Power distributional hybrid power speed changer

A hybrid and split-flow technology, applied in hybrid vehicles, power units, pneumatic power units, etc., to achieve the effects of high meshing efficiency between gears, low mechanical complexity, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

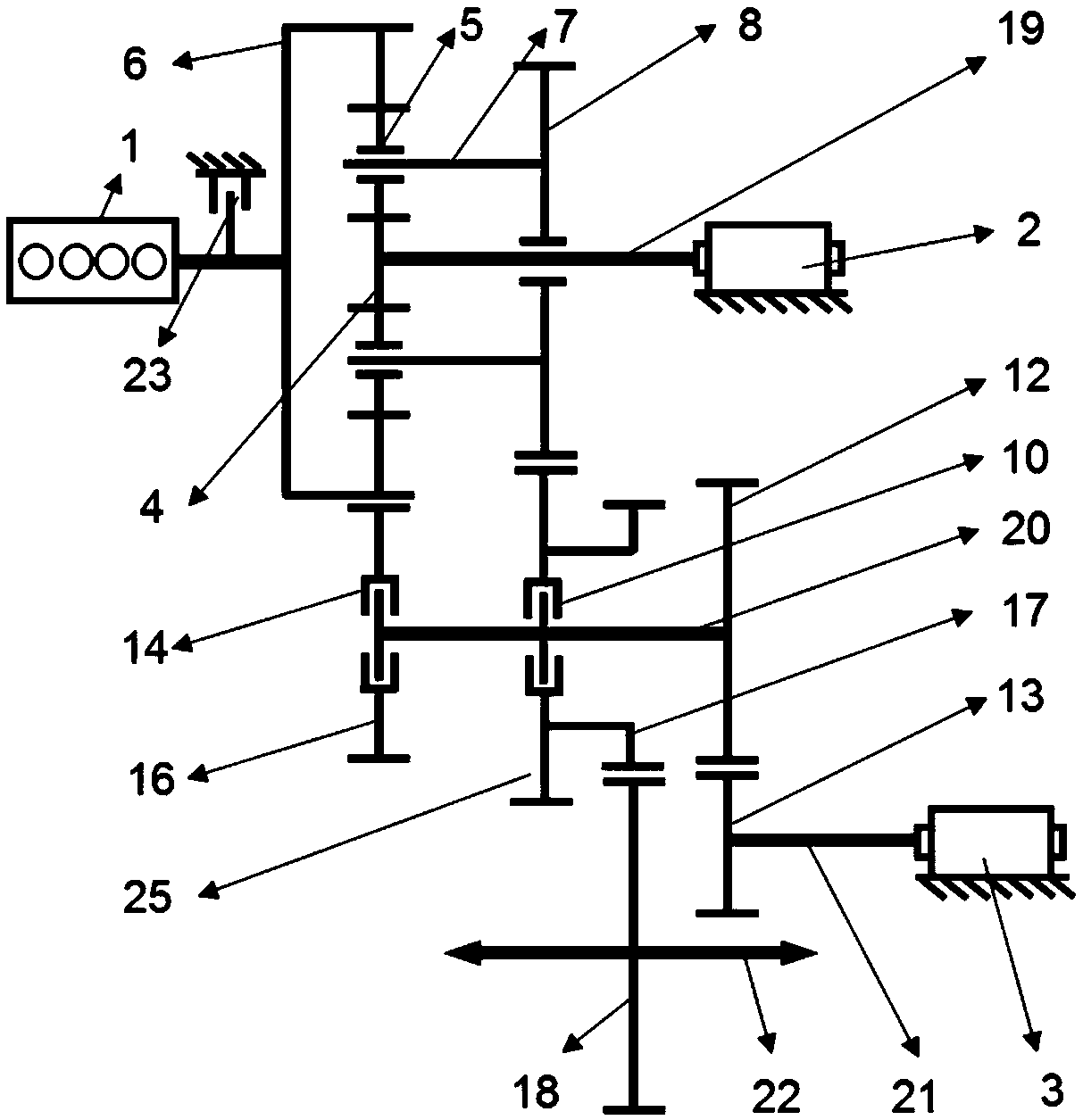

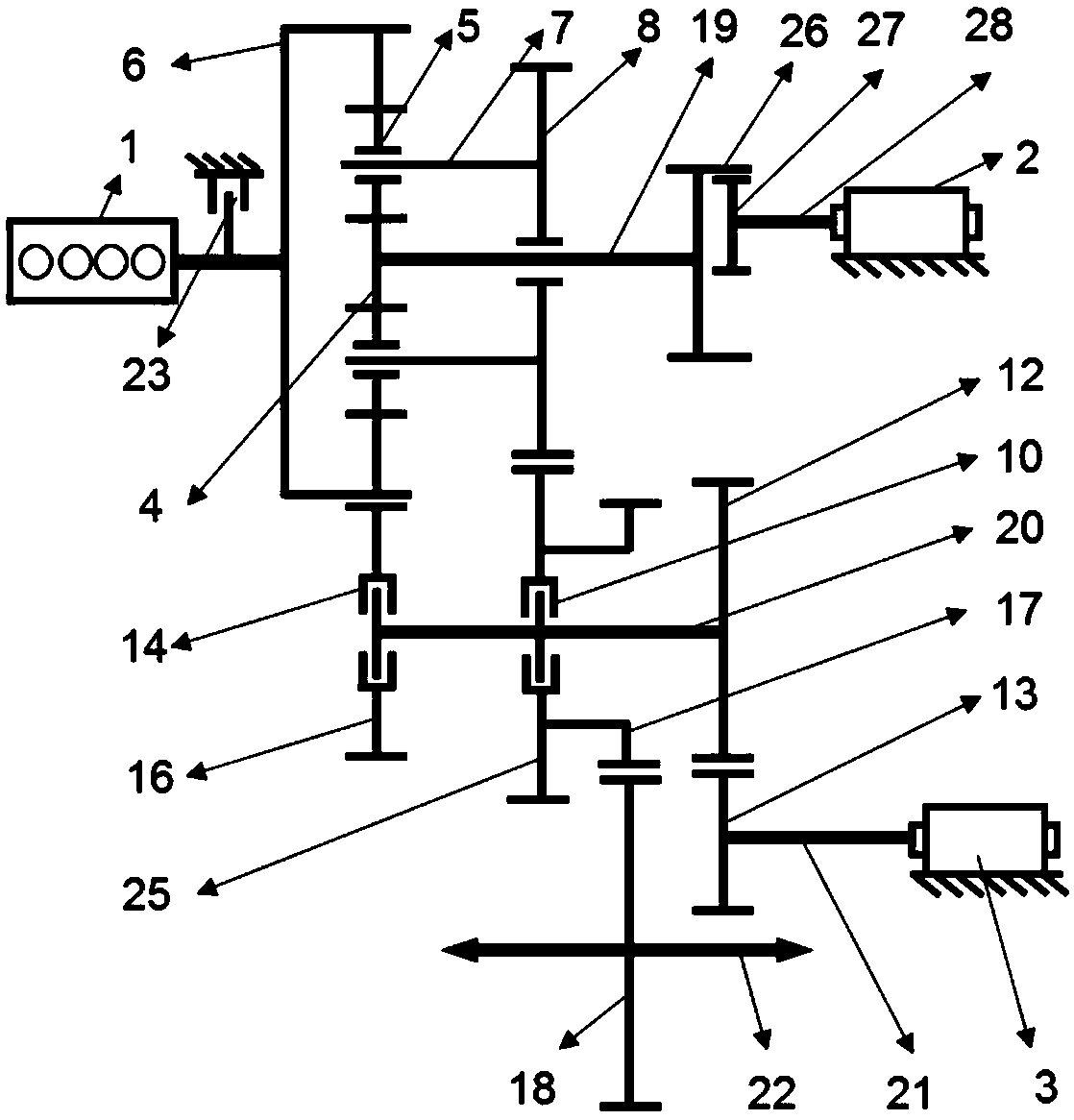

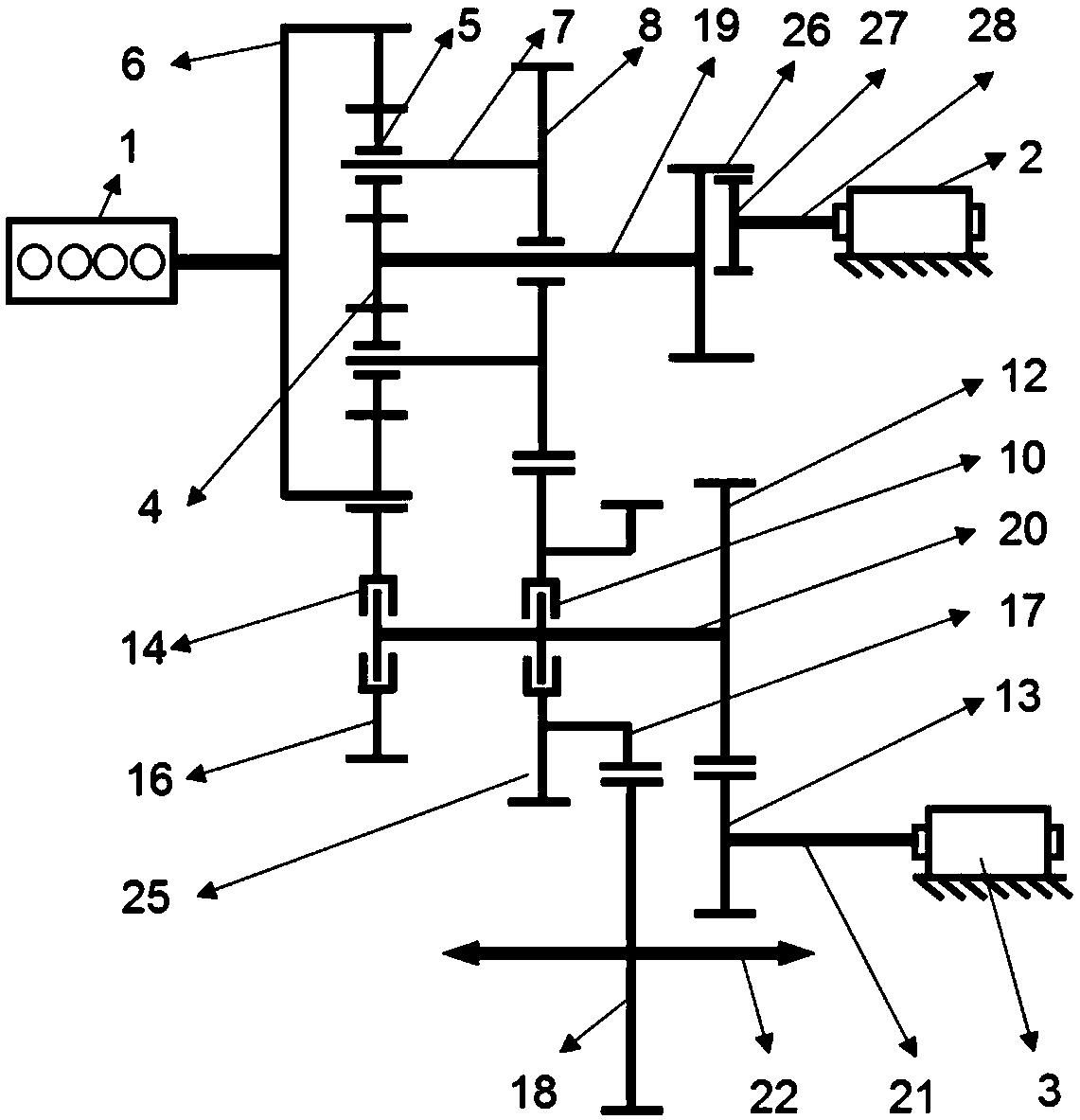

[0046] like figure 1 and as shown in Table 1, figure 1 An embodiment of the power-split hybrid transmission provided by the present invention includes

[0047] Single planetary row and 7 general gears: the single planetary row includes the outer ring gear 6, the sun gear 4, the planetary gear 5 and the planetary carrier 7 meshing with the outer ring gear 6 and the sun gear 4 respectively, wherein the outer ring gear 6 There are also external gears on the outside; the seven general gears include the first gear 8, the second gear 17, the third gear 16, the fourth gear 12, the fifth gear 18, the sixth gear 13 and the ninth gear 25, wherein the single planet sun gear 4 and the first gear 8 are respectively fixed and empty on the first transmission shaft 19, the fourth gear 12 and the third gear 16, the ninth gear 25, and the second gear 17 are respectively fixed and The empty sleeve is on the second transmission shaft 20 , the sixth gear 13 is fixed on the third transmission sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com