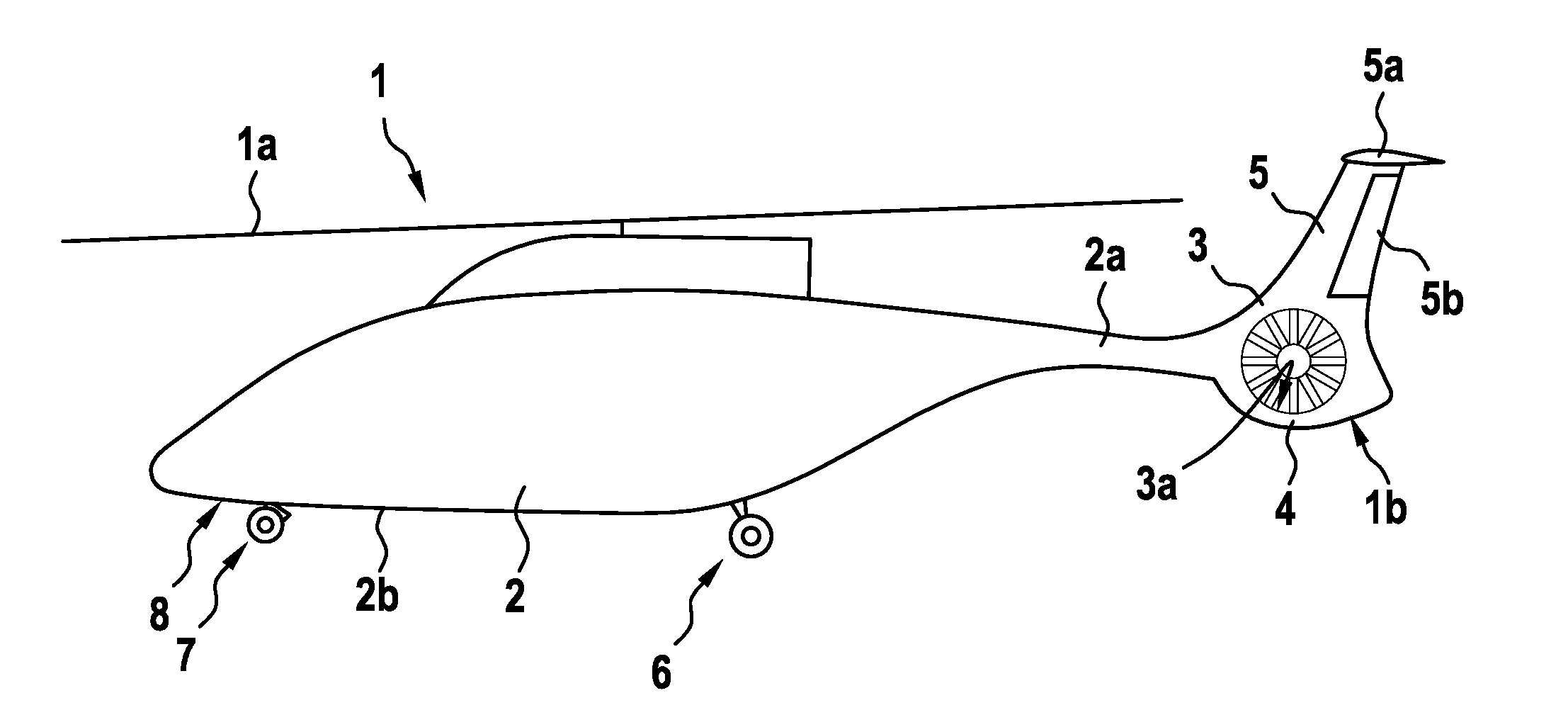

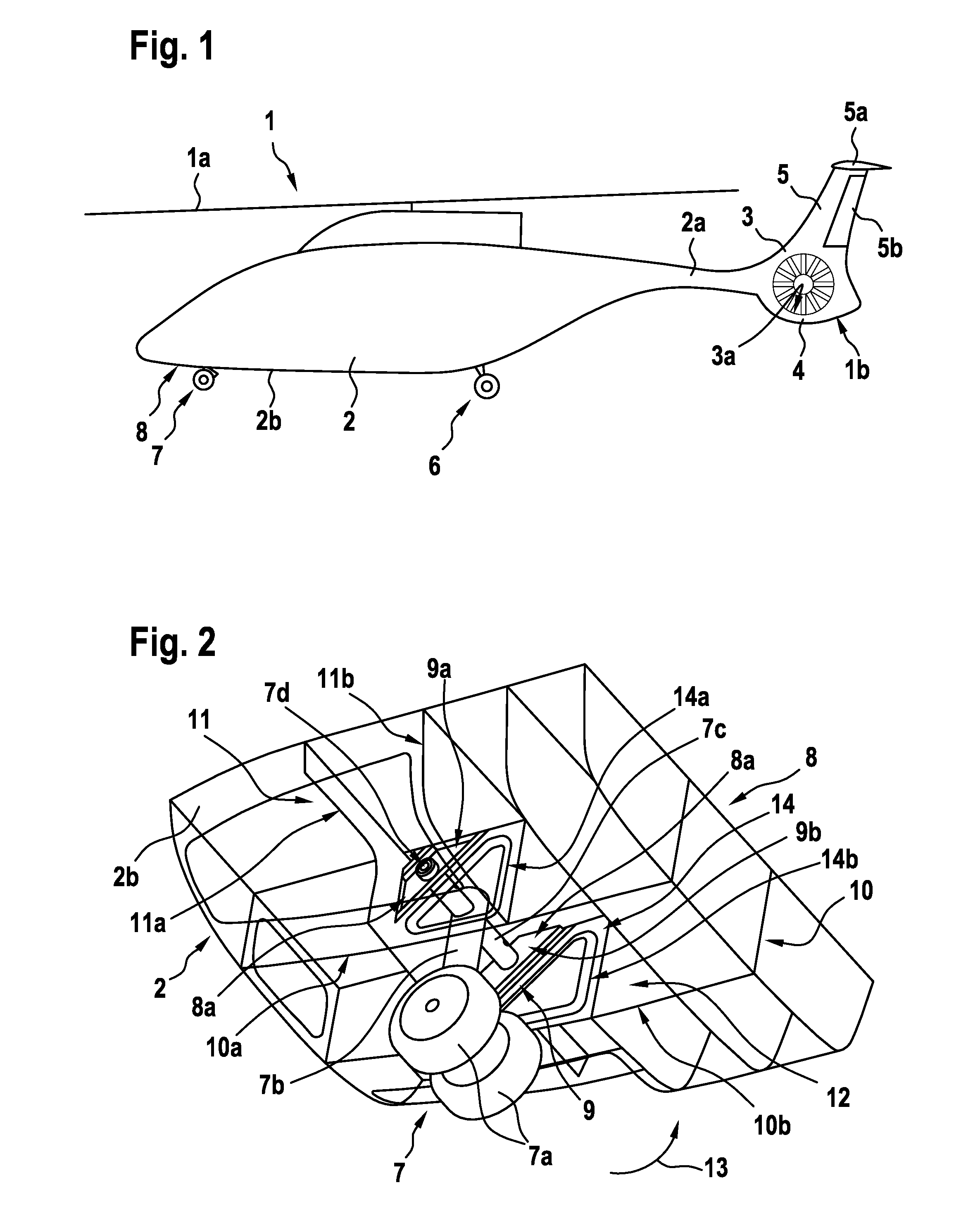

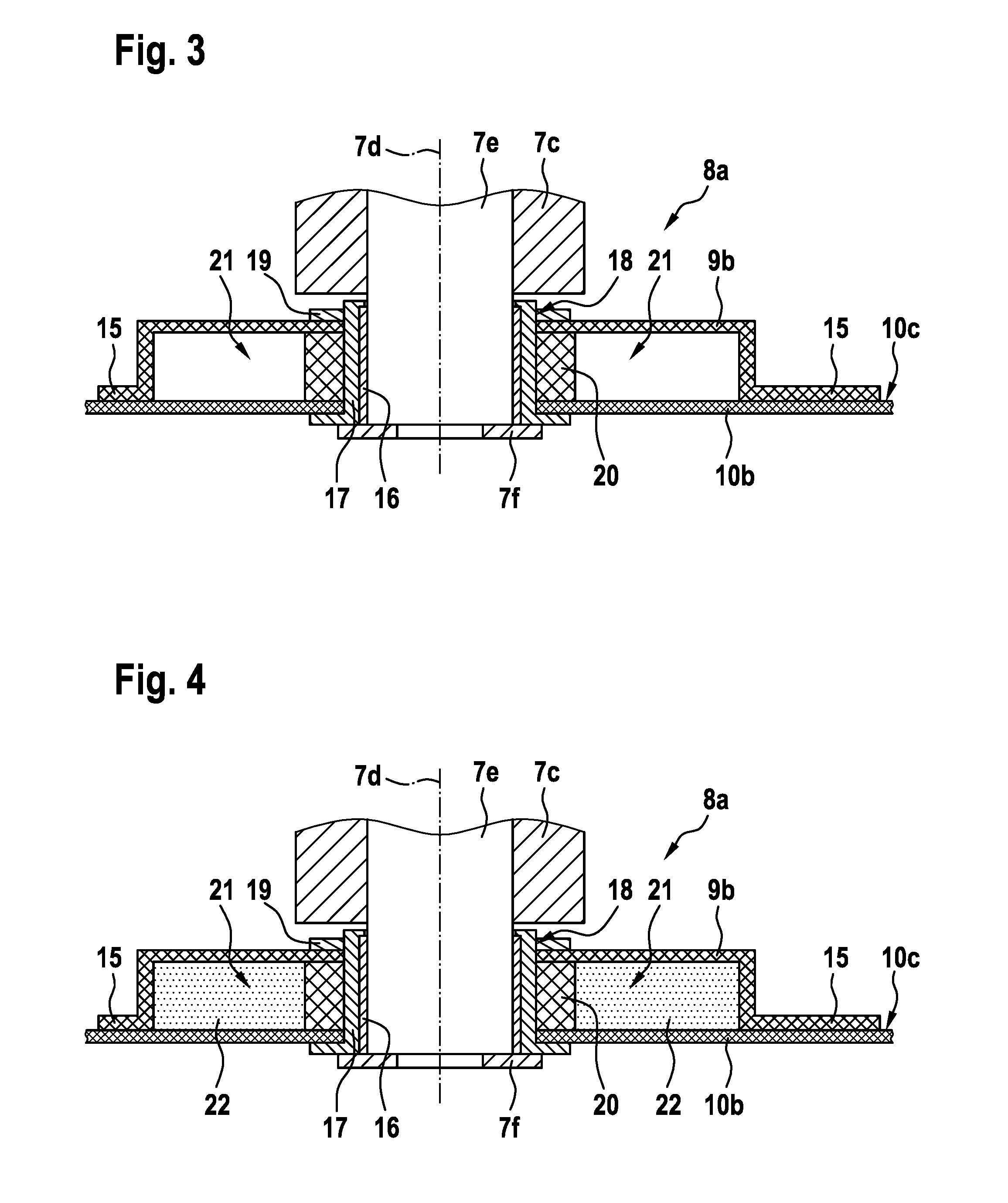

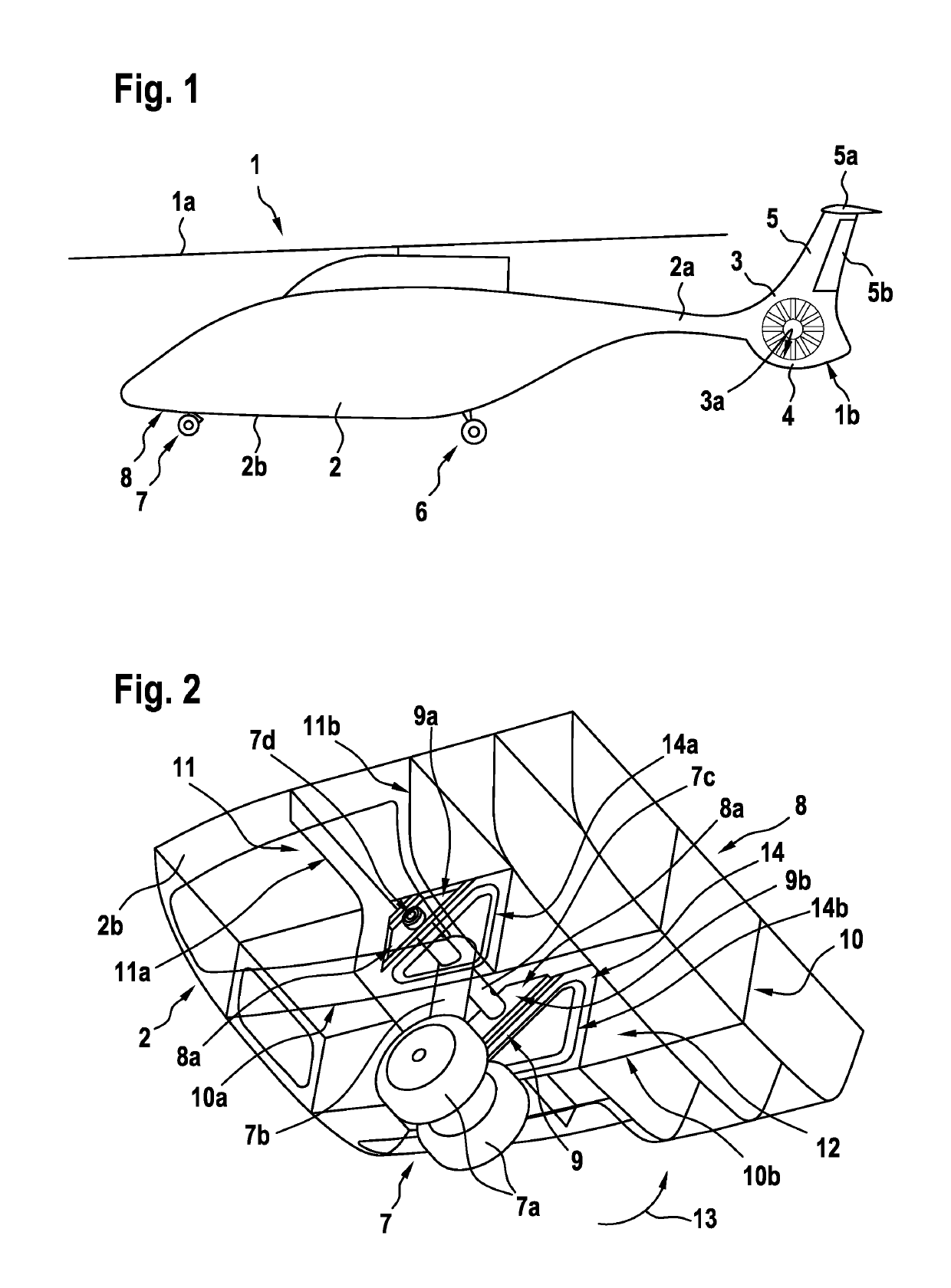

Aircraft structural component that is adapted for absorbing and transmitting forces in an aircraft

ActiveUS20160375979A1Reduce weightIncrease resistanceFuselage framesMaterial gluingFlight vehicleAirplane

An aircraft structural component that is adapted for absorbing and transmitting forces in an aircraft, the aircraft structural component comprising at least one panel element and at least one reinforcing structure. The at least one reinforcing structure is rigidly attached to the at least one panel element such that at least one cavity is defined between the at least one panel element and the at least one reinforcing structure, the at least one cavity being adapted for distributing forces that are absorbed by the aircraft structural component in operation.

Owner:AIRBUS HELICOPTERS DEUT GMBH

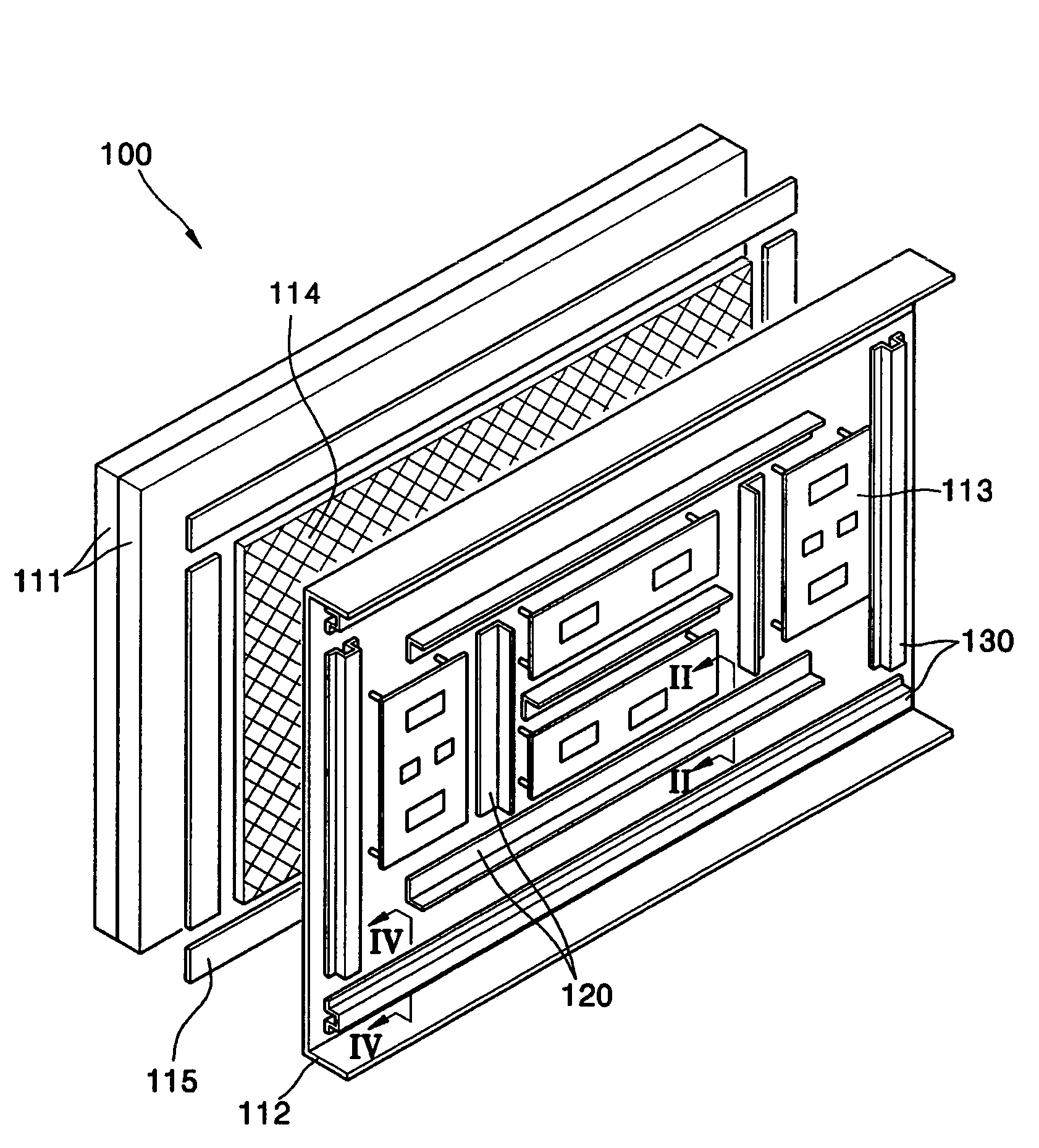

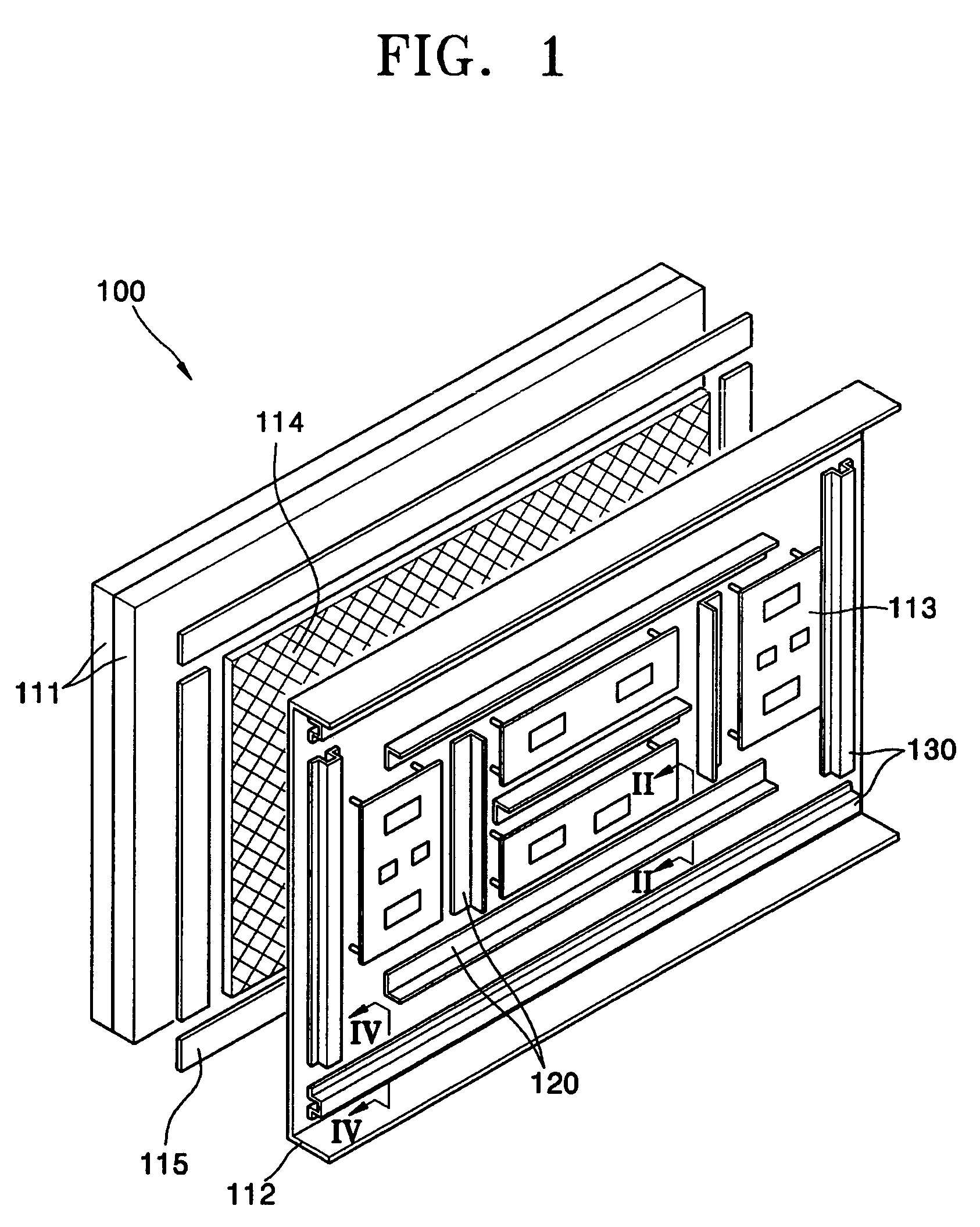

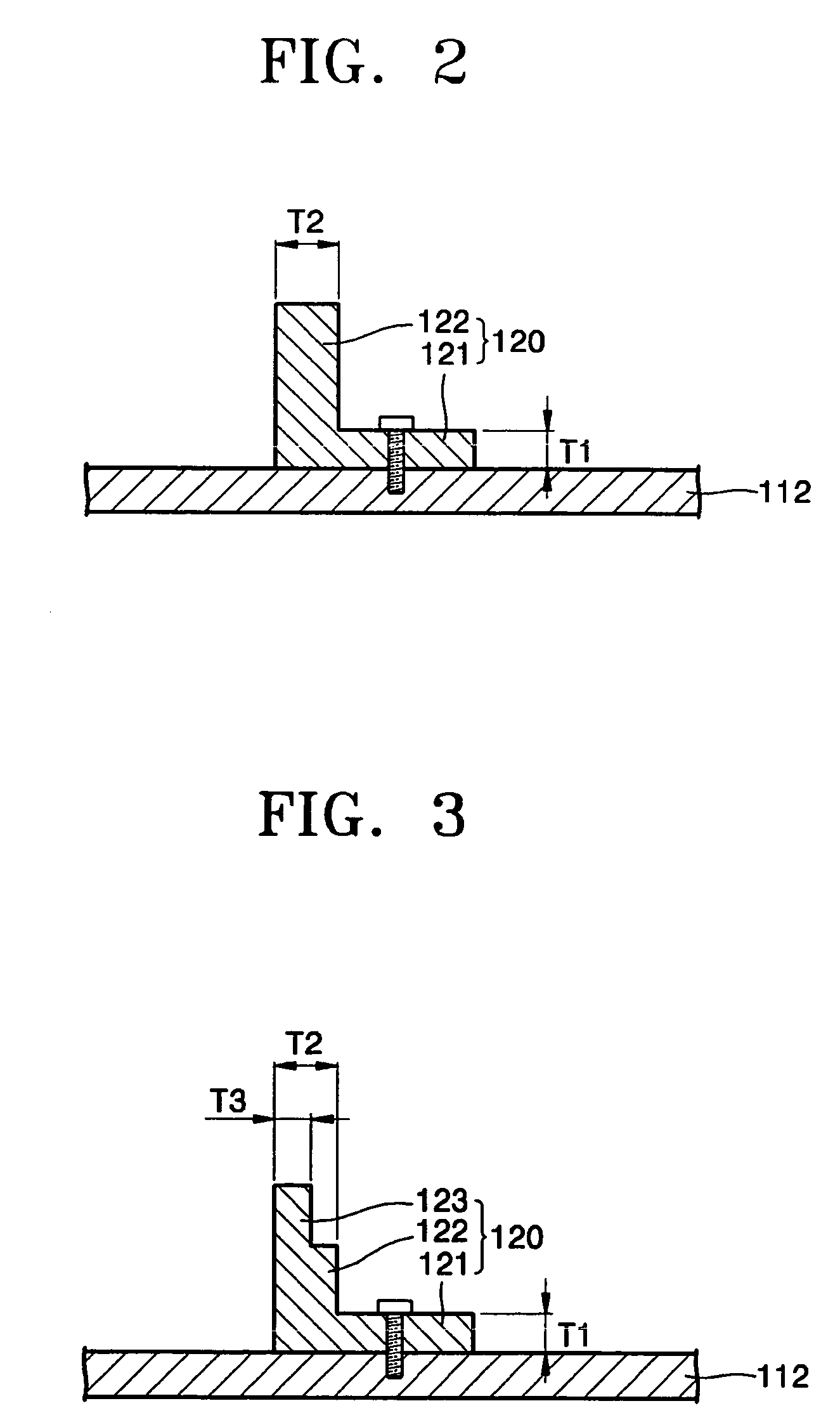

Plasma display apparatus

InactiveUS7321487B2Strong reinforcementReduce manufacturing costDigital data processing detailsLighting elementsEngineeringPlasma display

A plasma display apparatus including a display panel, a chassis base coupled to a rear of the display panel, and a reinforcement member. The reinforcement member includes a base portion coupled to the chassis base and an extended portion bent from the base portion. A cross-sectional thickness of the extended portion is different from a cross-sectional thickness of the base portion.

Owner:SAMSUNG SDI CO LTD

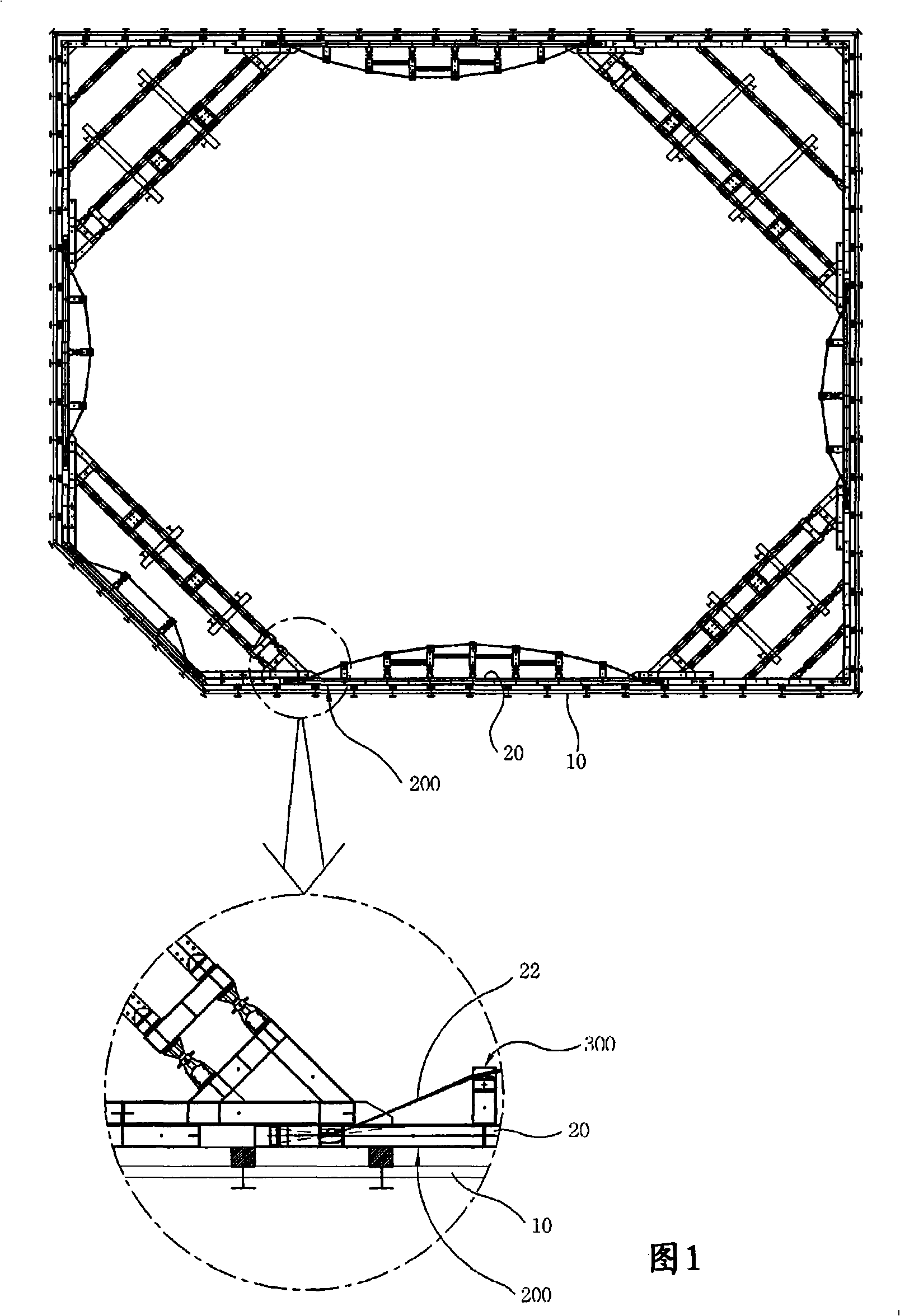

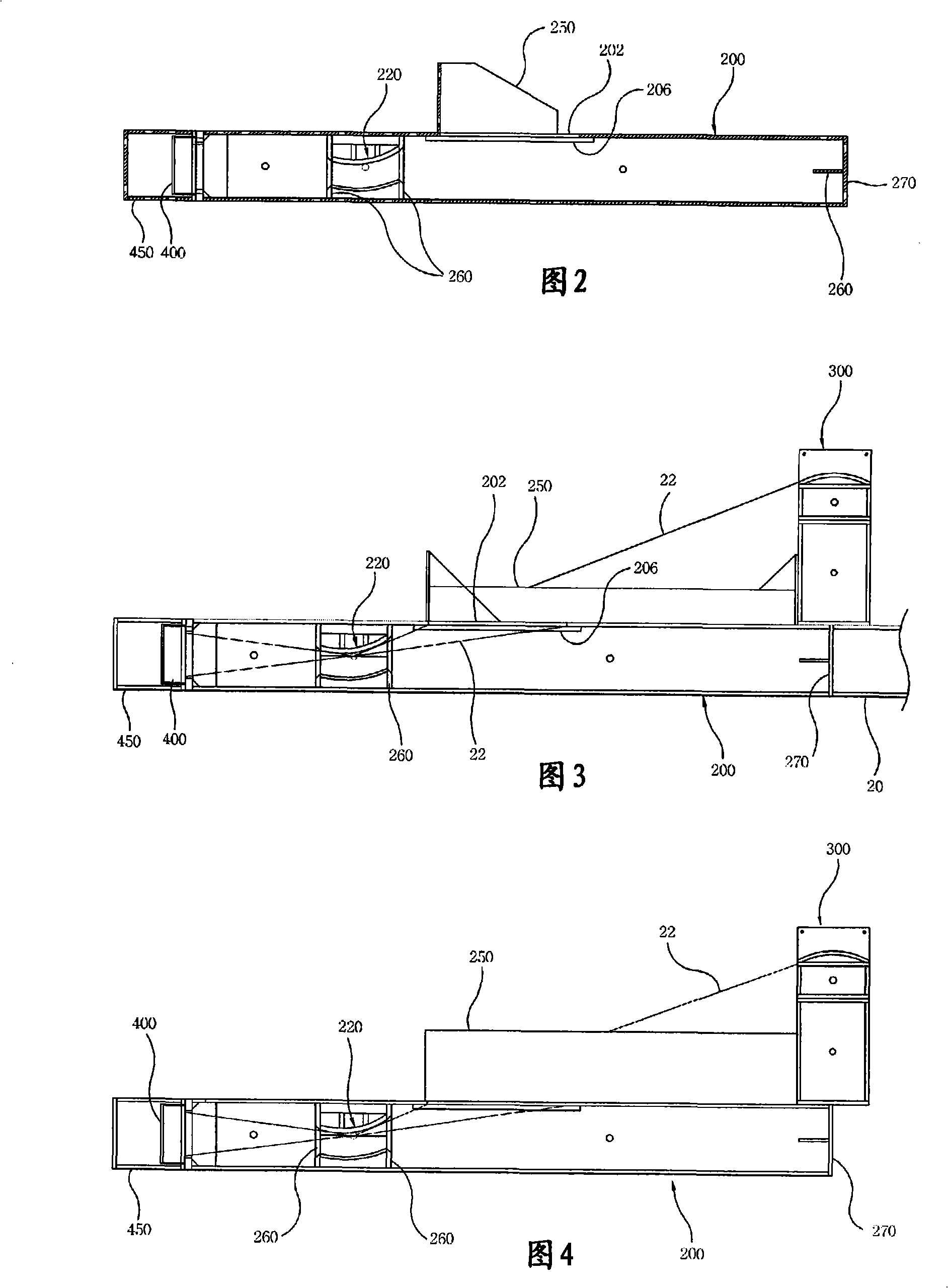

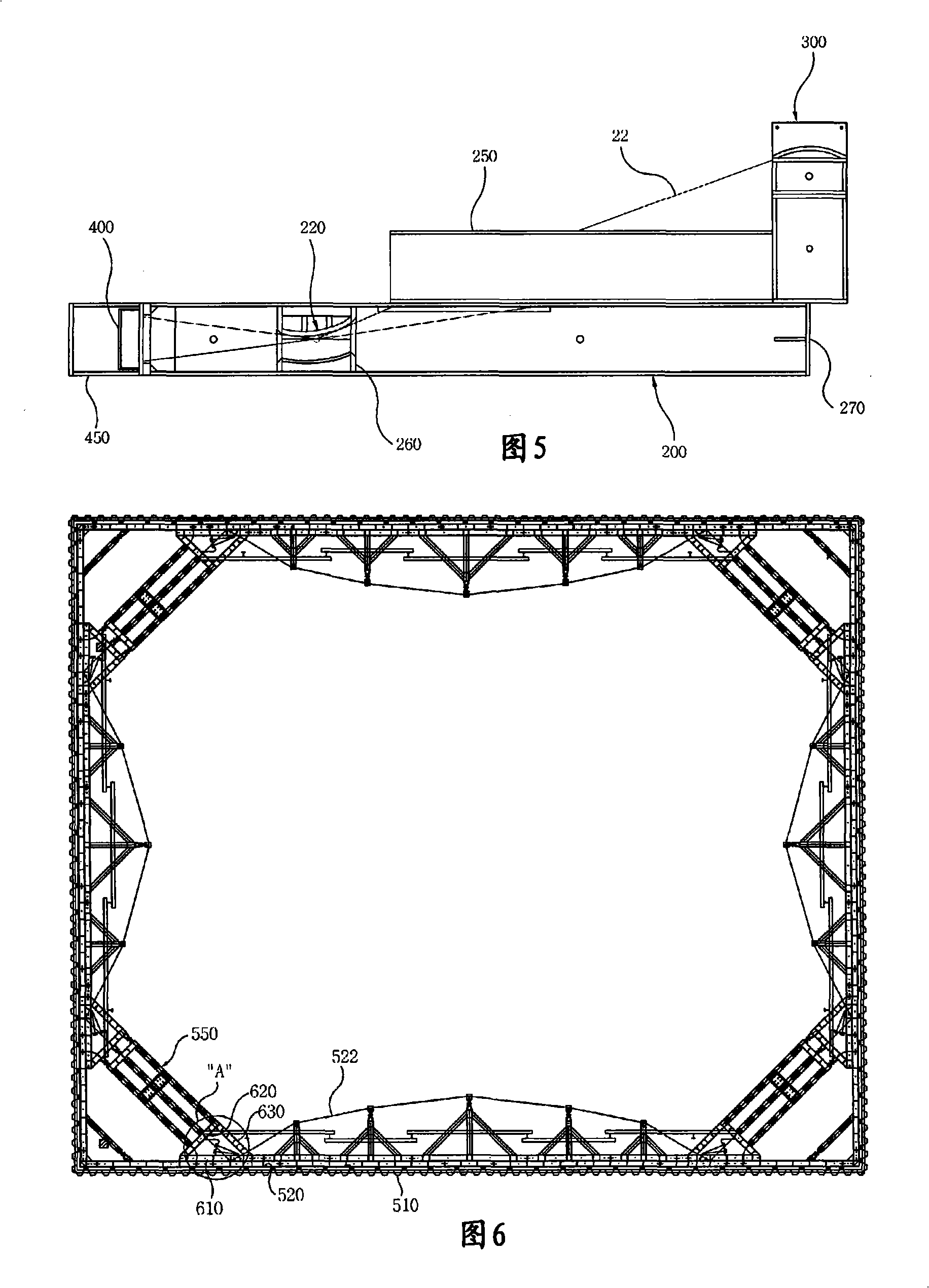

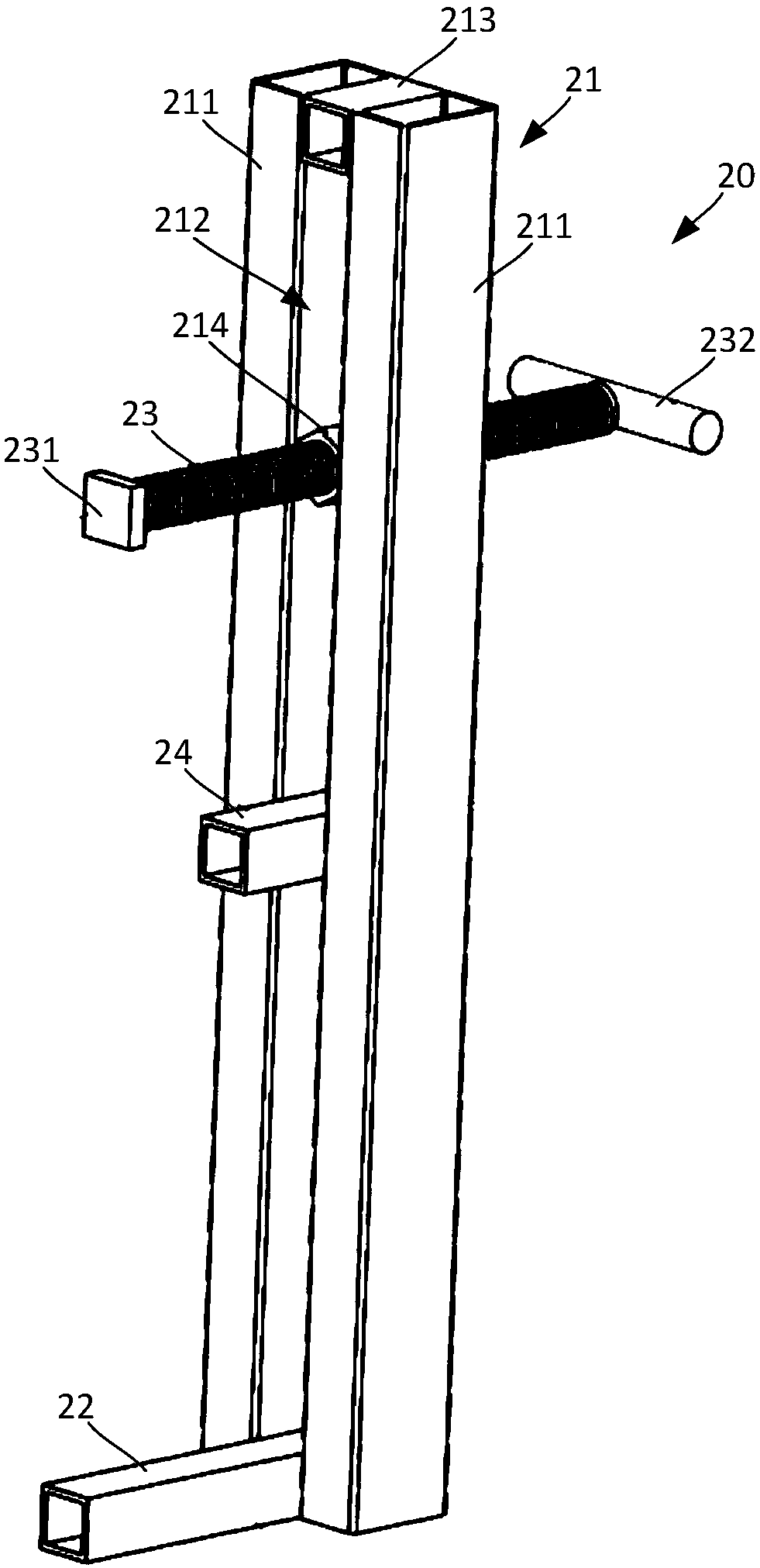

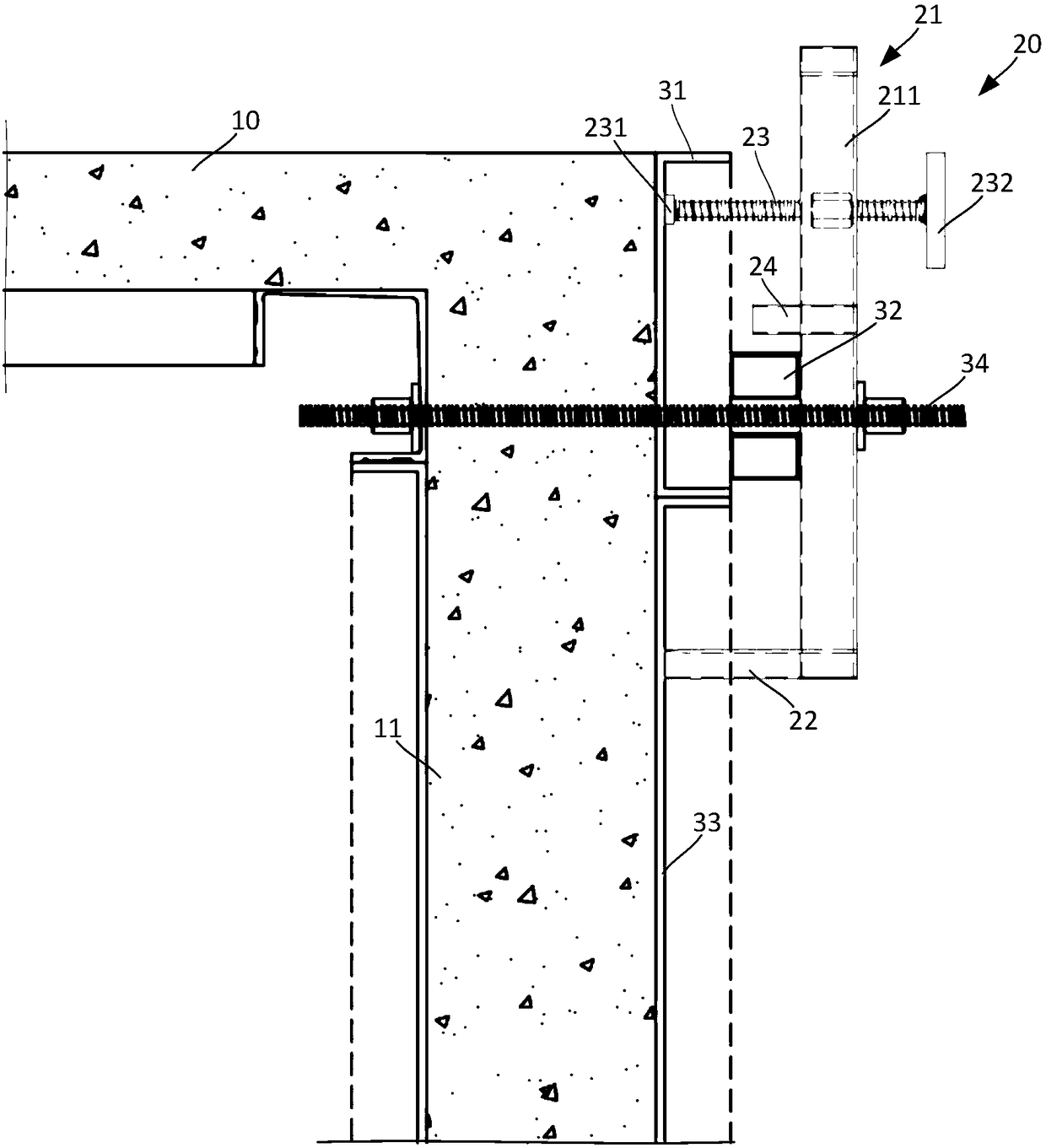

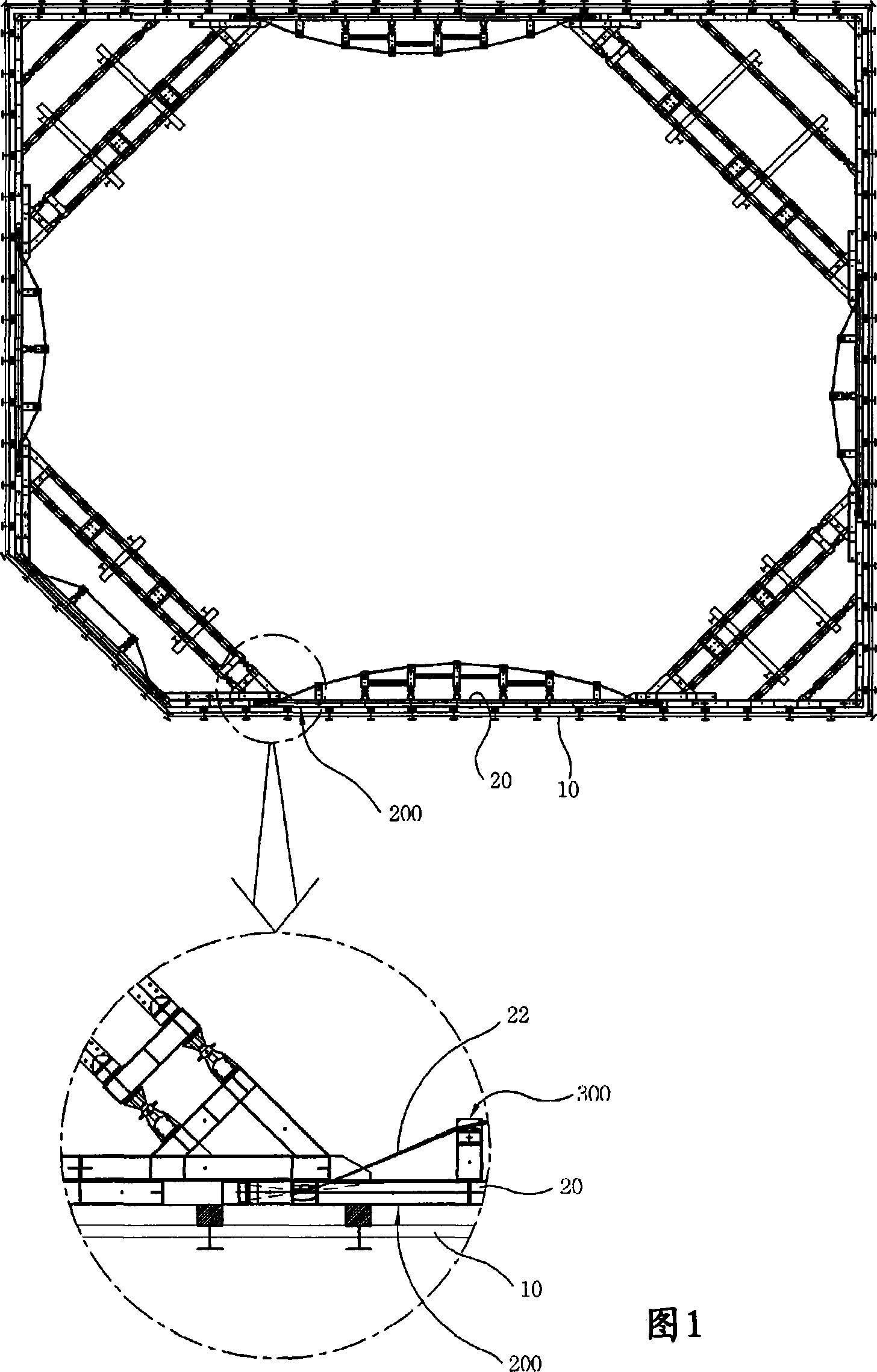

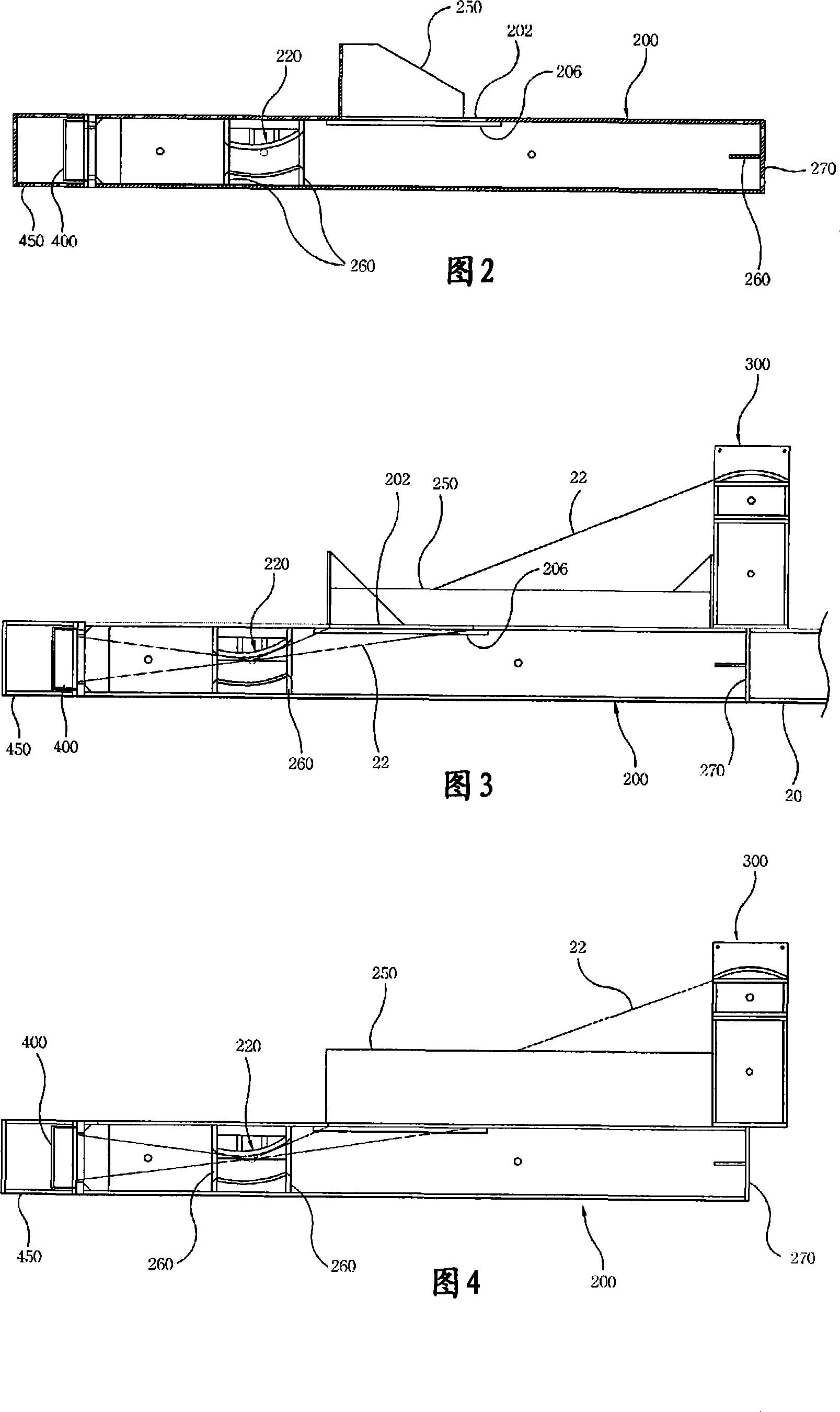

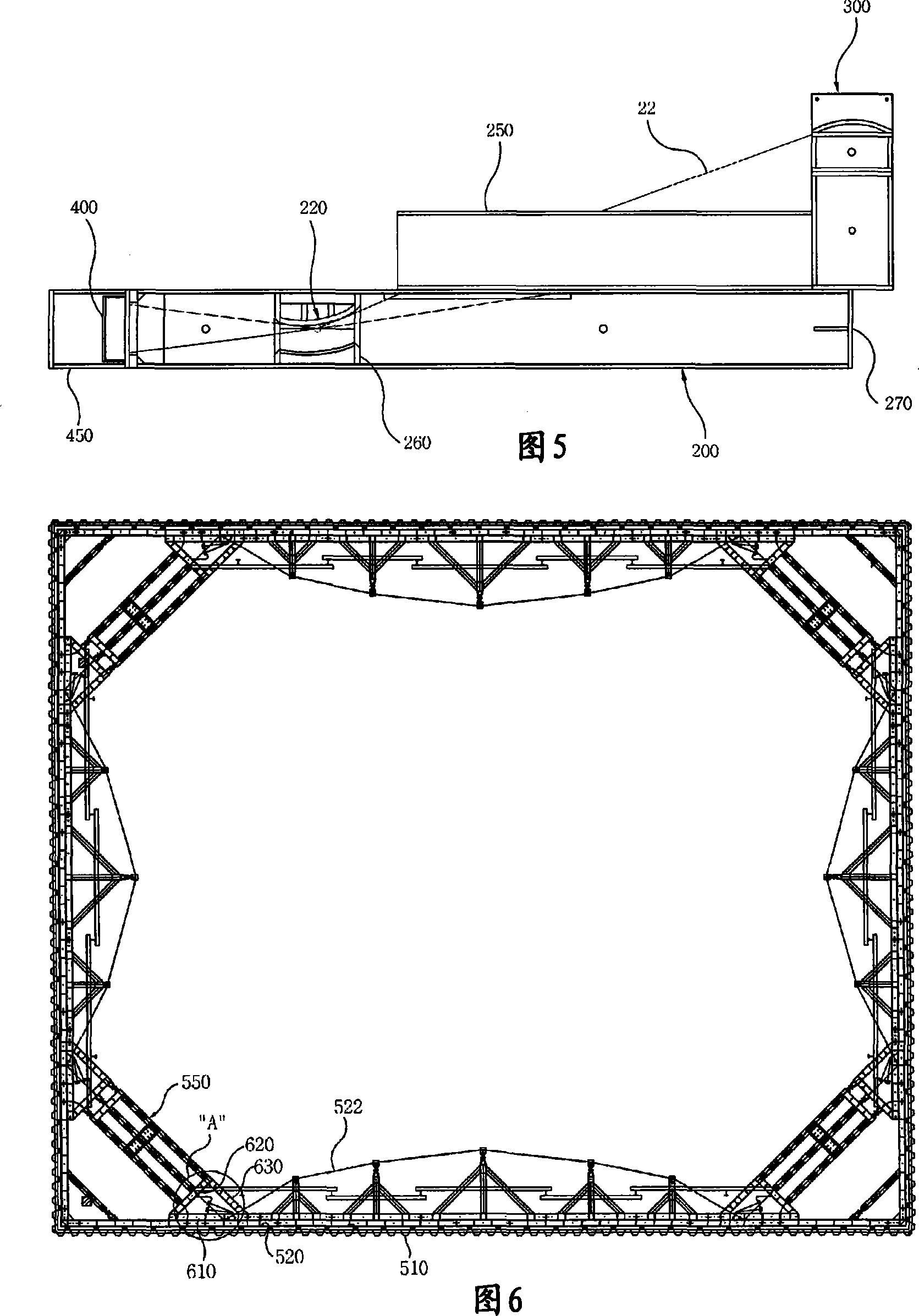

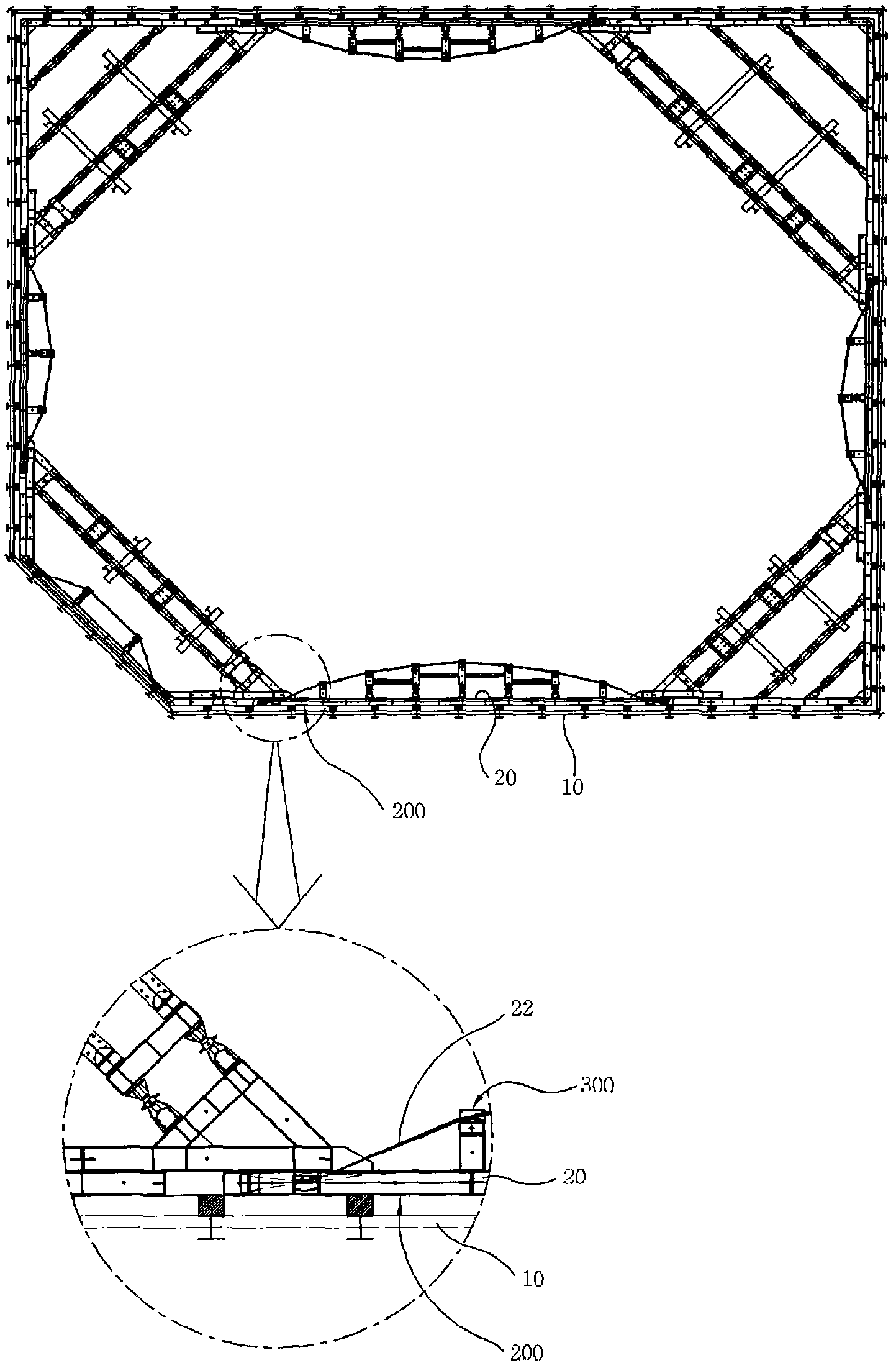

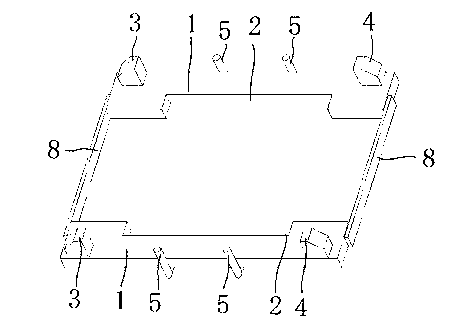

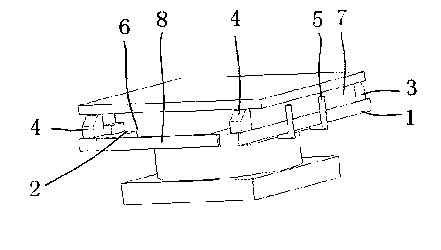

Apparatus for fixing a wale

The present invention provides an apparatus for fixing a steel wire of a wale. In an embodiment, the present invention has an improved structure capable of fixing the steel wire of a prestressed wale at a location spaced apart from one end of the wale during pit excavation work for constructing an underground structure. The fixing apparatus prevents a sharp angle from being formed in the steel wire, and instead allows the steel wire to extend in the form of an arc shape, thus securing sufficient moment. The fixing apparatus provides strong reinforcement of parts to which high compressive force and high tensile force are applied. In another embodiment, the present invention has an improved structure capable of supporting a bracing beam and fixing and tensioning the steel wire in the bracing beam in corners during pit excavation work. At the corner, the fixing apparatus forms a triangular structure which can stably support the bracing beam and can fix and tension the steel wire at the same time, thus improving work efficiency. Further, the fixing apparatus has a simple structure, thus reducing the consumption of materials and reducing construction expenses.

Owner:SUPPORTEC CO LTD

K plate reinforcement device and reinforcement method thereof

PendingCN108590177ASolve the problem of weak reinforcementSimple structureAuxillary members of forms/shuttering/falseworksForming/stuttering elementsArchitectural engineeringUltimate tensile strength

The invention relates to a K plate reinforcement device and a reinforcement method. The reinforcement device comprises a reinforcement piece, a top supporting piece and an adjusting piece, wherein thereinforcement piece is attached and fixed on the one side, away from the K plate, of the transverse dorsal bar; the top supporting piece is vertically fixedly arranged at the end, near an aluminum alloy formwork located under the K plate, of the reinforcement piece, and the end of the top supporting piece is tightly attached to the corresponding aluminum alloy formwork; and the adjusting piece isadjustably connected with the reinforcement piece, the adjusting piece corresponds to the top of the K plate, the adjusting piece is perpendicular to the reinforcement piece, and the end of the adjusting piece is supported at the top of the K plate through adjusting to prevent the top of the K plate from tilting outwards. The K plate reinforcement device and the reinforcement method solve the problem that the K plate is not firmly reinforced, and the molding quality and perception of the external wall are ensured. The reinforcement device can be reused, has light weight, simple structure, convenient installation, and can reduce the labor intensity of field construction.

Owner:中建铝新材料成都有限公司

Titanium-aluminum-based polycrystalline heat-resistant titanium alloy and preparation method thereof

The invention discloses a titanium-aluminum-based polycrystalline heat-resistant alloy and a preparation method thereof. According to the titanium-aluminum-based polycrystalline heat-resistant alloy and the preparation method thereof, the alloy performance is improved through multi-element alloying; an alloy structure evolution path is changed through microalloying; the alloy cast ingot structure is refined by adding boron and carbon; through solid solution and precipitation strengthening, the strength and creep resistance are improved, and the high-temperature oxidation resistance and environment embrittlement resistance are improved; the alloy is strengthened through hot working, heat treatment and rapid cooling phase change; and the high-temperature strength, the fracture toughness and the creep resistance are improved through the lamellar structure of the gamma (TiAl), and the purposes of improving the use temperature and prolonging the high-temperature service life are achieved.

Owner:XINJIANG UNIVERSITY

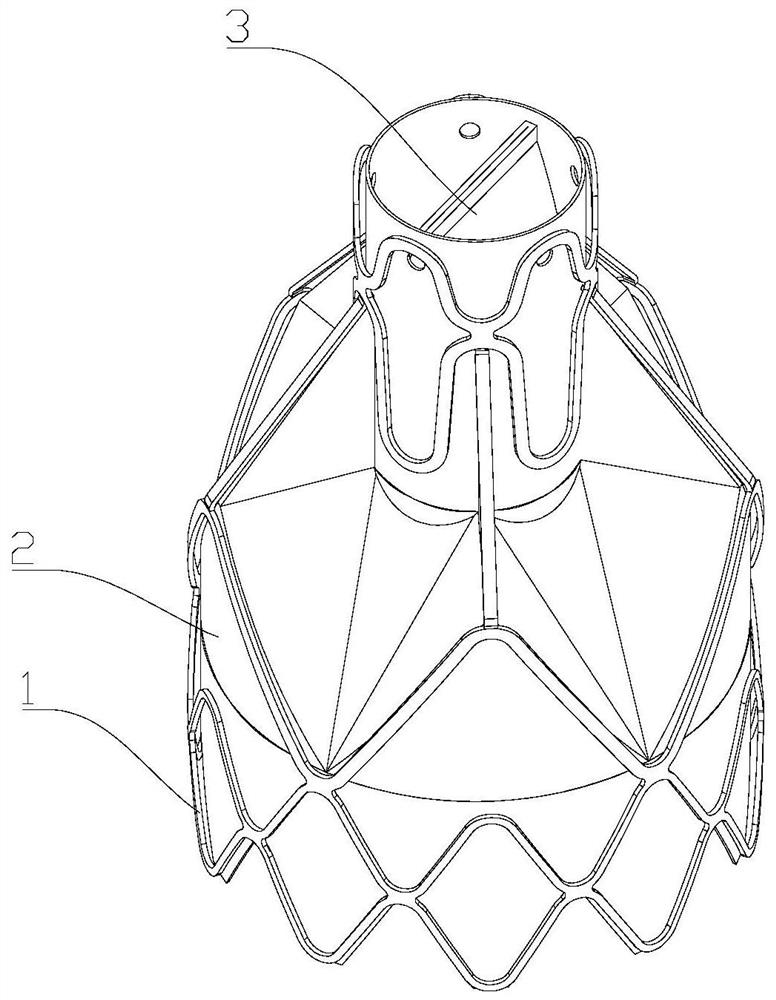

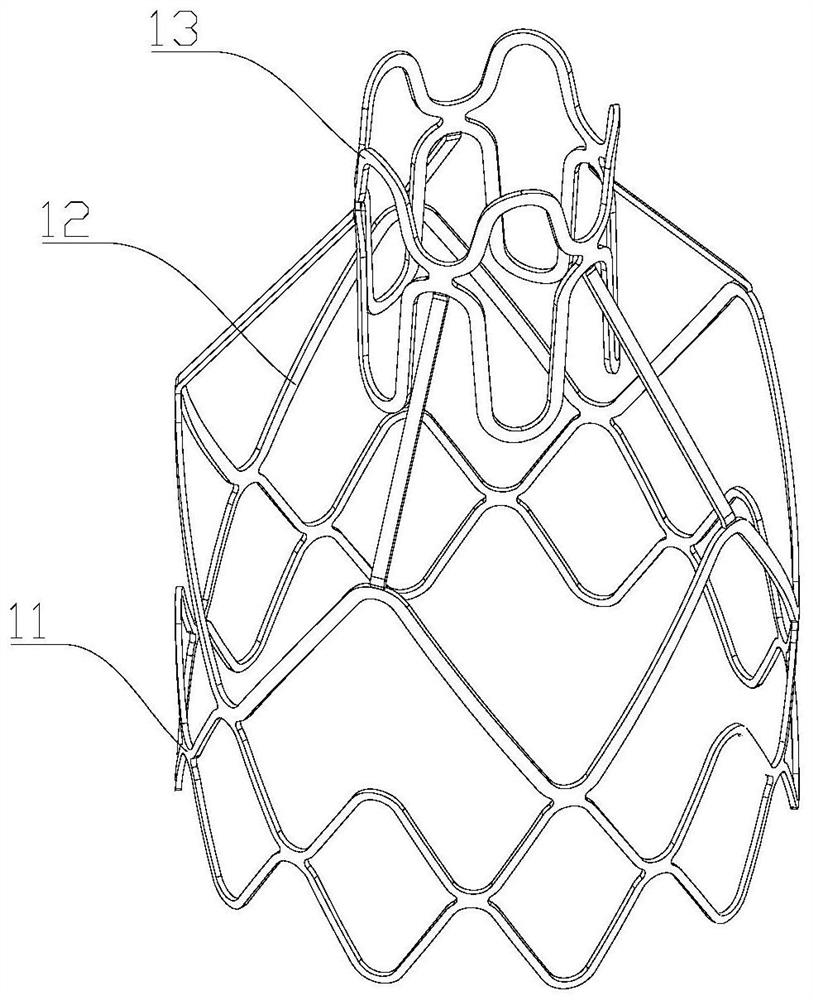

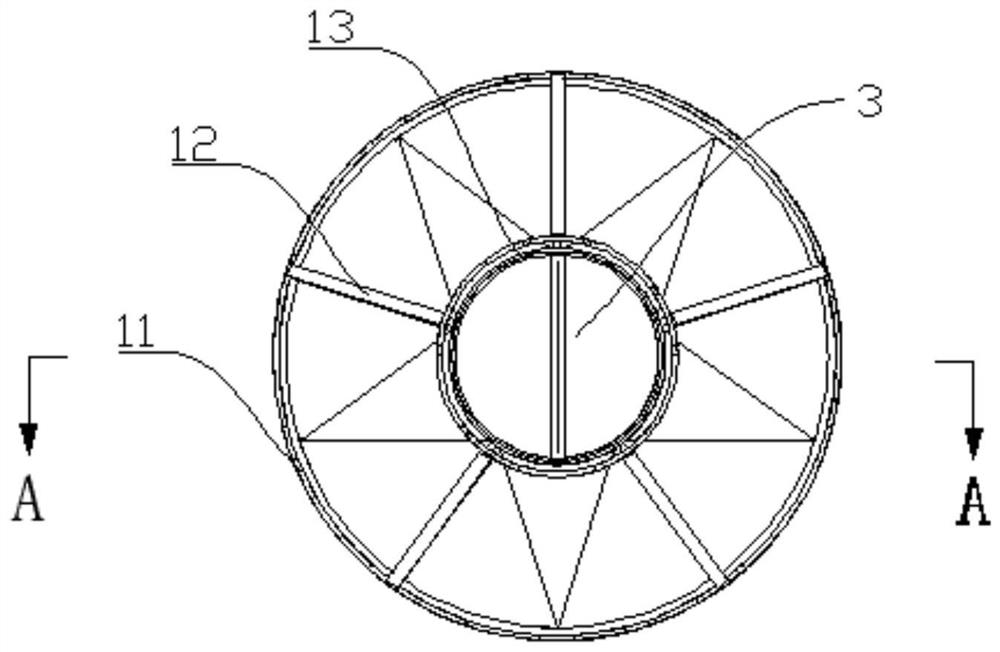

Bronchus one-way valve stent

The invention relates to the technical field of one-way valve stent, in particular to a bronchus one-way valve stent which is used for solving the problems that in the prior art, because of its limitation, a one-way valve stent is easy to deform and can not be restored in the working process, and the service life is short. The bronchus one-way valve stent provided by the invention comprises a stent body, a one-way conducting valve and a covering film, the stent body comprises a large-end stent section, a transition stent section and a small-end stent section which are sequentially connected from bottom to top, the large-end stent section and the small-end stent section are both cylindrical, and the transition stent section is conical. The large-end stent section and the small-end stent section are connected through the transition stent section, during use, the transition section can effectively prevent the whole stent body from forming rigid connection and difficult restoring the after deformation, so that the force on the the large-end stent section, the small-end stent section and the whole covering film can be effectively buffered and balanced, therefore, the performance and the service life of the one-way valve stent can be effectively improved.

Owner:郑州蓝跃生物科技股份有限公司

Magnesium phosphate cement with good water resistance and application thereof

ActiveCN111253142AImprove water resistanceGood controllability of coagulation timeSolid waste managementMagnesium phosphateMagnesium orthophosphate

The invention relates to the technical field of building materials, in particular to magnesium phosphate cement with good water resistance. The cement disclosed by the invention is prepared from the following raw materials in parts by weight: 50 to 100 parts of pre-modified caustic calcined magnesite, 15 to 30 parts of composite acidic phosphate, 6 to 12 parts of a water-reducing retarder, 6 to 12parts of a pH value regulating agent, 20 to 40 parts of ultrafine filling aggregate, 0.5 to 1.5 parts of a composite expansion component, 0.5 to 2 parts of a slow-release hydrophobic component and 0.5 to 2 parts of a thixotropic lubricant. The invention also provides a preparation method of the cement. The magnesium phosphate cement with good water resistance has the characteristics of good waterresistance, high setting time controllability, good construction performance, early strength, high strength, high bonding strength, strong rib protection performance and good aging resistance.

Owner:山东坊能新动能科学研究院有限公司

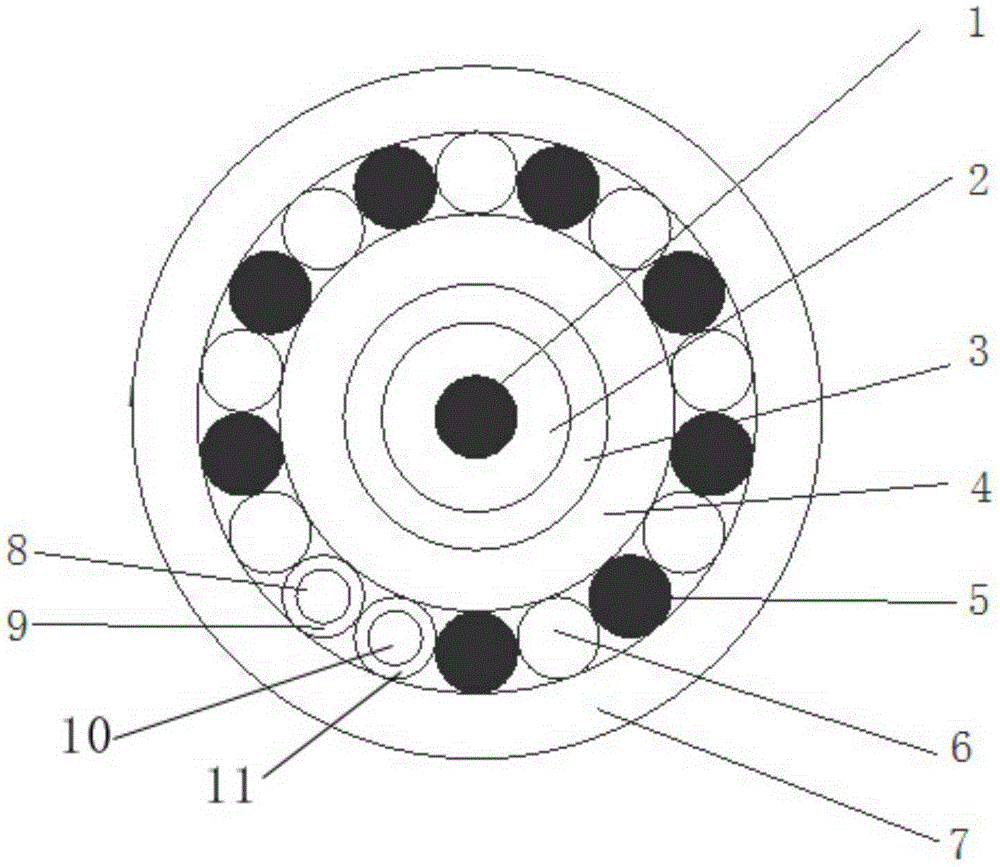

Reinforced high-power optical fibre composite control cable

InactiveCN105405507ASimple structureSmall outer diameterInsulated cablesInsulated conductorsUltrasound attenuationElectrical conductor

The invention discloses a reinforced high-power optical fibre composite control cable. The reinforced high-power optical fibre composite control cable comprises an inner conductor centre reinforced core, a buffer layer, an inner hollow conductor, an insulation layer, an outer conductor and an outer sheath from inside to outside; and bearing metal wires and conductive single wires of the outer conductor same in number are wound at intervals and then combined with one optical fibre unit and one control insulation wire core, such that the outer conductor is formed. The reinforced high-power optical fibre composite control cable disclosed by the invention is high in self-bearing reinforcement performance, low in attenuation and good in shielding effect and has the effects of transferring and controlling signals simultaneously.

Owner:JIANGSU LONG E CABLE

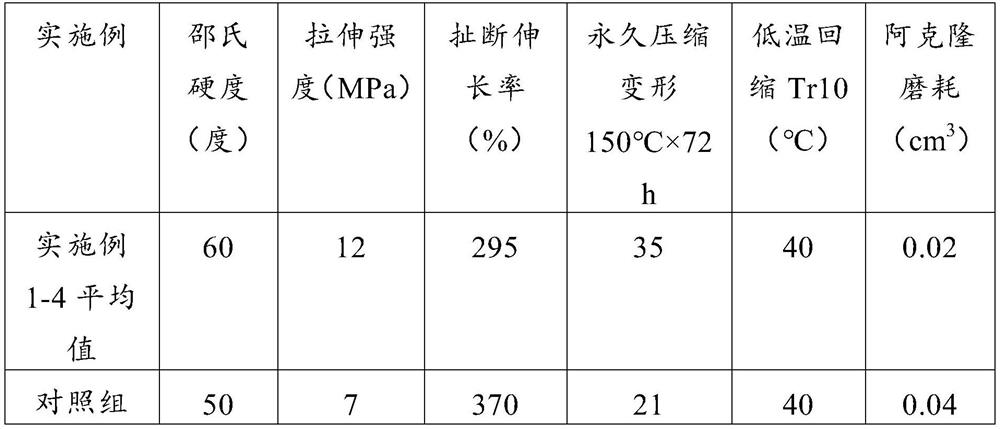

Low-temperature-resistant and low-pressure-change hydrogenated butadiene-acrylonitrile rubber for wind power and preparation method thereof

The invention discloses low-temperature and low-pressure-change-resistant hydrogenated nitrile rubber for wind power and a preparation method, and particularly relates to the technical field of rubber, and the low-temperature and low-pressure-change-resistant hydrogenated nitrile rubber is prepared from the following raw materials in parts by weight: 100 parts of hydrogenated nitrile rubber, 30-50 parts of filler, 10-30 parts of plasticizer, 1-5 parts of anti-aging agent, 1-10 parts of vulcanizing agent, 1-10 parts of accelerant and 1-20 parts of argil. The hydrogenated butadiene-acrylonitrile rubber prepared by the invention has excellent low temperature resistance, oil resistance and heat resistance, and good wear resistance; during preparation, the filler and the plasticizer are added in stages, so that the dispersity of rubber components is guaranteed, and in addition, the heat-resistant inorganic filler is added and dispersed in the rubber, so that the rubber is less affected by pressure change, and the service life of the rubber is prolonged. Therefore, the hydrogenated butadiene-acrylonitrile rubber prepared by the invention can be widely applied to a wind power equipment sealing environment with a severe climatic environment to replace foreign products.

Owner:陕西奉航科技有限责任公司

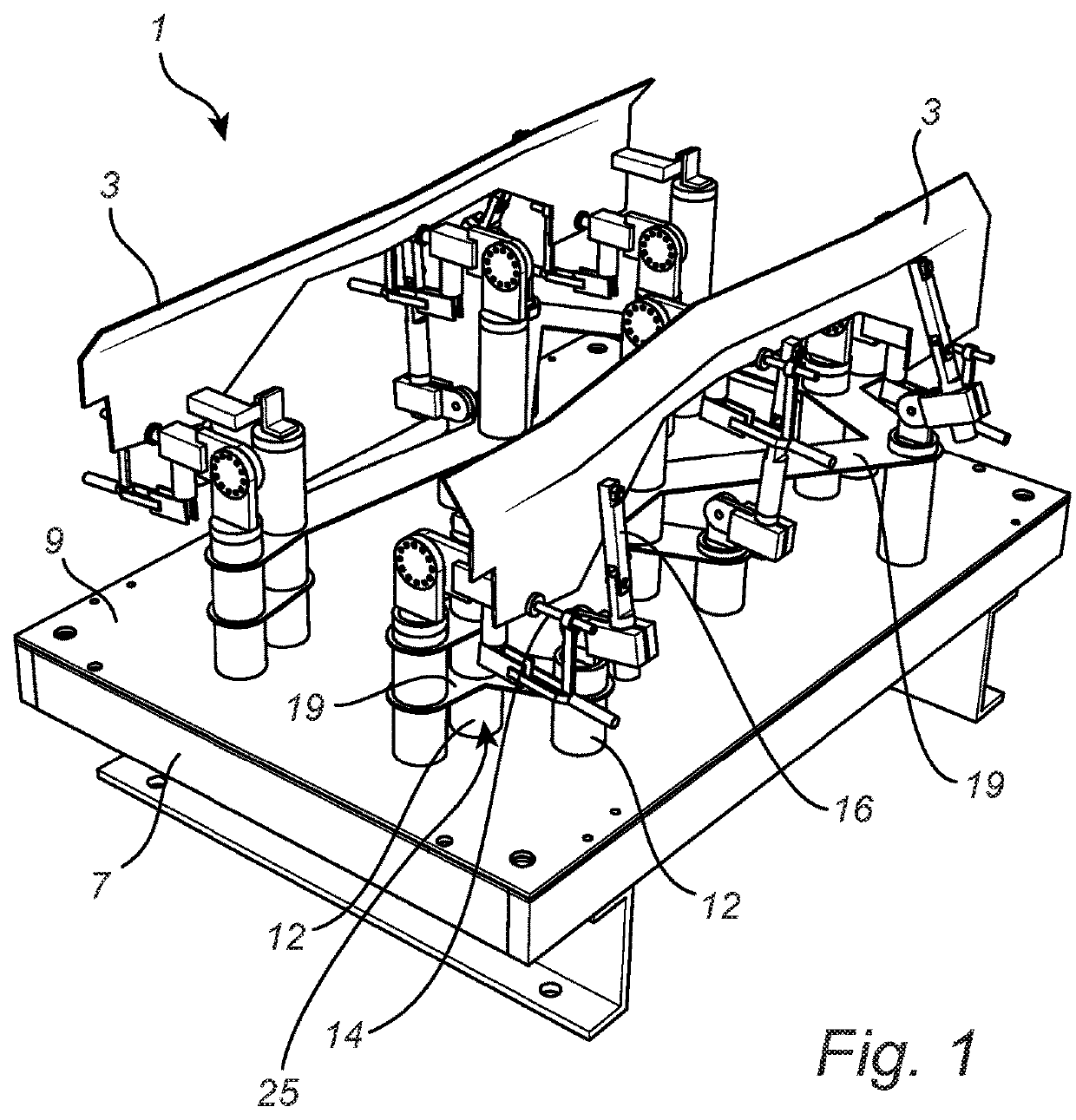

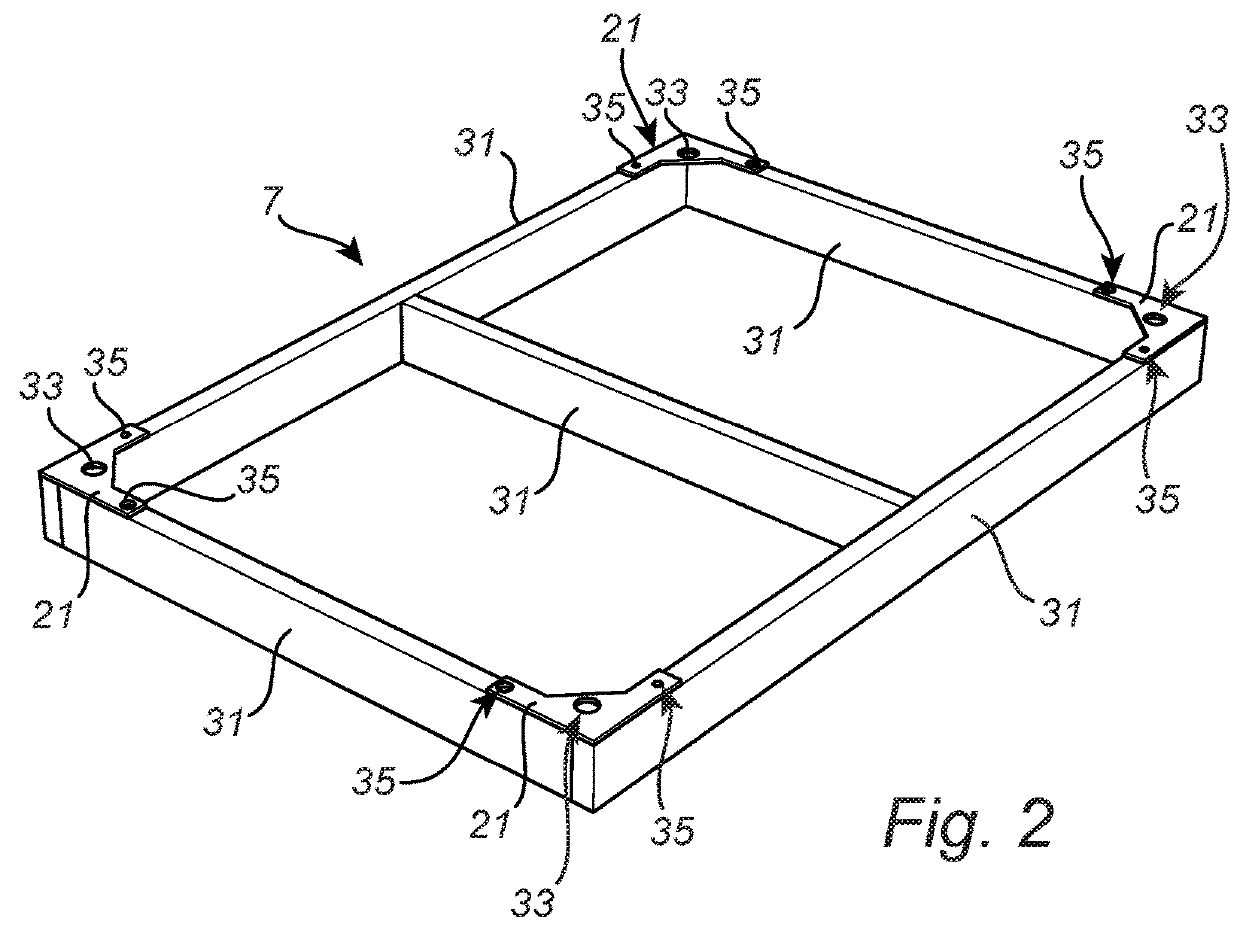

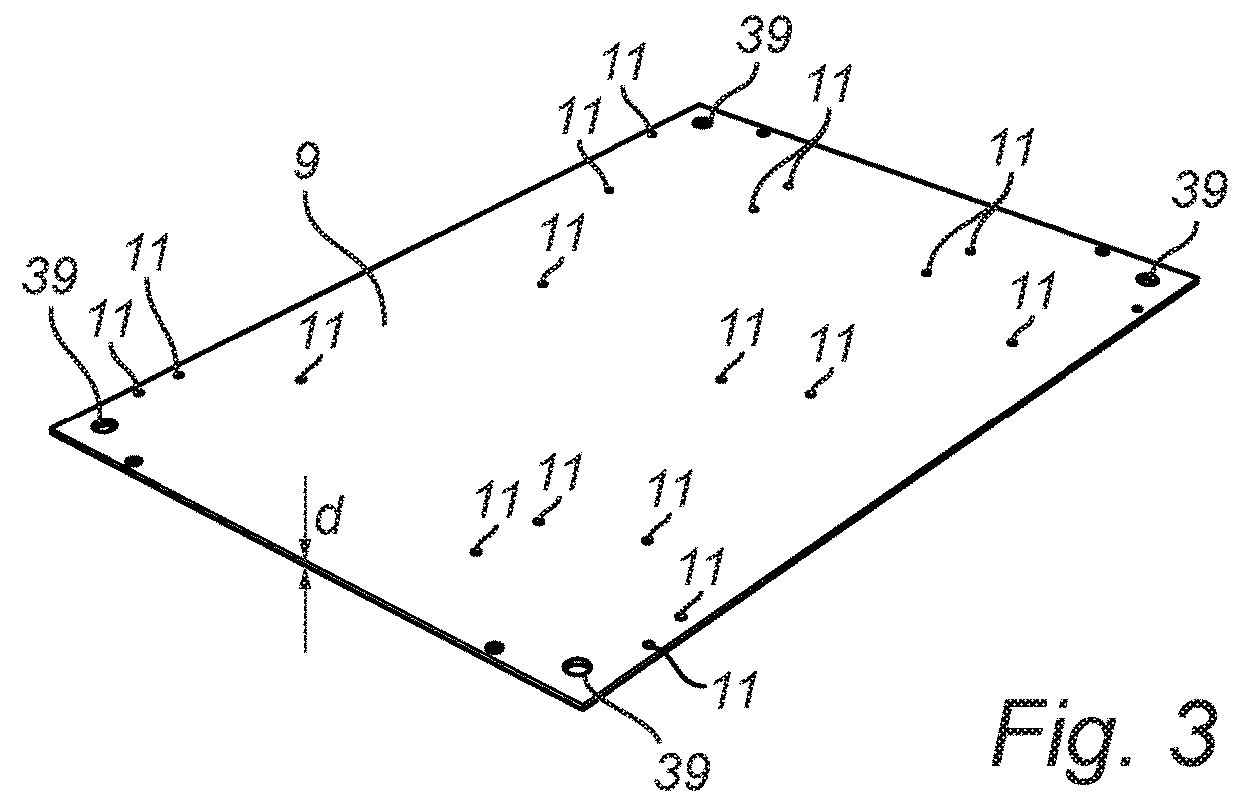

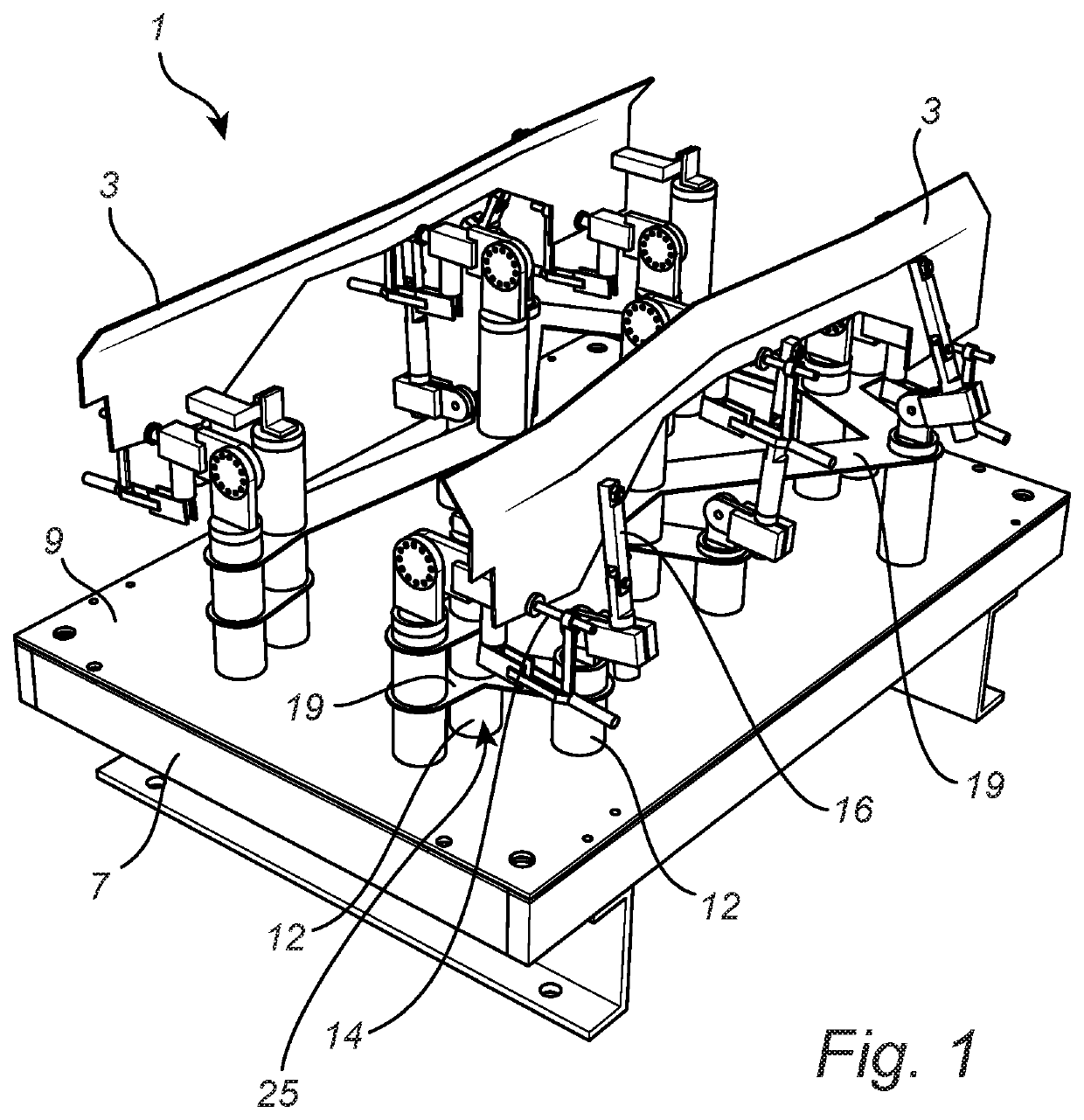

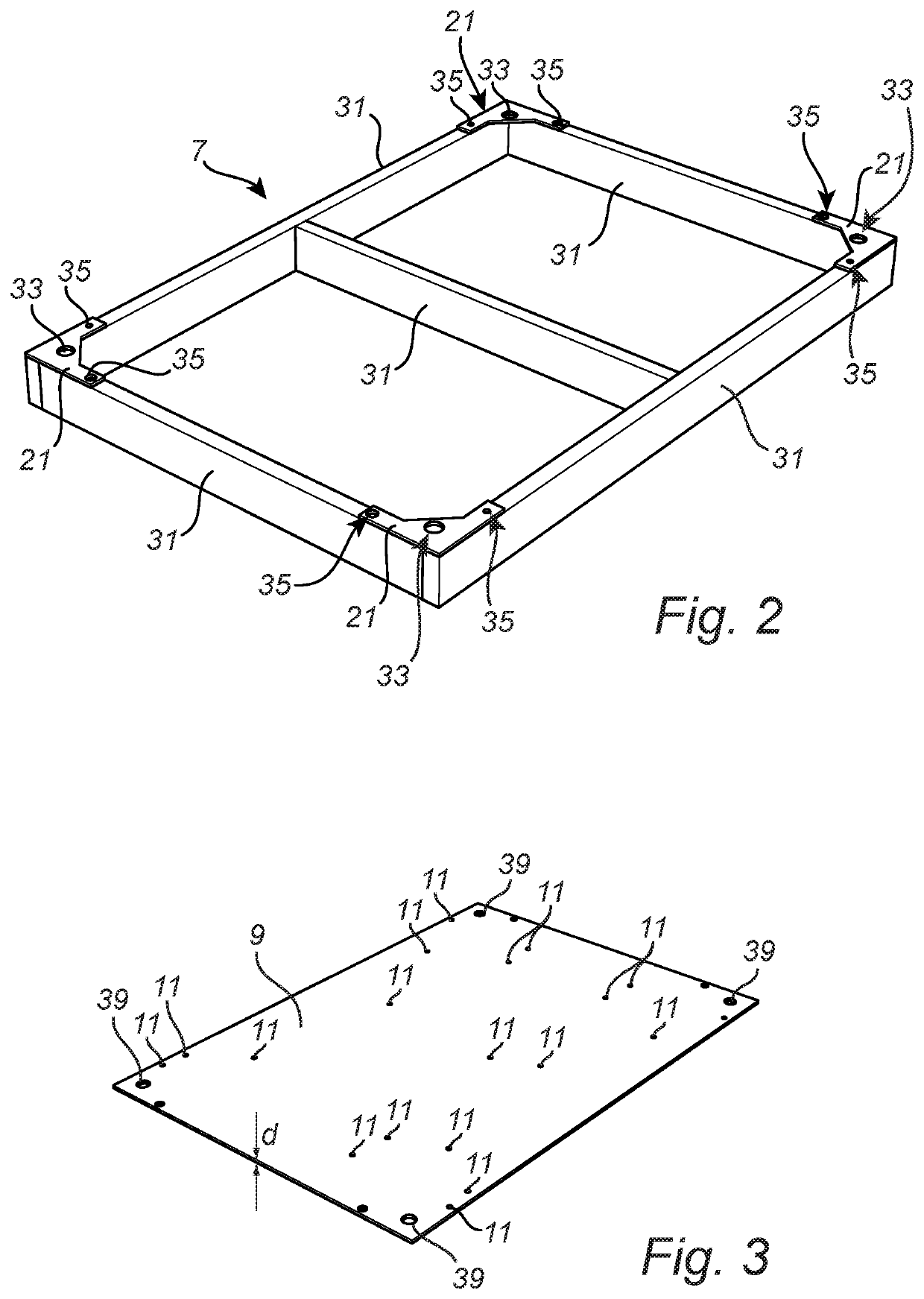

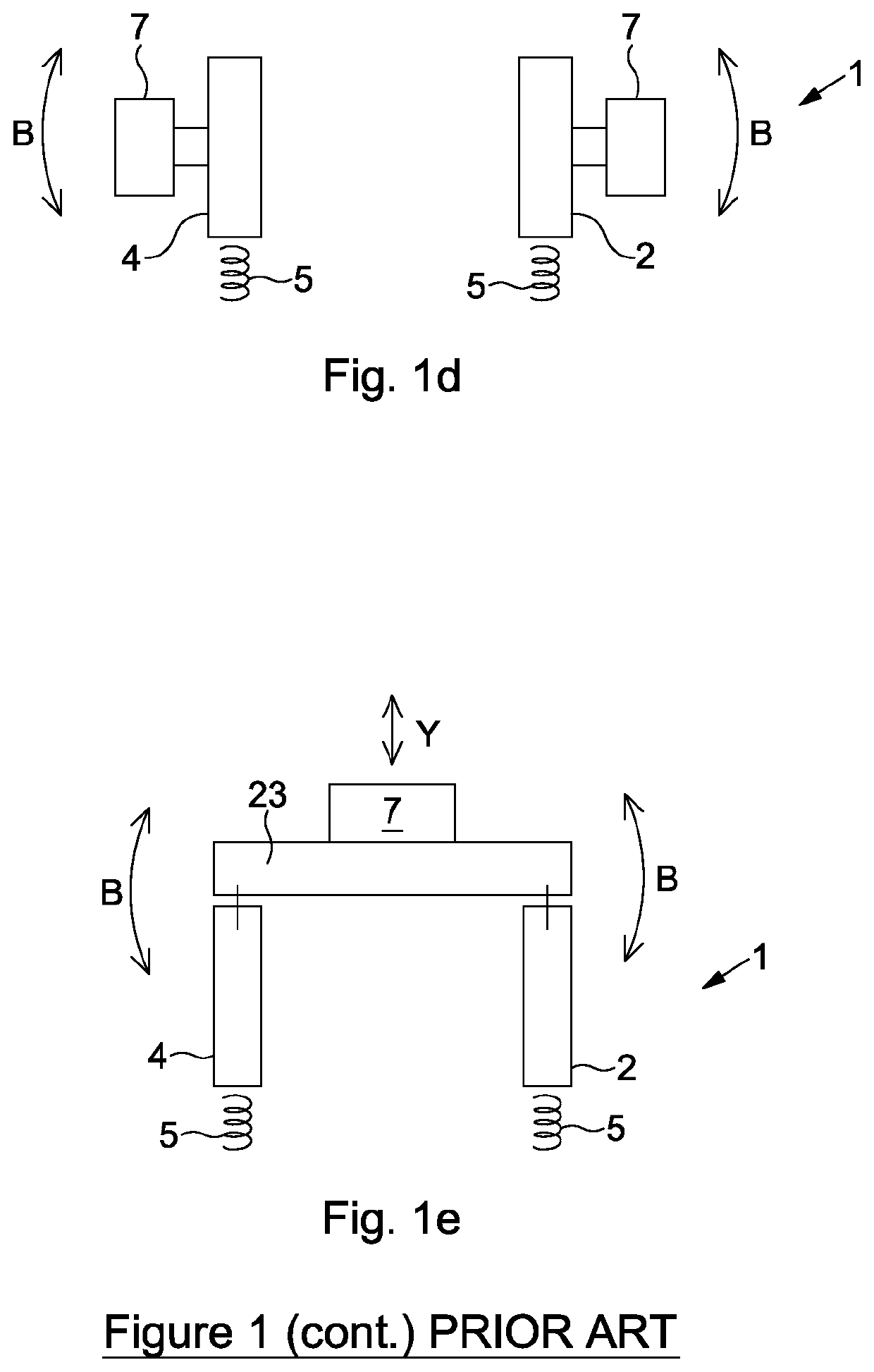

Checking fixture

ActiveUS20180265148A1Easy to produceEasy to manufactureOther manufacturing equipments/toolsVehicle design optimisationMeasurement deviceEngineering

The present invention relates to a checking fixture comprising: a bottom support frame; a metallic support sheet mechanically fixated to the bottom support frame, the metallic support sheet comprising a plurality of through holes arranged in a predetermined layout; a plurality of holder members for holding vehicle component holders or vehicle component measurement devices, the holder members being attached to the metallic support sheet in the through holes and being adapted to extend away from an upper surface of the metallic support sheet; at least one metallic sheet reinforcement structure arranged orthogonally separated from the metallic support sheet, the metallic sheet reinforcement structure being adapted to fixate the relative position of at least two of the holders members. The metallic support sheet and the metallic reinforcement sheet structure are made from laser cut sheet material.

Owner:VOLVO CAR CORP

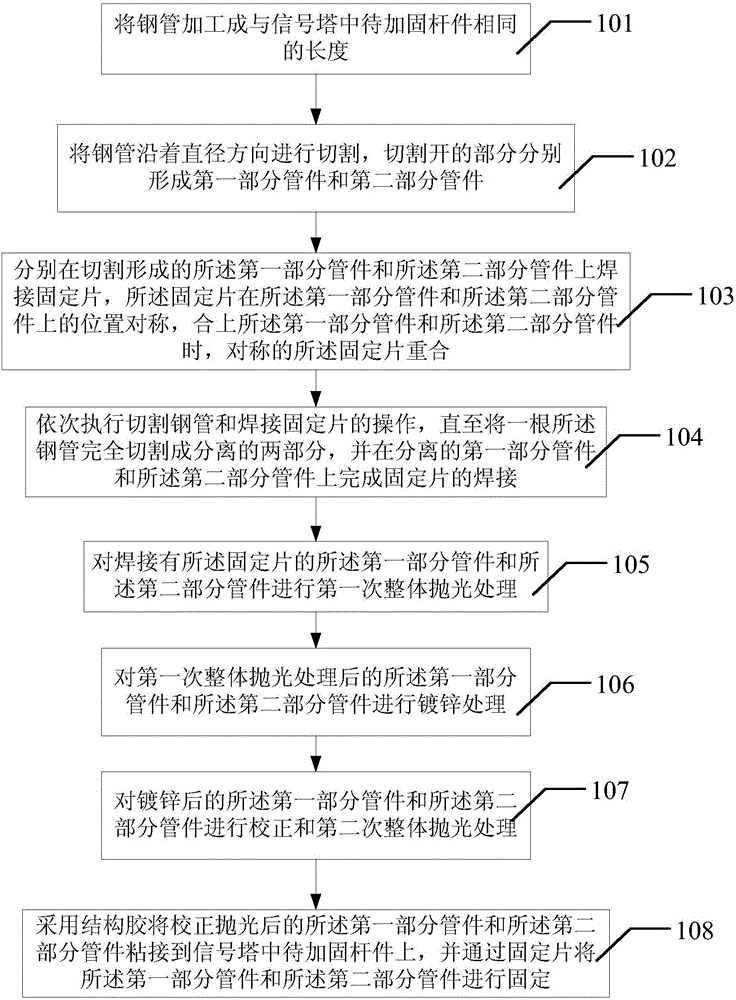

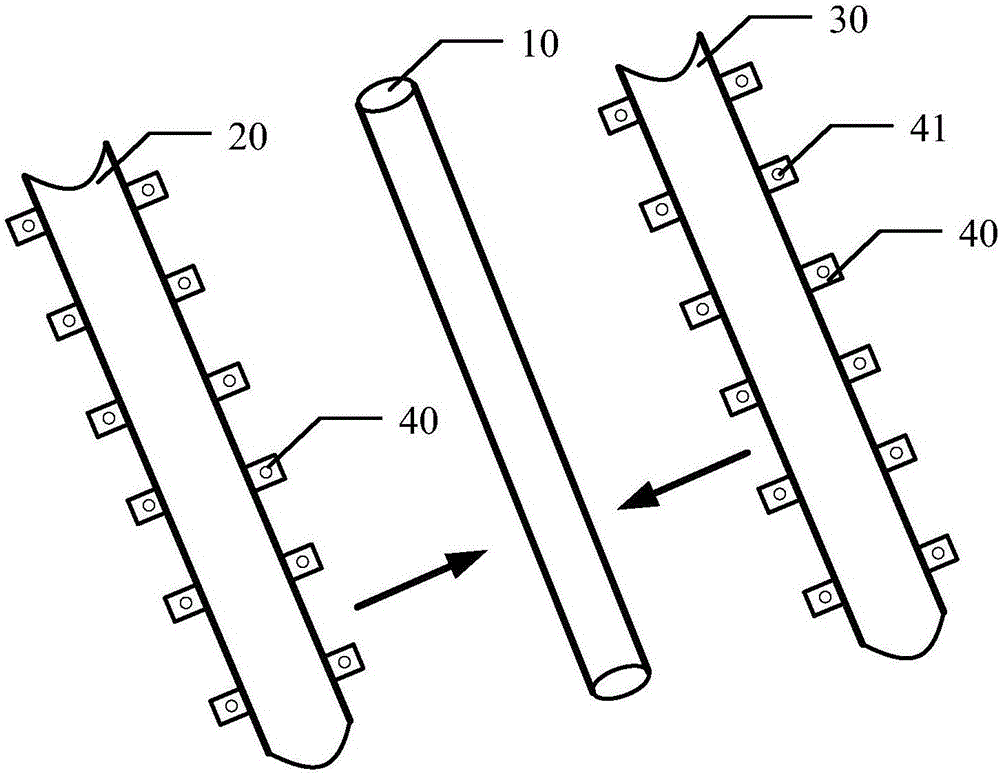

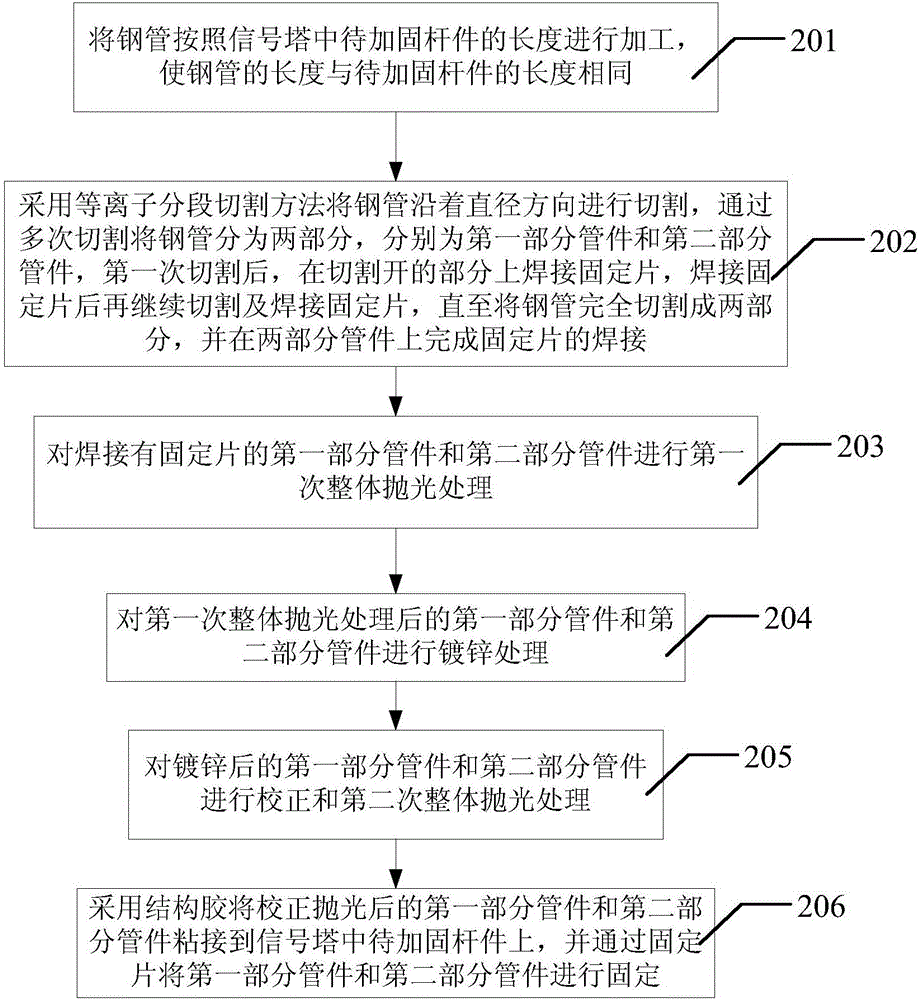

Reconstruction and reinforcement method for signal tower in communication base station and reinforced signal tower

InactiveCN106245925AIncreased cross-sectional areaImprove stabilityBuilding repairsTowersSteel tubeEngineering

The invention discloses a reconstruction and reinforcement method for a signal tower in a communication base station and a reinforced signal tower. The reconstruction and reinforcement method comprises the steps that first tubes and second tubes are manufactured; and structural adhesives are adopted for bonding the corrected and polished first tubes and the corrected and polished second tubes to a to-be-reinforced rod piece in the signal tower, and the first tubes and the second tubes are fixed through fixing pieces. Thus, the first tubes and the second tubes are bonded to the outer portion of the to-be-fixed rod piece through the structural adhesives by adoption of the method of enlarging the cross section and improving the stability through bonding, then the first tubes and the second tubes are fixed through bolts and made to tightly cover the to-be-fixed rod piece, pressure borne by the rod piece is transmitted through the bonding force of the structure adhesives and the friction force between the steel tubes, the structural adhesives, the tubes and the rod piece bear stress together, the cross section area of the rod piece is increased, and the rod piece is also reliably reinforced.

Owner:ZHONGTA XINXING COMM TECH

Aircraft structural component that is adapted for absorbing and transmitting forces in an aircraft

ActiveUS10399658B2Reduce weightIncrease resistanceFuselage framesMaterial gluingAirplaneStructural component

Owner:AIRBUS HELICOPTERS DEUT GMBH

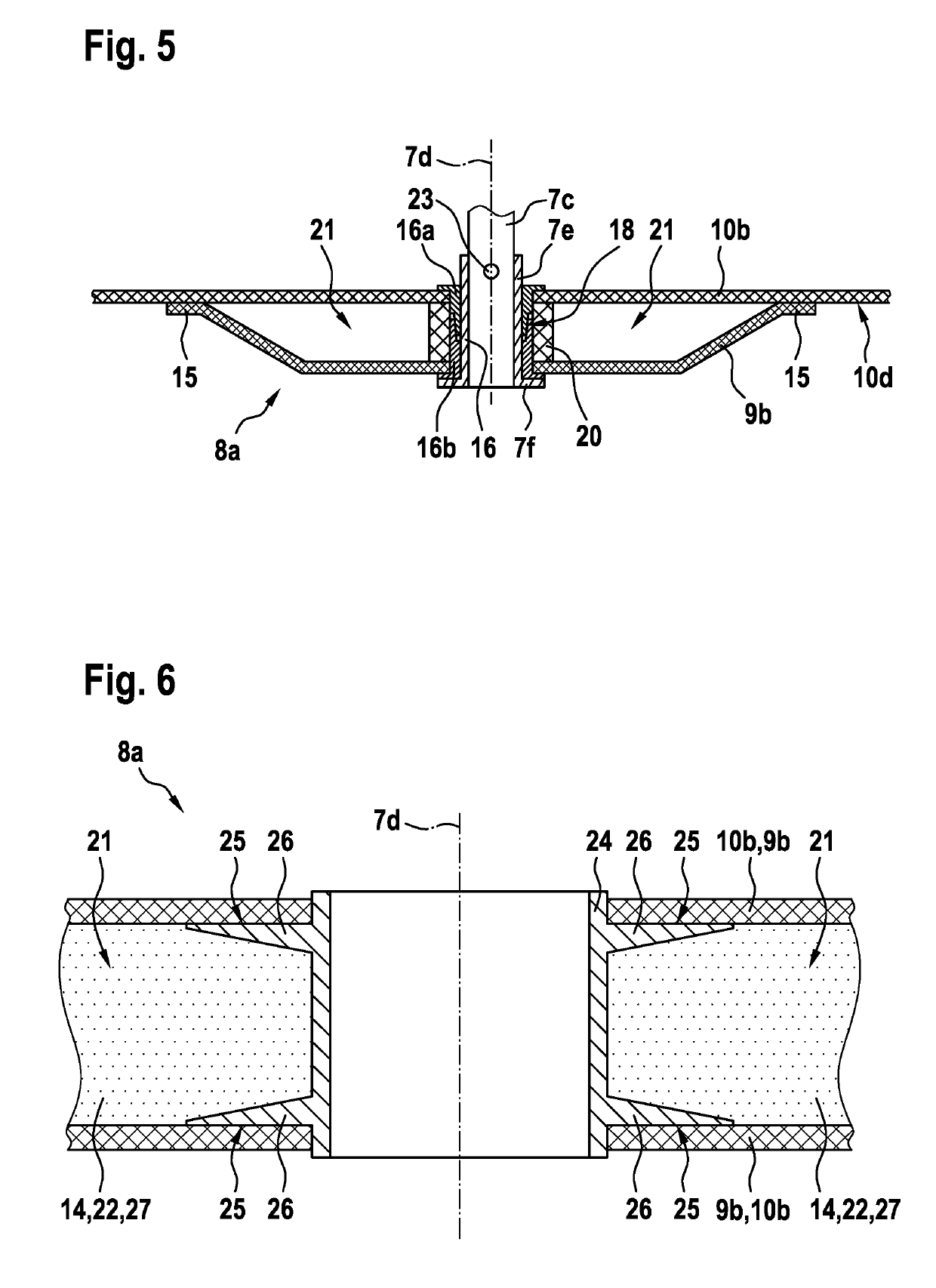

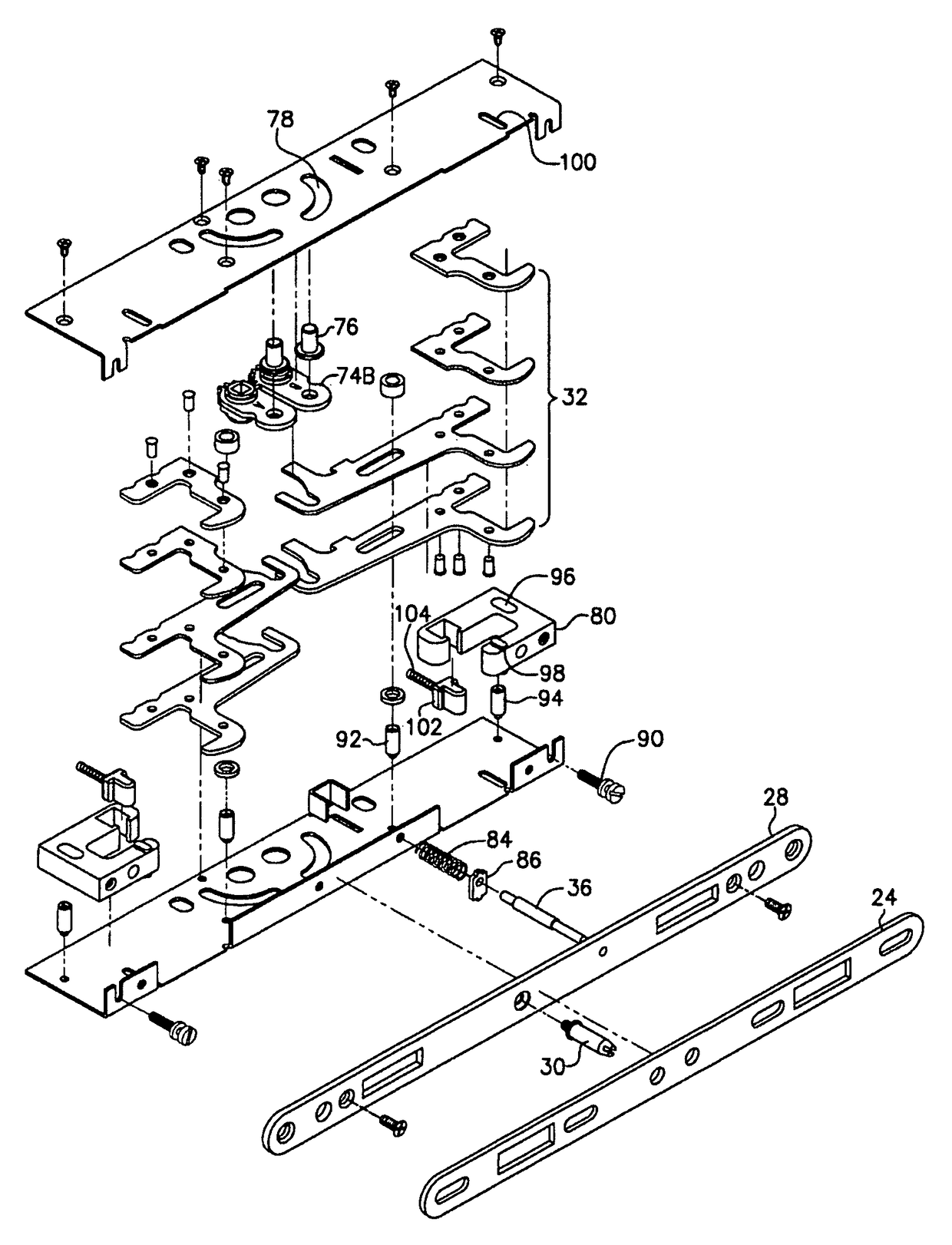

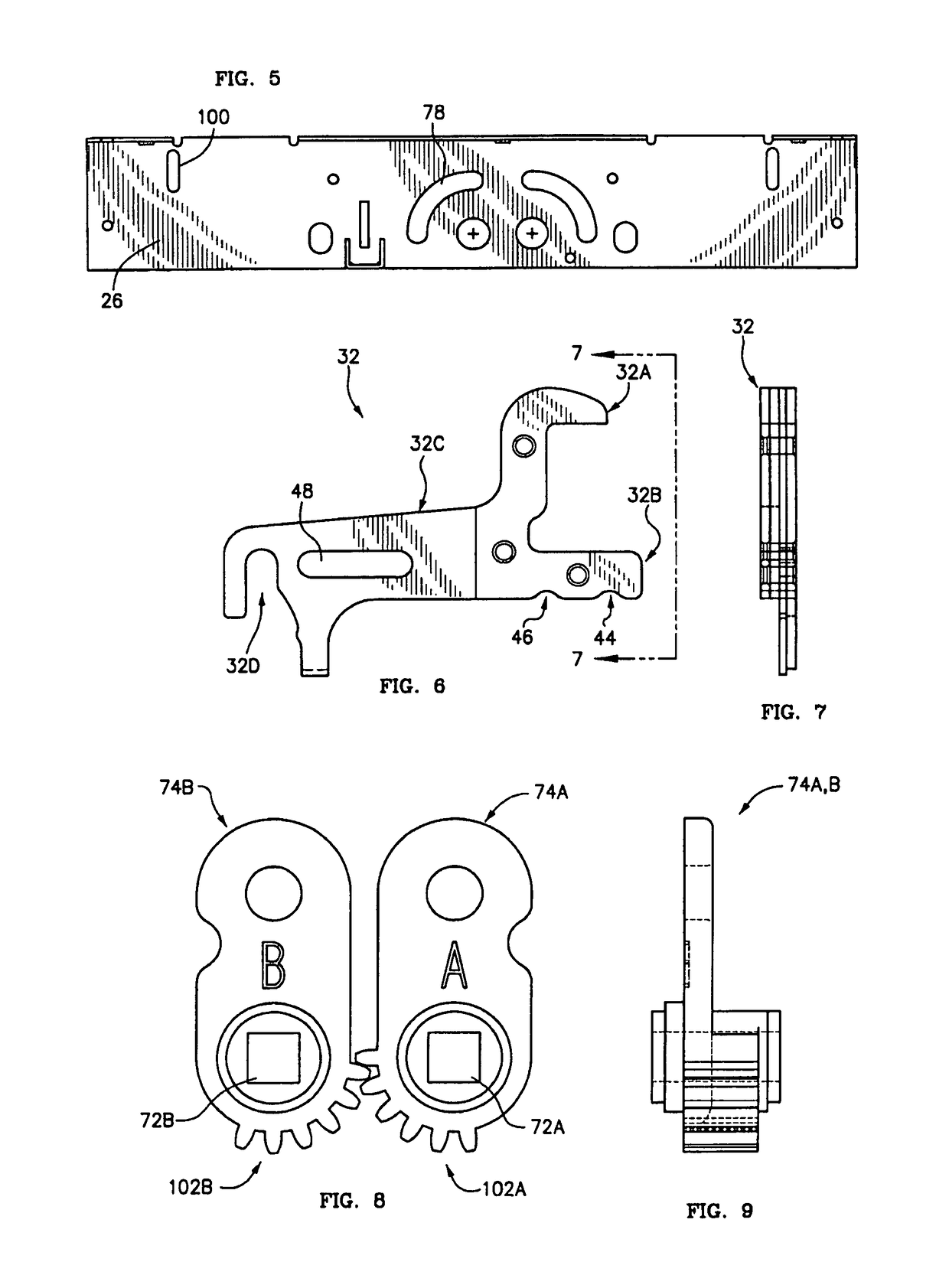

Multi-point sliding door latch

ActiveUS10053897B1Strong reinforcementMinimizing chanceBuilding locksWing fastenersEngineeringActuator

A multi-point sliding door latch intended to fit within standard sized opening in the stile of a sliding door. Preferably the latch has at least two hooks oriented in opposite directions that slide in a generally linear manner between an unlatched and latched position in response to rotation of a pair of actuators located within the latch housing. Preferably, the latch includes reinforcement blocks defining cavities with a portion of the hooks extending into the cavities when the hooks are in the latched position.

Owner:HAUBER PETER

Checking fixture

ActiveUS10625799B2Easy to produceEasy to manufactureOther manufacturing equipments/toolsVehicle design optimisationEngineeringLaser cutting

The present invention relates to a checking fixture comprising: a bottom support frame; a metallic support sheet mechanically fixated to the bottom support frame, the metallic support sheet comprising a plurality of through holes arranged in a predetermined layout; a plurality of holder members for holding vehicle component holders or vehicle component measurement devices, the holder members being attached to the metallic support sheet in the through holes and being adapted to extend away from an upper surface of the metallic support sheet; at least one metallic sheet reinforcement structure arranged orthogonally separated from the metallic support sheet, the metallic sheet reinforcement structure being adapted to fixate the relative position of at least two of the holders members. The metallic support sheet and the metallic reinforcement sheet structure are made from laser cut sheet material.

Owner:VOLVO CAR CORP

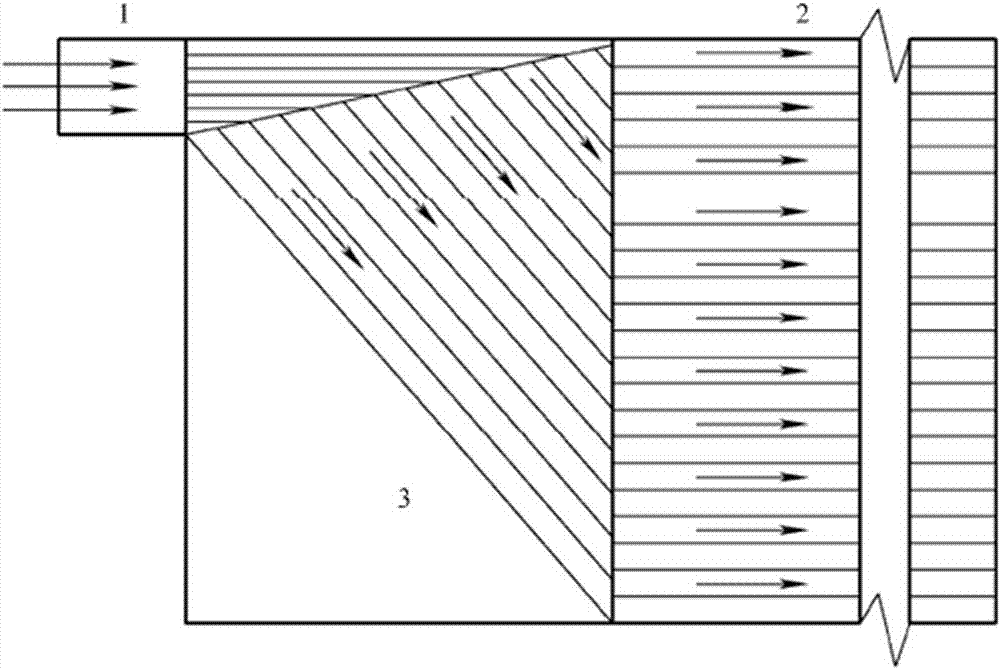

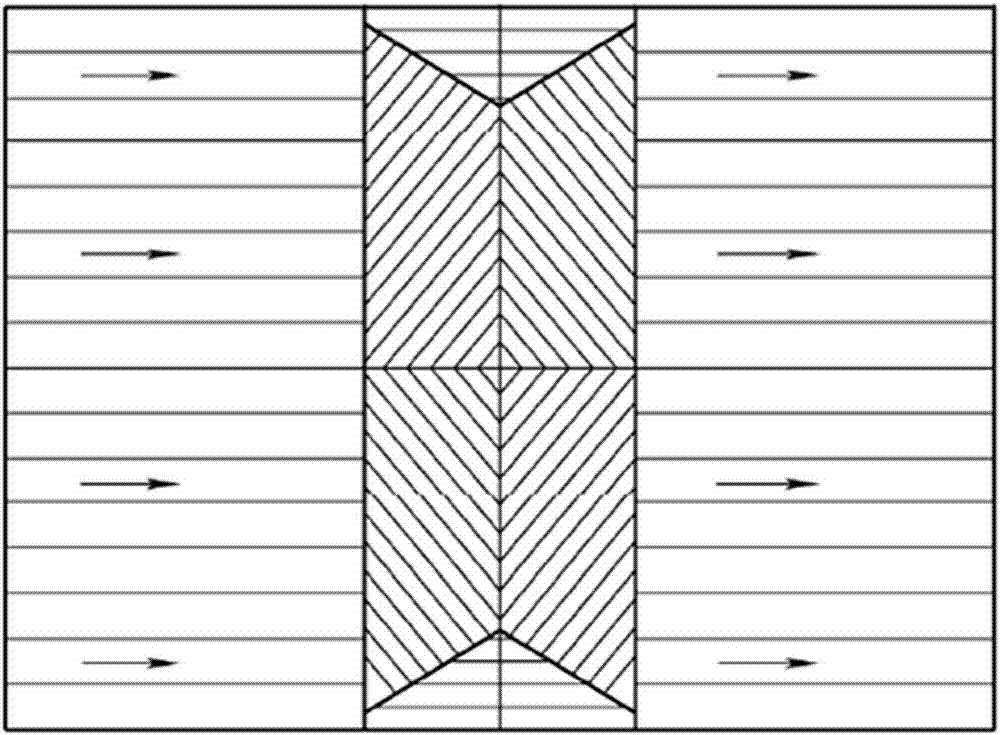

Novel flow-channel plate-fin type heat exchanger

InactiveCN106871673AIncrease the pressure valueEnhanced turbulence effectHeat transfer modificationStationary plate conduit assembliesEngineeringPlate fin heat exchanger

The new flow channel plate-fin heat exchanger adopts a new flow channel, mainly including fins, partitions, and deflectors. Each unit is welded together by vacuum brazing. The fin type in the heat exchange section mainly adopts new Fins, in order to make the pressure of the fluid inside the plate-fin heat exchanger higher than that of the traditional channel structure, to improve the fluid turbulence performance and the turbulent dissipation rate higher than the traditional structure, a new channel structure is adopted in the new channel structure Medium; due to the change of the channel structure, the turbulent dissipation rate of the fluid in the channel is greatly enhanced. Compared with the traditional channel structure, the average value of the turbulent dissipation rate at the inlet increases by 8.1 times, and the turbulent dissipation rate at other positions Both are greatly increased, and the heat dissipation effect is significantly improved.

Owner:李晓波

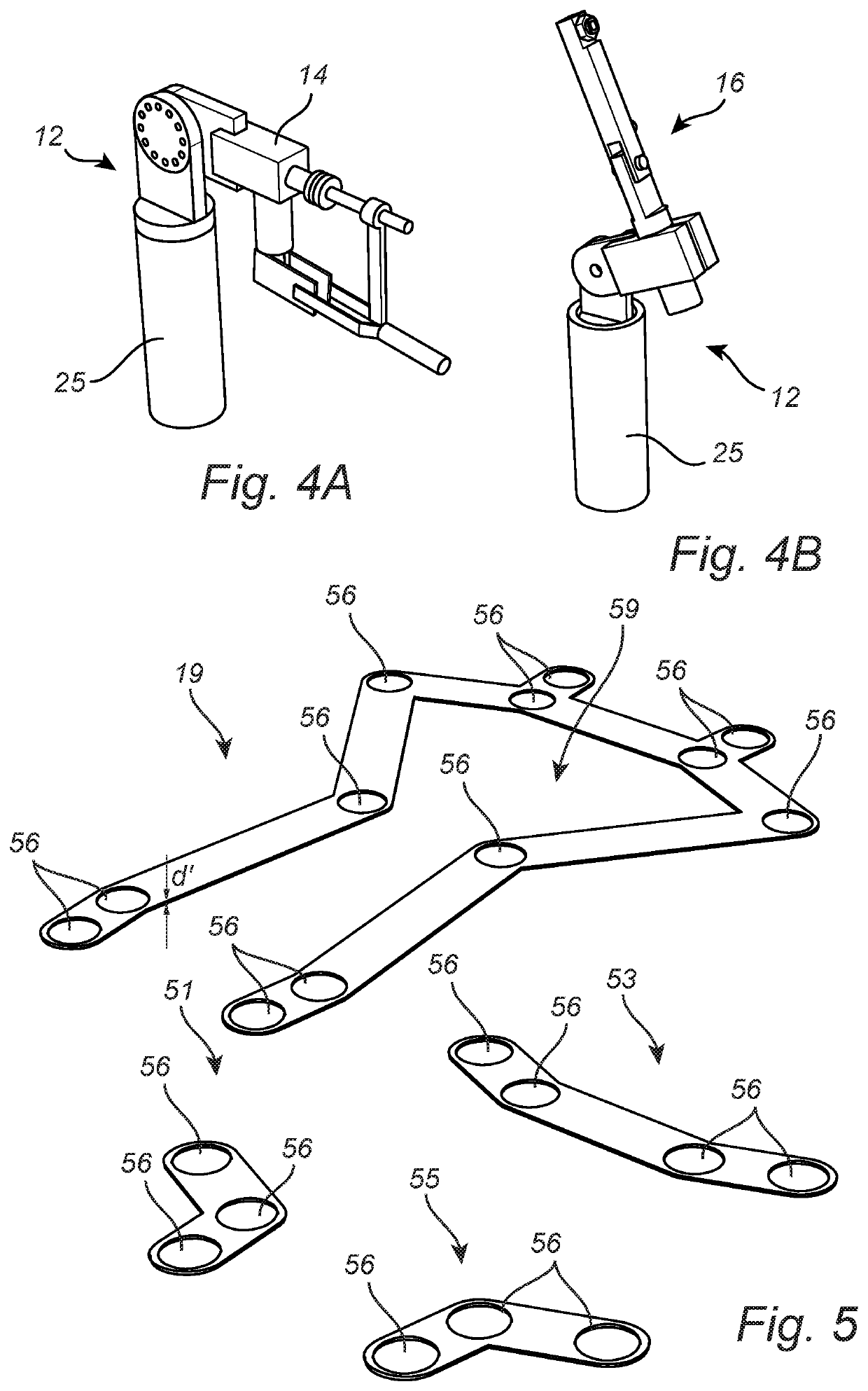

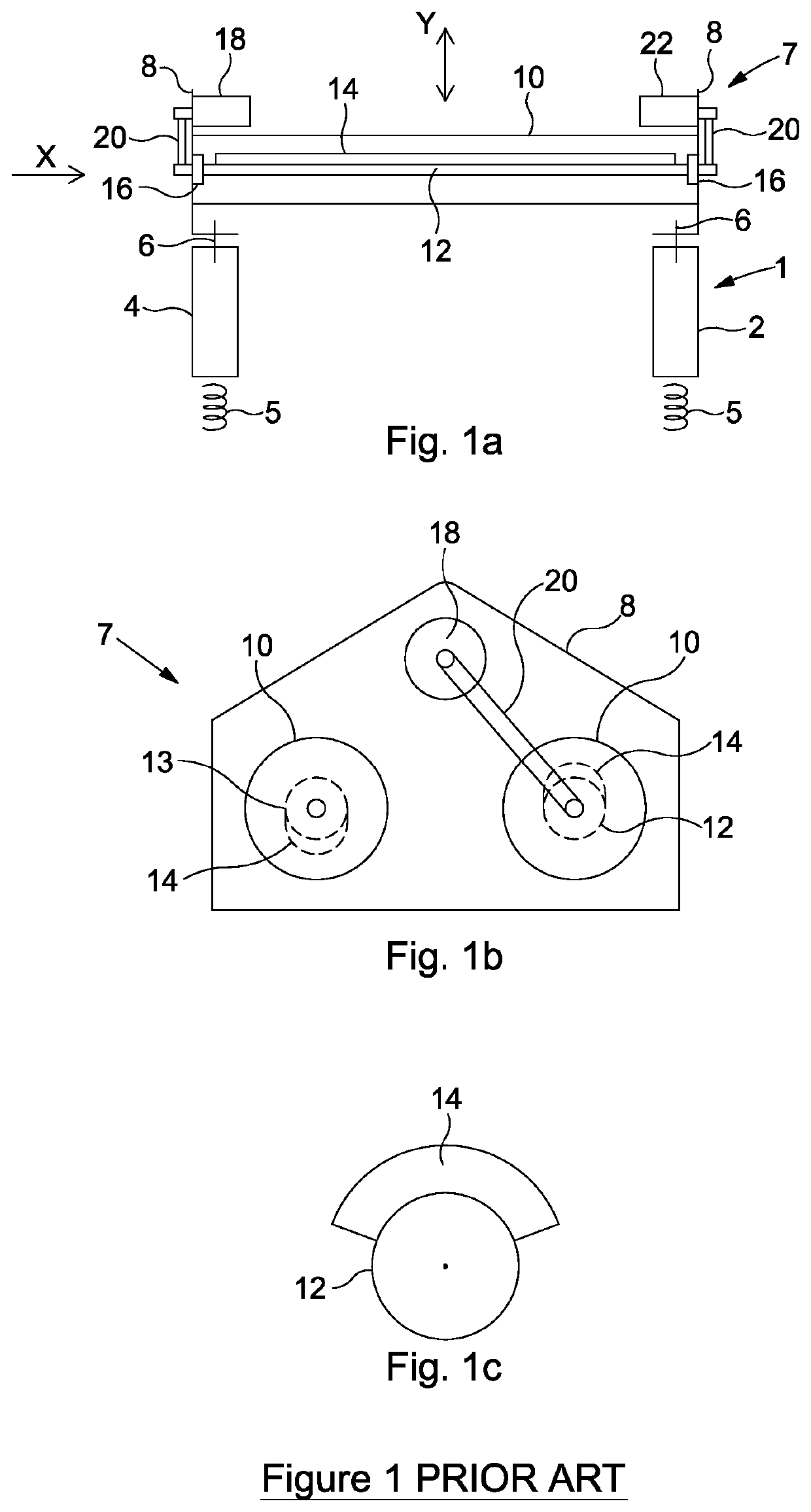

Screening apparatus

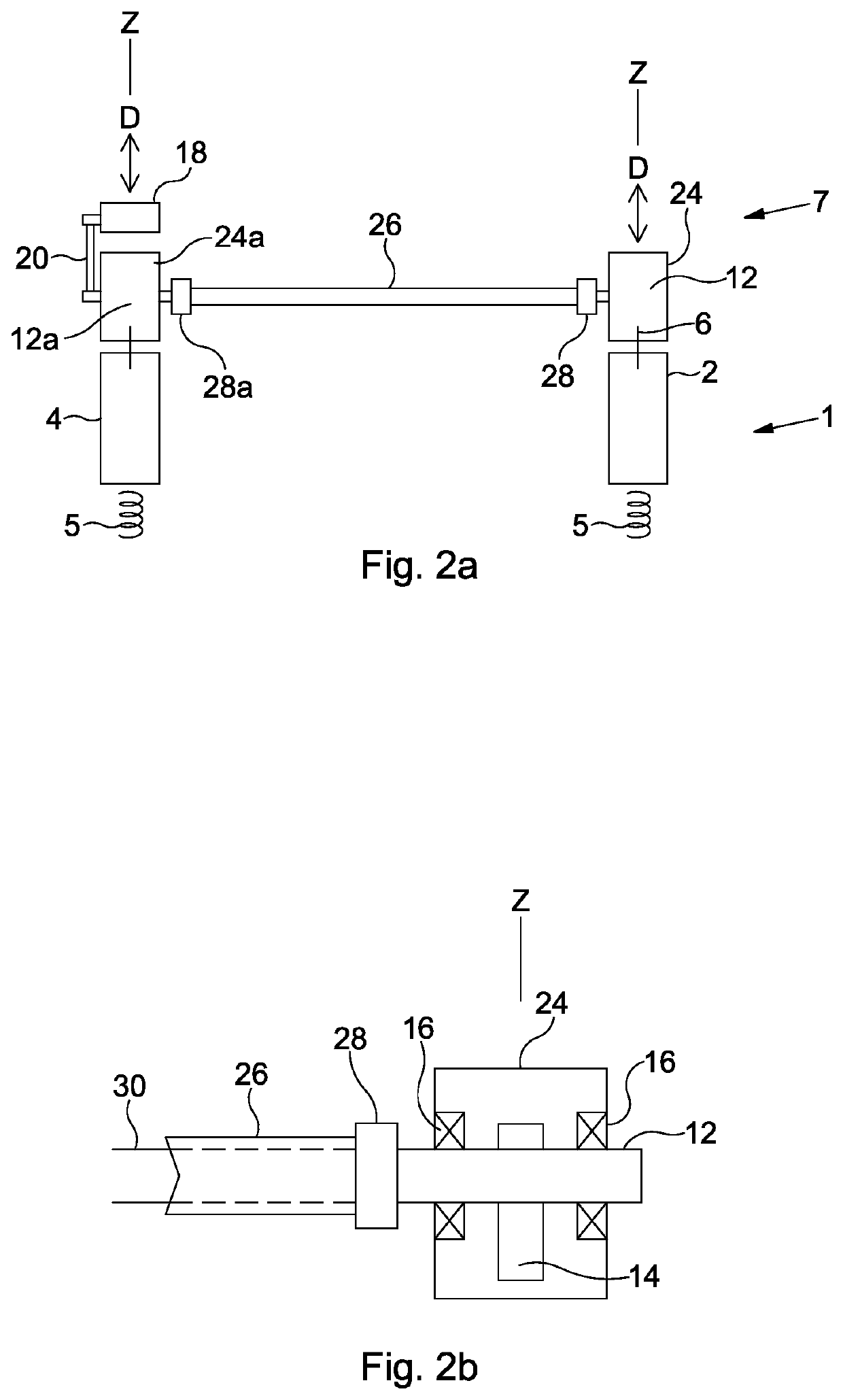

InactiveUS20200238336A1Reduce mechanical complexityStrong reinforcementSievingScreeningEngineeringMechanical engineering

A basket (1) for a shale shaker includes a front, solids discharge end (34) and a rear, feed end (36) spaced apart by opposed first and second sides (2,4). The first and second sides mount a drive mechanism (7). The drive mechanism includes a first eccentrically weighted shaft (12), mounted to the first side (2) of the basket for rotation about an axis transverse to the front to rear direction of the basket; a first shaft drive, coupled to the first shaft (12) and to a corresponding second eccentrically weighted shaft (12a), which is mounted to the second side of the basket (4) for rotation about an axis transverse to the front to rear direction of the basket. A drive module (48, 50) comprising two eccentrically weighted shafts mounted on bearings in a single housing (52) is also described.

Owner:AXIOM PROCESS

Apparatus for fixing a wale

The present invention provides an apparatus for fixing a steel wire of a wale. In an embodiment, the present invention has an improved structure capable of fixing the steel wire of a prestressed wale at a location spaced apart from one end of the wale during pit excavation work for constructing an underground structure. The fixing apparatus prevents a sharp angle from being formed in the steel wire, and instead allows the steel wire to extend in the form of an arc shape, thus securing sufficient moment. The fixing apparatus provides strong reinforcement of parts to which high compressive force and high tensile force are applied. In another embodiment, the present invention has an improved structure capable of supporting a bracing beam and fixing and tensioning the steel wire in the bracing beam in corners during pit excavation work. At the corner, the fixing apparatus forms a triangular structure which can stably support the bracing beam and can fix and tension the steel wire at the same time, thus improving work efficiency. Further, the fixing apparatus has a simple structure, thus reducing the consumption of materials and reducing construction expenses.

Owner:SUPPORTEC CO LTD

Processing technology of Ti5Mo5V2Cr3Al alloy

ActiveCN101543948BImprove malleabilityStrong reinforcementRoll force/gap control deviceTemperature control deviceRoom temperatureTitanium

The invention provides a processing technology of a titanium alloy, in particular a processing technology of a titanium alloy Ti5Mo5V2Cr3Al, which comprises the following steps: 1. forging stocks are blanked and forged on a forging machine at a temperature ranging from 780 DEG C to 1050 DEG C until the forging stocks achieve a deformation of larger than or equal to 60 percent, 2. hot rolling is carried out on the forging stocks on a rolling mill at a temperature ranging from 700 DEG C to 950 DEG C until the forging stocks achieve a rolling deformation of larger than or equal to 70 percent, 3.aging is carried out for the forging stocks for 1-8h at a temperature ranging from 480 DEG C to 580 DEG C, and air cooling is carried out until the temperature is reduced to the room temperature. Thetitanium alloy comprises the following main alloying elements by the weight percent:4.5-5.7 of Mo, 4.5-5.7 percent of V, 1.5-2.5 of Cr, 2.5-3.5 percent of Al, and the balanced titanium. The diameter of the rolled alloy bar is smaller or equal to 60 mm. With good match properties between high strength and high toughness, the titanium alloy processed by the processing technology can be used for manufacturing the landing gear of a plane and other large forgings used for an aeronautic and astronautic technology.

Owner:GRIMAT ENG INST CO LTD

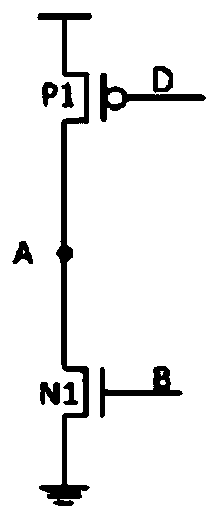

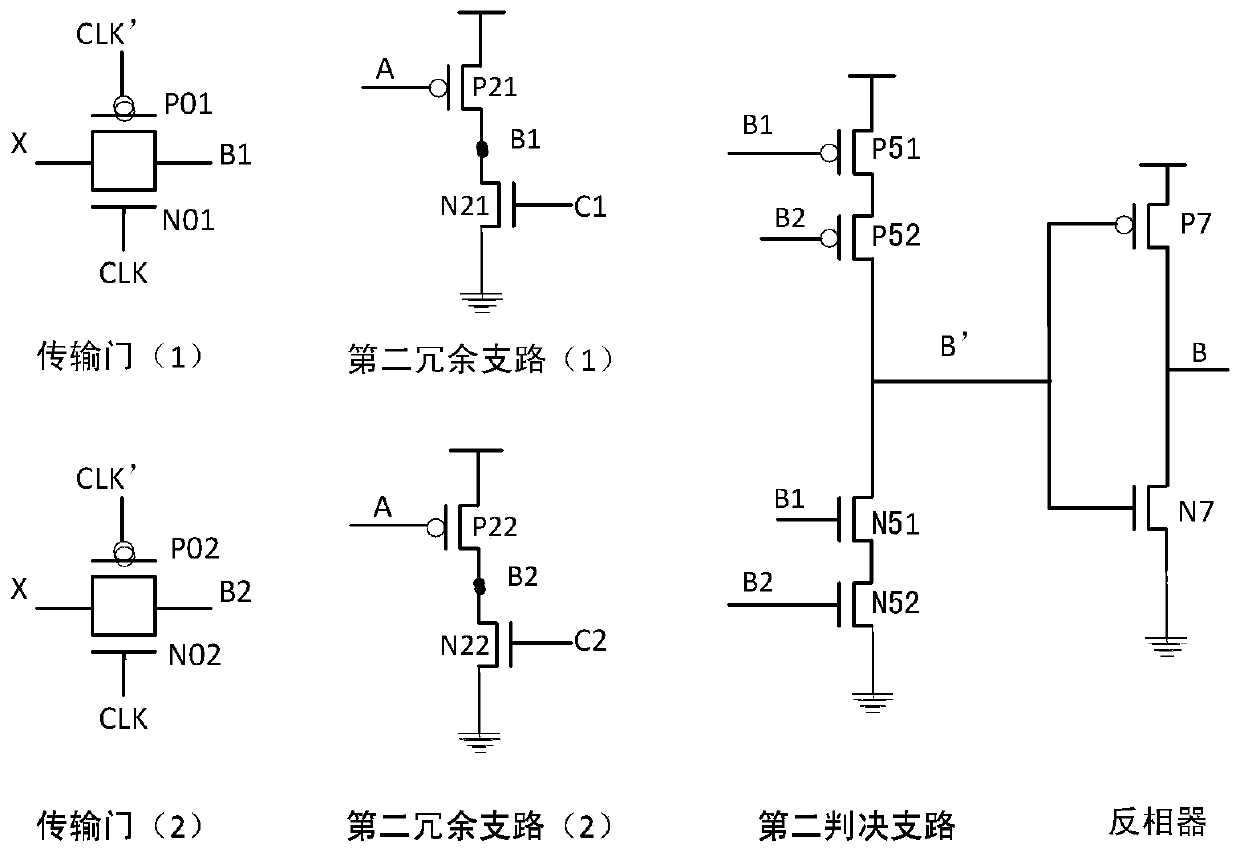

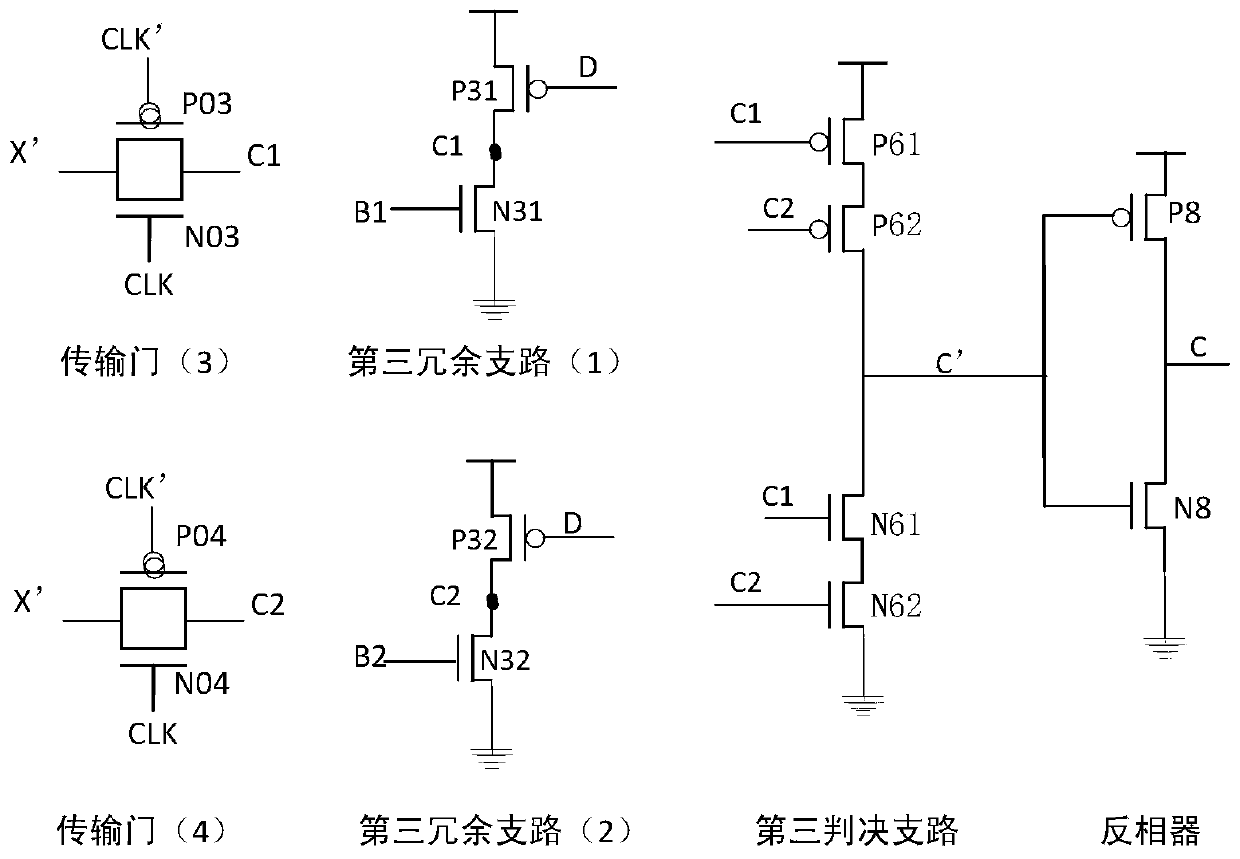

A single-event upset-resistant latch

ActiveCN106533420BRealize the reinforcement effectRealize the function of reinforcementReliability increase in field effect transistorsTransmission gateSingle event upset

The invention discloses a latching device for single event upset prevention. The latching device is composed of a first output branch, a second input branch, a third input branch and a fourth output branch. The second input branch consists of a transmission gate (1), a transmission gate (2), a second redundant branch (1), a second redundant branch (2), a second decision branch, and an inverter (1). The third input branch includes a transmission gate (3), a transmission gate (4), a third redundant branch (1), a third redundant branch (2), a third decision branch, and an inverter (2). According to the latching device disclosed by the invention, with the input X and the input X', single event upset (SEU) prevention is enhanced by the second and third redundant branches and the second and third decision branches of the second and third input branches; phase inversion is realized by using the inverter (1) and the inverter (2); and then because of an output node A(=X') and an output node D(=X) of the first and fourth output branches, SEU prevention is enhanced further.

Owner:HOHAI UNIV CHANGZHOU

Reinforcement device and reinforcement method for heightening support

ActiveCN102704389BEasy maintenanceWon't breakBridge structural detailsBridge erection/assemblyArchitectural engineeringSlide plate

Owner:丰泽智能装备股份有限公司 +1

Apparatus for fixing steel wire of wale

The present invention provides an apparatus for fixing a steel wire of a wale. In an embodiment, the present invention has an improved structure capable of fixing the steel wire of a prestressed wale at a location spaced apart from one end of the wale during pit excavation work for constructing an underground structure. The fixing apparatus prevents a sharp angle from being formed in the steel wire, and instead allows the steel wire to extend in the form of an arc shape, thus securing sufficient moment. The fixing apparatus provides strong reinforcement of parts to which high compressive force and high tensile force are applied. In another embodiment, the present invention has an improved structure capable of supporting a bracing beam and fixing and tensioning the steel wire in the bracing beam in corners during pit excavation work. At the corner, the fixing apparatus forms a triangular structure which can stably support the bracing beam and can fix and tension the steel wire at the same time, thus improving work efficiency. Further, the fixing apparatus has a simple structure, thus reducing the consumption of materials and reducing construction expenses.

Owner:SUPPORTEC CO LTD

Reinforcement device and reinforcement method for heightening support

ActiveCN102704389AEasy maintenanceWon't breakBridge structural detailsBridge erection/assemblyArchitectural engineeringSlide plate

Owner:丰泽智能装备股份有限公司 +1

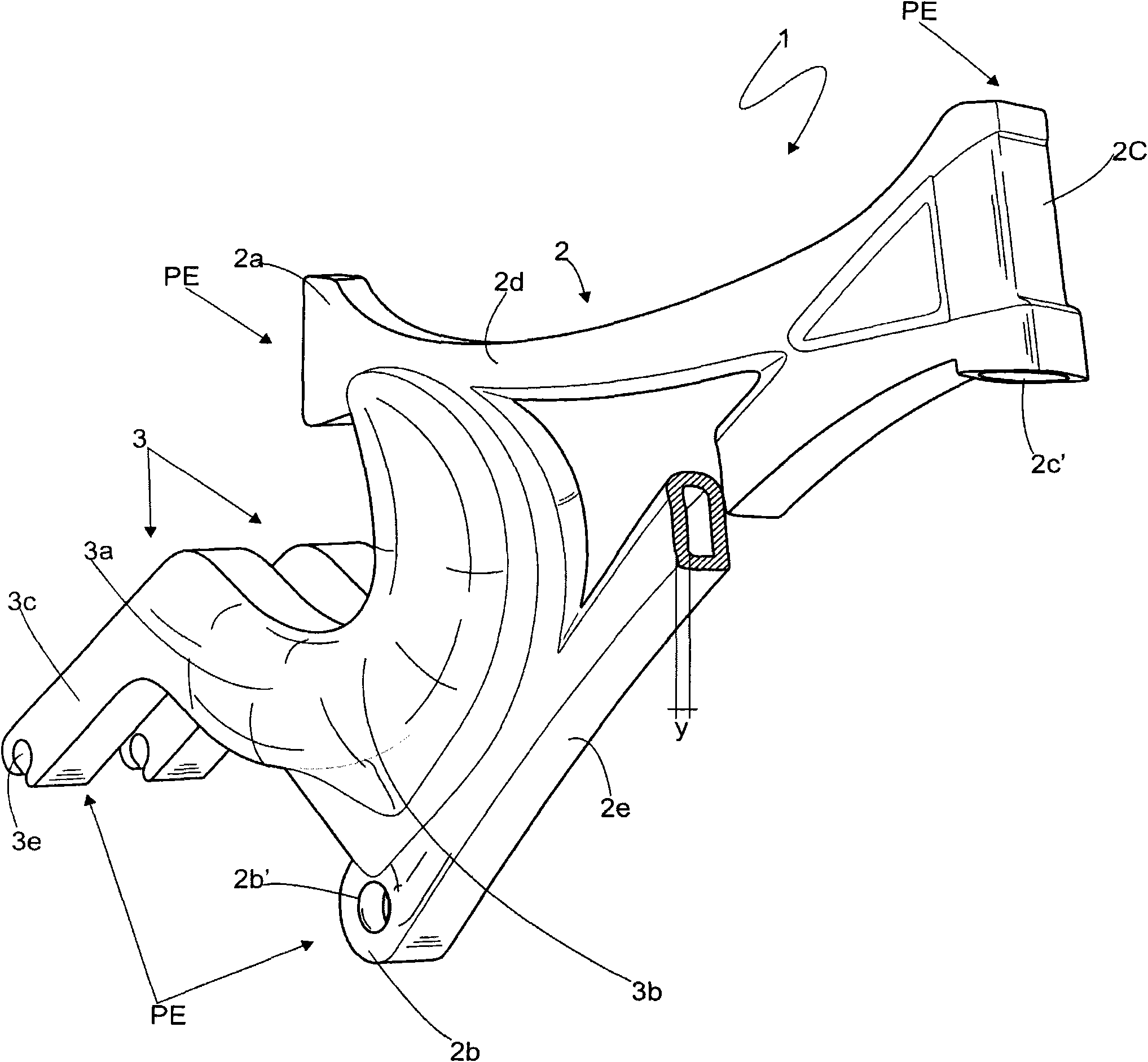

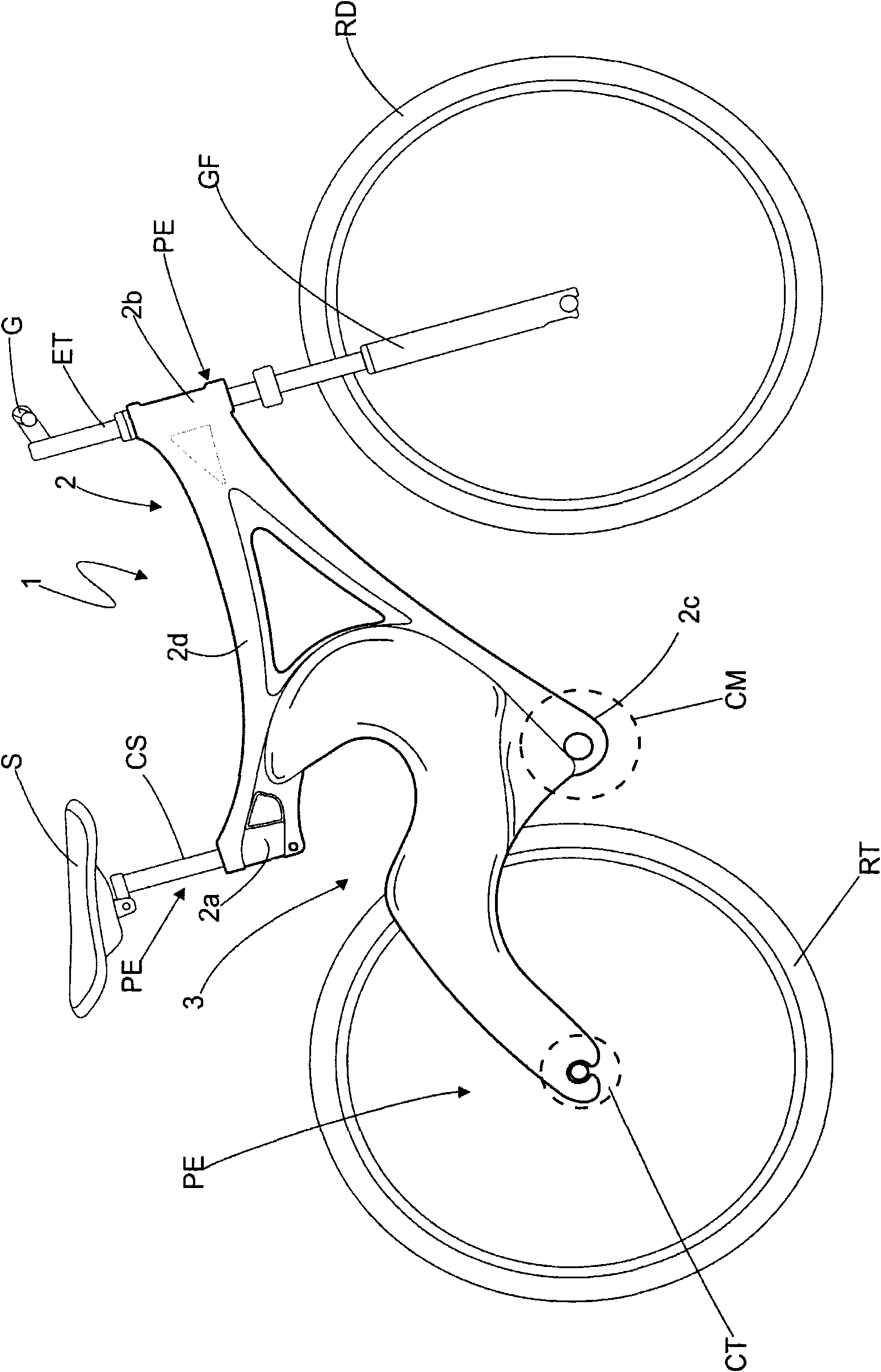

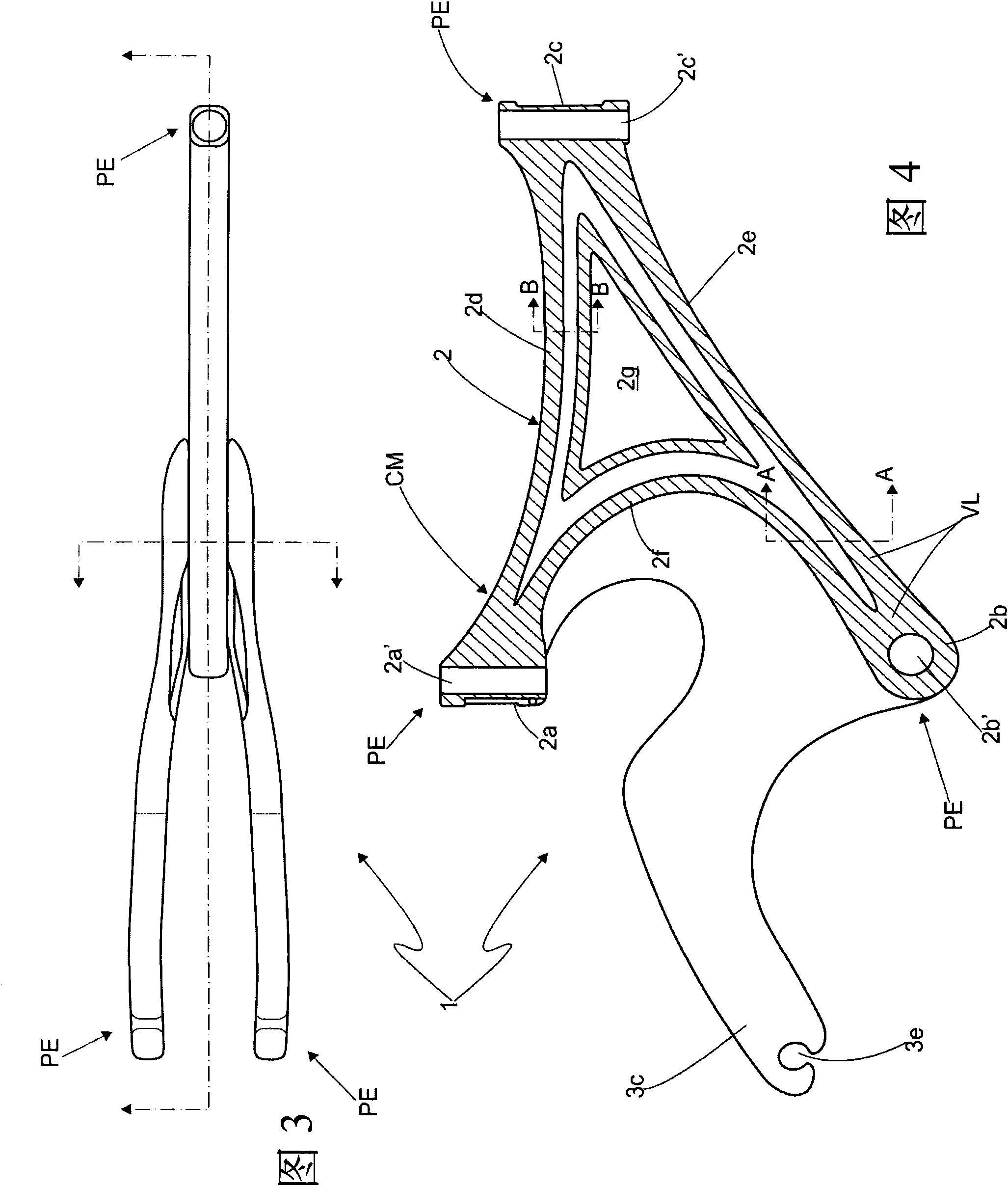

Improved type human engineering integral bicycle stand for bicycle and like

InactiveCN102464076AStrong reinforcementImprove and Safe OperationsCycle framesVehicle frameEngineering

The invention relates to an improved type human engineering integral bicycle stand for a bicycle and the like, in particular to a integral bicycle stand (1). The common components of the integral bicycle stand: such as a saddle tube rod (CS), a tube rod and an auxiliary chain wheel (CT) are jointed, wherein the tube rod is coupled with a handlebar (G) and a fronthead cross (GF). The integral bicycle stand comprises a single component made from fresh or recycling rigid polymer solid mold and a center longitudinal rod (2), and lateral and identical components (3) extend out of the center longitudinal rod. The integral bicycle stand disclosed by the invention has the advantage that the appearance is opaque or semi-transparent or the color is designed according to requirement.

Owner:胡安・卡洛斯・卡拉布雷斯・穆齐

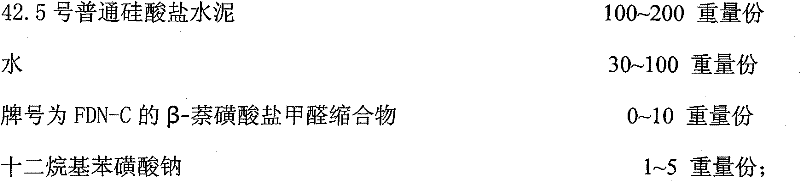

Polyurethane cement composite grouting material

ActiveCN101607807BFast reinforcementEasy to handleProtective foundationBridge erection/assemblyCement compositesCement mortar

The invention relates to a polyurethane cement composite grouting material. The invention aims to provide a polyurethane cement composite grouting material, and aims at compounding polyurethane grout and cement mortar into a composite grouting material, and getting the best out of the polyurethane grout and the cement mortar, which can lower cost and is also favorable for environment-friendly construction, and can achieve the purpose of quickly and effectively plugging water. The technical scheme for solving the problem is as follows: the polyurethane cement composite grouting material is characterized by consisting of a component A and a component B, and mixing ratios of raw materials are respectively as follows: the component A: 100 parts of an oil soluble polyurethane grouting materialby weight, 1-10 parts of a catalyst by weight and 0.5-2 parts of a silane coupling agent by weight; and the component B: 100-200 parts of cement by weight, 30-100 parts of water by weight, 0-10 partsof a water reducing agent by weight and 1-5 parts of a surfactant. The polyurethane cement composite grouting material is applicable to plugging of large flow water inrush.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com