Patents

Literature

497results about "Liquid ejecting guns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

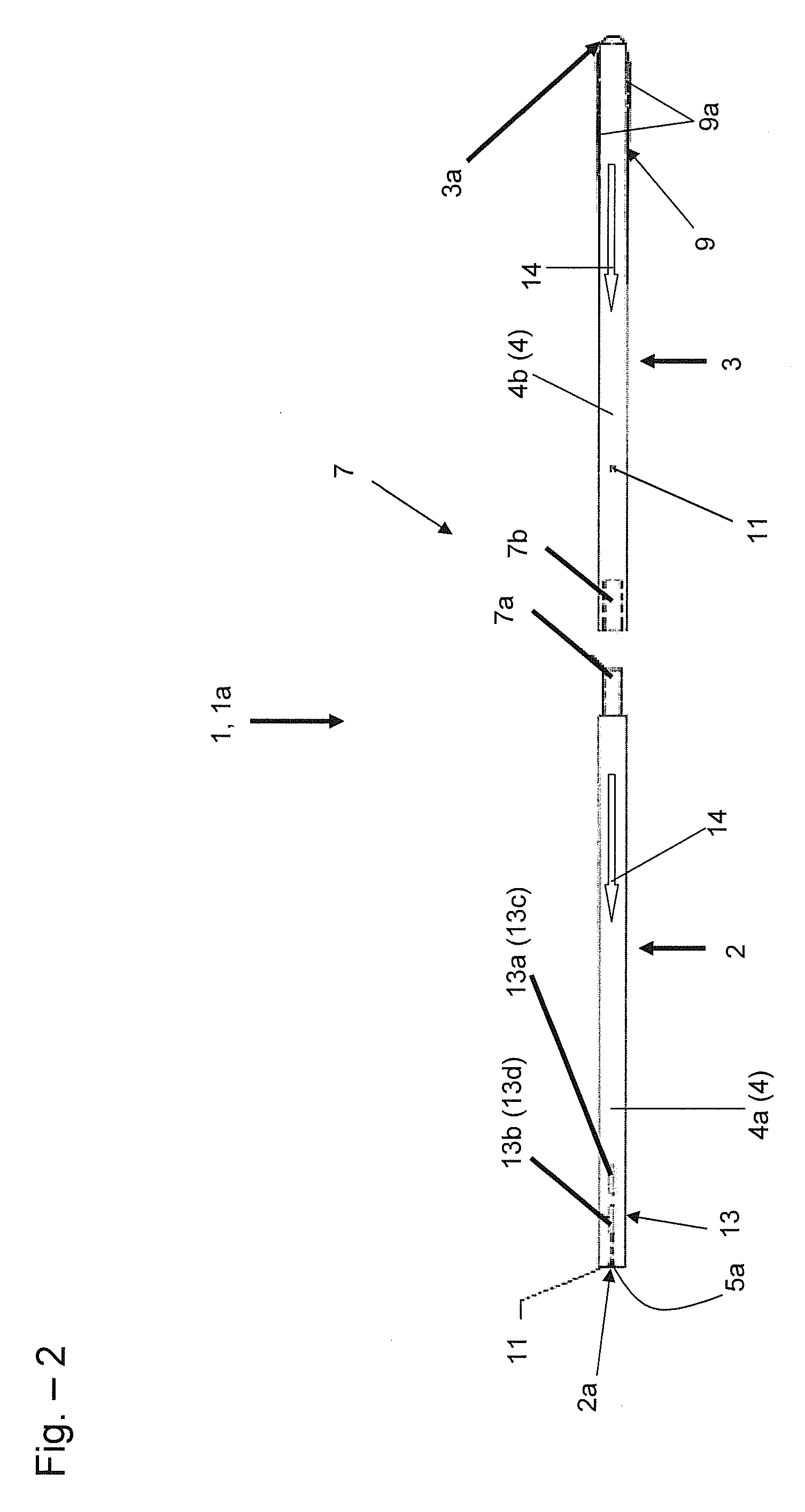

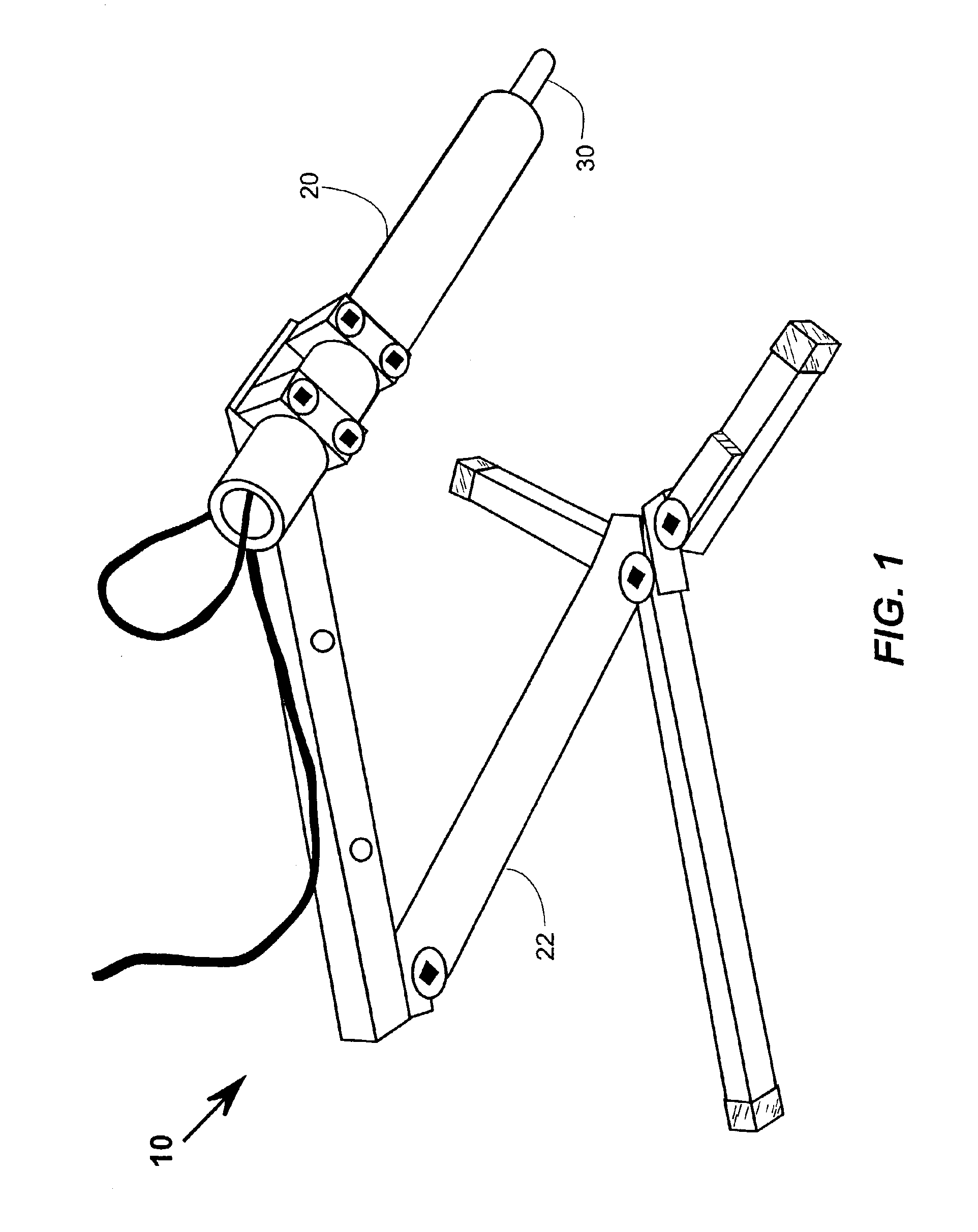

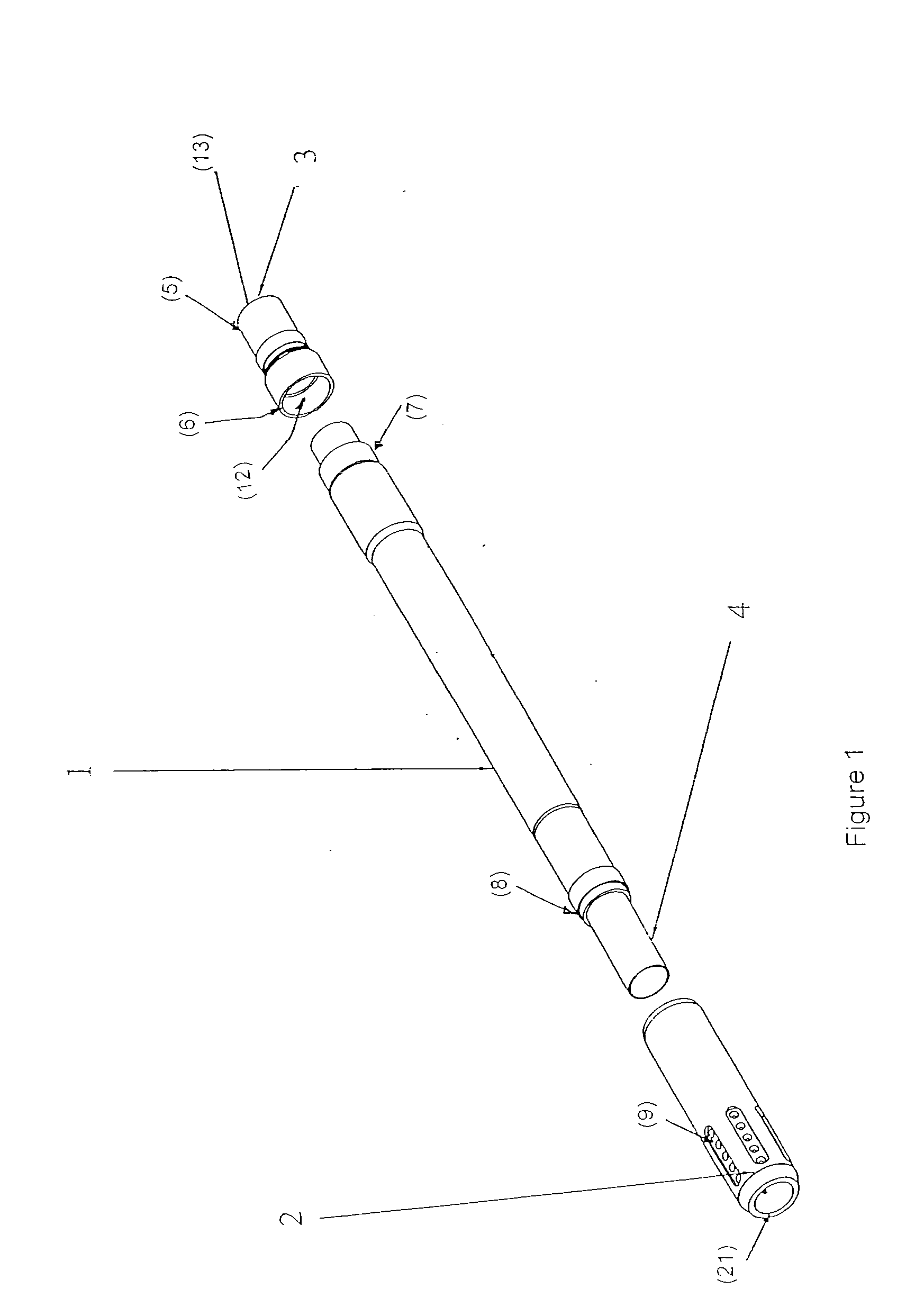

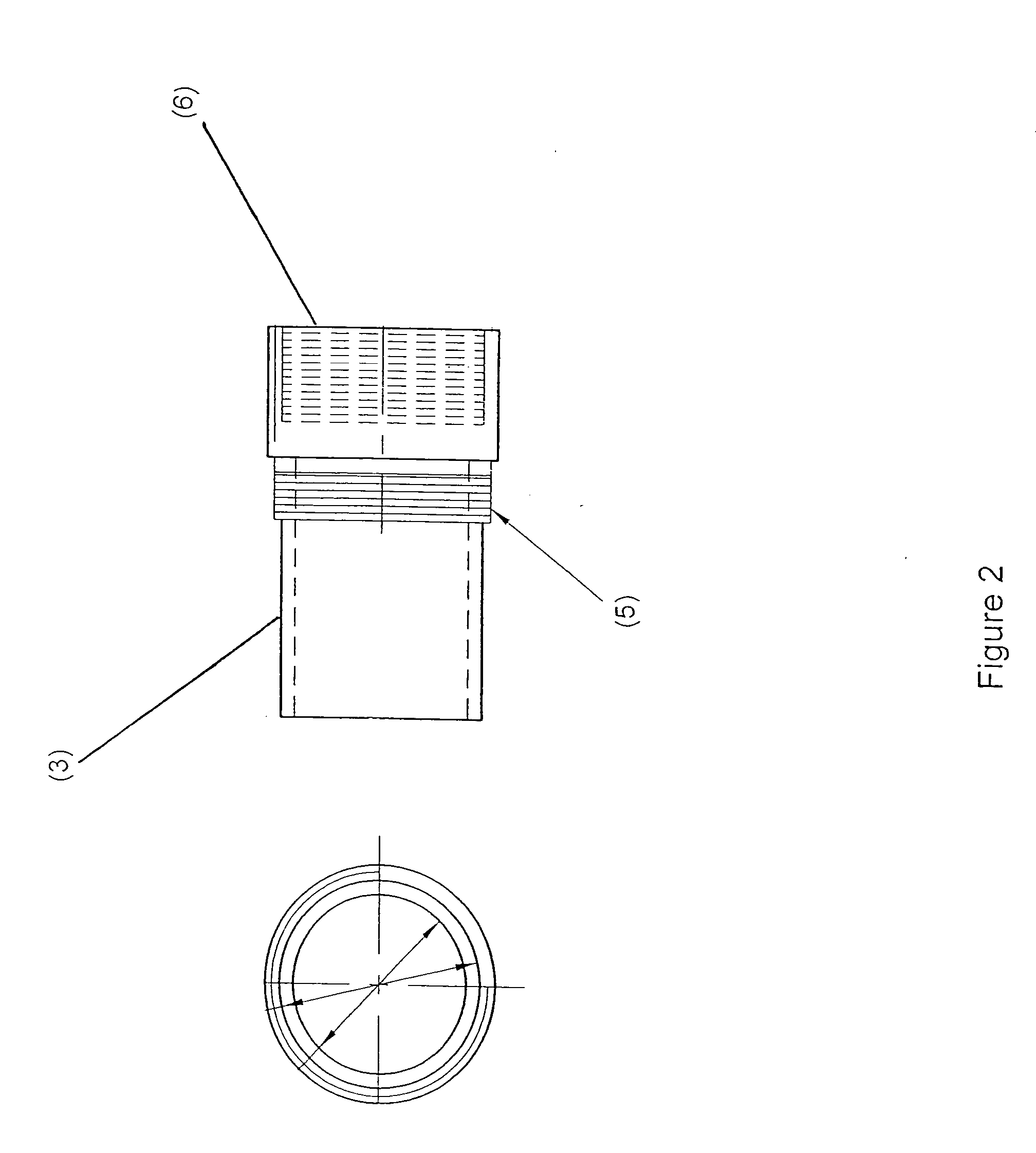

Lightweight air vehicle and pneumatic launcher

ActiveUS20050274845A1Easy to carryAvoid damageLaunching/towing gearUnmanned aerial vehiclesFlight vehicleUnmanned air vehicle

A portable unmanned air vehicle and launcher system is provided that includes a foldable unmanned air vehicle having a pressure tube; a launch gas reservoir for holding launch gas; a launch tube operatively connected to the launch gas reservoir and having a free end that is positioned in the pressure tube of the air vehicle; a free piston positioned within the launch tube; and a free piston stop to prevent the free piston from leaving the launch tube. A first portion of the launch gas in the launch gas reservoir is released into the launch tube and forces the free piston from an initial position to an end position at which the free piston is stopped by the free piston stop.

Owner:AIRPORTS AUTHORITY OF INDIA

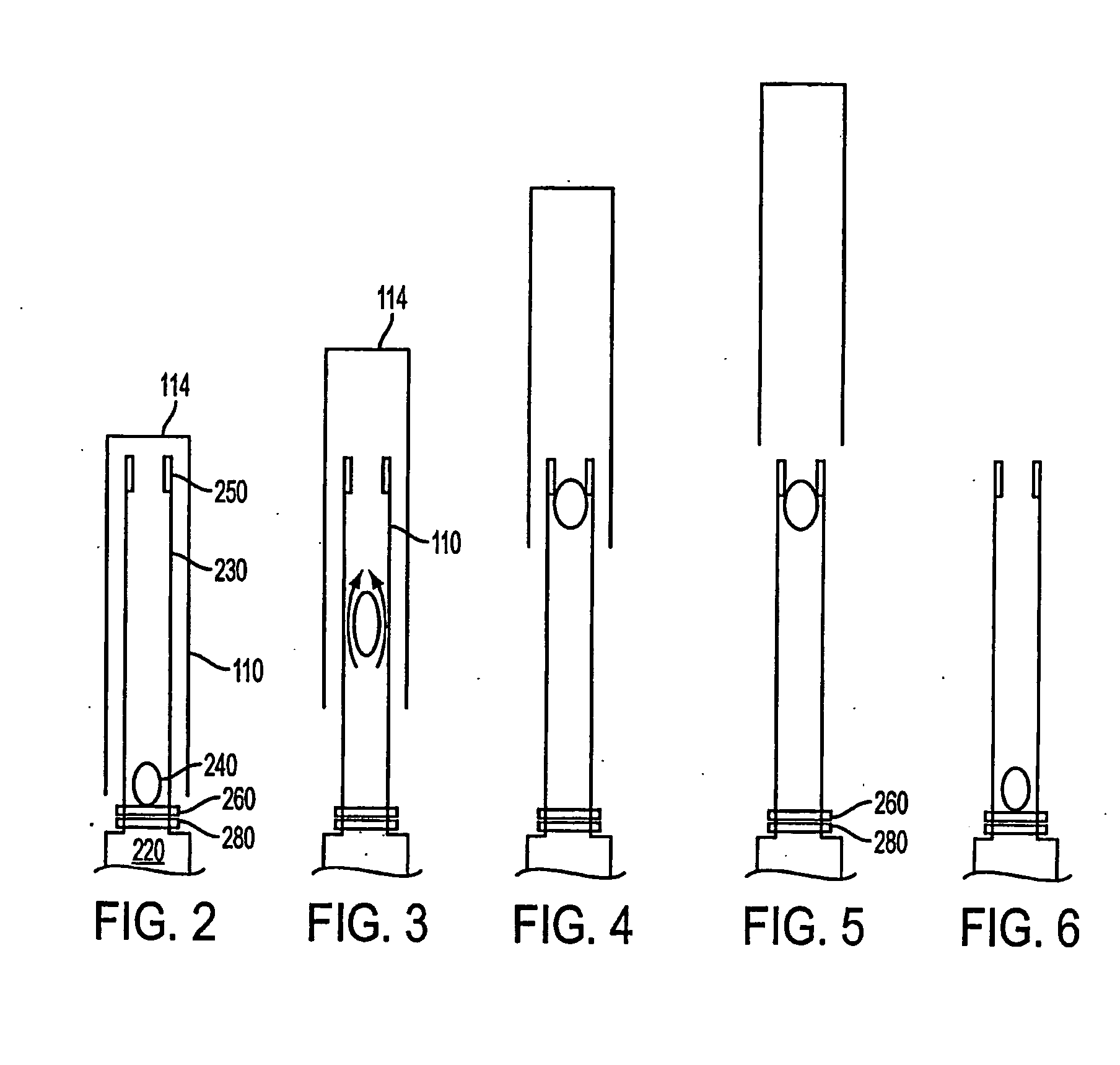

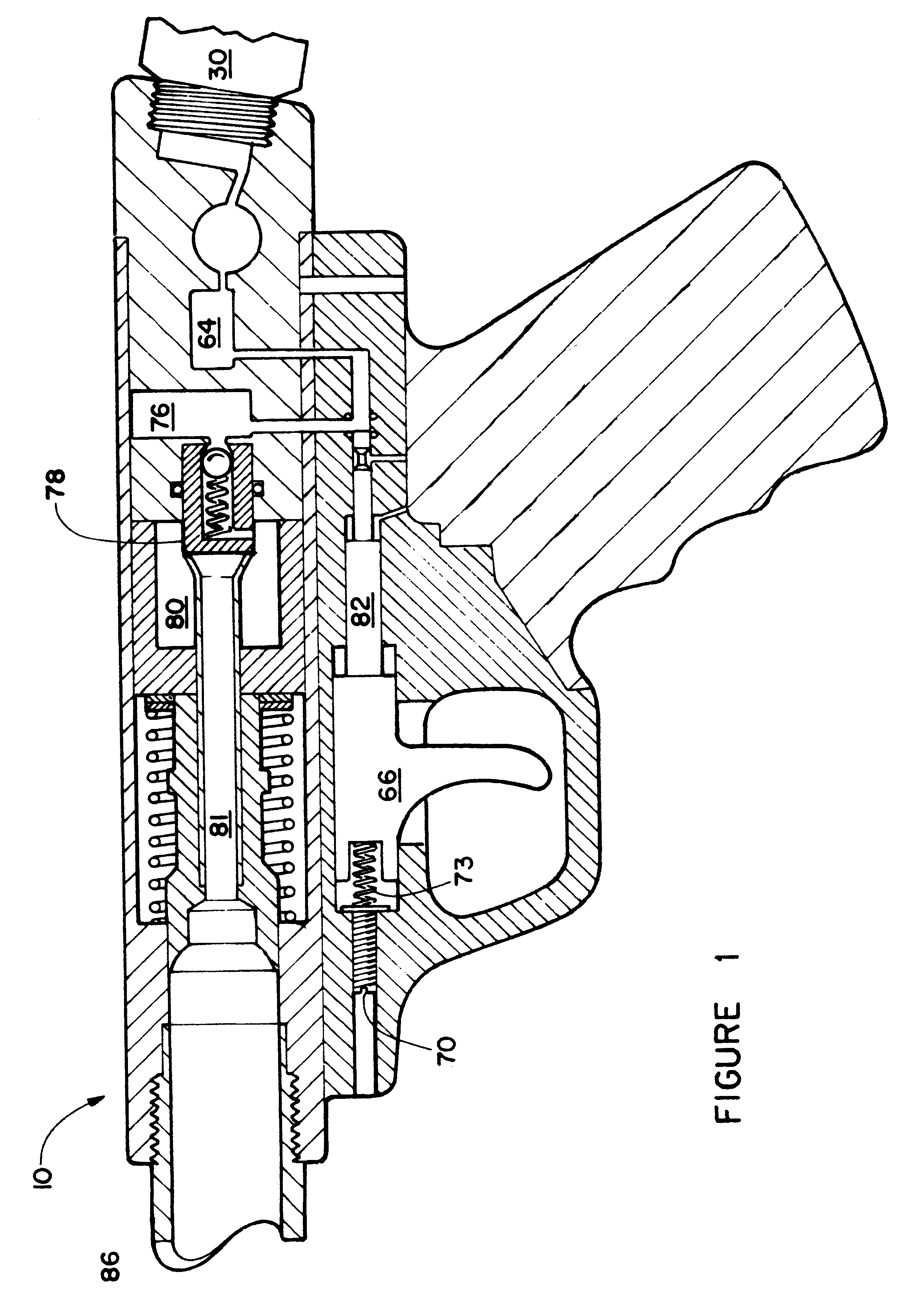

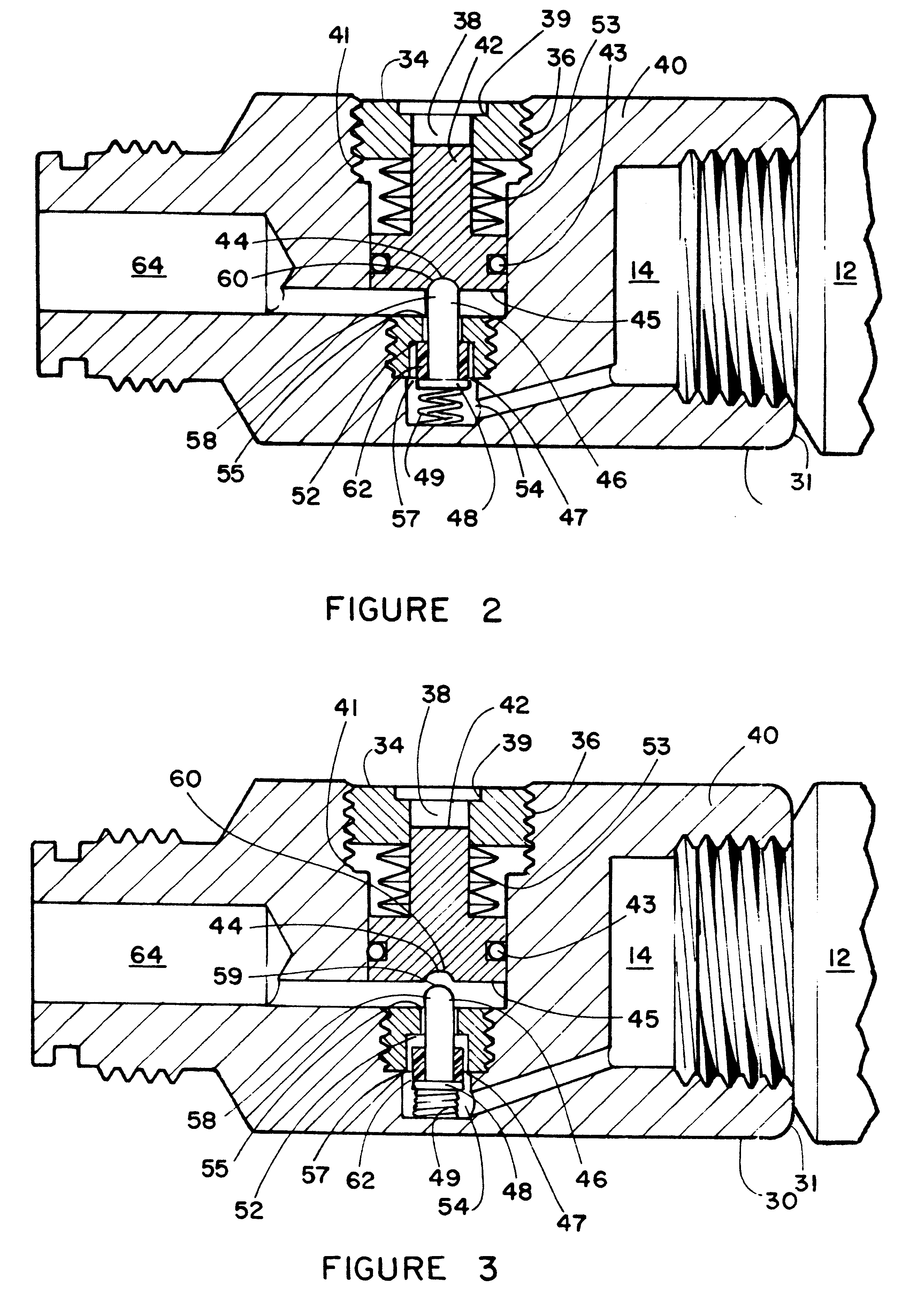

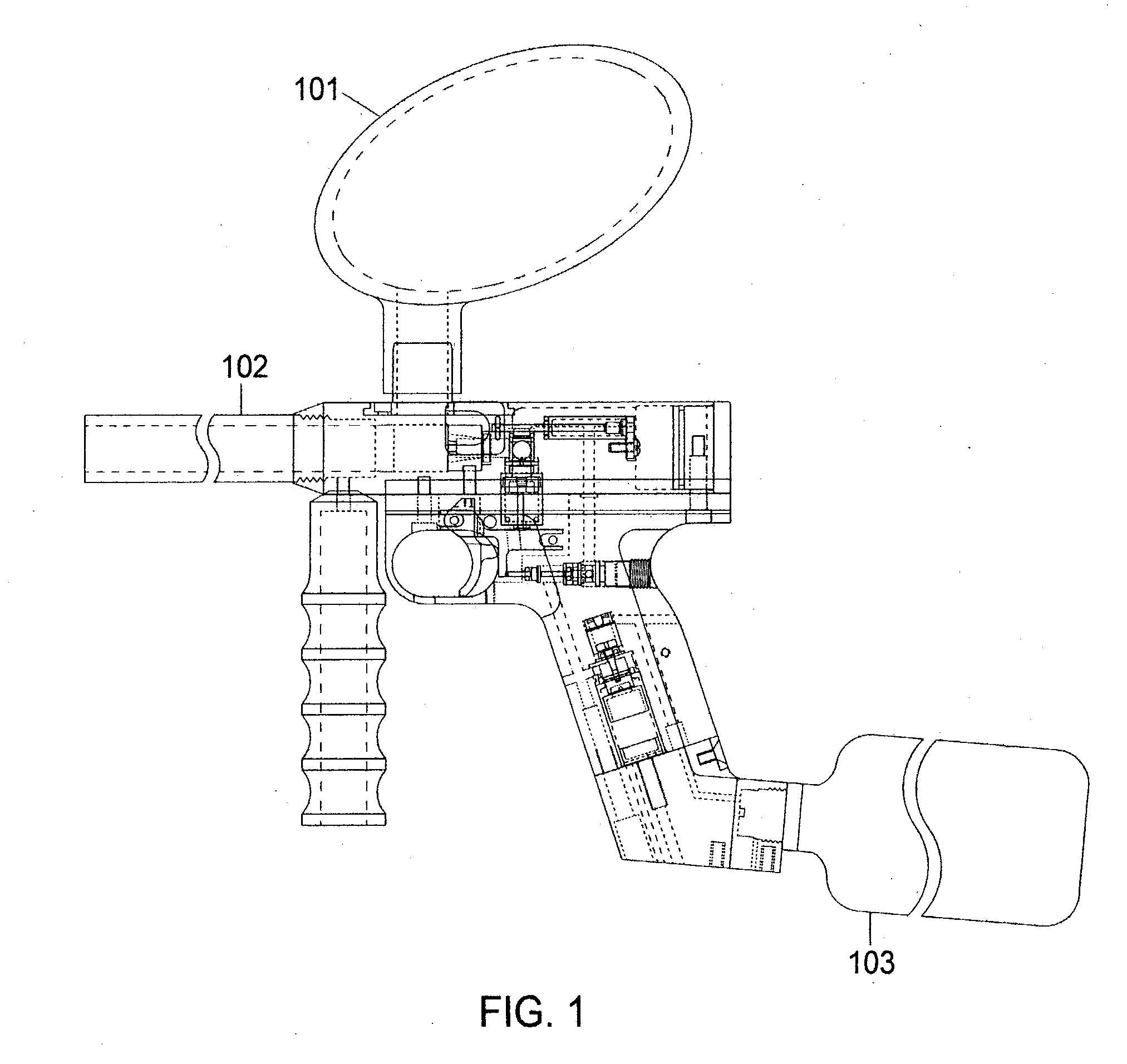

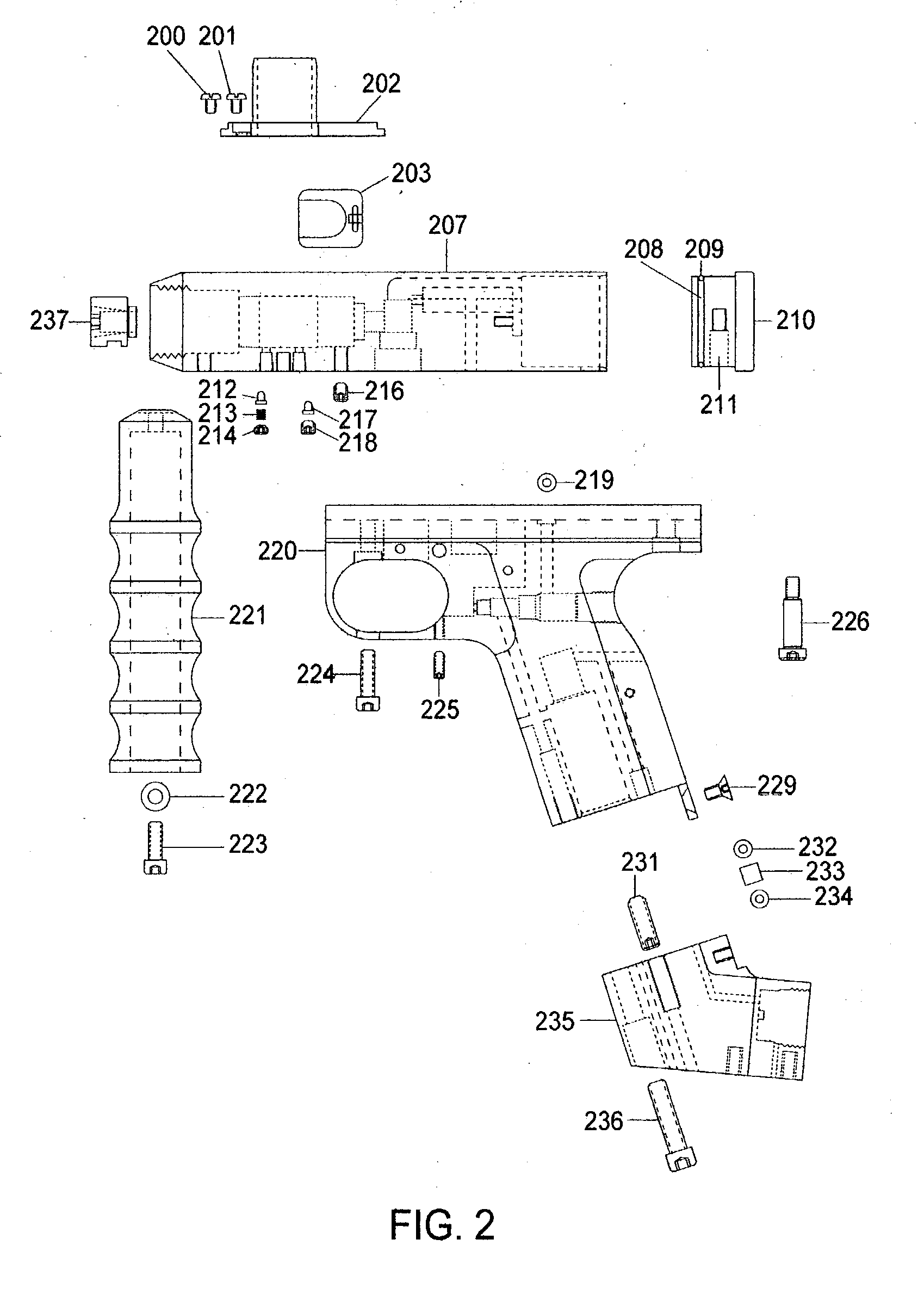

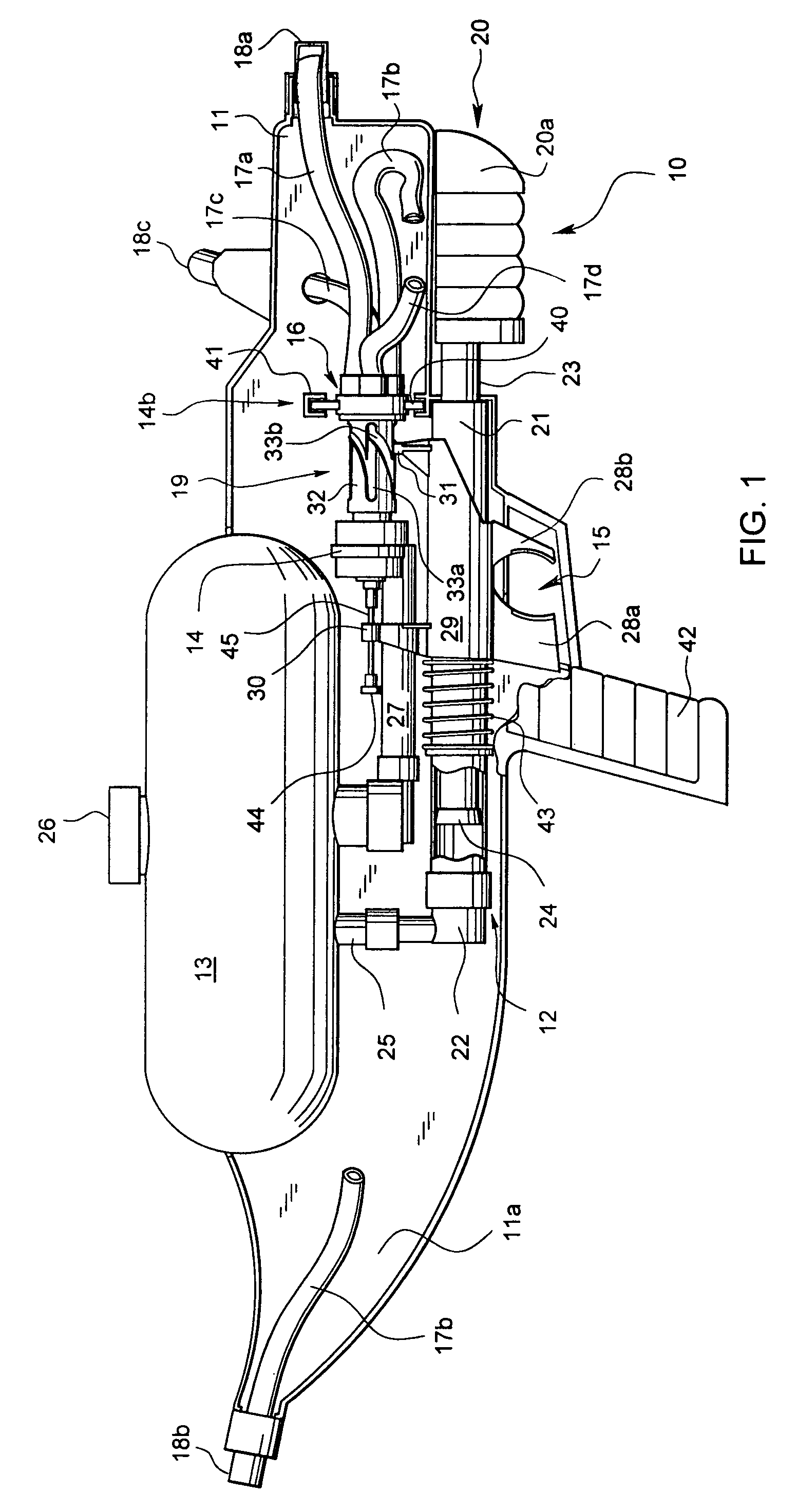

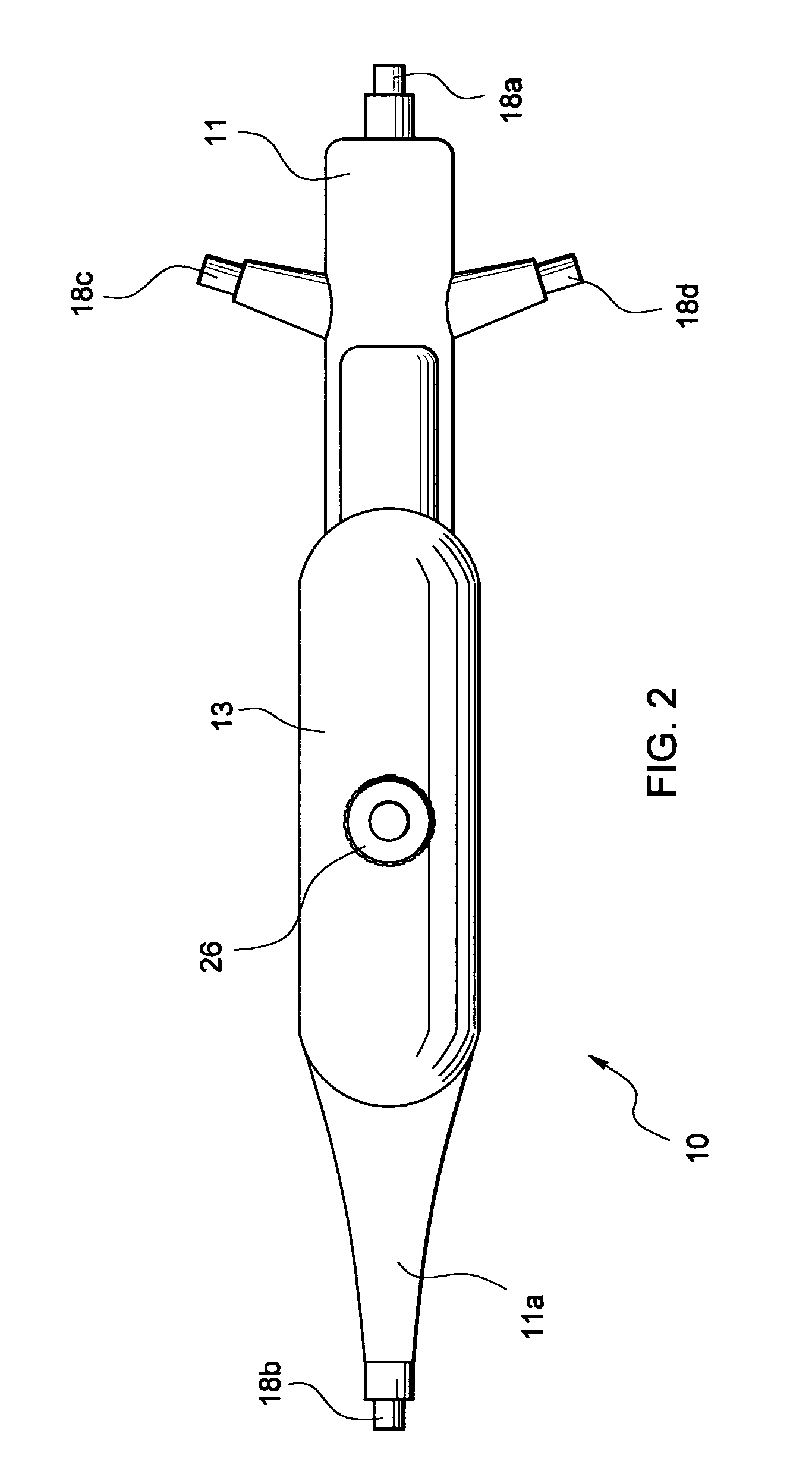

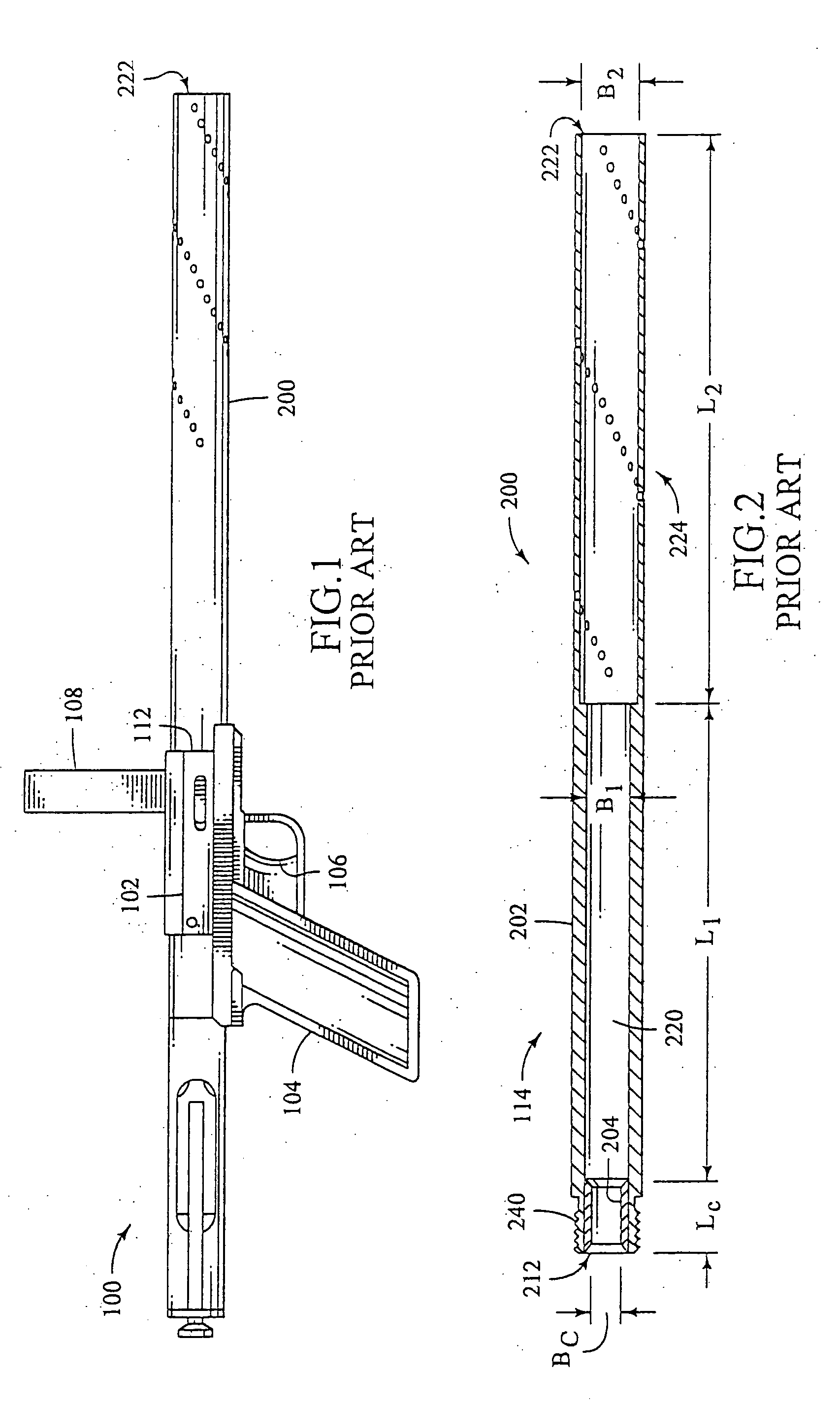

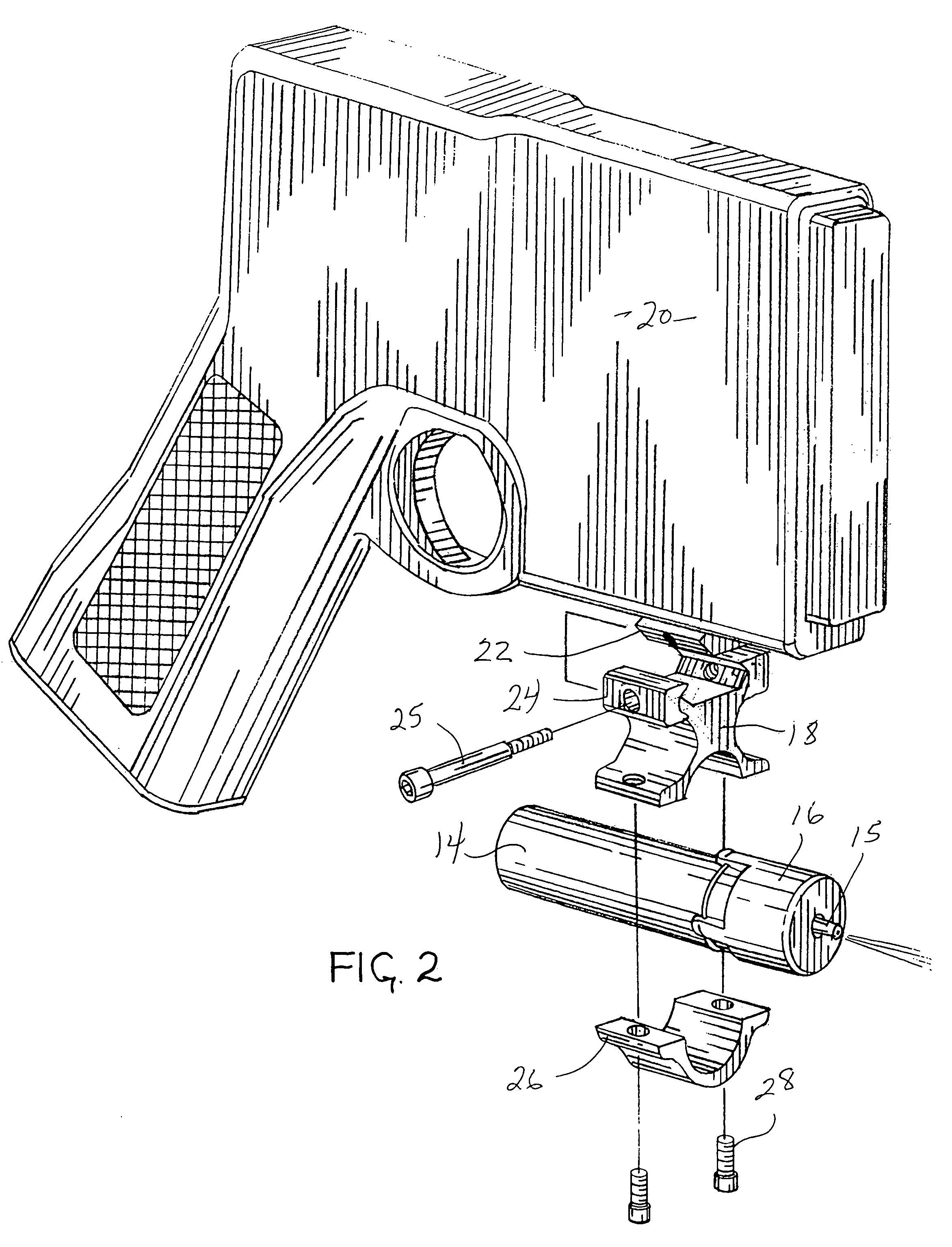

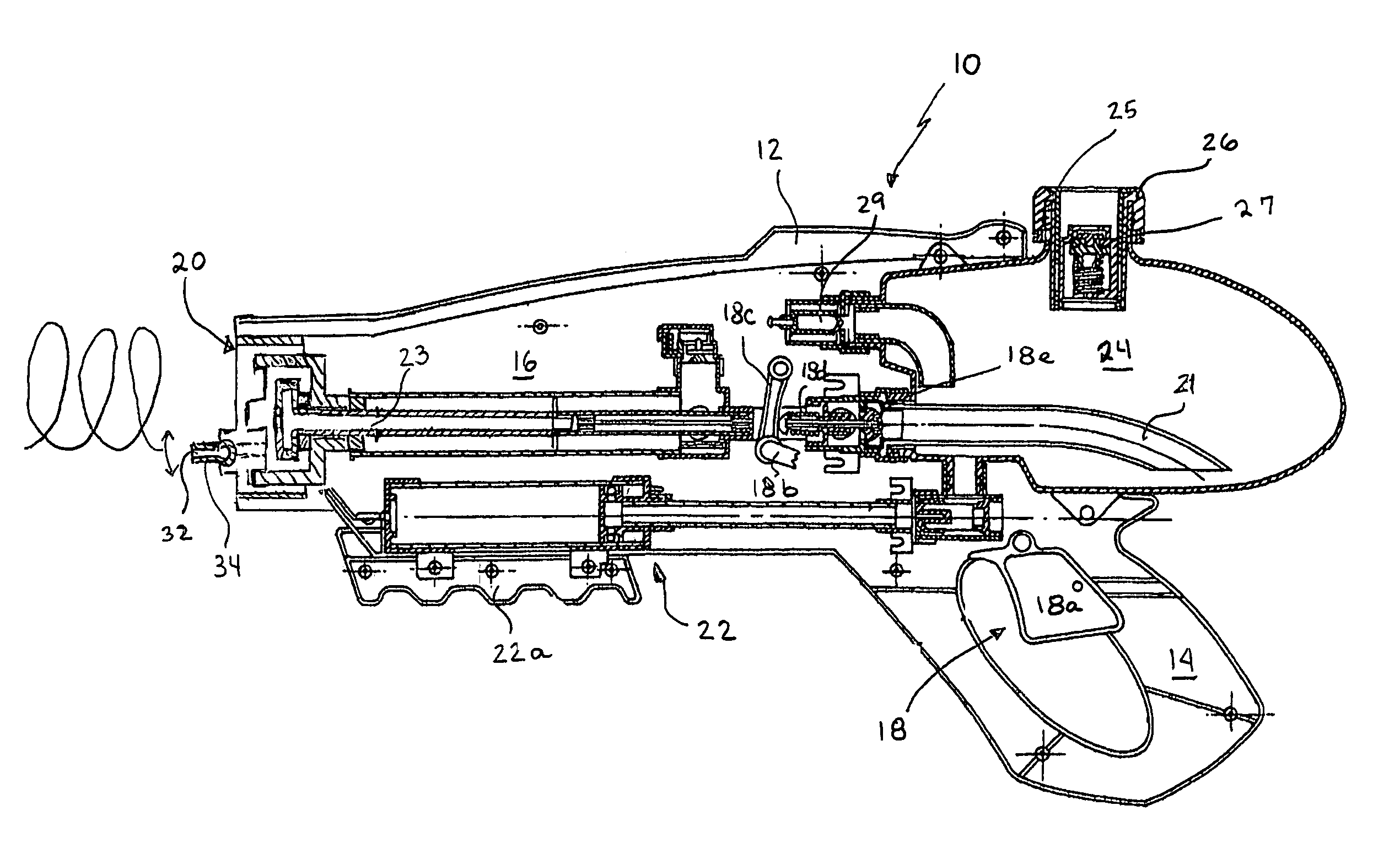

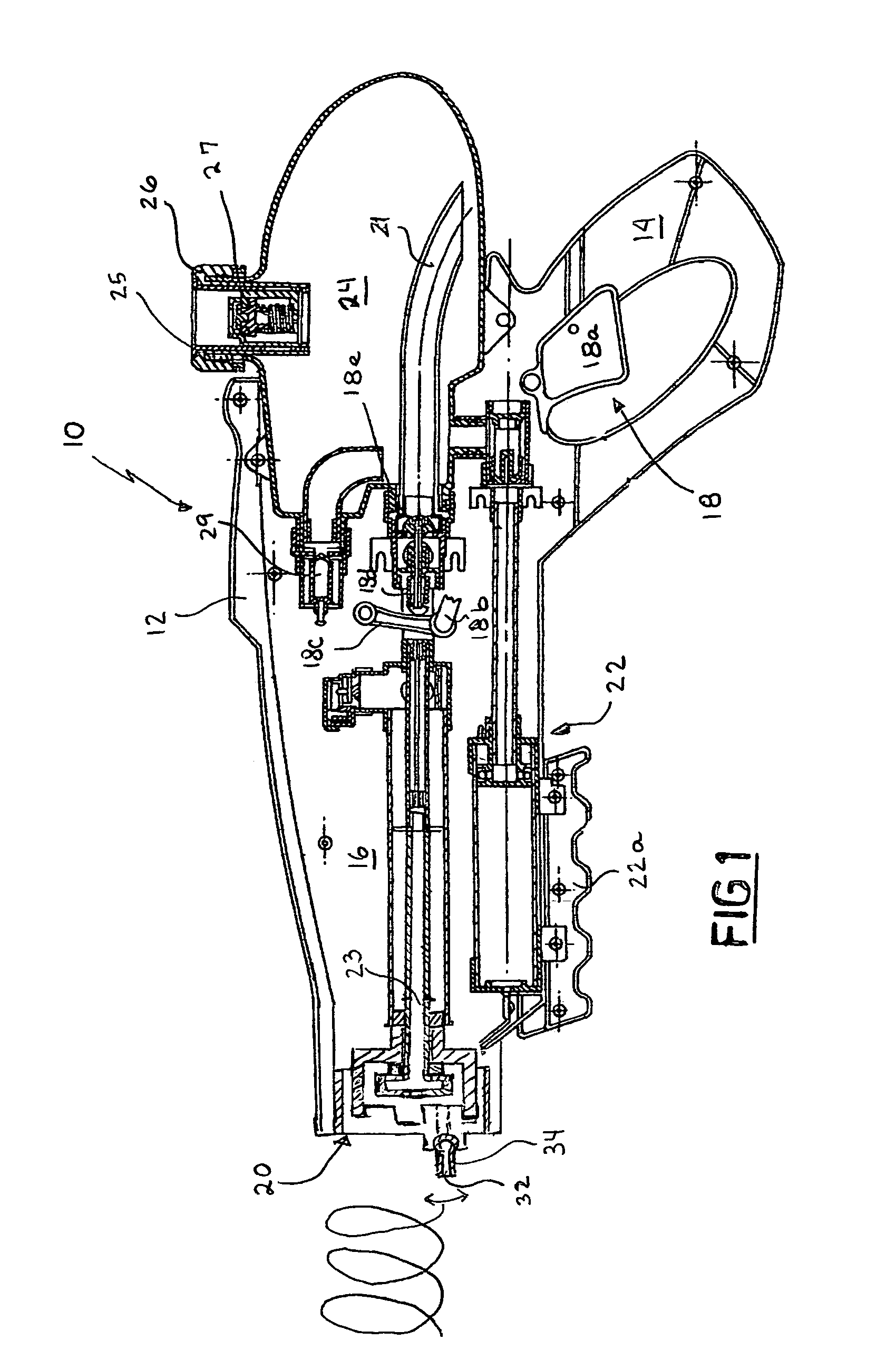

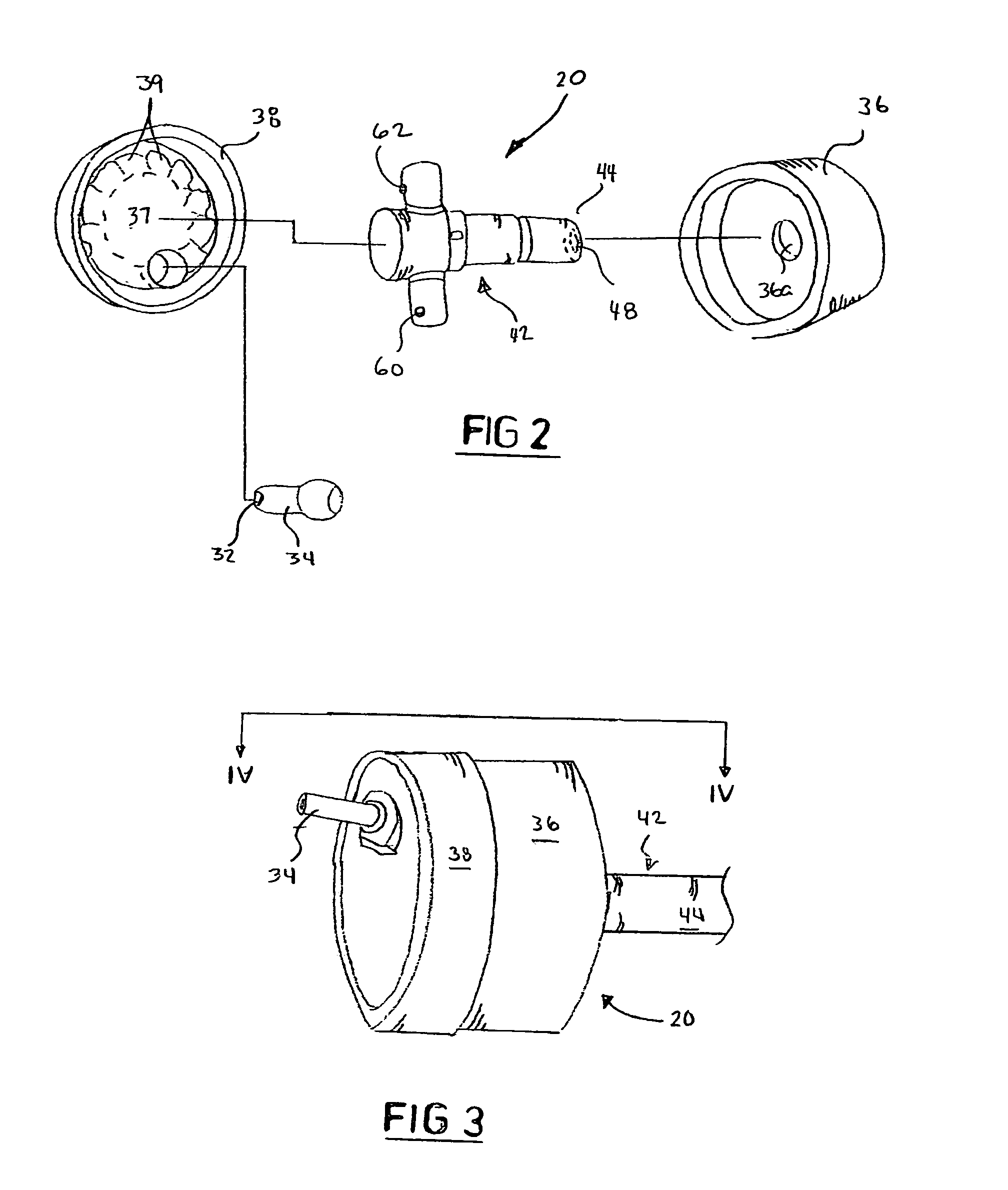

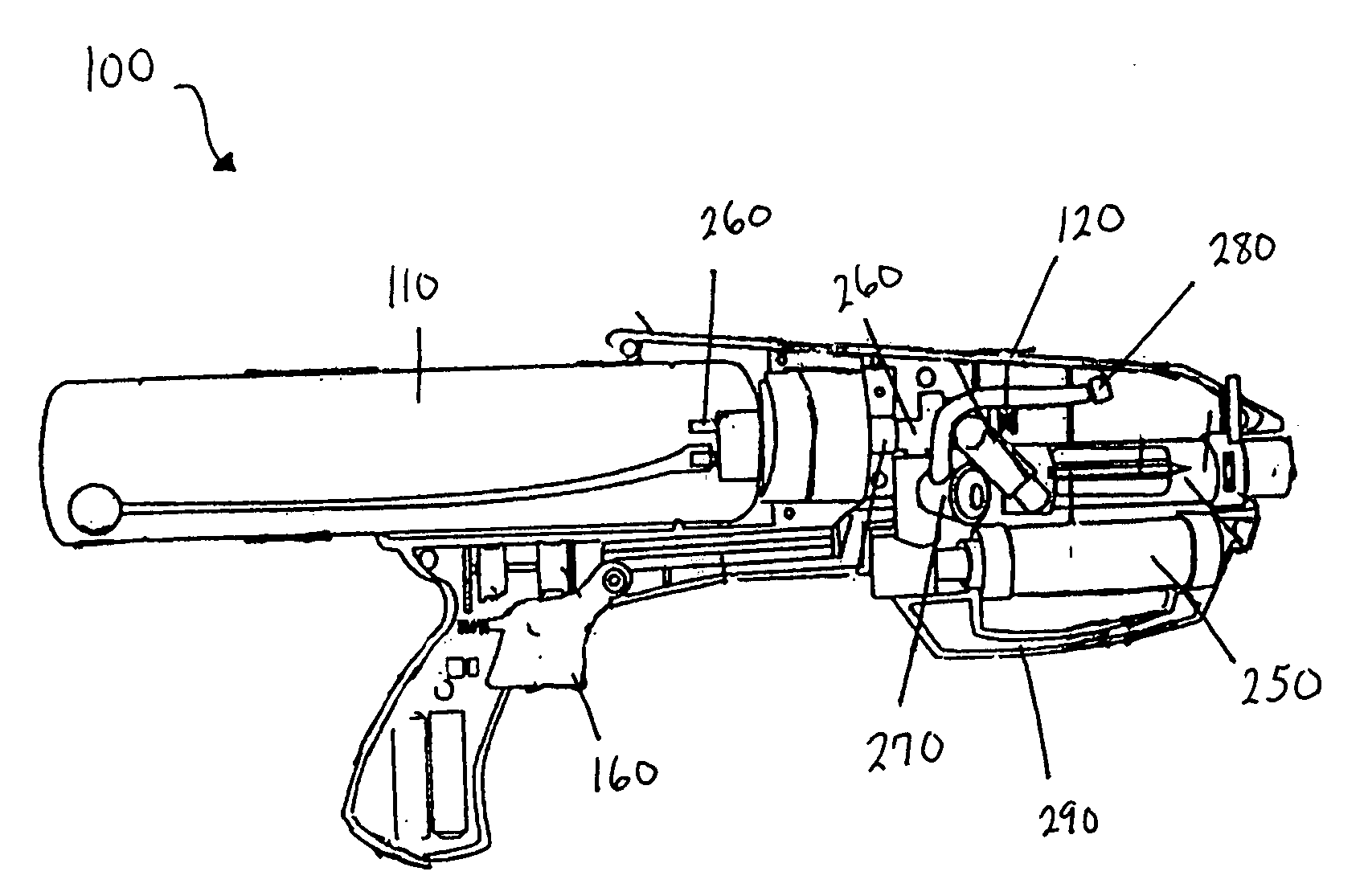

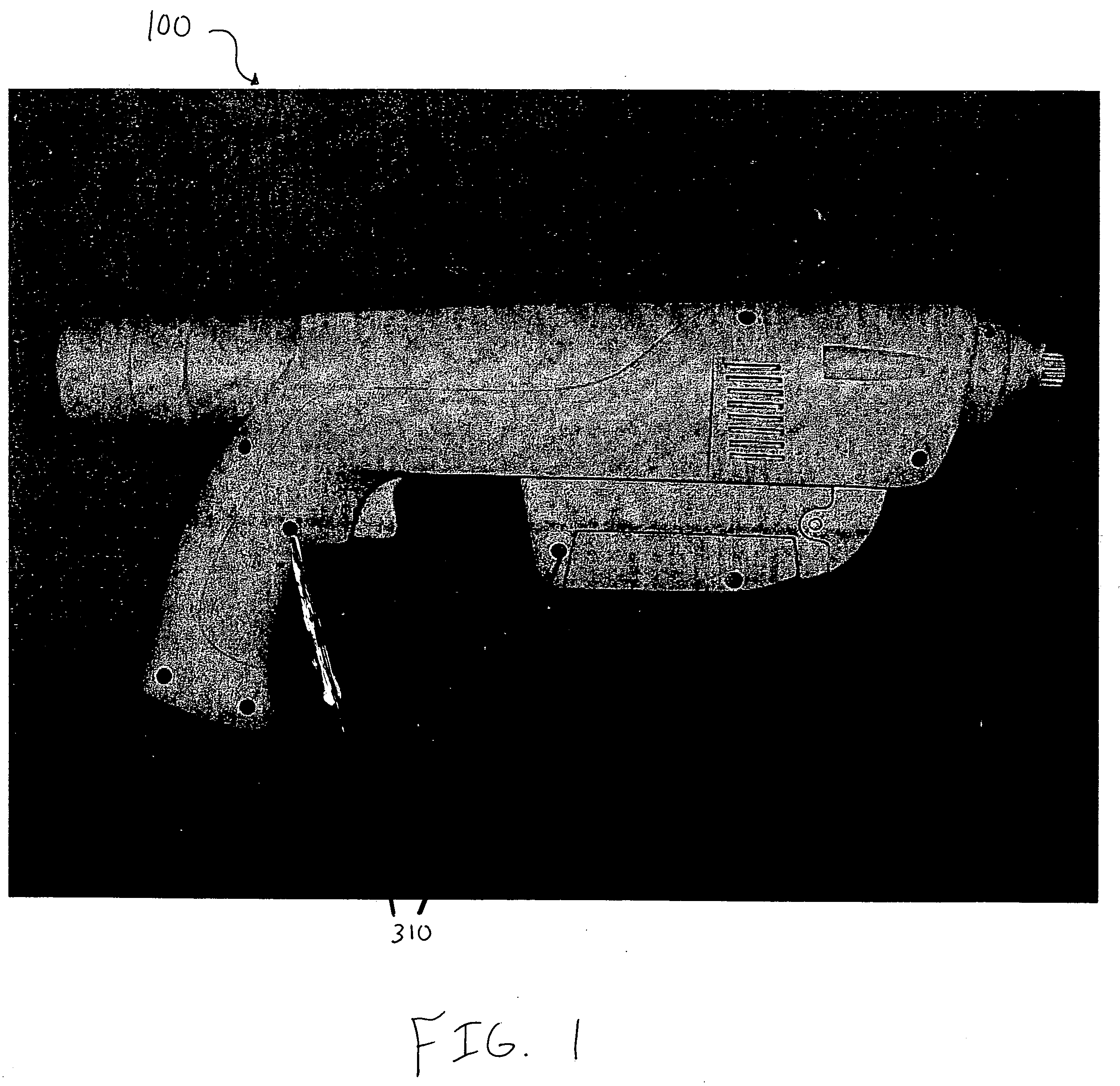

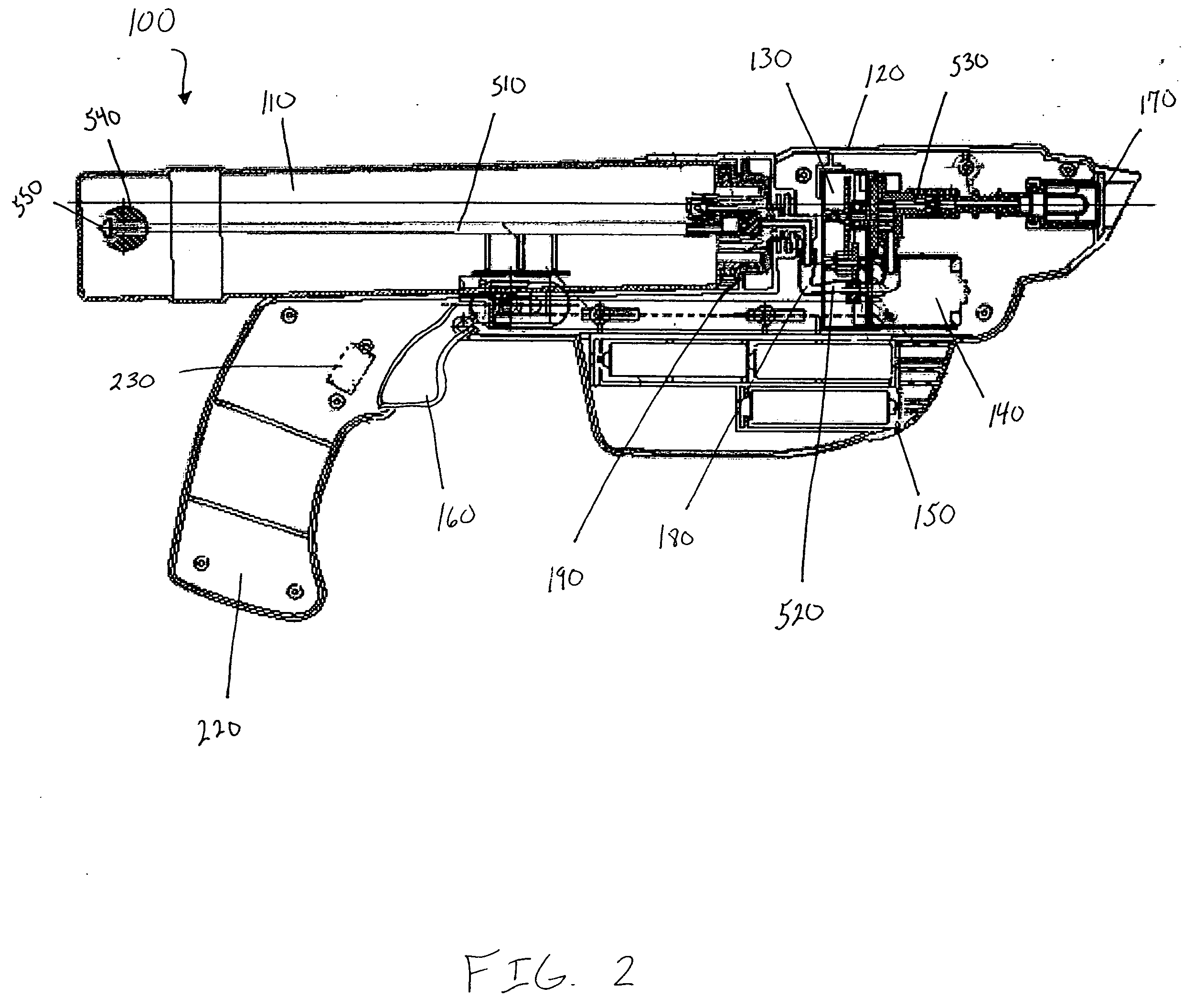

Gas powered gun and assemblies therefor

InactiveUS6276354B1Reduce mechanical complexityJam resistantFiring/trigger mechanismsLiquid ejecting gunsHeat transmissionEngineering

An improved air gun for firing paint balls, pellets,, consisting of a passively venting and freeze resistant regulator, a pressure differential trigger mechanism, and a muzzle break with angled sidewalls. The freeze resistant regulator regulates incoming high pressure gas to a user predetermined pressure to operate the gun while avoiding freezing of the regulator associated with frigid incoming compressed gases and high firing rates. This is accomplished by using a heat transmission component formed by the engagement between a hemispheric shaped tip of a regulating pin and a hemispheric cavity of an adjustment piston. Passive venting of gas from the gun upon removal of the pressurized gas supply is provided by the regulator using a reciprocating regulating pin and adjustment piston which combine to compress a seal into a seat only when pressurized gas is attached to the air gun. Once detached from a pressurized air supply the compressed air in the gun vents through the seat. Firing of the gun is achieved using a pressure differential trigger mechanism capable of fine pull adjustment using a trigger biasing mechanism. Greater accuracy of projectiles leaving the gun is provided by the muzzle break featuring of a plurality of elongated oval slots having angled sidewalls to parse propulsion gases from the projectile which reduces air turbulence encountered by the projectile upon exit from the gun.

Owner:DILLON JOSEPH

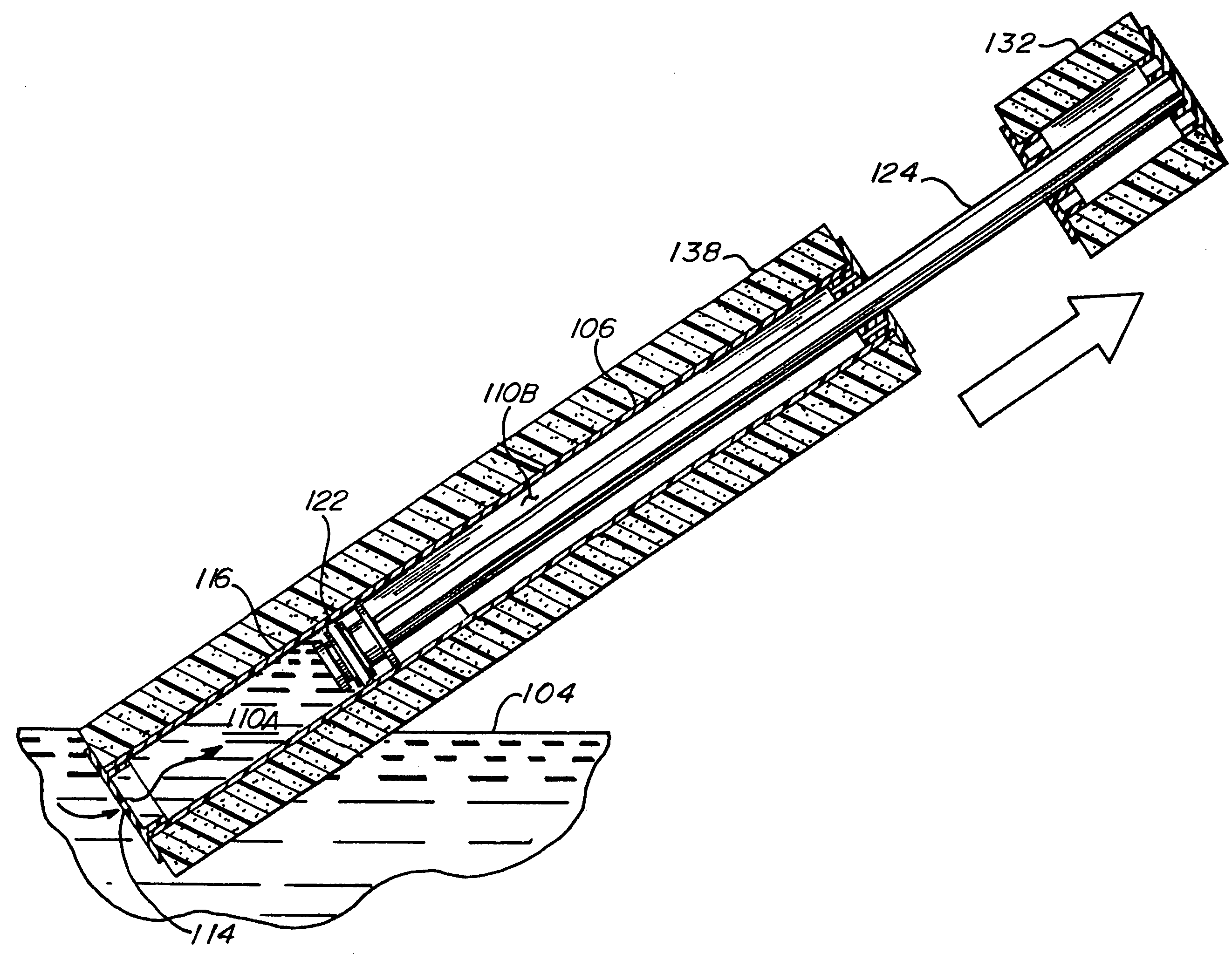

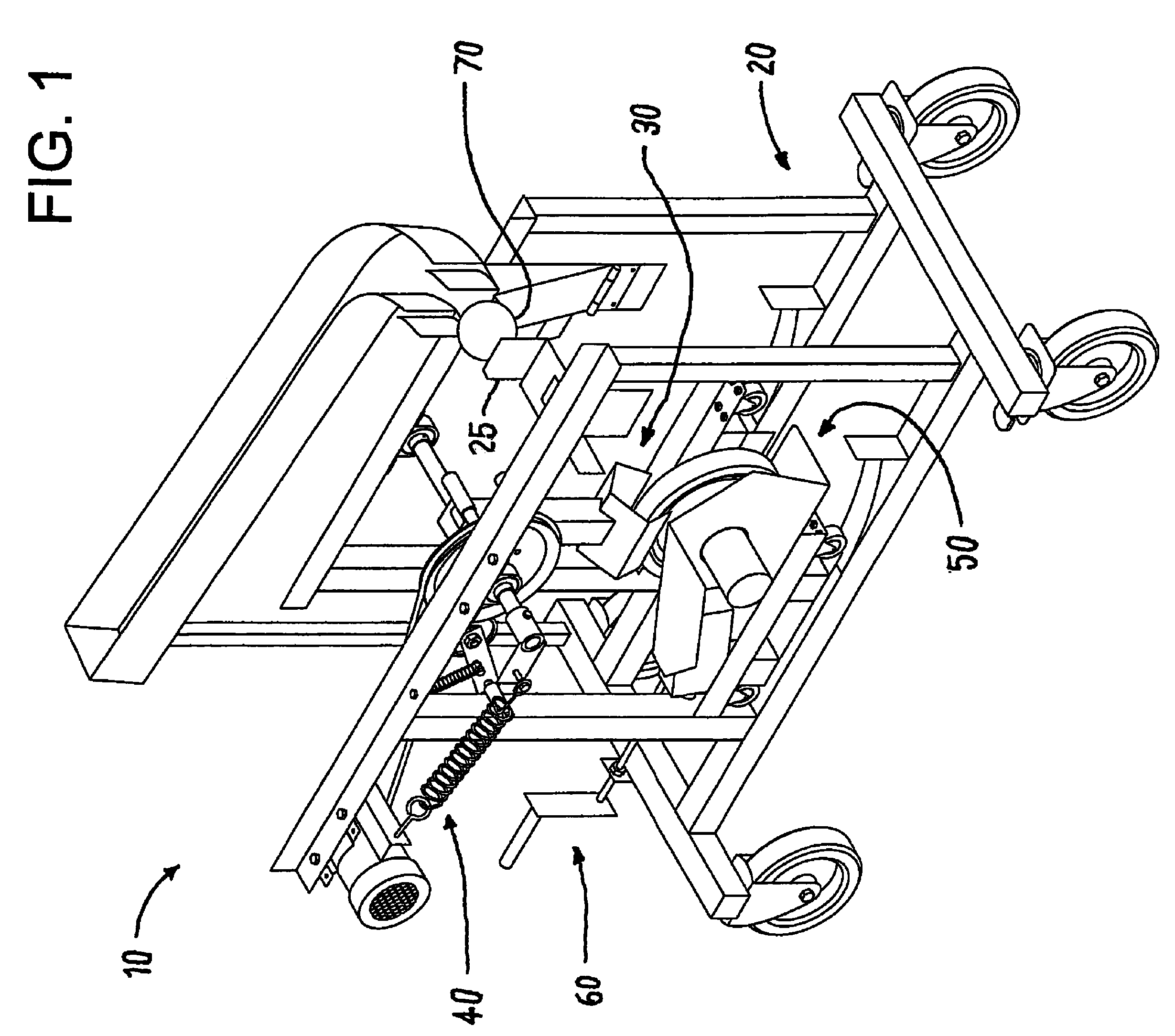

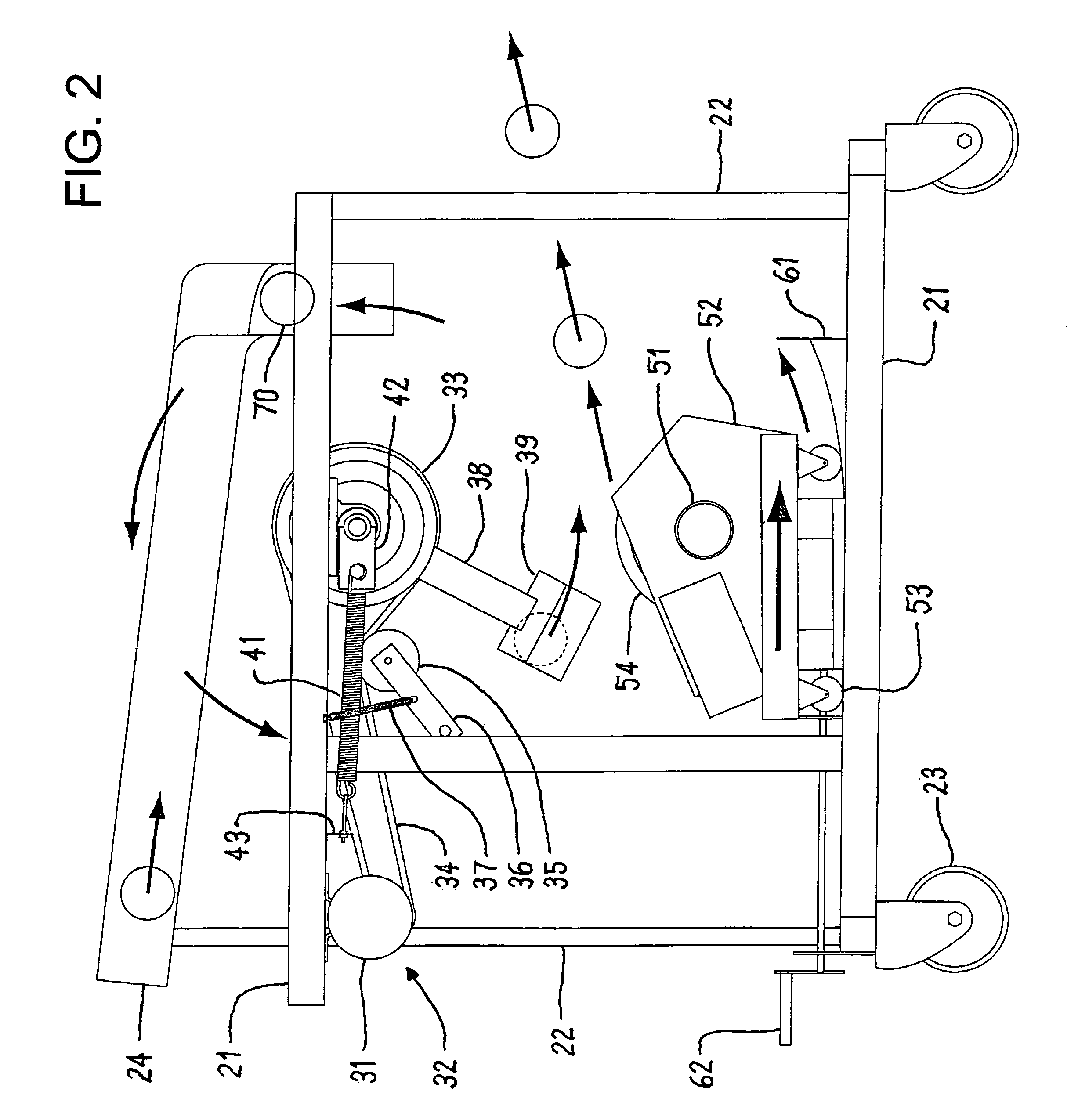

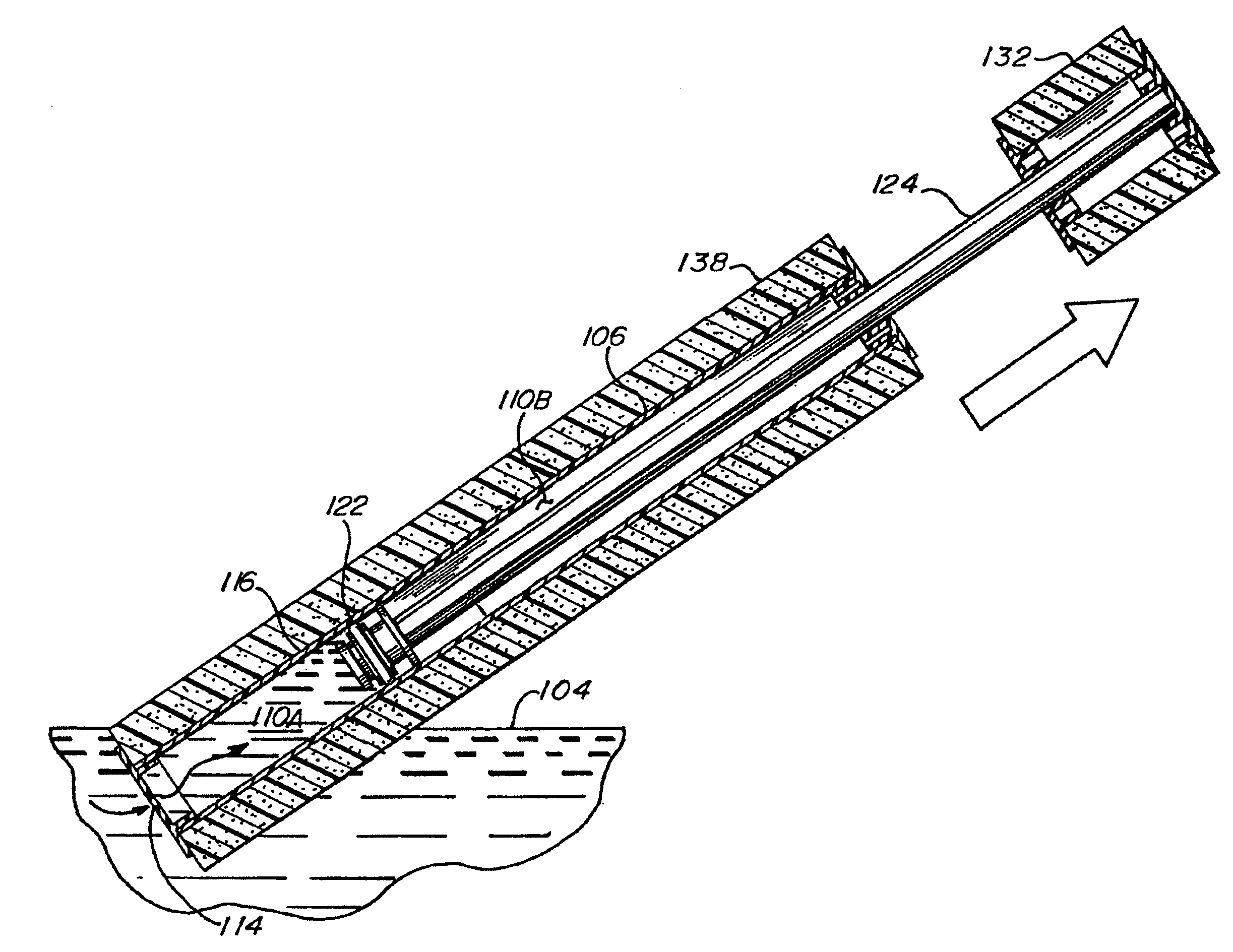

On-site land mine removal system

InactiveUS20090223355A1Reduced effectivenessReduce eliminateDefensive equipmentDefence devicesLiquid jetDetonation

A method of deactivating land mines buried in ground comprises projecting high-pressure water jets into ground, cutting through ground with the high-pressure water jets, and making at least one cut through a land mine or cutting through at least one land mine that had been under the ground, the cutting of the land mine reducing the performance of the land mine. The method may reduce the performance of the land mine by rendering the land mine inactive to normal detonation procedures for the land mine. To reach as many surface areas on the buried landmines, it is preferable that at least two high-pressure water jets are spaced apart are used to cut through the ground. The method may be practiced with the high-pressure water jet being carried on a vehicle and cutting is done in a line that is formed at least in part by movement of the vehicle over the ground while the high-pressure water jet is cutting ground. An apparatus for the reduction in effectiveness of land mines buried in ground may comprise a self-contained push-cart unit or a unit attached or attachable to a vehicle. A complete system could comprise a vehicle having a source of liquid, a high-pressure pump to move the liquid under high pressure, a nozzle directing a liquid jet path for the liquid, a support for the nozzle, abrasive delivery system, and nozzle being controllable to direct the liquid towards the ground while the nozzle is fixed relative to the vehicle.

Owner:MANDERS STEPHEN M

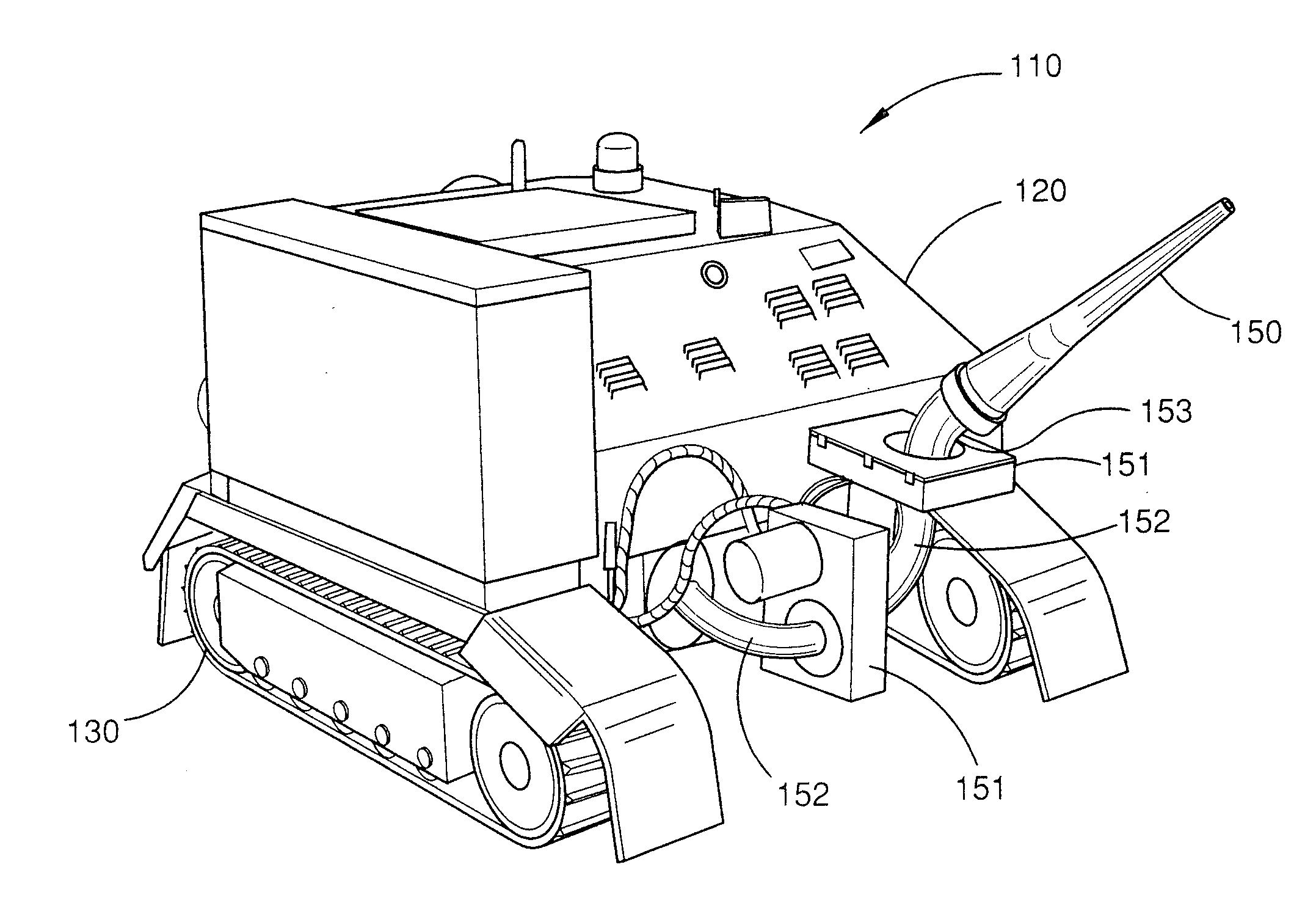

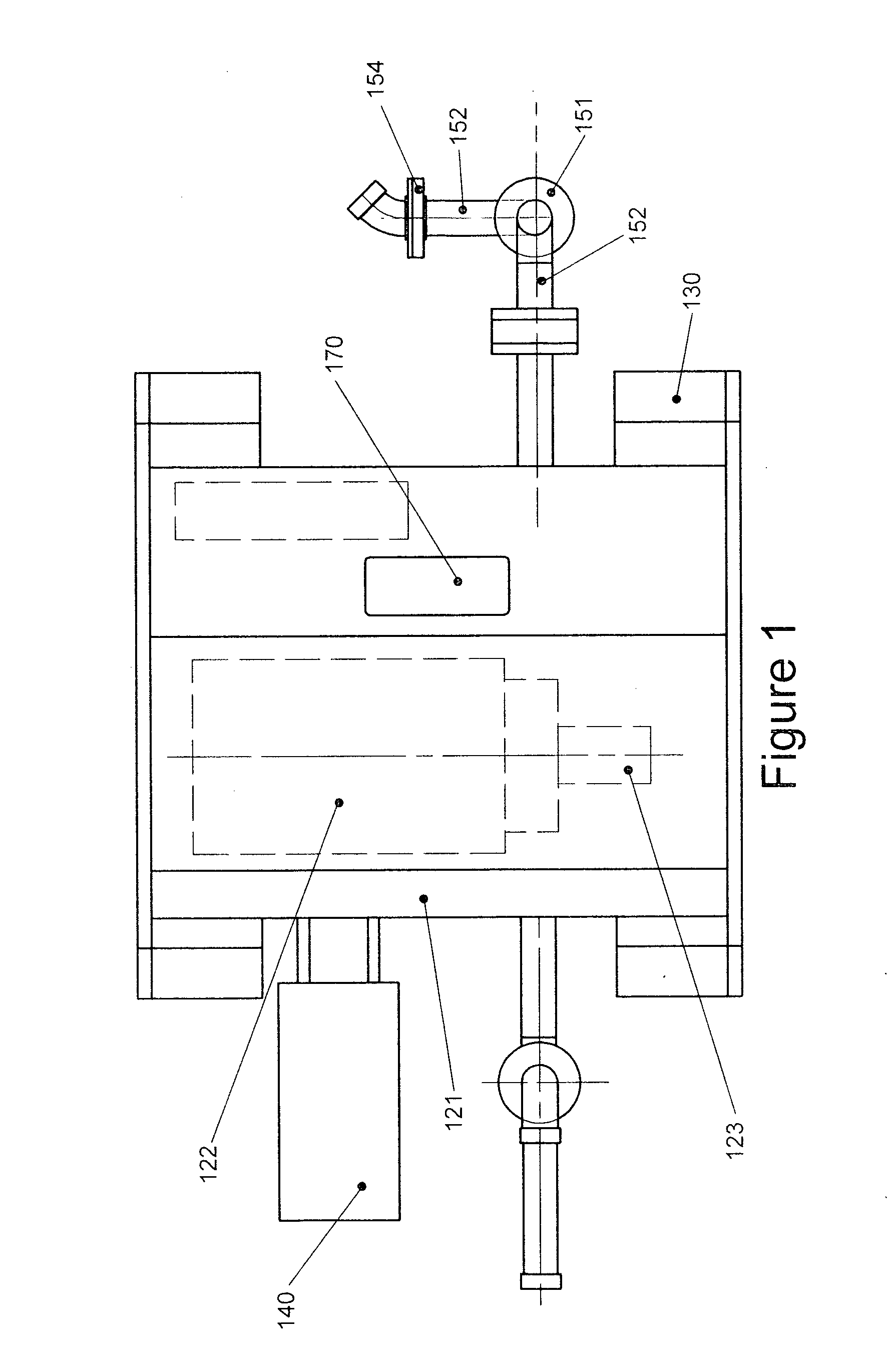

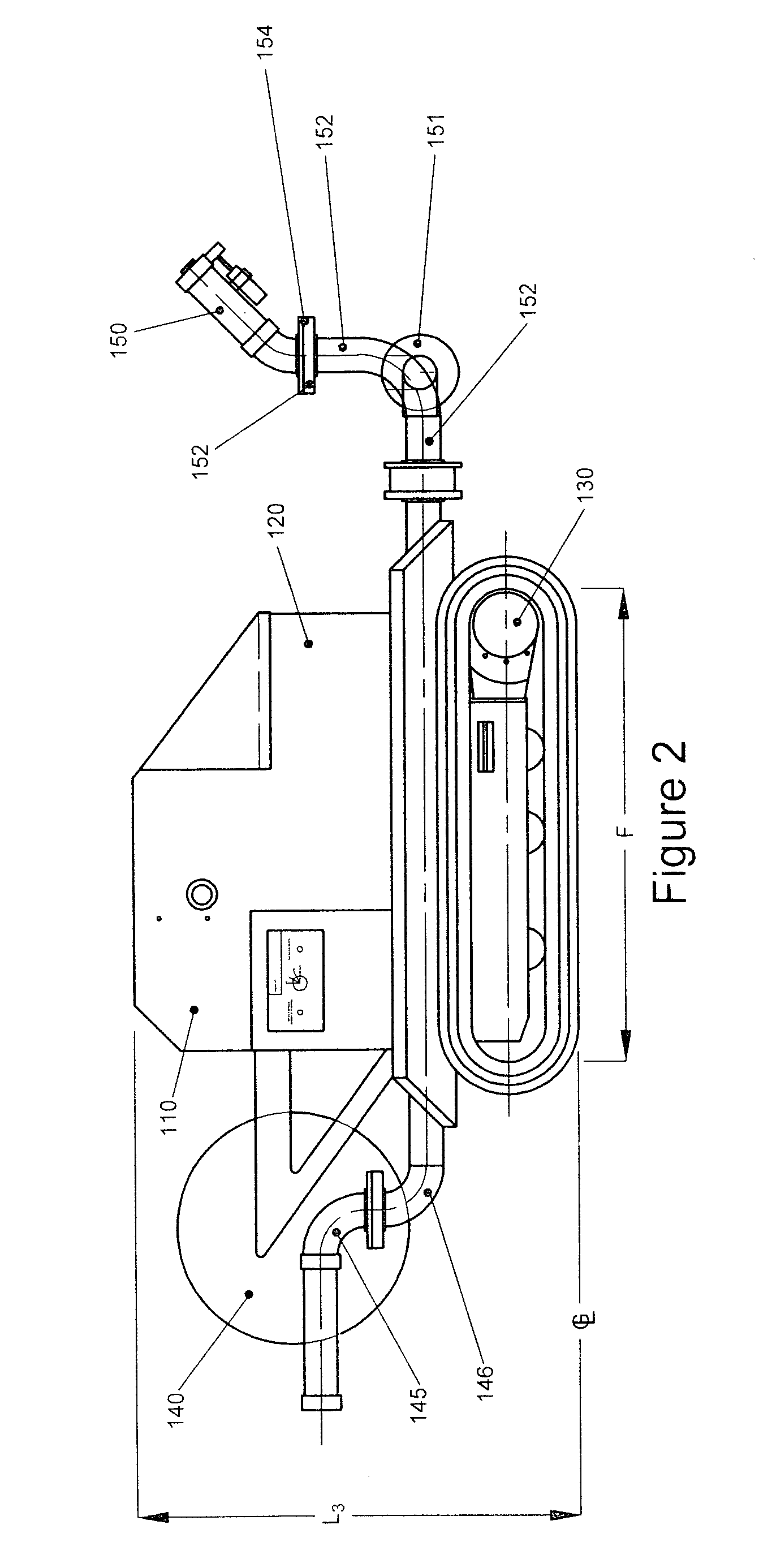

Vehicle mounted unmanned water cannon

InactiveUS20110186657A1Effective controlEffective guidanceMovable spraying apparatusSpraying vehiclesMobile vehicleGuide tube

An unmanned remotely controlled mobile vehicle mounted water cannon including, ground engaging drive means supporting a body, a nozzle mounted to a mounting arm extending from the forward end of the vehicle, the mounting arm being moveable relative to the body, means carried at the rear of the body for receiving fluid from a fluid supply and a pump to supply fluid through a conduit extending from the rear to the front of the vehicle; a power supply to supply power to the ground engaging drive means and a control means for receiving instructions from a remote controller.The ground engaging means moves the vehicle across a surface and the height of the body above the ground is less than the width and length of the vehicle. The mounting arm controls the direction of the nozzle by moving sections of the mounting arm and directing fluid projected there from, the mounting arm being structured to not rise above the height of the top of the vehicle. The control means controls the drive means and the nozzle direction in response to instructions received from the remote controller.

Owner:HAVILAND HLDG

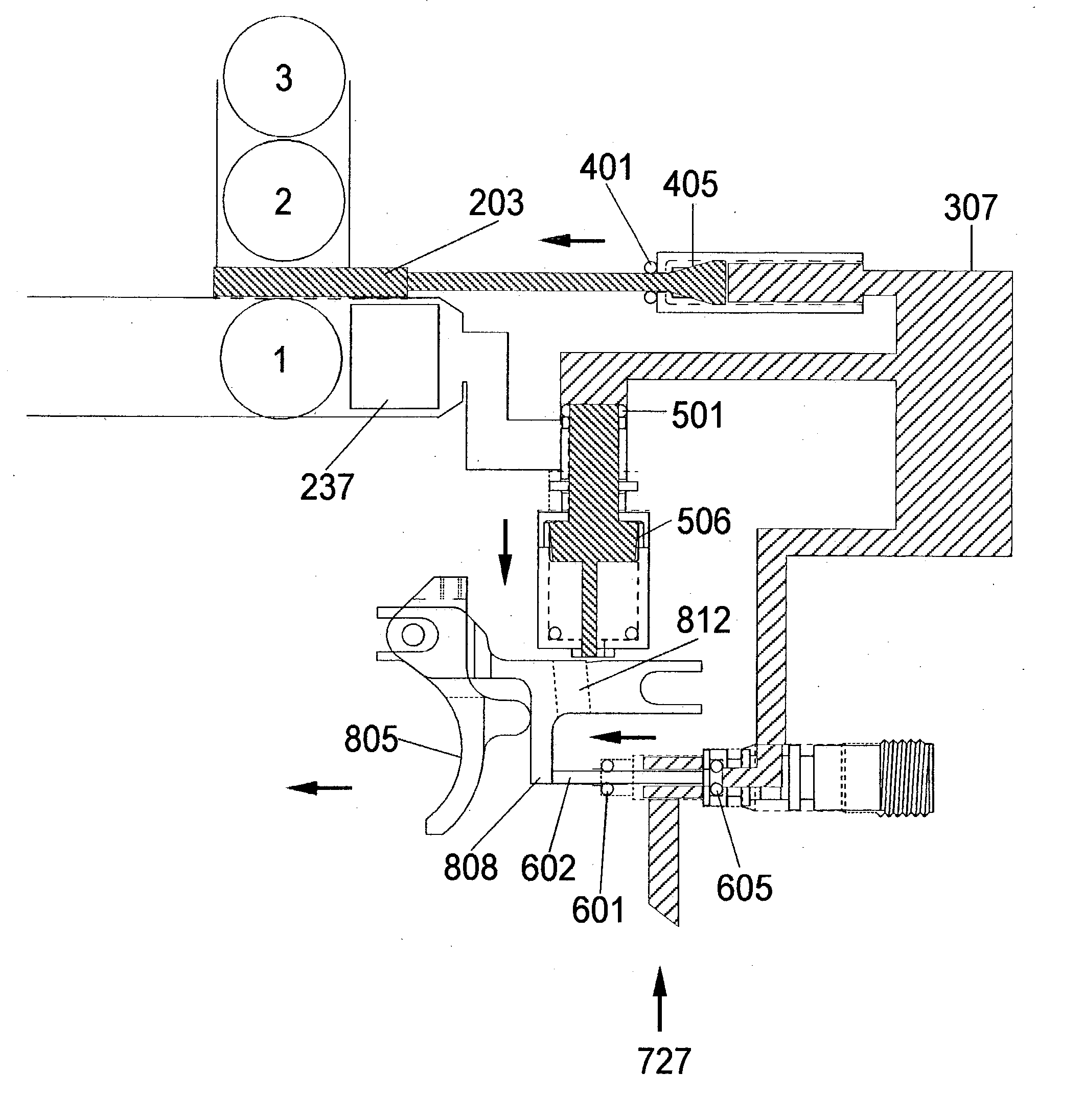

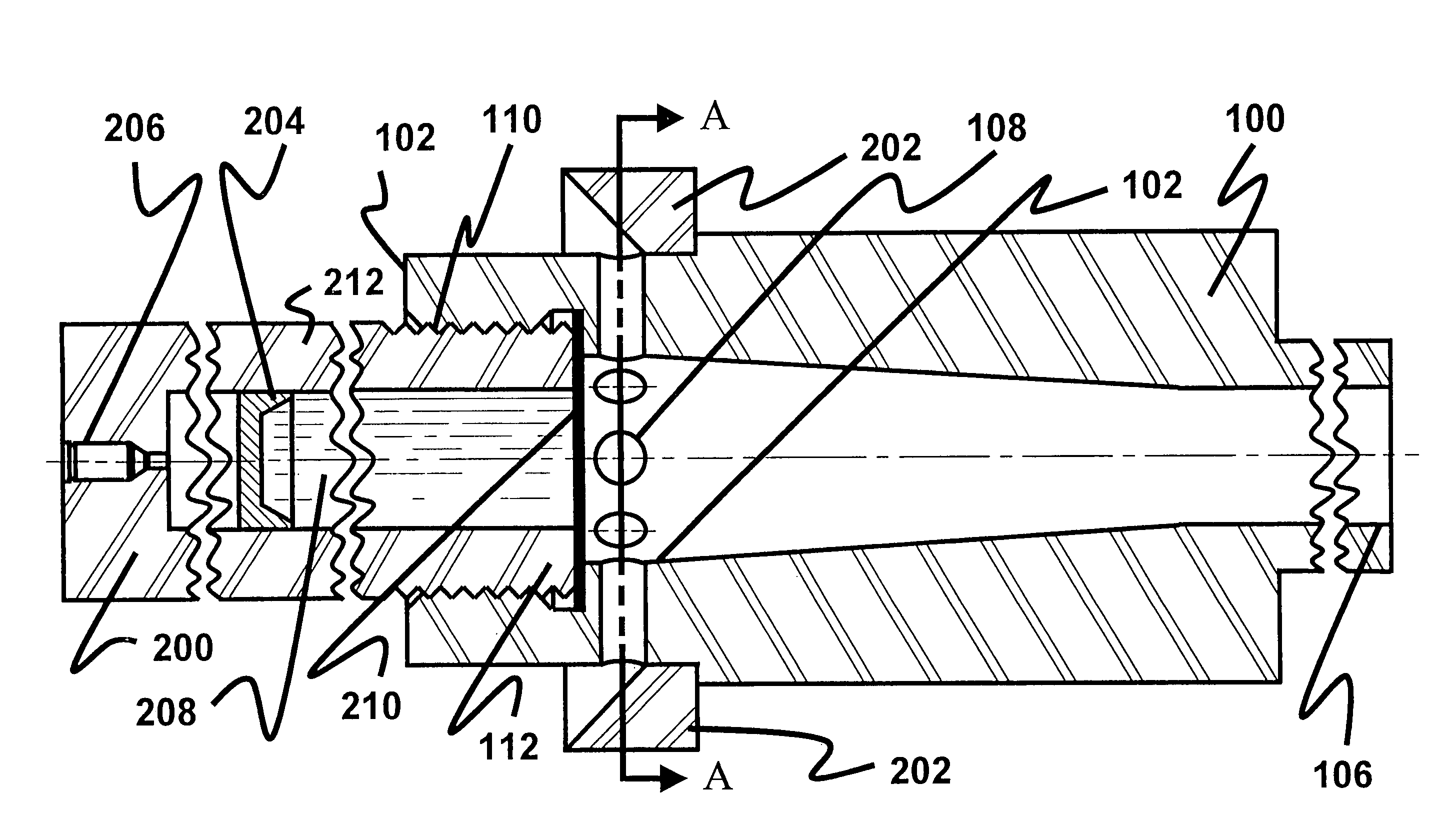

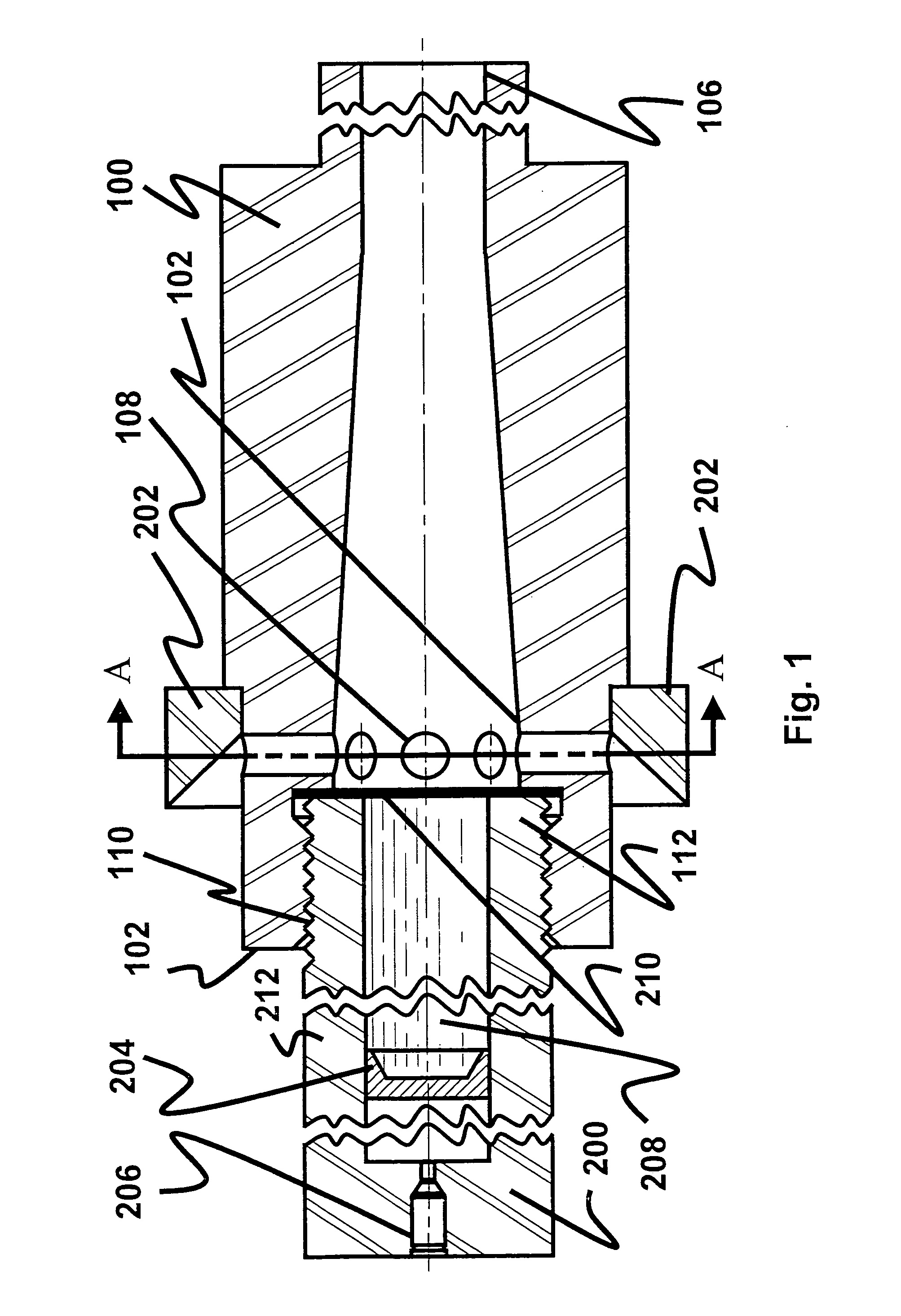

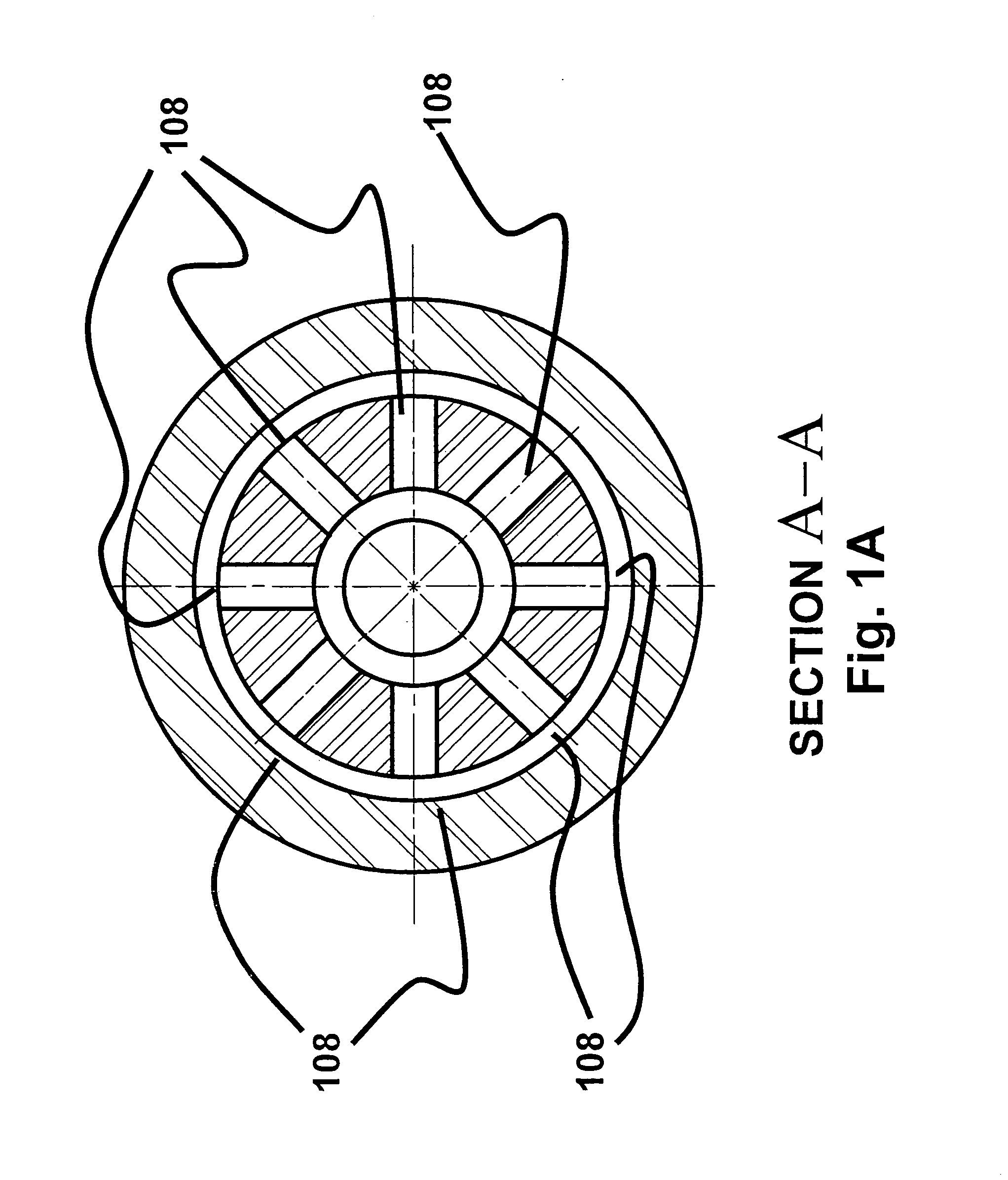

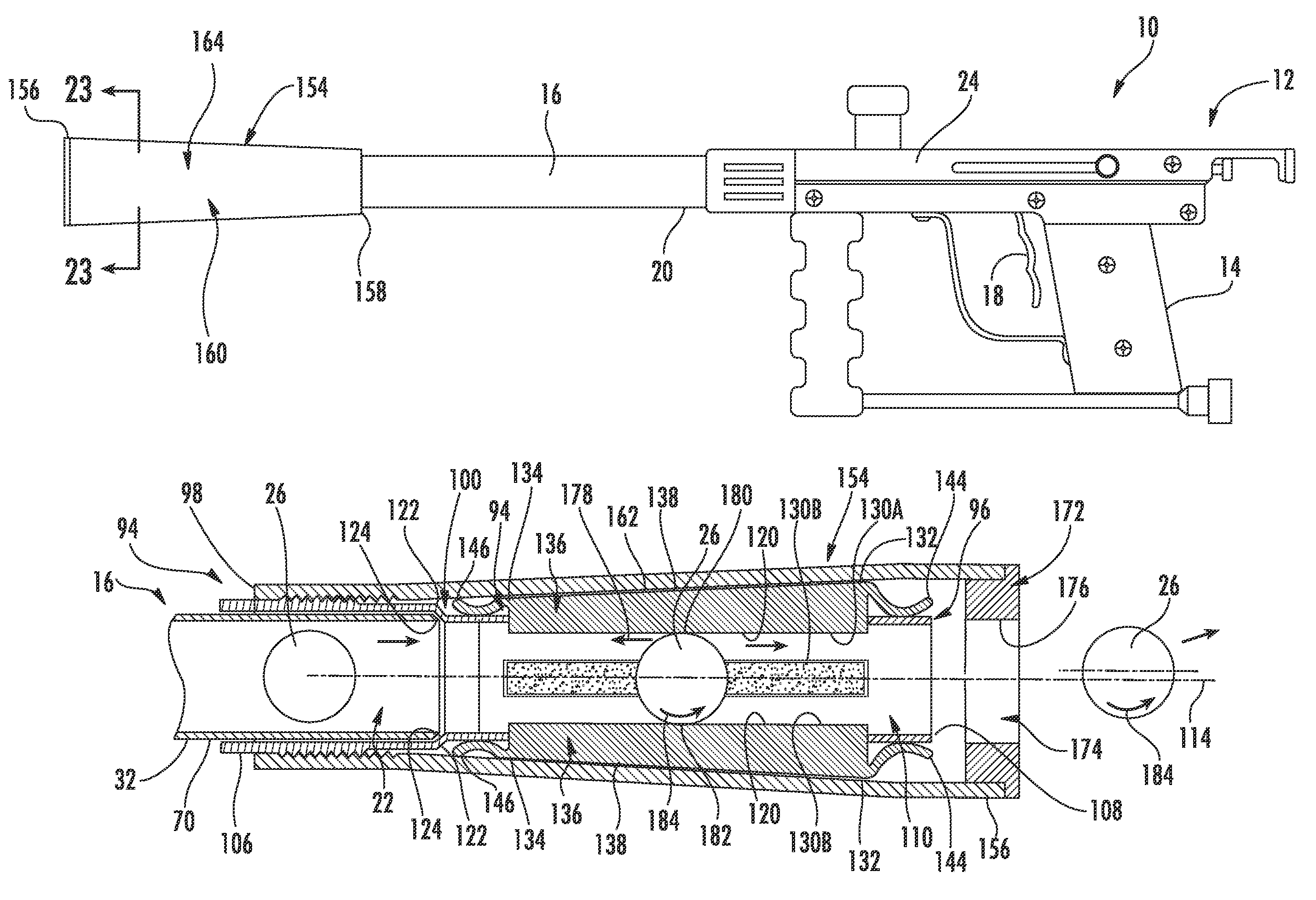

Pneumatic projectile launching apparatus with partition-loading apparatus

InactiveUS20030226555A1Improve consistencyLiquid ejecting gunsCompressed gas gunsCrowd controlPiston

An improved pneumatic launching apparatus is disclosed having both a partition apparatus for enabling a projectile, such as filled capsules used in paintball, marking devices or crowd control, to be loaded and readied for expulsion and a venting-pressure regulator. When the partition apparatus is in an open position, an aperture is exposed allowing a projectile of complimentary size and shape to transfer to the receiving chamber. The shape of the partition is such that a next projectile is gently cradled and separated from the receiving chamber during a closing movement. Further, the partition facilitates the projectile reaching a containing area and it creates a seal that on the chamber that significantly inhibits the escape of pressurized gas during a firing operation and facilitates the projectile loading into a containing area. The venting-pressure regulator utilizes opposed pistons with an escape mechanism to allow venting to occur without requiring a separate adjustment.

Owner:REIBLE JAMES PATRICK

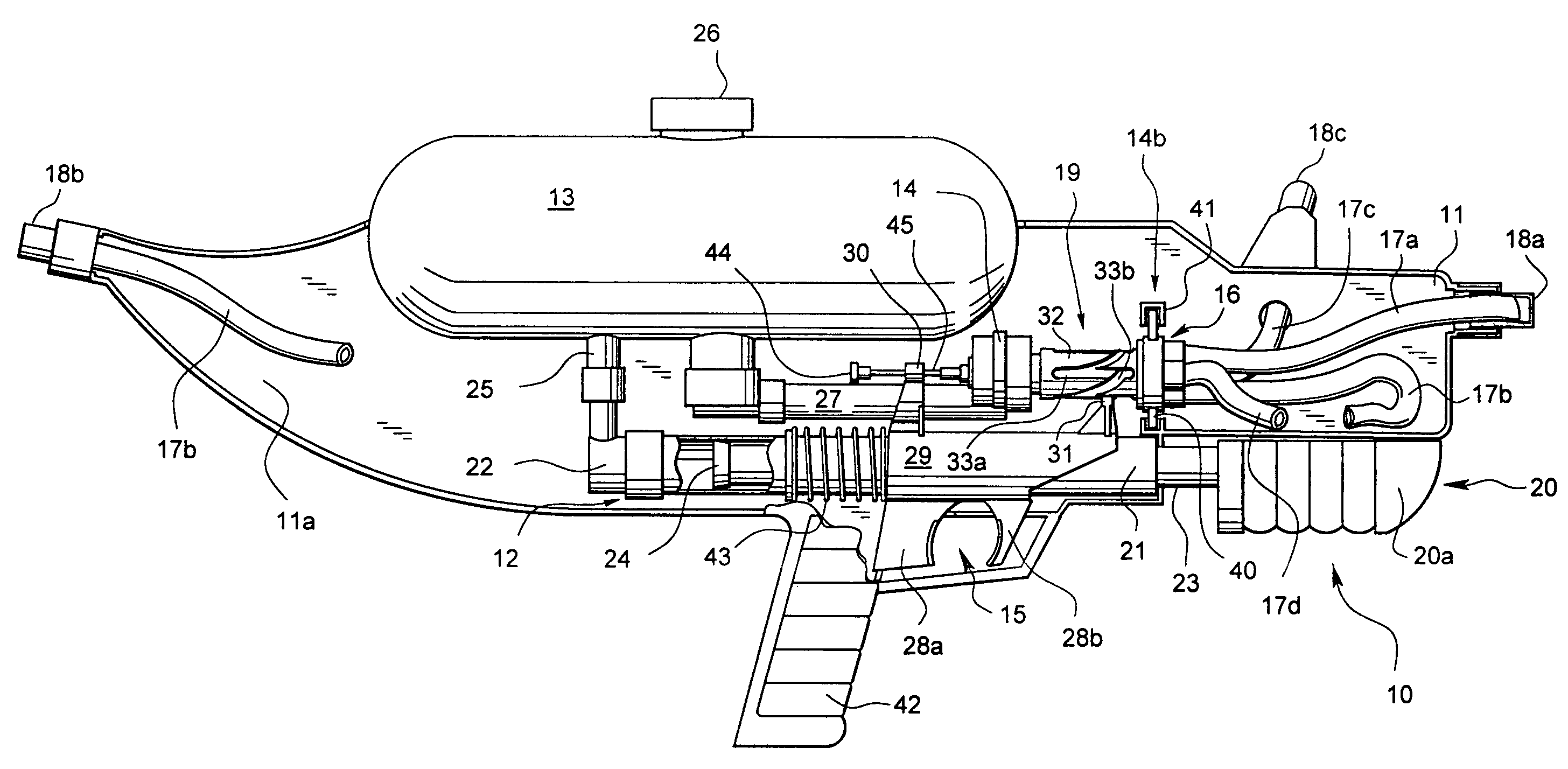

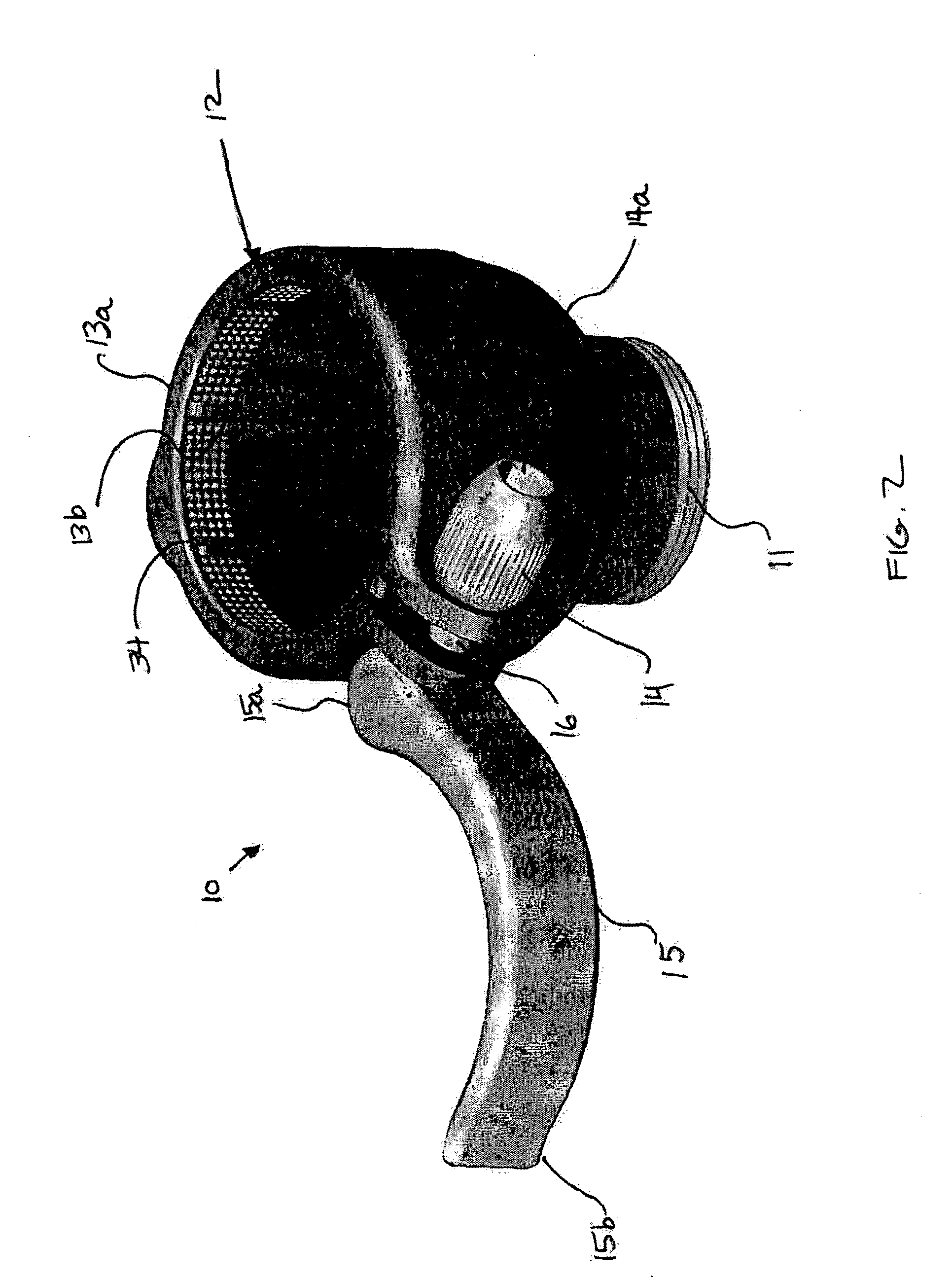

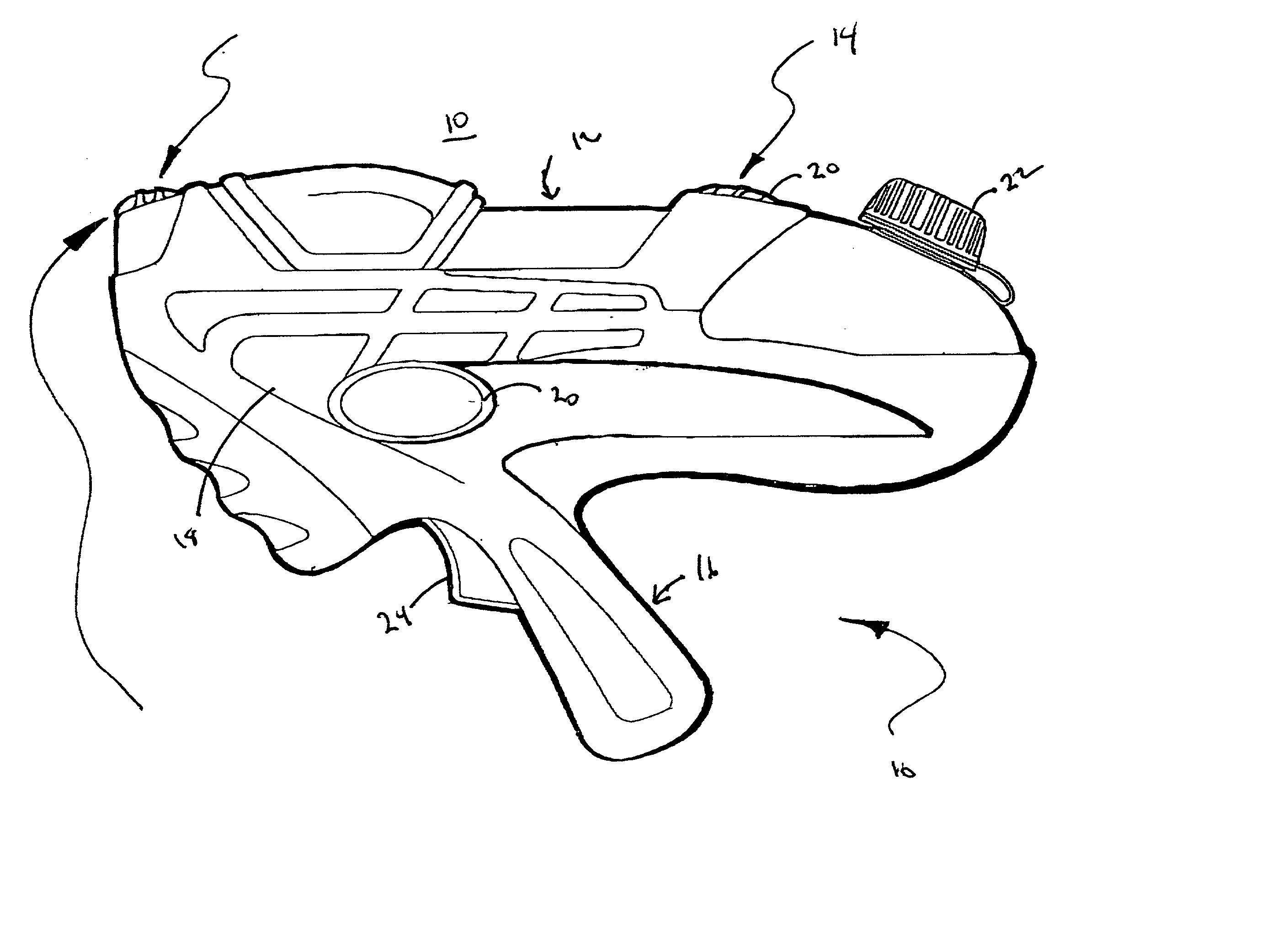

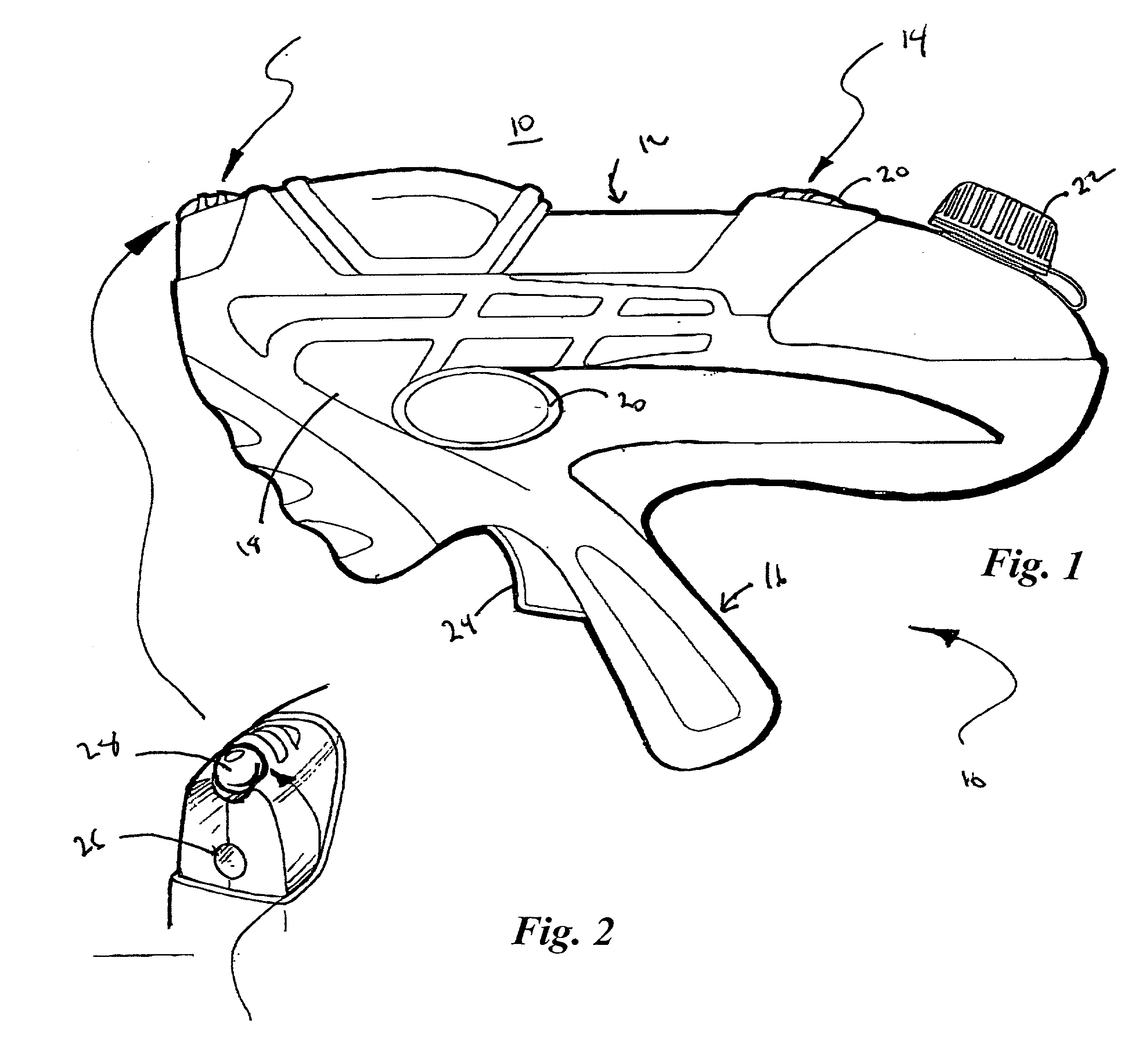

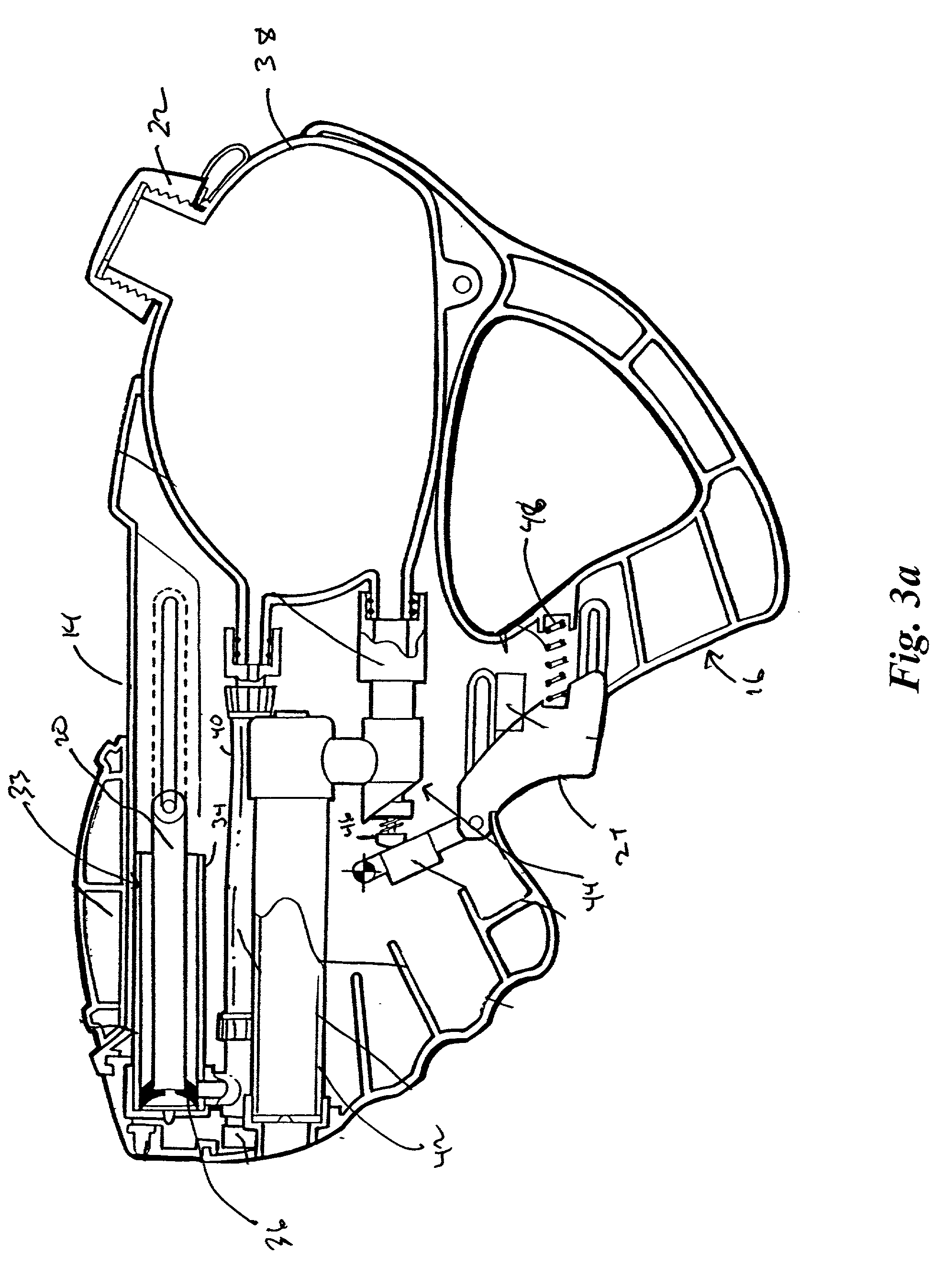

Toy water gun

A toy water gun provides a plurality of nozzles for discharging water in a variety of directions, volumes or spray patterns. A multi-position trigger or similar device controls selection of nozzles individually or in combinations whereby an operator can quickly choose among various modes of discharge by moving the trigger through corresponding positions.

Owner:CLAYTON RICHARD A

Squirting toy

A squirting toy is comprised of a cylindrical housing and a piston that slides within to force water into or out of the housing via a hole therein. The housing is encased within a polyethylene closed cell foam shell. The shell is non-absorbing, so that the foam remains buoyant and keeps the gun afloat indefinitely when left in water. The foam is soft, so that the gun is not a safety hazard when left floating in a swimming pool.

Owner:EASEBON SERVICES

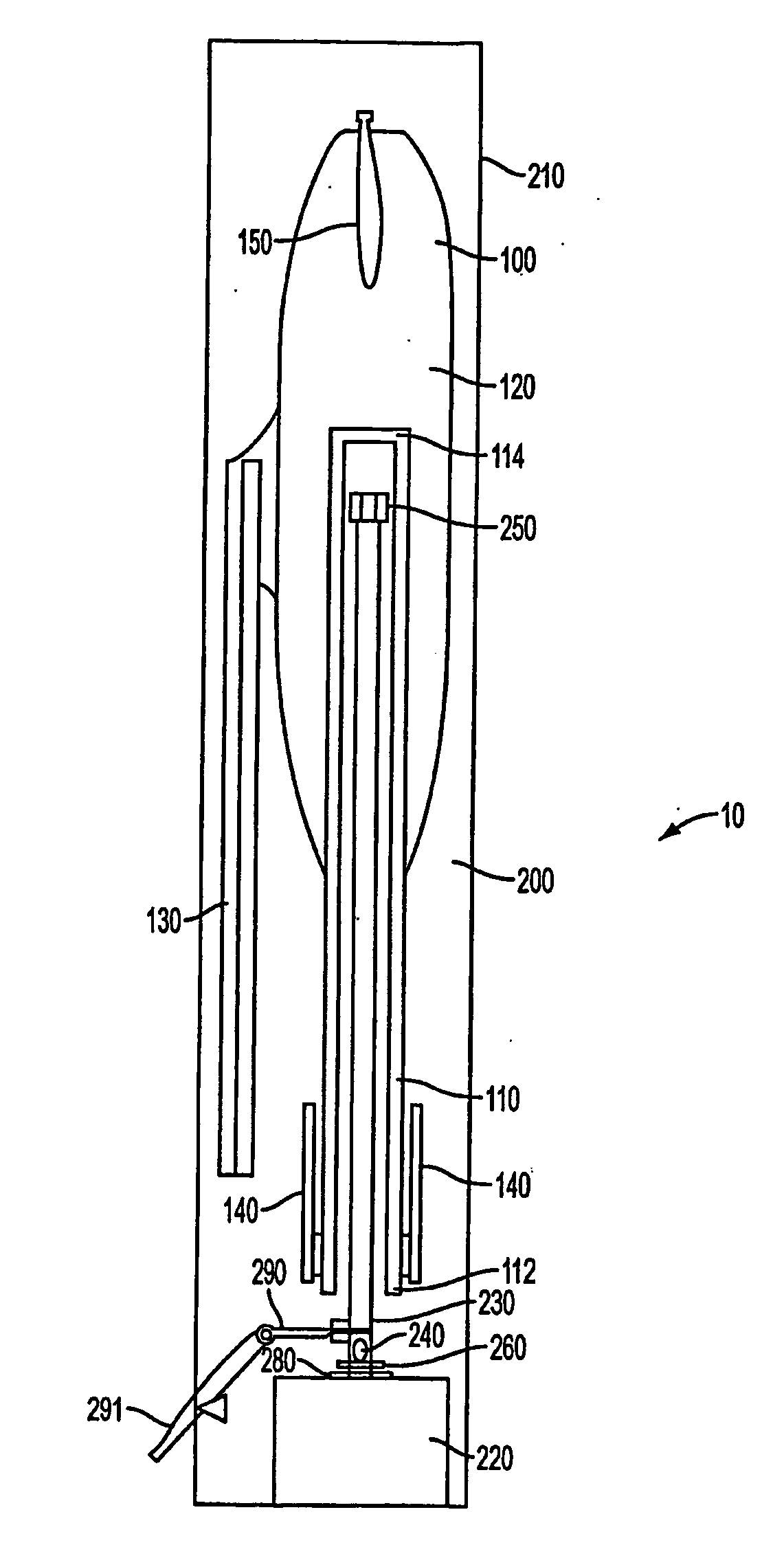

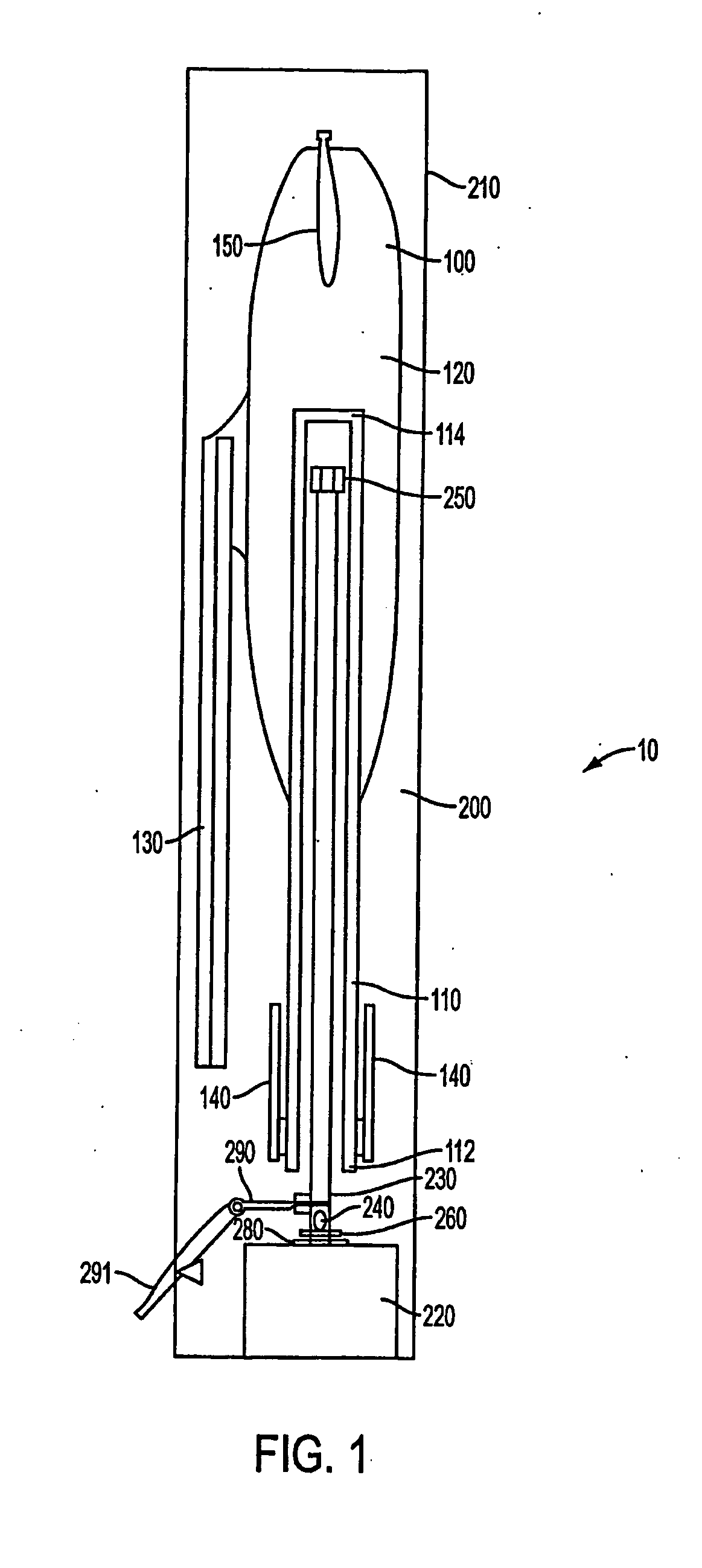

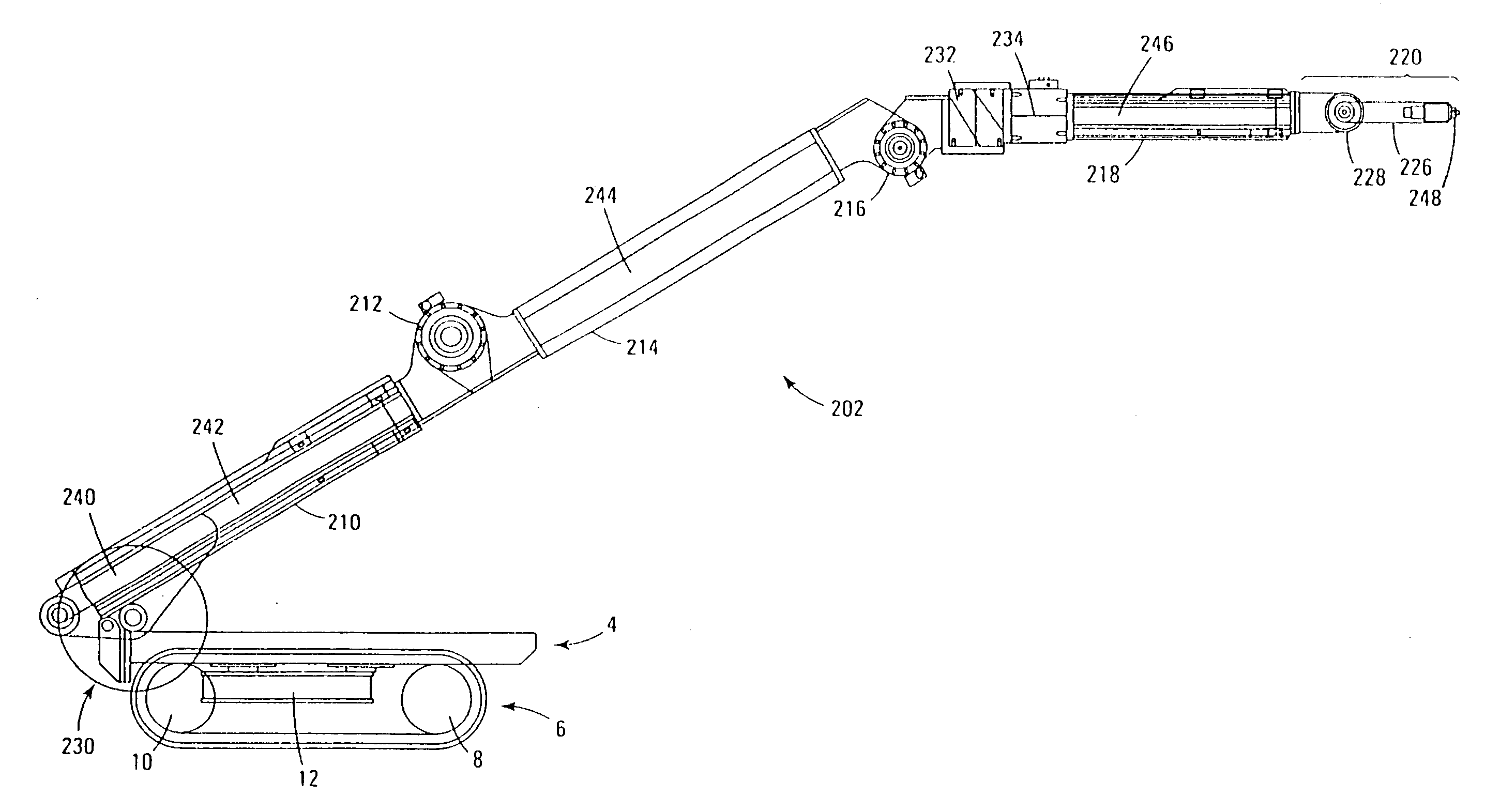

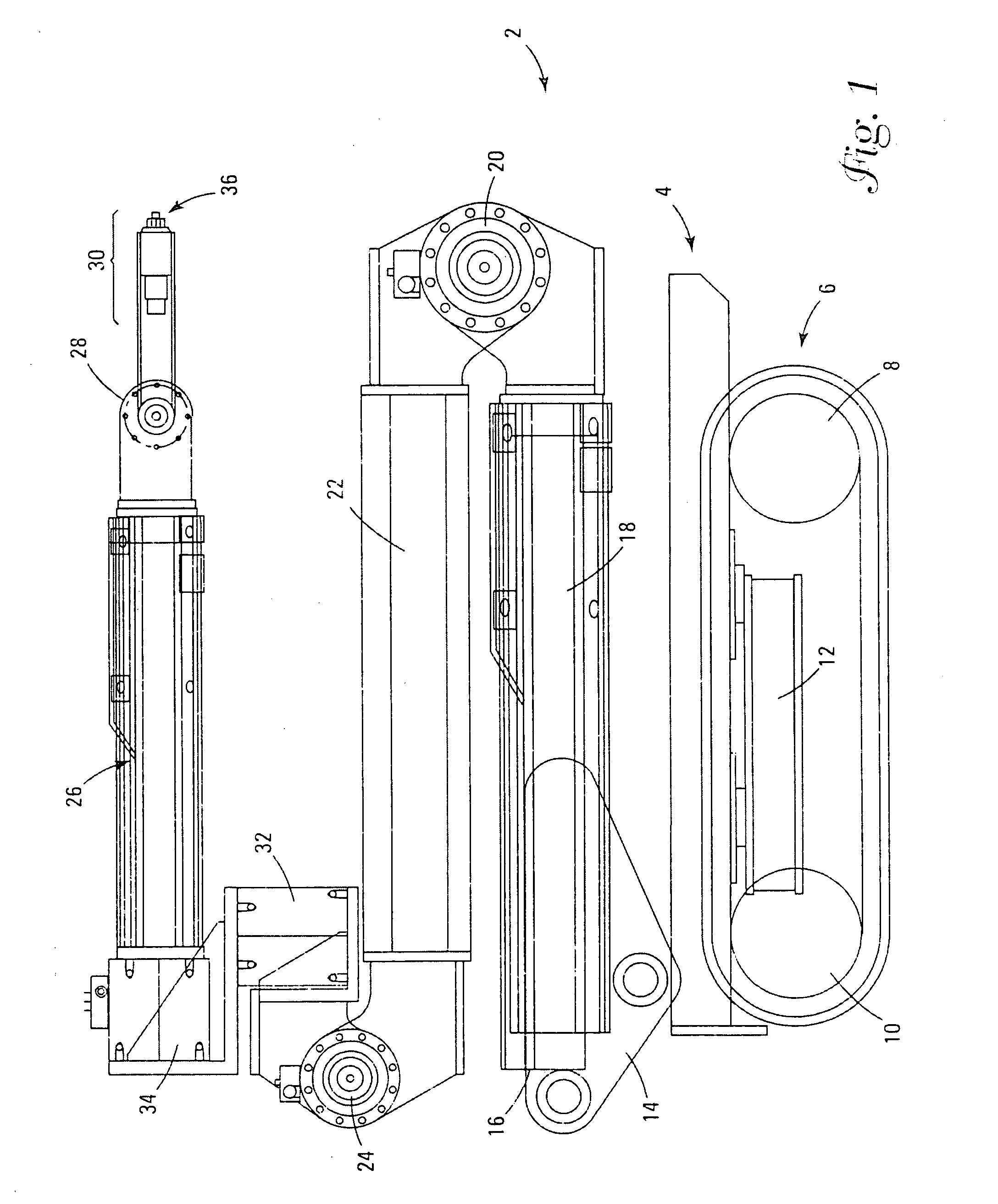

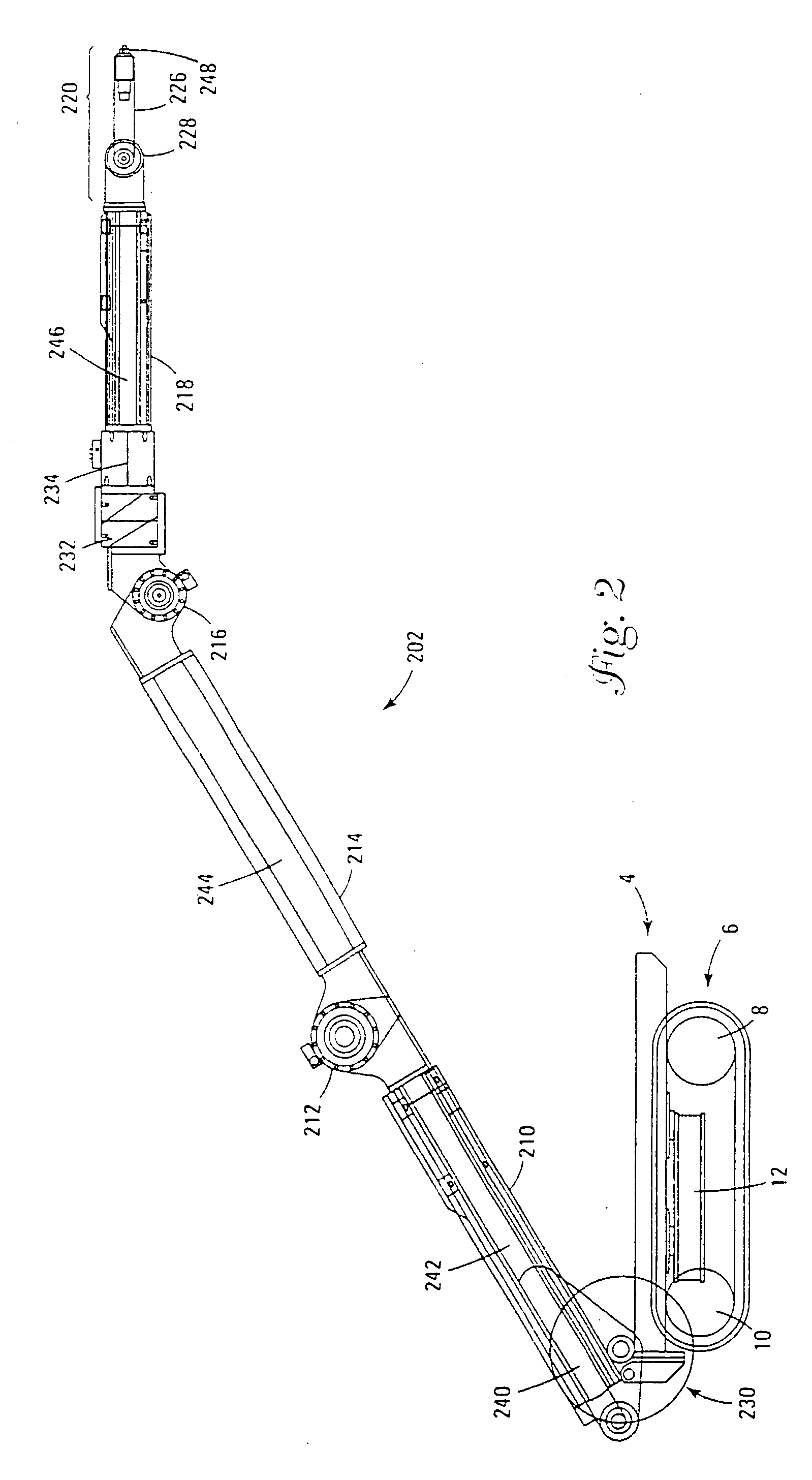

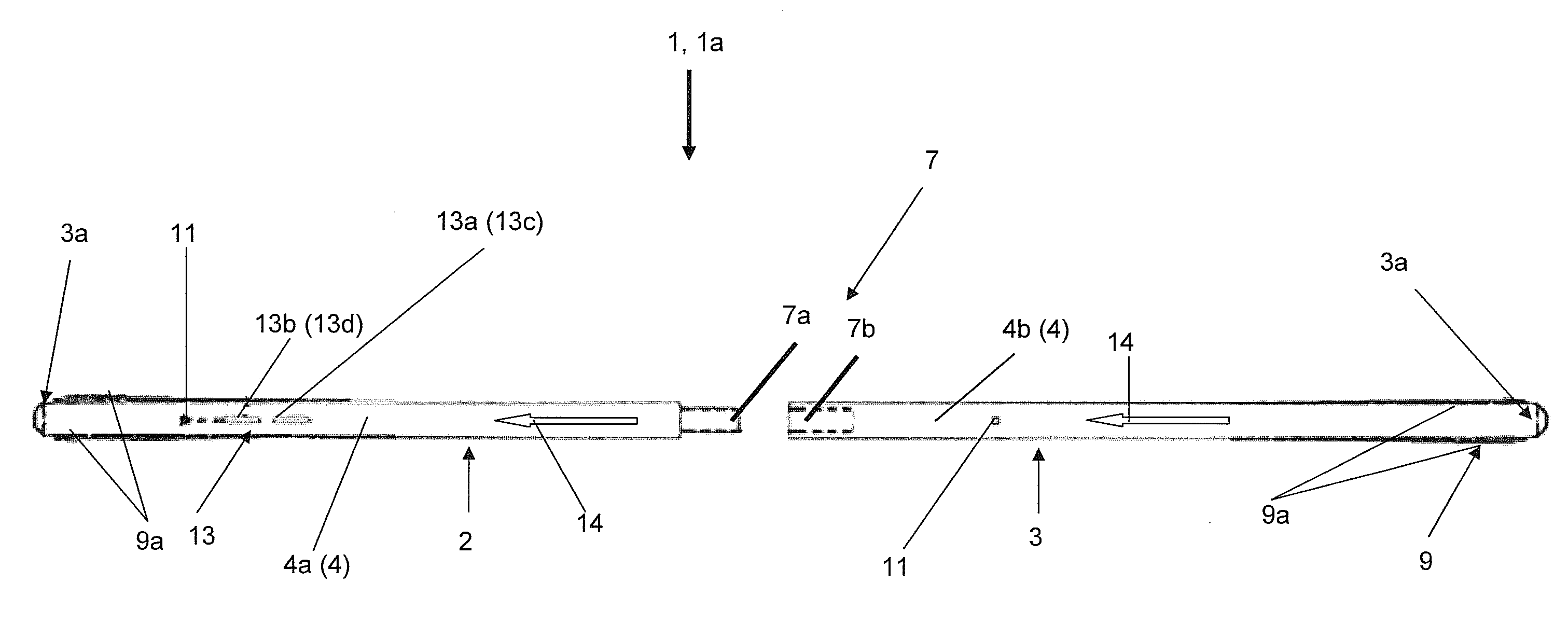

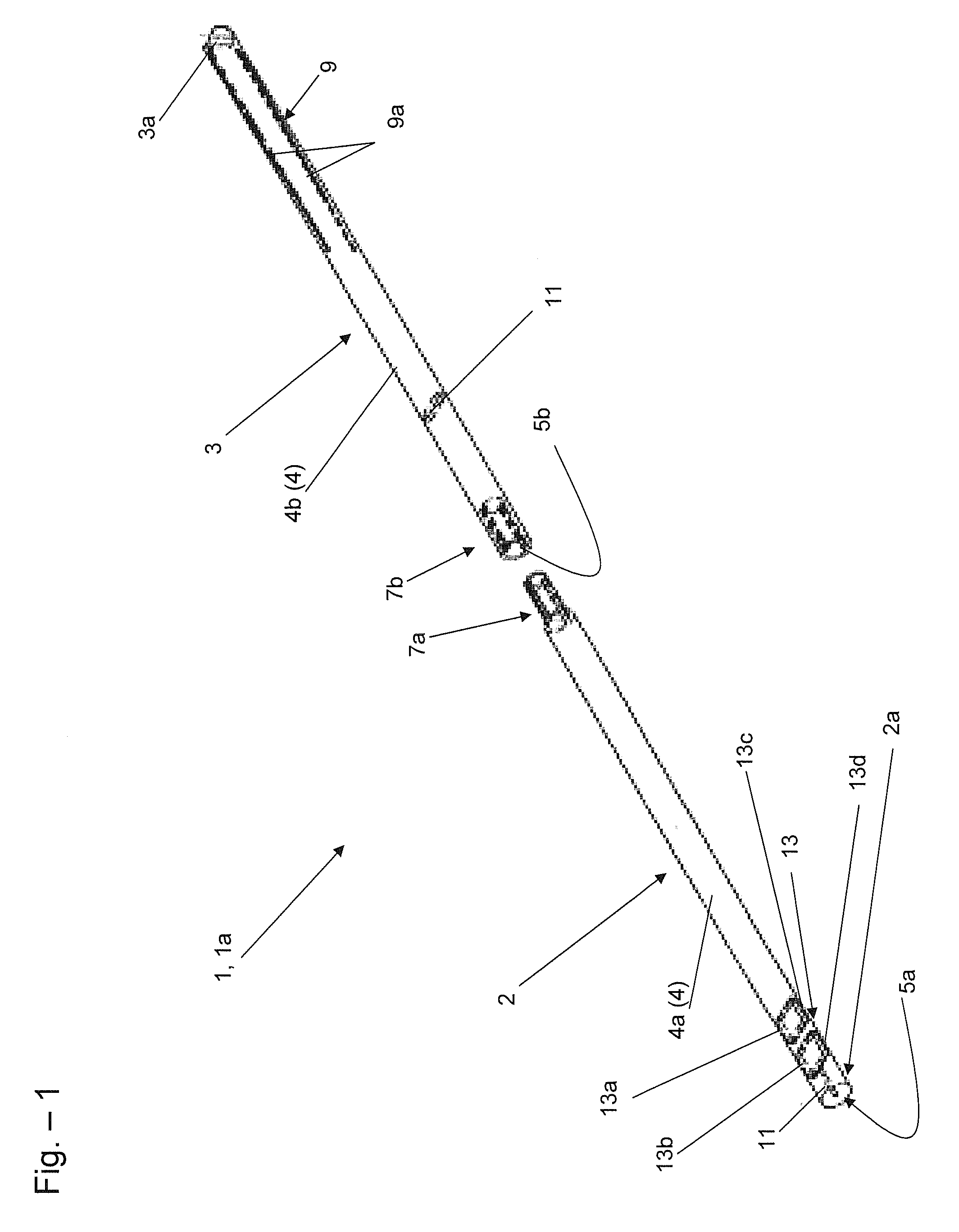

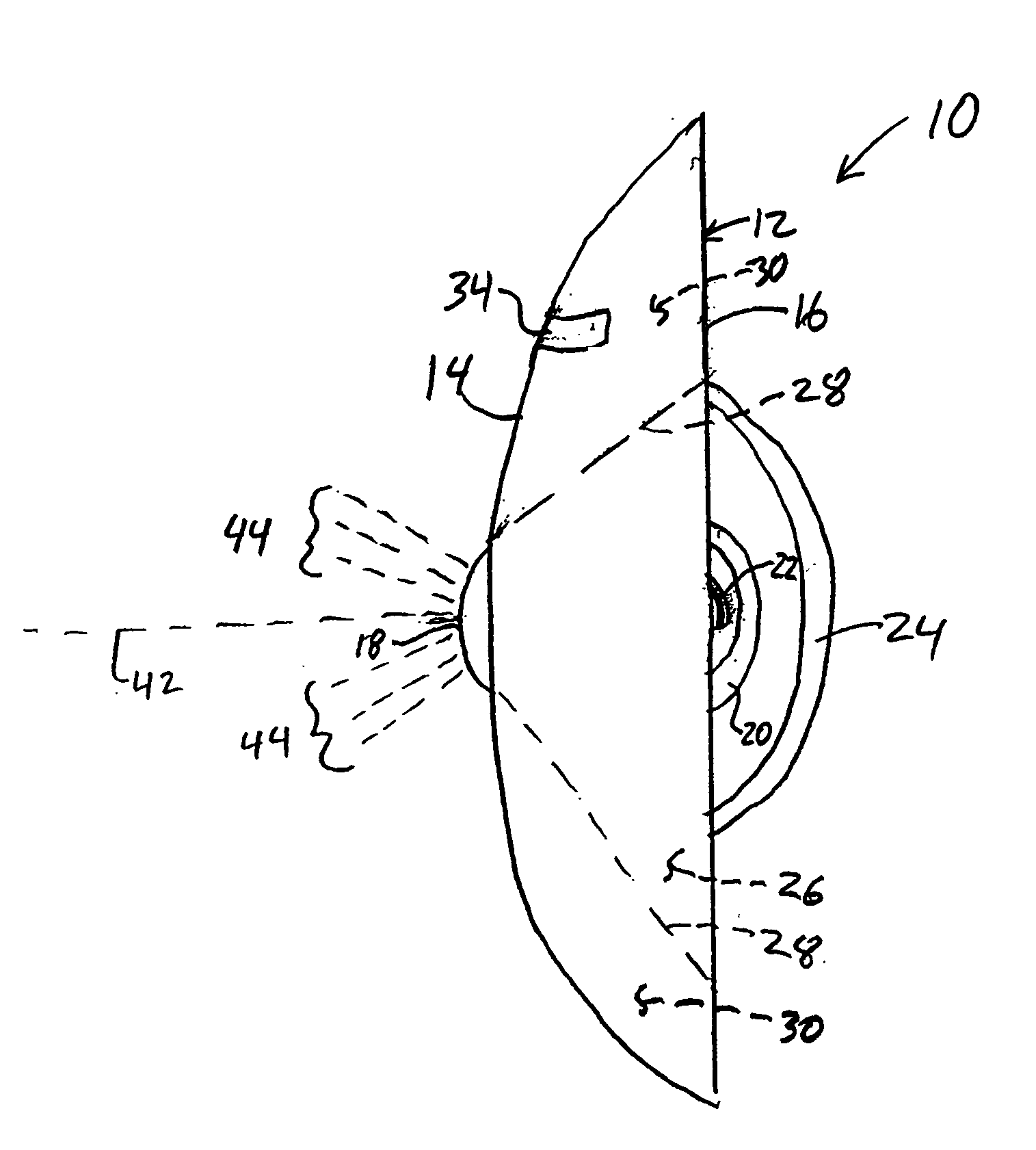

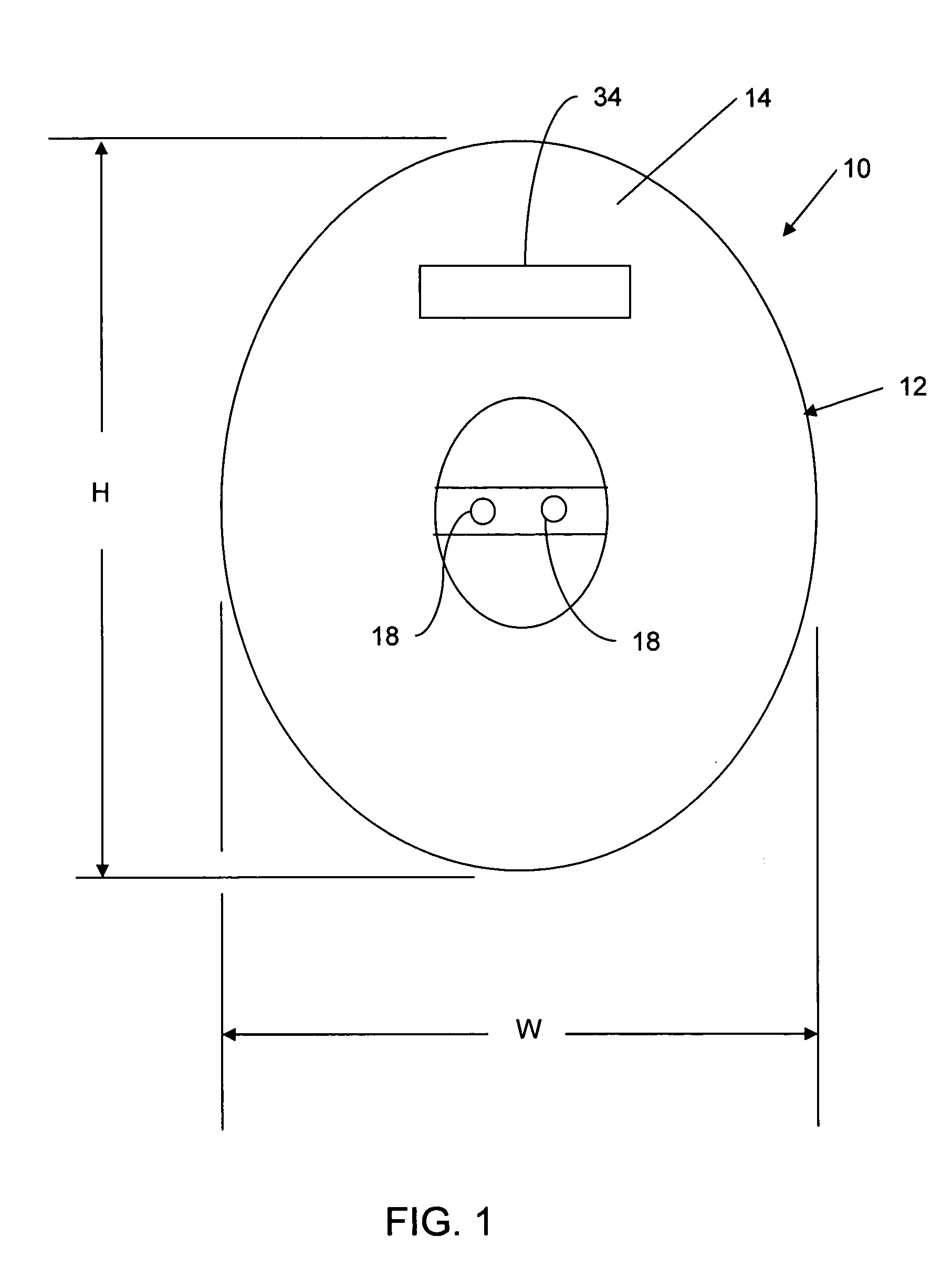

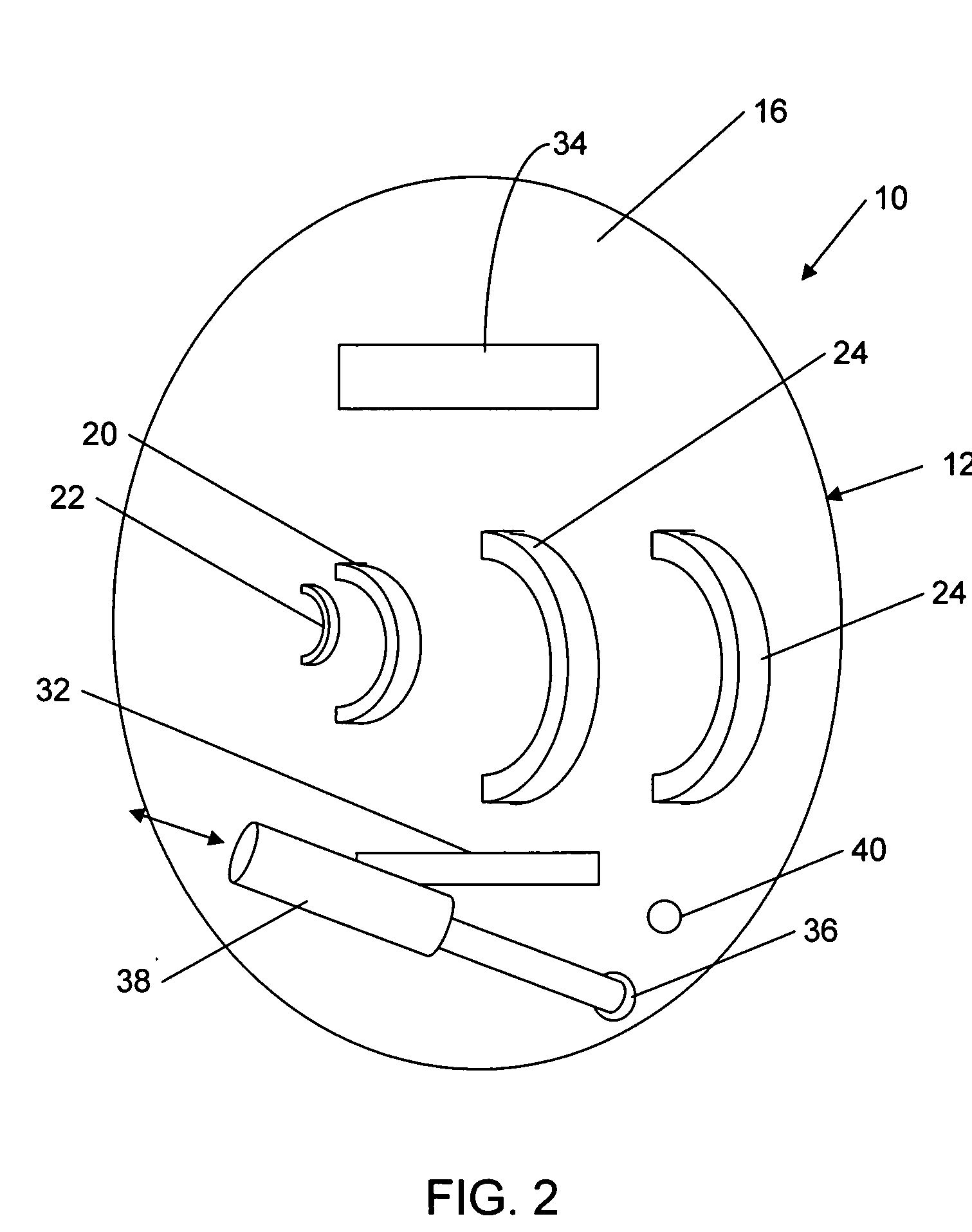

Lightweight air vehicle and pneumatic launcher

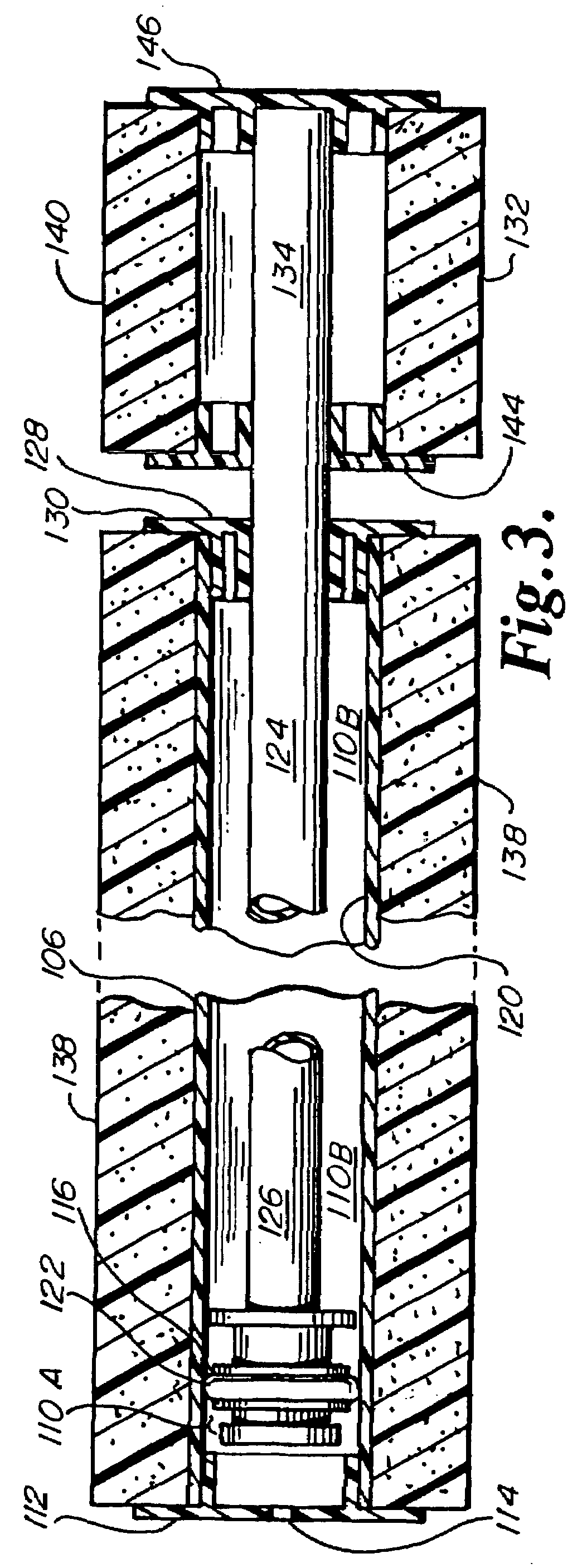

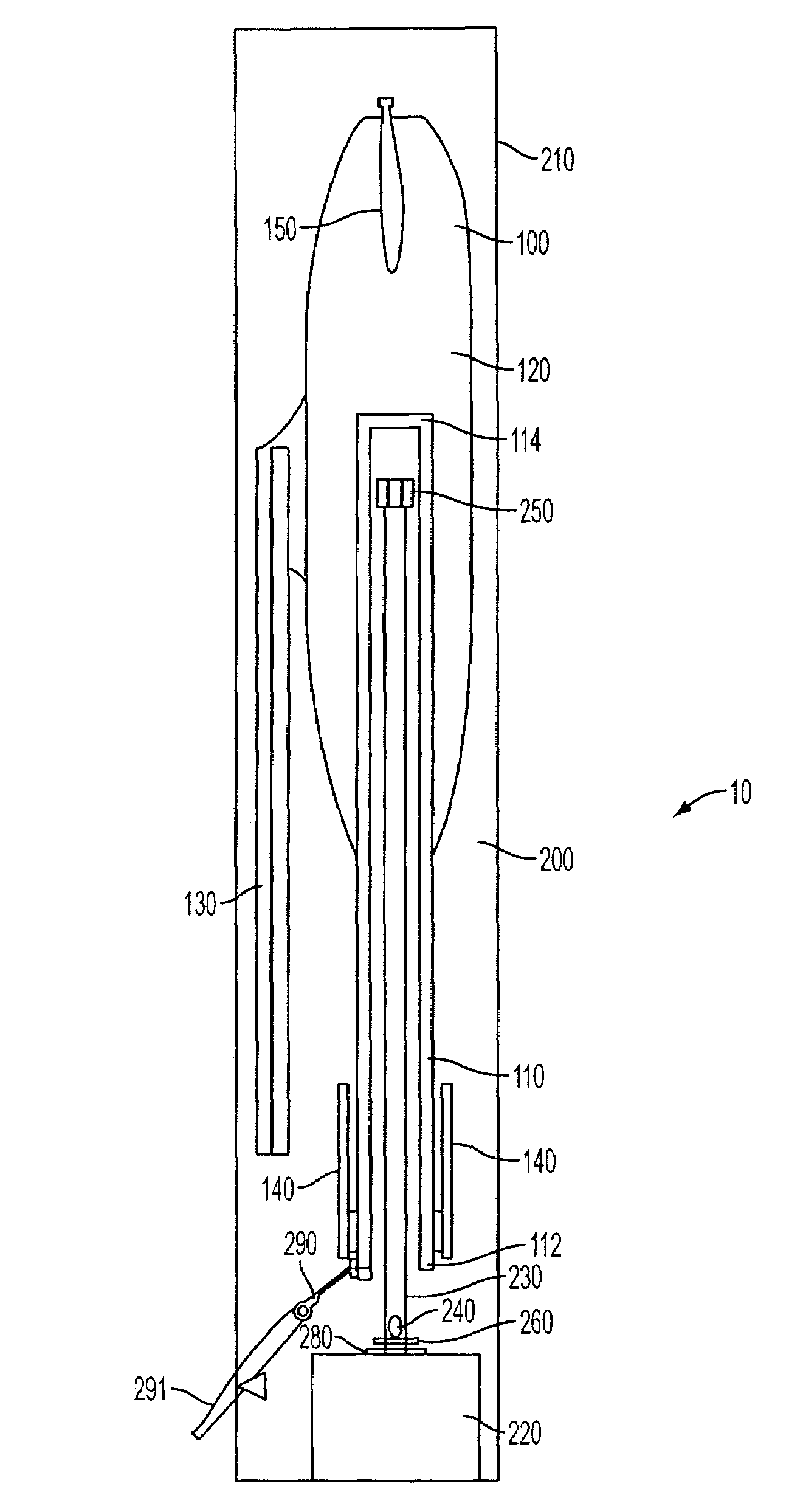

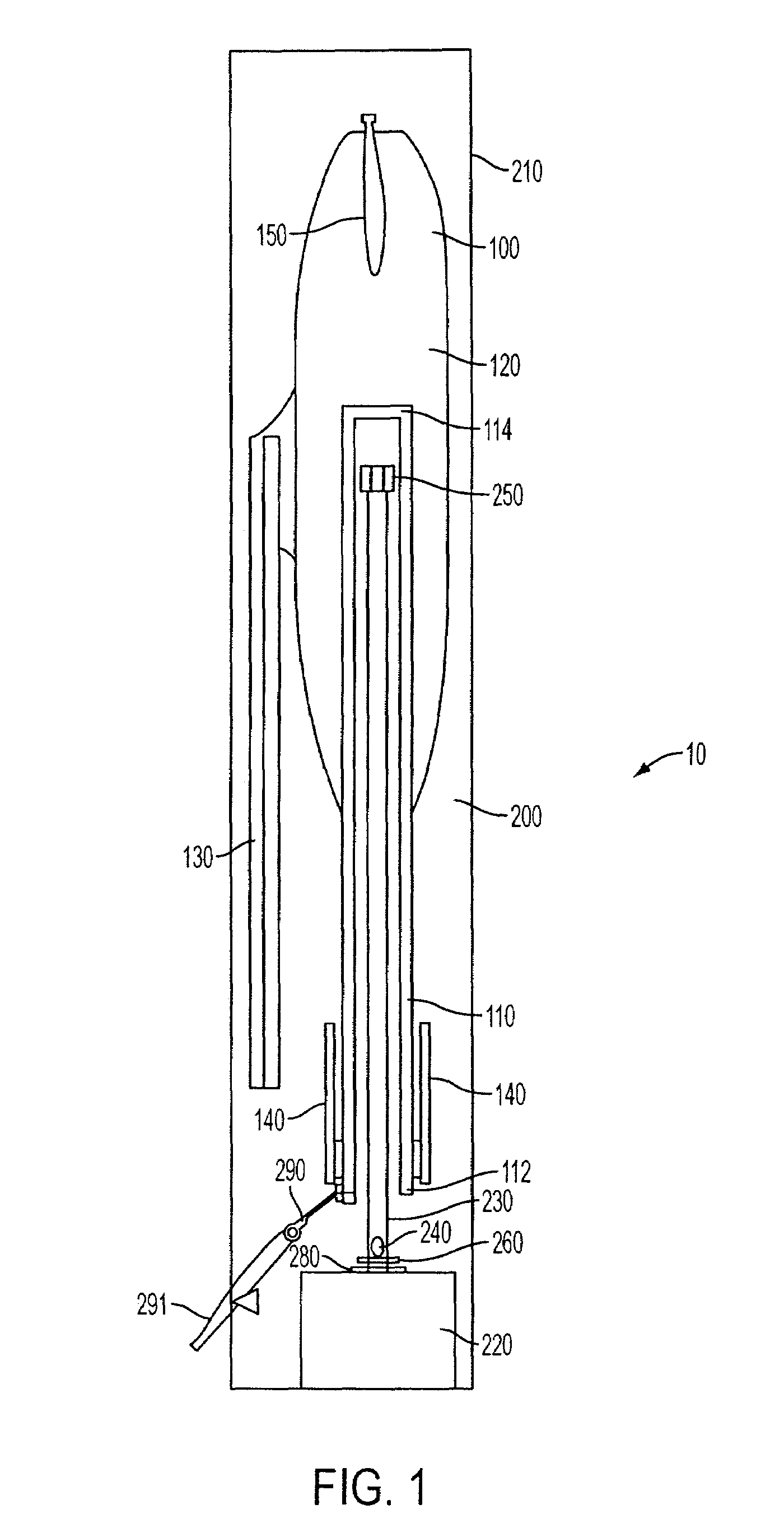

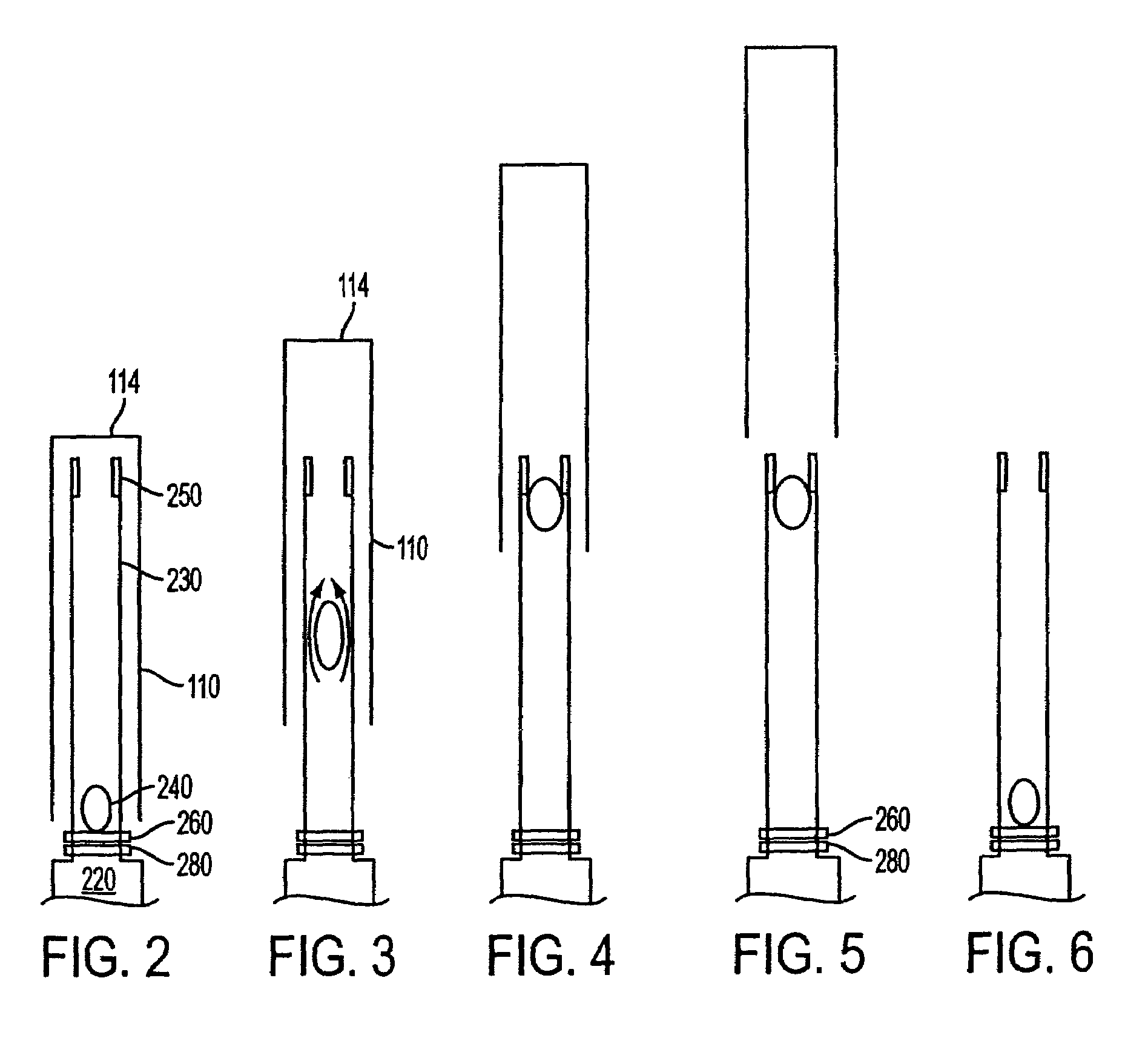

ActiveUS7410124B2Easy to carryMore transportableUnmanned aerial vehiclesLaunching/towing gearUnmanned air vehiclePiston

A portable unmanned air vehicle and launcher system including a foldable unmanned air vehicle with a pressure tube; a launch gas reservoir for holding launch gas; a launch tube operatively connected to the launch gas reservoir and having a free end that is positioned in the pressure tube of the air vehicle; a free piston positioned within the launch tube; and a free piston stop to prevent the free piston from leaving the launch tube. A first portion of the launch gas in the launch gas reservoir is released into the launch tube and forces the free piston from an initial position to an end position at which the free piston is stopped by the free piston stop.

Owner:AIRPORTS AUTHORITY OF INDIA

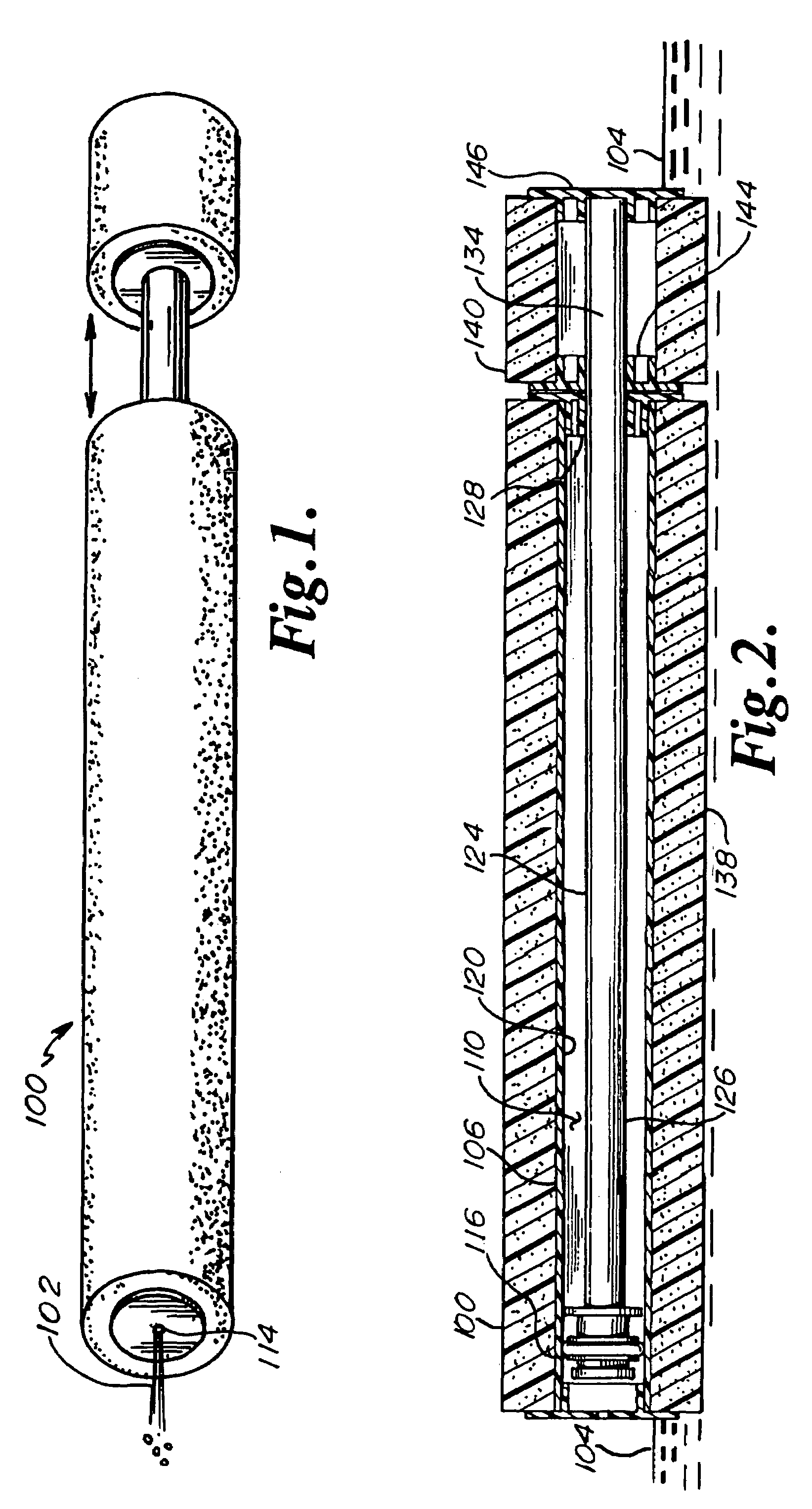

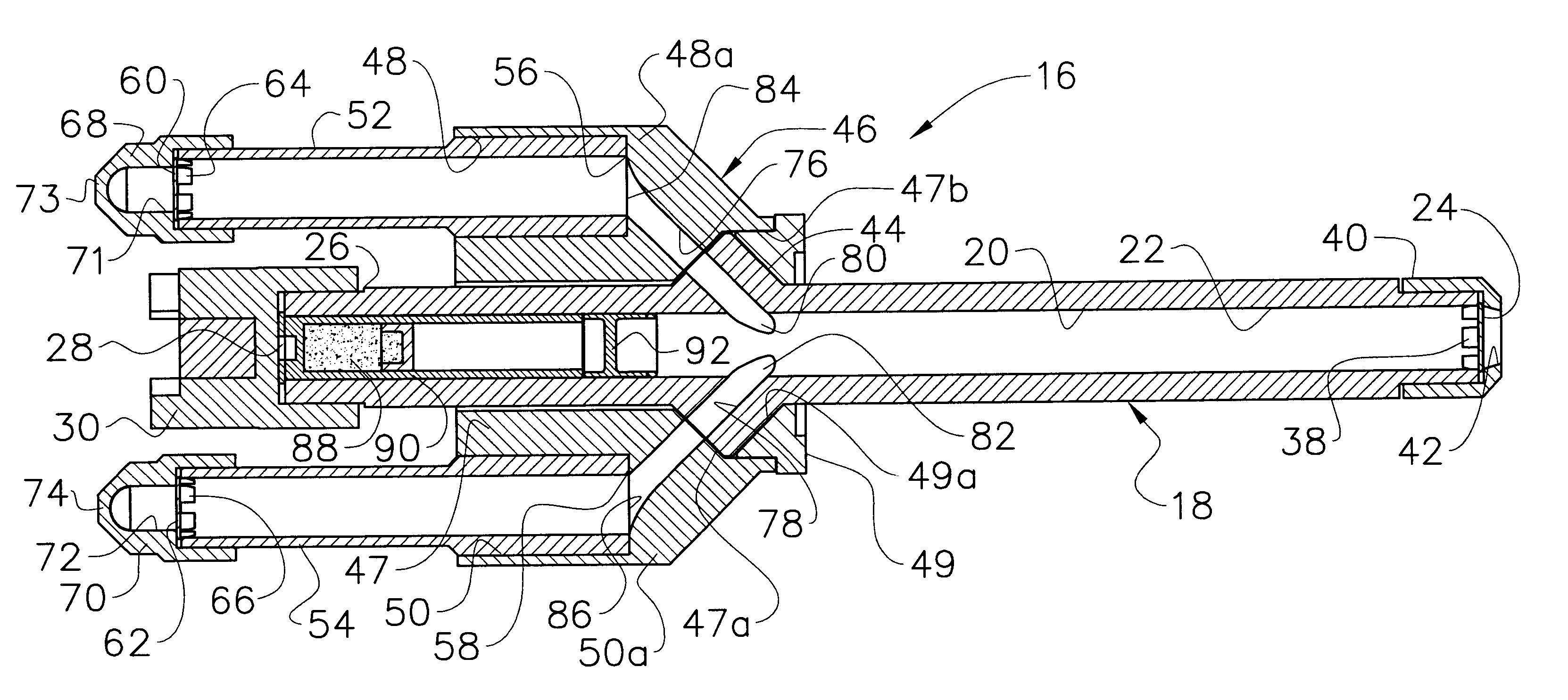

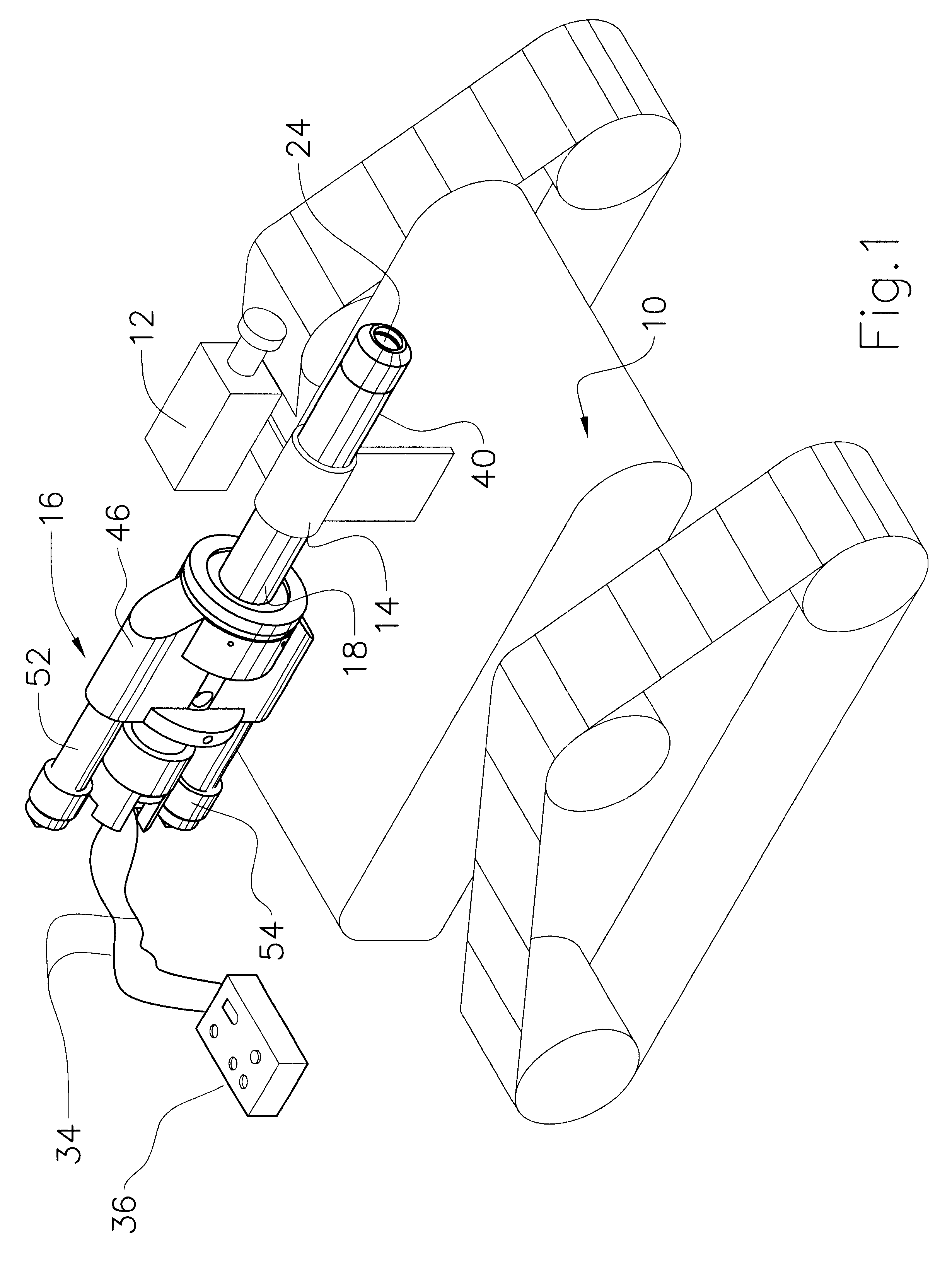

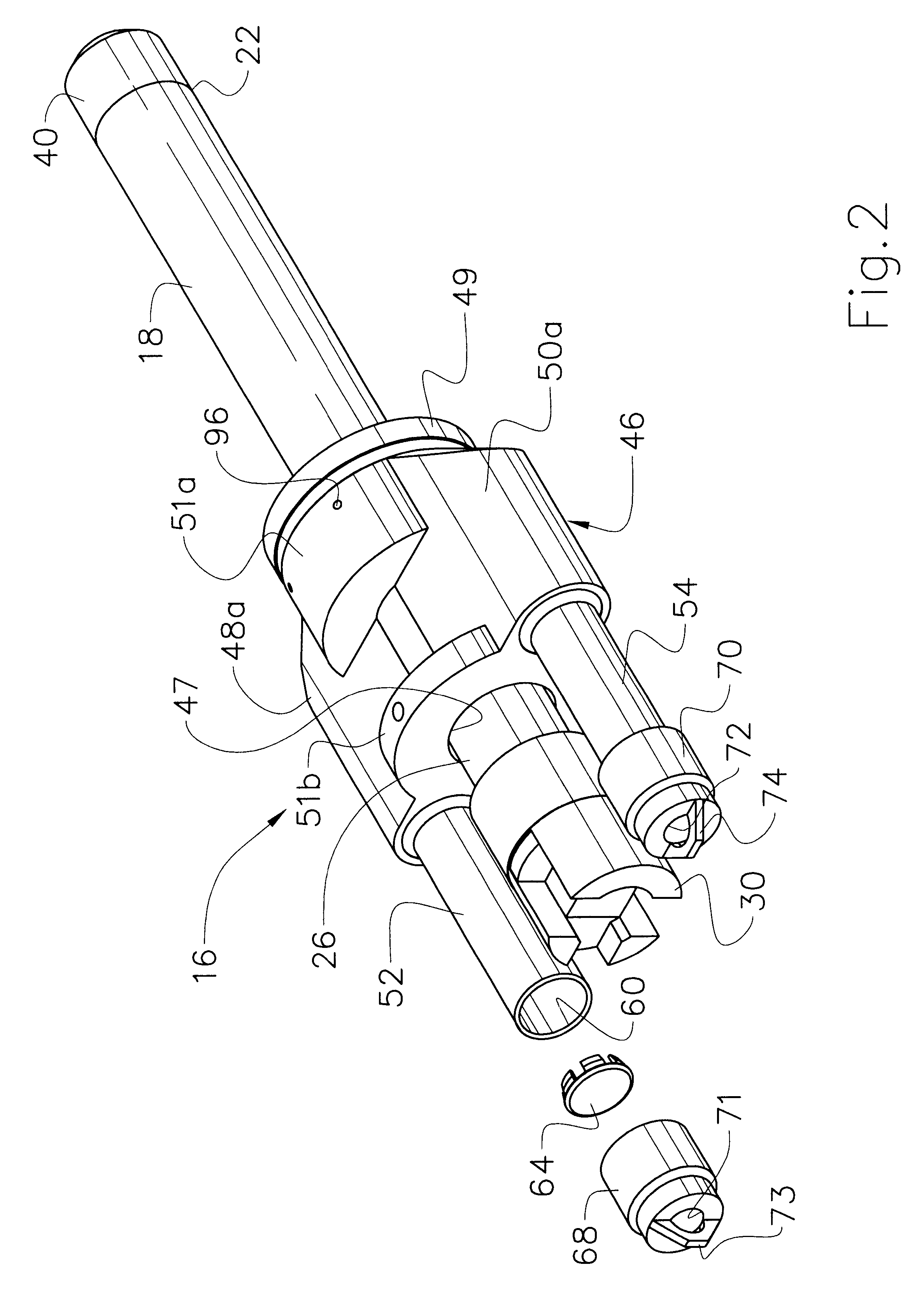

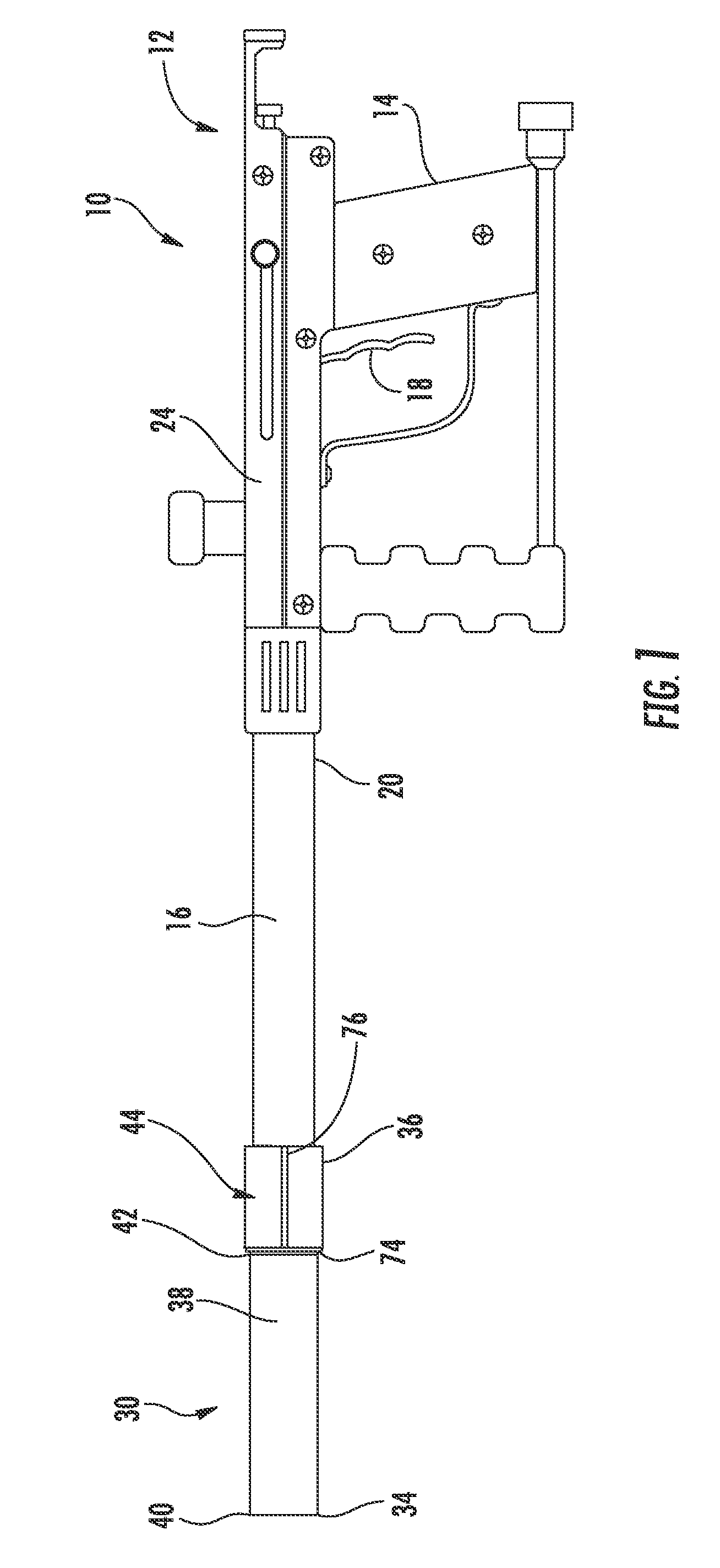

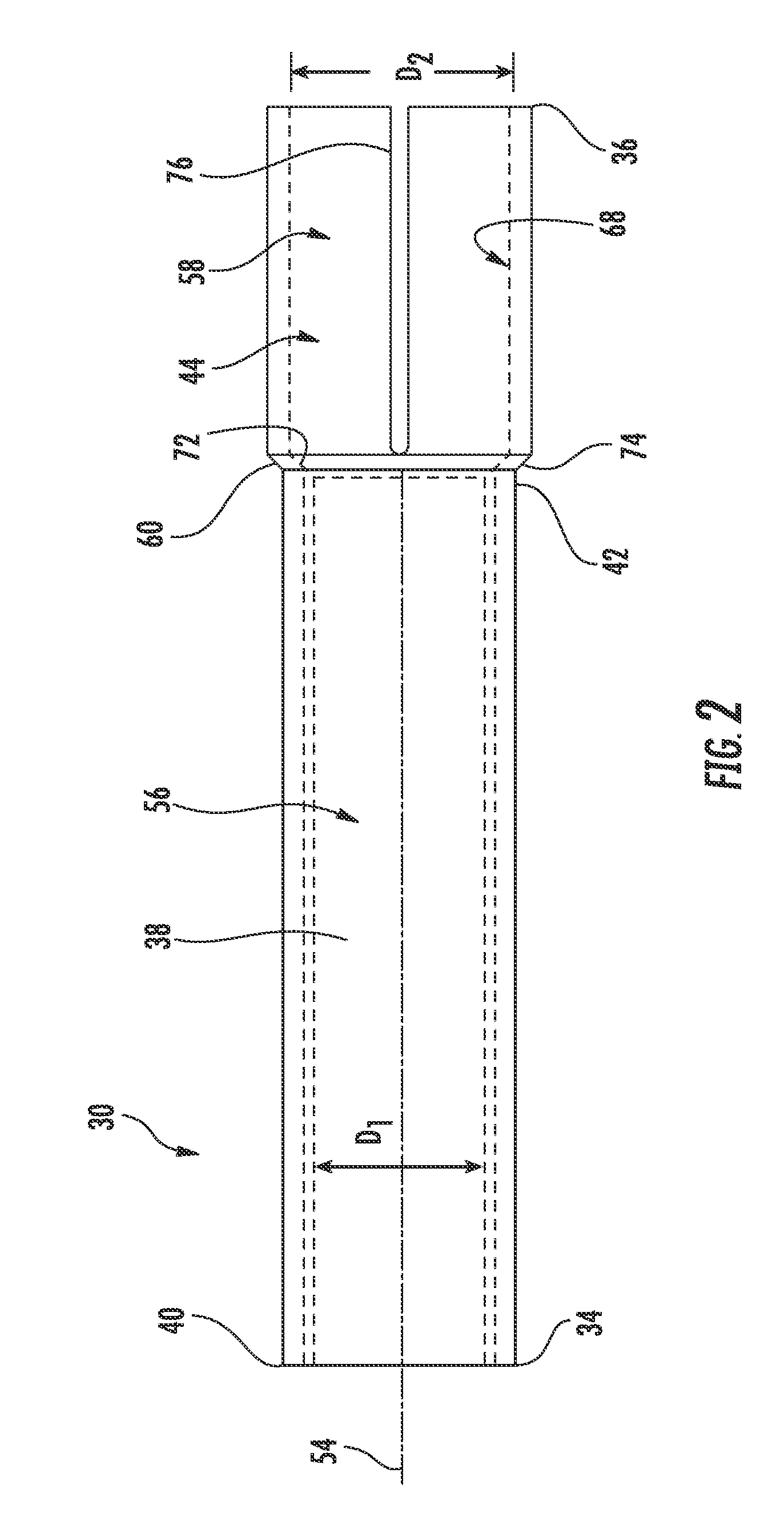

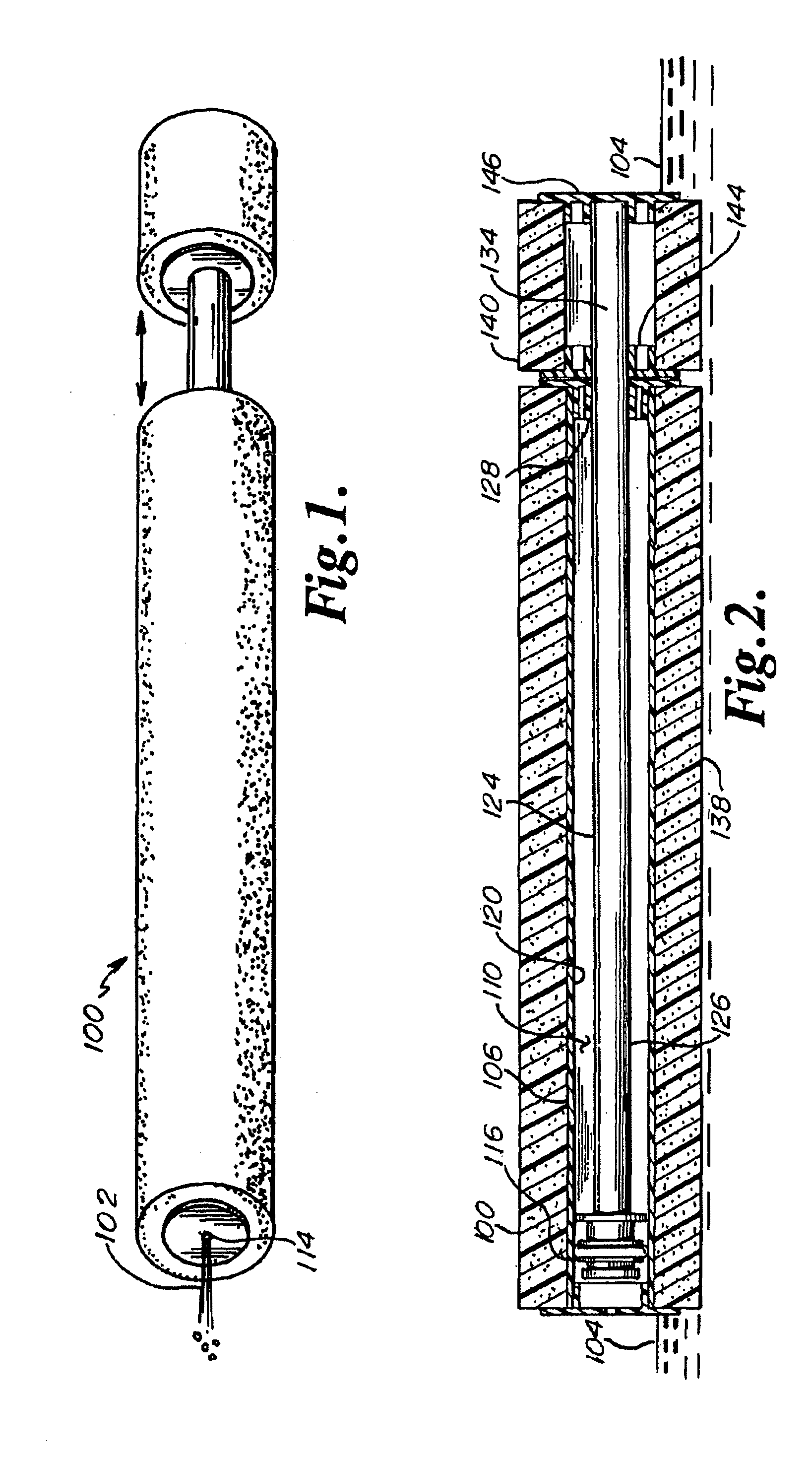

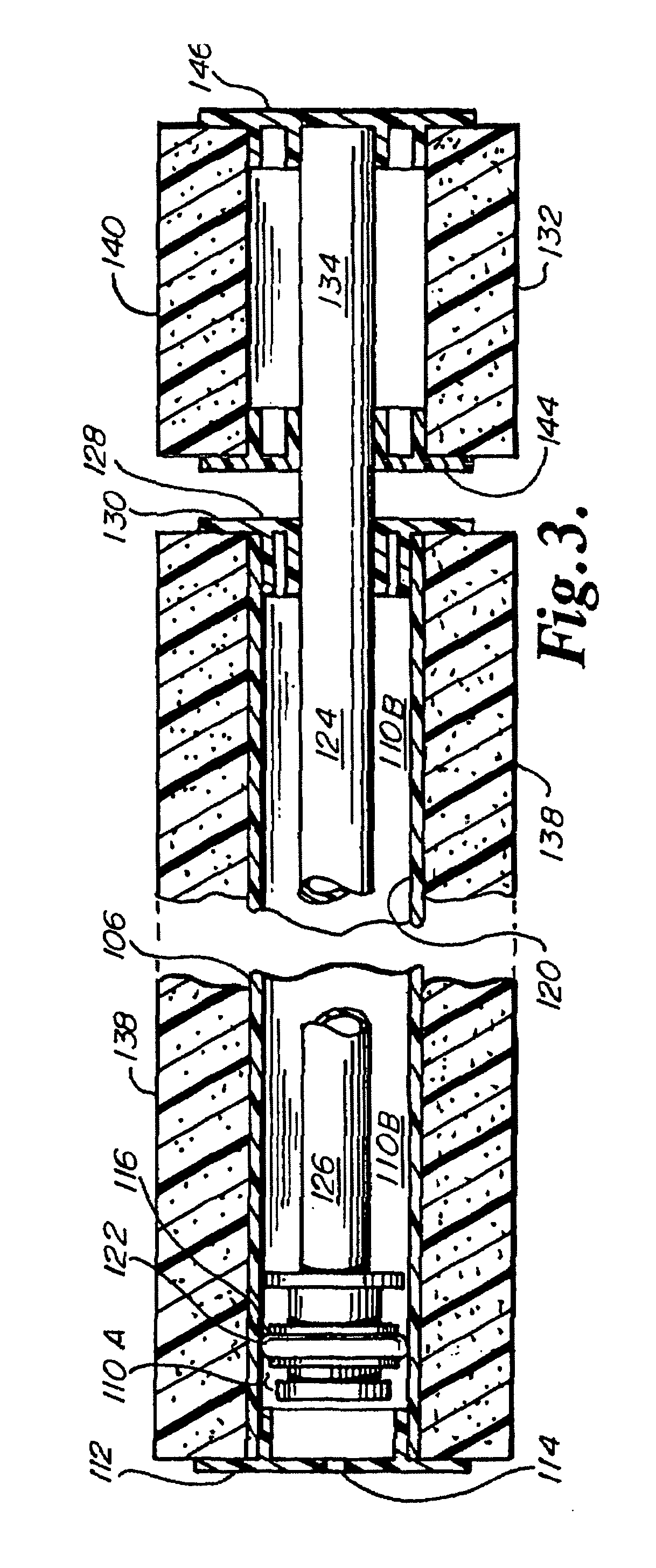

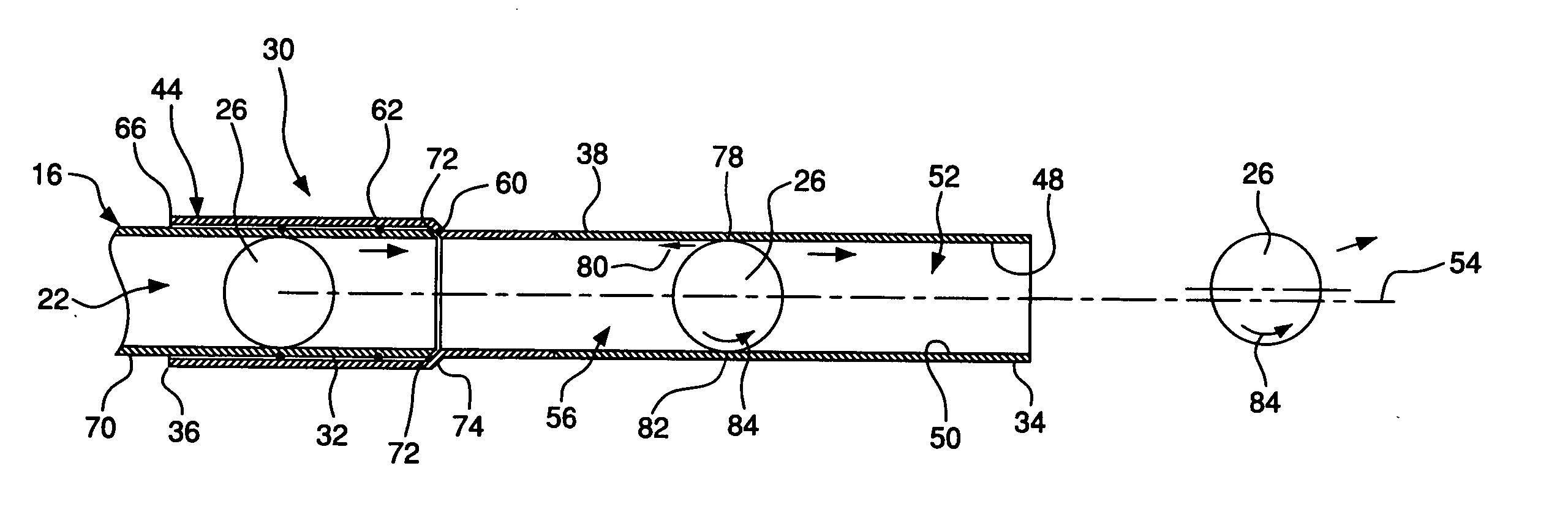

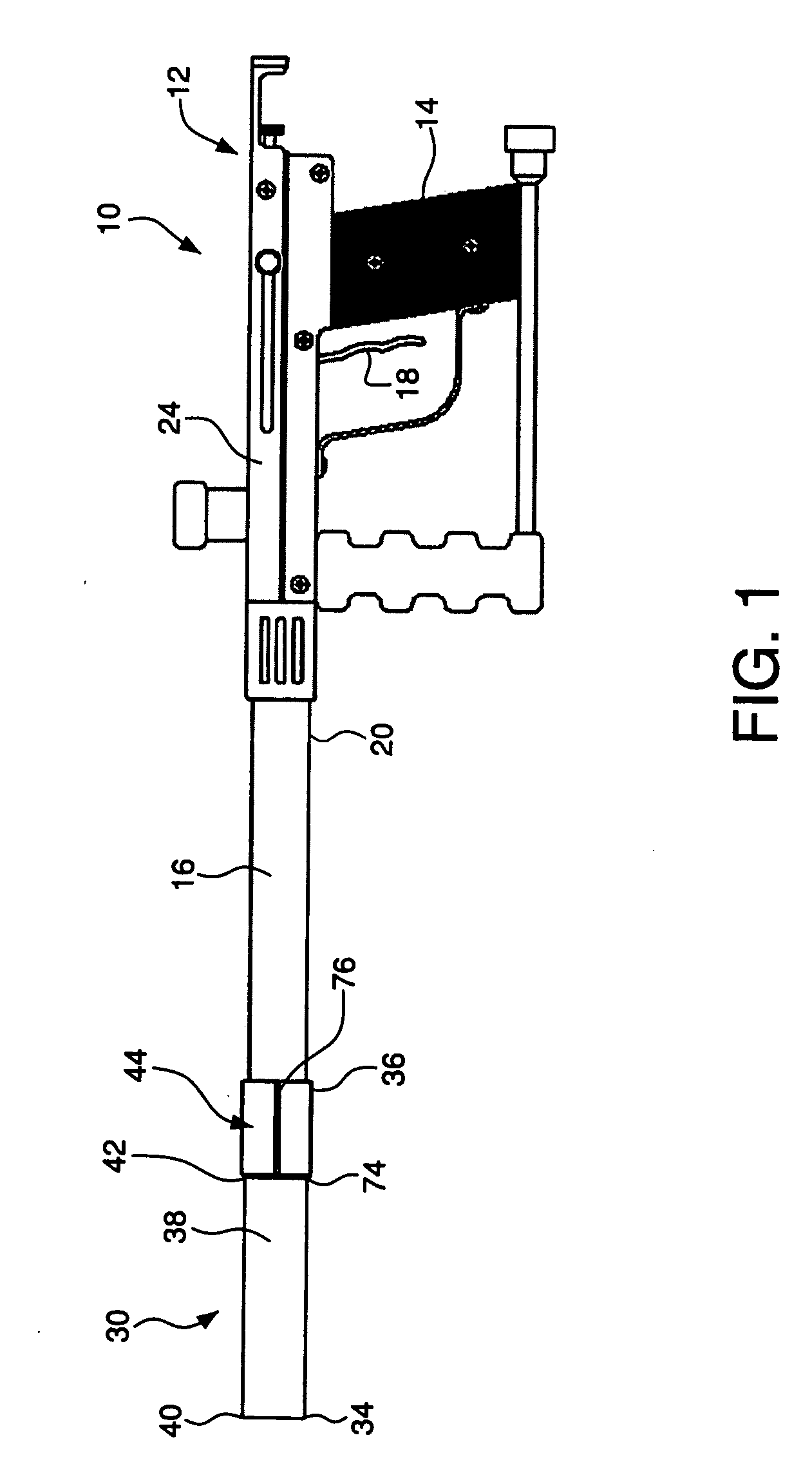

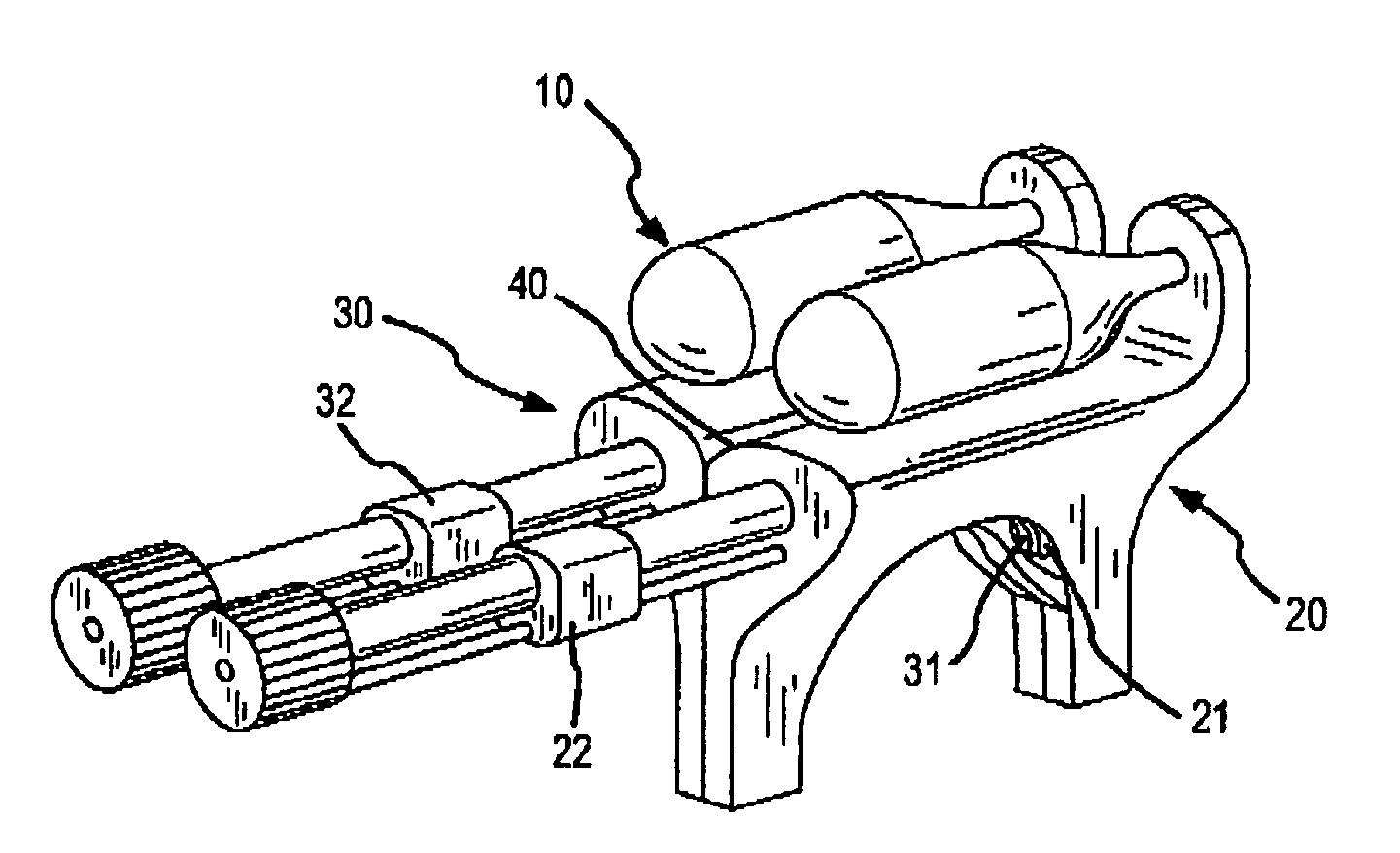

Liquid disrupter with reduced recoil

InactiveUS6408731B1Avoid collateral damageImprove efficiencyMissile propulsionLiquid ejecting gunsDetonationGun barrel

The disrupter (16) includes an elongated hollow barrel (18) having a cylindrical inner chamber (20), a closed rear (26) end and an opened front end (22), the latter closed with a front frangible seal (38). A channel member (46) partly surrounds an intermediate portion of the barrel, and is securely attached thereto. A pair of recoil channels (76, 78) extend from the barrel inner chamber, radially outwardly and rearwardly through the barrel and the channel member, and are linked to rearwardly oriented recoil tubes (52, 54) which have opened rear end portions (60, 62) closed with rear frangible seals (64, 66). In use, a cartridge (90) including an explosive charge (88) is to be inserted in the barrel inner chamber at its rear end, and the barrel, recoil channels and recoil tubes (52, 54) are to be filled with water. The frangible seals (38, 64, 66) prevent the water from leaking out of the disrupter while it is positioned near a bomb to be deactivated. A trigger (36) is linked to the disrupter, and more particularly to the cartridge, to remotely detonate the explosive charge. Upon the explosive charge being detonated, a portion of the water is propelled and ejected at high velocity out through the barrel front end, rupturing the front frangible seal, to puncture the bomb outer shell and deactivate the bomb inner detonating components. Another portion of the water is redirected through the side recoil channels and recoil tubes, rupturing the rear frangible seals, to be ejected rearwardly out of the disrupter. The recoil created by the detonation of the explosive charge which ejects the water through the barrel front end, is at least partially counteracted by the water being laterally and rearwardly redirected to be ejected rearwardly out through the recoil tubes. The recoil tubes have at their rear ends (60, 62) transverse blades (73, 74) for wide angle dispersal of the fluid jet being ejected rearwardly.

Owner:PROPARMS

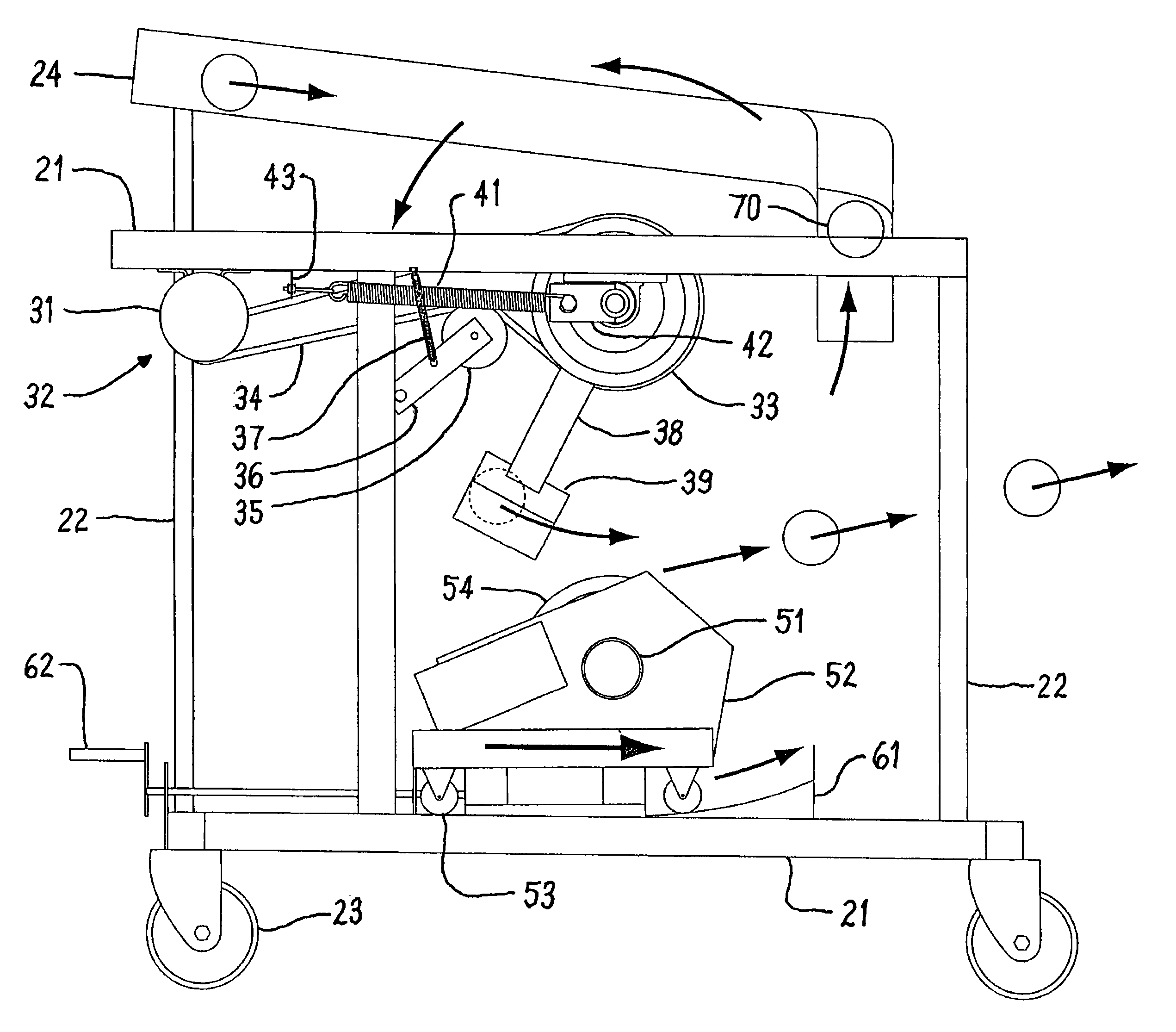

Pitching machine

InactiveUS7806788B1Light weightReduce manufacturing costLiquid ejecting gunsCompressed gas gunsEngineeringMechanical engineering

A pitching machine contains a pitching arm that vertically rotates at a speed of about 5 to 15 rpm, picks up a ball from the ball cradle at a pick-up point in its rotation, and then releases the ball at a release point in its rotation to provide a first velocity component to the ball. The pitching machine also contains a wheel that vertically rotates at a speed of about 300 to 3000 rpm. The wheel is positioned at the release point of the pitching arm to provide a second velocity component to the ball and to pitch the ball at an initial launch angle.

Owner:NEUMAN DANIEL R

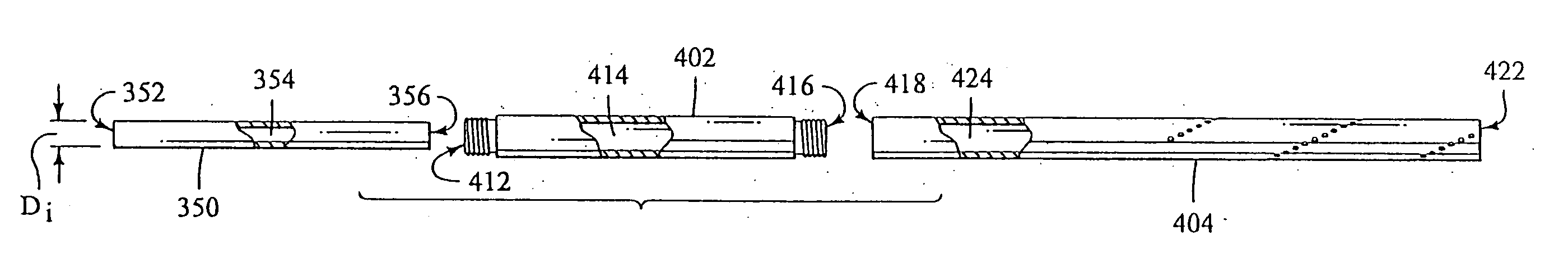

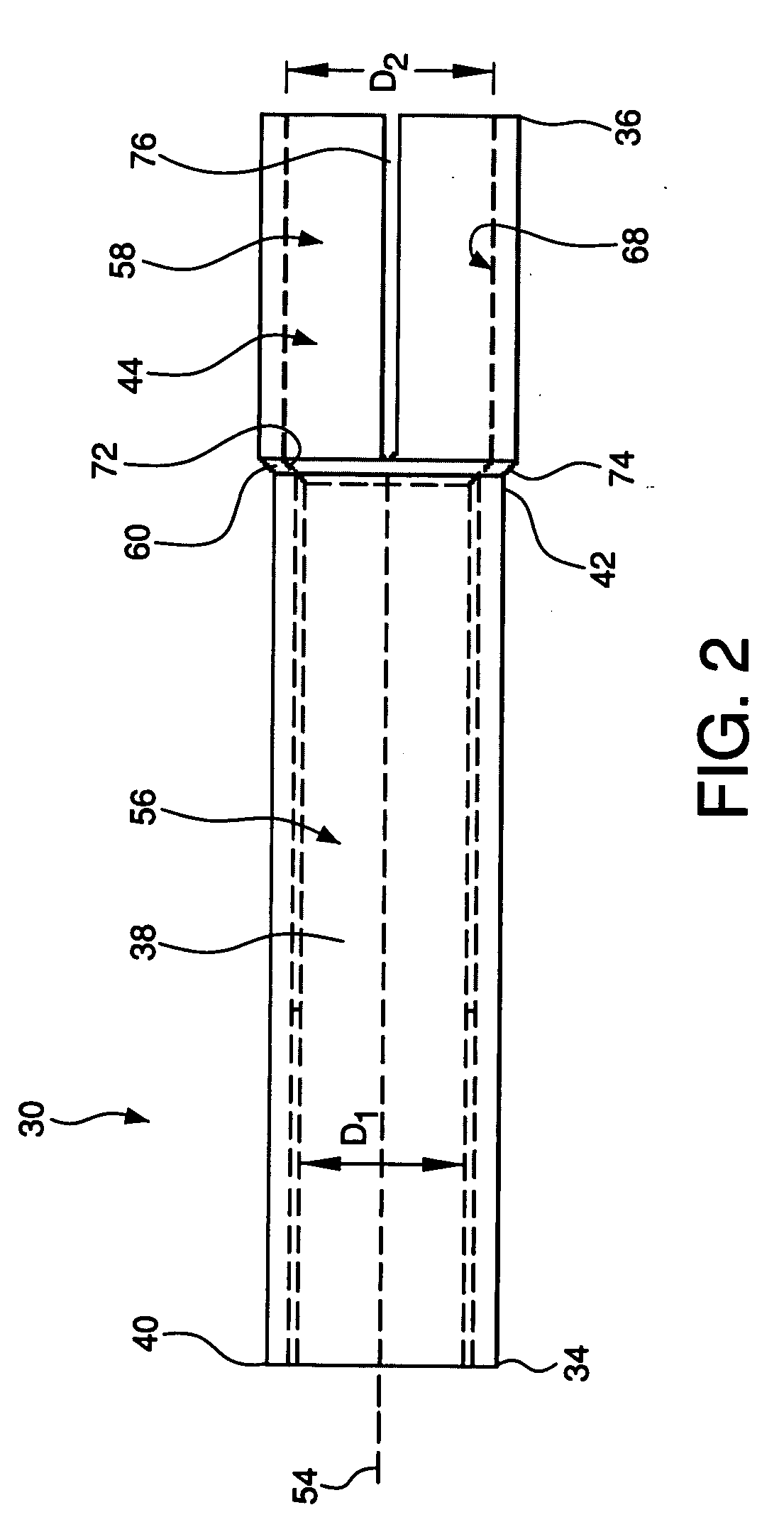

Adjustable feed tube

ActiveUS20060032488A1Easy to operateEasy to adjustPipe elementsLiquid ejecting gunsEngineeringMechanical engineering

Owner:KEE ACTION SPORTS I +2

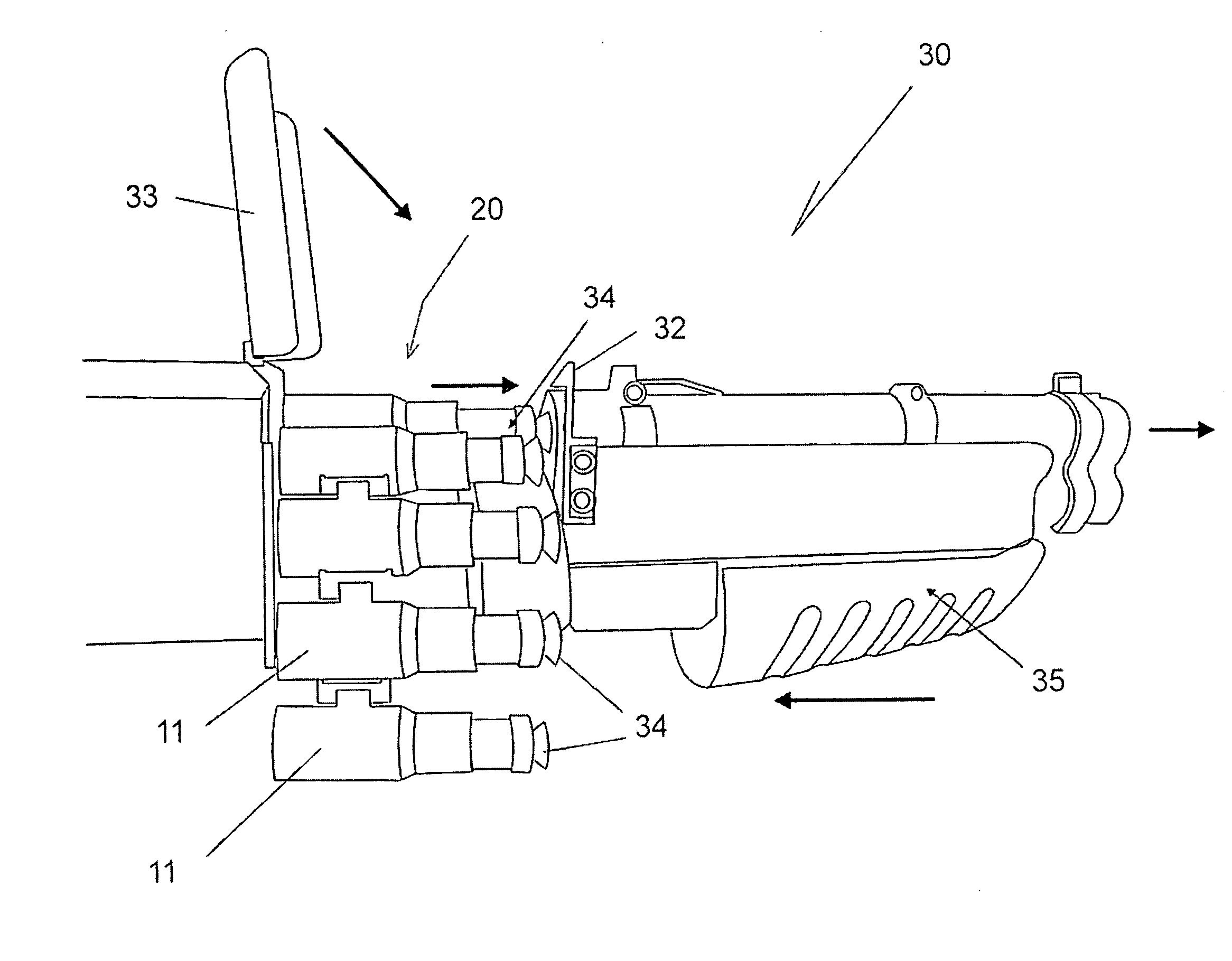

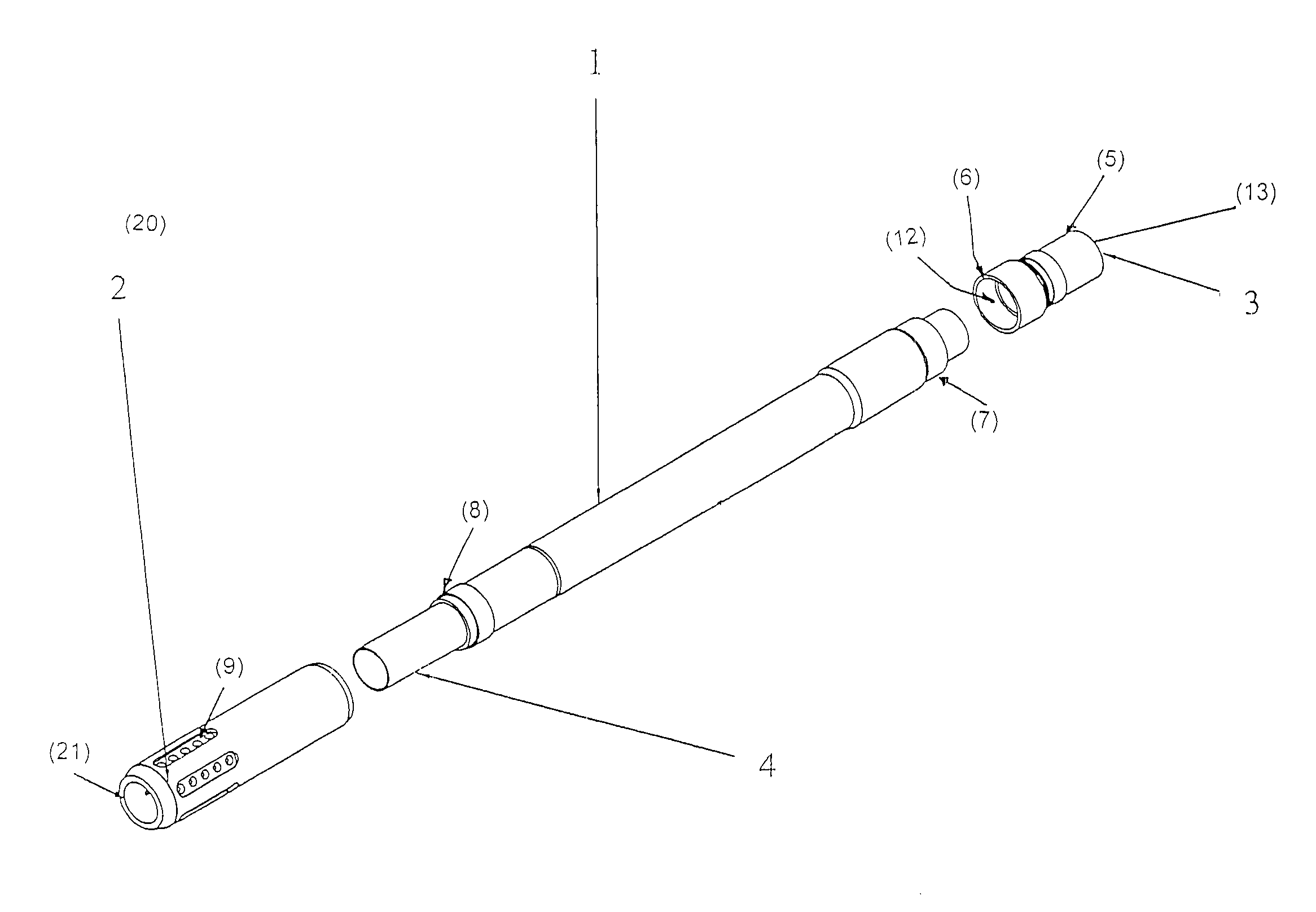

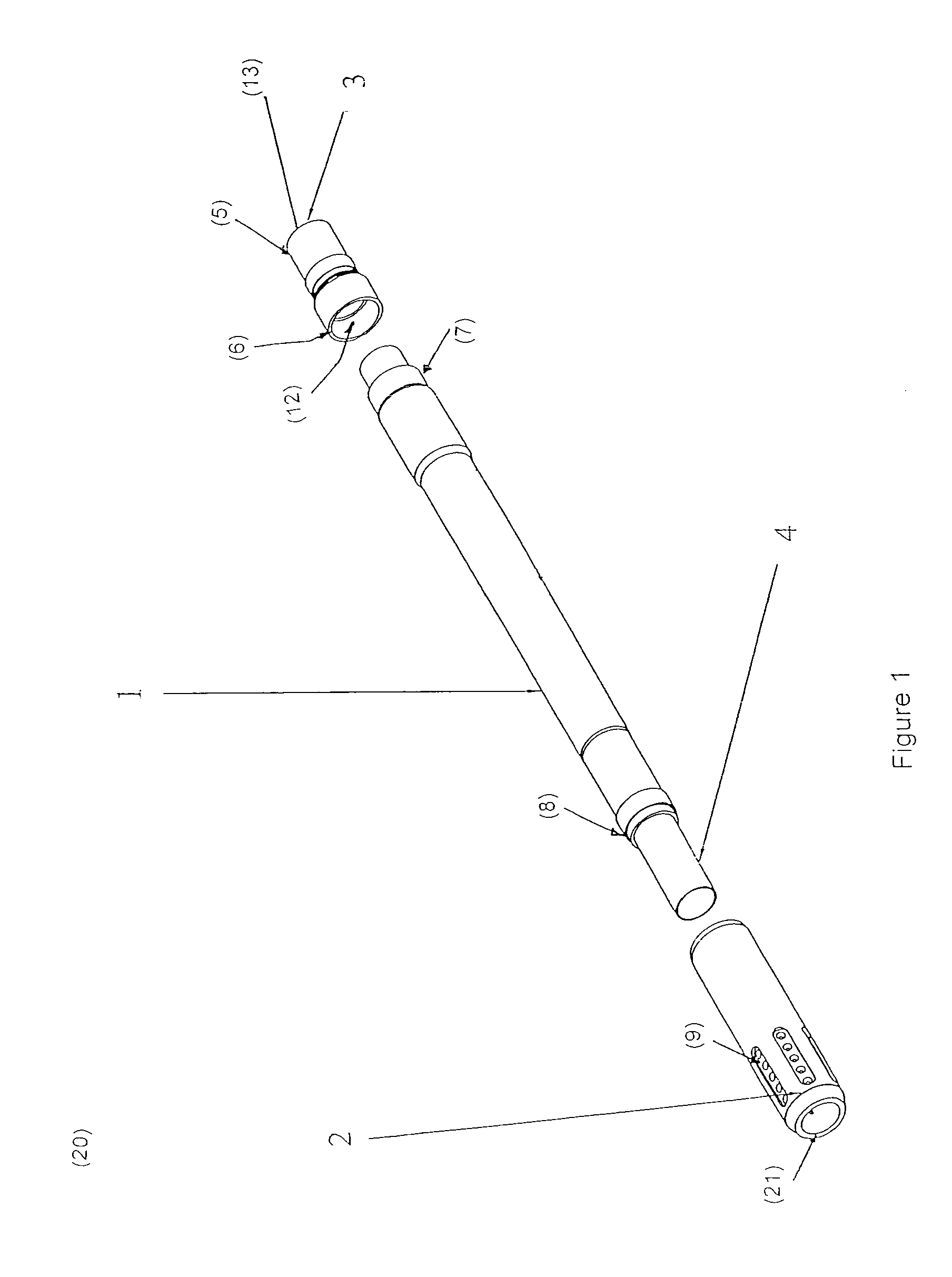

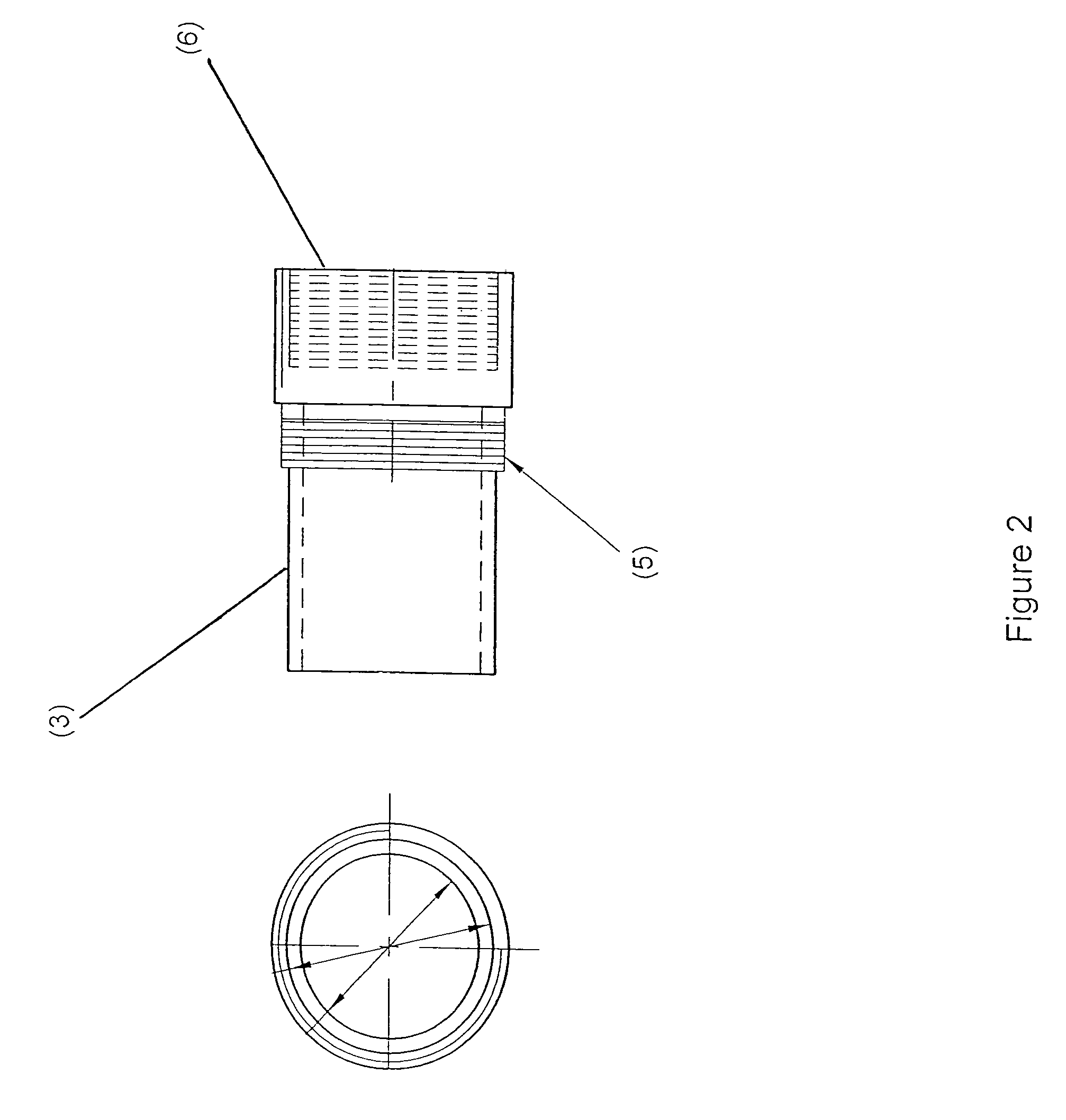

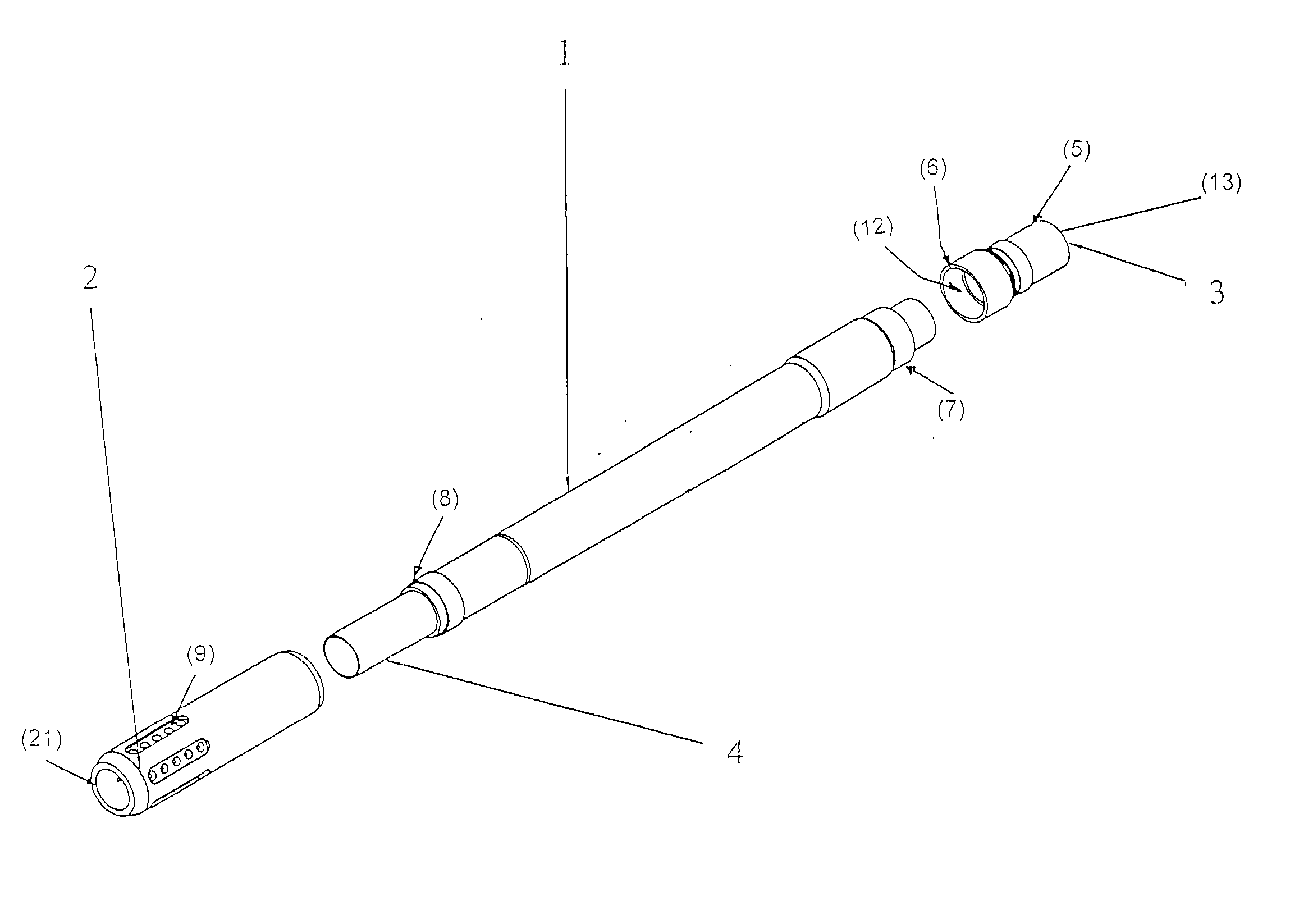

Water pressured destruct enhancer

InactiveUS6896204B1More focused energyImprove permeabilityDust removalFire preventionBomb deviceEngineering

The present invention comprises an extension tube that attaches to the bore end of a water jet producing device that is used to render safe improvised explosive devices by disrupting the firing train of said devices. The present invention comprises an extension tube having a sudden enlargement of cross section, that may be formed by adjusting the dimensions of the interior diameter of the extension tube, at the point of attachment, and a series of apertures in the attachment tube. The extension tube provides a more uniform jet of water with more focused energy by containing the jet until breech pressures are vented. Better control of the water jet will be maintained during firing operations. Further, more energy may be put into the water jet to accomplish specific tasks.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Barrel attachment for gas gun

This invention is a barrel attachment attachable to the firing end of the barrel of a compressed gas gun and a method of using the same. The barrel attachment allows a user to spin a projectile fired from the gas gun just before it exits the barrel attachment. This spin alters the projectile's normally straight trajectory; in other words, it makes the projectile curve. The barrel attachment is adjustable. In the preferred embodiment, the user or shooter can adjust the amount of spin and thereby the amount that the projectile curves by rotating an adjustment sleeve about the barrel attachment, which causes contact pads to protrude into the passage of the barrel attachment. In the preferred embodiment, the user can adjust the direction of curve by rotating the barrel attachment about the gun barrel.

Owner:KORE OUTDOOR US INC

Ammunition chain for toy projectiles

A link for a toy ammunition chain made up of a plurality of links hinged together side-by-side in articulated fashion includes a cylindrical body adapted to receive a soft projectile. A first hinge component extends laterally from the body and has a pair of hinge pins. A second hinge component extends laterally from the body at a position opposite the first hinge component and has a pair of recesses each for pivotally receiving a hinge pin of an adjacent link in the chain.

Owner:BUZZ BEE TOYS

Unloading Bolt

A device for allowing a crossbow to be released from a drawn position without damaging the crossbow. The device may comprise an elongated member having a substantially cylindrical shape that can be positioned on the upper surface of the barrel of a crossbow. The device may comprise a notched end shaped to receive the bowstring of the crossbow and allows the device to be projected by the bowstring upon actuation of the crossbow's trigger lever.

Owner:HUNTERS MFG CO INC

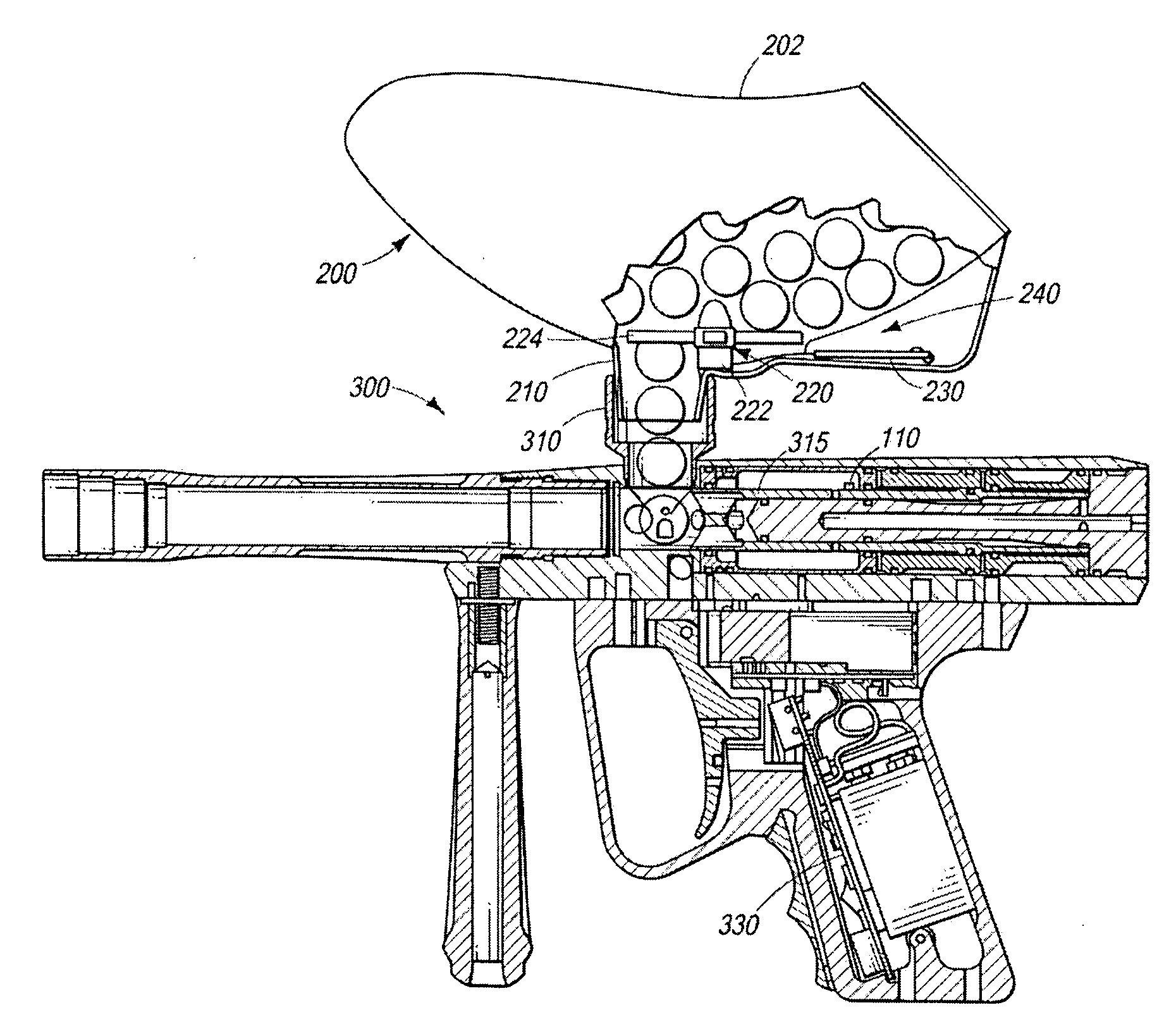

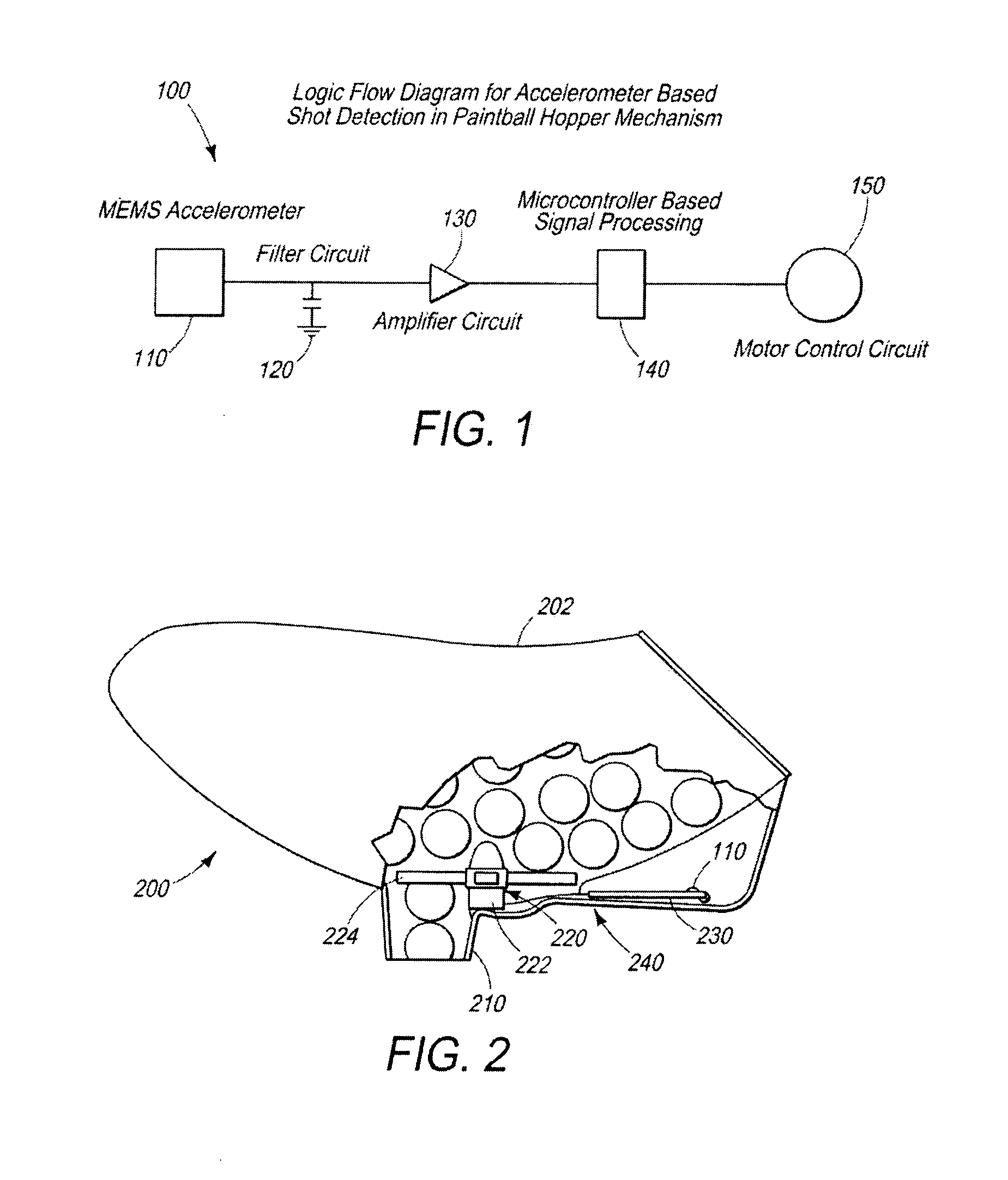

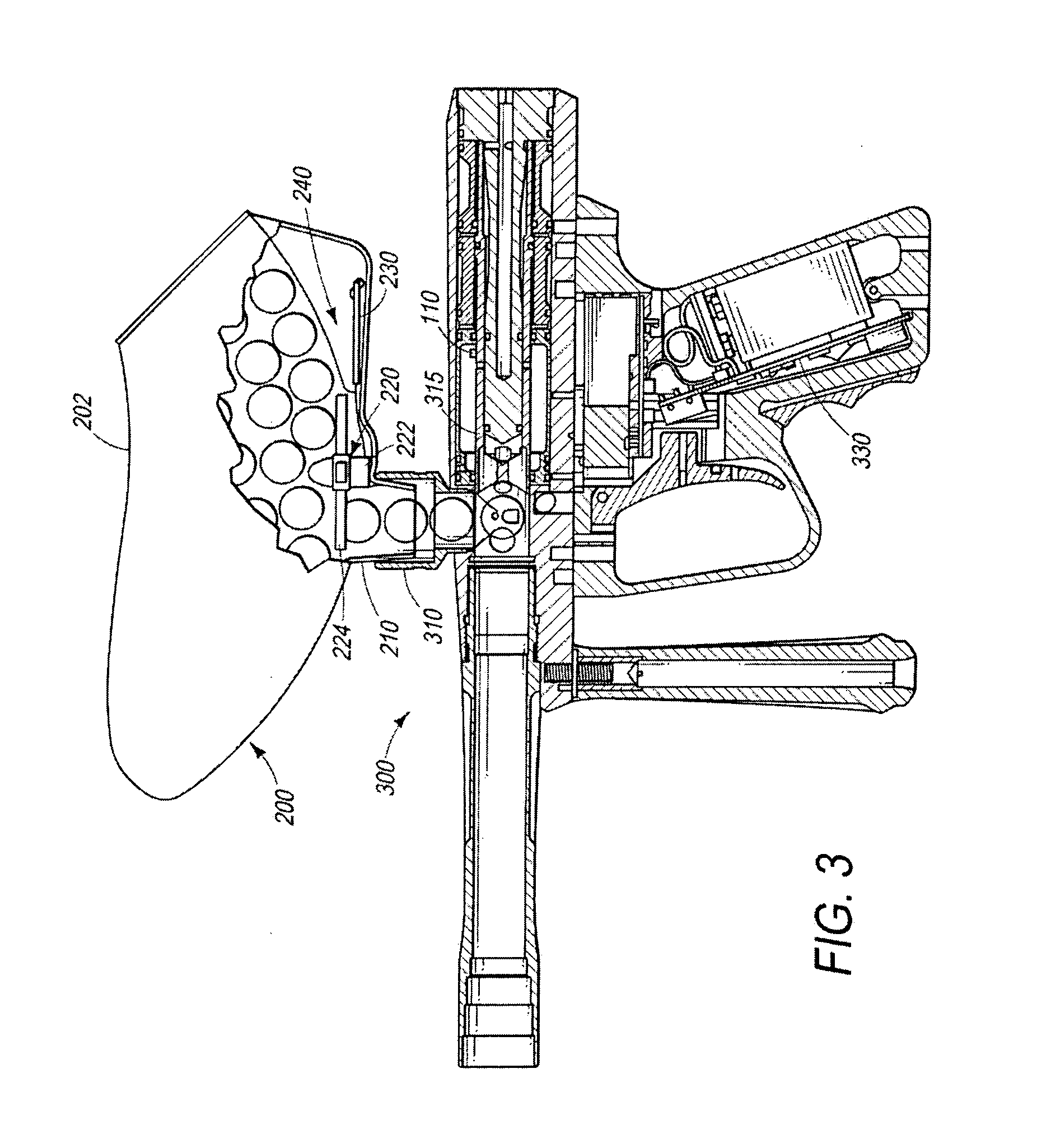

Acceleration-sensing loader activation system and method

InactiveUS20080178859A1Liquid ejecting gunsAmmunition loadingDigital signal processingAudio power amplifier

An acceleration-sensing loader activation system can include an acceleration sensor configured to generate an electrical signal corresponding to the magnitude and periodicity of movement of a marker or loader body or a marker or loader component. A signal filter circuit can be arranged in communication with the acceleration sensor to receive and filter the electrical signal. A signal amplifier circuit can be arranged in communication with the signal filter circuit to amplify a signal from the signal filter circuit and transmit the amplified signal to a signal processing circuit. The signal processing circuit can be programmed to evaluate the incoming signal and determine whether it corresponds to a desired actuation event (such as a firing event). If the signal processing circuit determines that a desired actuation event has occurred, it can then send a control signal to a control circuit to activate a feed device of the loader. A method of activating a loader assembly preferably includes using an acceleration sensor to detect movement of a paintball marker or loader's operating mechanisms and / or body and to output an electrical signal proportional to the magnitude and periodicity of the movement. The resulting signal is then preferably processed using filtering, amplification, and digital signal processing circuitry to determine whether the movement corresponds to a desired actuation event and, if so, to provide an activation signal to activate a loading operation of the paintball loader's internal feed mechanism.

Owner:SMART PARTS

Amusement device and method

The subject invention provides an amusement device and method of play using the device, wherein the device includes a gun for shooting a liquid and / or a light beam, wherein the gun comprises a generally elongated barrel, a tank for containing a liquid, a source of power, a pump for pressurizing the tank, valve structures suitable for controlling the flow of the liquid, at least one light source, and a trigger mechanism which may selectively cause a stream of liquid to be discharged and one or more of the light sources to be activated.

Owner:JAKKS PACIFIC +1

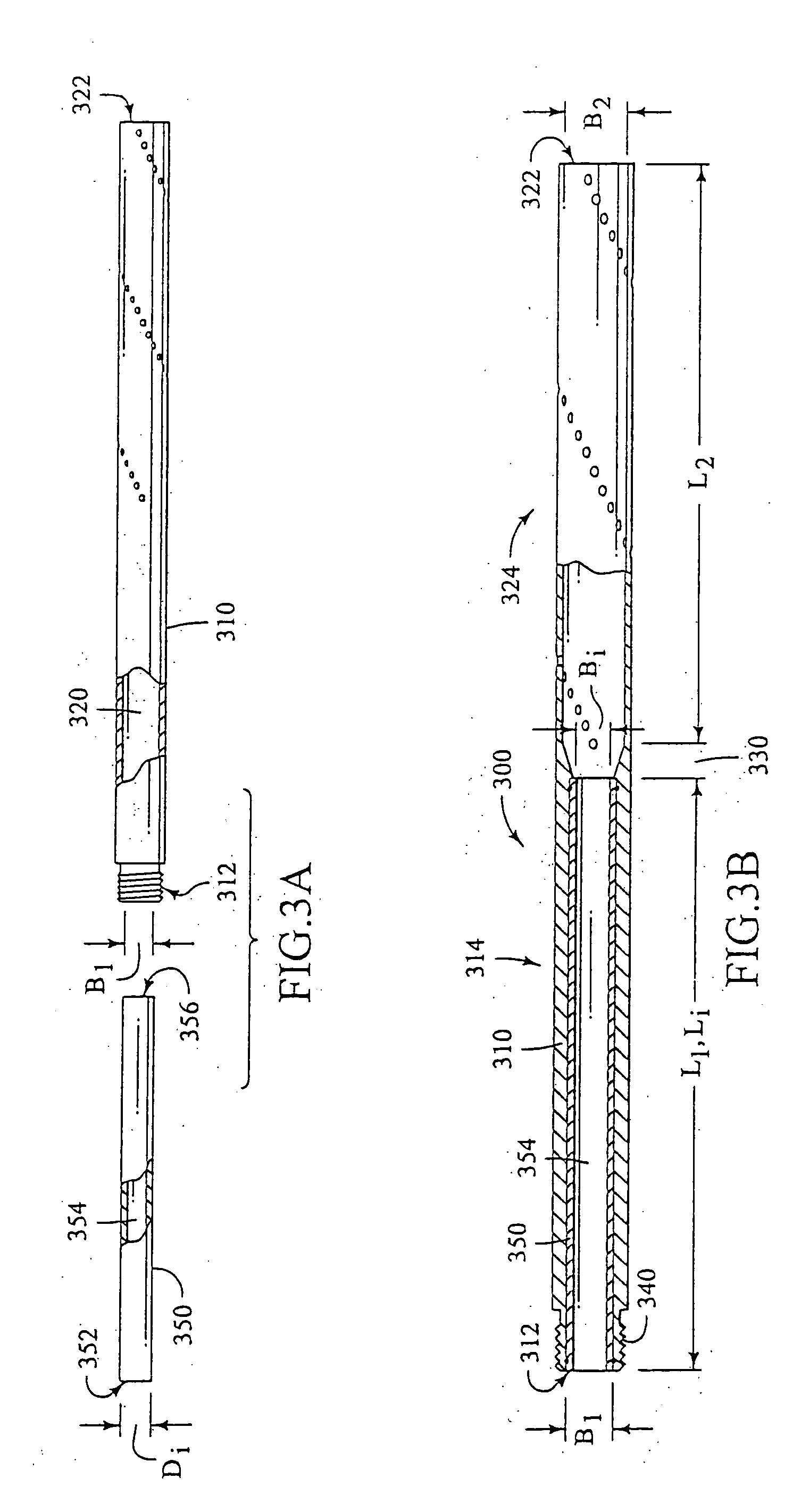

Barrel assembly with removable barrel insert for pneumatic paintball gun

InactiveUS20050091901A1Conveniently adaptedPerformance maximizationLayered productsLiquid ejecting gunsEngineeringGun barrel

A barrel assembly for a pneumatic paintball gun includes a barrel body and a barrel insert. The barrel body has a breech end, a muzzle end, and a barrel bore extending longitudinally through the barrel body from the breech end to the muzzle end. The barrel insert has a breech end, a distal end, and an insert bore, and is configured to be removably housed within a breech portion of the bore of the barrel body. The breech end of the barrel body is configured to attach to a breech end of the paintball gun. The barrel insert collaborates with the barrel body to provide a firing bore for the barrel assembly which guides a paintball fired from the breech end of the gun through the barrel and out the muzzle end of the barrel body. The barrel insert can be constructed having a thin, flexible wall so as to permit lateral deformation of the barrel insert. This lateral flexibility enables the insert to dynamically adapt to the shape and diameter of the paintball, thereby increasing the efficiency of the energy transfer from the compressed gas to the paintball.

Owner:KORE OUTDOOR US INC

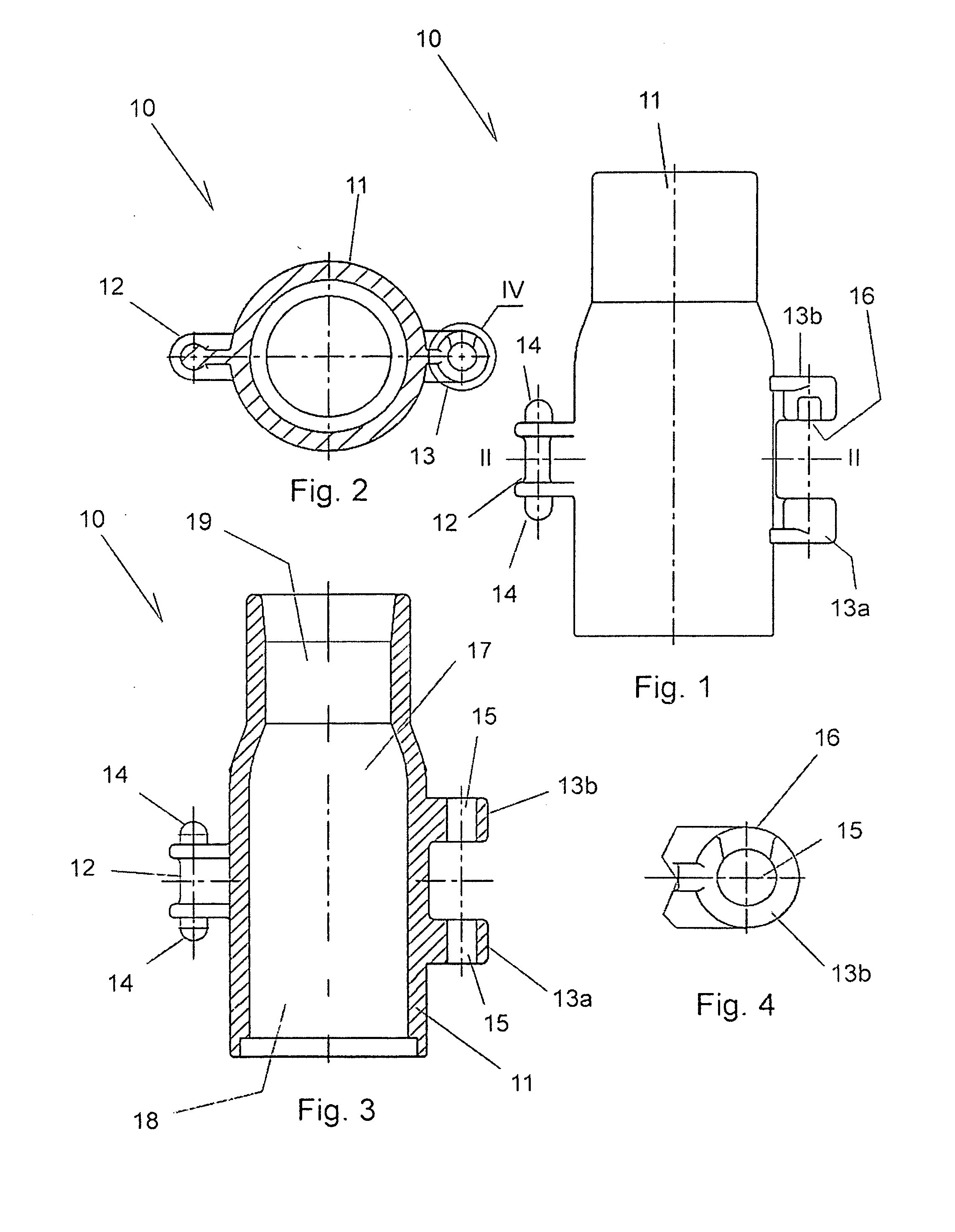

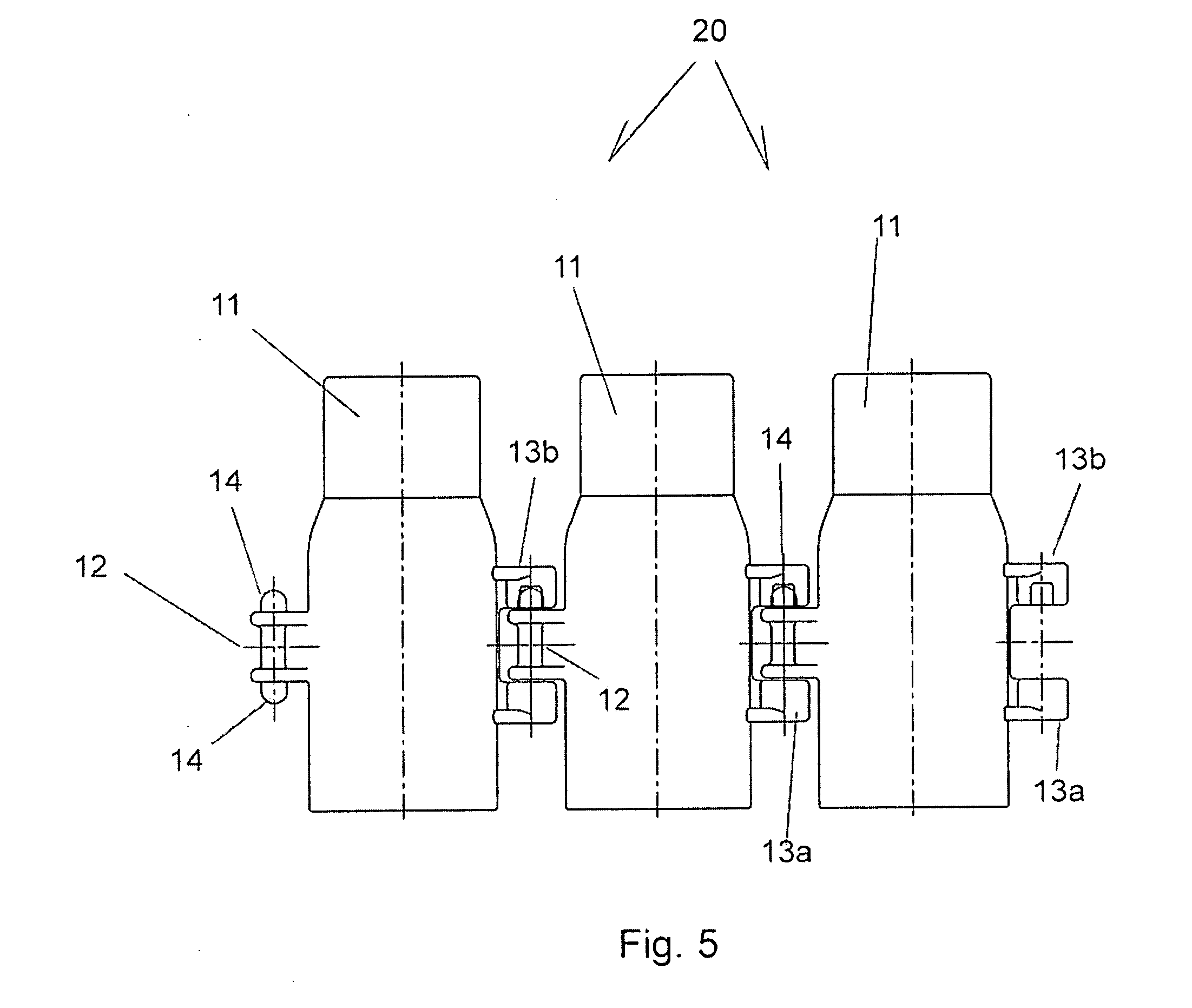

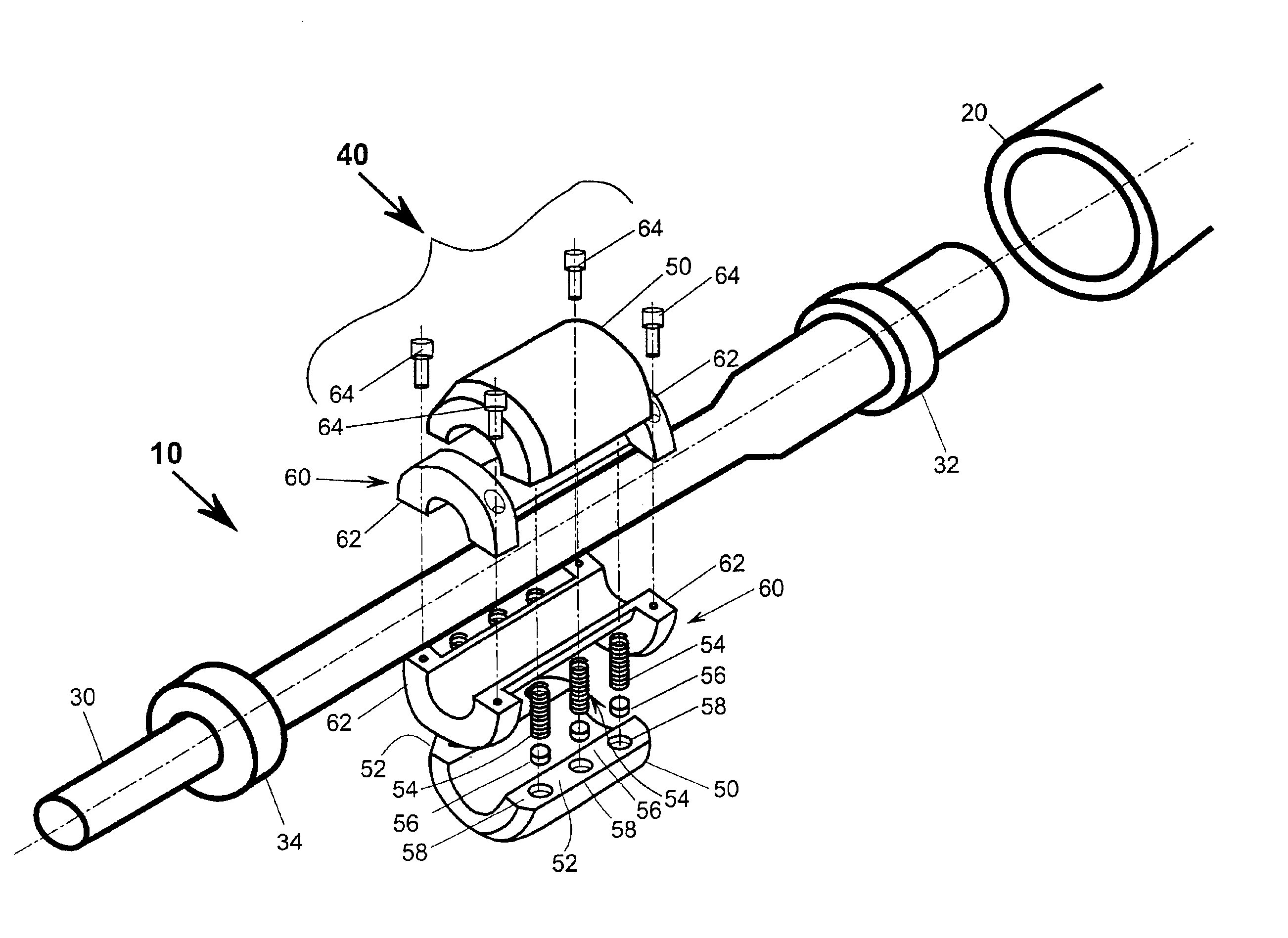

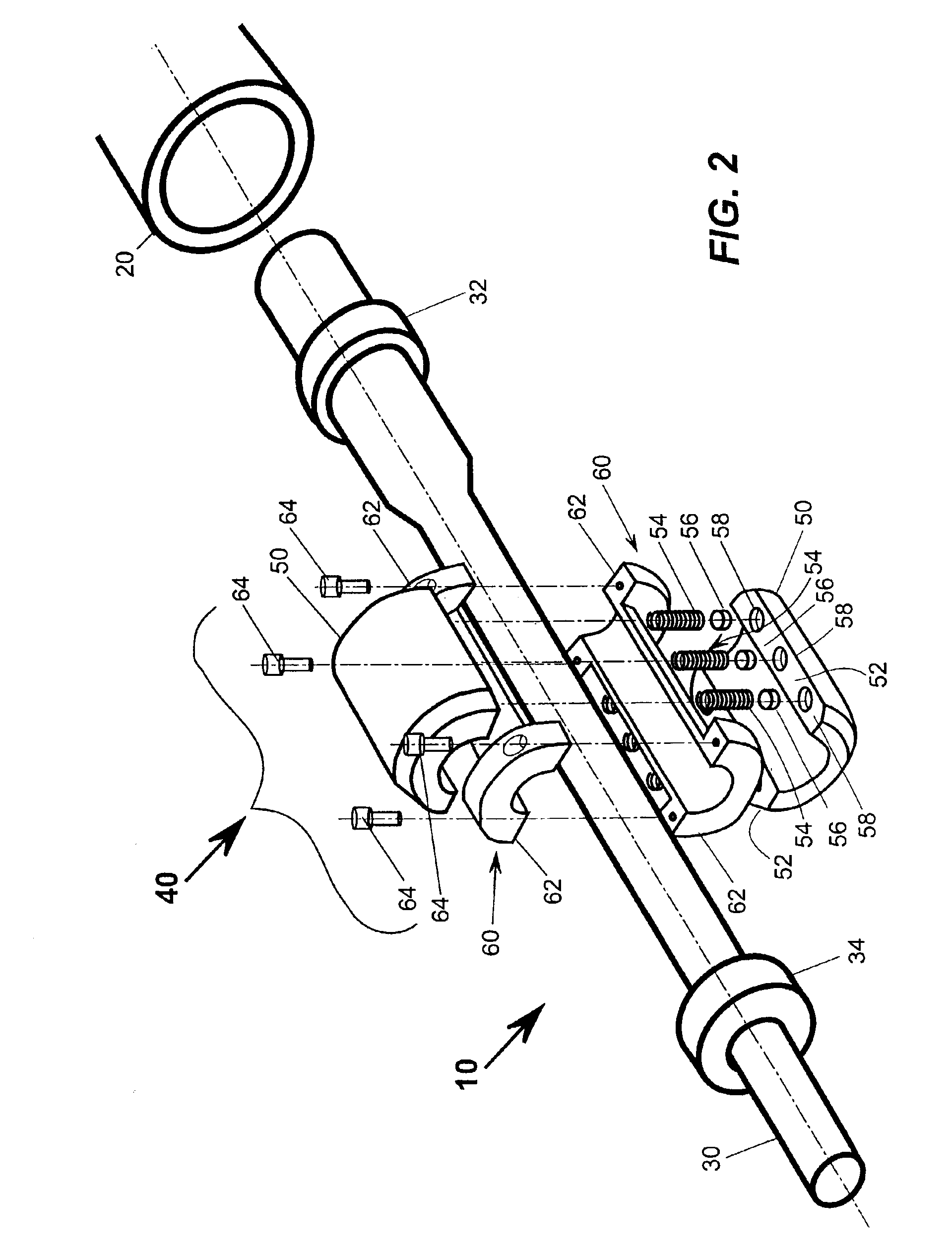

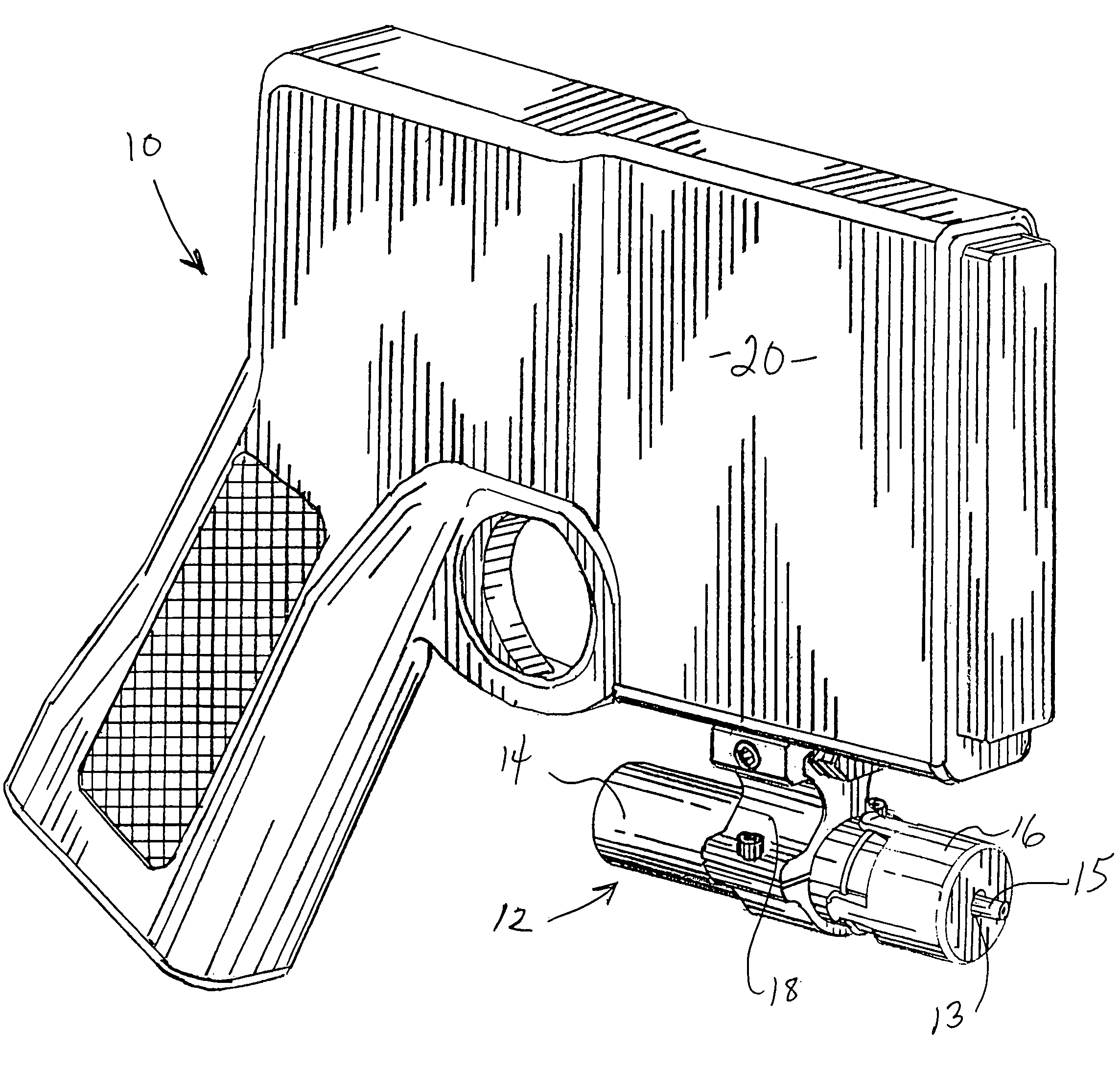

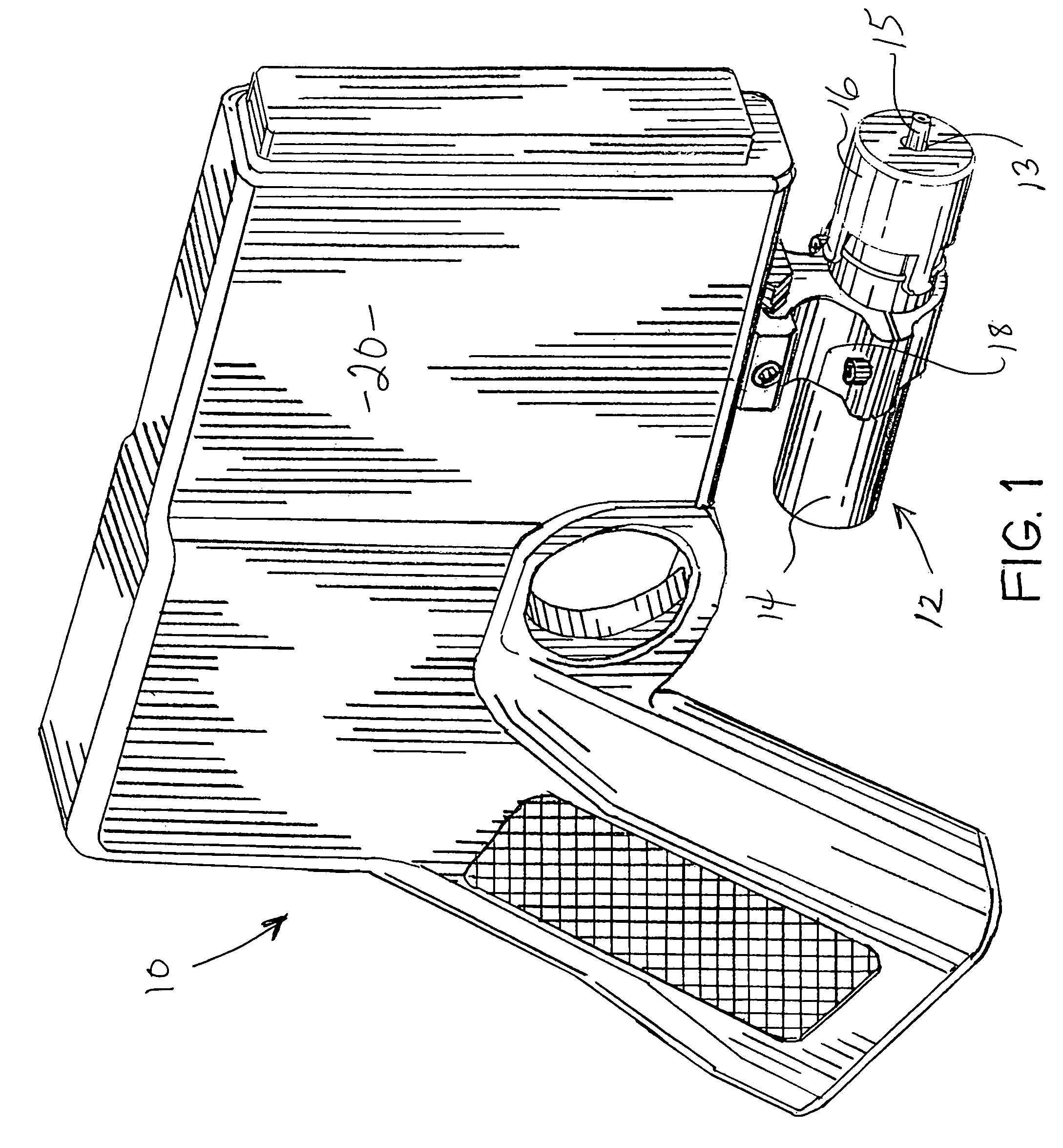

Recoil mitigation device

InactiveUS6889594B2Recoil is mitigatedPrevent lateral movementLiquid ejecting gunsGun mountingsEngineeringBrake shoe

A recoil mitigation apparatus for a projectile-firing device, such as an explosives disrupter, is provided. At least one brake shoe is positioned proximate the projectile-firing device and means are provided for urging the at least one brake shoe toward the projectile-firing device. The urging of the at least one brake shoe provides a frictional force to mitigate the recoil of the projectile-firing device. In a preferred embodiment, at least one pair of brake shoes are provided. In a further preferred embodiment, the each of the at least one pair of brake shoes are positioned in a facing, spaced apart relationship and the at least one pair of brake shoe combination is positioned in a coaxial relationship to the projectile-firing device.

Owner:BATTELLE MEMORIAL INST

Pneumatic paintball marker, universal barrel, adaptor and insert combination

InactiveUS7076905B2Easy to adaptThe process is simple and convenientWeapon assembly/disassemblyLiquid ejecting gunsEngineeringGun barrel

The present invention comprises a pneumatic paintball marker for use with an adaptor, the pneumatic paintball marker comprising a marker body which has a back portion and a front portion. The back portion is adapted to receive a paintball and the front portion is adapted to detachably connect with a barrel to discharge a paintball through the barrel. The barrel comprising a hollow elongated cylindrical tube, which comprises an interior diameter, a breech end and a connection means at the breech end and adapted for connection with the front portion of the marker and a paintball discharge muzzle end.

Owner:ZOUBOULAKIS TERRY

Floating squirting toy

A squirting toy is comprised of a cylindrical housing and a piston that slides within to force water into or out of the housing via a hole therein. The housing is encased within a shell creating a water impervious volume sufficient for the toy to float in water. The shell is soft, so that the gun is not a safety hazard when left floating in a swimming pool. Handles associated with one or both actuating portions of the squirting toy are provided for gripping and operating the squirting toy more effectively.

Owner:EASEBON SERVICES

Pneumatic paintball marker, universal barrel, adaptor and insert combination

InactiveUS20050066953A1Extend play timeEasy to adaptWeapon assembly/disassemblyLiquid ejecting gunsEngineeringGun barrel

The present invention comprises a pneumatic paintball marker for use with an adaptor, the pneumatic paintball marker comprising a marker body which has a back portion and a front portion. The back portion is adapted to receive a paintball and the front portion is adapted to detachably connect with a barrel to discharge a paintball through the barrel. The barrel comprising a hollow elongated cylindrical tube, which comprises an interior diameter, a breech end and a connection means at the breech end and adapted for connection with the front portion of the marker and a paintball discharge muzzle end.

Owner:ZOUBOULAKIS TERRY

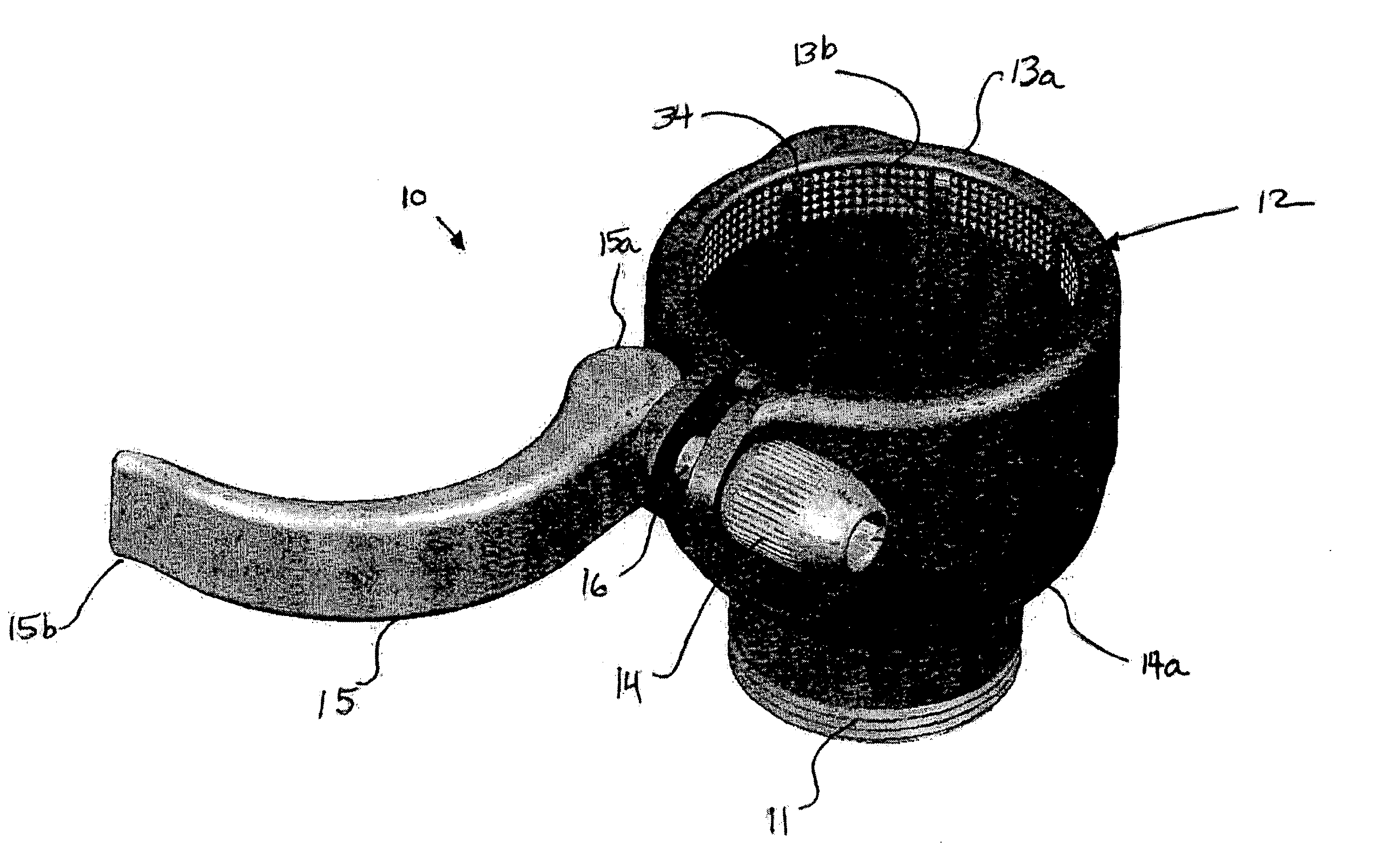

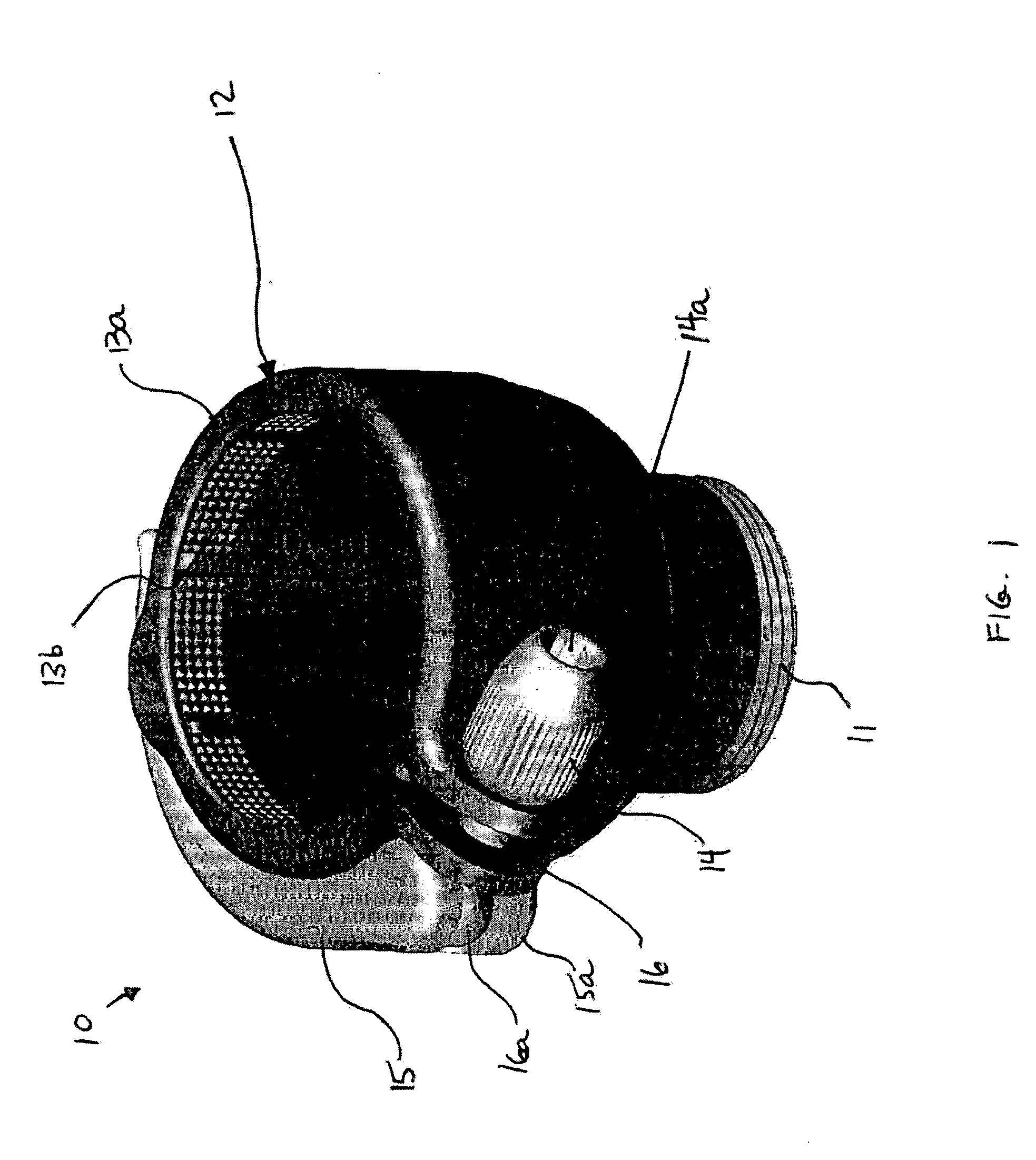

Housing for chemical irritant dispenser

A housing can be mounted to a pistol or other weapon and conveniently fired therefrom and can be used as a discrete weapon itself. A cap has a central aperture which secures the nozzle and / or valve stem of a canister of chemical irritant from movement and is secured to the proximal end of a hollow tube. A feature of the new invention is a slot access running along the length of the tube for some distance from its distal end. The tube may be either open or closed at its distal end. Toward the distal end of the tube, an interior ridge or stop cooperates with the cap aperture to secure the canister of irritant. When a canister is installed in the housing, the operator can release an irritant spray axially from the canister by pressing a digit against the side of the canister's storage cylinder and, thereby, displace its longitudinal axis along an arc. The housing need have no other mechanisms, except the housing and canister. This method also allows for convenient triggering of a spray from a canister within the housing when the housing is secured under or adjacent to the barrel of a handgun. In some embodiments an actuator compresses against a spring-loaded pusher to contact the side of the storage cylinder and move the longitudinal axis of the storage cylinder to release a spray.

Owner:LAW ENFORCEMENT ASSOC

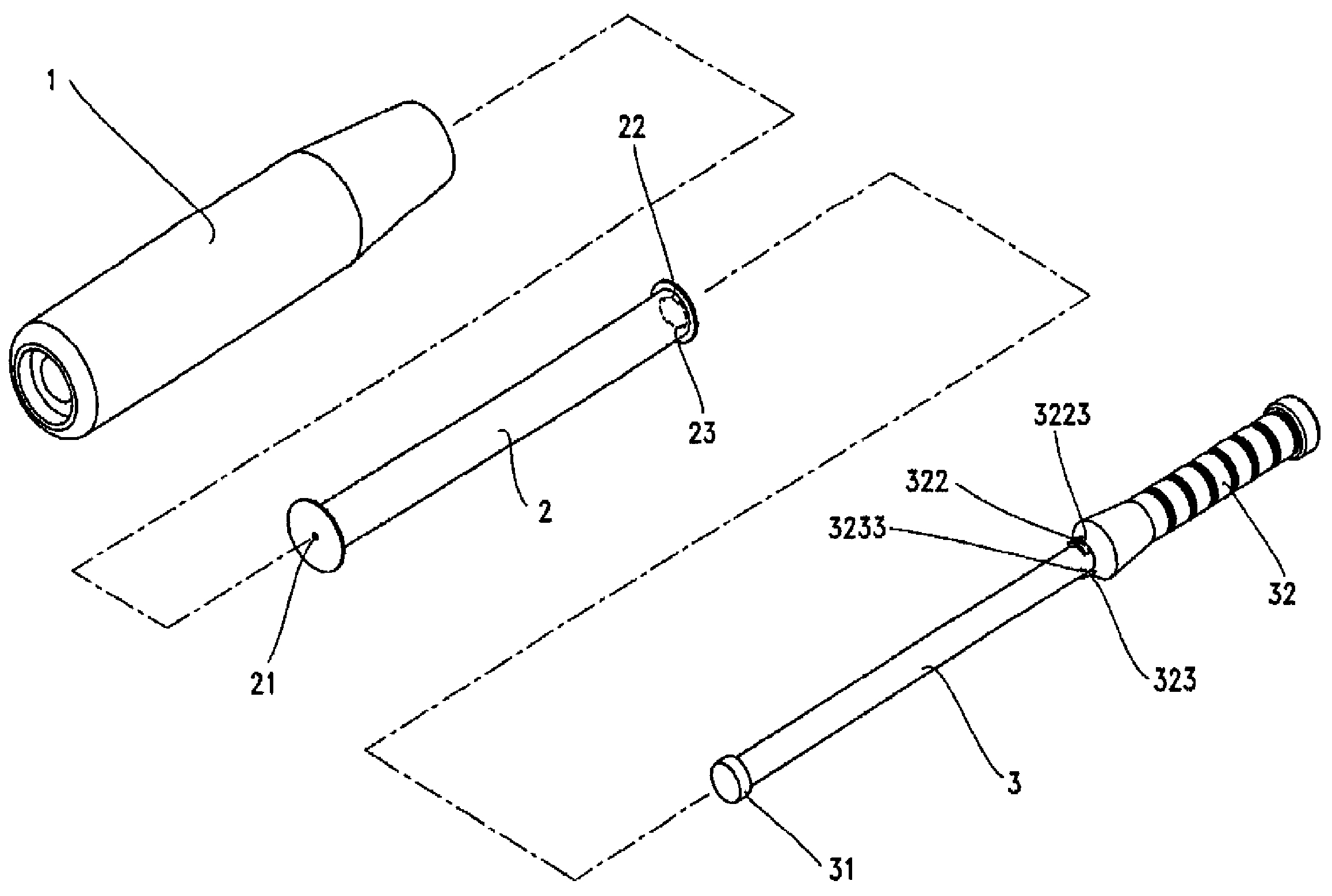

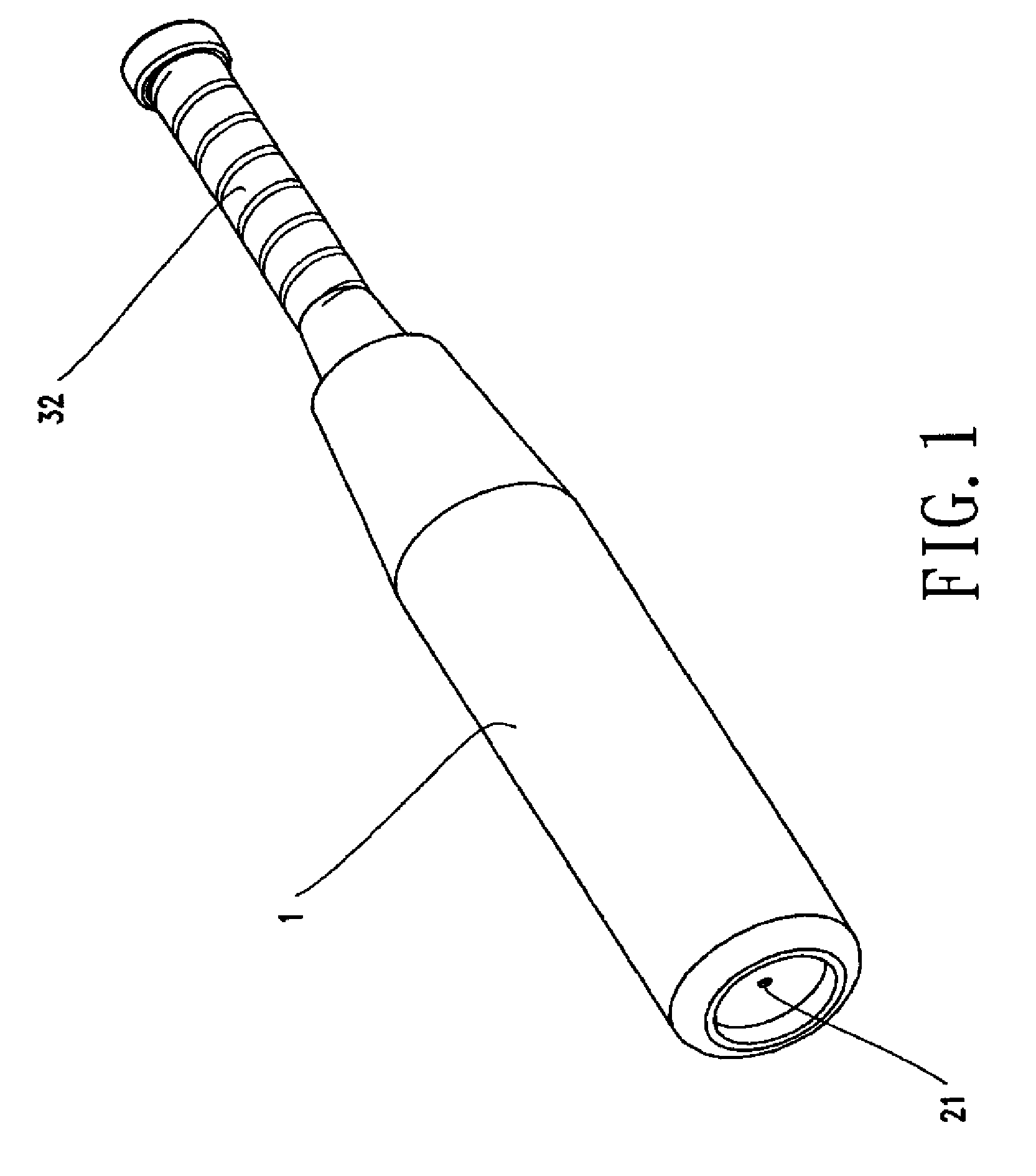

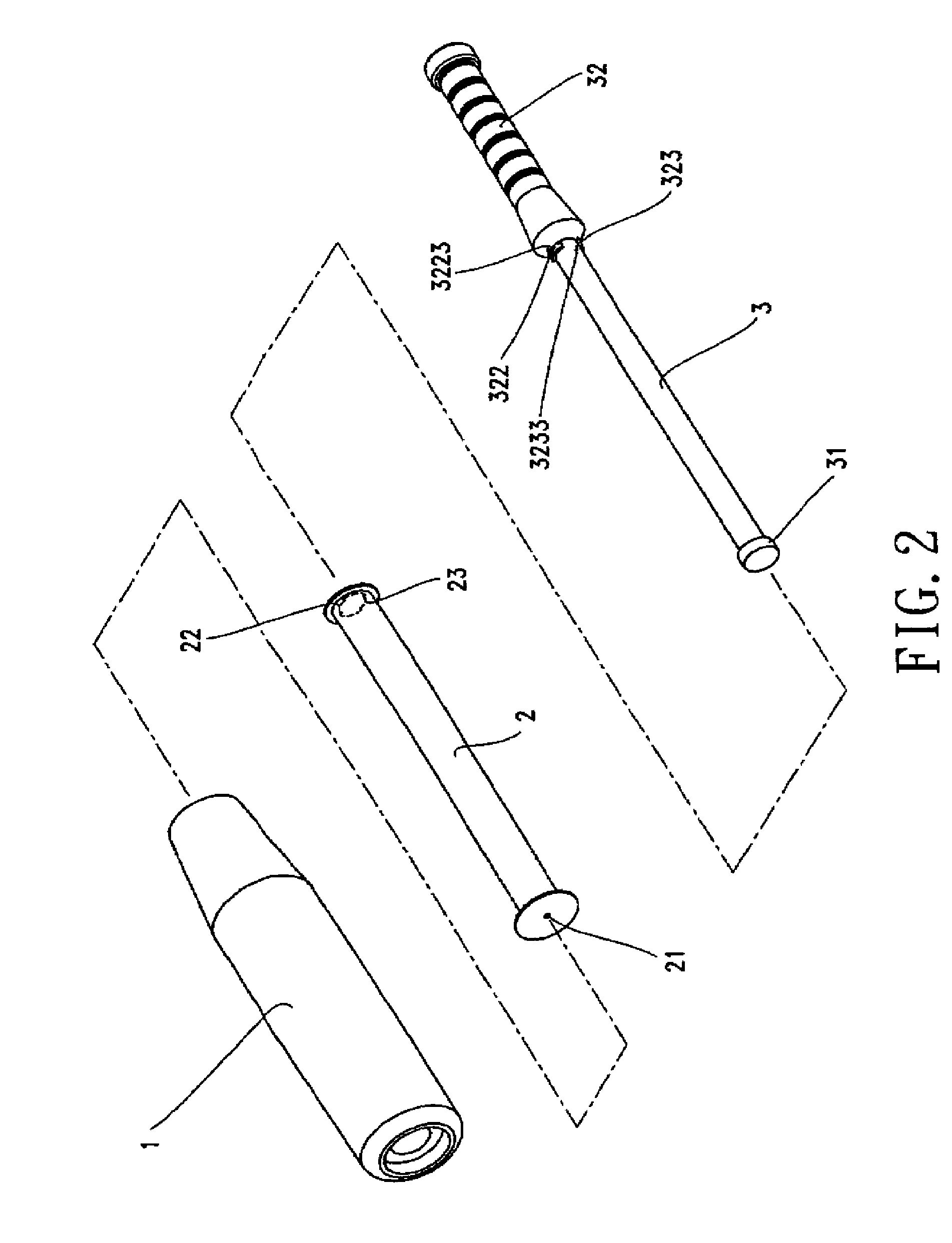

Rotatable water-spraying bat

A rotatable water-spraying bat is disclosed. The bat comprises a soft material mount, a water storage cylinder and a push pushing-piston. The soft material covers the external of the water storage cylinder, and the inner diameter of the water storage cylinder provides the insertion of the pushing-piston cylinder as one unit. The bat is characterized in that at an open area of the water storage cylinder being provided with two fastening ring is mounted with a recess for the insertion of the corresponding L-shaped fastening plate and is then rotated, the protruded ring urges the recess to be in a fastening position so that the great impact onto the spray bat will not dislocate the spray bat the guiding corner at the front end of the recess allows the protruded ring to be engaged and dislocation is not possible.

Owner:OW AE ENTERPRISE

Water shield

A water shield includes a shield blank including a front surface and a back surface. Disposed on the front surface is one or more nozzle, and disposed on the back surface are a handle and a trigger. The operator of the water shield grabs the handle to maneuver the water shield in position to block any incoming streams of water from ordinary water guns. In return, the operator activates the trigger to eject a stream of water from the nozzle.

Owner:DIXON MARK H

Water gun amusement devices and methods of using the same

Toy water guns include a housing supporting a liquid storage chamber, a conduit for establishing fluid communication between the chamber and a discharge orifice disposed proximate a front end of the housing, a trigger mechanism, a fluid transfer system adapted to develop forces for causing a continuous or pulsed stream of liquid to flow through the conduit and out of the discharge orifice when the trigger is pressed. A first embodiment employs a rotatable nozzle assembly that is dimensioned and arranged to spin as it receives a stream of liquid via the conduit. The nozzle assembly ejects a stream of liquid as it spins to thereby obtain a helical “tornado” flow pattern. In a second embodiment, a fixed or movable deflector is used so that water exiting a nozzle strikes a surface of the deflector to thereby develop a “wave” or “hard rain” discharge pattern. Multiple modes of operation are also contemplated.

Owner:THOUGHT DEVMENT

Barrel attachment for gas gun

This invention is a barrel attachment attachable to the firing end of the barrel of a compressed gas gun and a method of using the same. The barrel attachment allows a user to spin a projectile fired from the gas gun just before it exits the barrel attachment. This spin alters the projectile's normally straight trajectory; in other words, it makes the projectile curve. The barrel attachment is adjustable. In the preferred embodiment, the user or shooter can adjust the amount of spin and thereby the amount that the projectile curves by rotating an adjustment sleeve about the barrel attachment, which causes contact pads to protrude into the passage of the barrel attachment. In the preferred embodiment, the user can adjust the direction of curve by rotating the barrel attachment about the gun barrel.

Owner:KORE OUTDOOR US INC

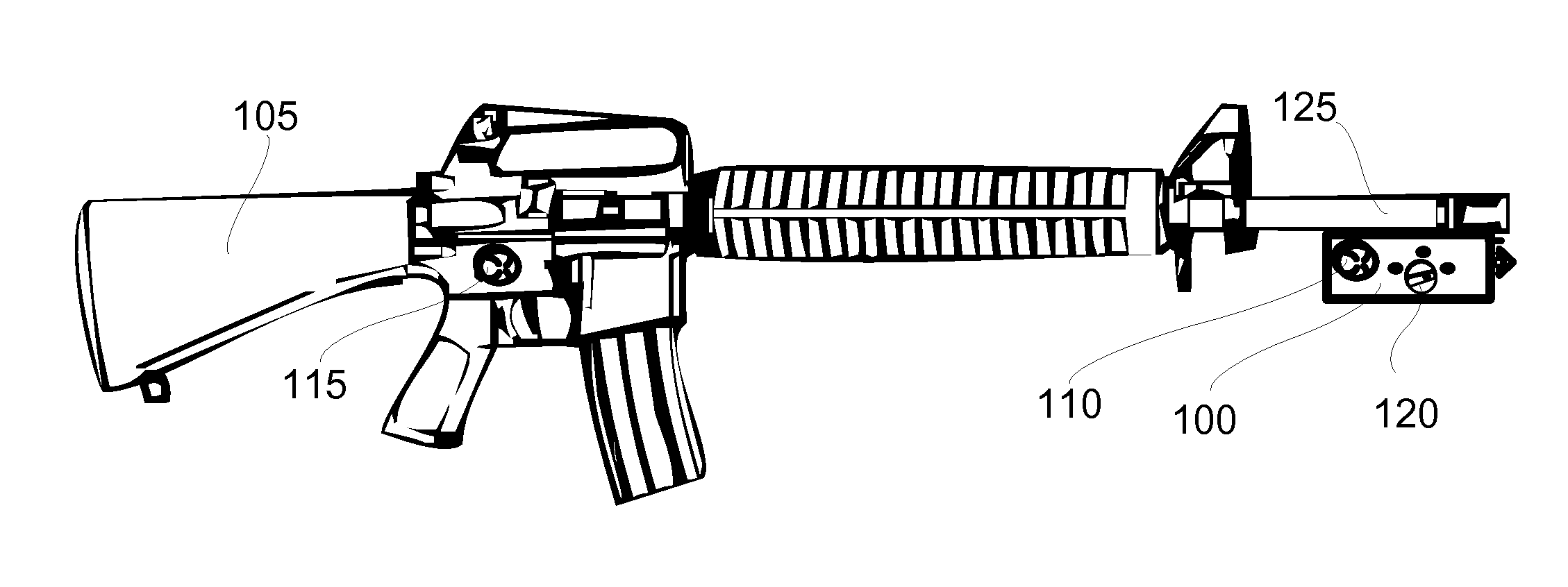

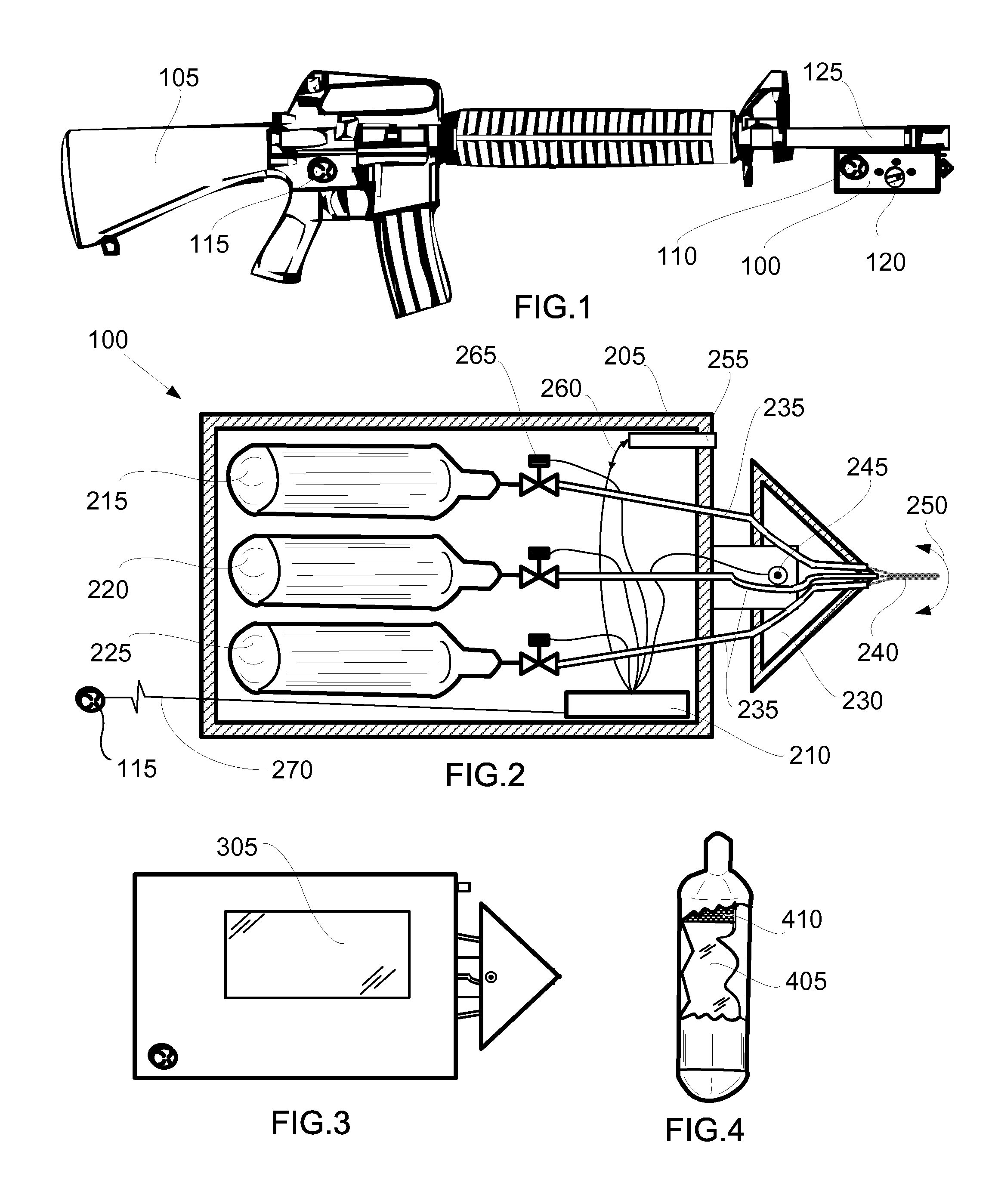

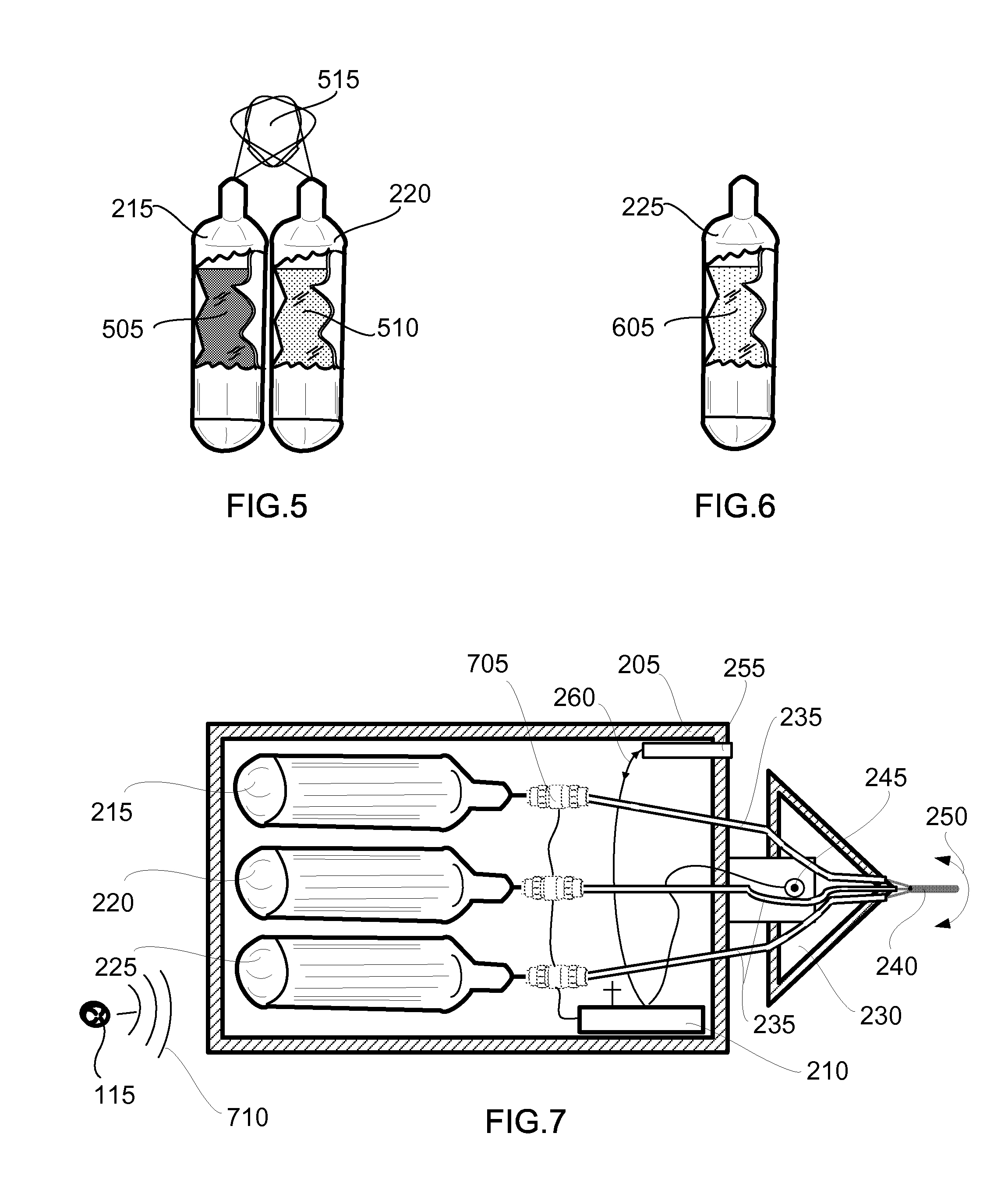

Instant eye-sealing weapon

A weapon is usable instantly seal a person's eyes when fired into a target's face. The weapon includes a container that is removably attached to a barrel of a firearm. Once removed, it can be used independently of the firearm. The weapon includes a central processing unit mounted within the container. The container holds three or more bottles, each containing one of a cyanoacrylate adhesive base, an activator to speed curing of the adhesive base, and a chemical agent to affect the target. At a minimum, the adhesive base and the activator may be ejected to form a single stream which cures or hardens within 10 seconds. Additionally, the contents of various chemical agents may also be ejected into the single stream as may be preselected by the shooter using a selector switch or a touch screen display.

Owner:IESW ASSOC TRUSTEE FOR INSTANT EYE SEALING WEAPON CRT TRUST

Delivery system

ActiveUS20060000854A1Safe distanceConvenient distanceClosuresLiquid flow controllersOff the shelfEngineering

The present invention relates to an apparatus and method for delivering or dispensing substances. The delivery apparatus comprises a housing, a cartridge for containing the fluid or liquid to be delivered, a conduit system, a nozzle, a pump and an actuating mechanism for actuating a stream of fluid or liquid. The delivery apparatus may include a motor and power source adapted to power the pump. The cartridge containing the fluid or liquid is typically an off-the-shelf container that may be purchased in stores, such as insecticides or household cleaners. The conduit system has an intake opening in fluid communication with the fluid inside the container and another portion in fluid communication with the intake of the nozzle. The conduit system further includes a structure for causing the stream of fluid or liquid to be generally laminar.

Owner:SC JOHNSON & SON INC

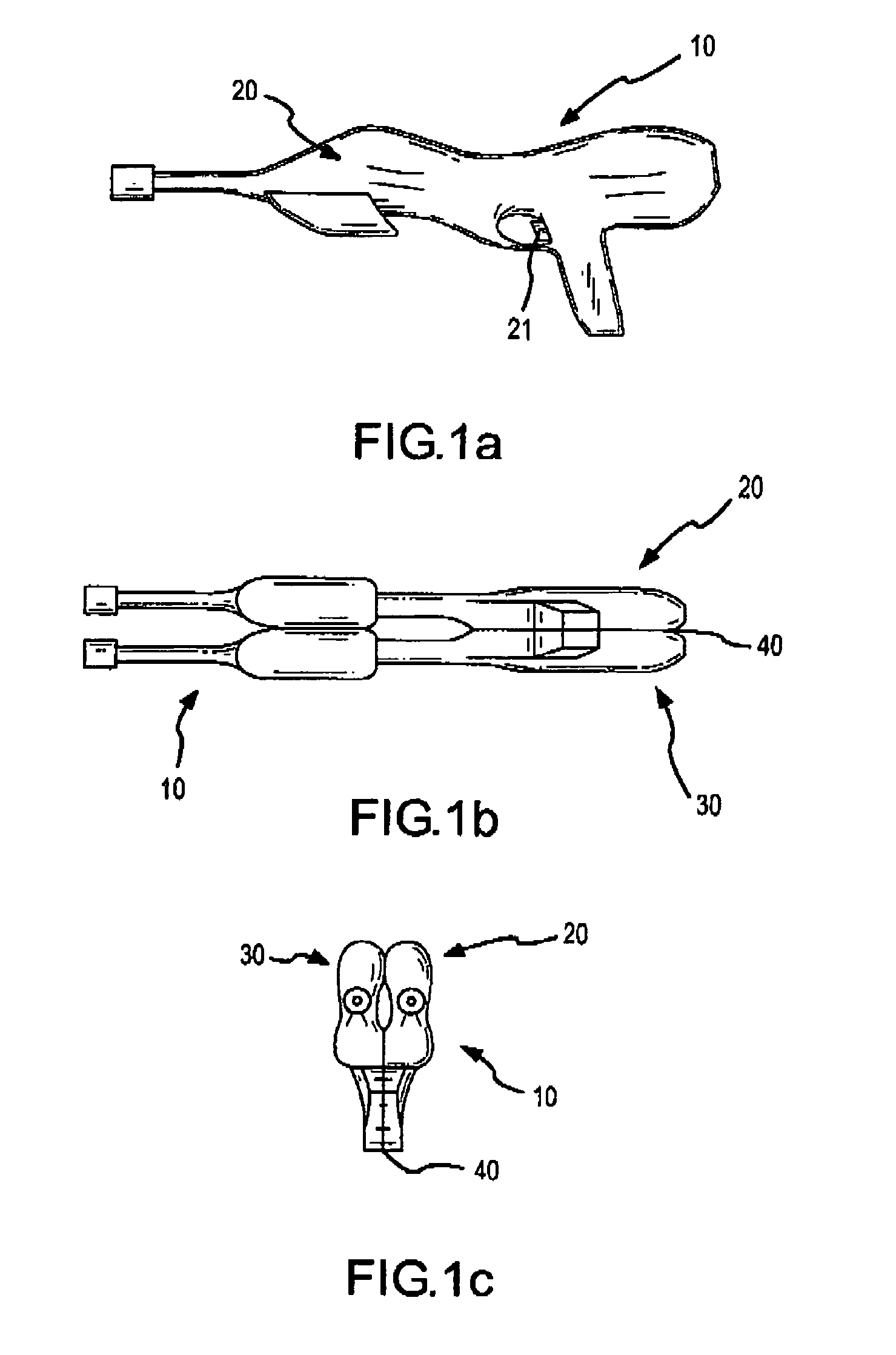

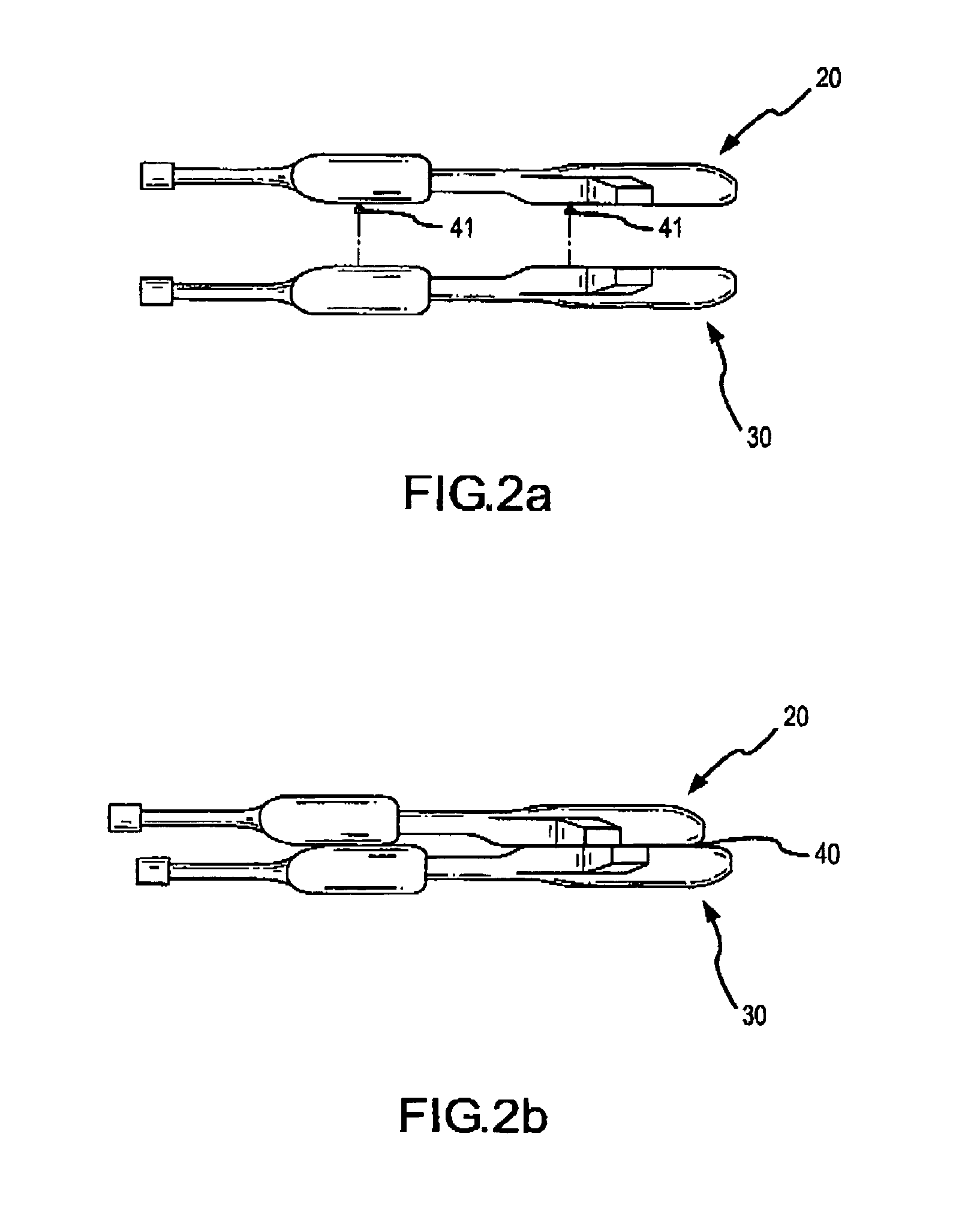

Separable toy gun

Owner:CUISINIER JARRET PETER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com