Reinforcement device and reinforcement method for heightening support

A reinforcement device and support technology, applied in the direction of bridge reinforcement, erection/assembly of bridges, bridge parts, etc., can solve the problems of baffle deformation, welding reinforcement block restrictions, poor welding quality, etc., to achieve convenient installation and disassembly, reinforcement Strong performance and firm fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The structure of the reinforcement device for the height adjustment support proposed by the present invention will be further described below in conjunction with the accompanying drawings.

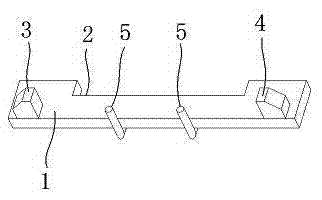

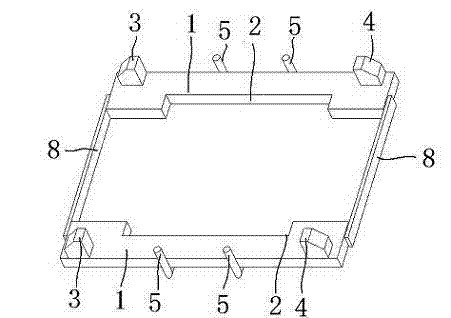

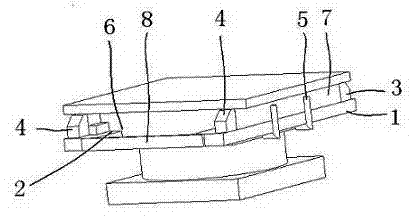

[0023] Such as figure 1 Shown is a structural schematic diagram of the reinforcement device for the height adjustment support. Its structure includes a plate-shaped reinforced body 1. On one side of the reinforced body 1, there are U-shaped slots 2 that can be snapped into the two sides of the upper seat plate of the support. Vertical first fixed block 3 and second fixed block 4, the first fixed block 3 and the second fixed block 4 are located outside the two ends of the upper sliding plate of the height adjustment support. Such as image 3 As shown, the U-shaped card slot 2 of the reinforced body 1 is tightly clamped on both sides of the upper seat plate 6 of the support, and the first fixed block 3 and the second fixed block 4 are tightly clamped on the outer sides of the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com