Polypropylene/montmorillonite nanometer composite material preparation method

A technology of nanocomposite materials and montmorillonite, which is applied in the field of preparation of polypropylene/montmorillonite nanocomposite materials, can solve the problems of not being able to improve the overall performance of composite materials, and achieve perfect comprehensive performance, high feasibility and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

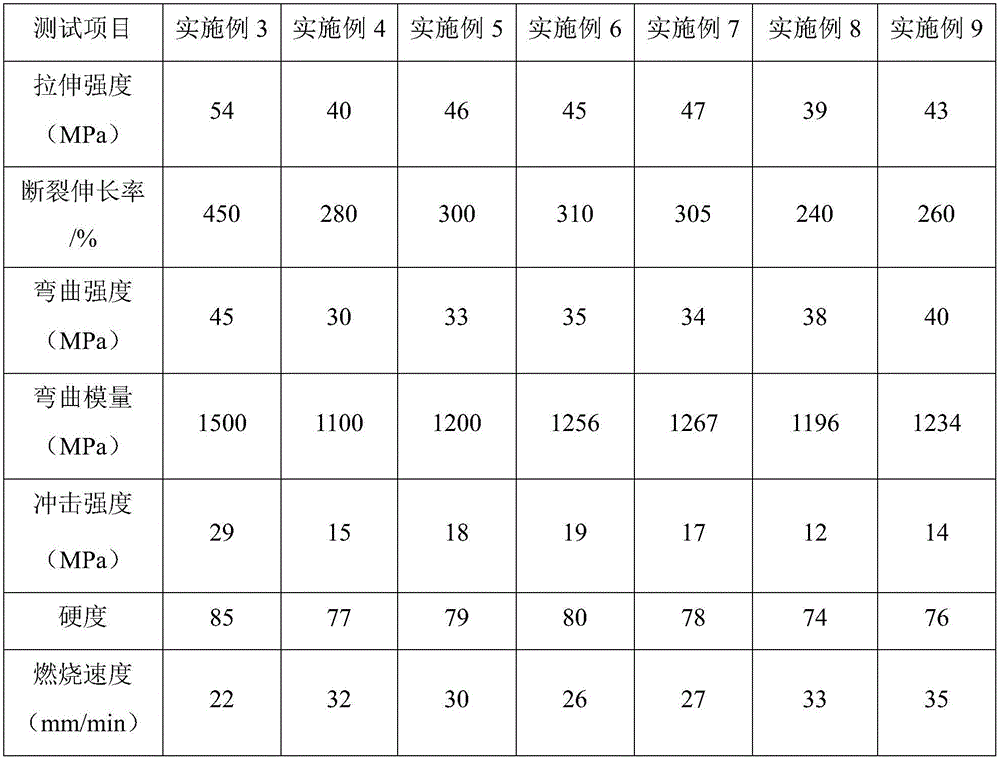

Examples

Embodiment 1

[0031] A preparation method of polypropylene / montmorillonite nanocomposite, comprising the following steps:

[0032]Step 1, the pretreatment of montmorillonite: in parts by weight, get 0.3 parts of montmorillonite with a cation exchange capacity of 50mep / 100g, divide it into three equal parts, and disperse the montmorillonite of the first equal part in 3 parts of deionized water, placed in an ultrasonic wave for 10 minutes, and then quickly put into an ice-salt bath for rapid solidification to obtain a first solidified body, which was packed into a first cloth bag, and the second solidified body was A cloth bag is placed in a vacuum drying oven with a pressure of 1.33 Pa and a temperature of 35° C. to remove the moisture in the first solidified body to obtain the dried first pretreated montmorillonite;

[0033] Disperse the second equal portion of montmorillonite in 3 parts of absolute ethanol, place it in an ultrasonic wave for 10 minutes, and then quickly put it into a cooli...

Embodiment 2

[0042] A preparation method of polypropylene / montmorillonite nanocomposite, comprising the following steps:

[0043] Step 1, pretreatment of montmorillonite: in parts by weight, get 2.7 parts of montmorillonite with a cation exchange capacity of 150mep / 100g, divide into three equal parts, and disperse the montmorillonite of the first equal part in 9 parts of deionized water, placed in an ultrasonic wave for 20 minutes of ultrasonic vibration, and then quickly put into an ice-salt bath for rapid solidification to obtain a first solidified body, and put the first solidified body into a first cloth bag, and place the first solidified body in a cloth bag. A cloth bag is placed in a vacuum drying oven with a pressure of 1.33 Pa and a temperature of 40° C. to remove the moisture in the first solidified body to obtain the dried first pretreated montmorillonite;

[0044] Disperse the second equal portion of montmorillonite in 9 parts of absolute ethanol, place it in an ultrasonic wave...

Embodiment 3

[0053] A preparation method of polypropylene / montmorillonite nanocomposite, comprising the following steps:

[0054] Step 1, pretreatment of montmorillonite: in parts by weight, get 1.5 parts of montmorillonite with cation exchange capacity of 100mep / 100g, divide into three equal parts, disperse the montmorillonite of the first equal part in 6 parts of deionized water were placed in an ultrasonic wave for 15 minutes of ultrasonic vibration, and then quickly put into an ice-salt bath for rapid solidification to obtain a first solidified body, which was packed into a first cloth bag, and the second solidified body was A cloth bag is placed in a vacuum drying oven with a pressure of 1.33 Pa and a temperature of 38° C. to remove the moisture in the first solidified body to obtain the dried first pretreated montmorillonite;

[0055] Disperse the second equal portion of montmorillonite in 6 parts of absolute ethanol, place it in an ultrasonic wave for 15 minutes, and then quickly pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com