Polyurethane cement composite grouting material

A grouting material, polyurethane technology, applied in water conservancy projects, protection devices, sea area projects, etc., can solve the problems of being easily diluted or washed away by water, and the treatment of fine cracks cannot obtain satisfactory results, so as to achieve environmental protection and curing Fast, Visible Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The ratio of raw materials of polyurethane cement composite grouting material in this example is:

[0026] Component A:

[0027] Oil-soluble polyurethane grouting material (brand: HK-9105, viscosity: 150-300) 100 parts by weight

[0028] N-methylmorpholine + dibutyltin dilaurate 2 parts by weight

[0029] 1 weight part of 3-glycidyl etheroxypropyl trimethoxysilane

[0030] Component B:

[0031] No. 42.5 Ordinary Portland Cement 100 parts by weight

[0032] 30 parts by weight of water

[0033] 1 part by weight of sodium dodecylbenzenesulfonate.

[0034] Stir the raw materials of component A in proportion to make liquid A, put them into the slurry storage tank, then put the raw materials of component B in the cement slurry mixing equipment in proportion to mix them evenly to make liquid B, and put them into another slurry storage tank;

[0035] Put the two grout inlet pipes of the automatic variable grouting equipment (double liquid pump, which is commonly used equi...

Embodiment 2

[0040] The ratio of raw materials of polyurethane cement composite grouting material in this example is:

[0041] Component A:

[0042] Oil-soluble polyurethane grouting material (brand: HK-9105, viscosity: 150-300) 100 parts by weight

[0043] N-methylmorpholine + stannous octoate 4 parts by weight

[0044] 1 weight part of 3-glycidyl etheroxypropyl trimethoxysilane

[0045] Component B:

[0046] No. 42.5 Ordinary Portland Cement 100 parts by weight

[0047] 50 parts by weight of water

[0048] 1 part by weight of sodium dodecylbenzenesulfonate.

[0049] The preparation process of this example and the equipment involved are the same as in Example 1, and the mixing ratio is adjusted by A liquid: B liquid=1:2 to adjust the amount of slurry. The catalyst N-methylmorpholine + stannous octoate in component A is 2 parts by weight each. No superplasticizer is used in component B.

[0050] The technical index of the product that present embodiment obtains is as follows:

[0...

Embodiment 3

[0053] The ratio of raw materials of polyurethane cement composite grouting material in this example is:

[0054] Component A:

[0055] Oil-soluble polyurethane grouting material (brand: HK-9106, viscosity: 150-300) 100 parts by weight

[0056] N-methylmorpholine + dibutyltin dilaurate 2 parts by weight

[0057] 1 weight part of 3-glycidyl etheroxypropyl trimethoxysilane

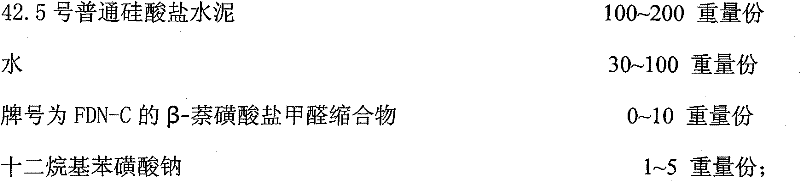

[0058] Component B:

[0059] No. 42.5 Ordinary Portland Cement 100 parts by weight

[0060] 30 parts by weight of water

[0061] Water reducer (brand: FDN-C, β-naphthalenesulfonate formaldehyde condensate) 0.5 parts by weight

[0062] 1 part by weight of sodium dodecylbenzenesulfonate.

[0063] The preparation process of this example and the equipment involved are the same as in Example 1, and the mixing ratio is A liquid: B liquid=1: 1 to adjust the amount of slurry. The catalyst N-methylmorpholine + dibutyltin dilaurate in component A is 1 part by weight each.

[0064] The technical index of the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com