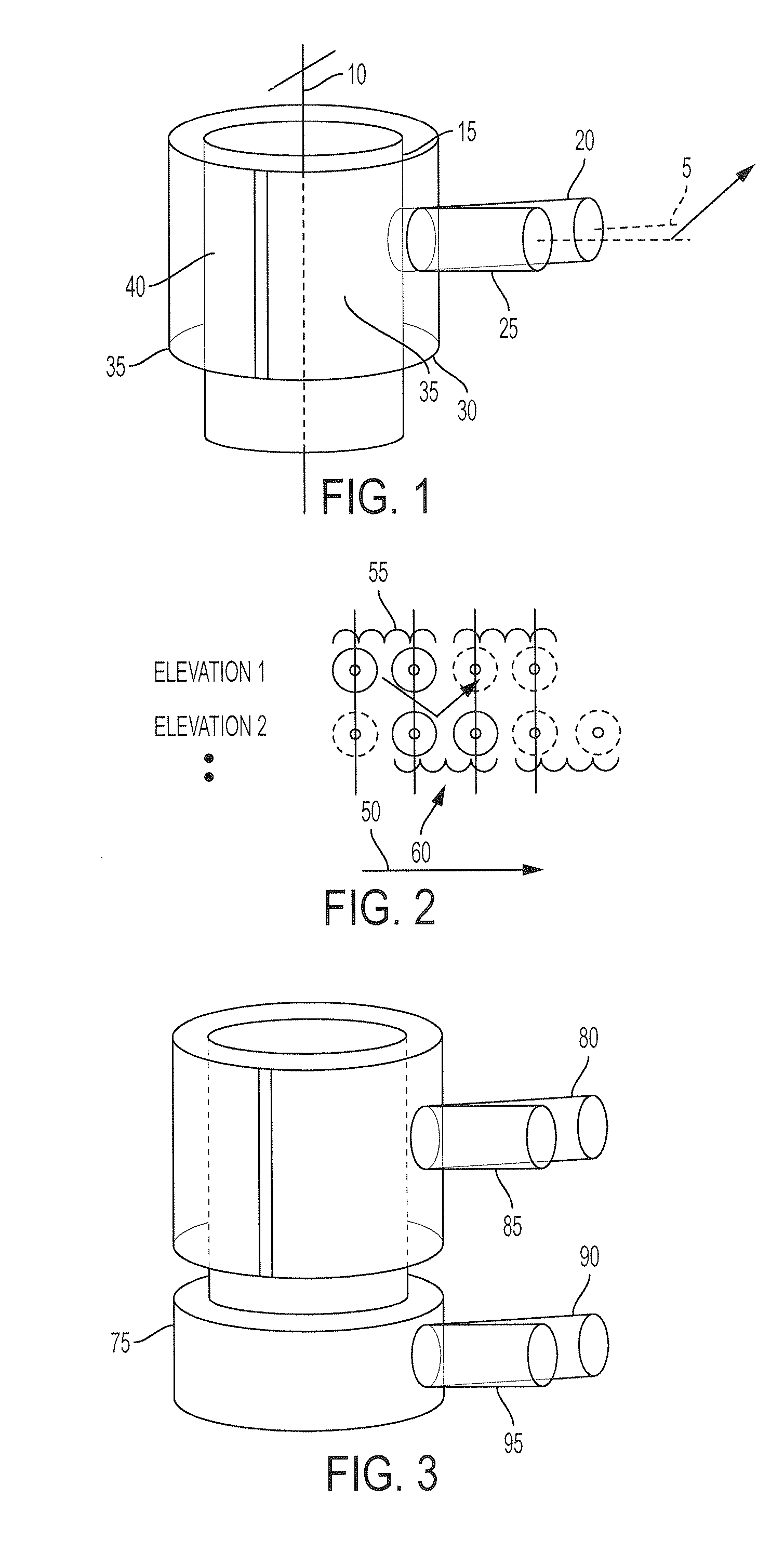

Patents

Literature

143results about How to "Reduce mechanical complexity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

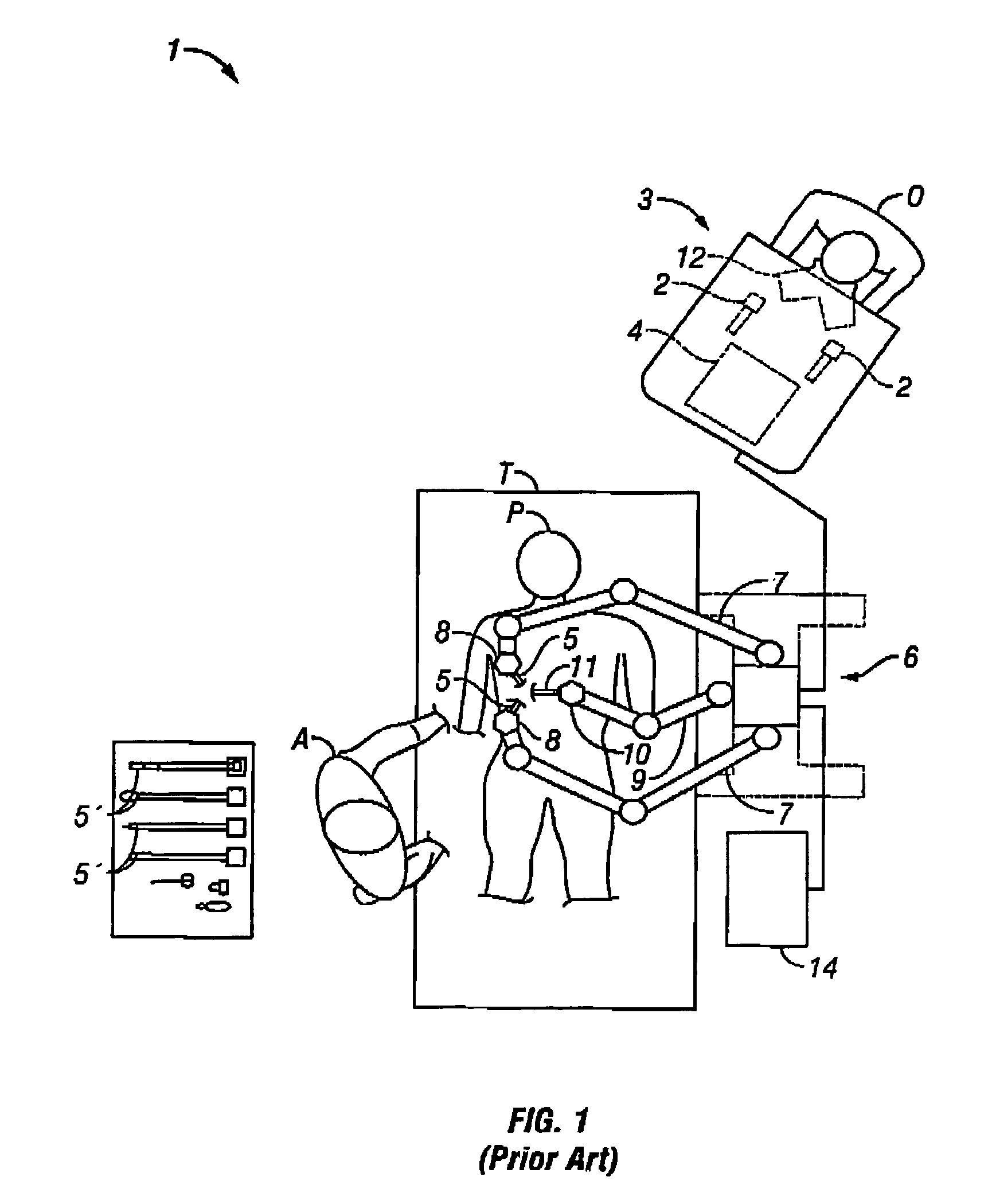

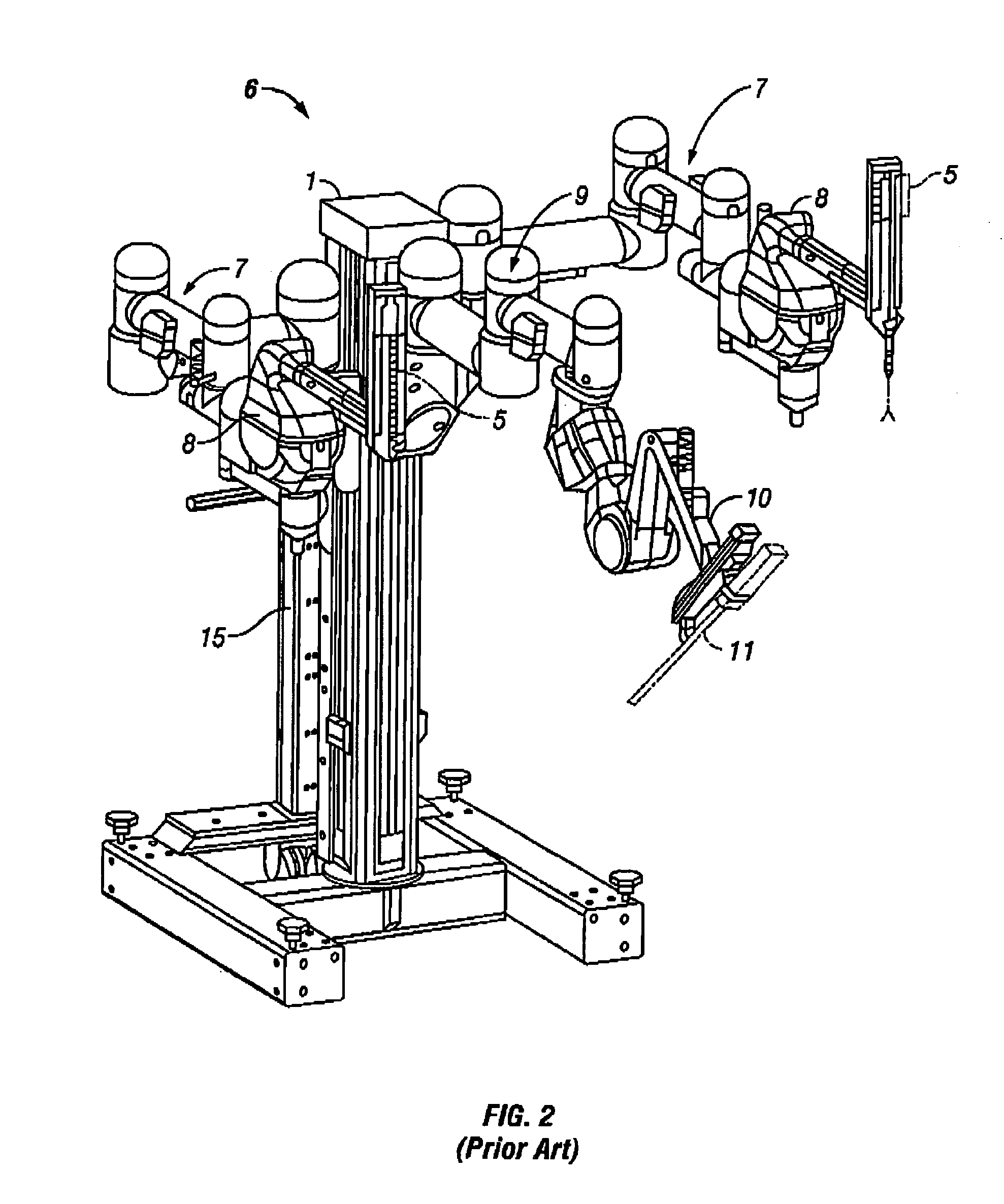

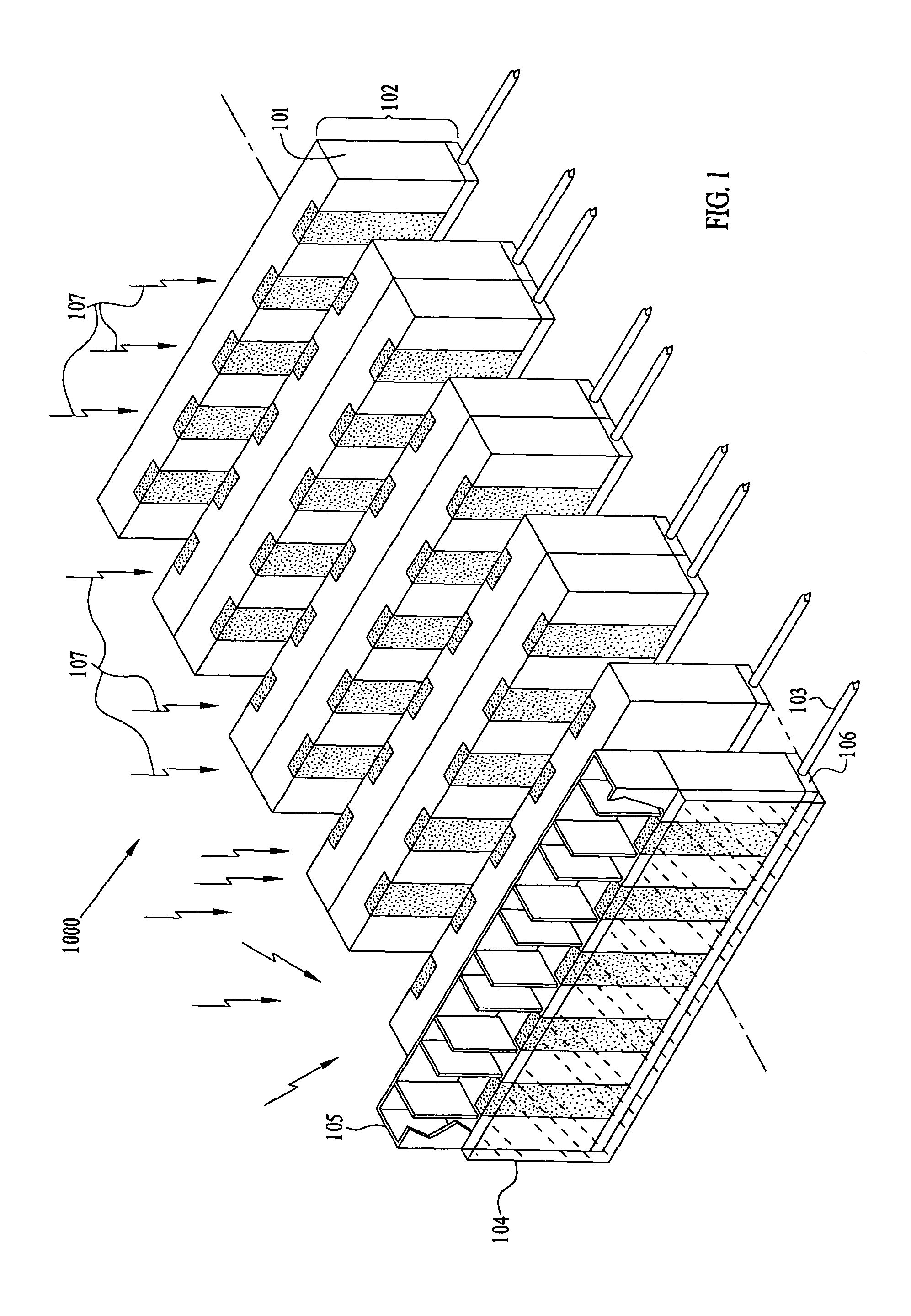

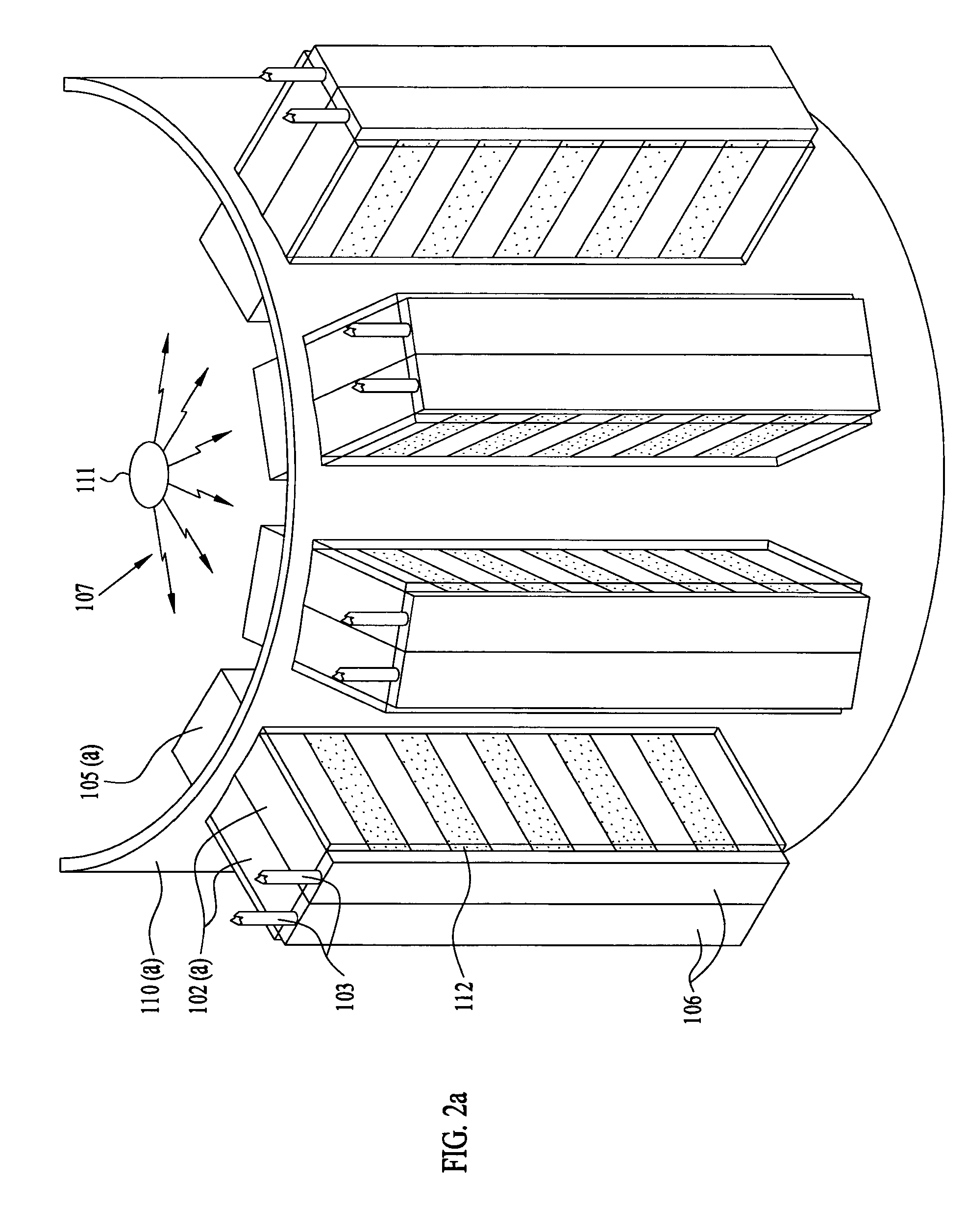

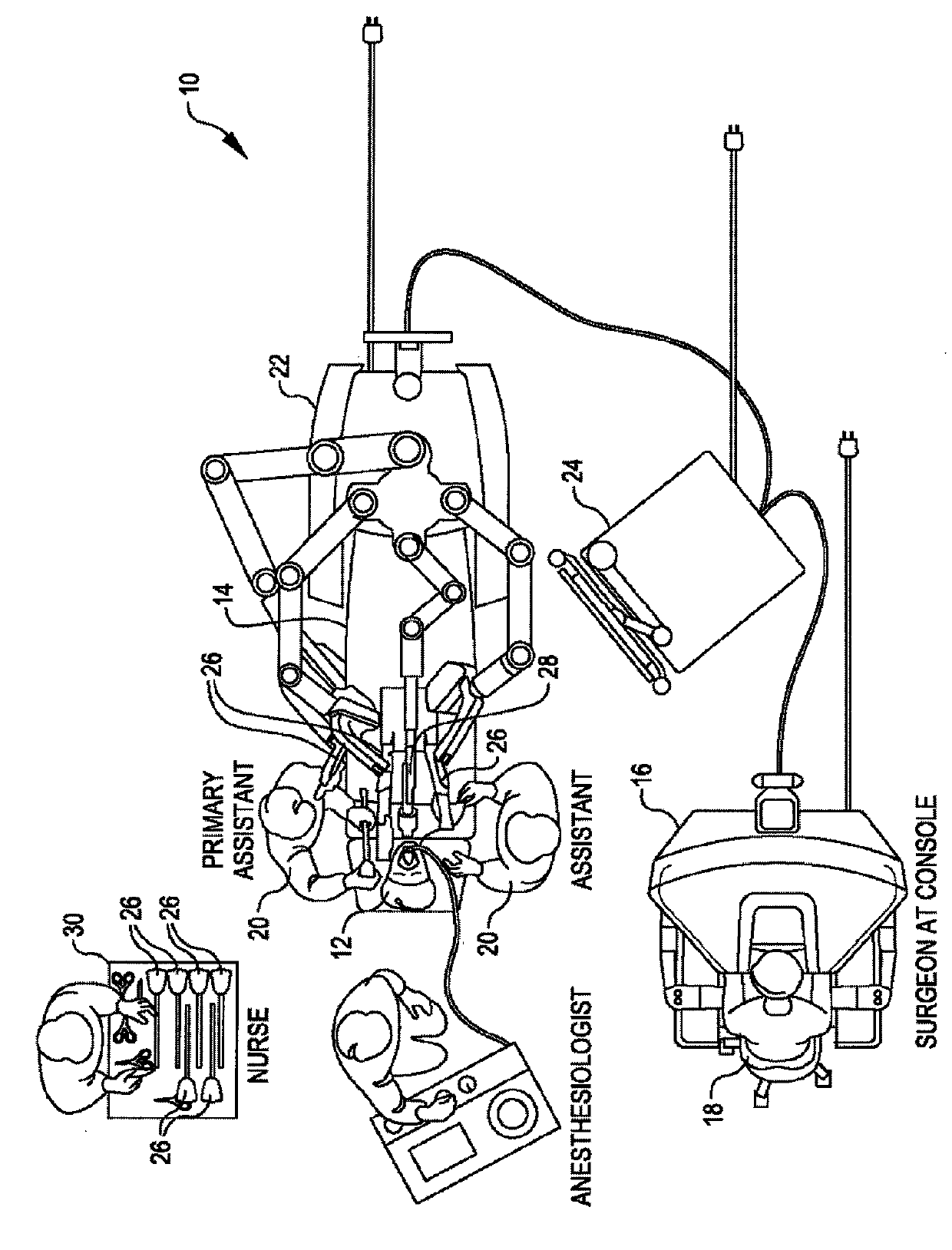

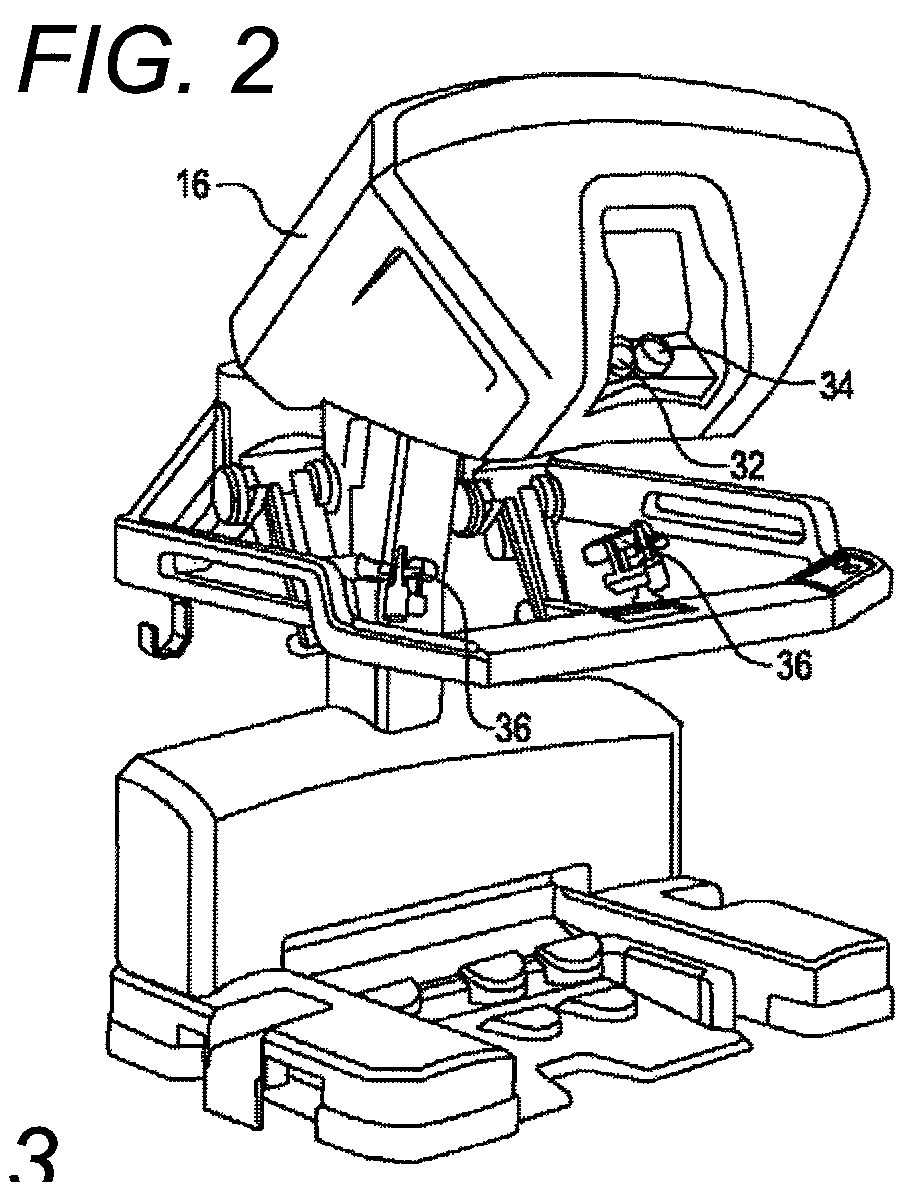

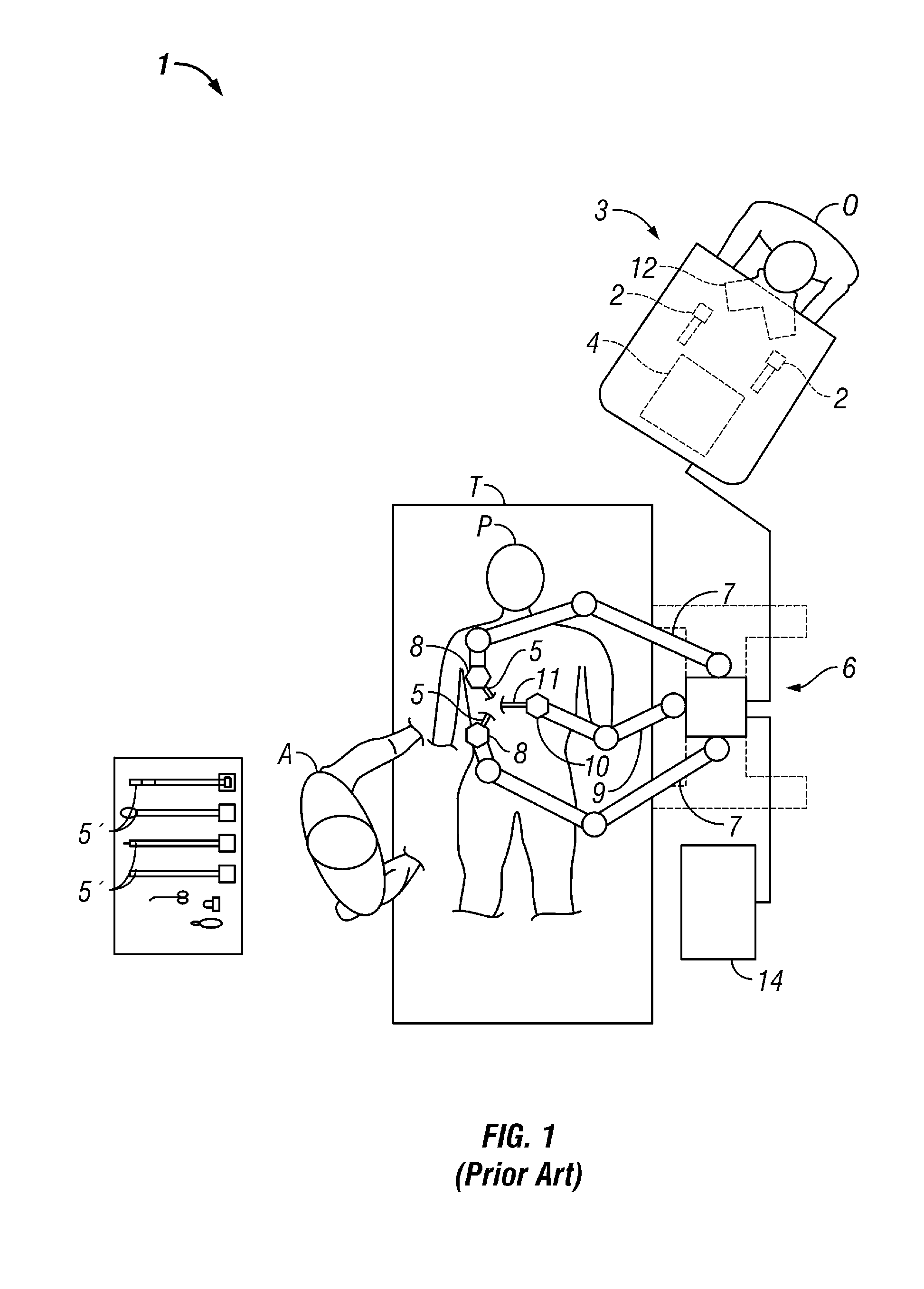

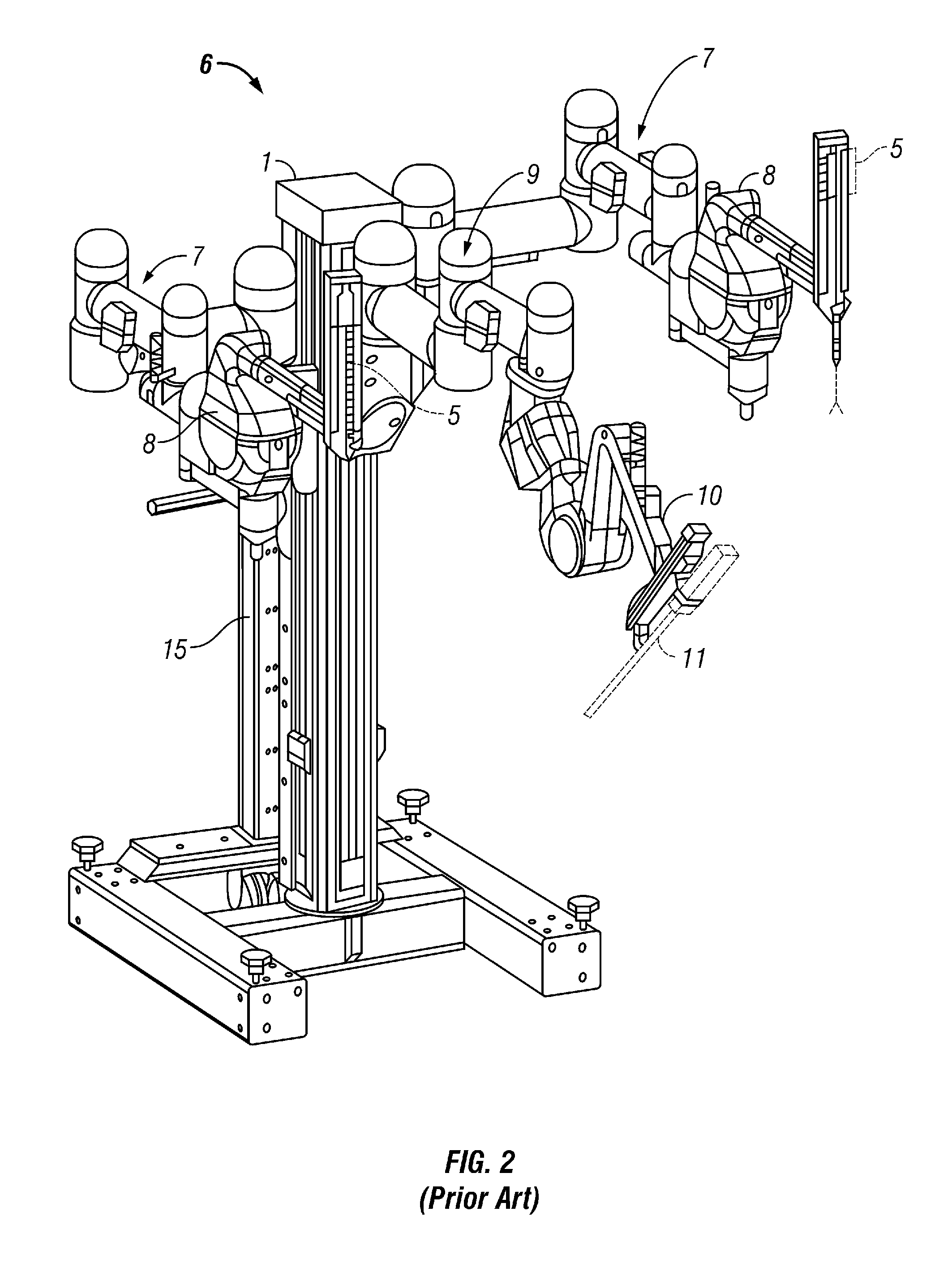

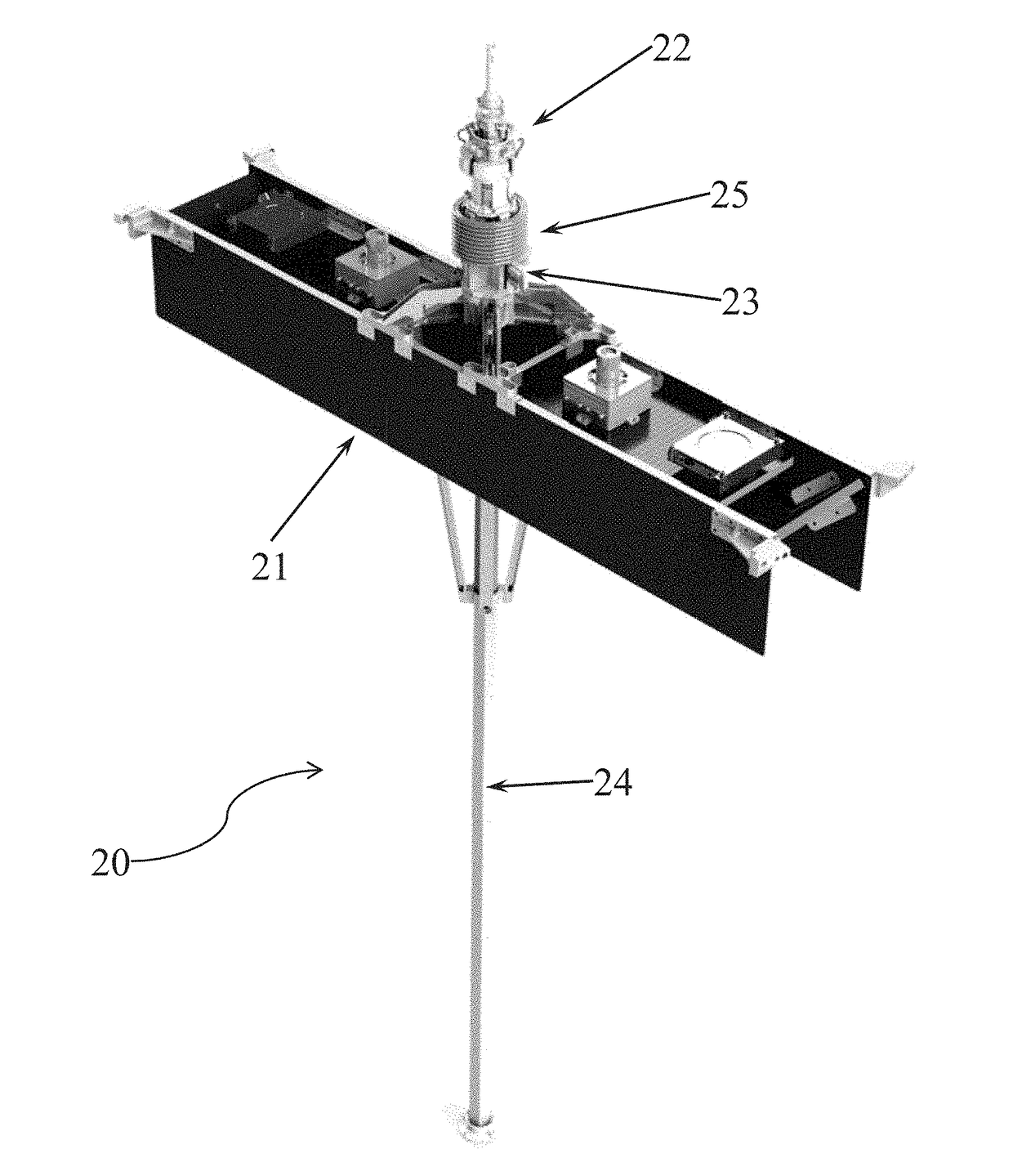

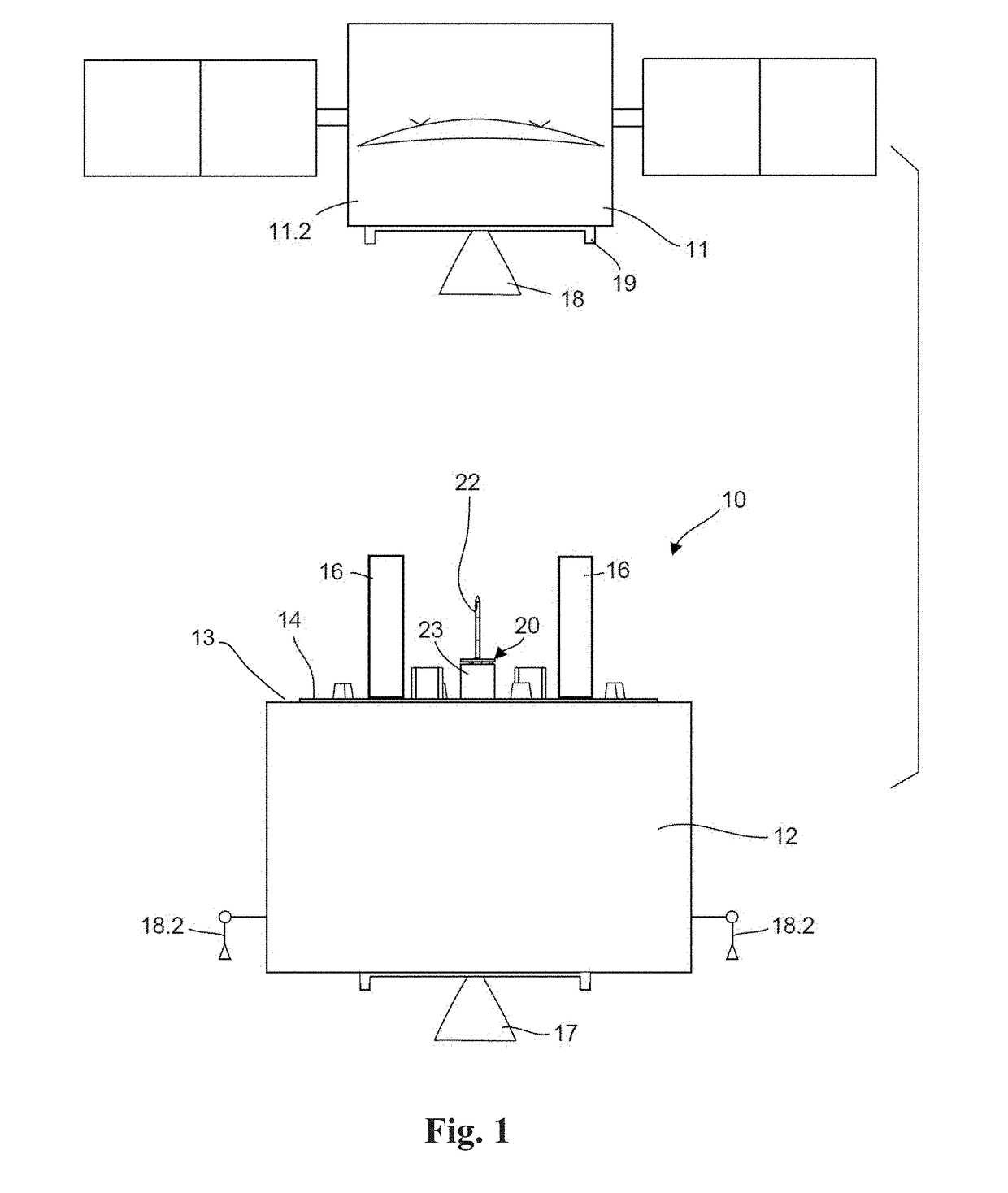

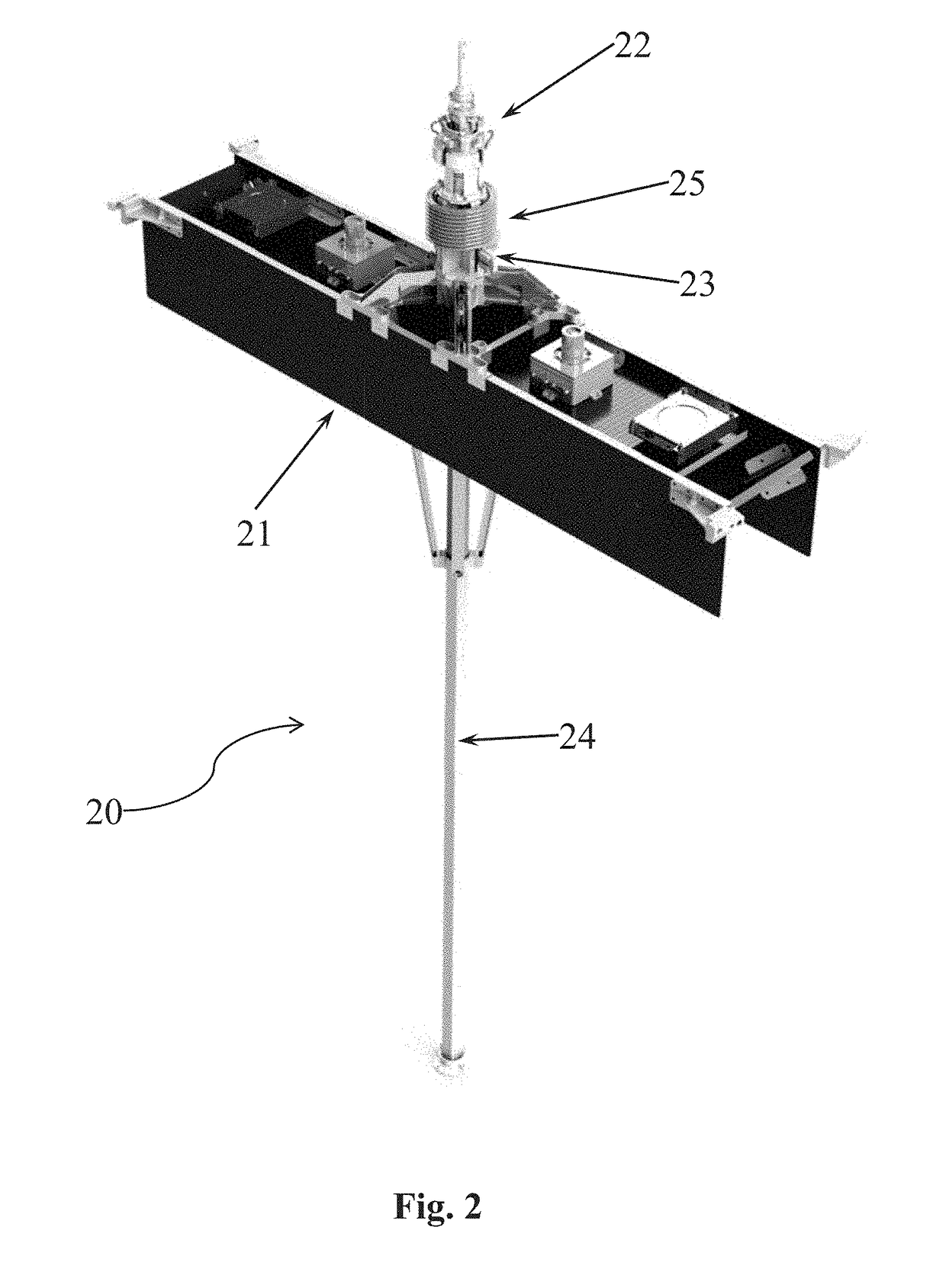

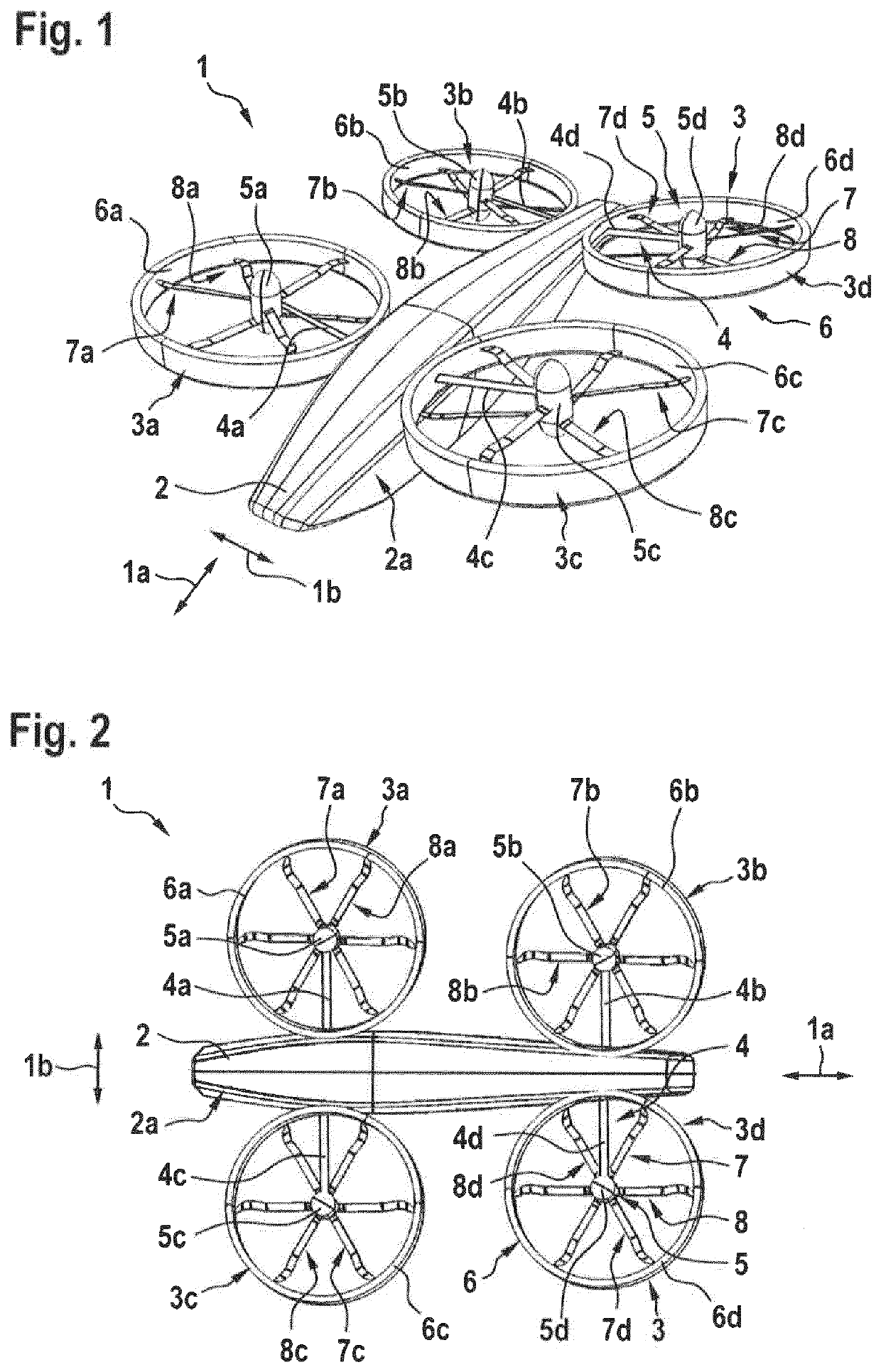

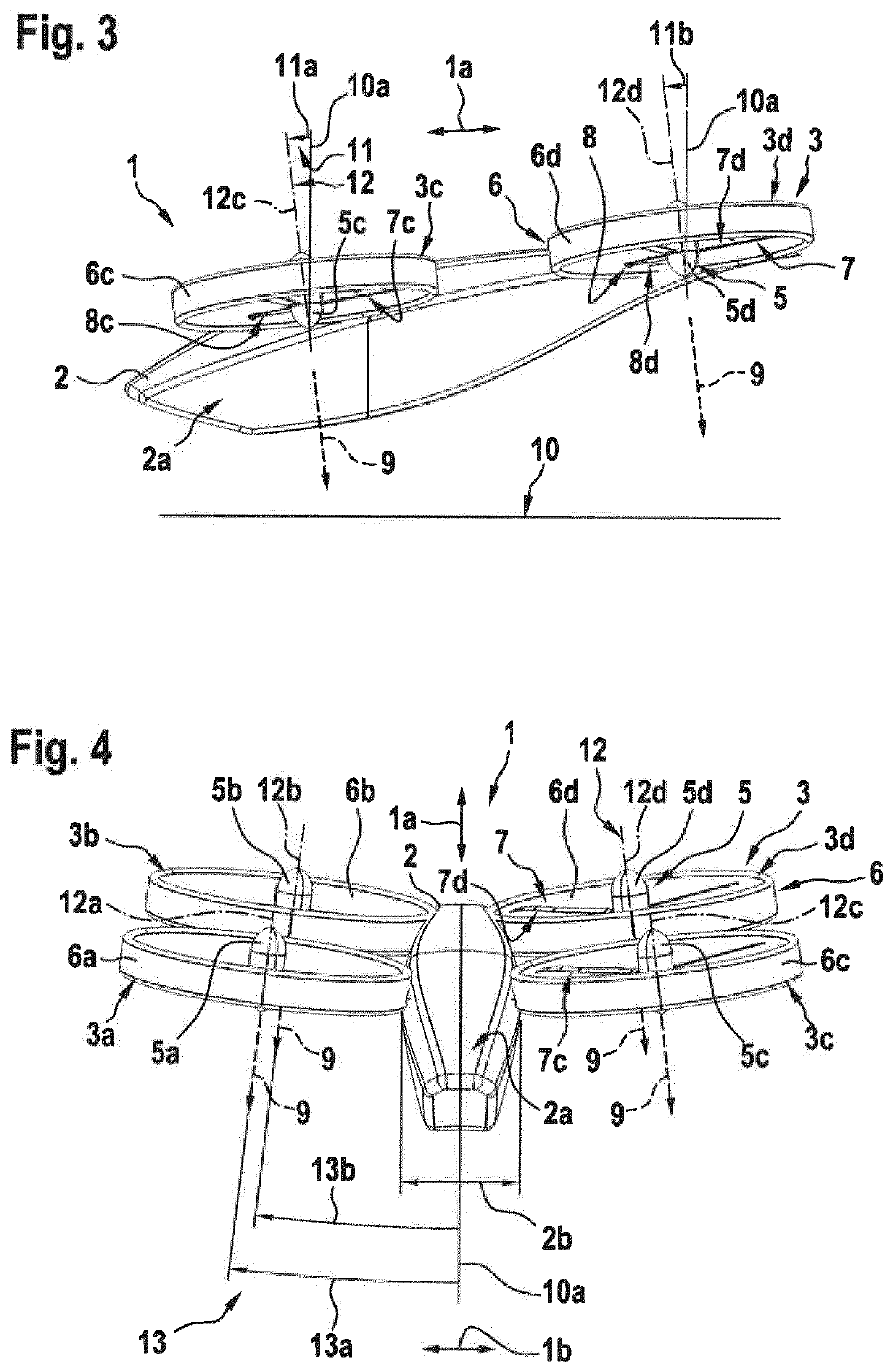

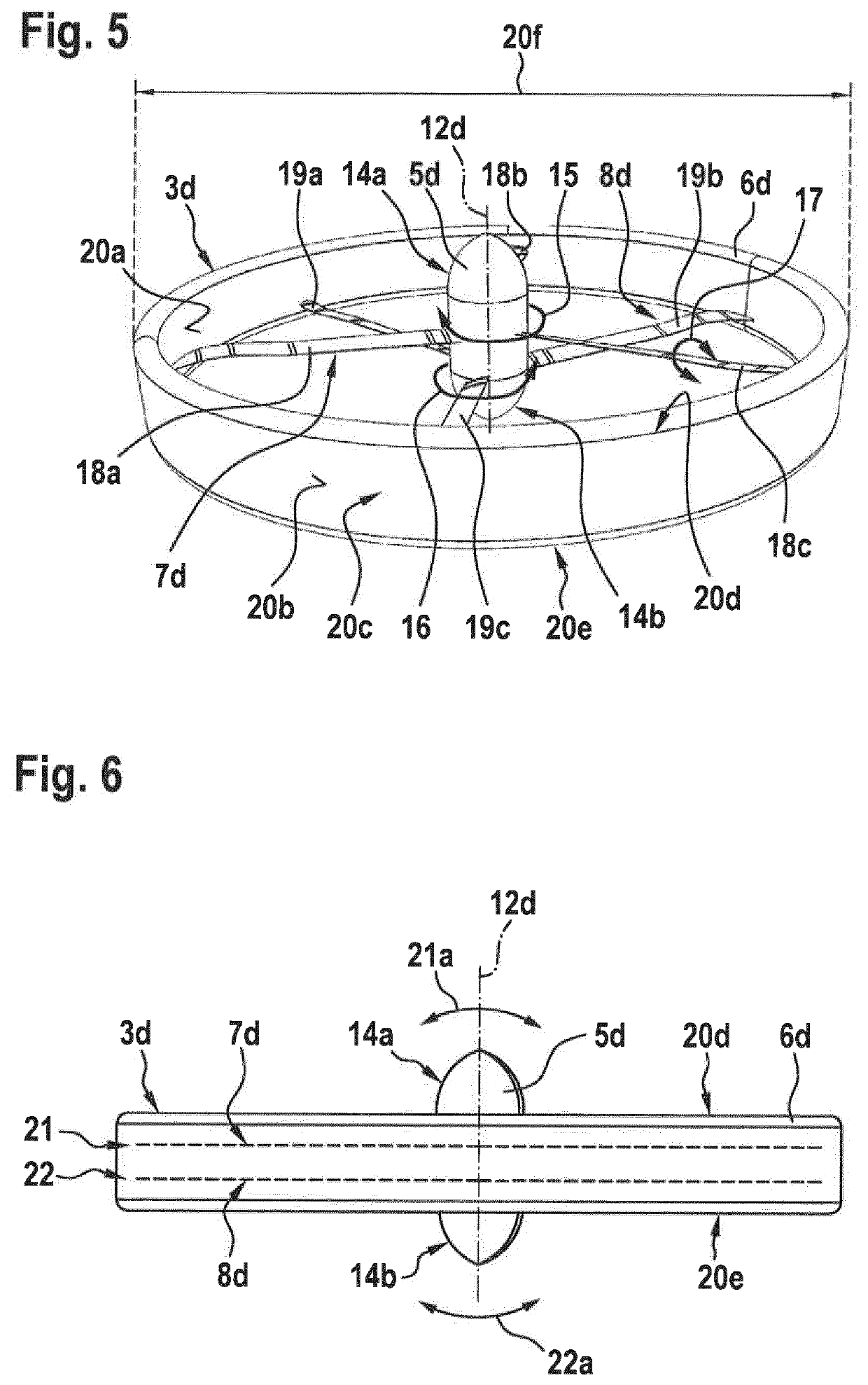

Modular manipulator support for robotic surgery

InactiveUS7763015B2Simple structureReduce complexityDiagnosticsRobotSurgical instrumentationModularity

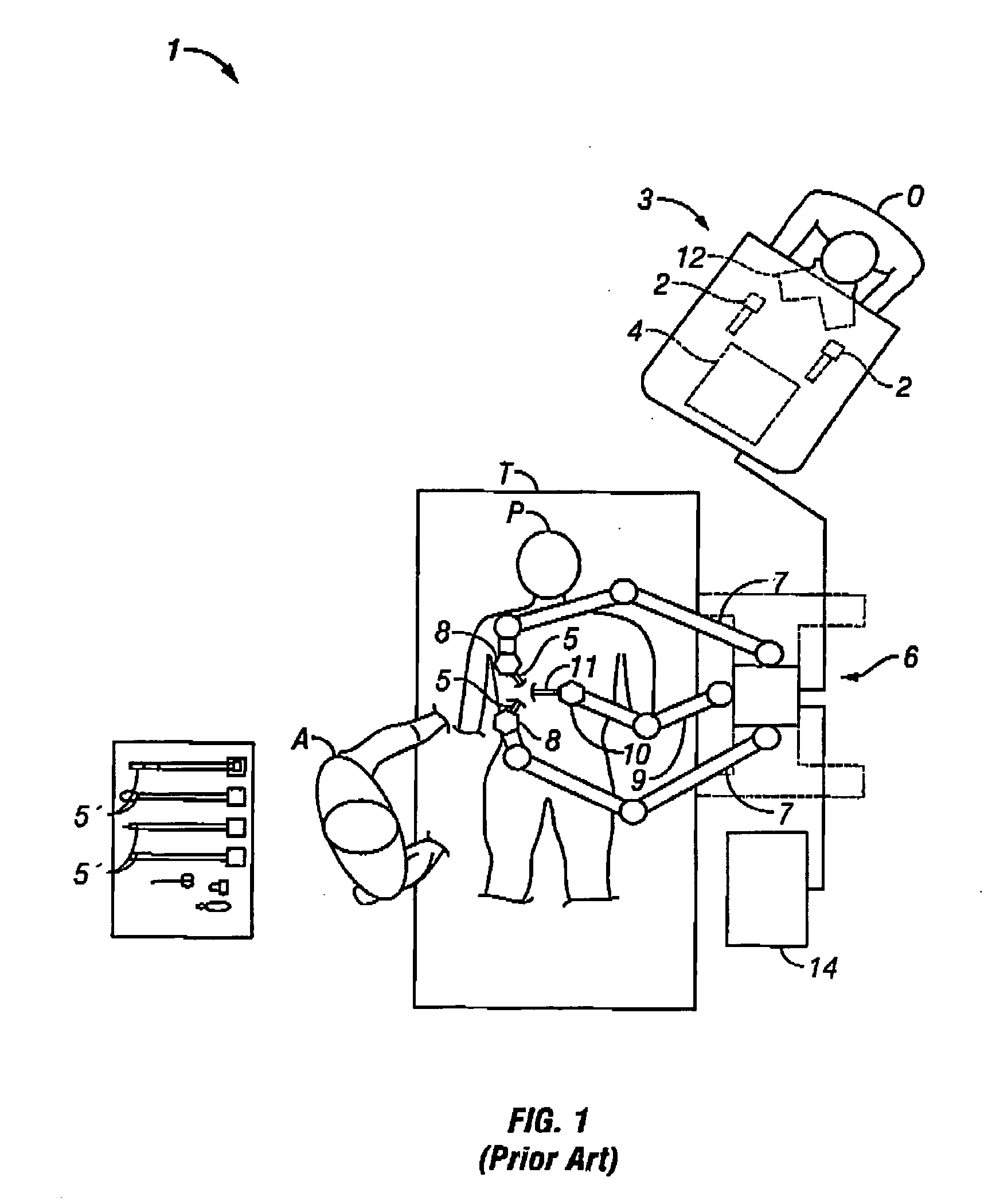

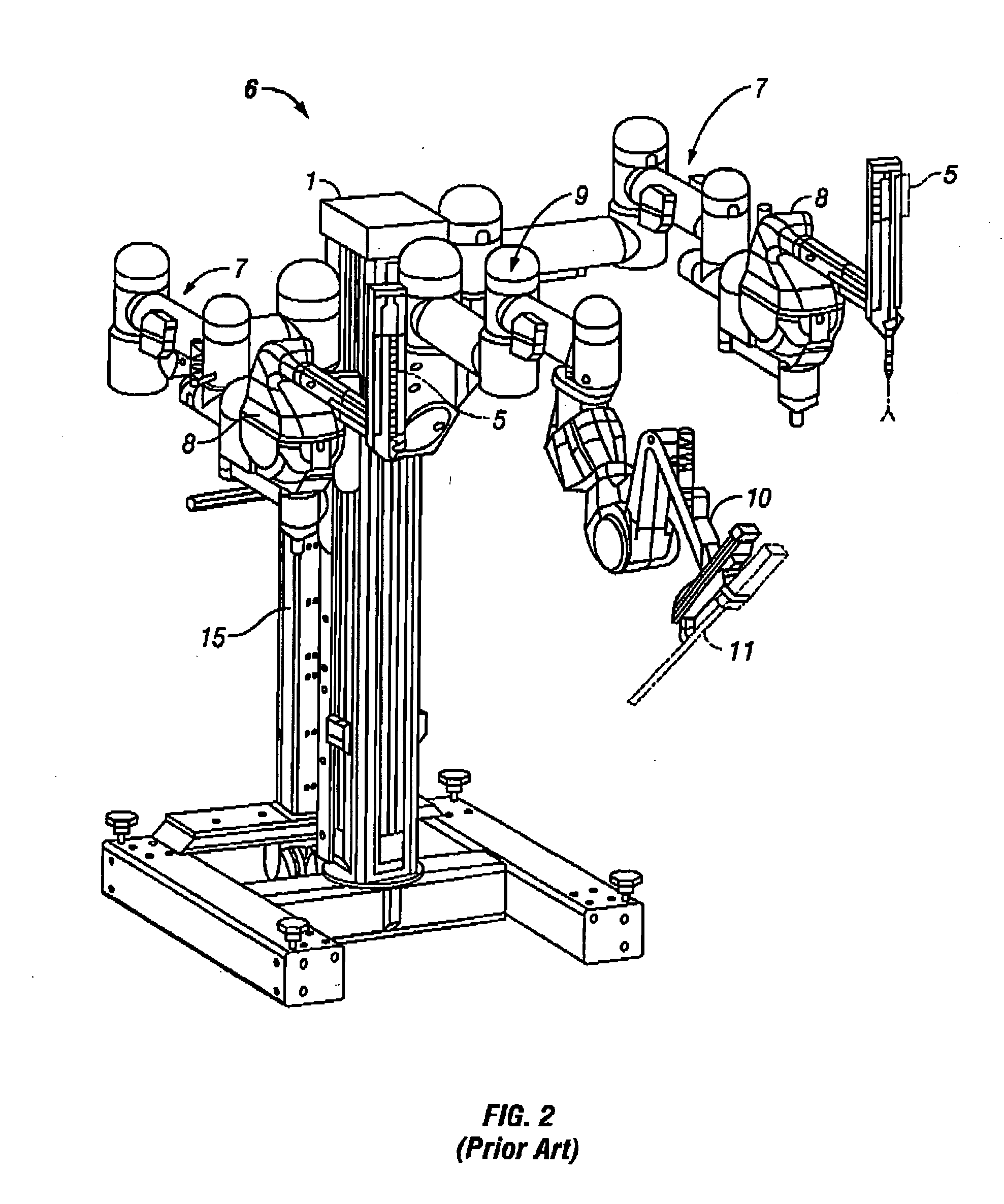

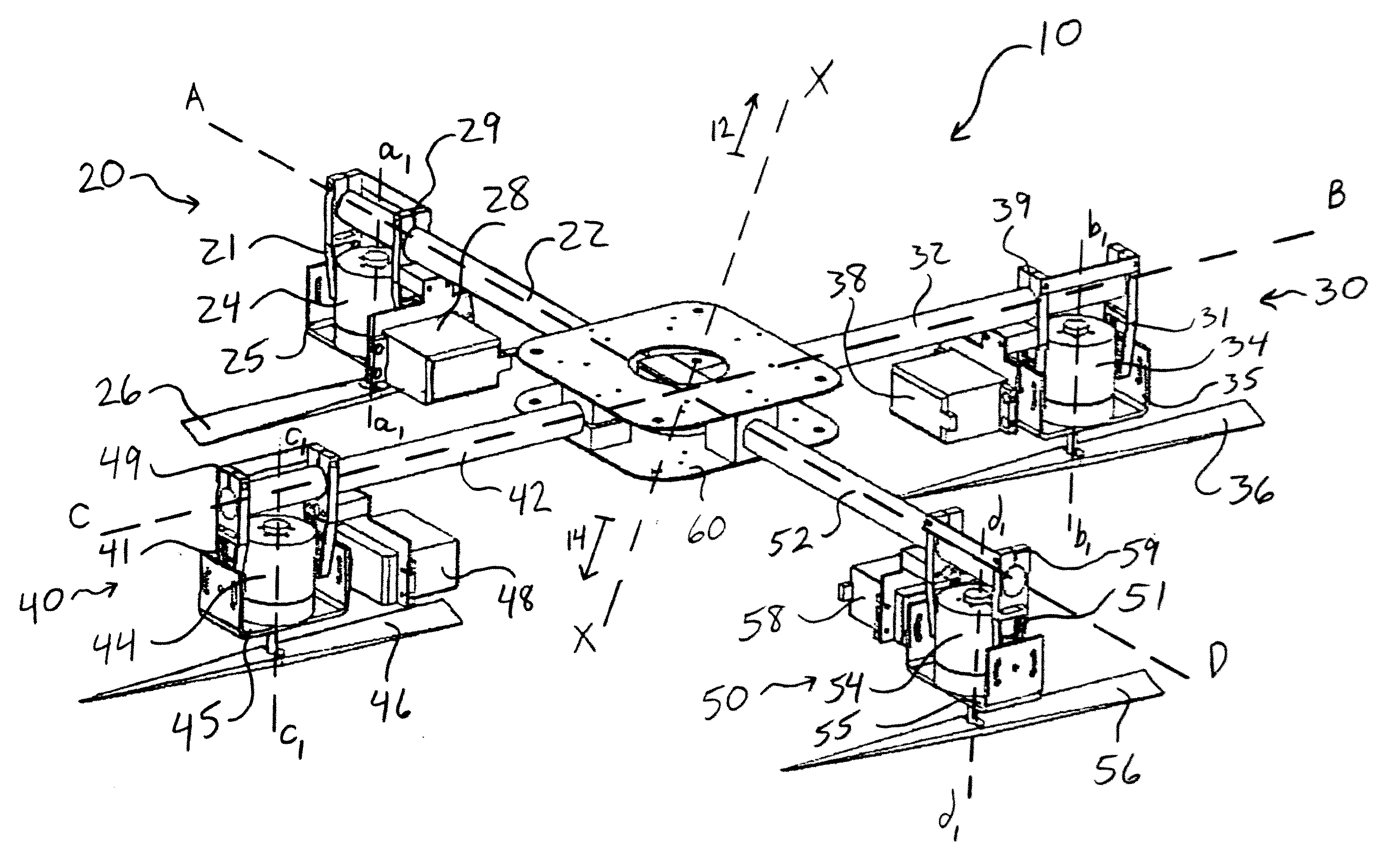

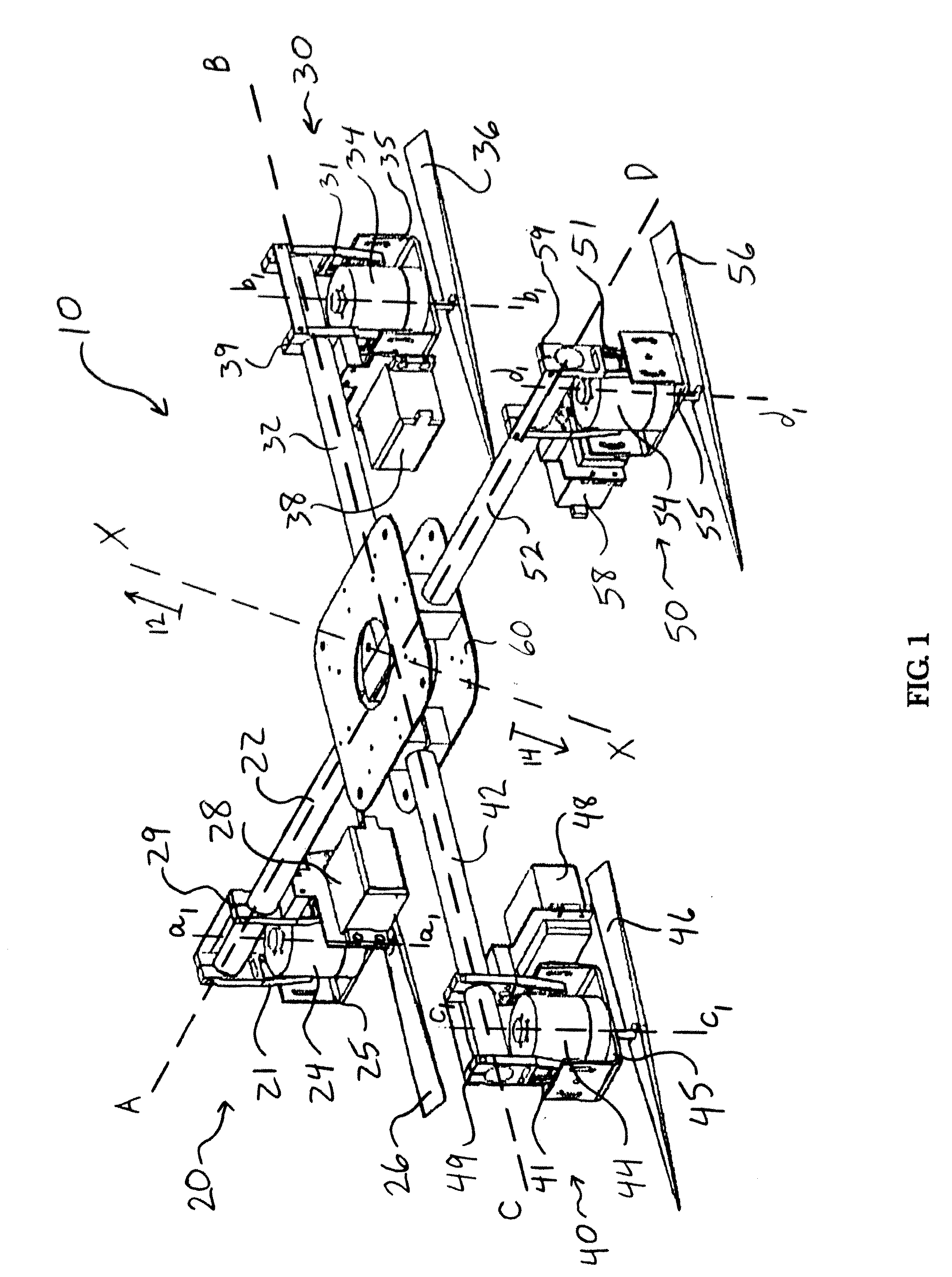

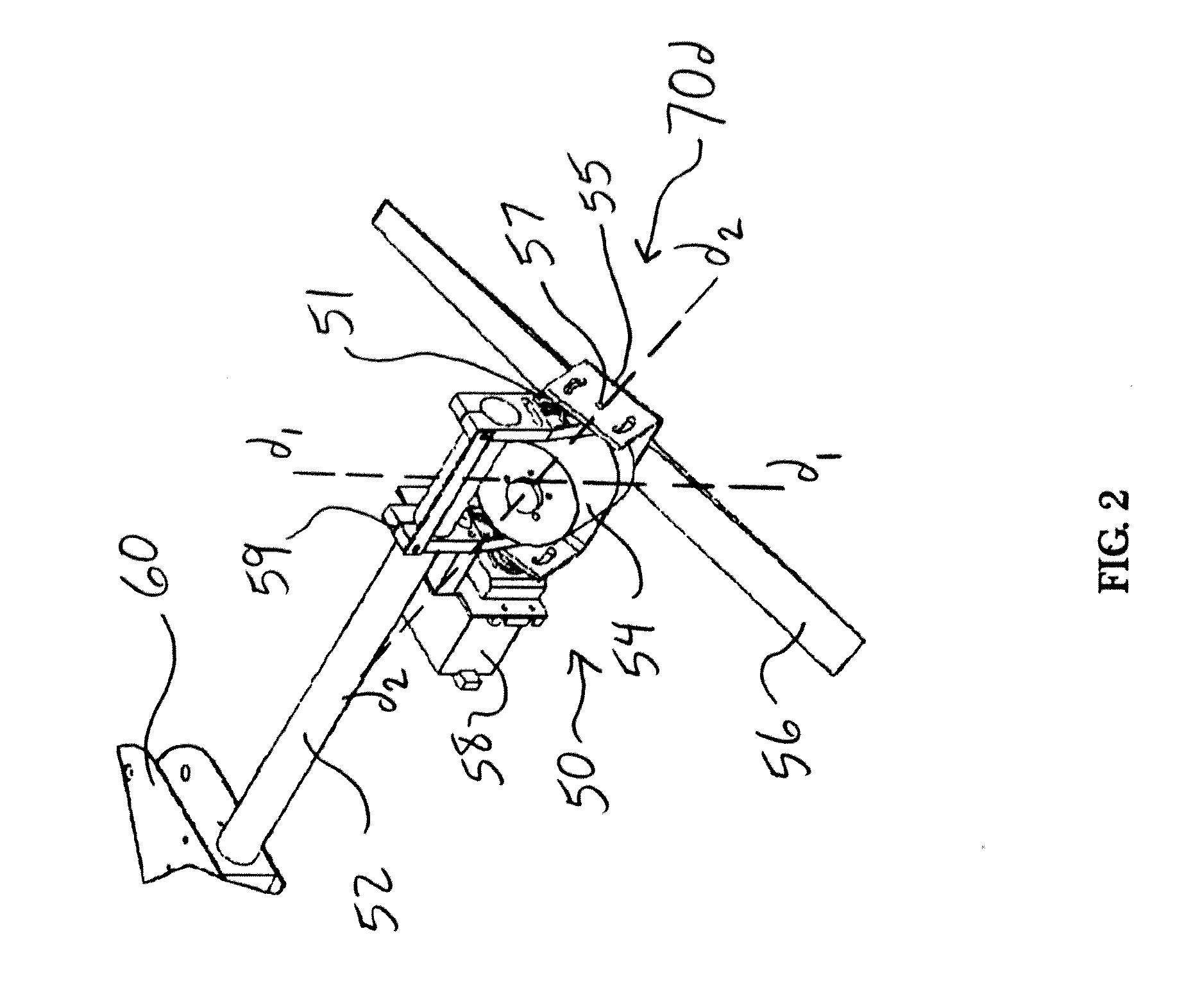

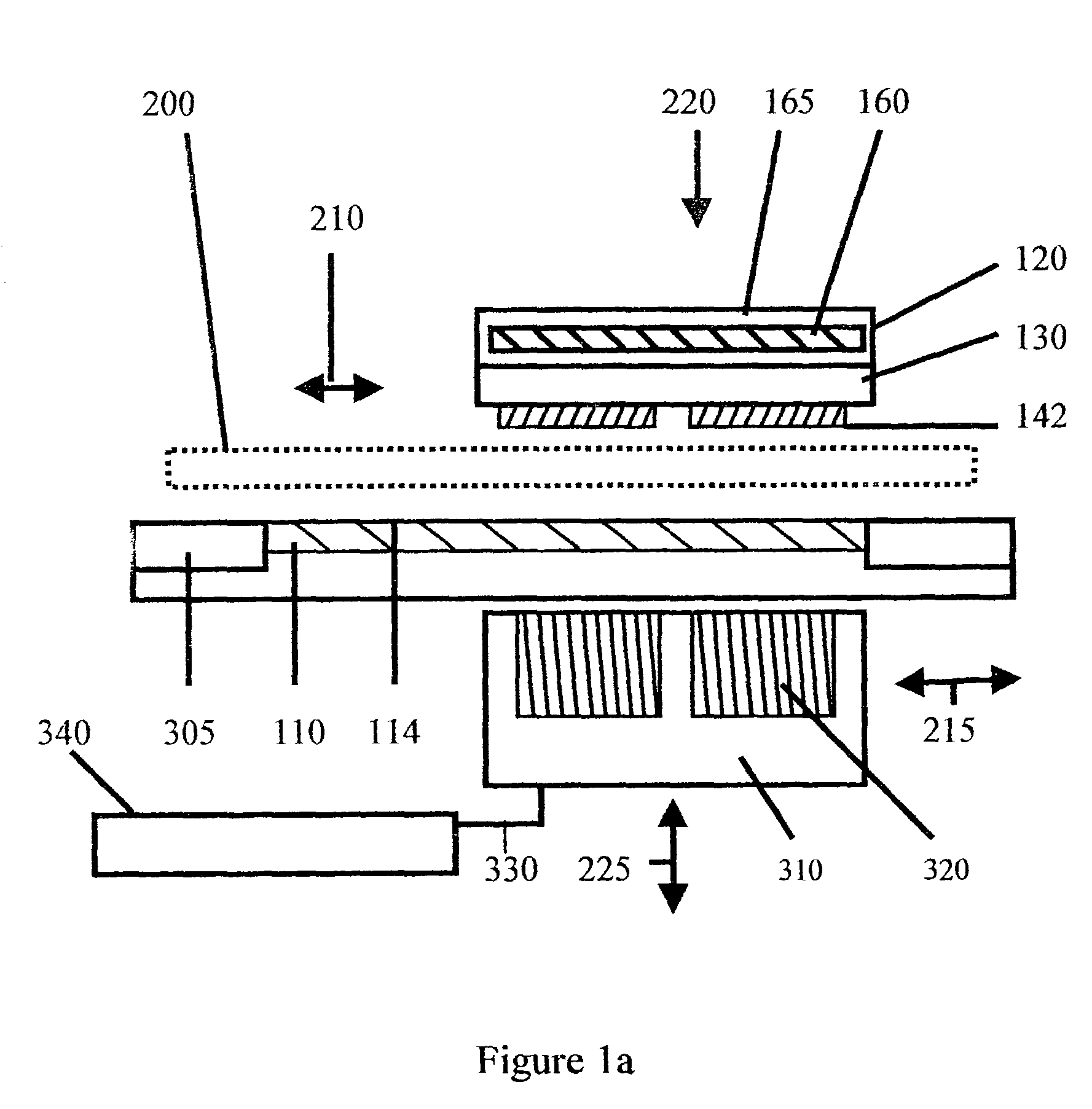

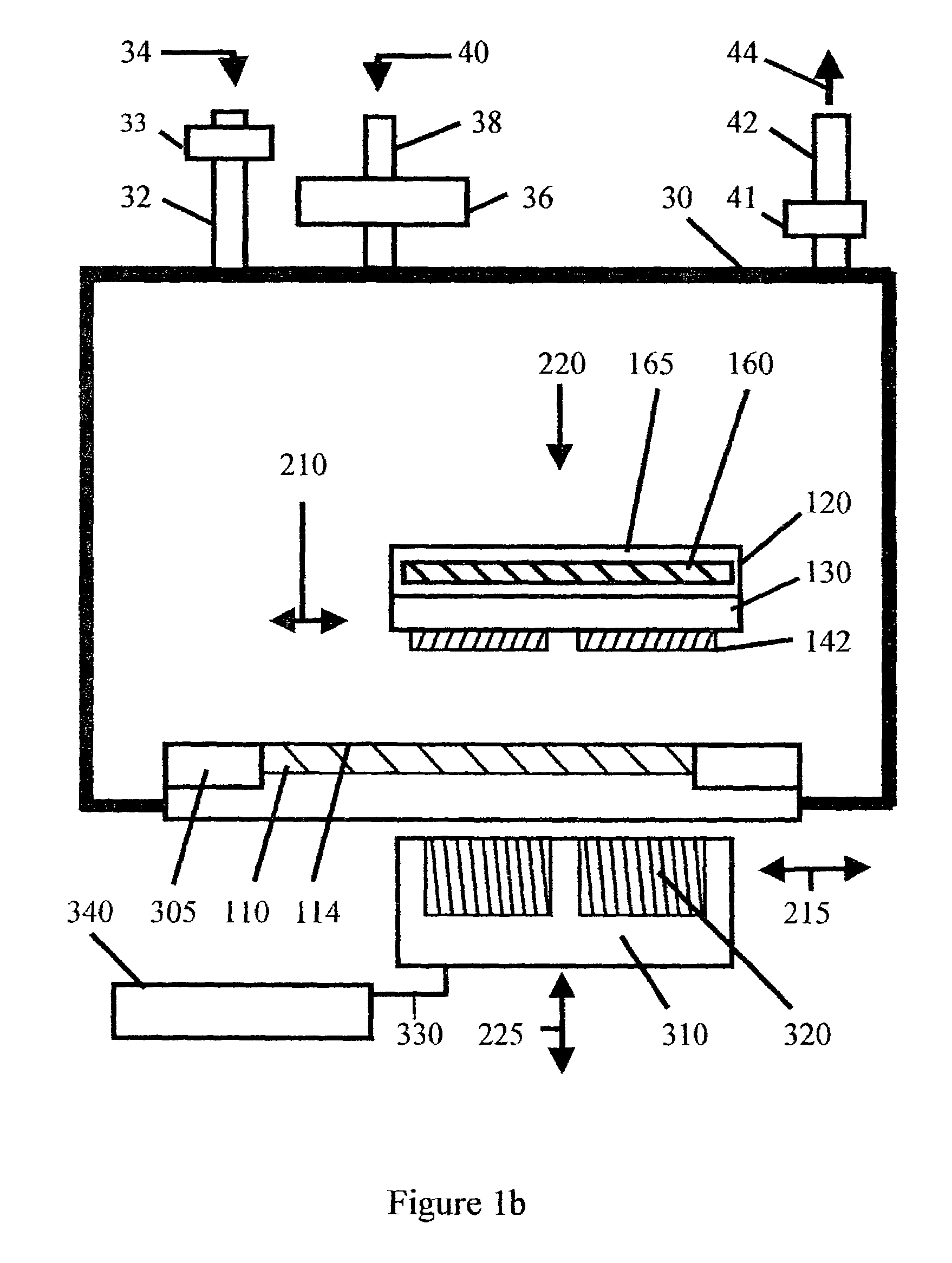

A robotic surgery system comprises a mounting base, a plurality of surgical instruments, and an articulate support assembly. Each instrument is insertable into a patient through an associated minimally invasive aperture to a desired internal surgical site. The articulate support assembly movably supports the instruments relative to the base. The support generally comprises an orienting platform, a platform linkage movably supporting the orienting platform relative to the base, and a plurality of manipulators mounted to the orienting platform, wherein each manipulator movably supports an associated instrument.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Modular manipulator support for robotic surgery

InactiveUS20060167440A1Simple structureReduce complexityDiagnosticsSurgical manipulatorsSurgical siteModularity

A robotic surgery system comprises a mounting base, a plurality of surgical instruments, and an articulate support assembly. Each instrument is insertable into a patient through an associated minimally invasive aperture to a desired internal surgical site. The articulate support assembly movably supports the instruments relative to the base. The support generally comprises an orienting platform, a platform linkage movably supporting the orienting platform relative to the base, and a plurality of manipulators mounted to the orienting platform, wherein each manipulator movably supports an associated instrument.

Owner:INTUITIVE SURGICAL OPERATIONS INC

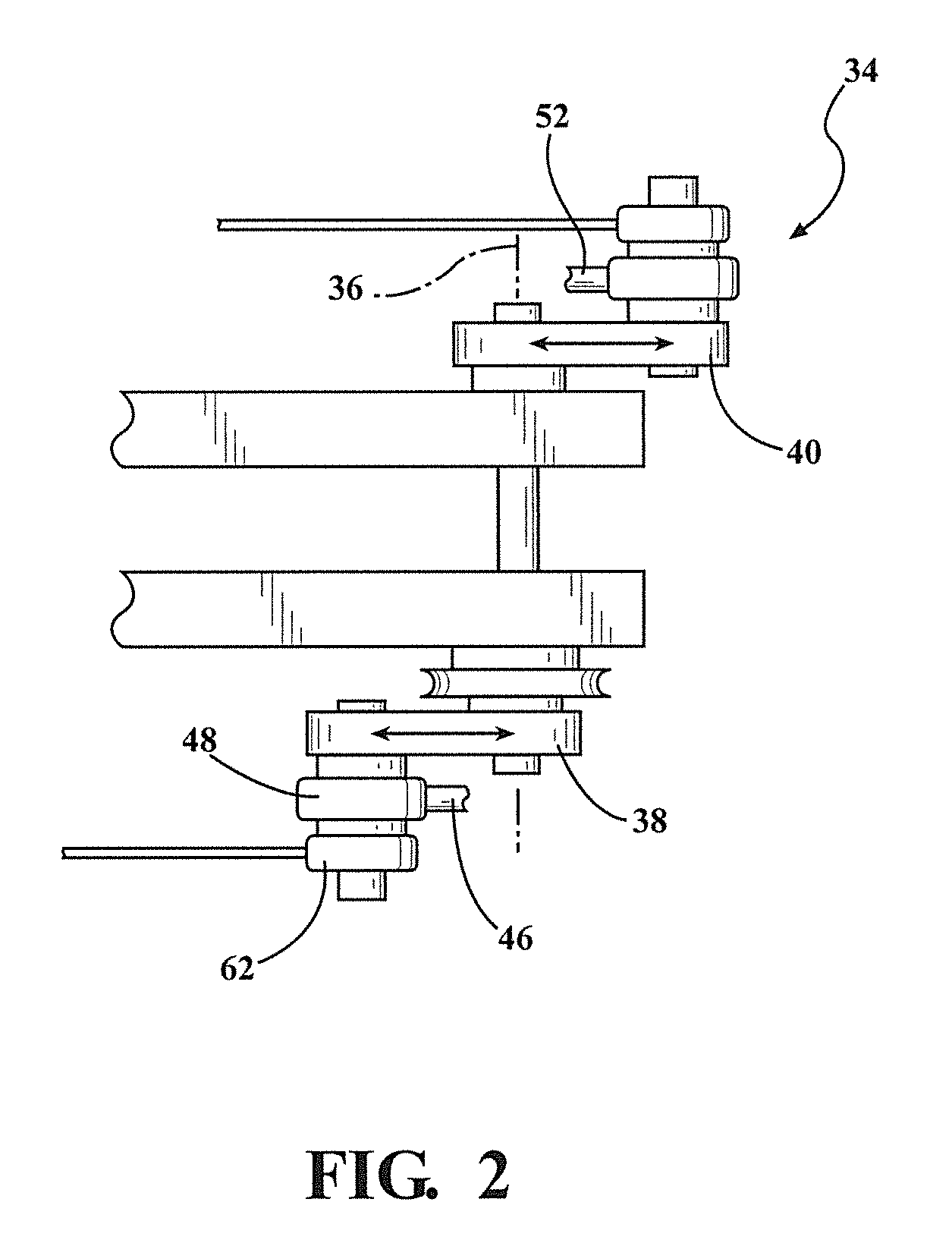

Rotary wing vehicle

InactiveUS20110226892A1Simpler and fast translation control responseReduce thrustAircraft navigation controlUnmanned aerial vehiclesFlight vehicleEngineering

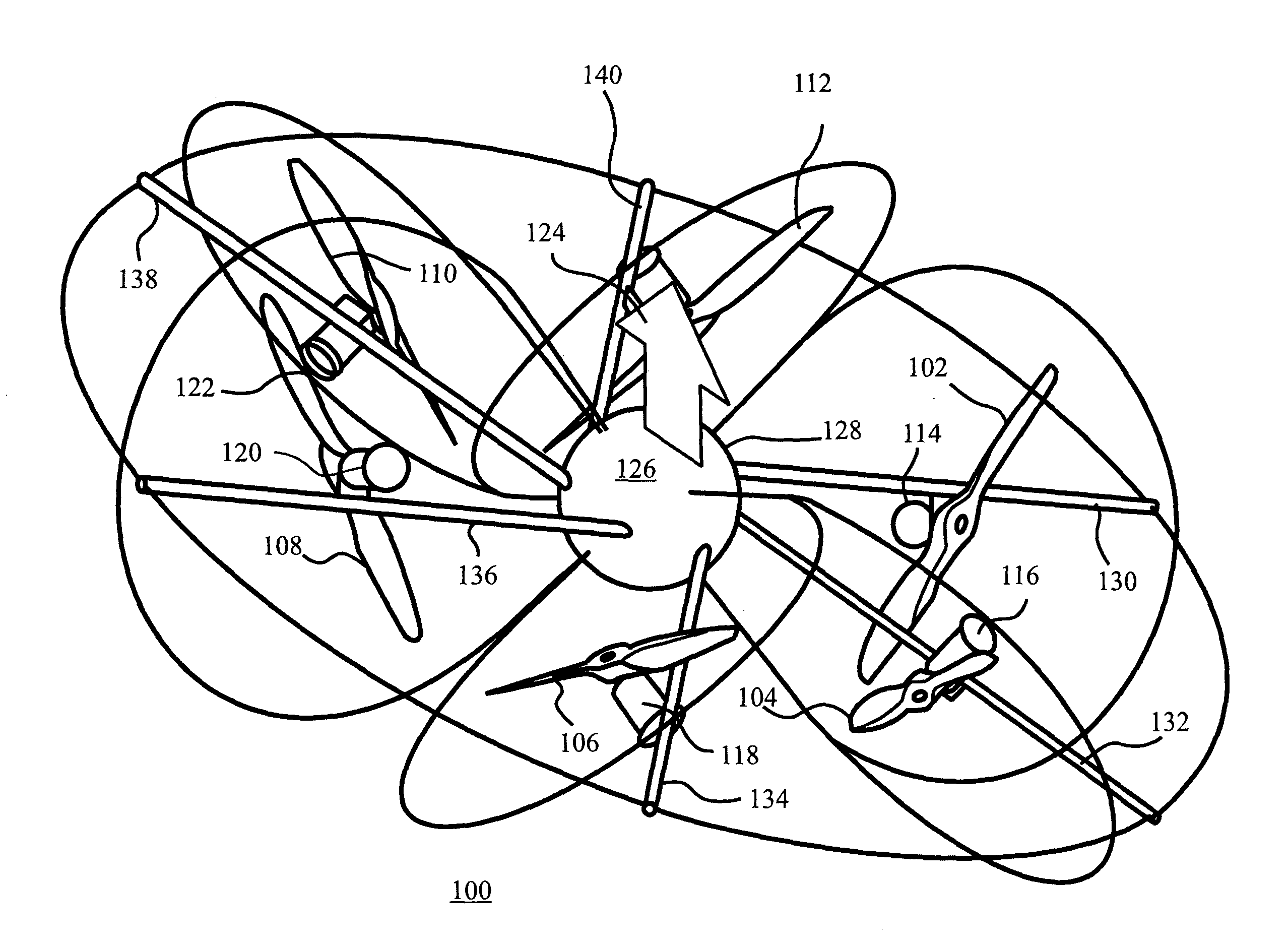

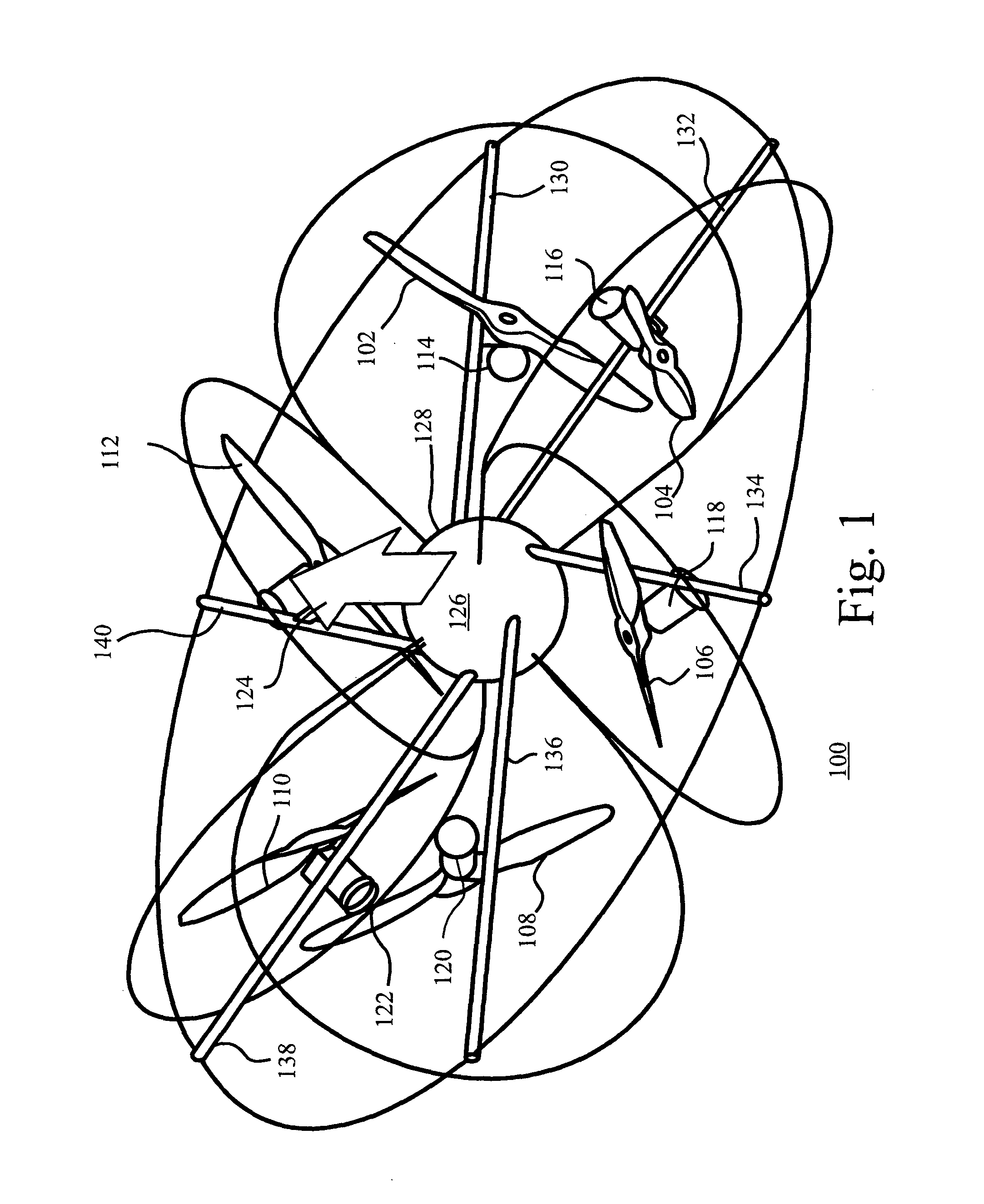

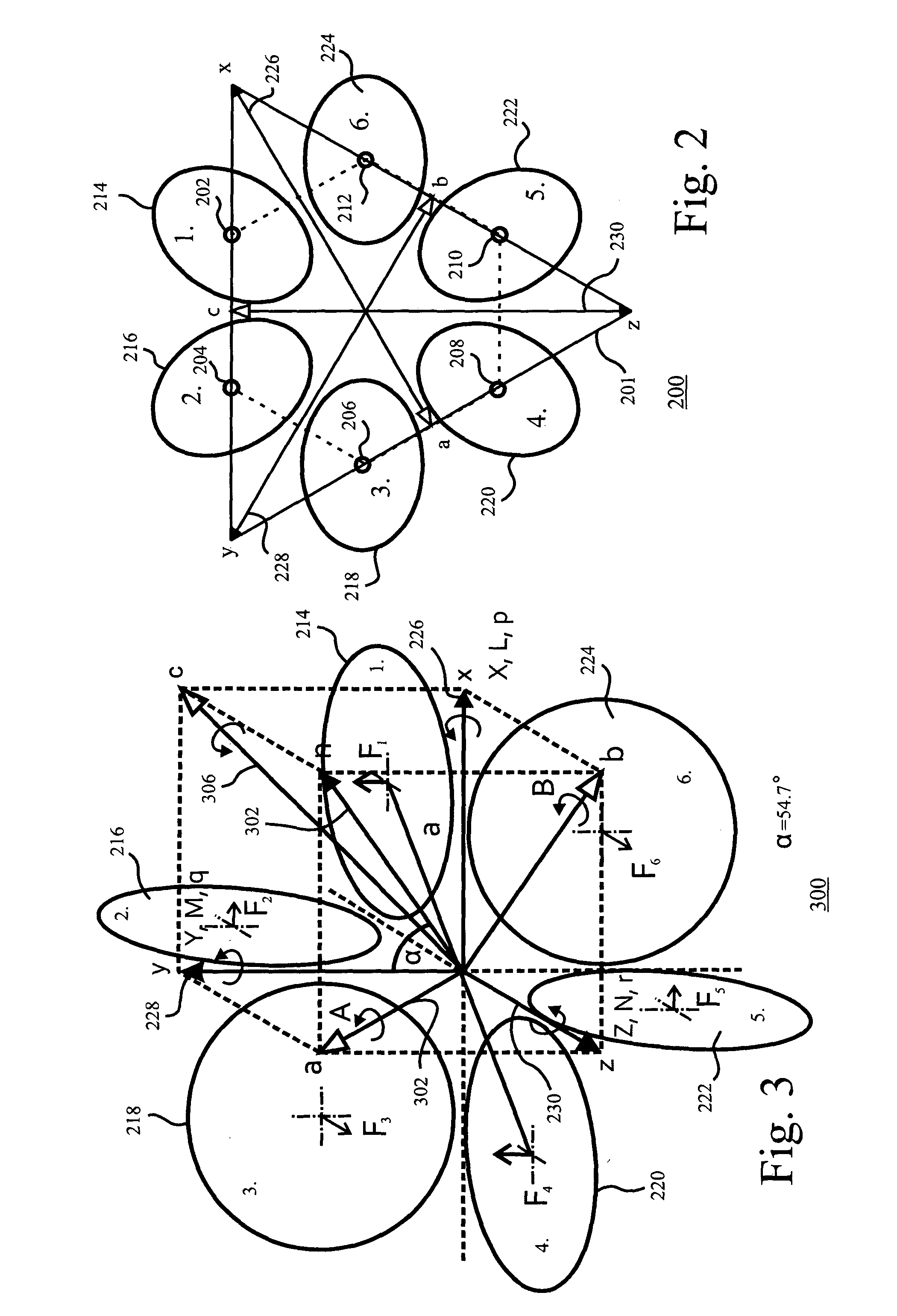

Embodiments of the invention relate to a vehicle comprising a plurality of inclined rotors that are operable to provide at least one of thrust and torque vectoring according to a desired thrust and / or torque vectors.

Owner:UNIV OF MANCHESTER

Quad tilt rotor vertical take off and landing (VTOL) unmanned aerial vehicle (UAV) with 45 degree rotors

InactiveUS20130105635A1Maintain balance and stabilityIncreased payload capacityUnmanned aerial vehiclesRemote controlled aircraftFlight vehicleClassical mechanics

A system and method to control the stability and direction of a quad tilt vertical takeoff and landing (VTOL) unmanned aerial vehicle (UAV) by manipulating the rotational speed of propellers at each rotor while simultaneously tilting the rotors in a 45 degree configuration related to a central axis for directional control. Each rotor is attached to a tilting mechanism configured to be symmetrically aligned at a 45 degree angle from a central axis to manipulate a directional angle of each rotor along a first and second axis. The first and fourth rotors are aligned on the first axis while the second and third rotors are aligned on the second axis. A controller includes a first control loop for manipulating the rotational speed of the propellers to control the aircraft balance and a second control loop for controlling lateral movement by tilting the rotors along the first and second axis.

Owner:KING ABDULLAH II DESIGN & DEV BUREAU

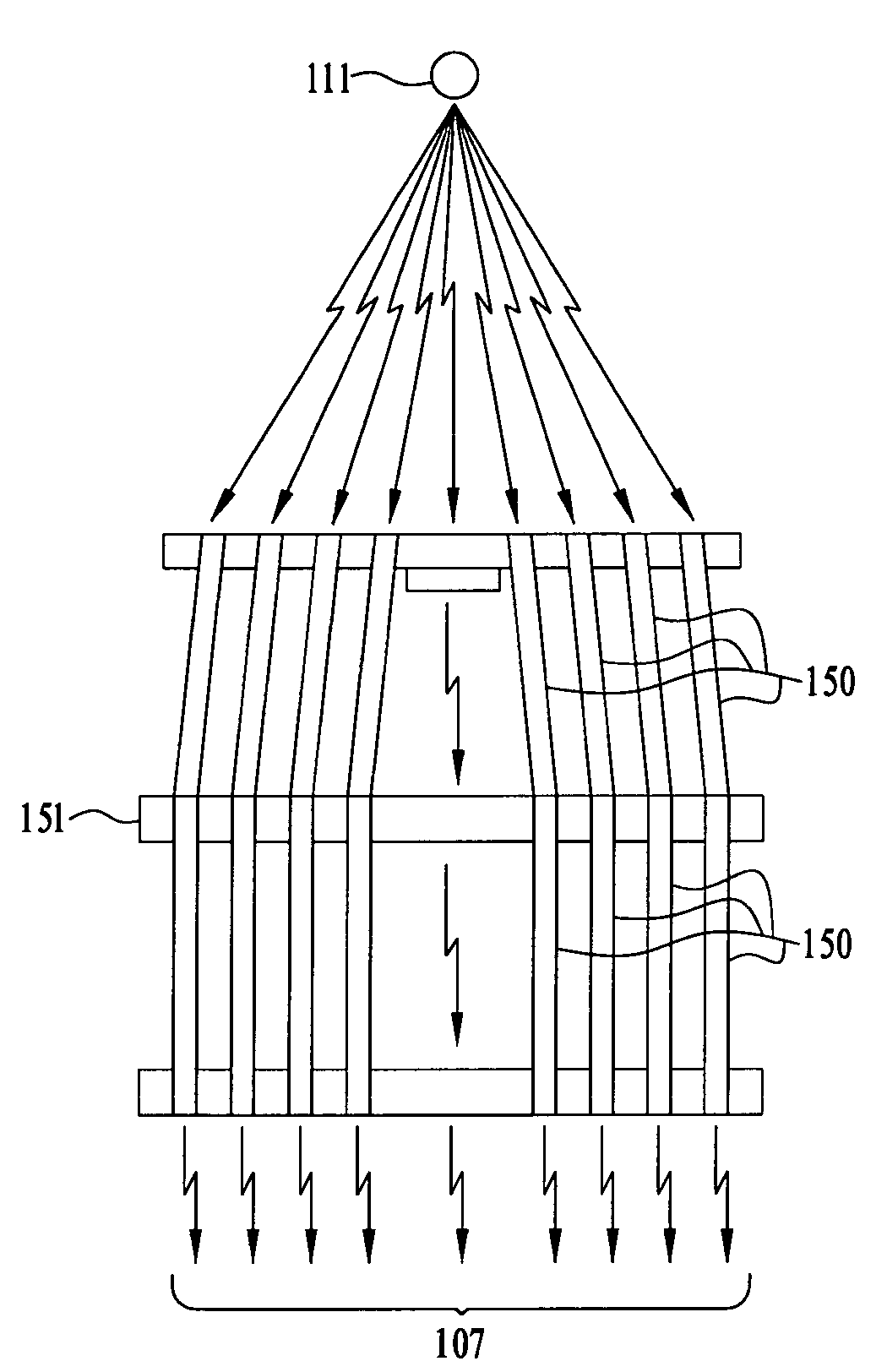

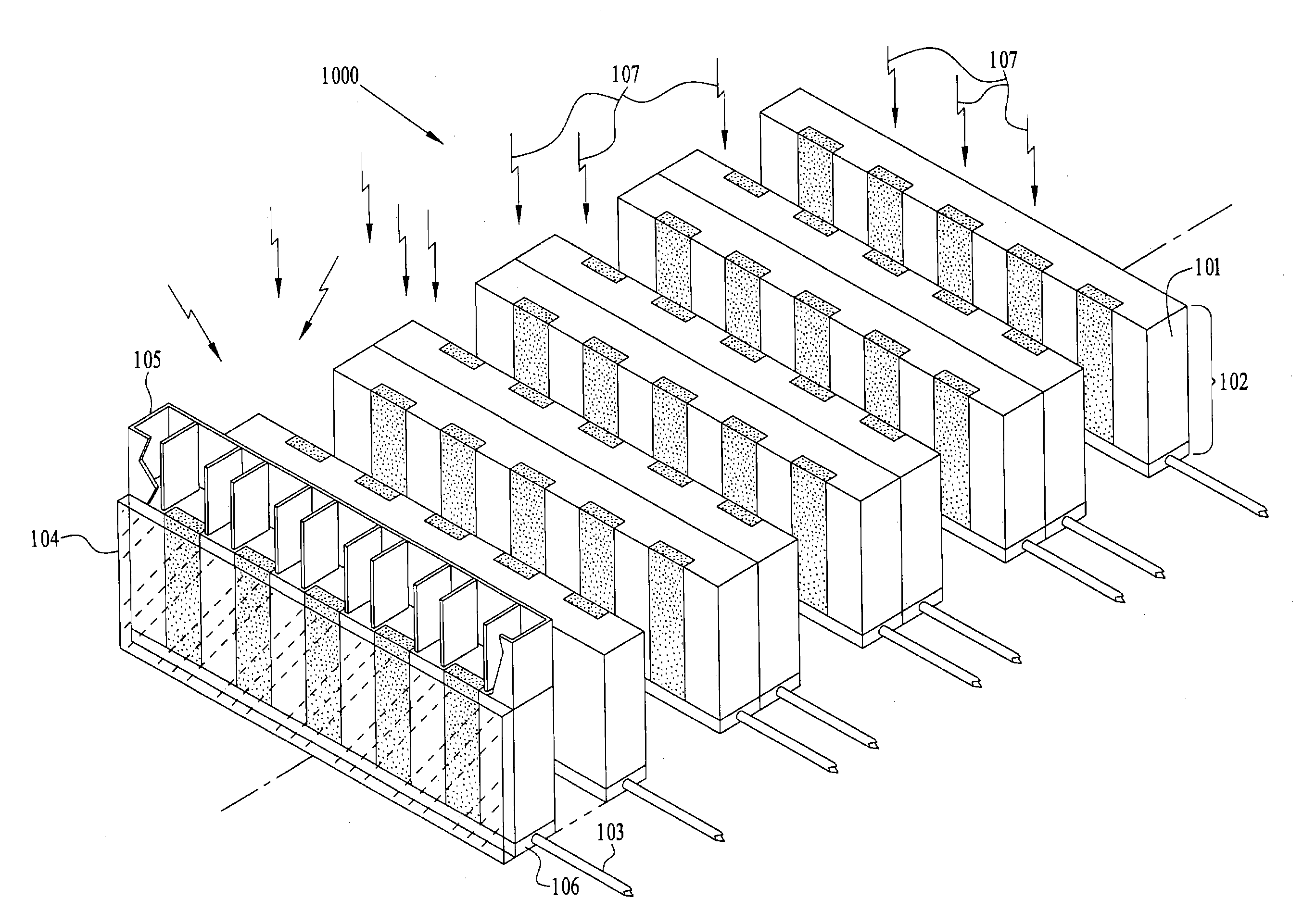

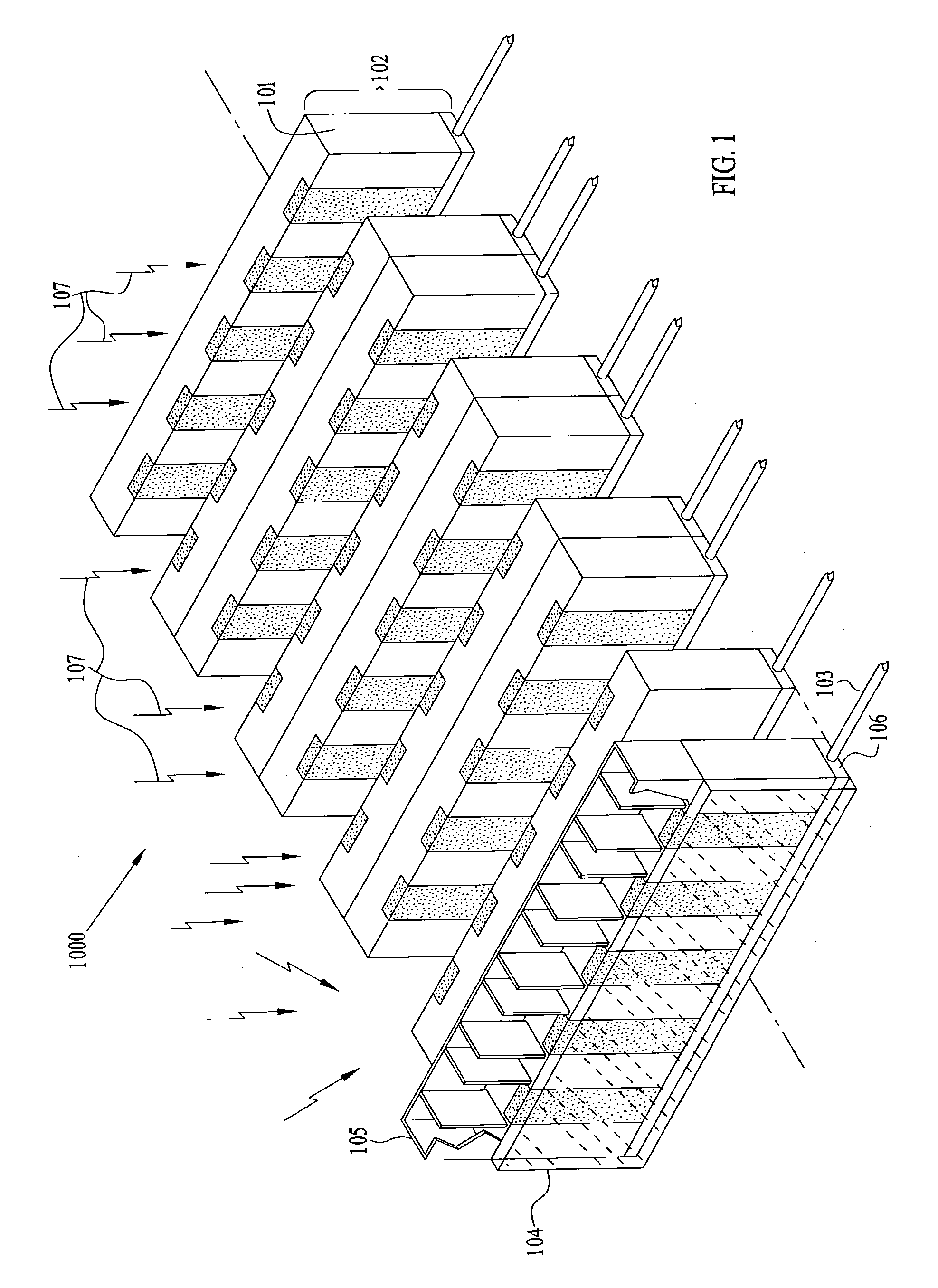

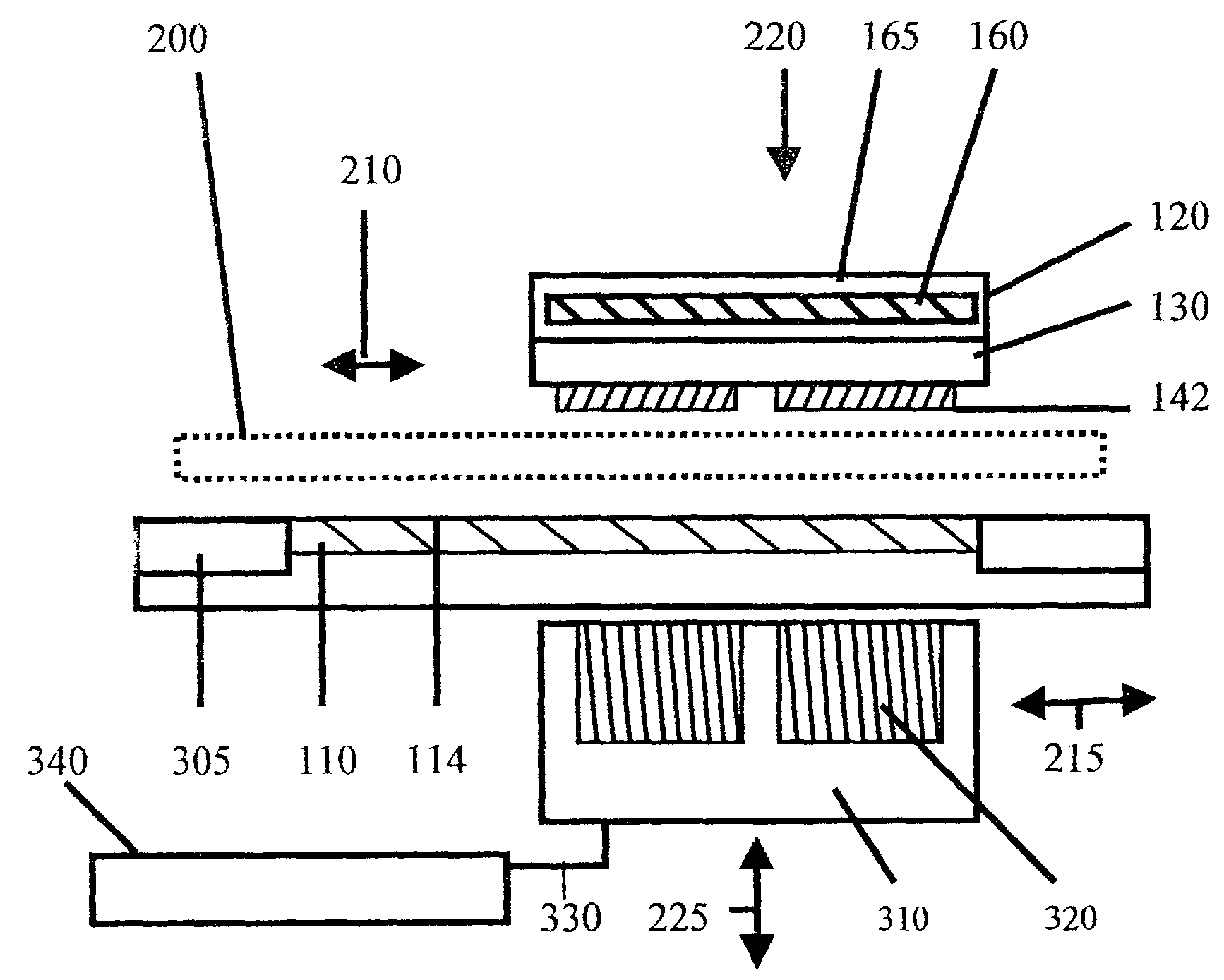

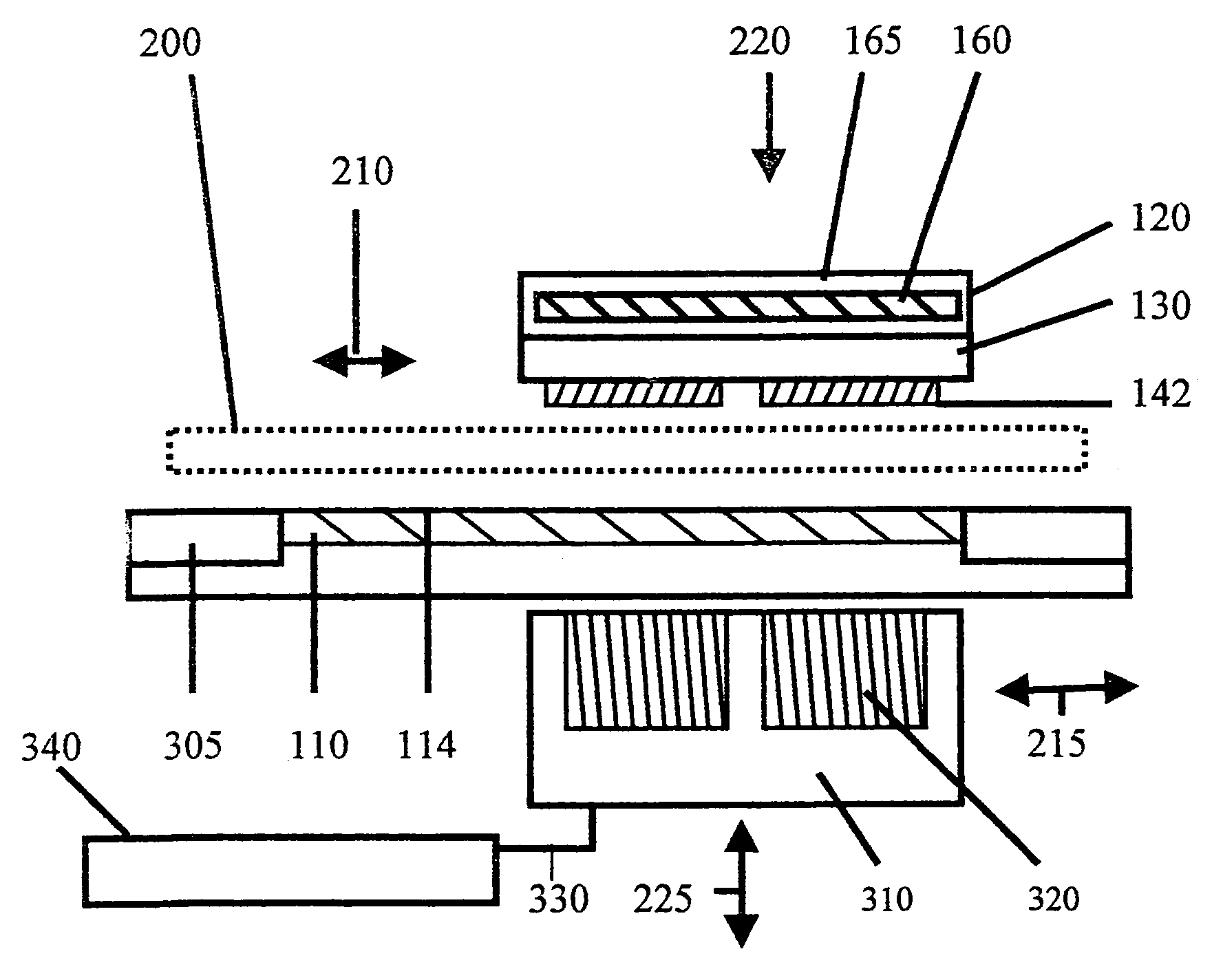

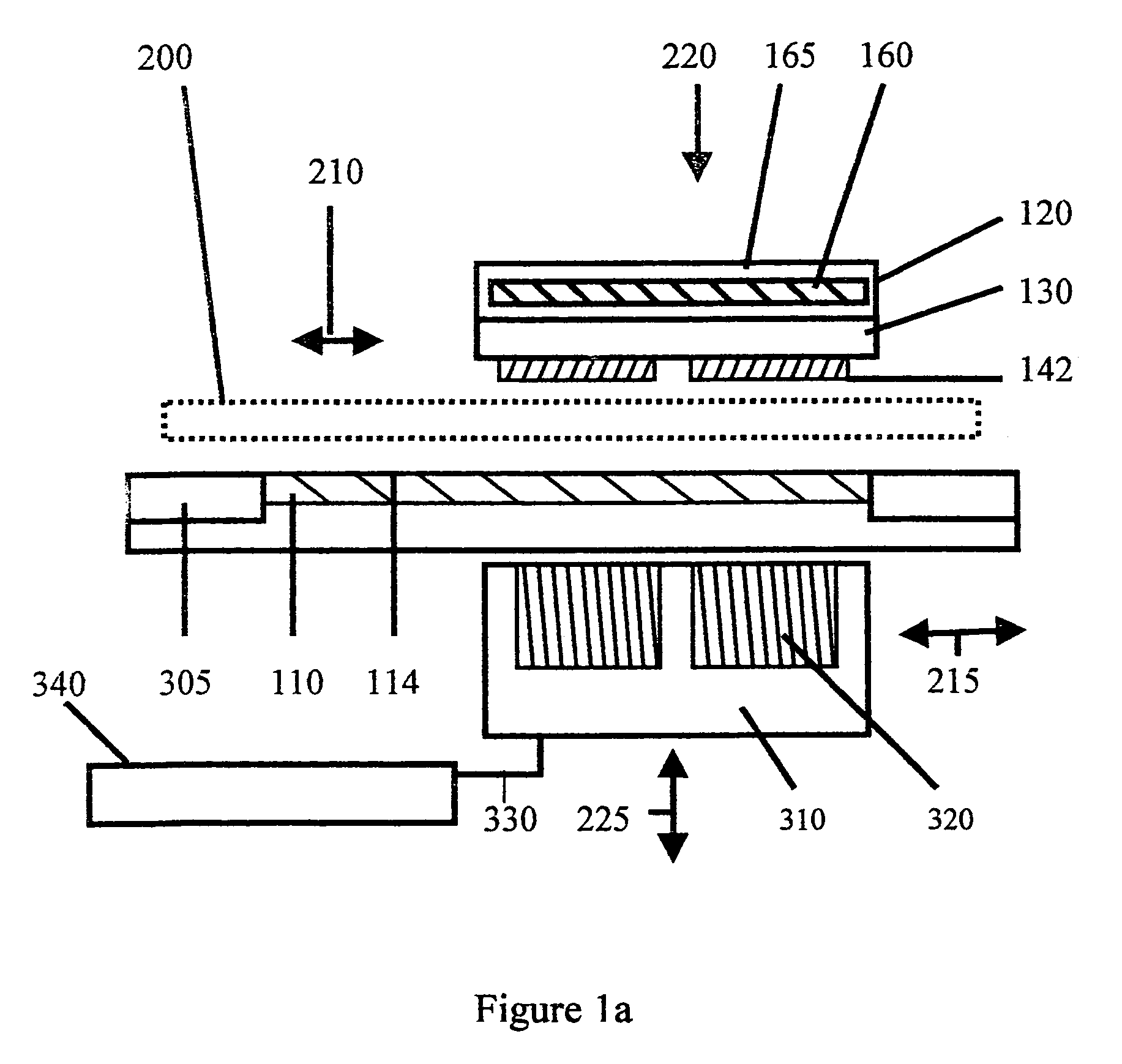

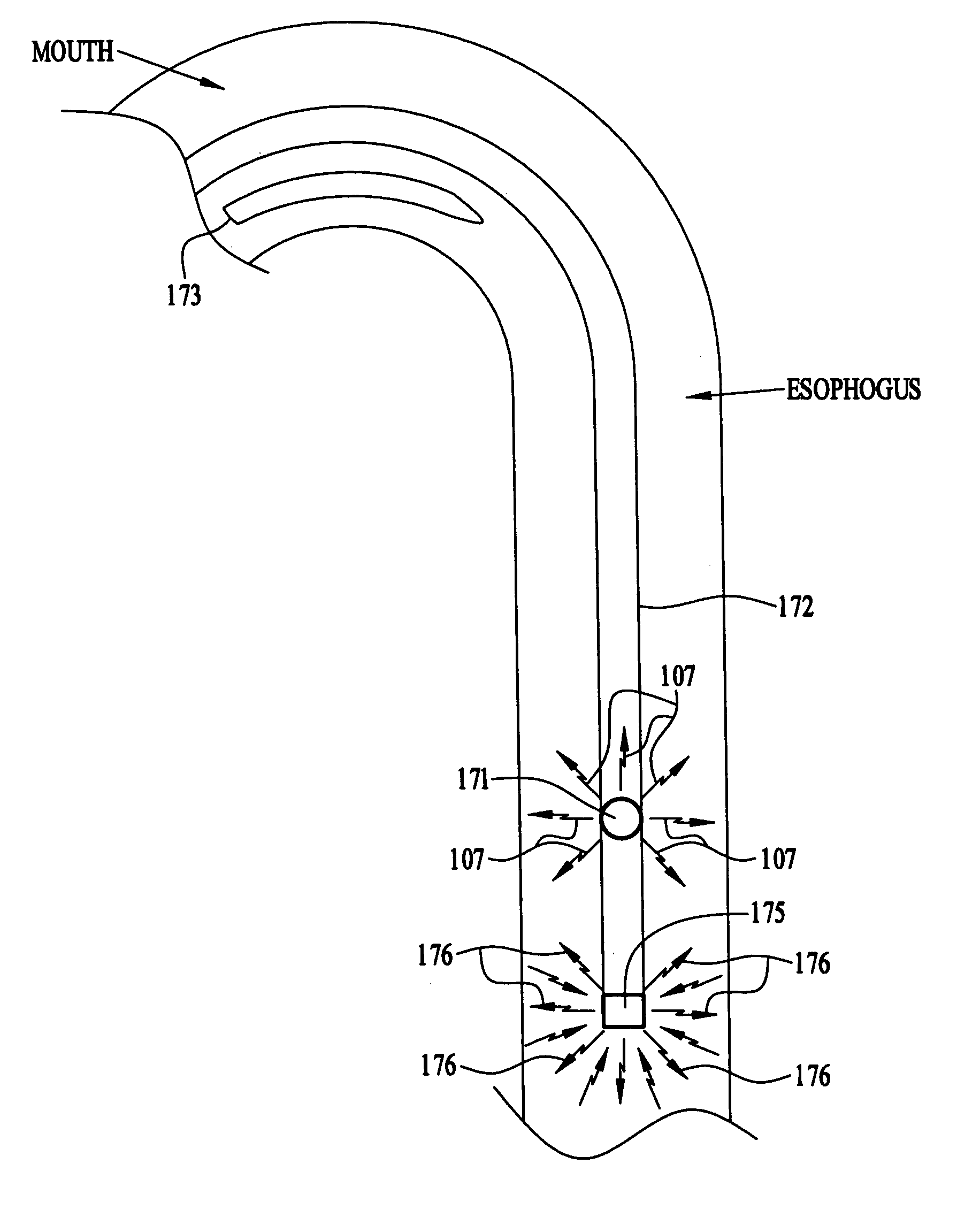

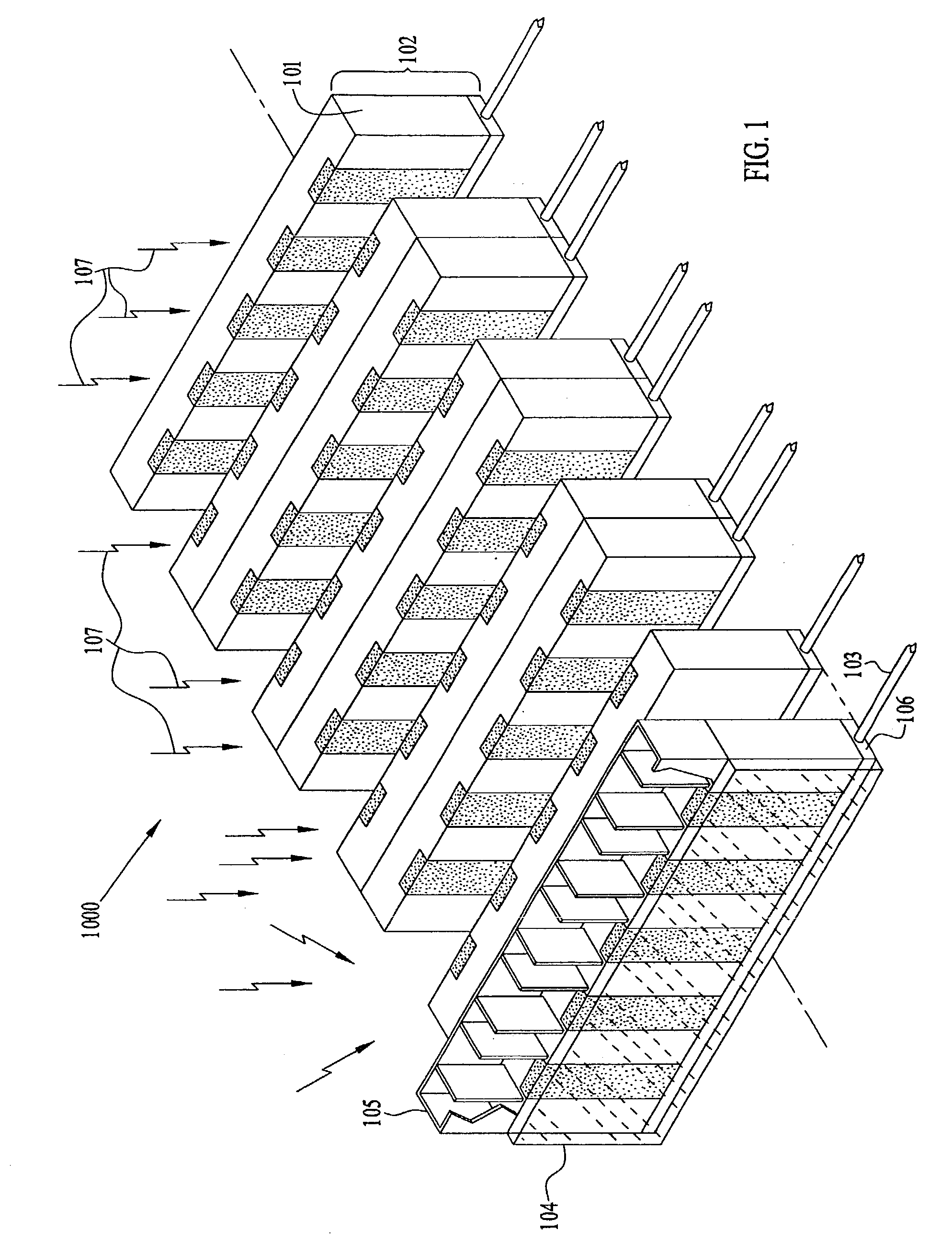

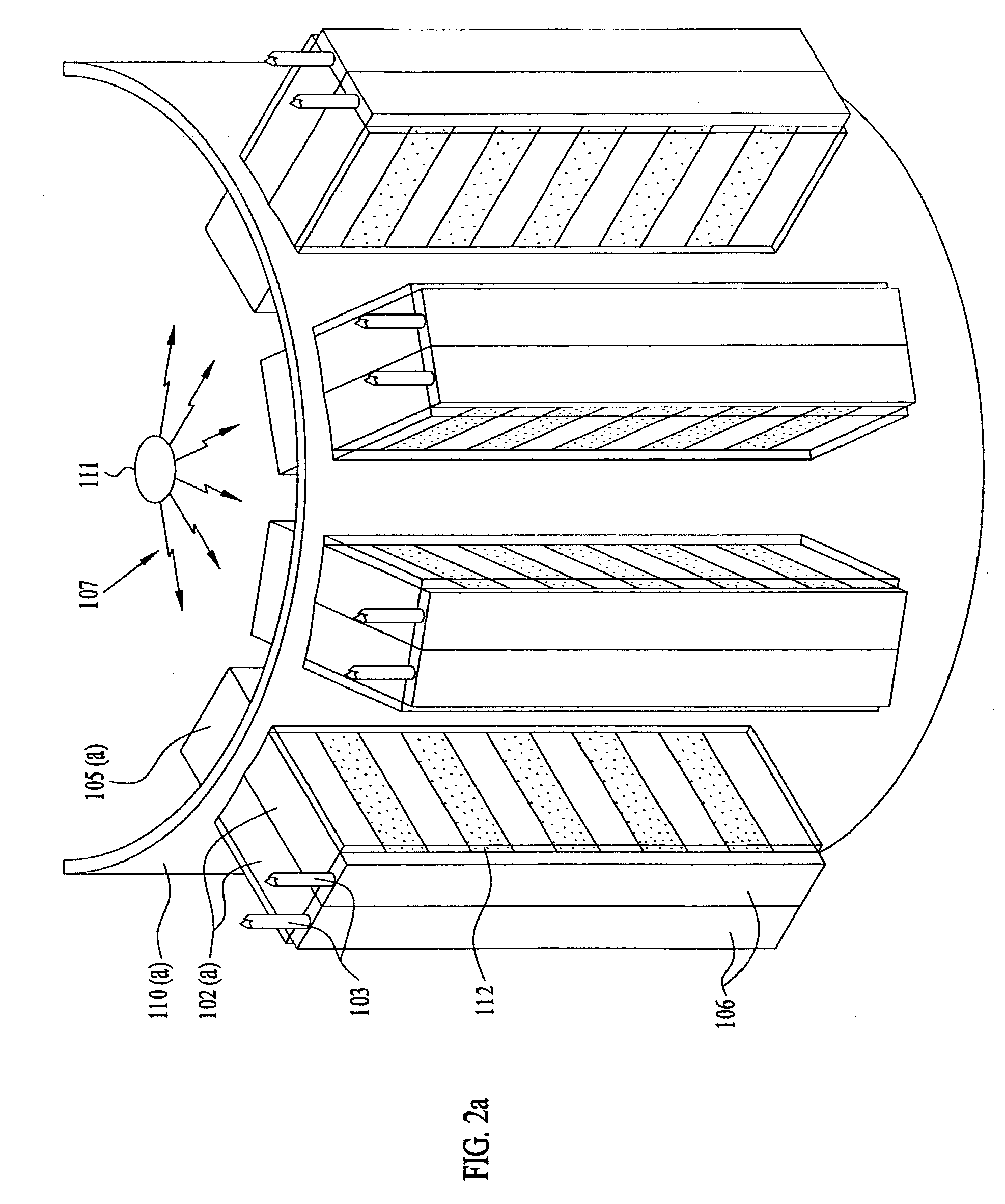

Device and system for enhanced SPECT, PET, and Compton scatter imaging in nuclear medicine

ActiveUS7291841B2Easy to optimizeEnhance analysis capabilitySolid-state devicesMaterial analysis by optical meansCorrelative imagingPhysics

A method and apparatus for detecting radiation including x-ray, gamma ray, and particle radiation for radiographic imaging, and nuclear medicine and x-ray mammography in particular, and material composition analysis are described. A detection system employs fixed or configurable arrays of one or more detector modules comprising detector arrays that may be electronically manipulated through a computer system. The detection system, by providing the ability for electronic manipulation, permits adaptive imaging. Detector array configurations include familiar geometries, including slit, slot, plane, open box, and ring configurations, and customized configurations, including wearable detector arrays, that are customized to the shape of the patient. Conventional, such as attenuating, rigid geometry, and unconventional collimators, such as x-ray optic, configurable, Compton scatter modules, can be selectively employed with detector modules and radiation sources. Novel Compton gamma camera designs can be implemented. Edge-on detector resolution may be enhanced by measuring the interaction location along the height of the aperture. Edge-on detectors may be irradiated from the side. The components of the imaging chain can be calibrated or corrected using processes of the invention. X-ray mammography and scintimammography are enhanced by utilizing sectional compression and related imaging techniques.

Owner:MINNESOTA IMAGING & ENG

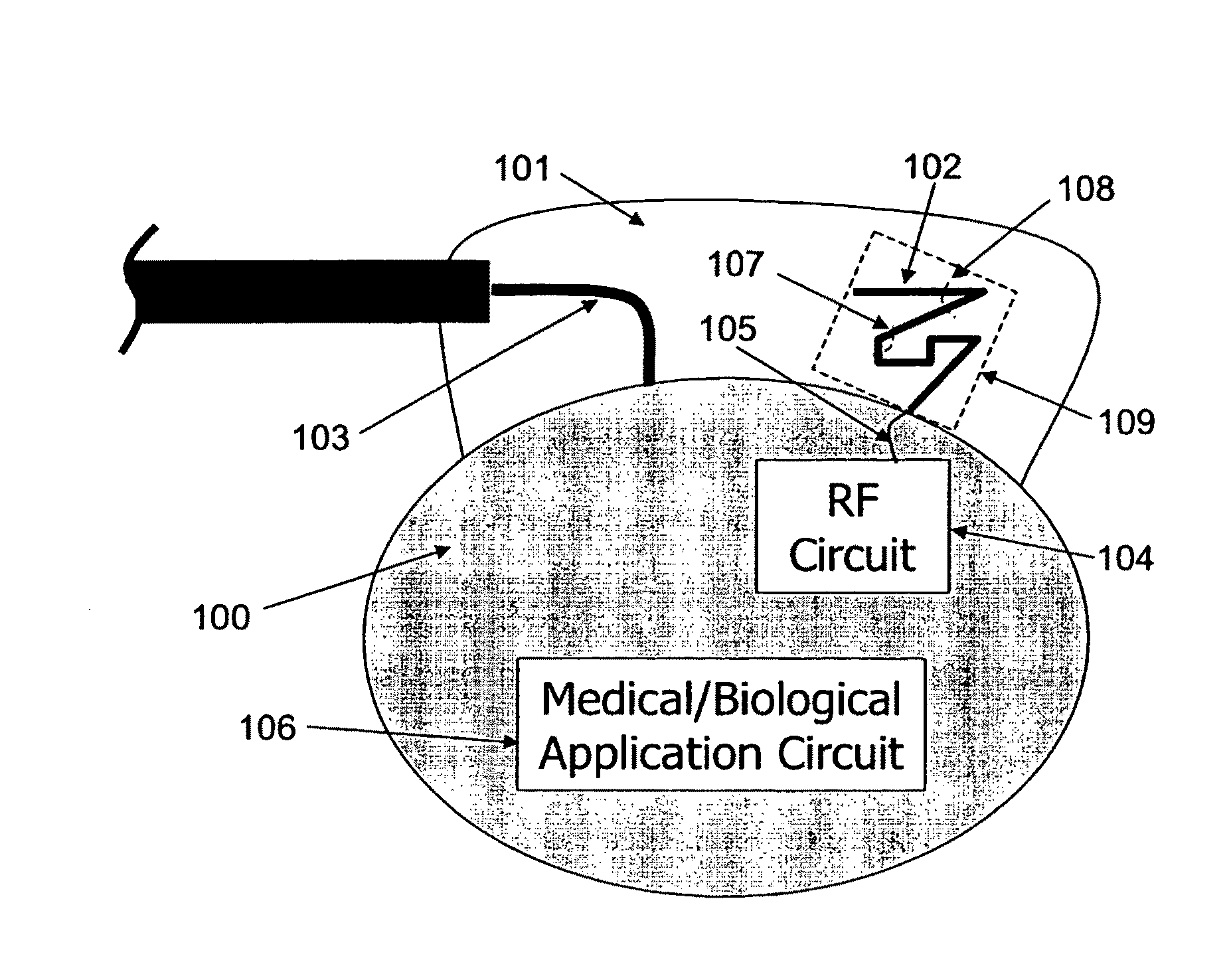

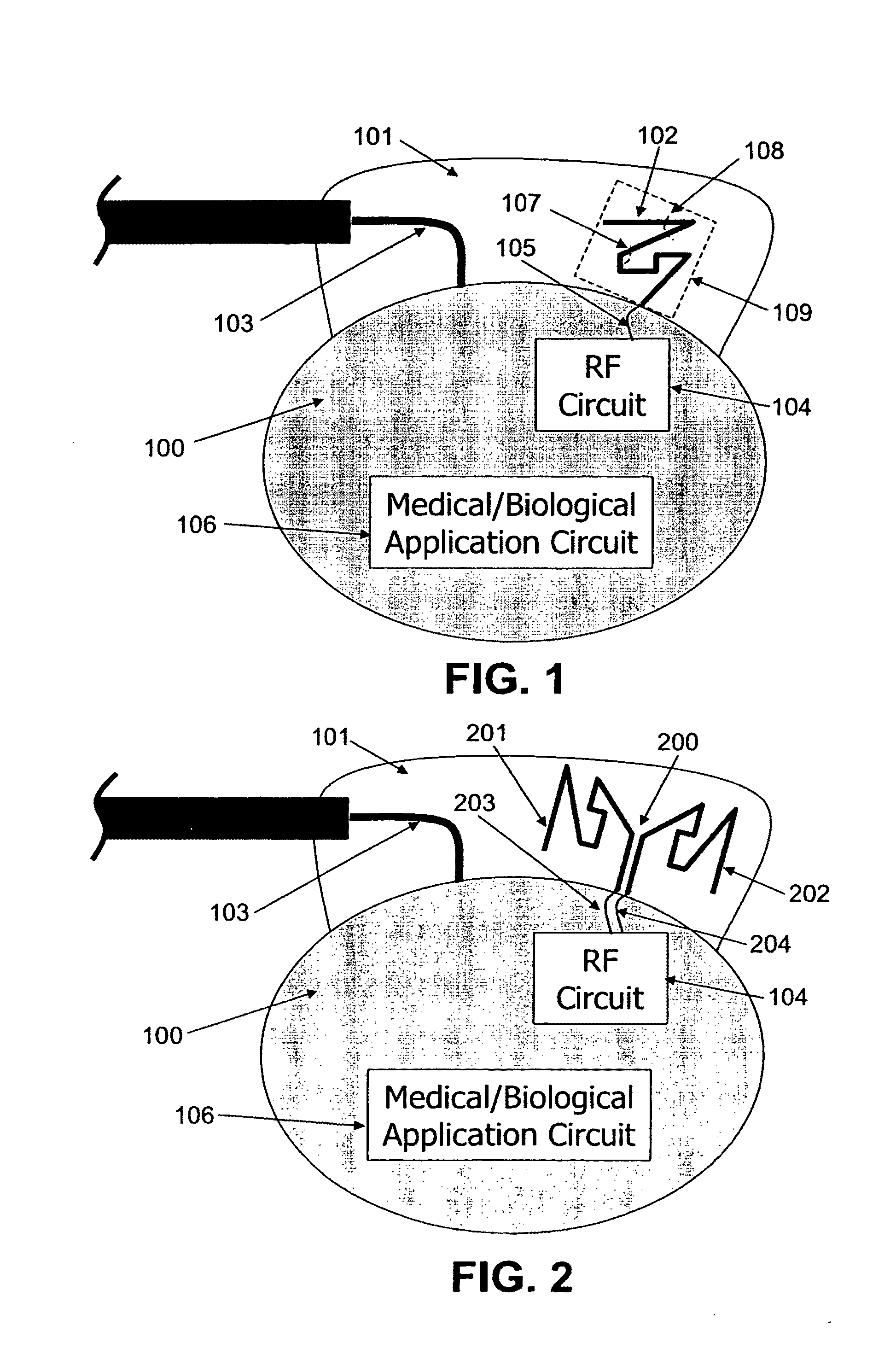

Wireless Implantable Medical Device

ActiveUS20090248112A1Provide goodLow dielectric constantElectrotherapyRadiating elements structural formsElectromagnetic couplingElectricity

One aspect of the invention relates to an implantable medical device comprising a device housing (100), at least one radio frequency circuit (104) for radio frequency communication, at least one antenna, at least one terminal to electromagnetically couple said at least one antenna to said at least one radio frequency circuit, and a dielectric compartment (101, 1661) that encompasses at least a portion of said at least one antenna. The antenna comprises a conducting pattern, at least a portion of which is shaped as a curve, wherein said curve comprises at least five segments, wherein each of said at least five segments forms an angle with each adjacent segment in said curve, wherein at least three of the at least five segments of said curve are shorter than one-fifth of the longest free-space operating wavelength of the antenna, wherein each angle between adjacent segments is less than 180°, and at least two of the angles between adjacent sections are less than approximately 115°.

Owner:FRACTUS

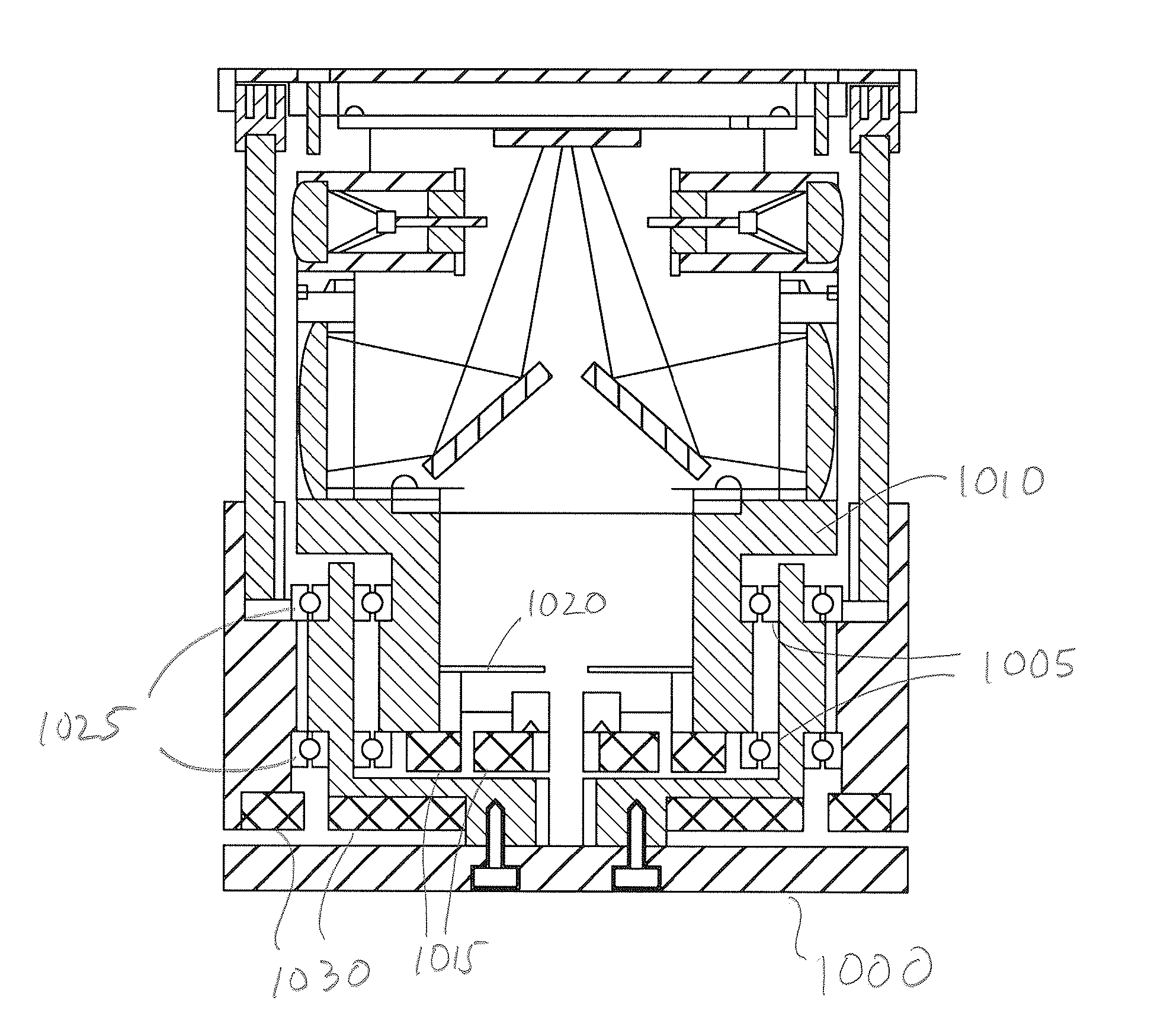

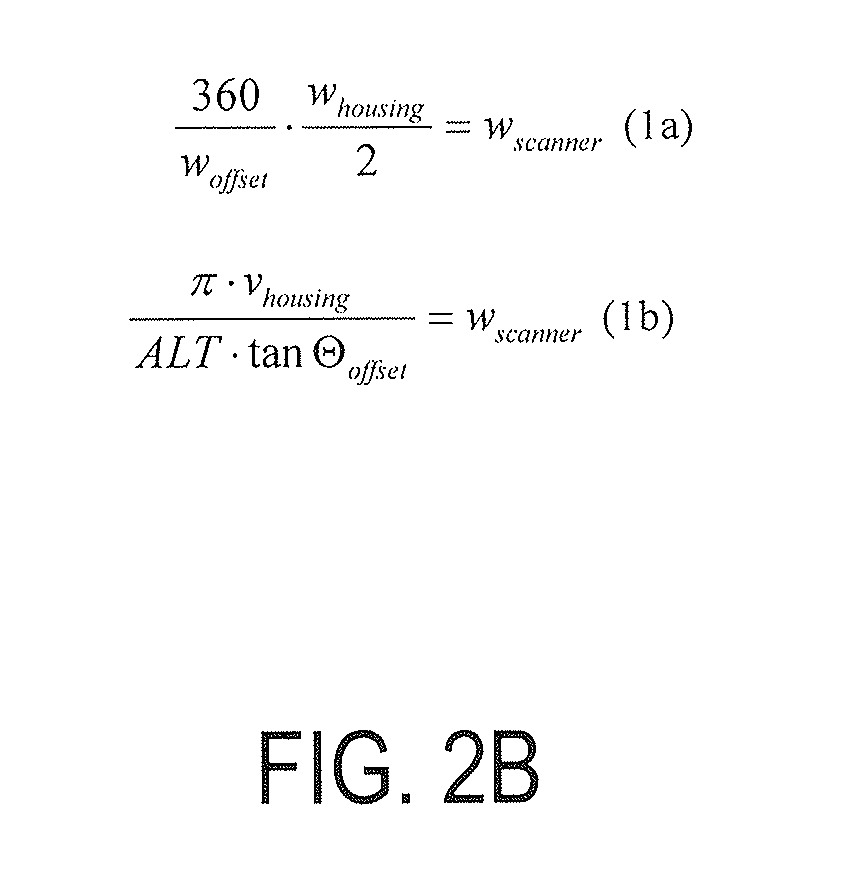

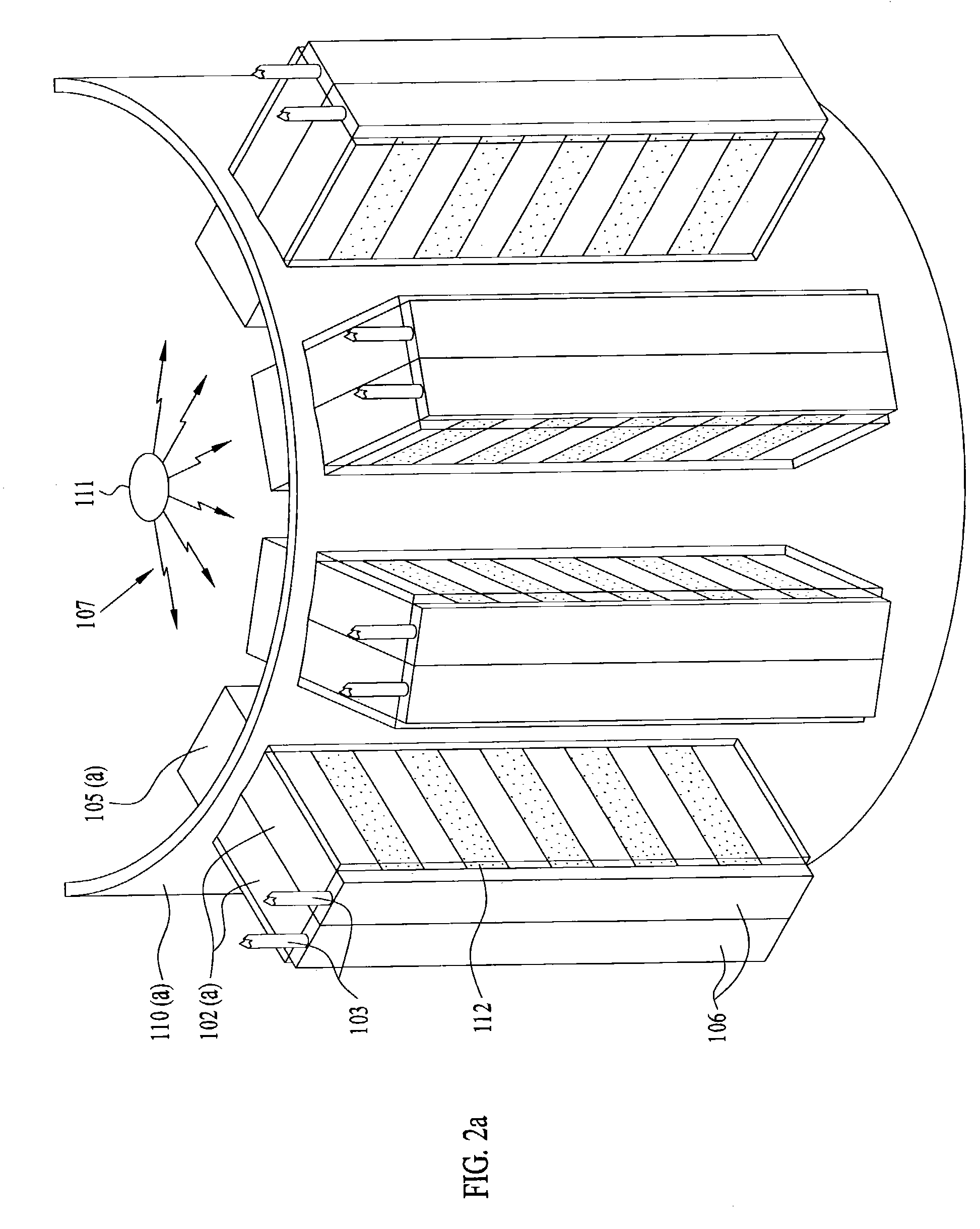

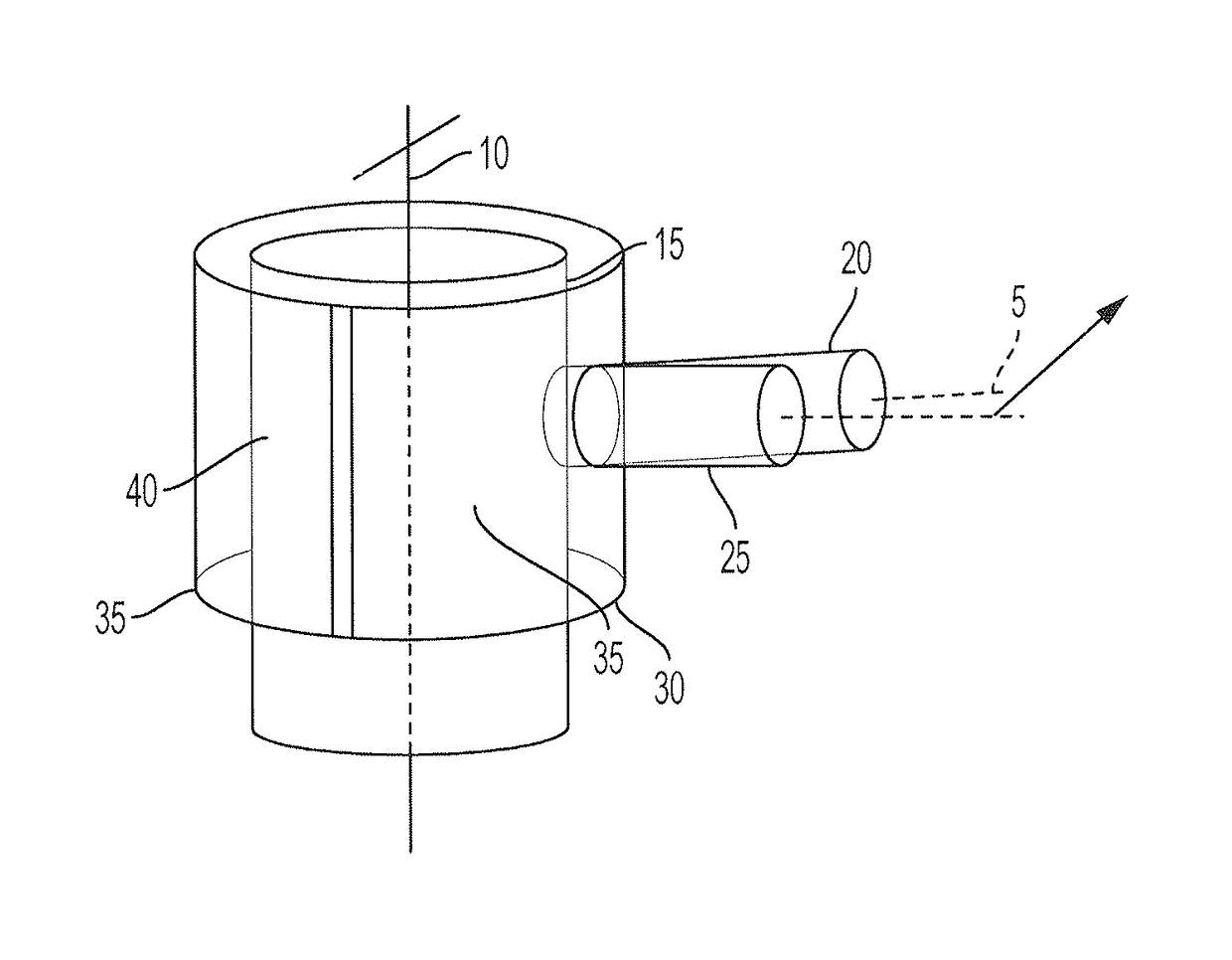

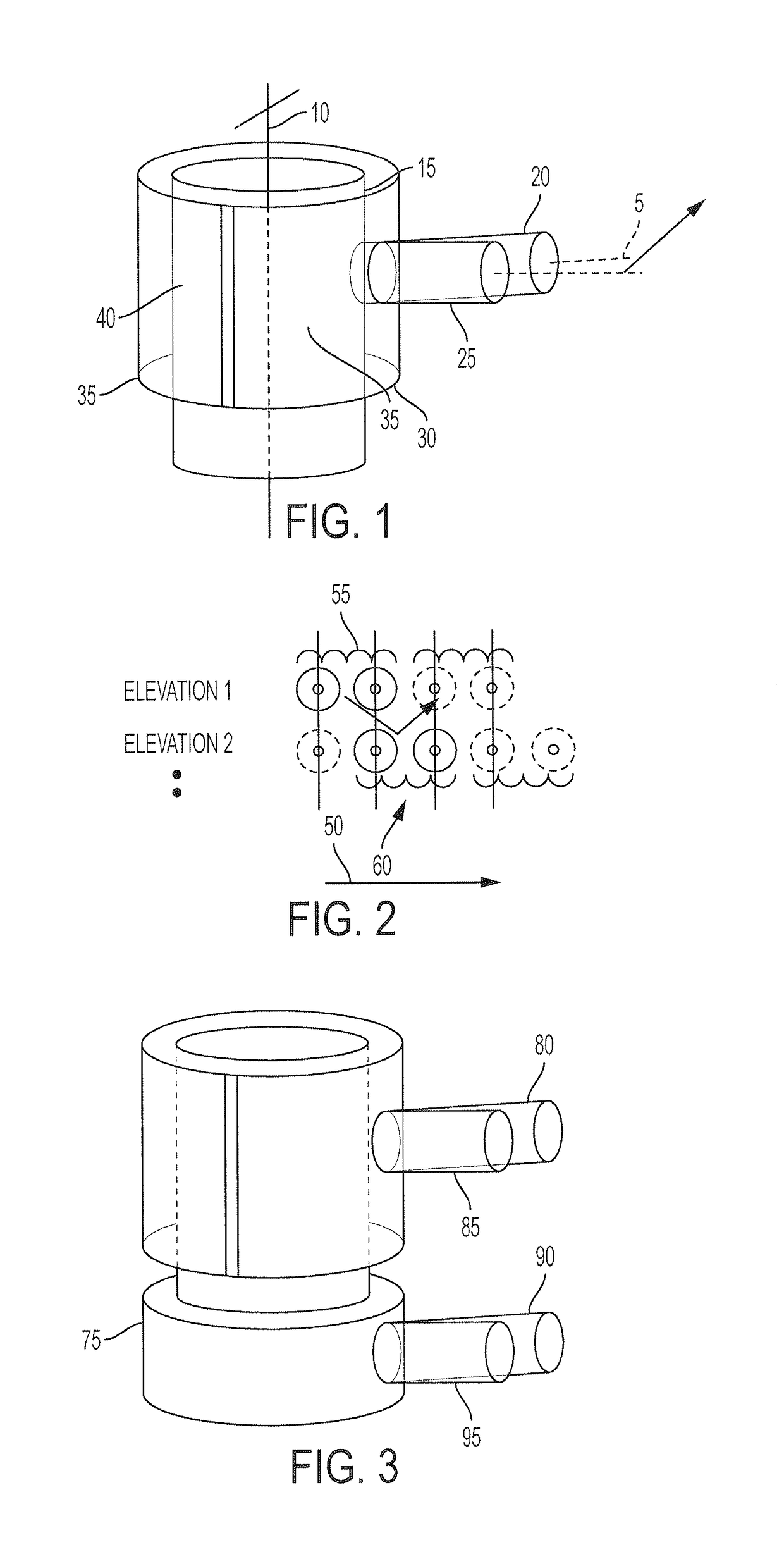

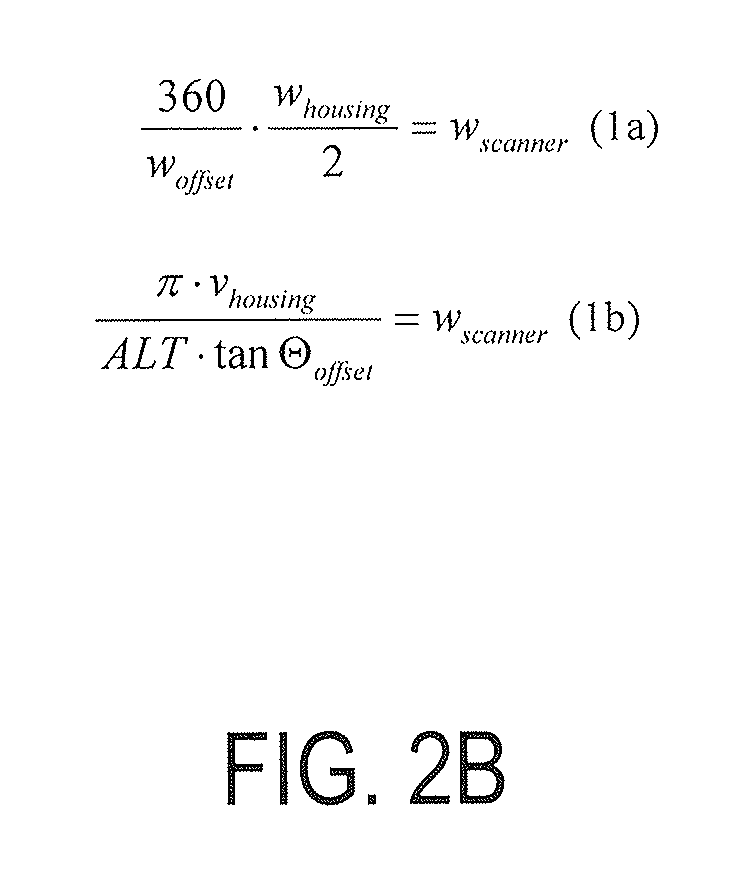

Lidar optical scanner system

ActiveUS20150260843A1Reduce system complexityImprove update rateOptical rangefindersCondensersRadarOptical scanners

An optical scanner system comprises a housing, a detector contained within the housing configured to produce at least two resolvable azimuth fields-of-view relative to a center-axis of the housing, and an external scanner rotating relative to the center-axis of the housing, and switching between at least two elevations relative to a nominal optical axis of a receiver. Motion of the housing azimuthally results in the receiver producing a continuous coverage pattern at multiple elevations produced by the external scanner.

Owner:GARMIN

Device and system for improved imaging in nuclear medicine and mammography

InactiveUS7147372B2Easy to optimizeEnhance analysis capabilityMaterial analysis using wave/particle radiationRadiation/particle handlingAdaptive imagingDetector array

A method and apparatus for detecting radiation including x-ray, gamma ray, and particle radiation for radiographic imaging, and nuclear medicine and x-ray mammography in particular, and material composition analysis are described. A detection system employs fixed or configurable arrays of one or more detector modules comprising detector arrays which may be electronically manipulated through a computer system. The detection system, by providing the ability for electronic manipulation, permits adaptive imaging. Detector array configurations include familiar geometries, including slit, slot, plane, open box, and ring configurations, and customized configurations, including wearable detector arrays, that are customized to the shape of the patient. Conventional, such as attenuating, rigid geometry, and unconventional collimators, such as x-ray optic, configurable, Compton scatter modules, can be selectively employed with detector modules and radiation sources. The components of the imaging chain can be calibrated or corrected using processes of the invention. X-ray mammography and scintimammography are enhanced by utilizing sectional compression and related imaging techniques.

Owner:MINNESOTA IMAGING & ENG

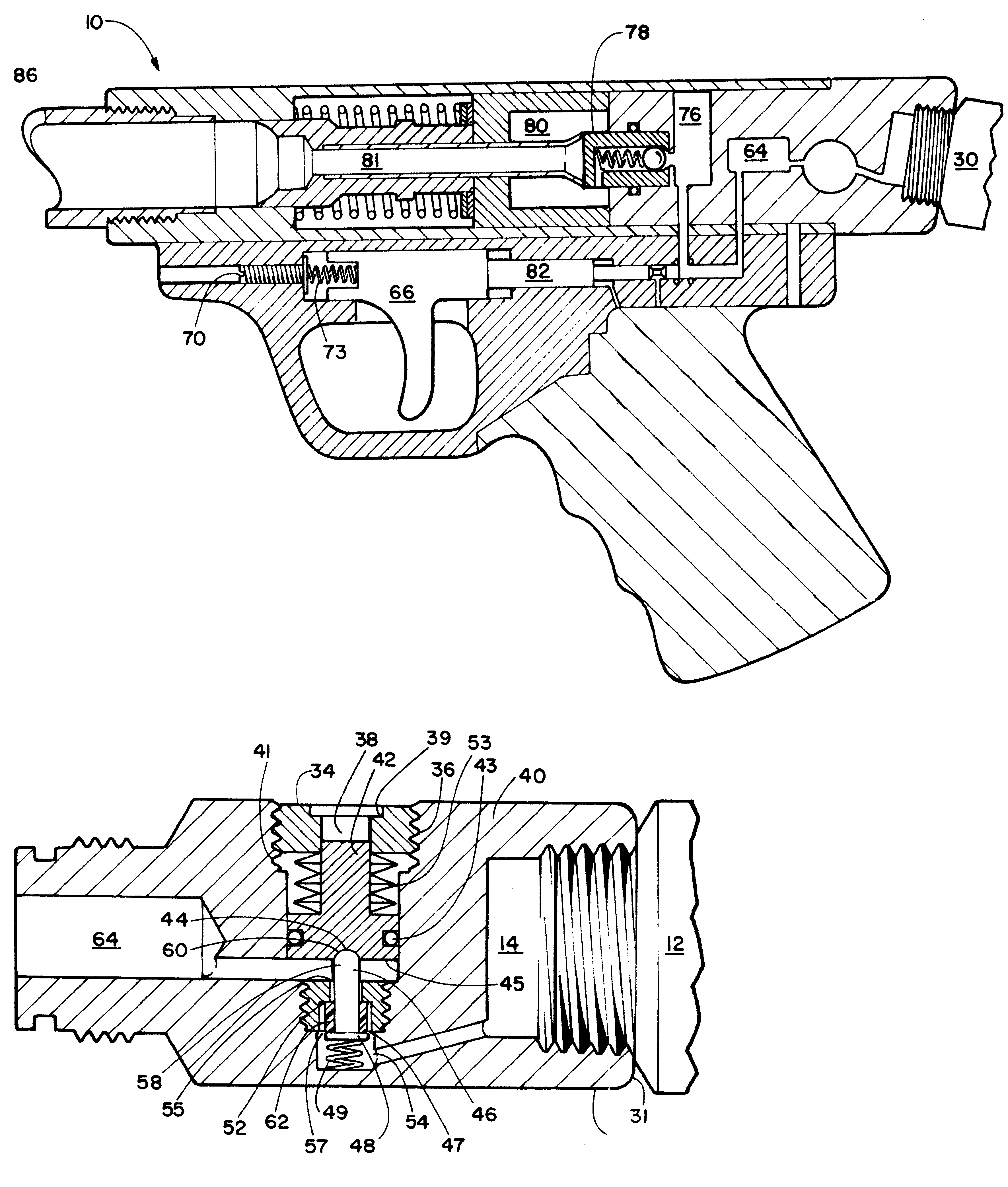

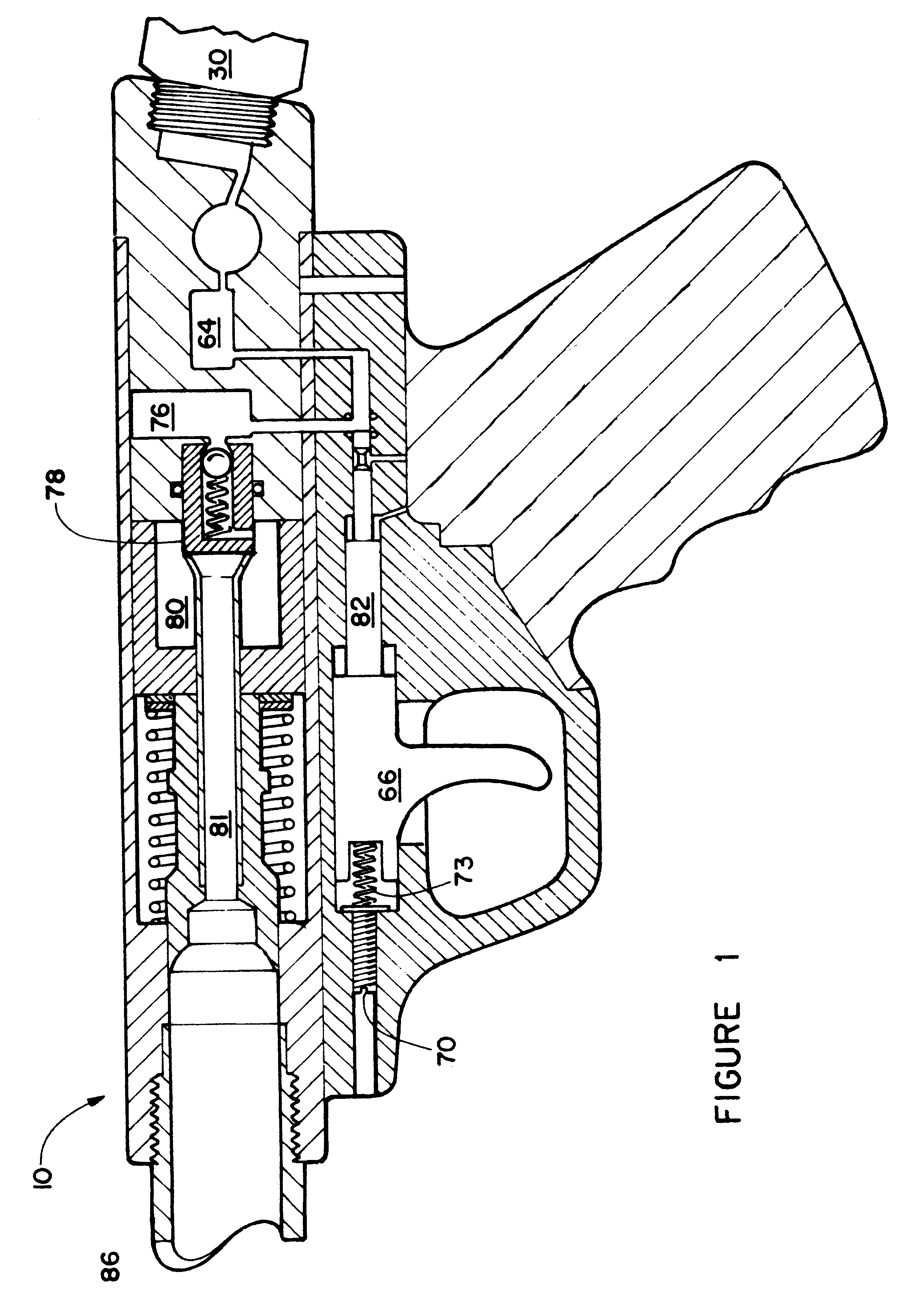

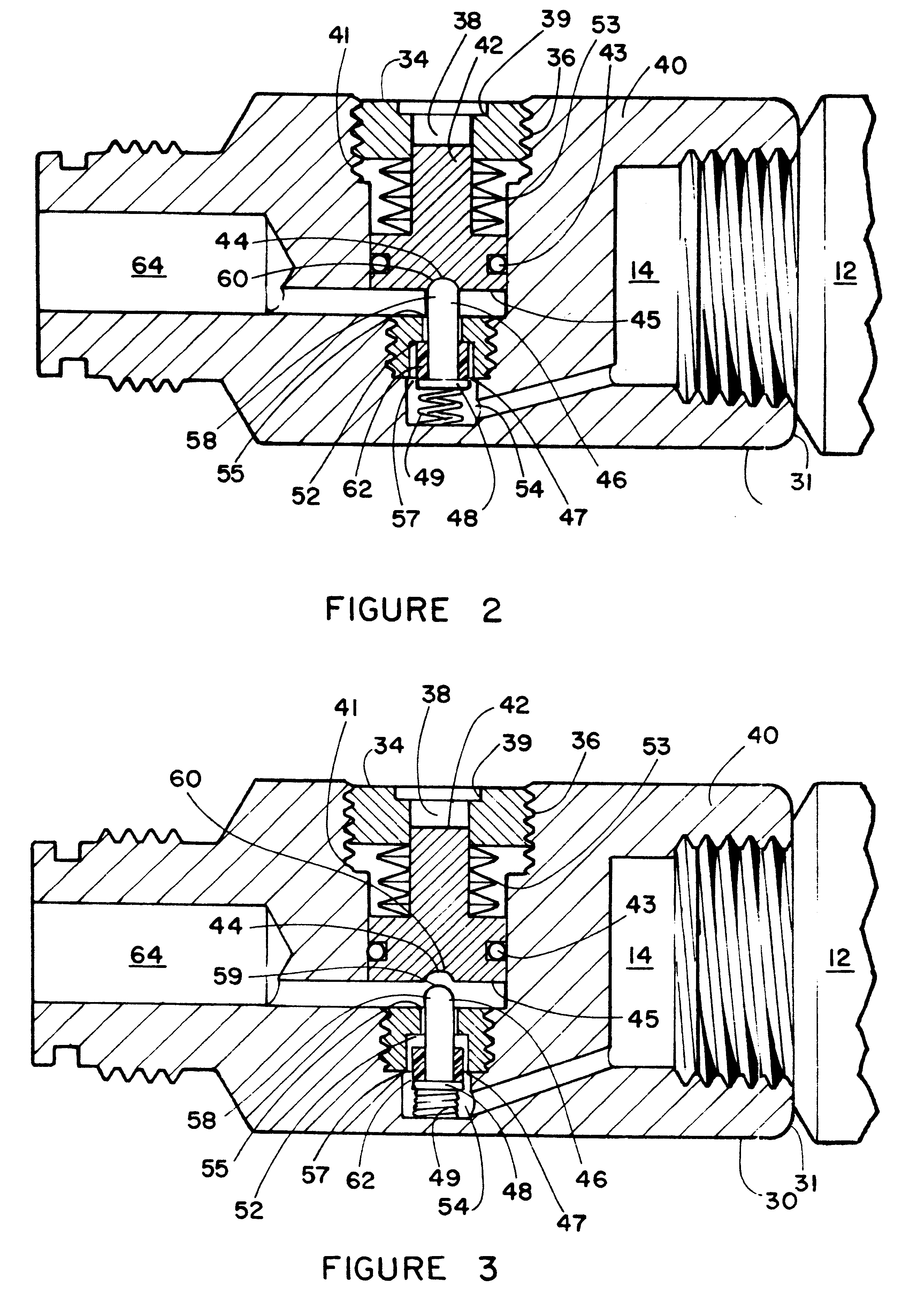

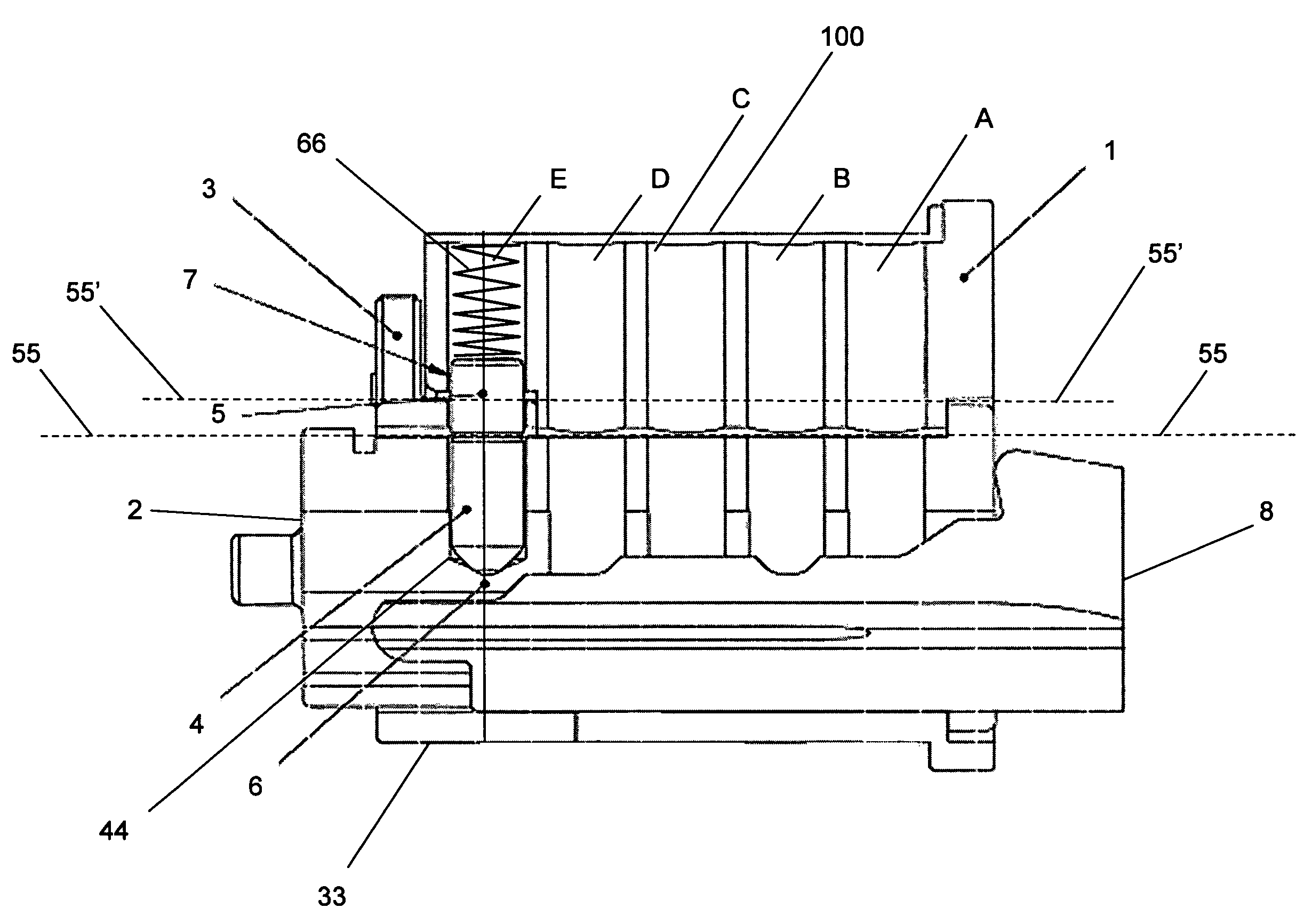

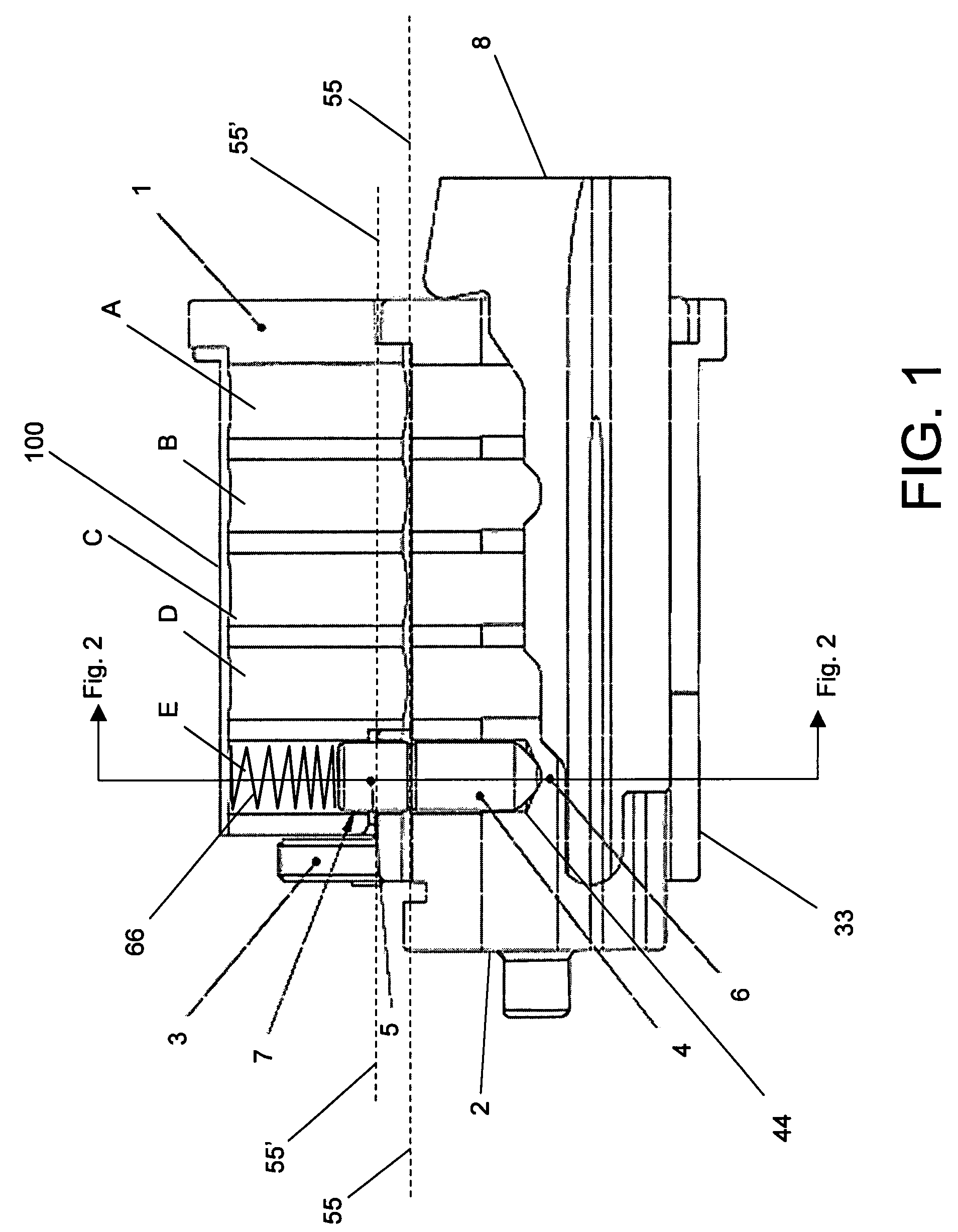

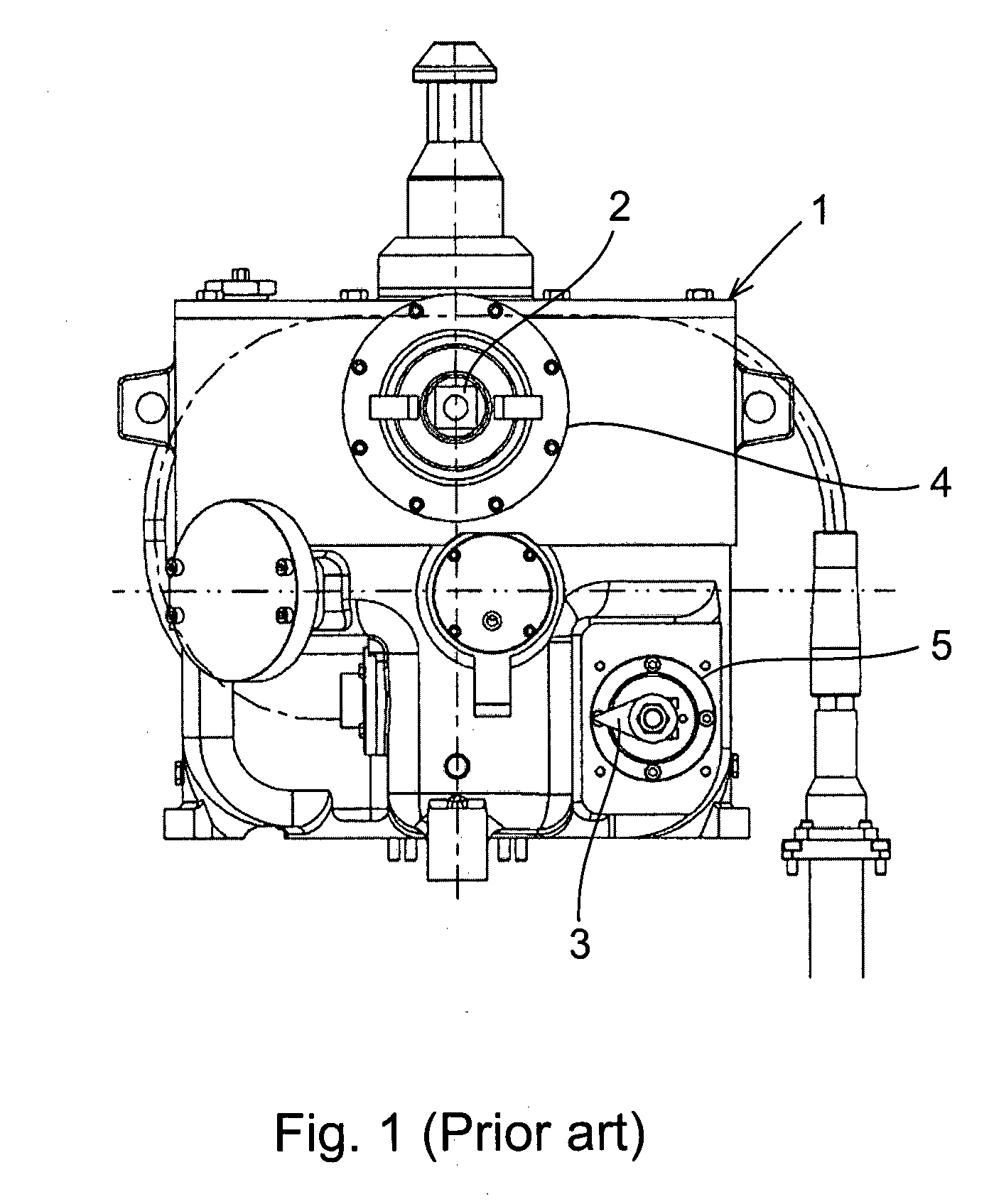

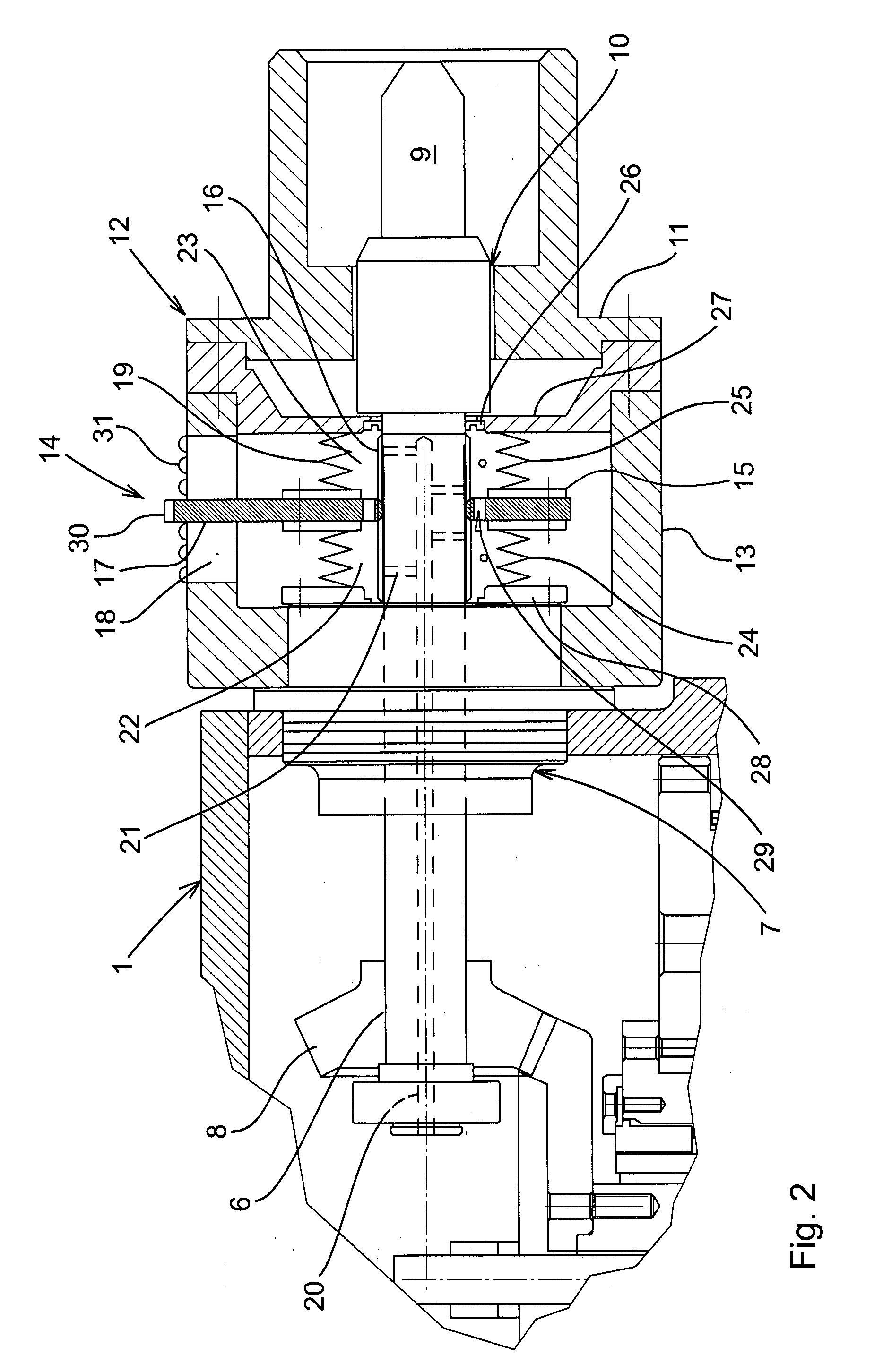

Gas powered gun and assemblies therefor

InactiveUS6276354B1Reduce mechanical complexityJam resistantFiring/trigger mechanismsLiquid ejecting gunsHeat transmissionEngineering

An improved air gun for firing paint balls, pellets,, consisting of a passively venting and freeze resistant regulator, a pressure differential trigger mechanism, and a muzzle break with angled sidewalls. The freeze resistant regulator regulates incoming high pressure gas to a user predetermined pressure to operate the gun while avoiding freezing of the regulator associated with frigid incoming compressed gases and high firing rates. This is accomplished by using a heat transmission component formed by the engagement between a hemispheric shaped tip of a regulating pin and a hemispheric cavity of an adjustment piston. Passive venting of gas from the gun upon removal of the pressurized gas supply is provided by the regulator using a reciprocating regulating pin and adjustment piston which combine to compress a seal into a seat only when pressurized gas is attached to the air gun. Once detached from a pressurized air supply the compressed air in the gun vents through the seat. Firing of the gun is achieved using a pressure differential trigger mechanism capable of fine pull adjustment using a trigger biasing mechanism. Greater accuracy of projectiles leaving the gun is provided by the muzzle break featuring of a plurality of elongated oval slots having angled sidewalls to parse propulsion gases from the projectile which reduces air turbulence encountered by the projectile upon exit from the gun.

Owner:DILLON JOSEPH

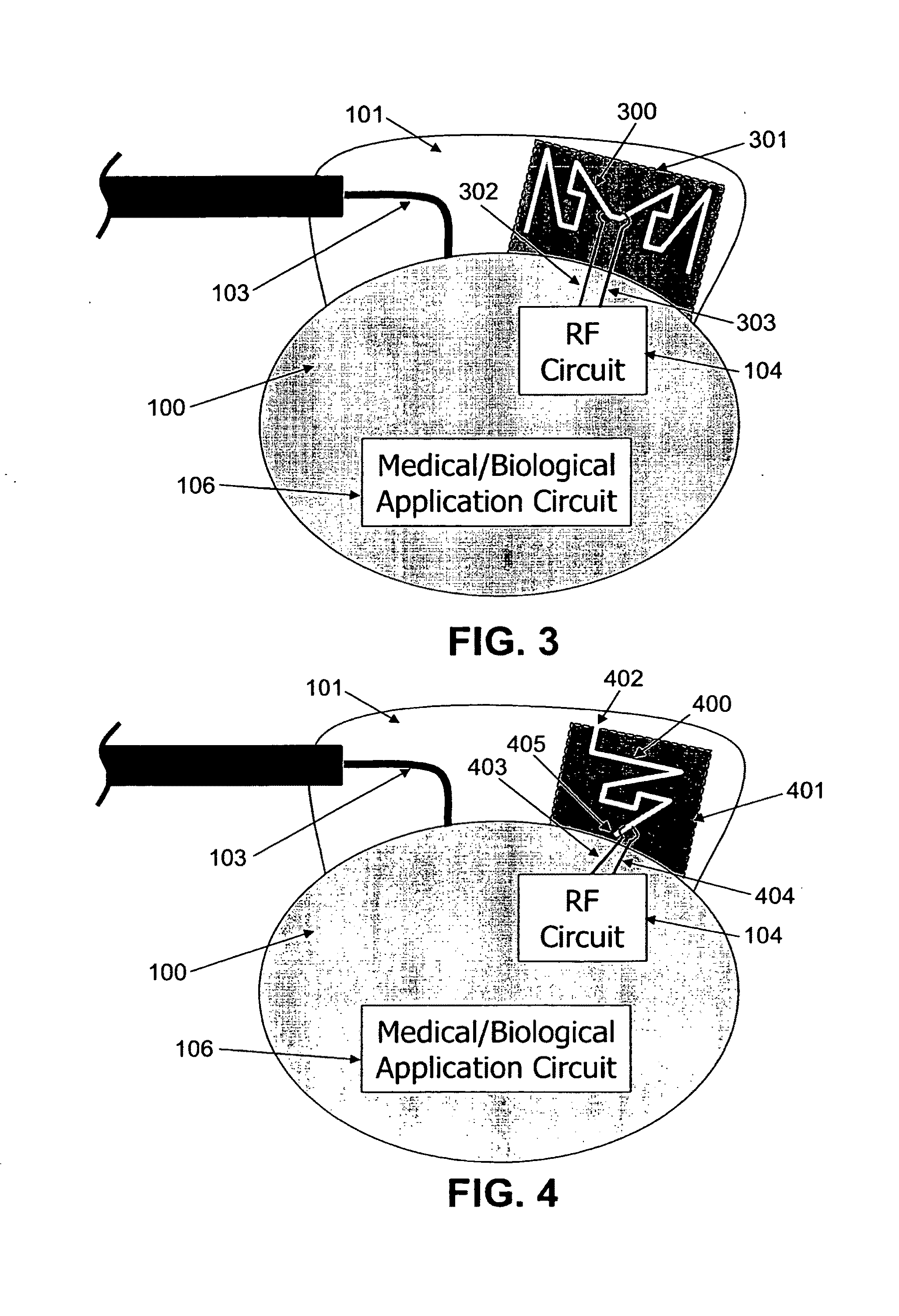

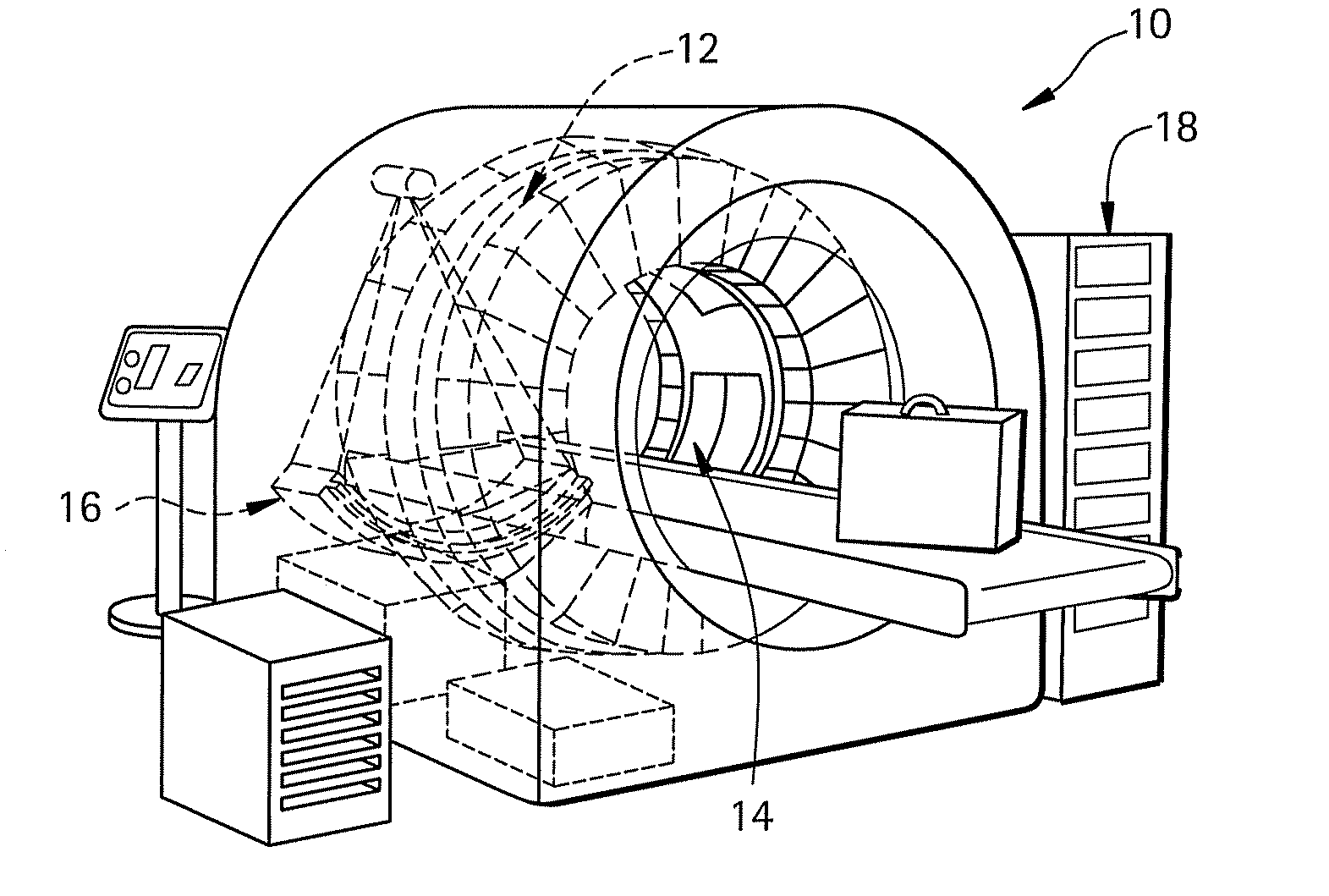

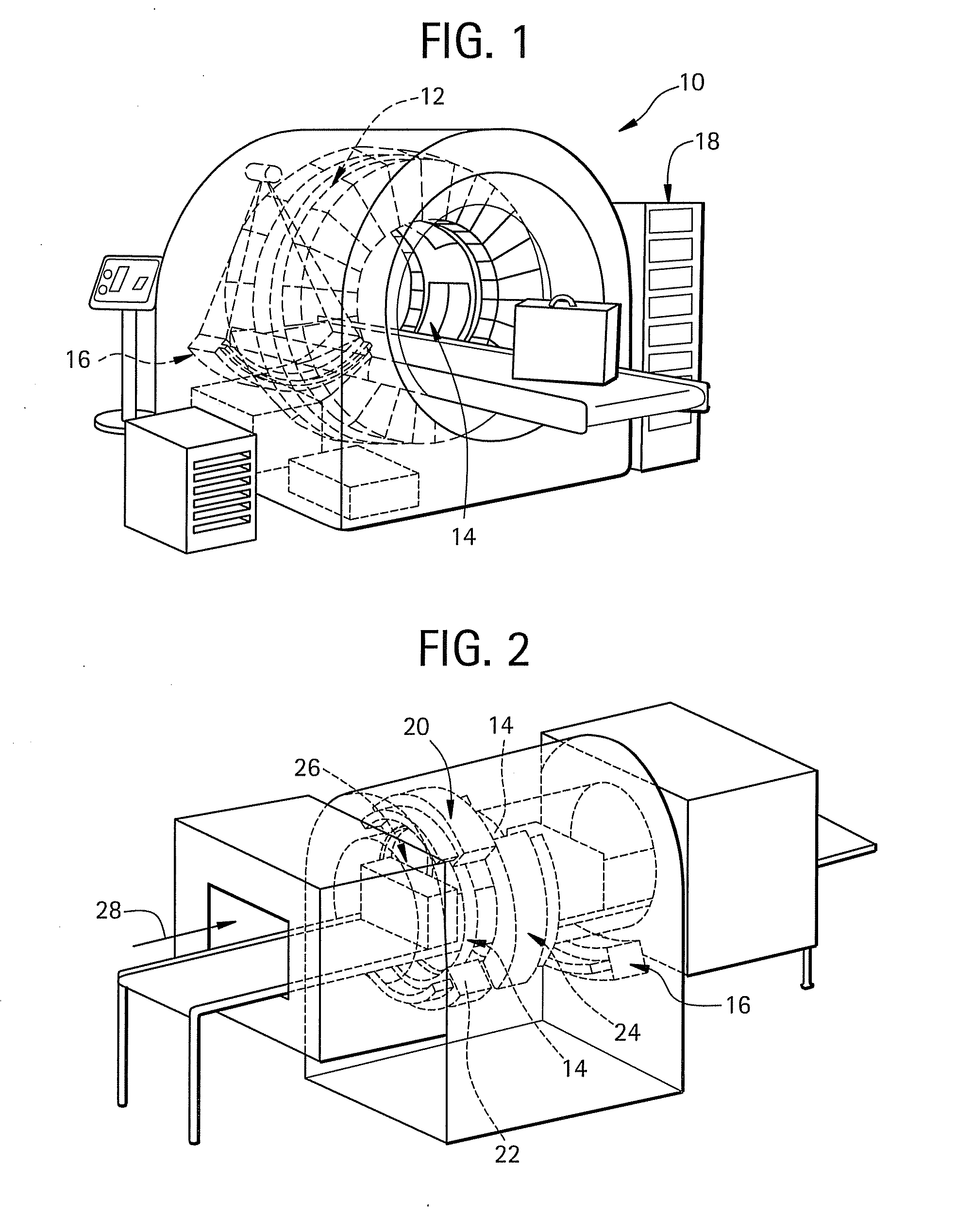

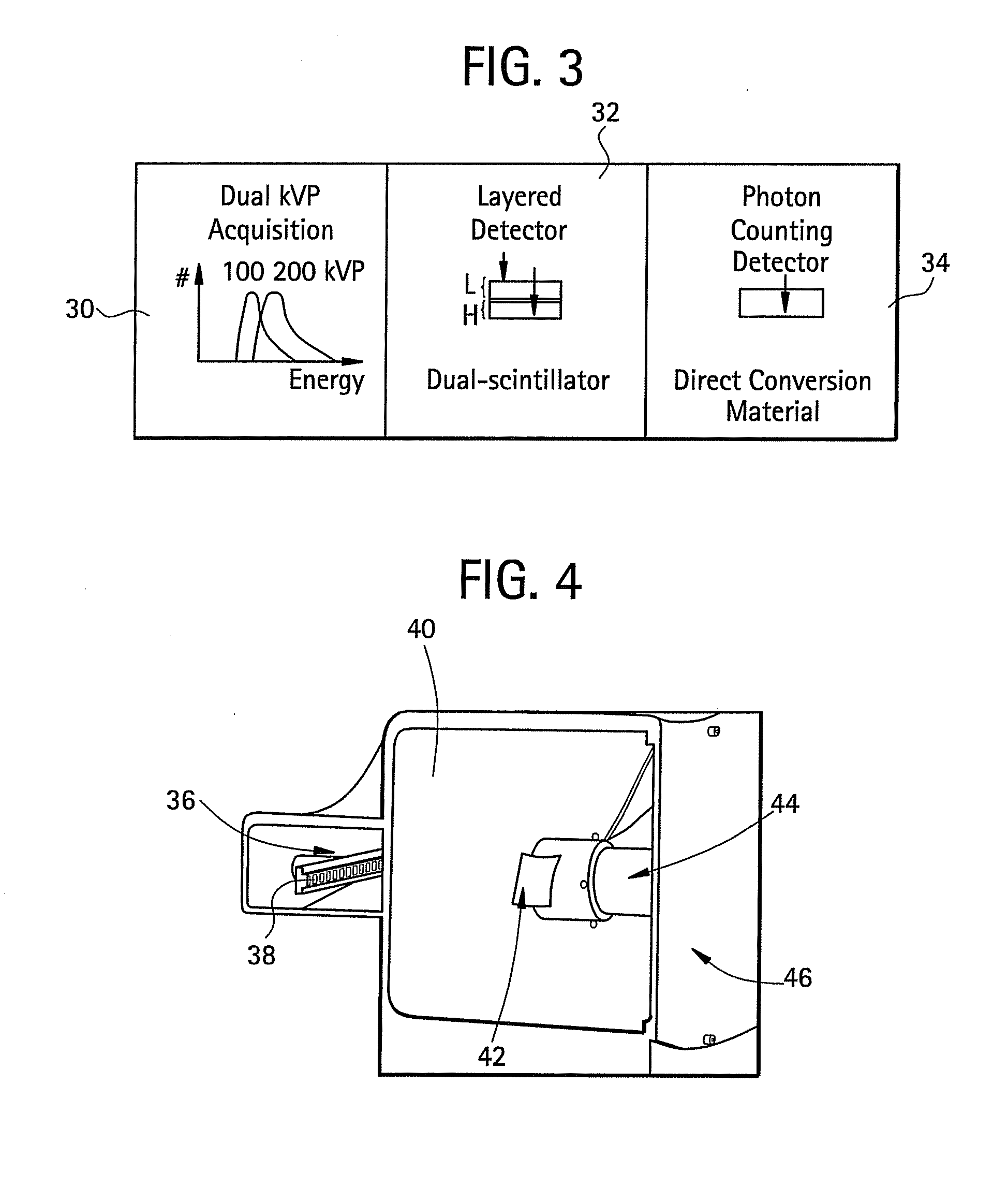

Integrated multi-sensor systems for and methods of explosives detection

InactiveUS20090003514A1Improve throughputReducing false alarmRadiation/particle handlingX-ray apparatusComputed tomographyHigh flux

An integrated, multi-sensor, Level 1 screening device is described, which system provides a next-generation Explosives Detection System (EDS) that enables high throughput, while drastically reducing false alarms. In exemplary embodiments, the present system comprises a non-rotational, Computed Tomography (CT) system and a non-translational, X-ray diffraction (XRD) system, both in an inline configuration.

Owner:MORPHO DETECTION INC

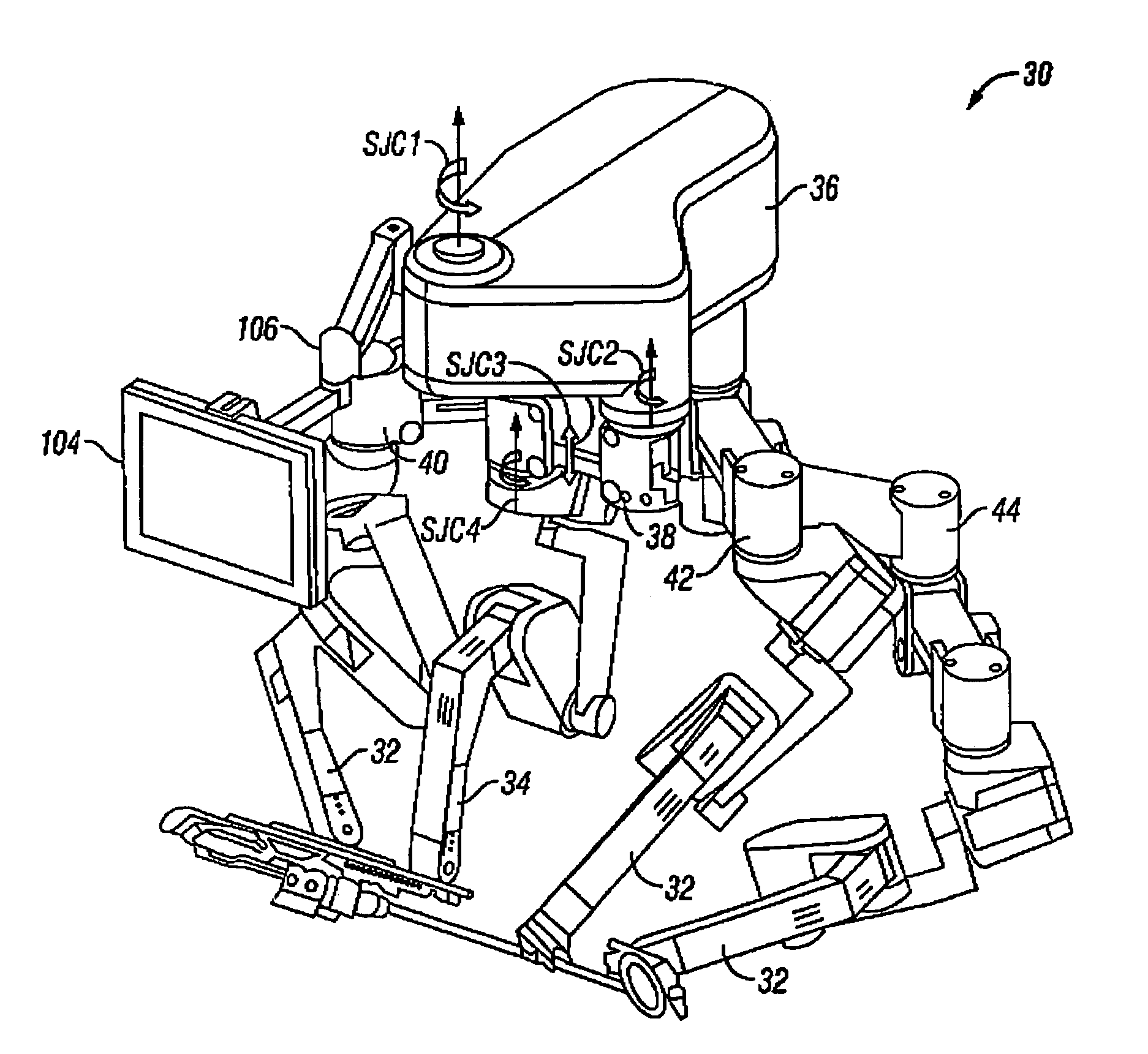

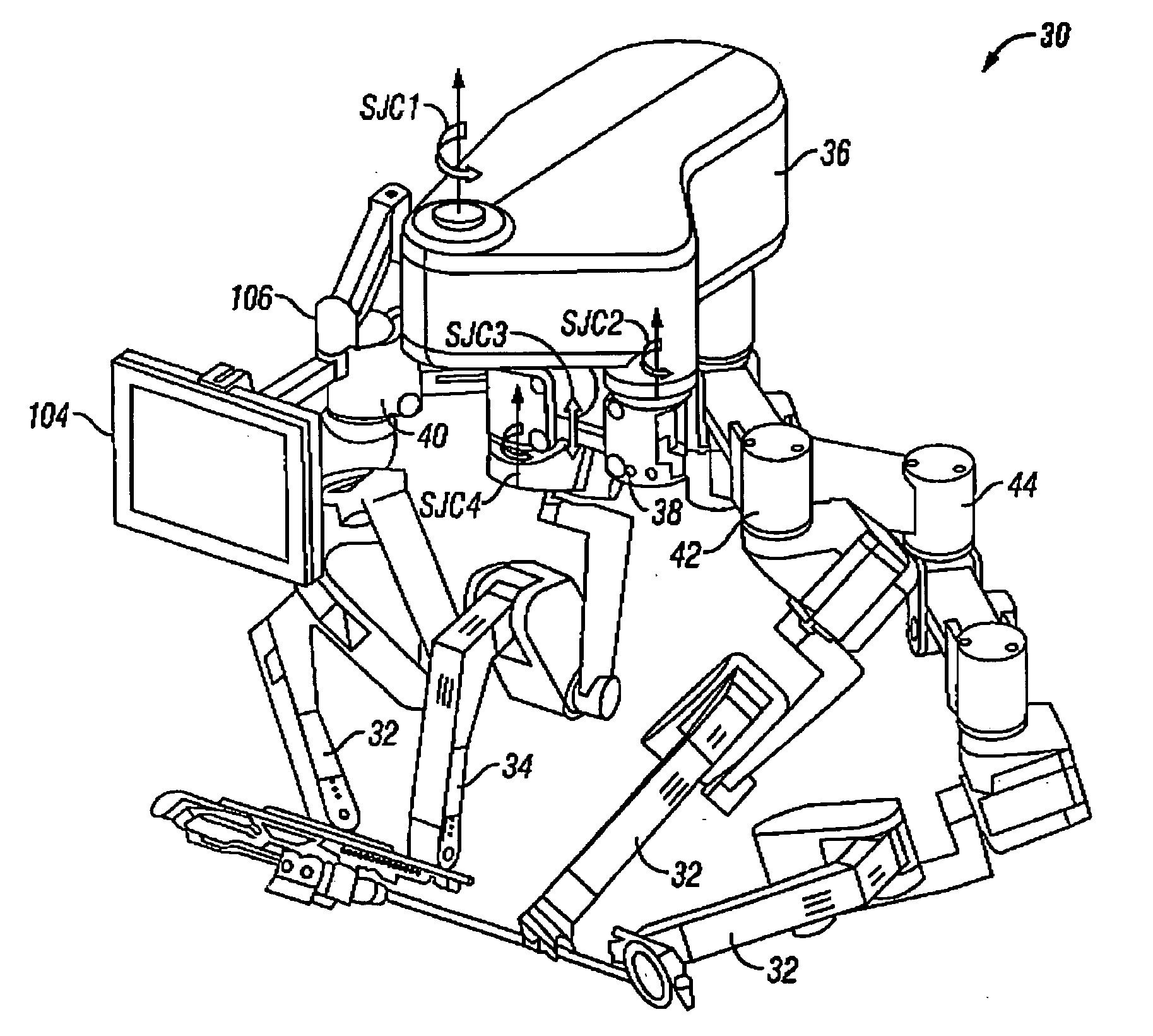

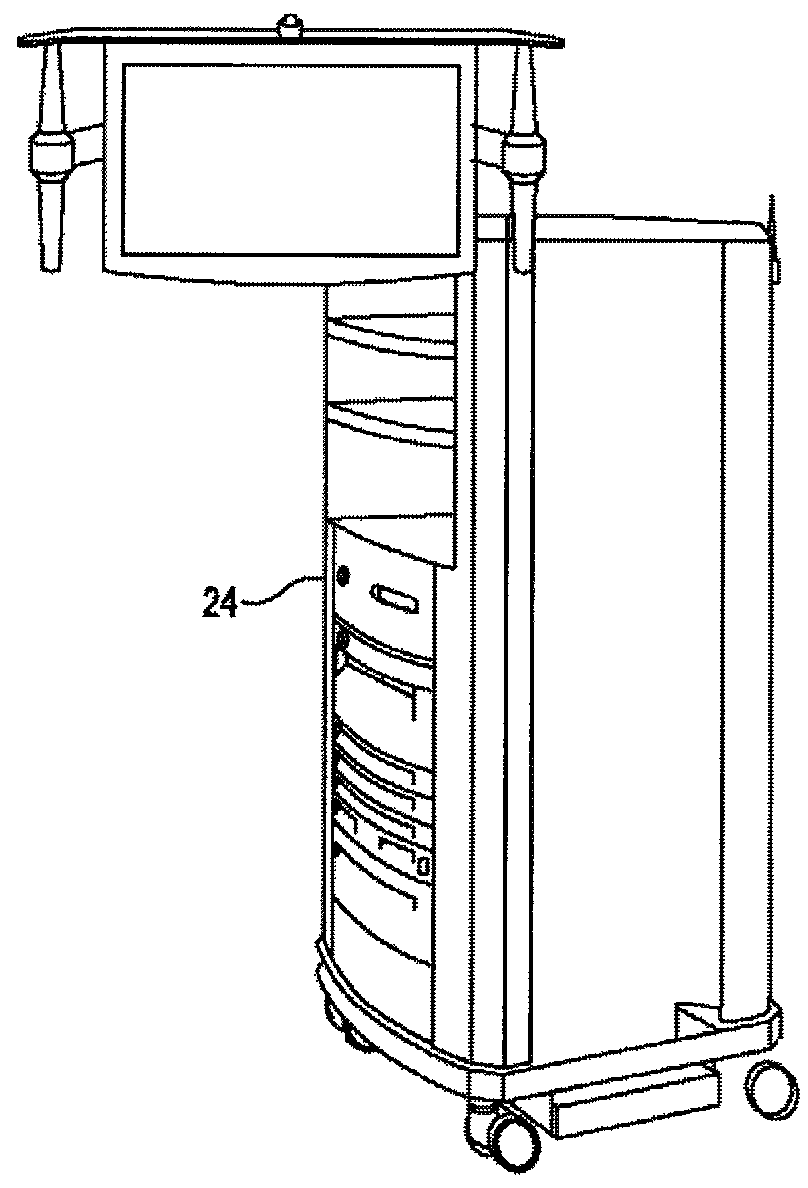

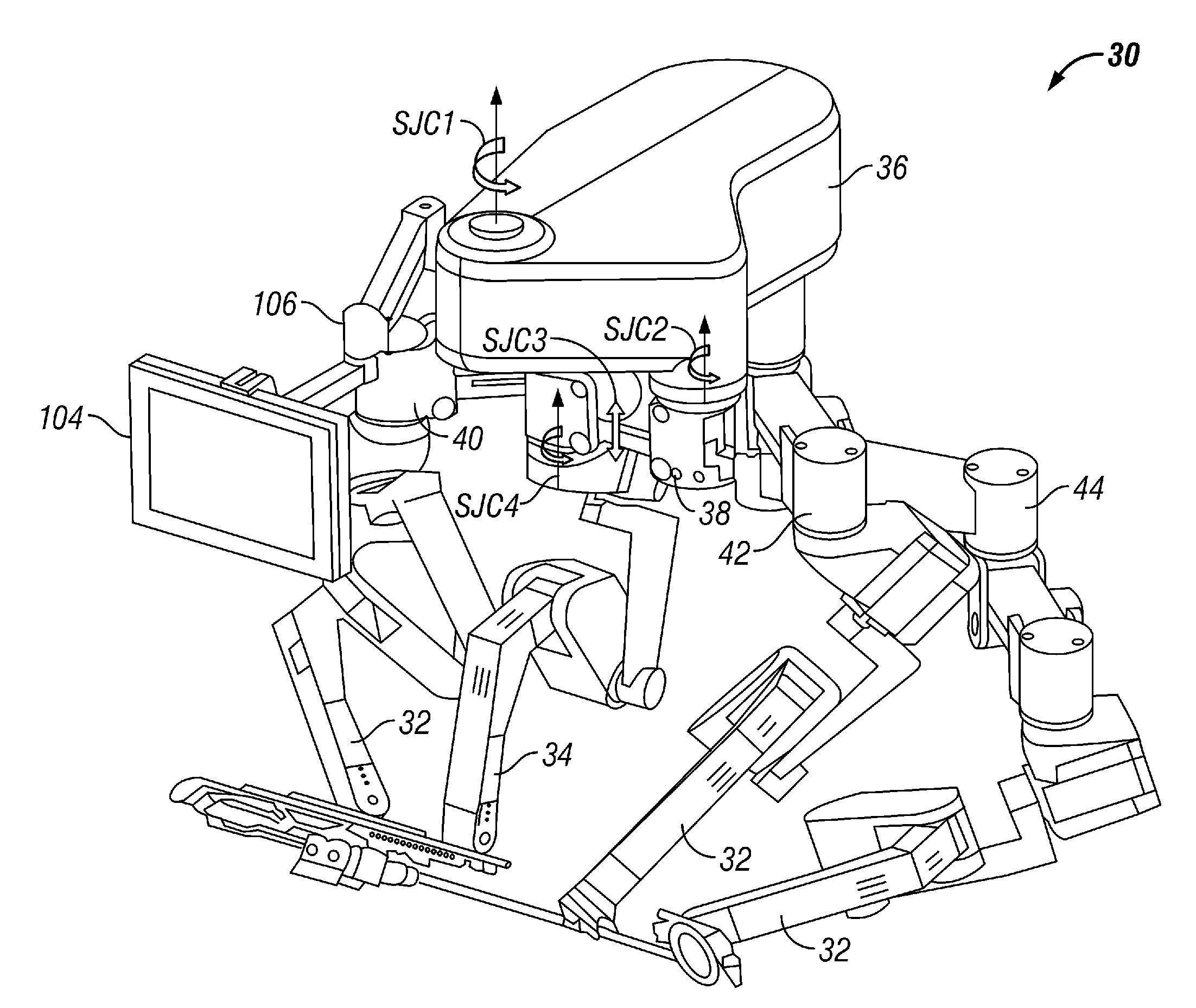

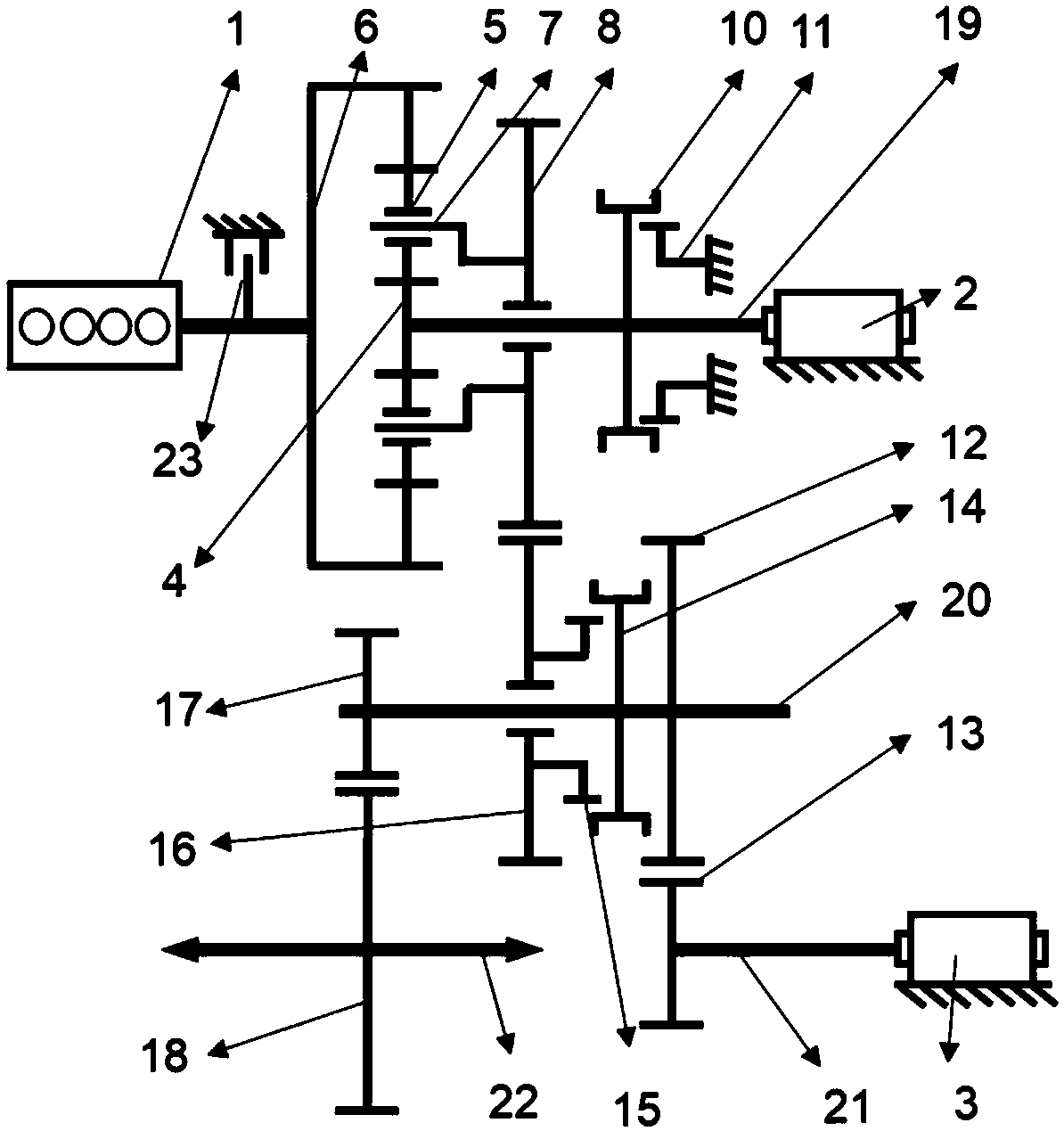

Multi-port surgical robotic system architecture

ActiveUS9358074B2Improve space utilizationAvoid collisionDiagnosticsStands/trestlesRobotic systemsEngineering

A robotic surgery system includes an orienting platform, a support linkage movably supporting the orienting platform, a plurality of surgical instrument manipulators, and a plurality of set-up linkages. Each of the manipulators includes an instrument holder and is operable to rotate the instrument holder around a remote center of manipulation (RC). At least one of the manipulators includes a reorientation mechanism that when actuated moves the attached manipulator through a motion that maintains the associated RC in a fixed position.

Owner:INTUITIVE SURGICAL OPERATIONS INC

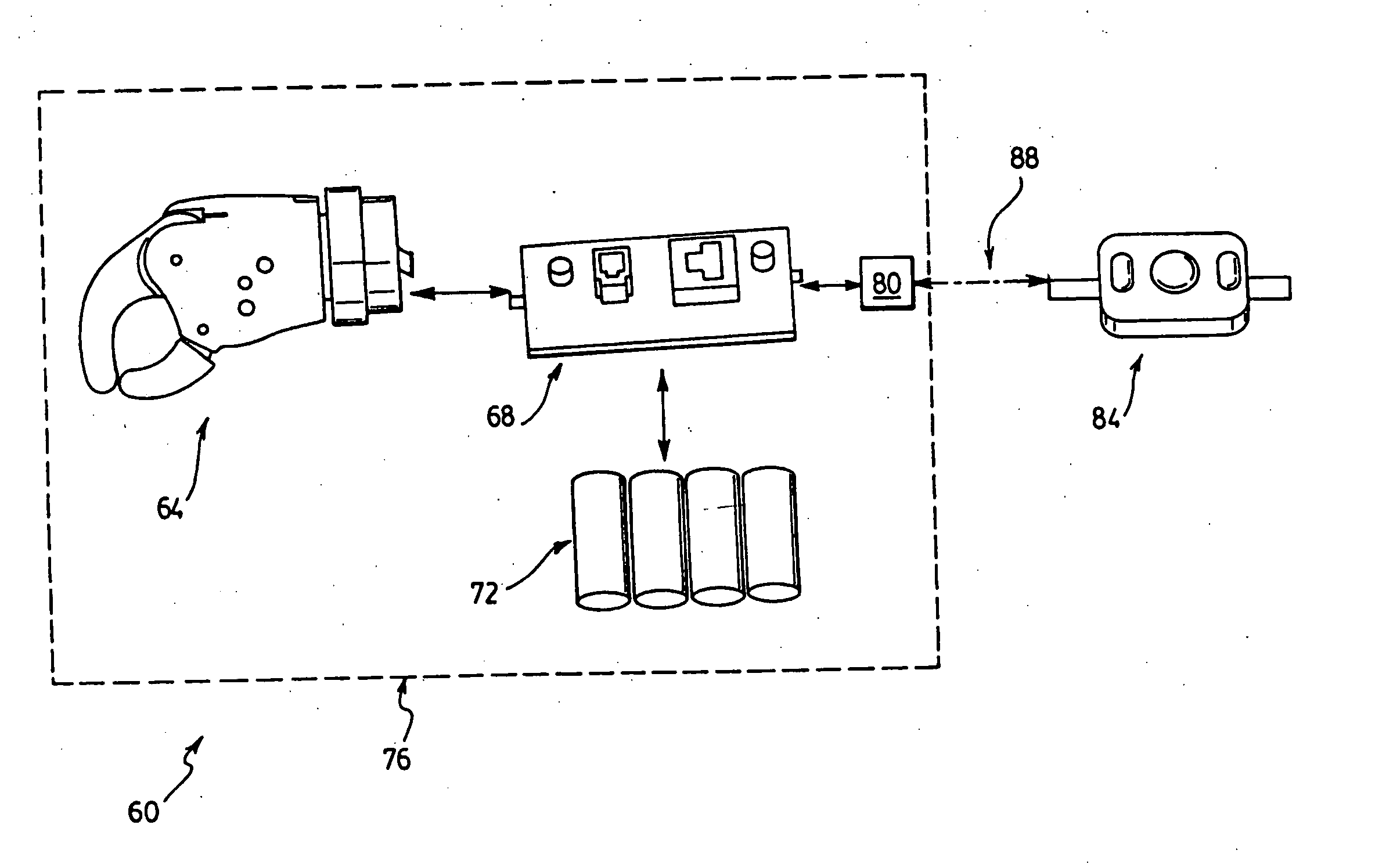

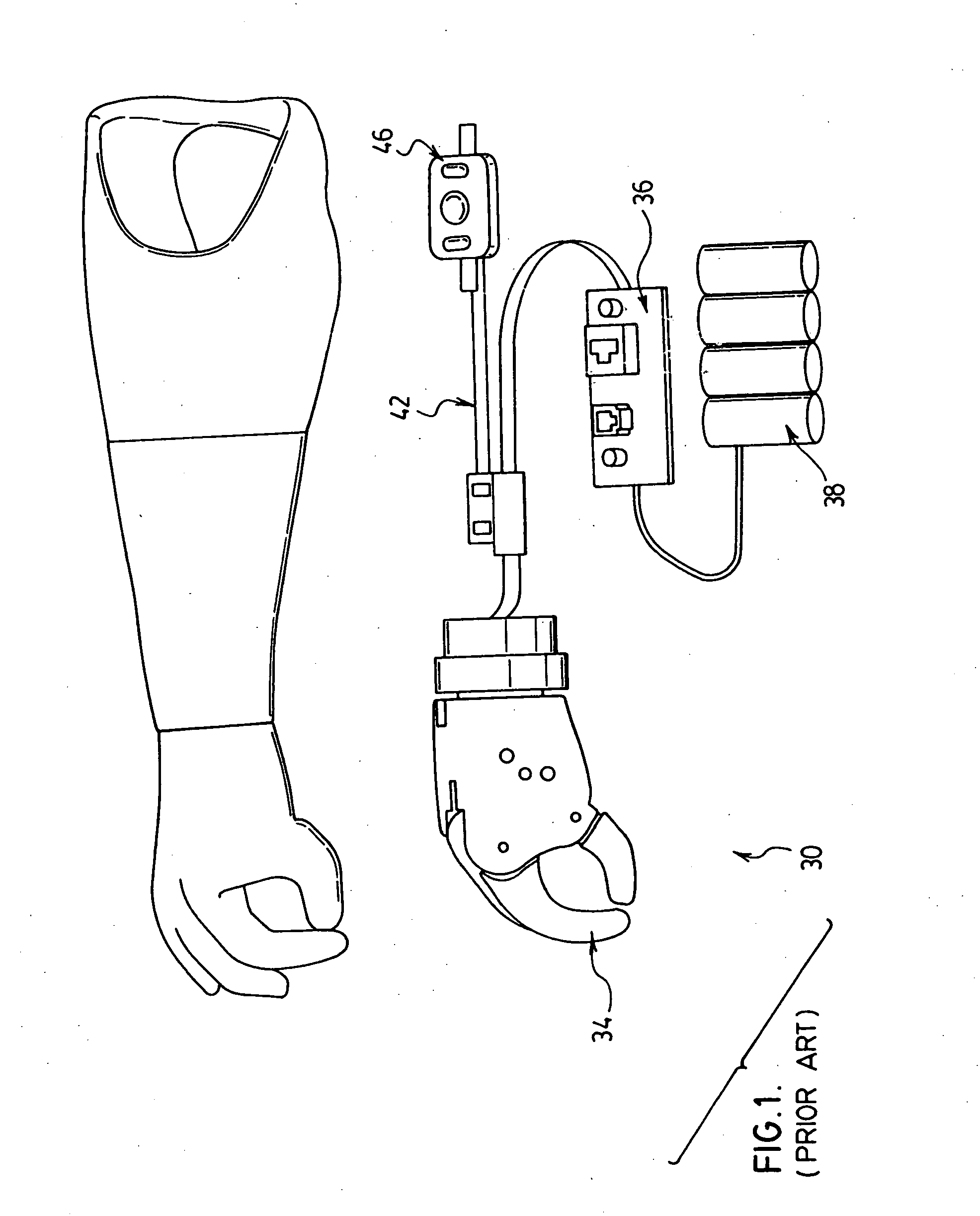

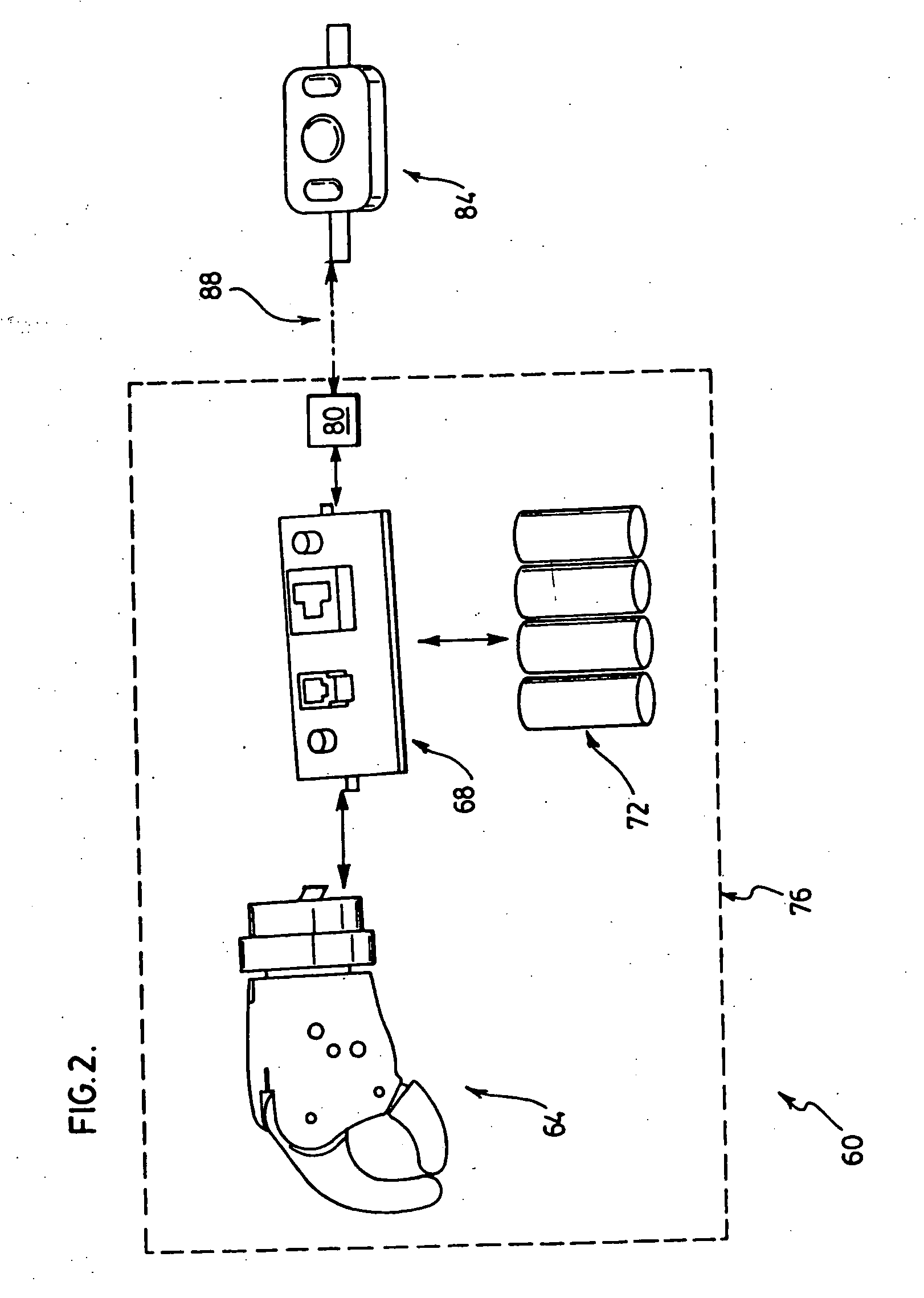

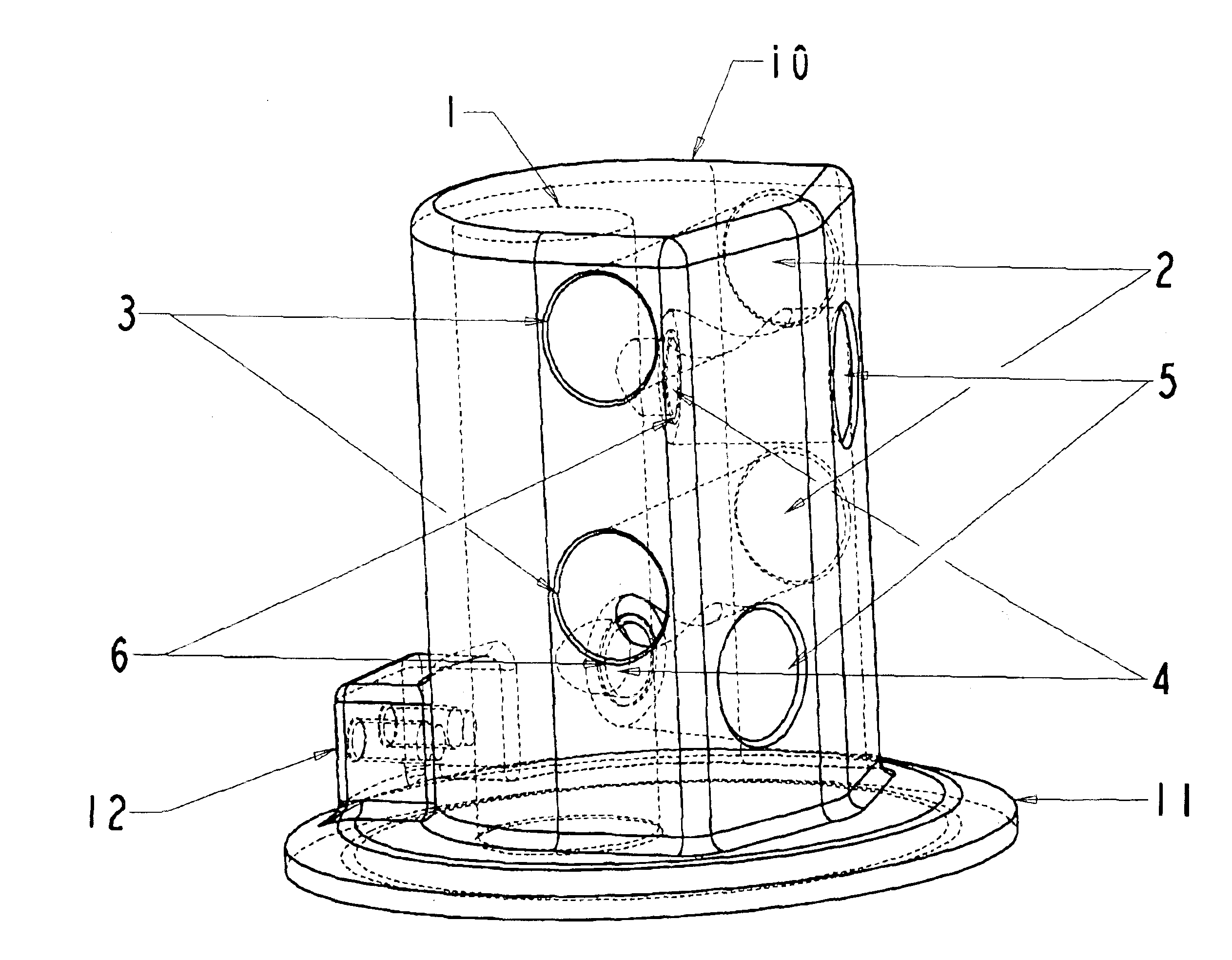

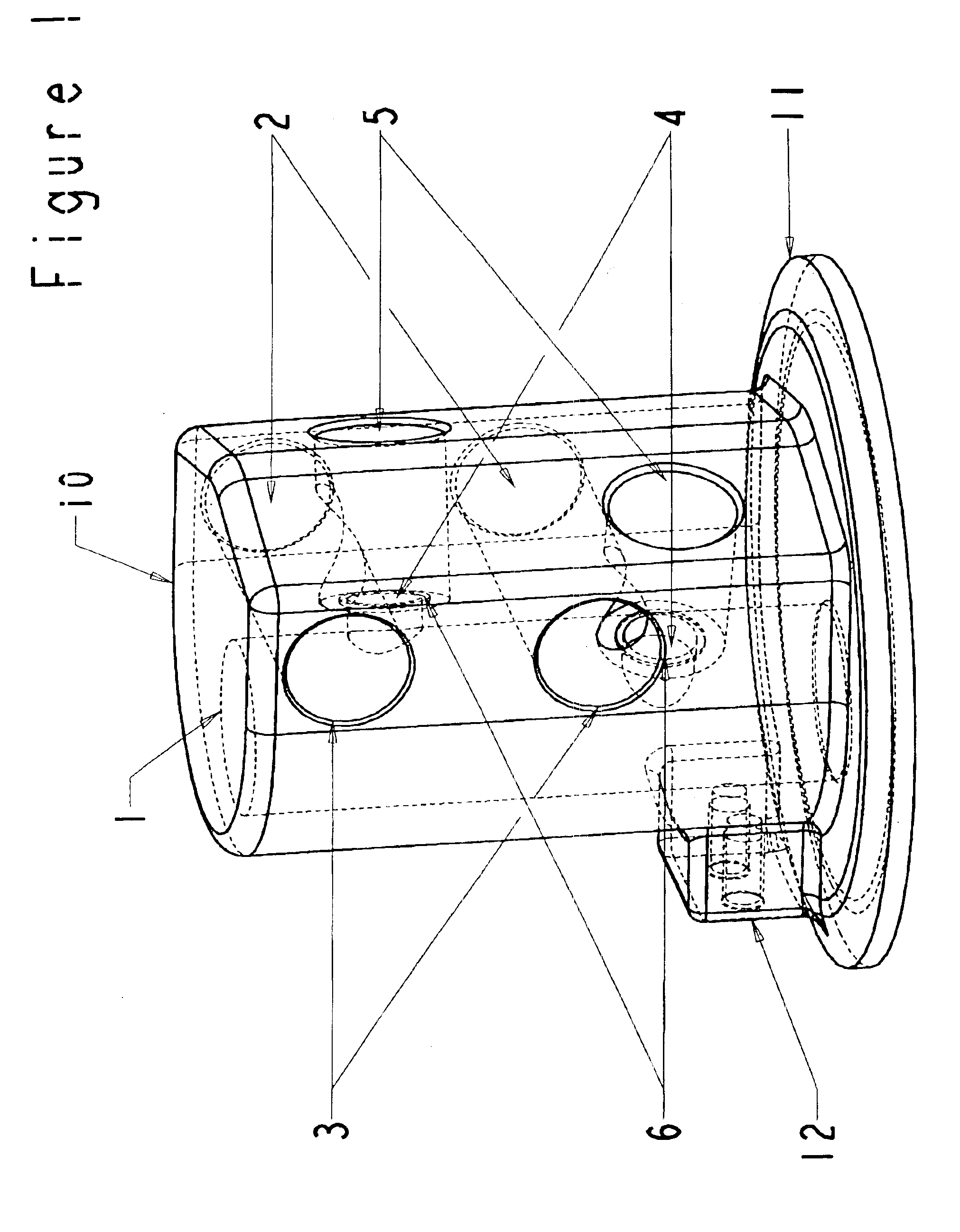

Electromyographic sensor

InactiveUS20060155386A1Improve reliabilityLimited accessibilityElectromyographyPerson identificationEngineeringProsthetic limb

An electromyographic sensor is provided. The sensor includes electrodes for receiving signals from tissue when the electrodes are placed in contact with the tissue. The sensor also includes circuitry for converting the signals into a format suitable for transmission. the sensor also includes a transmitter for transmitting the signals to a receiver. The receiver can be part of a controller for a prosthetic limb, or the like.

Owner:BLOORVIEW MACMILLAN CHILDRENS CENT

Modular mainpulator support for robotic surgery

Owner:INTUITIVE SURGICAL OPERATIONS INC

Advanced wafer refining

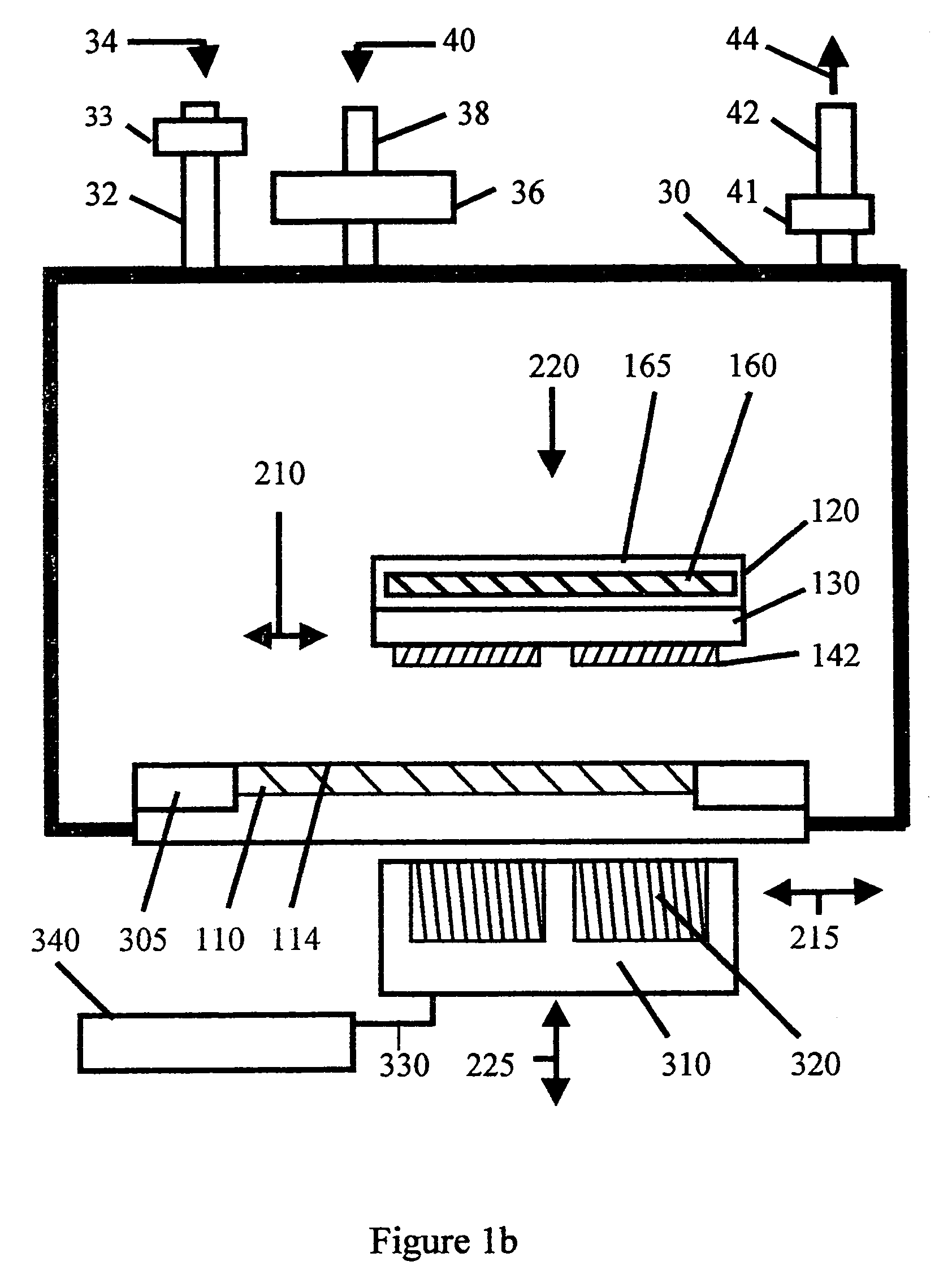

InactiveUS7008300B1Accessible costImprove refining methodSemiconductor/solid-state device testing/measurementSolid-state devicesManufacturing cost reductionElectrolysis

A refining apparatus having magnetically responsive refining elements that can be smaller than the workpiece being refined are disclosed. The refining apparatus can supply a parallel refining motion to the refining element(s) through magnetic coupling forces. The refining apparatus can supply multiple different parallel refining motions to multiple different refining elements solely through magnetic coupling forces to improve refining quality and versatility. New refining methods, refining apparatus, and refining elements disclosed. Methods of refining using frictional refining, chemical refining, tribochemical refining, and electrochemical refining and combinations thereof are disclosed. A refining chamber can be used. New methods of control are refining disclosed. The new magnetic refining methods, apparatus, and magnetically responsive refining elements can help improve yield and lower the cost of manufacture for refining of workpieces having extremely close tolerances such as semiconductors wafers. Refining fluids are preferred. Reactive refining aids are preferred. Electro-refining for adding and removing material is disclosed. A method to use business calculations combined with physical measurements to improve control is discussed. Use of business calculations to change the cost of finishing semiconductor wafers is discussed. The method can help cost of manufacture forecasting for pre-ramp-up, ramp-up, and commercial manufacture. Actively based accounting can be preferred for some applications. New methods and new apparatus for non-steady state refining control are disclosed.

Owner:SEMCON TECH

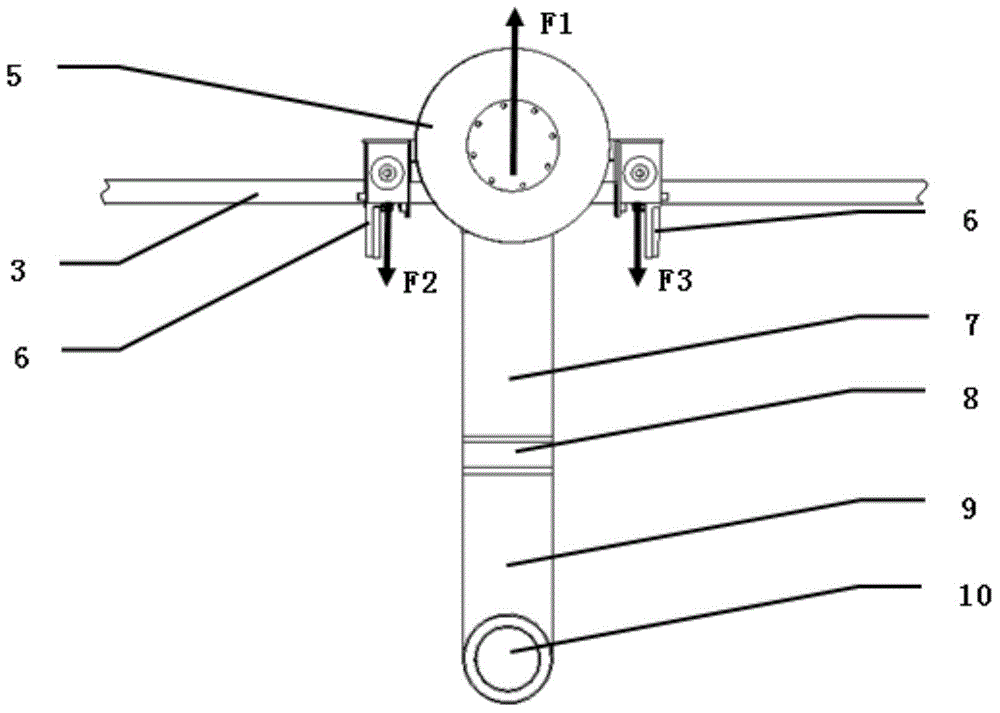

Power line inspection robot and obstacle surmounting method thereof

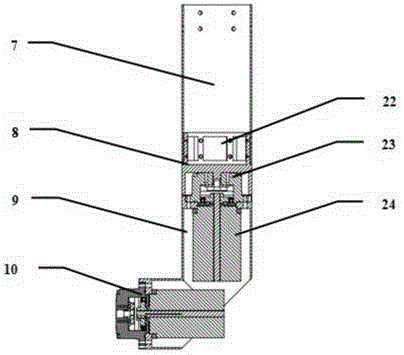

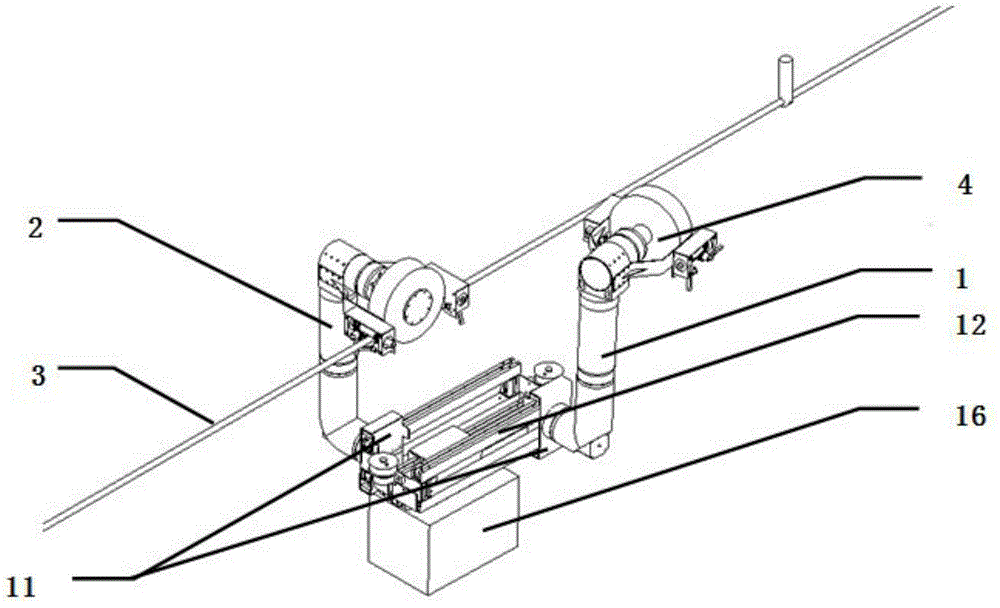

ActiveCN104608112ALow costReduce torqueManipulatorApparatus for overhead lines/cablesSimulationCantilever

The invention provides a power line inspection robot and an obstacle surmounting method of the power line inspection robot. The power line inspection robot comprises a first cantilever and a second cantilever, wherein the first cantilever and the second cantilever are hung on a power line through a tail end execution mechanism above the first cantilever and the second cantilever, the first cantilever and the second cantilever are connected to a robot body in a sliding mode through a sliding block below the first cantilever and the second cantilever and can slide relative to the robot body, a balancing weight is connected to the lower portion of the robot body through a supporting frame, the first cantilever and the second cantilever both comprise an upper arm and a front arm, the lower ends of the upper arms are connected with the sliding block through a pitching mechanism, the sliding block is connected with a first sliding rail on the robot body in a sliding mode, and a driving mechanism of the sliding block makes the first cantilever and the second cantilever slide relative to the robot body. The power line inspection robot can better surmount obstacles during power line inspection.

Owner:SHANGHAI JIAO TONG UNIV

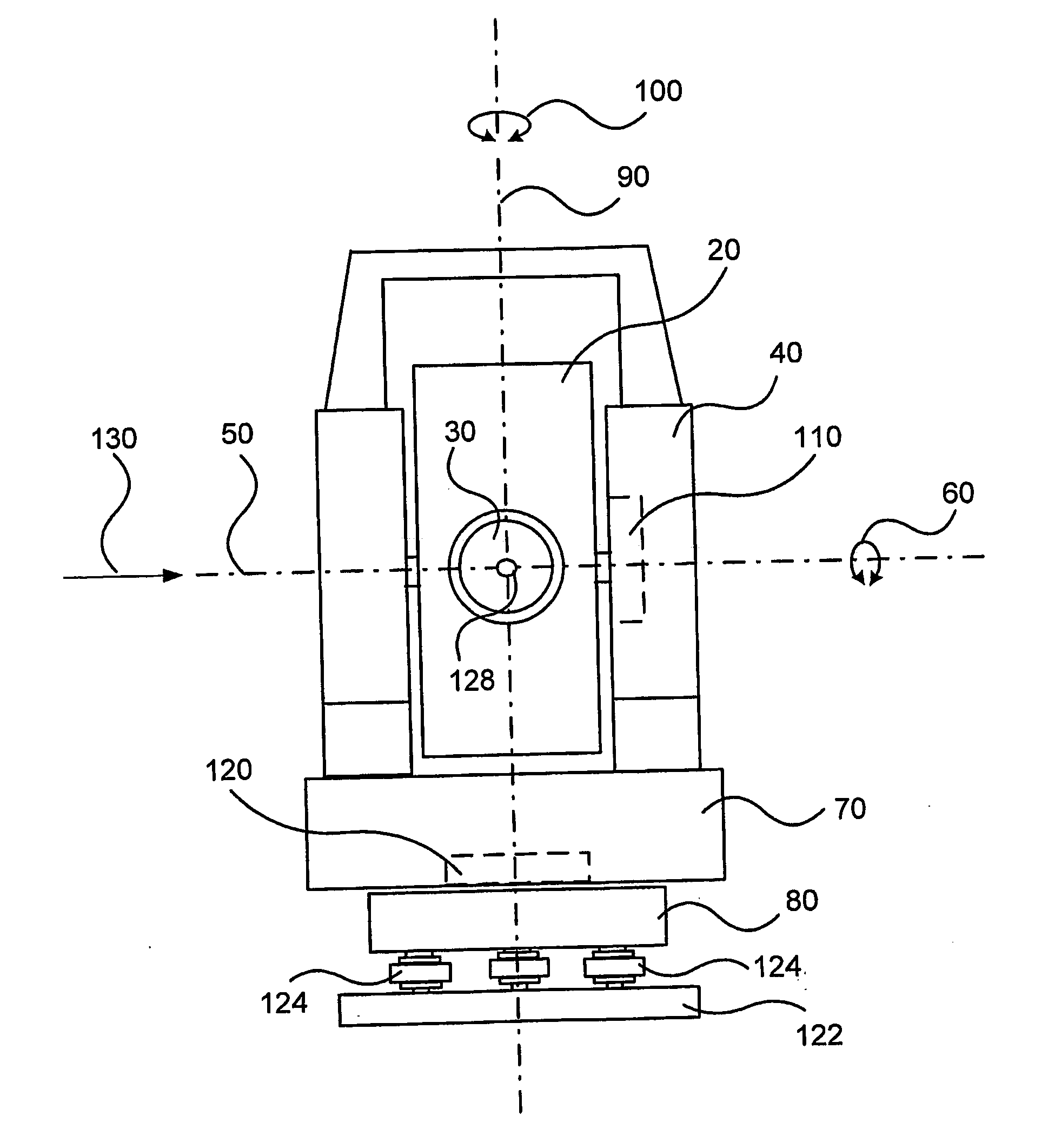

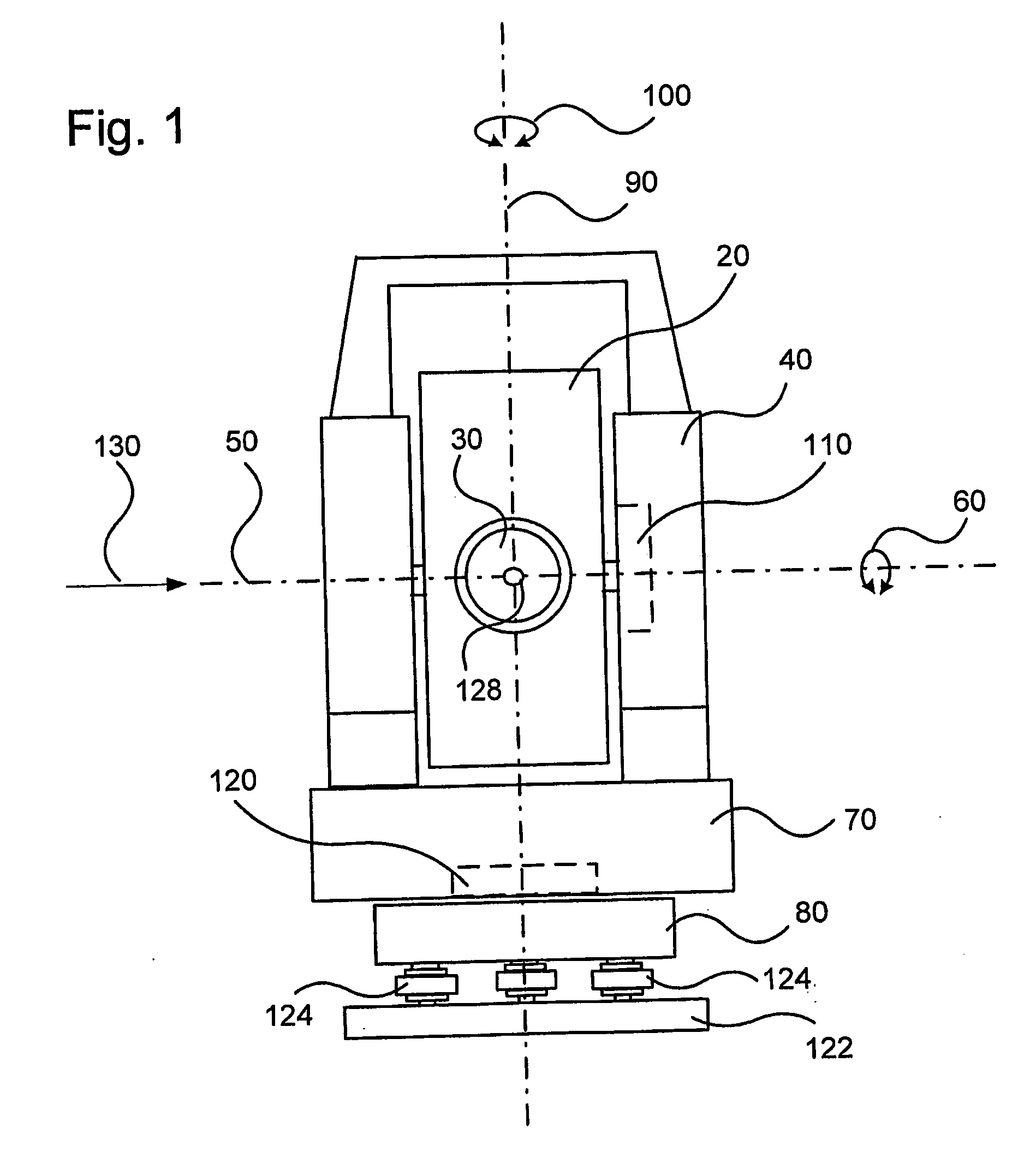

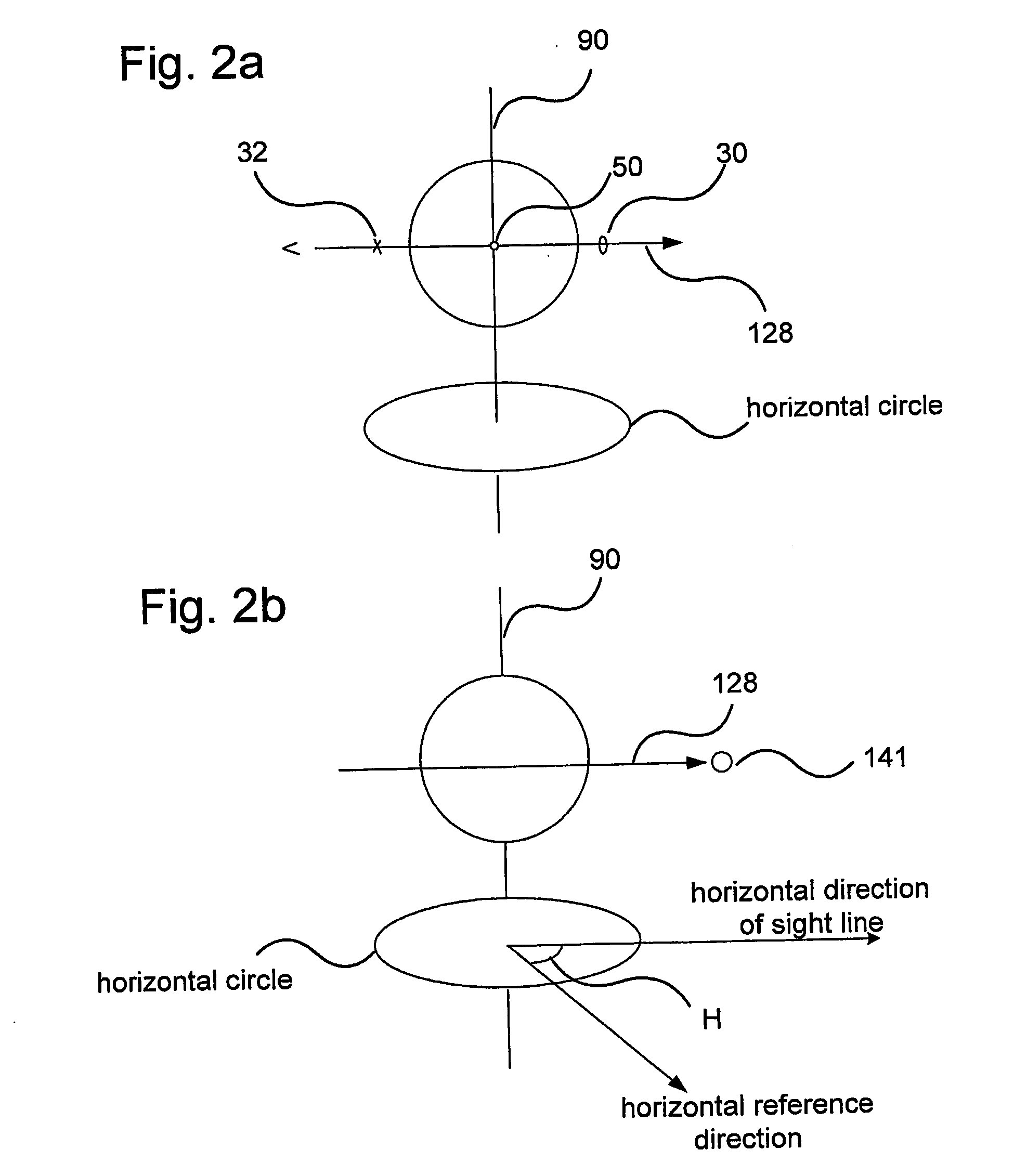

Surveying instrument with compensation for mechanical errors

ActiveUS20070180716A1Large mechanical inaccuracyImprove accuracyHeight/levelling measurementReference line/planes/sectorsSurvey instrumentMeasuring instrument

The invention relates to a method of operating a surveying instrument (10) placed in a orthogonal XYZ-system at (0,0,0) having a movable unit (20), said instrument defining a sight line (128) that is controllably rotatable around a first axis (50), essentially horizontal, and around a second axis (90), essentially vertical, wherein said second axis (90) may be inaccurately positioned so that it deviates from a true vertical axis, and said first axis (50) may deviate from being orthogonal to the second axis (90); the method comprising the steps of determining at least one of the following group of errors relating to the instrument and / or its location: a) a trunnion axis error T as a function of the deviation from 90 degrees between the first axis (50) and the second axis; b) a horizontal collimation error CH, being the deviation between the sight line (128) and the perpendicular angle as related to the first axis (50); and c) a total plumb error defined by components, PI and PII, being two separate angular values defining the tilt of the instrument as related to the plumb line through the same; and d) using these determined values in continuously controlling the alignment when aiming the instrument. The invention also relates to a surveying instrument for use with the method and an error compensation system for a surveying instrument.

Owner:TRIMBLE INC

LIDAR optical scanner system

ActiveUS9658322B2Reduce gapReduce mechanical complexityCondensersElectromagnetic wave reradiationOptical axisRadar

Owner:GARMIN

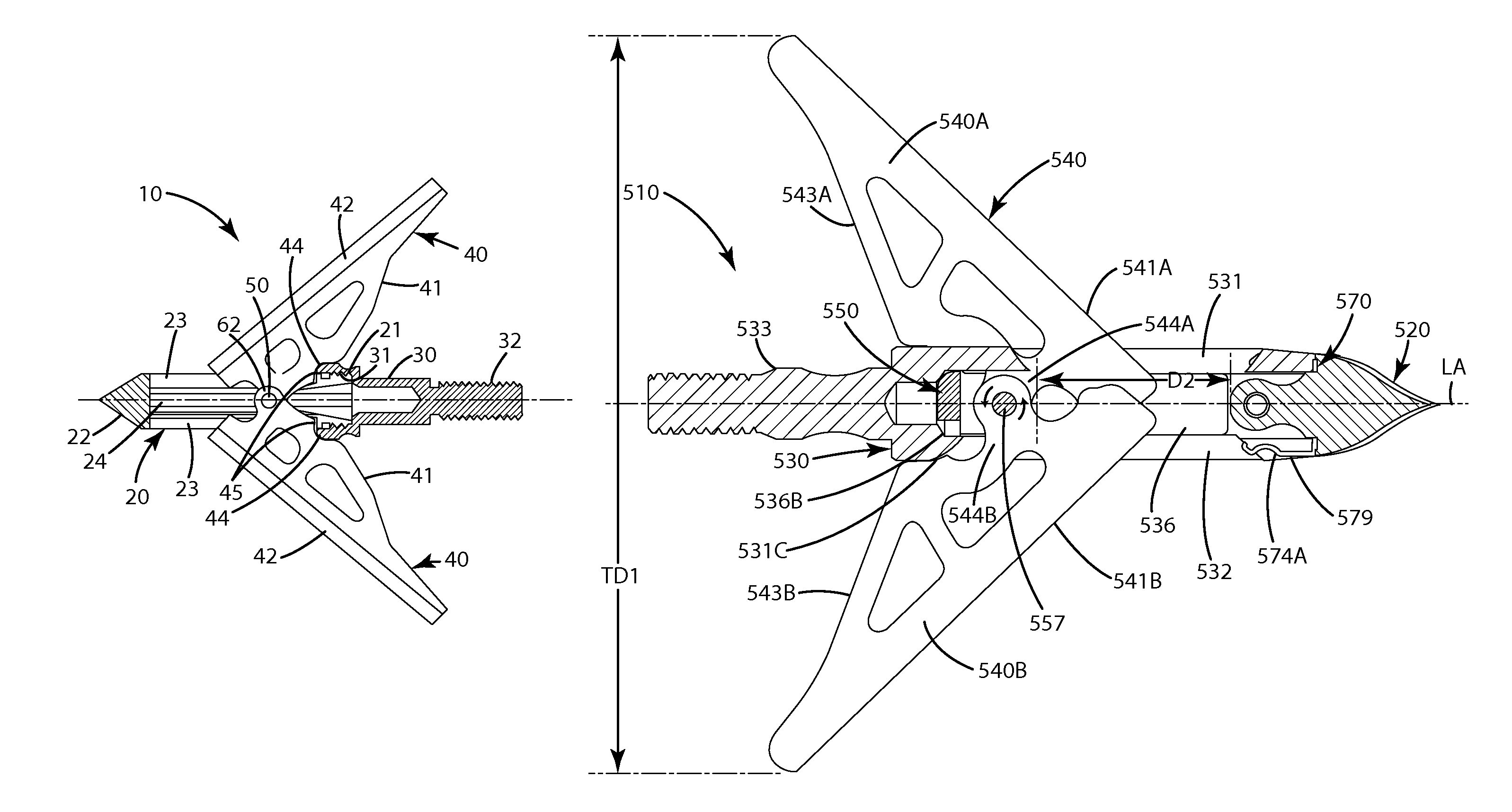

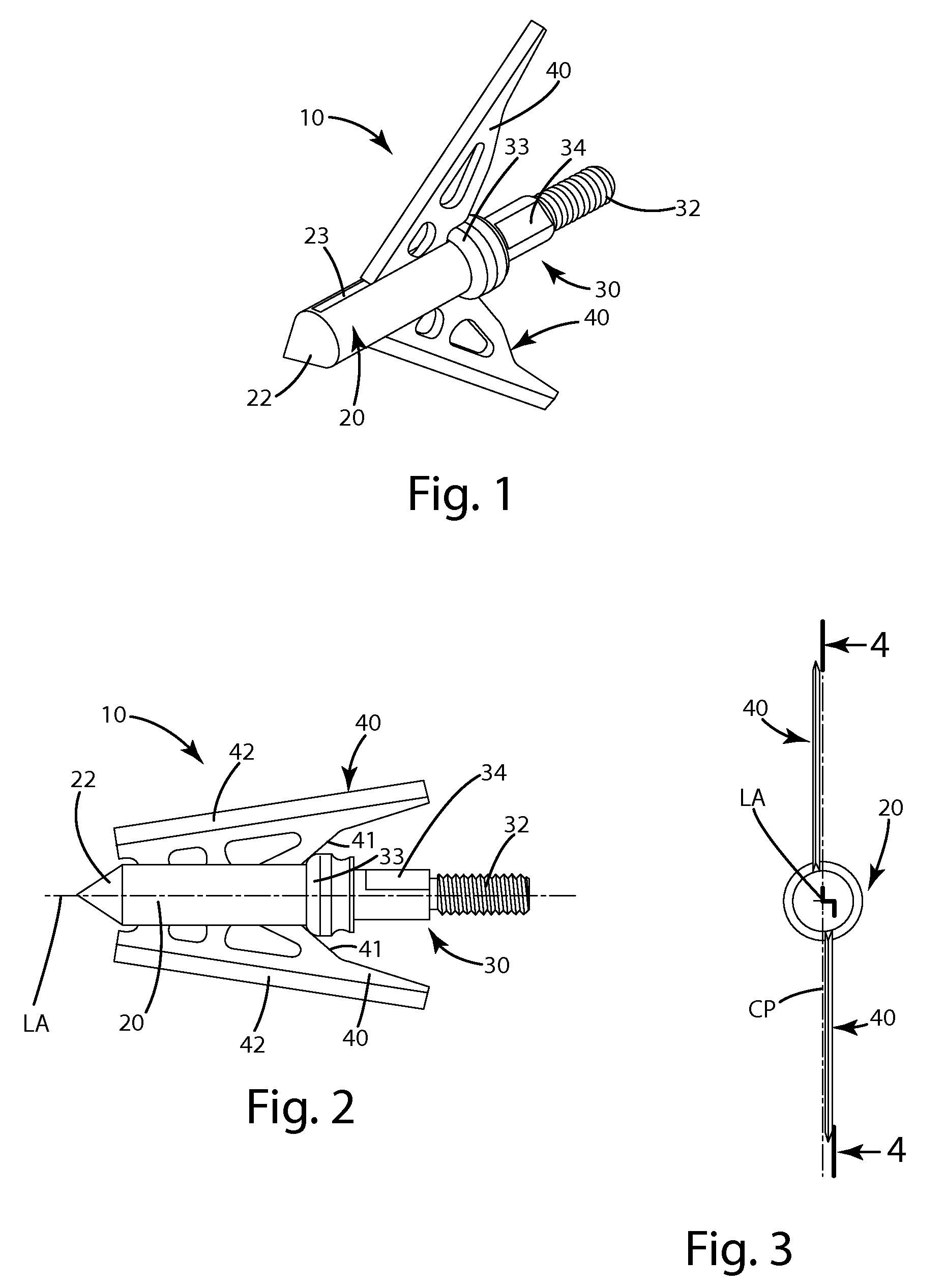

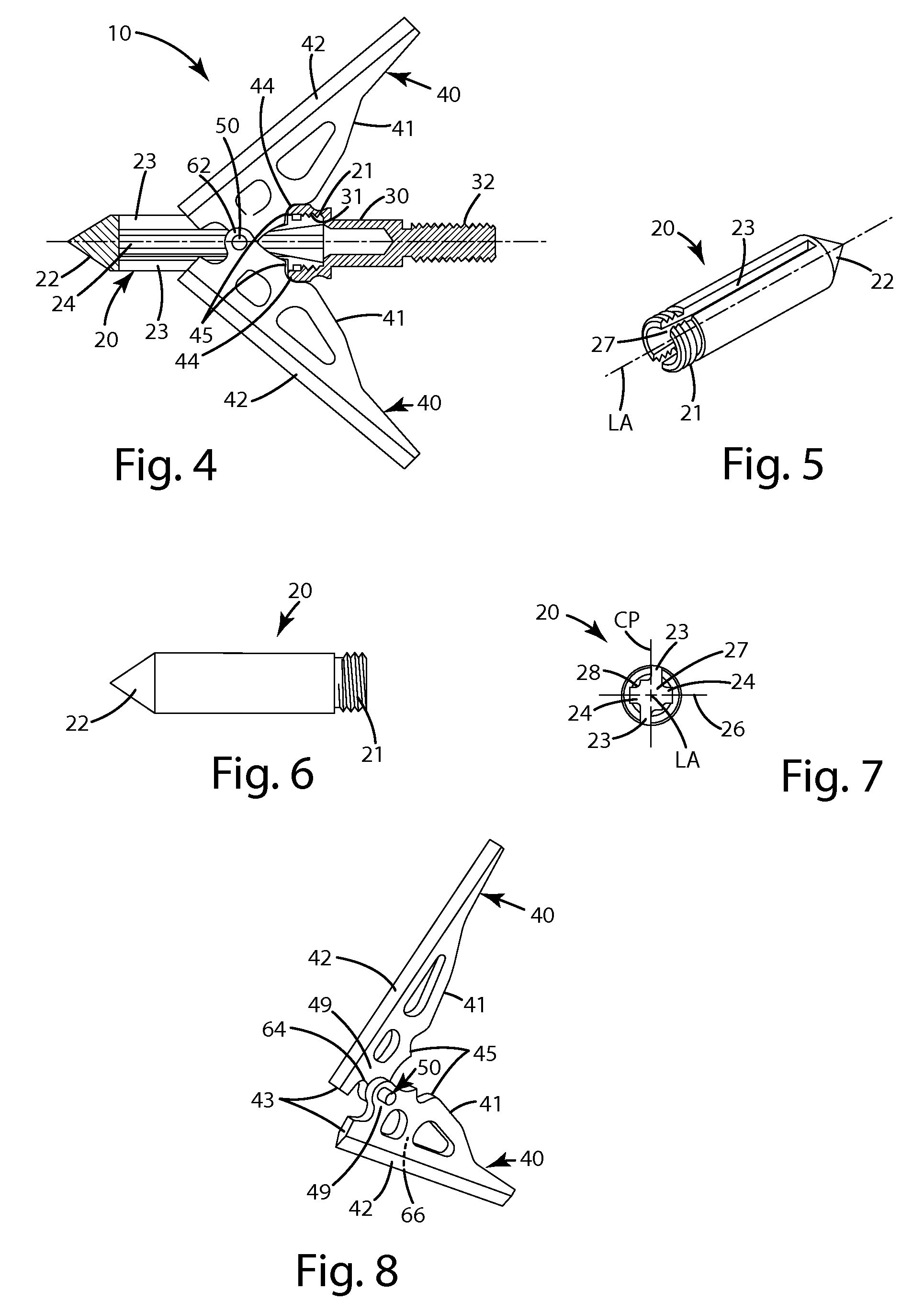

Mechanical broadhead

A mechanical broadhead including rearwardly deploying and / or sliding blades. The broadhead includes a ferrule defining a bore joined with a penetrating tip. A connector body, such as a carriage element or a pin, is slidably and moveably disposed within the bore, distal from the tip. One or more cutting blades is joined with the connector body. The connector body moves together in unison with the cutting blades as they expand from a retracted, in flight mode to a deployed, target penetrating mode. The connector body and blades can be joined with the ferrule so that the broadhead converts from a deployed mode to an unbarbed mode to facilitate broadhead removal. Optionally, the broadhead can include an internal retainer element that is resilient and durable enough to be used for multiple deployments. A related method of operating the broadhead also is provided.

Owner:GRACE ENG

Versatile wafer refining

InactiveUS7377836B1Easy to organizeReduce manufacturing costElectrolysis componentsSemiconductor/solid-state device testing/measurementManufacturing cost reductionElectrolysis

Methods of refining using a plurality of refining elements are discussed. A refining apparatus having refining elements that can be smaller than the workpiece being refined are disclosed. New refining methods, refining apparatus, and refining elements disclosed. Methods of refining using frictional refining, chemical refining, tribochemical refining, and electrochemical refining and combinations thereof are disclosed. A refining apparatus having magnetically responsive refining elements that can be smaller than the workpiece being refined are disclosed. The refining apparatus can supply a parallel refining motion to the refining element(s) for example through magnetic coupling forces. The refining apparatus can supply multiple different parallel refining motions to multiple different refining elements for example solely through magnetic coupling forces to improve refining quality and versatility. A refining chamber can be used. New methods of control are refining disclosed. The new refining methods, including magnetic refining methods, apparatus, and refining elements, including magnetically responsive refining elements, can help improve yield and lower the cost of manufacture for refining of workpieces having extremely close tolerances such as semiconductor wafers. New methods of control are also discussed. Methods and apparatus which use processor readable memory devices are discussed. Refining fluids are preferred. Reactive refining aids are preferred. Electro-refining for adding and removing material is disclosed. New methods and new apparatus for non-steady state refining control are disclosed.

Owner:SEMCON TECH

Device and system for improved imaging in nuclear medicine

InactiveUS7015460B2Superior detectorCost-effectiveCalibration apparatusTomographyPhysicsRadiation attenuation

A method and apparatus for detecting radiation including x-ray, gamma ray, and particle radiation for nuclear medicine are described. A detection system employs fixed or configurable arrays of one or more detector modules comprising detector arrays that may be electronically manipulated through a computer system. The detection system, by providing the ability for electronic manipulation, permits adaptive imaging. The components of the imaging chain can be calibrated or corrected using processes of the invention. One or more reference sources with know properties (such as shape, composition, radionuclide activity distribution and energies, incorporated magnetic, acoustic inductive, or x-ray attenuating materials) can be inserted into the subject. The position of the reference sources can be monitored. Once the reference sources are near the desired location or locations they can be used to calibrate or tune the detection system. The detection system can be focused. Radiation attenuation information (absorption and scattering) can be measured and used to correct for these attenuation effects in the acquired images of the subject.

Owner:MINNESOTA IMAGING & ENG

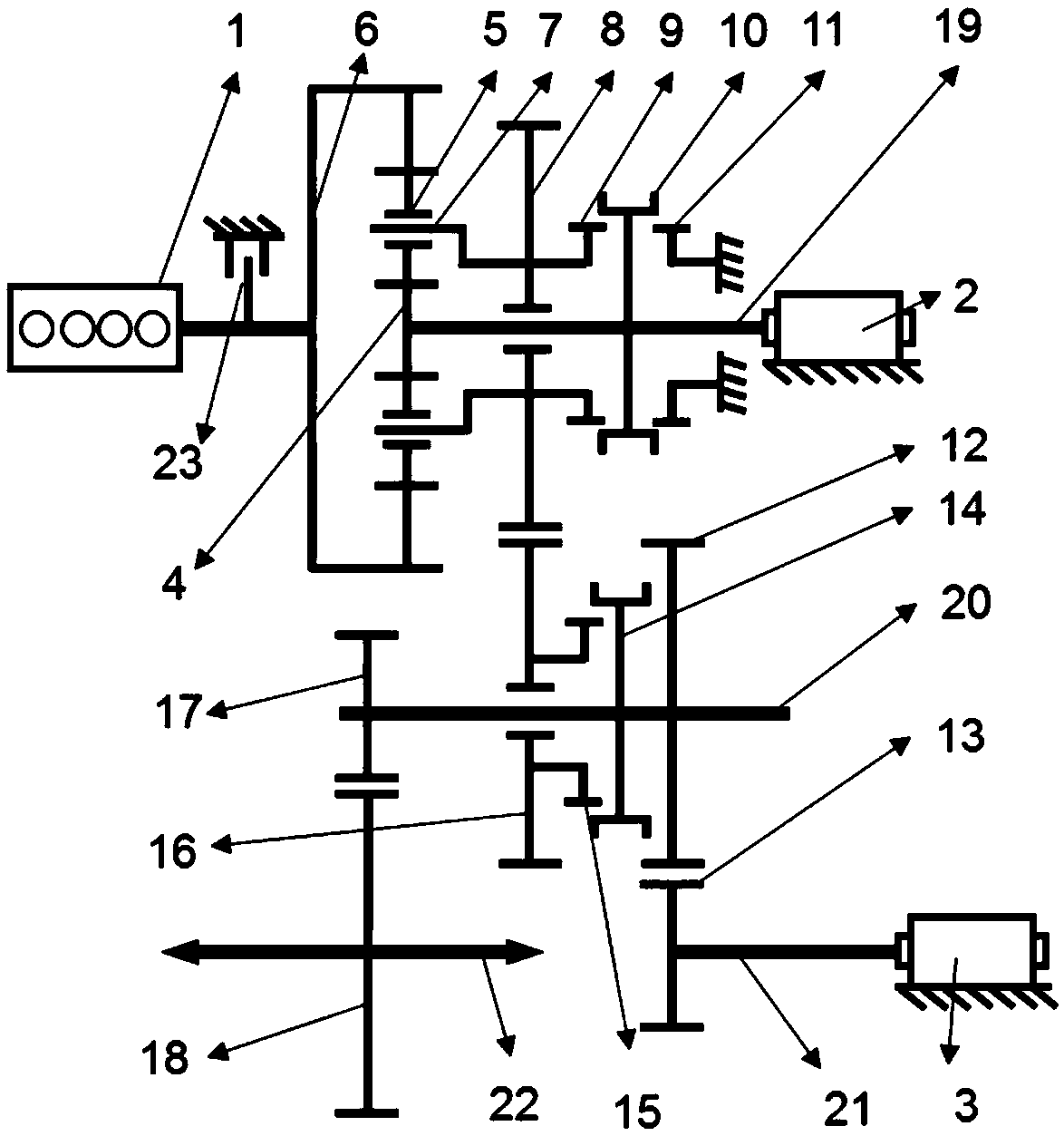

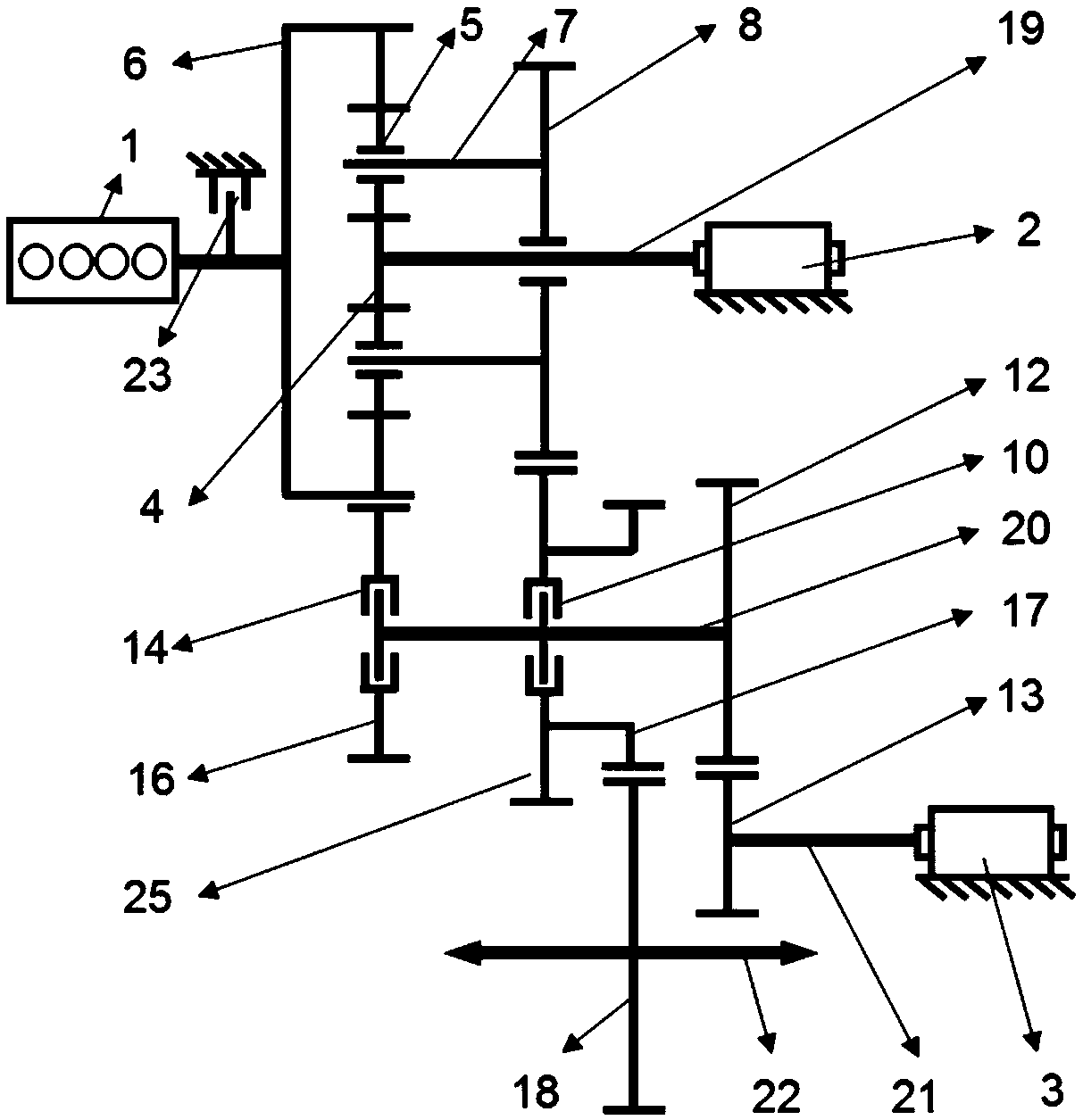

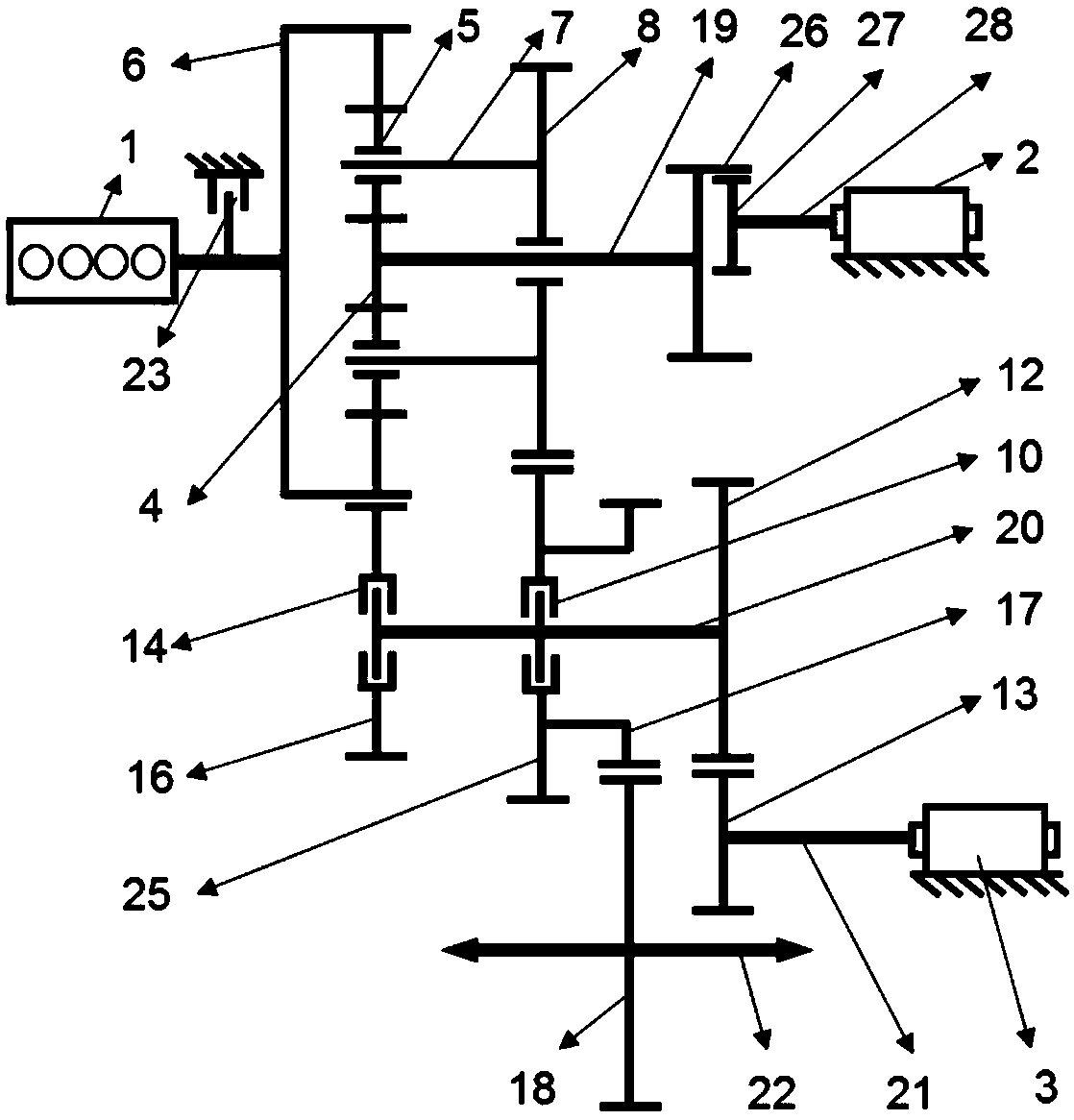

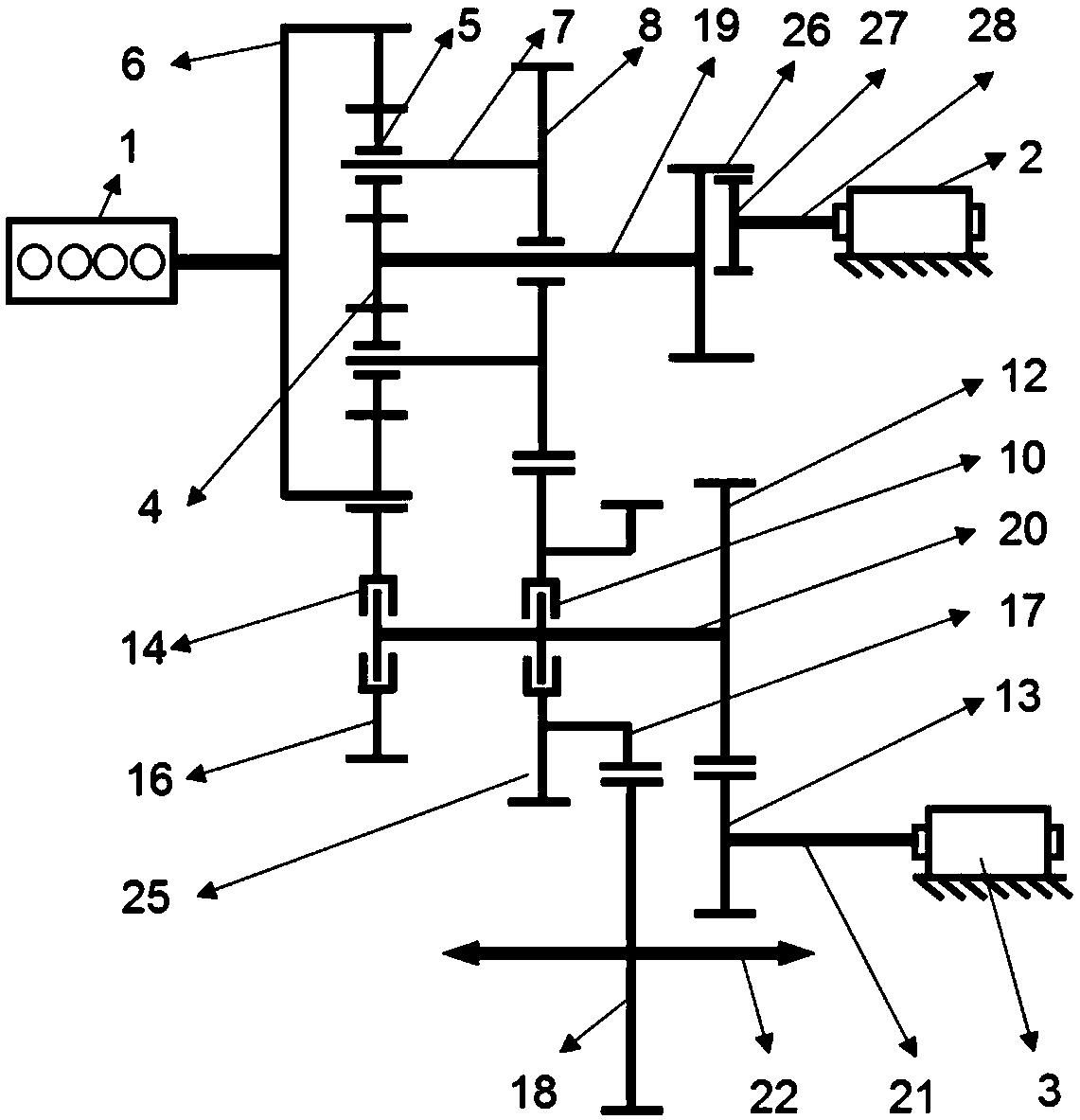

Single planetary gear hybrid power transmission system

PendingCN108725177AReduce manufacturing costLow application costHybrid vehiclesToothed gearingsReducerMultiple modes

The present invention relates to a single planetary gear hybrid power transmission system which comprises a single planetary row, wherein the single planetary row comprises three rotatable parts, namely, an outer gear ring, a sun gear and a planetary gear respectively meshed with the outer gear ring and the sun gear, and the planetary gear is connected to a planetary frame; a power supply, whereinthe power supply comprises an engine, a first motor and a second motor respectively connected to the single planetary row in a transmission manner, and a power storage battery for charging and powerutilization is mounted on the first motor and the second motor; a gear shift component, wherein the gear shift component comprises a gear shift element and a single-phase clutch or a brake for lockingthe transmission of the engine and the single planetary row; and an output shaft, wherein the output shaft is connected to the single planetary row in a transmission manner, and a main reducer is mounted on the output shaft. Compared with the prior art, the invention has the advantages of low mechanical complexity, low control difficulty, multiple modes and so on.

Owner:陈海军

Systems for capturing a client vehicle

ActiveUS20180297723A1Simple docking architectureImprove reliabilityAircraft componentsArtificial satellitesBiomedical engineeringSpacecraft

Capture assemblies and compliant extension assemblies may be utilized for insertion into a nozzle of a liquid engine of a spacecraft. The capture assembly may include an apparatus such as a probe for insertion into the nozzle and an assembly at least partially enclosed in a forward portion of the probe. The assembly may include a plurality of actuated fingers for deploying outwardly from the probe when the probe is inserted into the nozzle. The compliant extension assembly may be at least partially enclosed in a housing connected to the capture assembly for axial movement of the probe. The compliant extension assembly may facilitate axial movement of the probe between a retracted position and an extended position, wherein the probe is extended forwardly, relative to the housing.

Owner:NORTHROP GRUMMAN SYST CORP

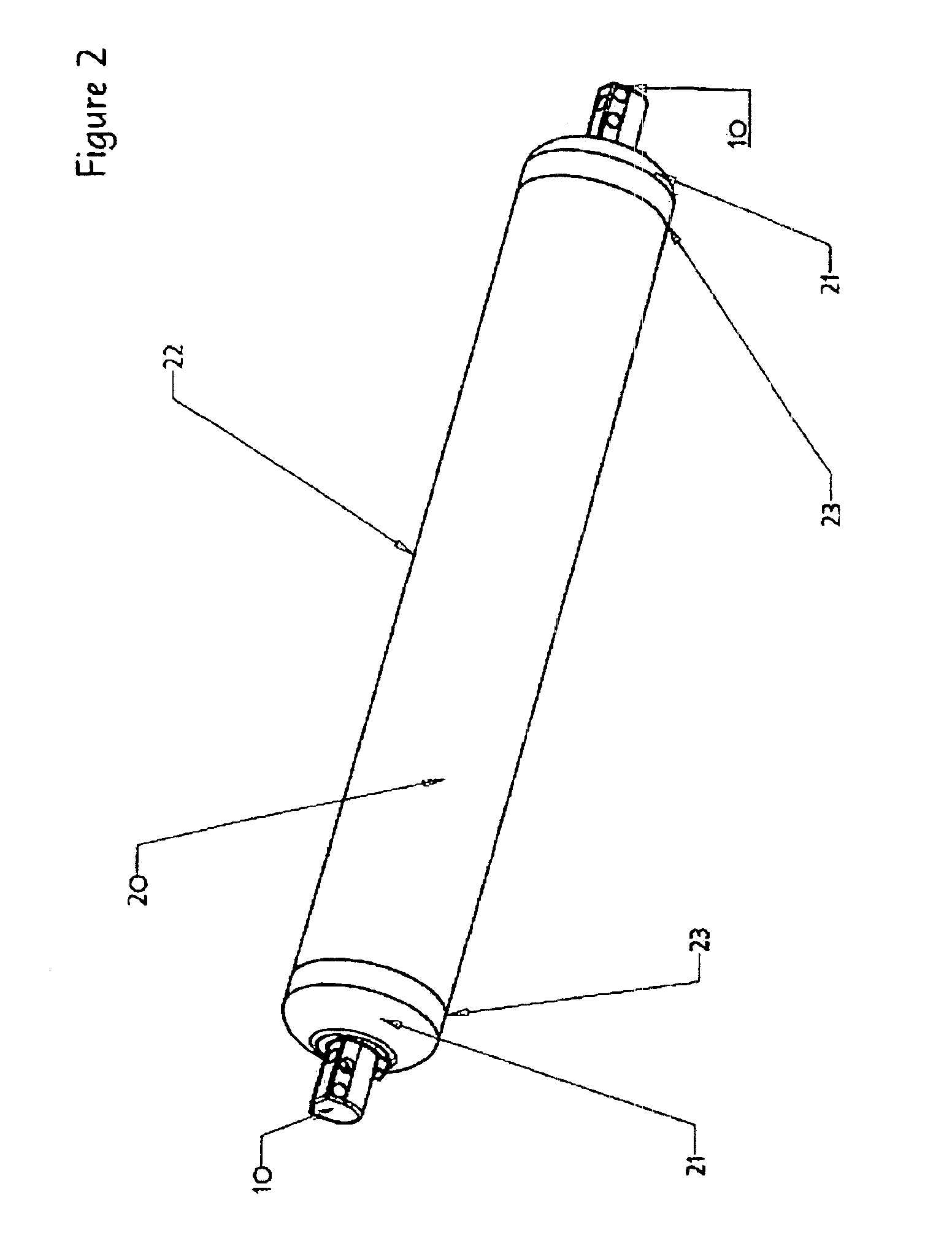

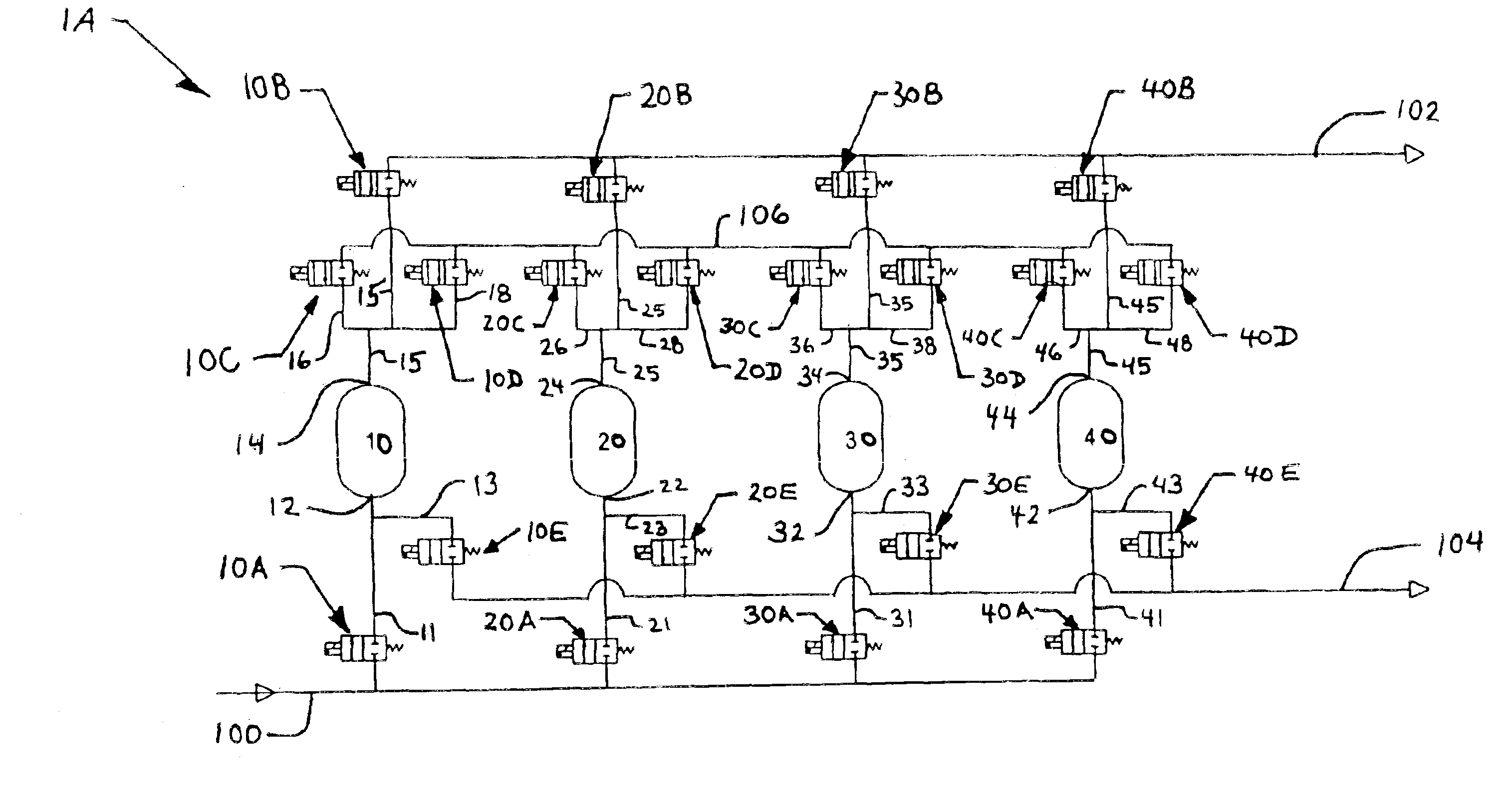

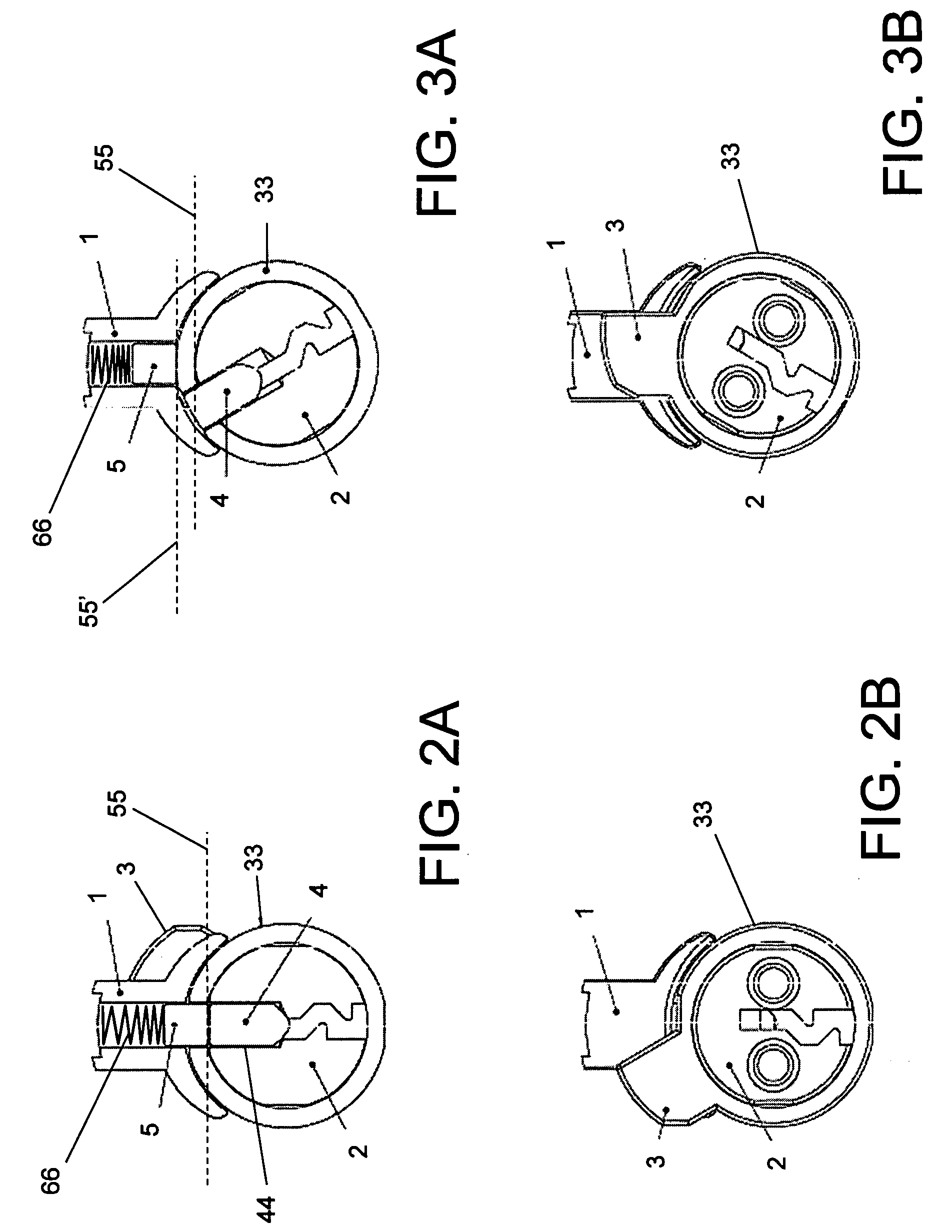

Method and apparatus for pressure swing adsorption

InactiveUS6929683B2Cost-effective and reliableEasy to controlGas treatmentIsotope separationBiomedical engineeringPressure vessel

A pressure swing adsorption system including a pressure vessel having an opening and a valve manifold including a body having a first cavity fluidly connected to the opening. The body further includes a passage and a channel, such that the passage connects the channel to the cavity. The valve manifold further includes a valve provided within the passage. The valve is configured to selectively permit and restrict flow between the channel and the cavity via the passage.

Owner:LUMMUS TECH INC

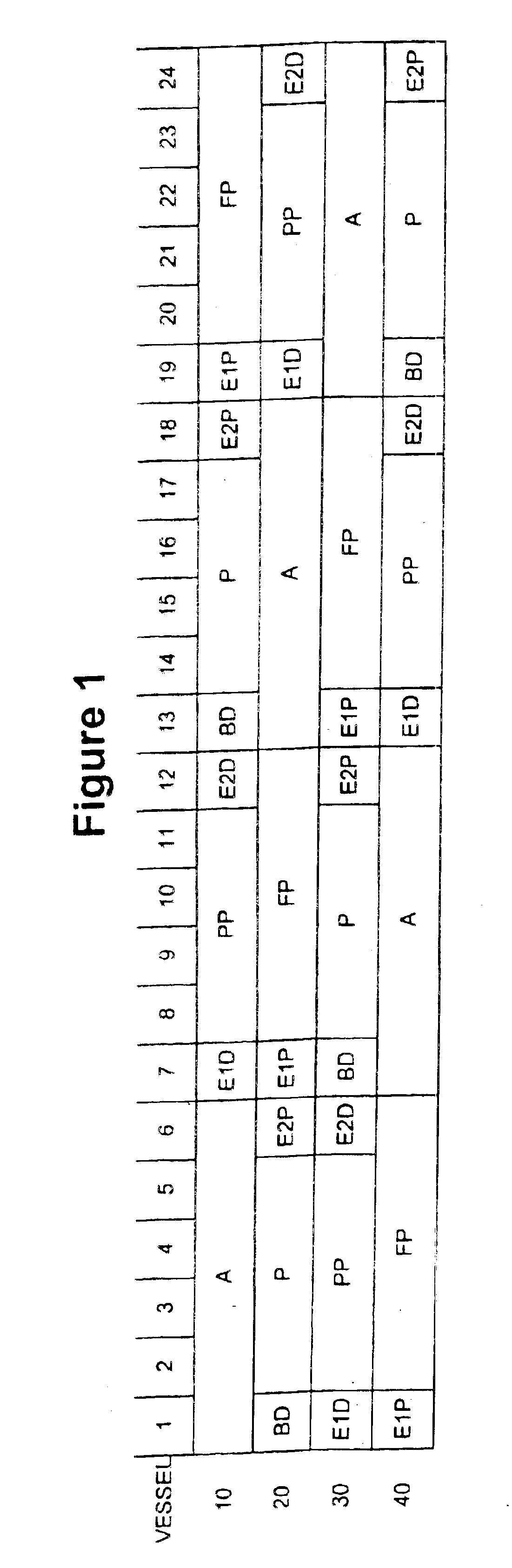

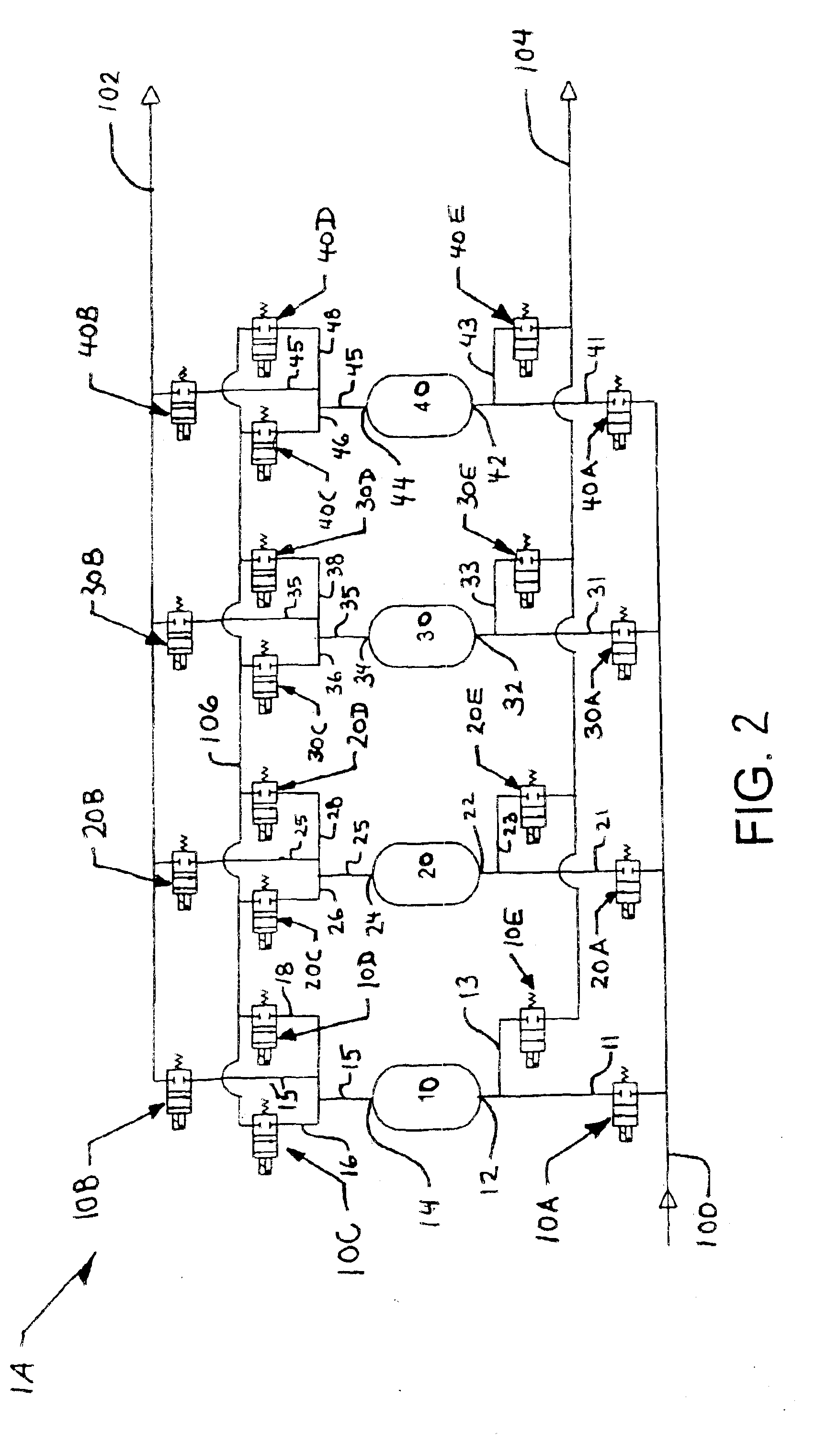

High recovery PSA cycles and apparatus with reduced complexity

InactiveUS6858065B2Improved PSA operating cycleReduce complexityGas treatmentIsotope separationPressure decreaseEngineering

A pressure swing adsorption process including the step of separating a gas mixture by absorbing a gas component in adsorbent beds provided within vessels, where the separating step has at least a two-stage pressure equalization and is performed with no more than five valves per vessel of the plurality of vessels. The process includes an adsorption step, a first pressure equalization step having at least two stages where the pressure decreases, a purge step, and a second pressure equalization step having at least two stages where the pressure increases. A pressure swing adsorption system is provided with vessels each having a first opening connected to a source manifold via a first valve and connected to a waste manifold via a second valve, and a second opening connected to a product manifold via a third valve and connected to an equalization conduit via a fourth valve and a fifth valve.

Owner:LUMMUS TECH INC

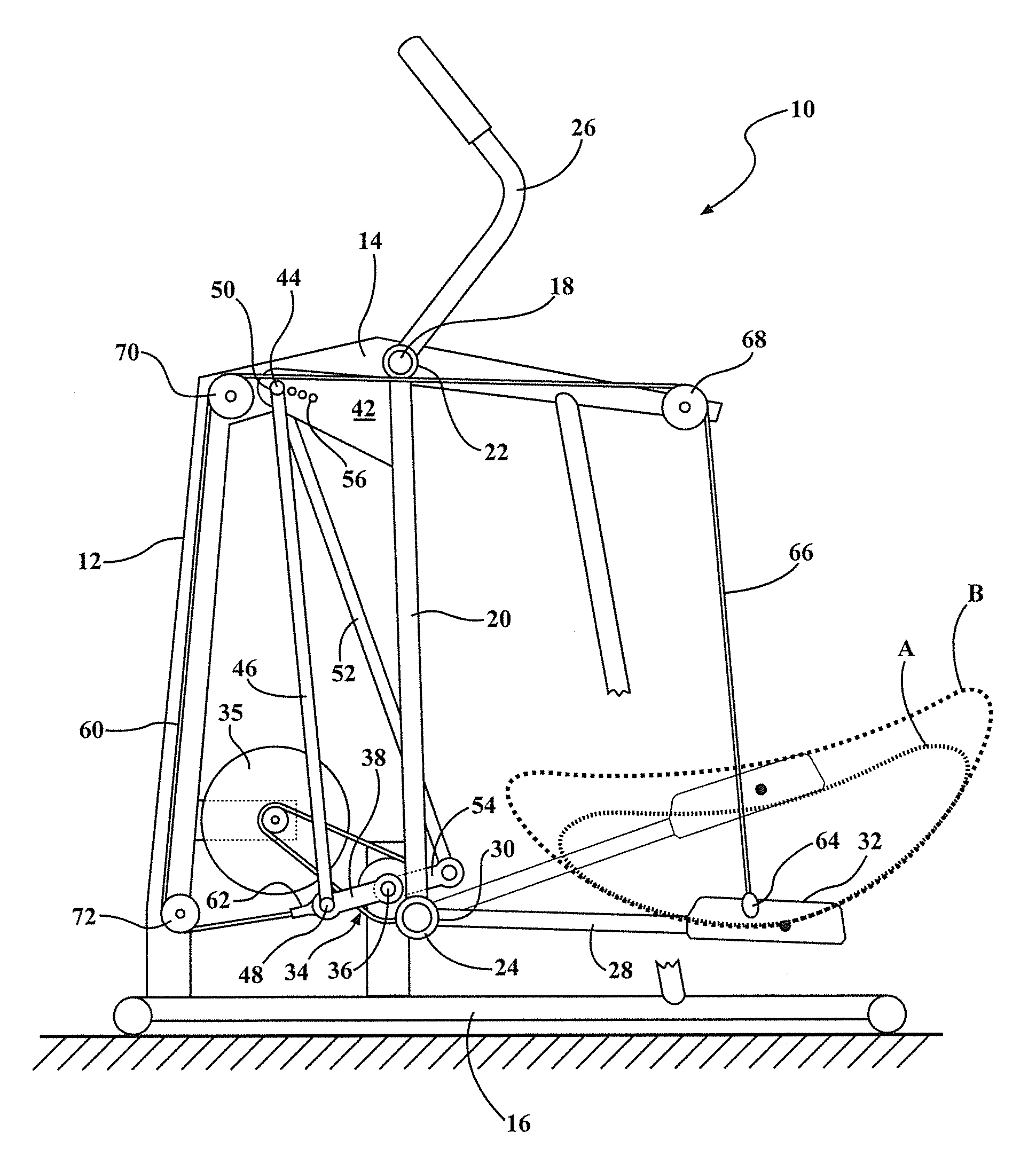

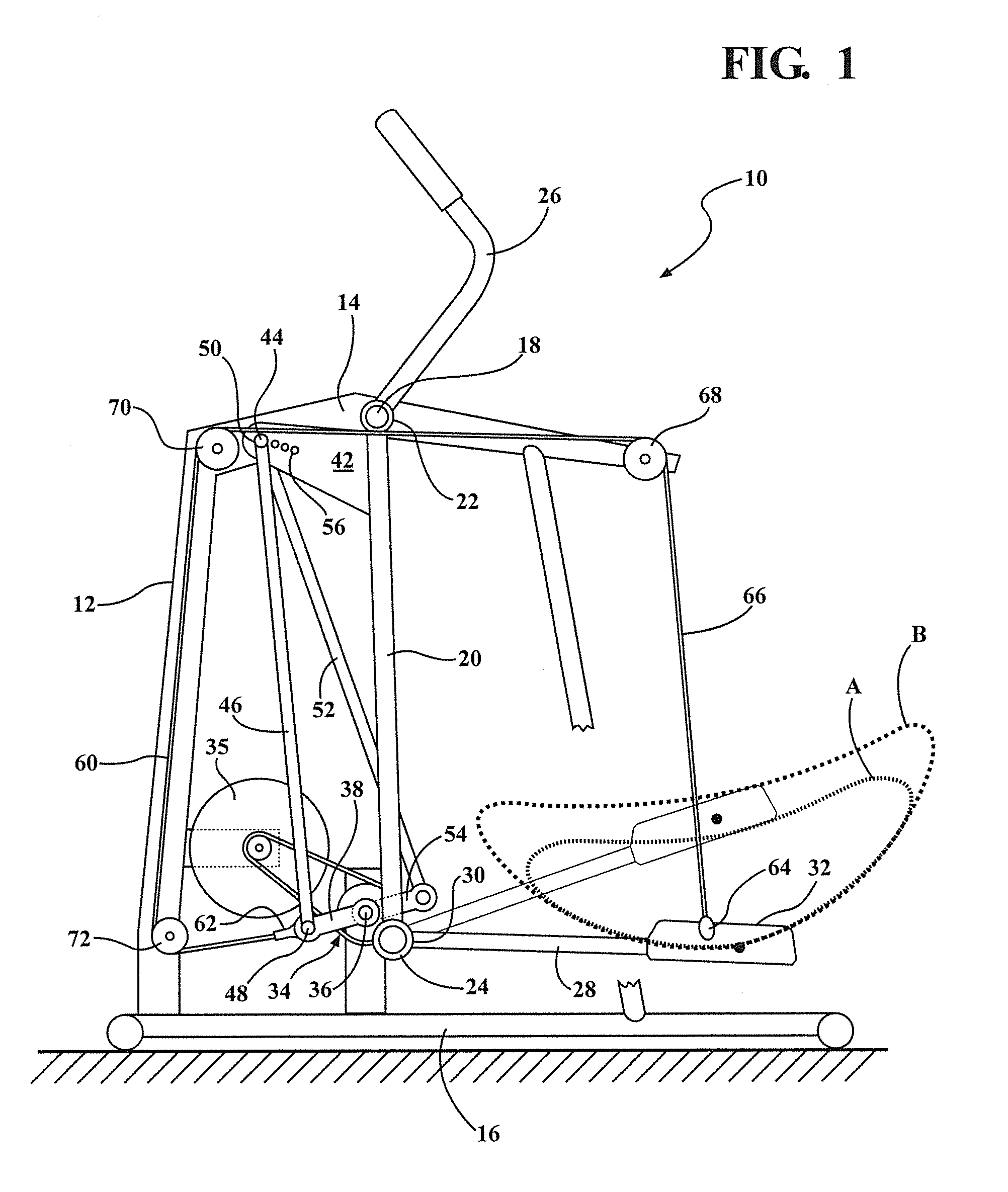

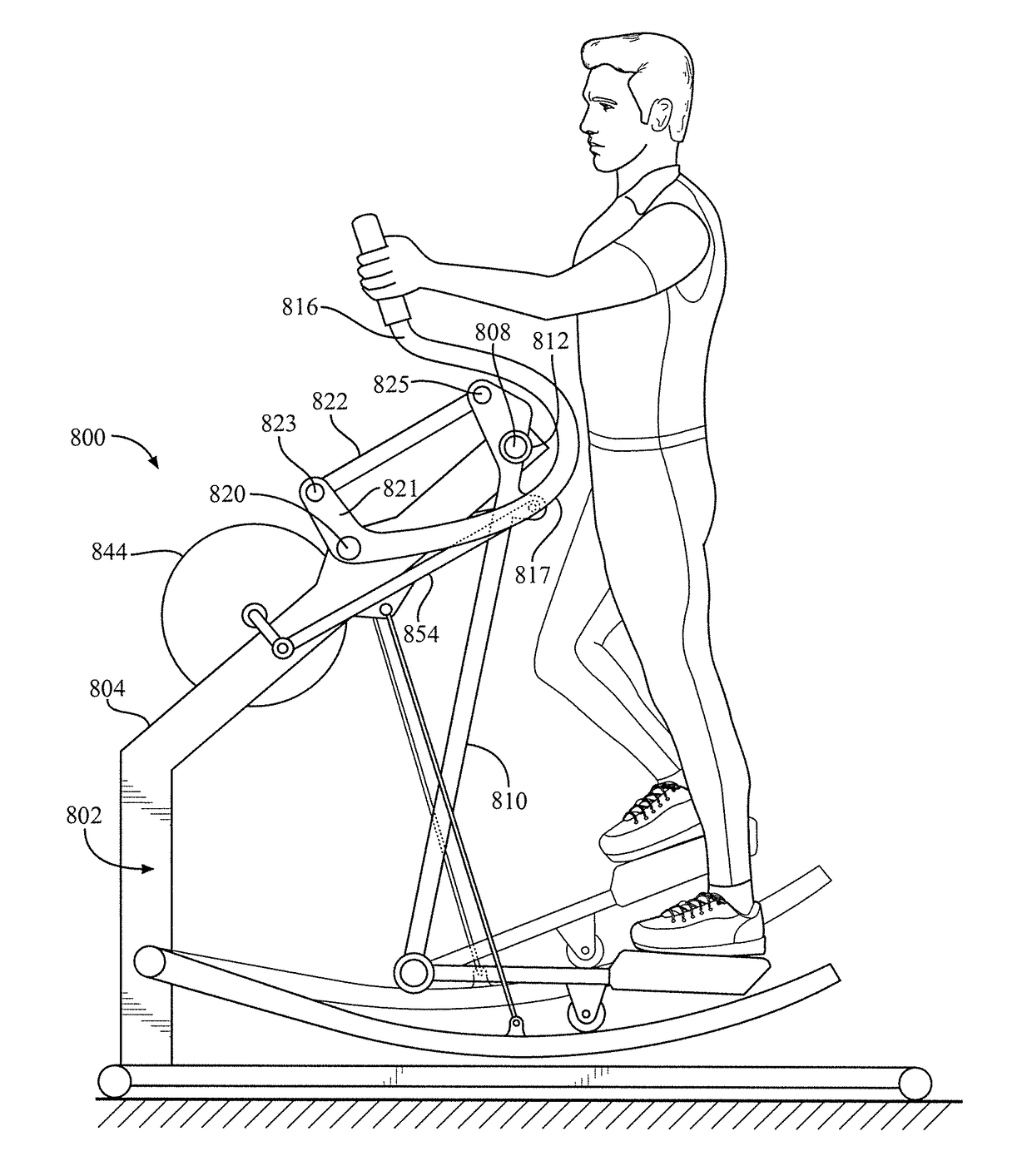

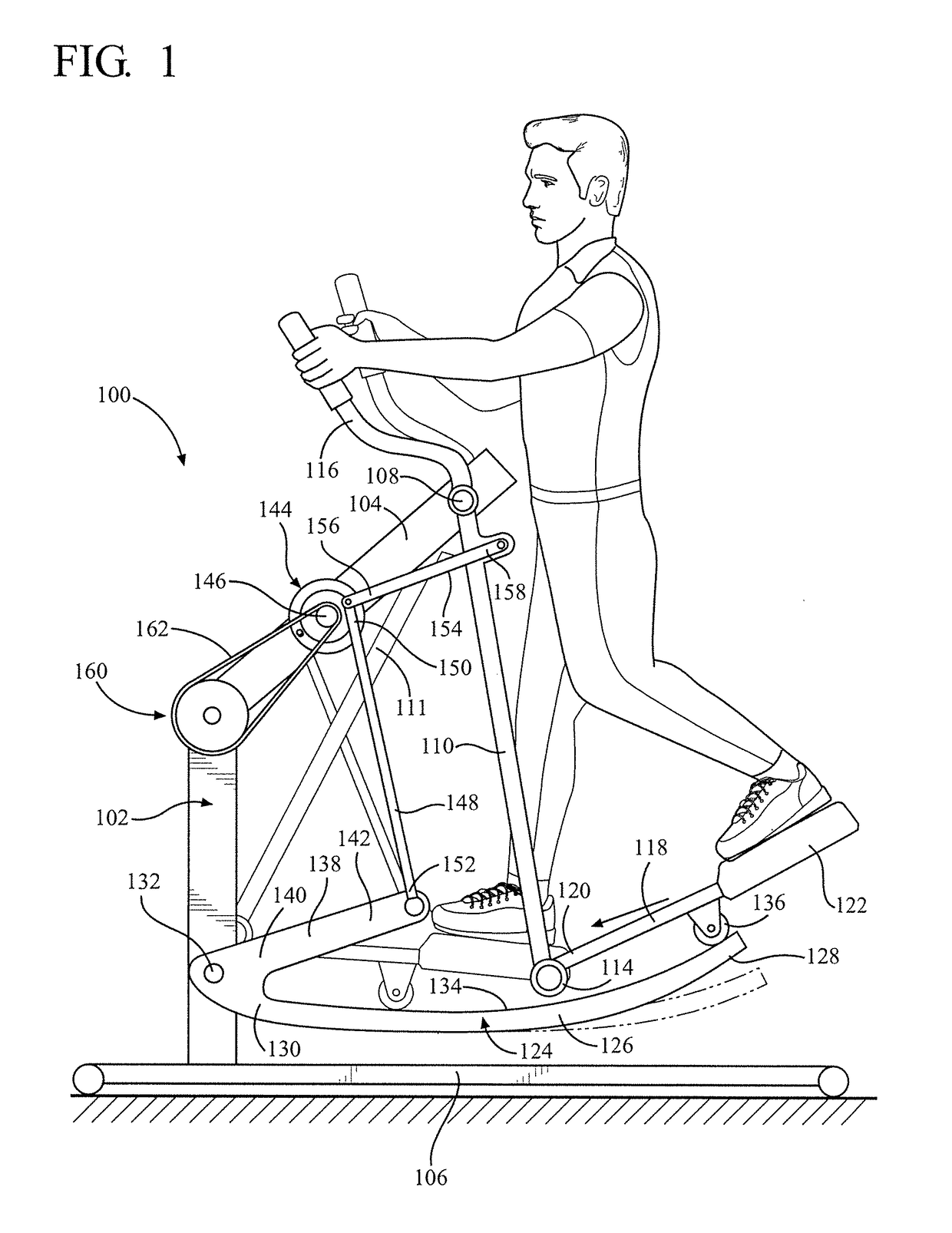

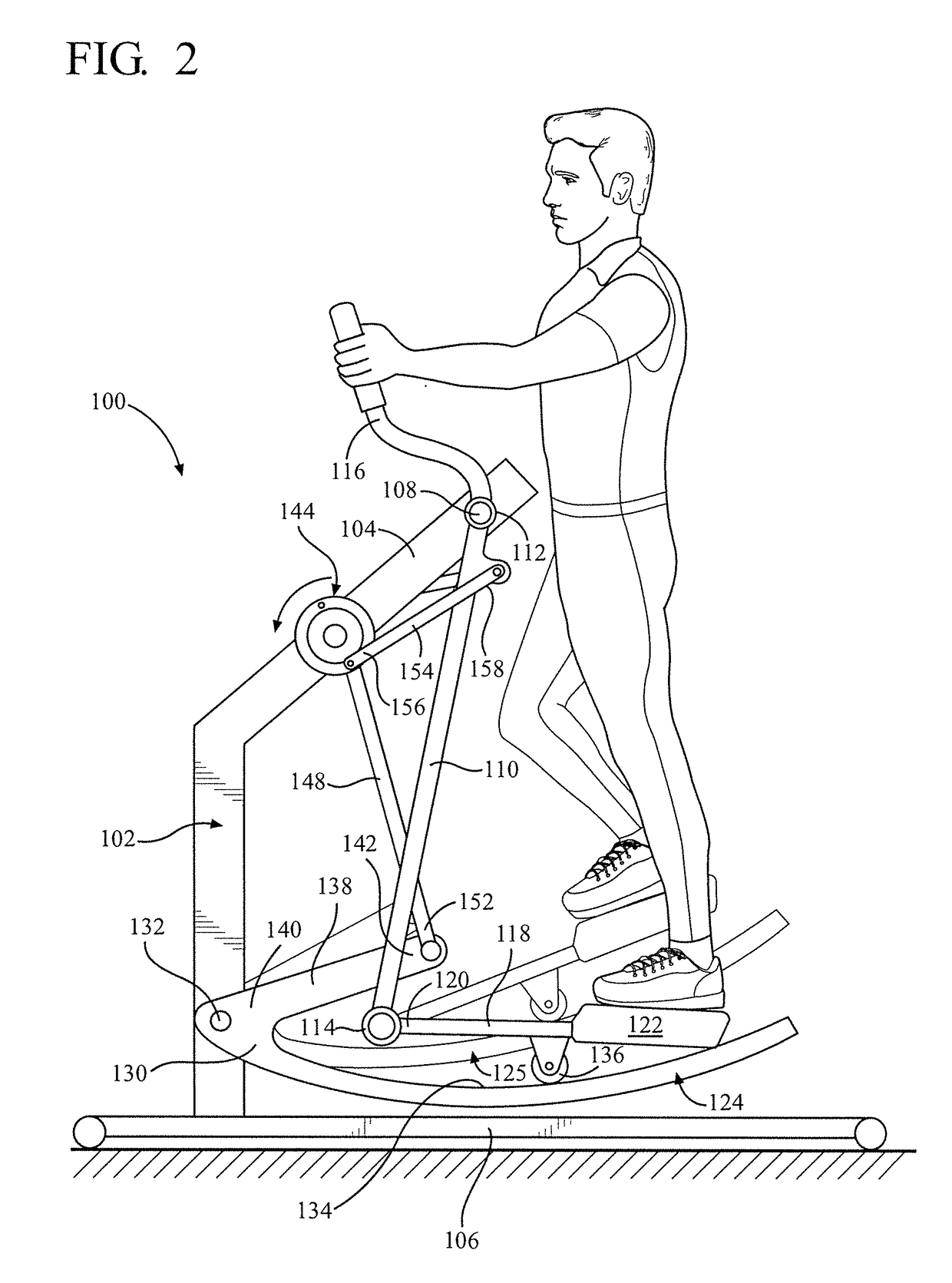

Elliptical exercise device

InactiveUS20140336006A1Reduce mechanical complexityCompact formMuscle exercising devicesMovement coordination devicesEllipsePhysical exercise

An elliptical exercise device includes a frame supporting guide links which provide for horizontal motion of associated foot support links. A mechanical coupling couples the foot support links to the crank system and intermediate links connect the crank system to the guide links such that a foot receiving area of each foot support link moves in an elliptical path when the crank system rotates.

Owner:LARRY D MILLER TRUST

Multirotor electric aircraft with redundant security architecture

ActiveUS20200283134A1Provided safety levelImprove security levelElectric power distributionPropulsion by batteries/cellsElectric aircraftFlight vehicle

A multirotor aircraft with at least two thrust producing units, the multirotor aircraft being adapted for transportation of passengers and comprising an aircraft operating structure that is adapted for operation of the multirotor aircraft in failure-free operating mode, and a redundant security architecture that is at least adapted for operation of the multirotor aircraft in case of a failure of the aircraft operating structure in operation, the redundant security architecture being provided to comply with applicable authority regulations and certification requirements regarding passenger transportation.

Owner:AIRBUS HELICOPTERS DEUT GMBH

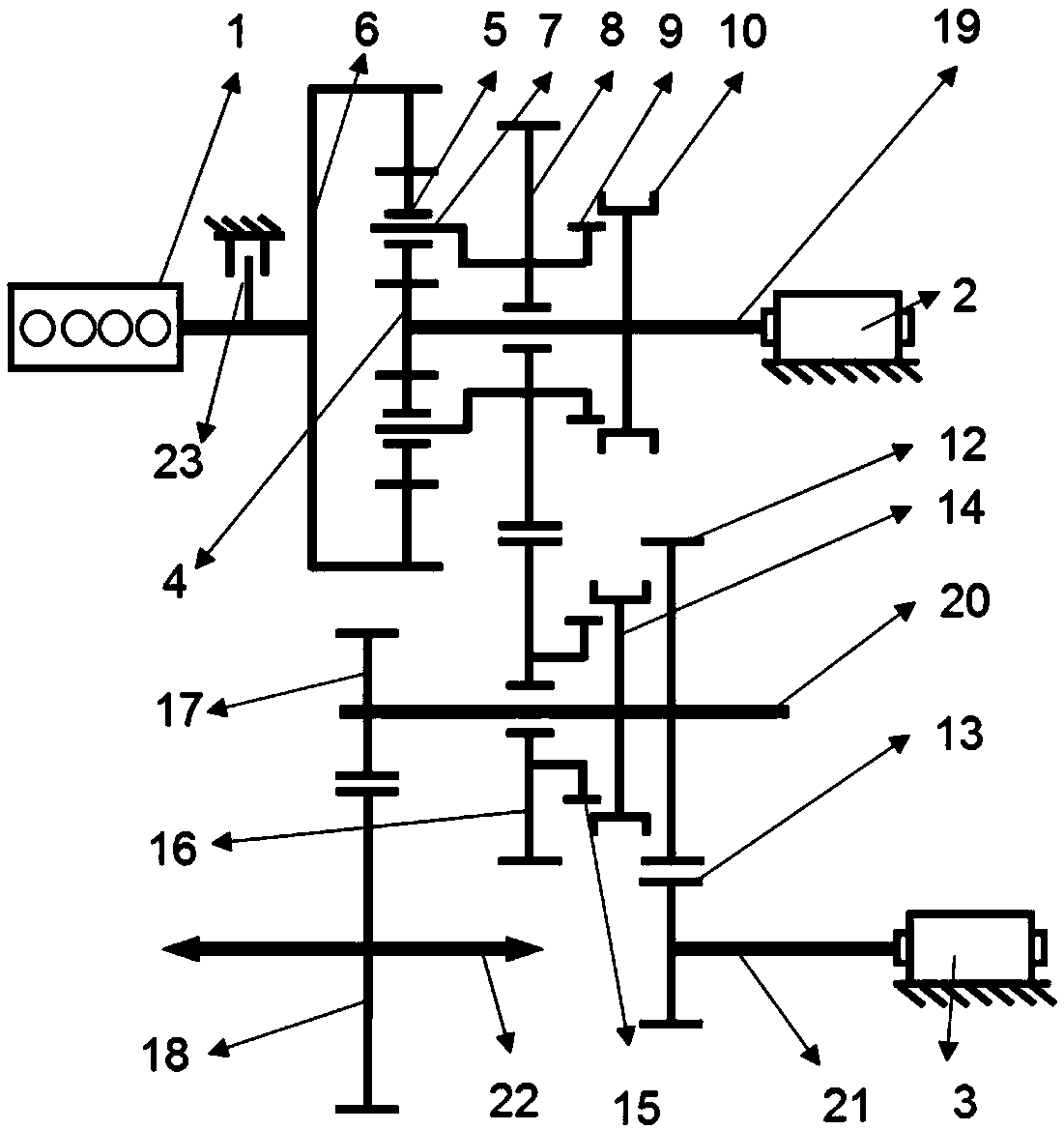

Power distributional hybrid power speed changer

PendingCN108725176AReduce manufacturing costLow application costHybrid vehiclesGas pressure propulsion mountingElectric machineControl theory

The invention relates to a power distributional hybrid power speed changer which is respectively connected with an engine, and odd number or even number of motors. The power distributional hybrid power speed changer comprises a single planet row, a gear shifting element and a common gear, wherein the single planet row comprises a sun wheel, an outer gear ring, a planet wheel and a planet carrier;the planet wheel is respectively meshed with the outer gear ring and the sun wheel; the single planet row is provided with two rotation freedom degrees; the rotating speeds of the components can be determined through the two rotation freedom degrees; the gear shifting element comprises two clutches; the common gear has a single rotation freedom degree; the rotating speeds of the components can bedirectly or indirectly determined through the single planet row freedom degree. Compared with the prior art, the power distributional hybrid power speed changer provided by the invention has the advantages of low mechanical complexity, low cost, low control difficulty and the like.

Owner:陈海军

Elliptical exercise device with moving control tracks

InactiveUS9649529B1Reduce mechanical complexityCompact formFrictional force resistorsMovement coordination devicesEngineeringFoot supports

An elliptical exercise device has a frame and guide link pivotally attached thereto. A foot support link is pivotally connected to a lower attachment point of each guide link so that when the guide links pivot relative to the frame, foot receiving areas of the foot support links move in a path of travel having a horizontal component of motion. Vertical control tracks are pivotally connected to the frame and support the foot support links. A vertical drive is coupled to the forward portion of the frame and vertical control elements connect the vertical drive to the vertical control tracks. A horizontal drive and horizontal control links control pivoting of the guide links.

Owner:LARRY D MILLER TRUST

Key operated pin tumbler locks and methodology

ActiveUS8336348B2Improve functionalityReduce mechanical complexityLock casingsCylinder locksBiological activationMechanical engineering

Apparatus and associated methodology are provided for key operated pin tumbler locks, some of which may incorporate a removable core pin tumbler lock. A selected tumbler of a type commonly used in pin tumbler locks is configured along with a driver pin to control operation of a retainer that, when rotated by use of a control key inserted in the lock, allows alternate selective removal and replacement of the core assembly in the lock. Also, or separate therefrom, one or more tumbler holes may be formed or drilled in a manner so as to prevent engagement of a tumbler with the bite of a key. Presently disclosed structures and associated methodology help to reduce any susceptibility to unauthorized techniques practiced against the lock, such as unintentional activation of the tumblers by unauthorized persons through use of a key with so-called “bumping” techniques.

Owner:COMPX INTERNATIONAL

Subsea valve actuator having visual manual position indicator connected to a manual override shaft

ActiveUS20120234410A1Reduce mechanical complexityReduce in quantitySpindle sealingsOperating means/releasing devices for valvesAxial displacementValve actuator

A subsea valve actuator is disclosed, comprising an override shaft (6) reaching from inside a fluid filled and pressure compensated actuator housing (1) to the exterior thereof via a bearing and sealing arrangement (7), wherein a visual valve position indicator (14) is arranged exterior to the actuator housing. The visual indicator (14) is pivotally mounted to the override shaft and guided non-rotatably to be forced in axial displacement on the override shaft when the override shaft is rotated, wherein the mounting of the visual indicator (14) on the override shaft (6) is encased in a fluid filled, pressure compensated indicator mounting enclosure (19) surrounding the override shaft (6) in sealing (26) relation outside of the actuator housing (1).

Owner:VETCO GRAY SCANDINAVIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com