Apparatus for fixing steel wire of wale

A steel wire fixing and cross bracing technology, which is applied in construction, excavation, infrastructure engineering, etc., can solve the problems of reducing the working efficiency of tensioning steel wires, increasing construction costs, and wasting materials, so as to reduce material consumption, prevent space reduction, reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

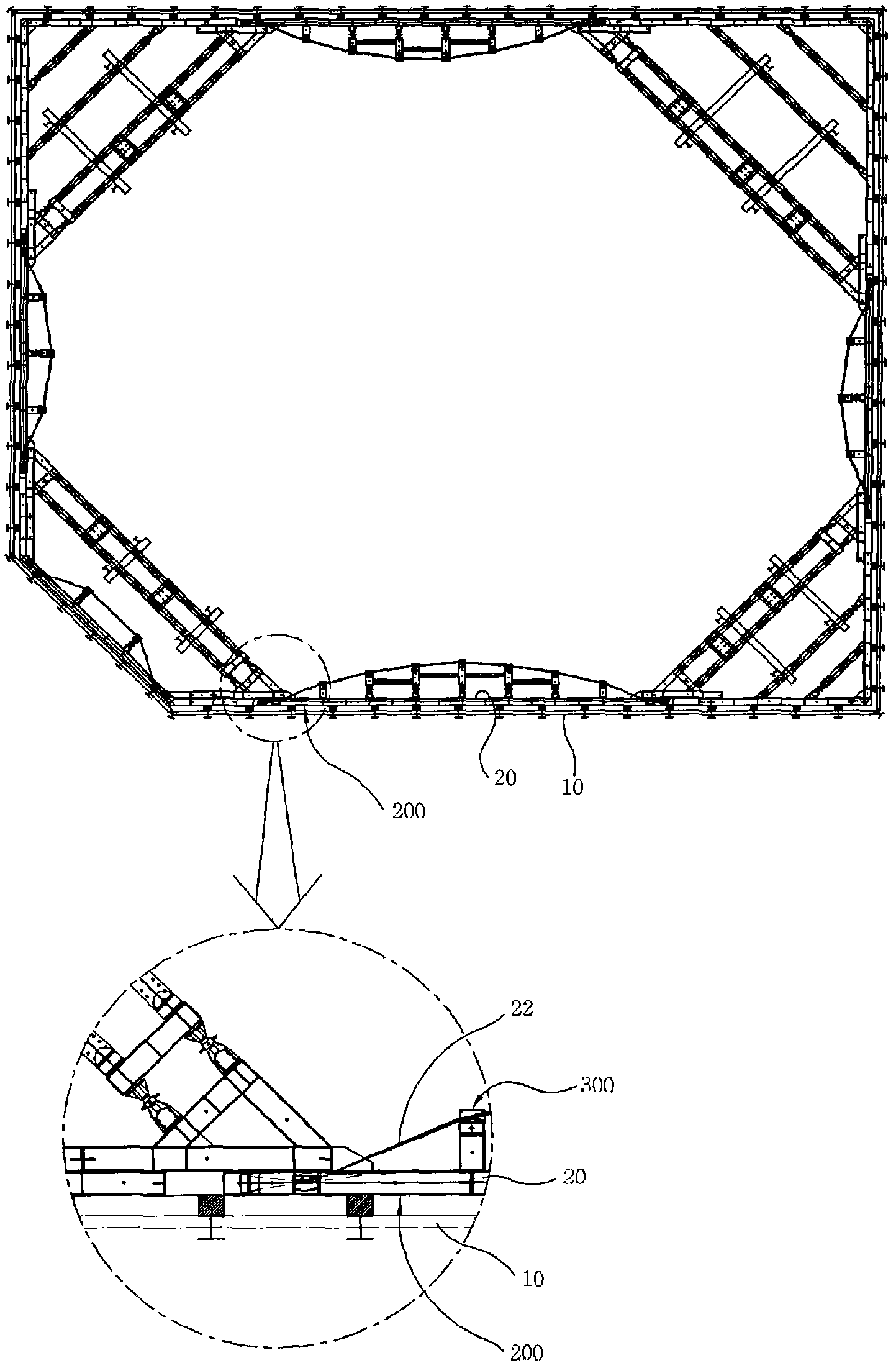

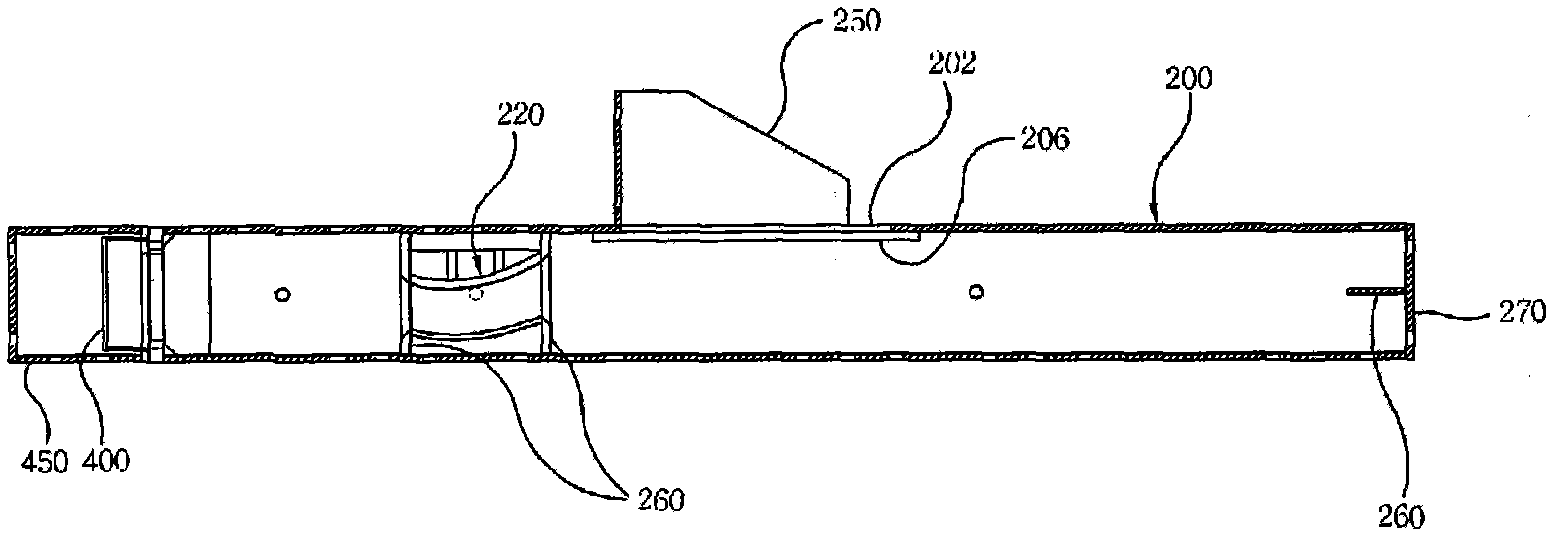

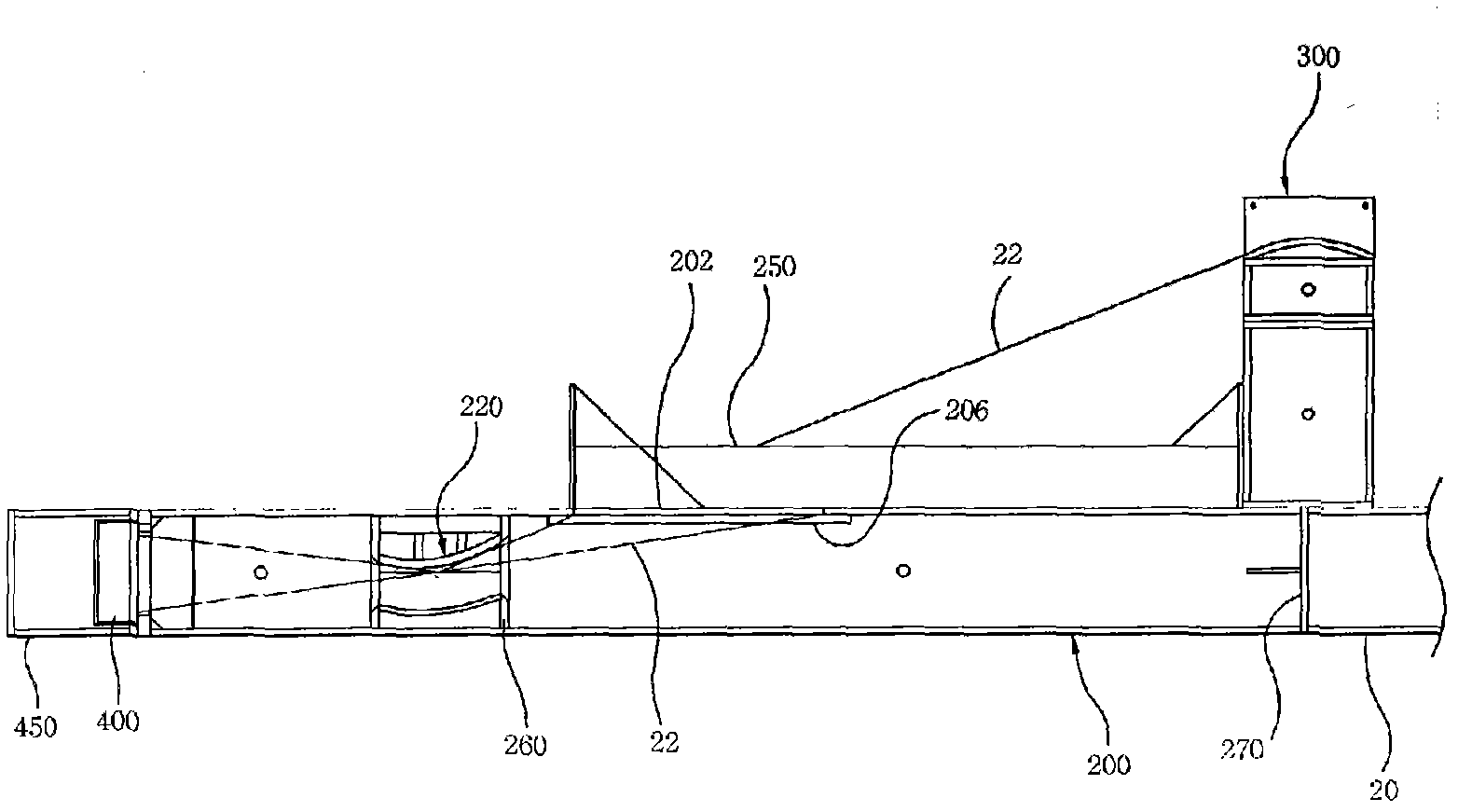

[0036] refer to Figure 1 to Figure 3 , according to the first embodiment of the present invention, the cross brace steel wire fixing device includes: a prestressed cross brace 20, which is integrally formed in front of the supporting wall 10, and has a tension force for tensioning the steel wire 22; a fixing body 200, Its first end is connected to one end of the cross brace 20 by bolts, and has a coupling hole 202, allowing the steel wire 22 to pass through the coupling hole 202; spacer 400, which is located at the second end of the fixed body 200, and fixes the inserted spacer 400 end of the wire 22;

[0037] In detail, the fixing body 200 is configured in the form of a beam integrated with and protruding from the end of the cross brace 20 , and a conventional wide I-beam is preferably used.

[0038] When using a wide I-beam as the fixing body 200, it is necessary to reinforce the flange of the beam having the coupling hole 202 so that the reinforcement plate 206 is mounted...

Embodiment 2

[0057] The following will refer to the attached Figures 6 to 10 A brace wire fixing device according to a second embodiment of the present invention will be described. The fixture includes a beam 610 connected to one end of a cross brace 520 for supporting the retaining wall 510 . The compression beam 620 is obliquely connected to one end of the beam 610 and integrated with at least one coupling beam 550 . The brace beam 630 is obliquely connected to one end of the compression beam 620 and one end of the cross beam 610 at the same time, thereby connecting the beams 610 and 620 to each other. A coupling hole 632 is formed in the brace beam 630 adjacent to the cross brace 520 and allows the steel wire 522 of the cross brace 520 to enter the hole 632 . The first and second spacers 710 and 720, respectively, are located in the triangle formed by the compression beam 620, the brace beam 630 and the cross beam 610, such that the first and second spacers 710 and 720 individually s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com