Acceleration-sensing loader activation system and method

a technology of acceleration sensing and activation system, which is applied in the field of acceleration sensing loader activation system and method, can solve the problems of noise generation, noise generation, and noise generation, and the sound activation mechanism is also subject to errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

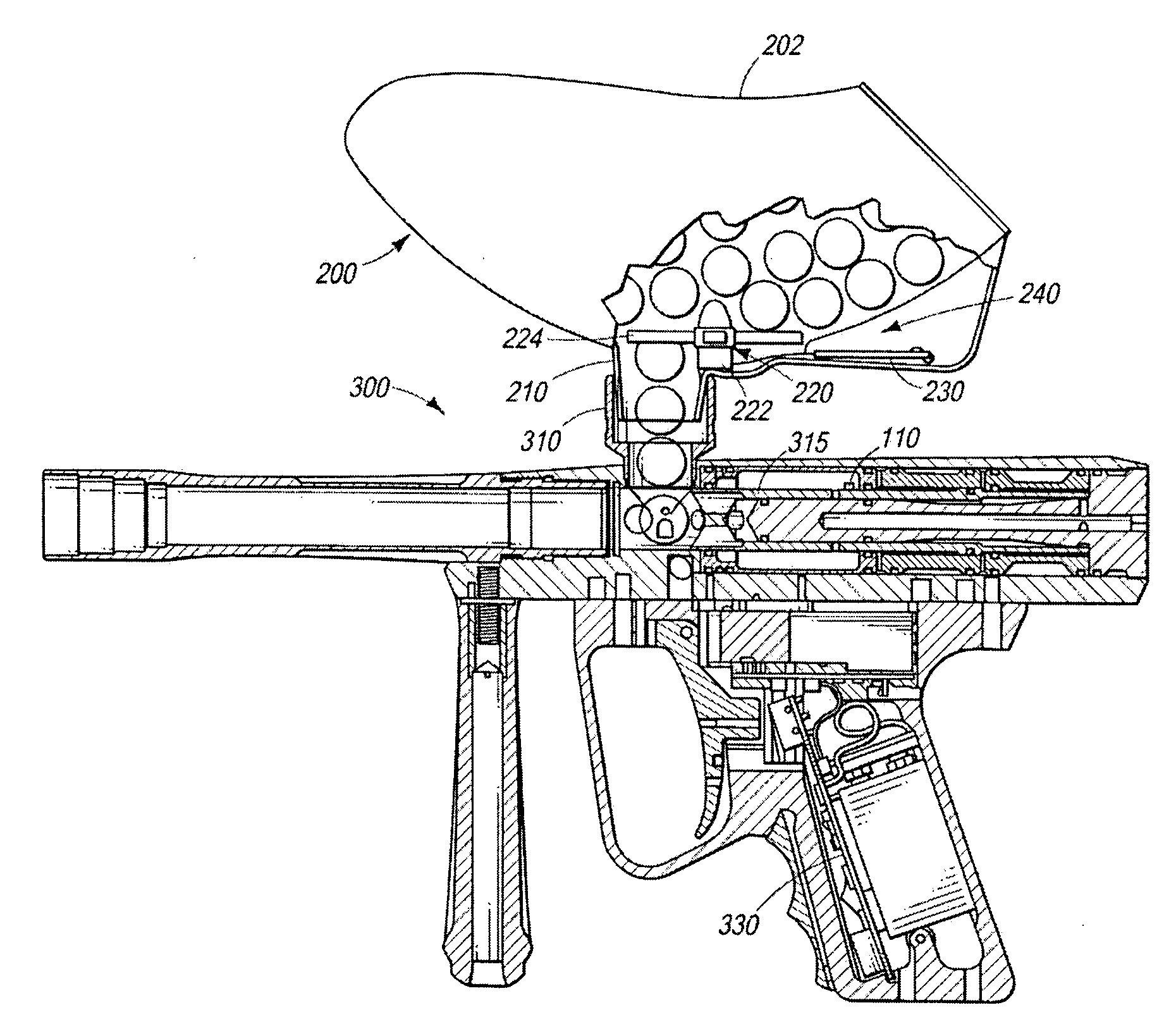

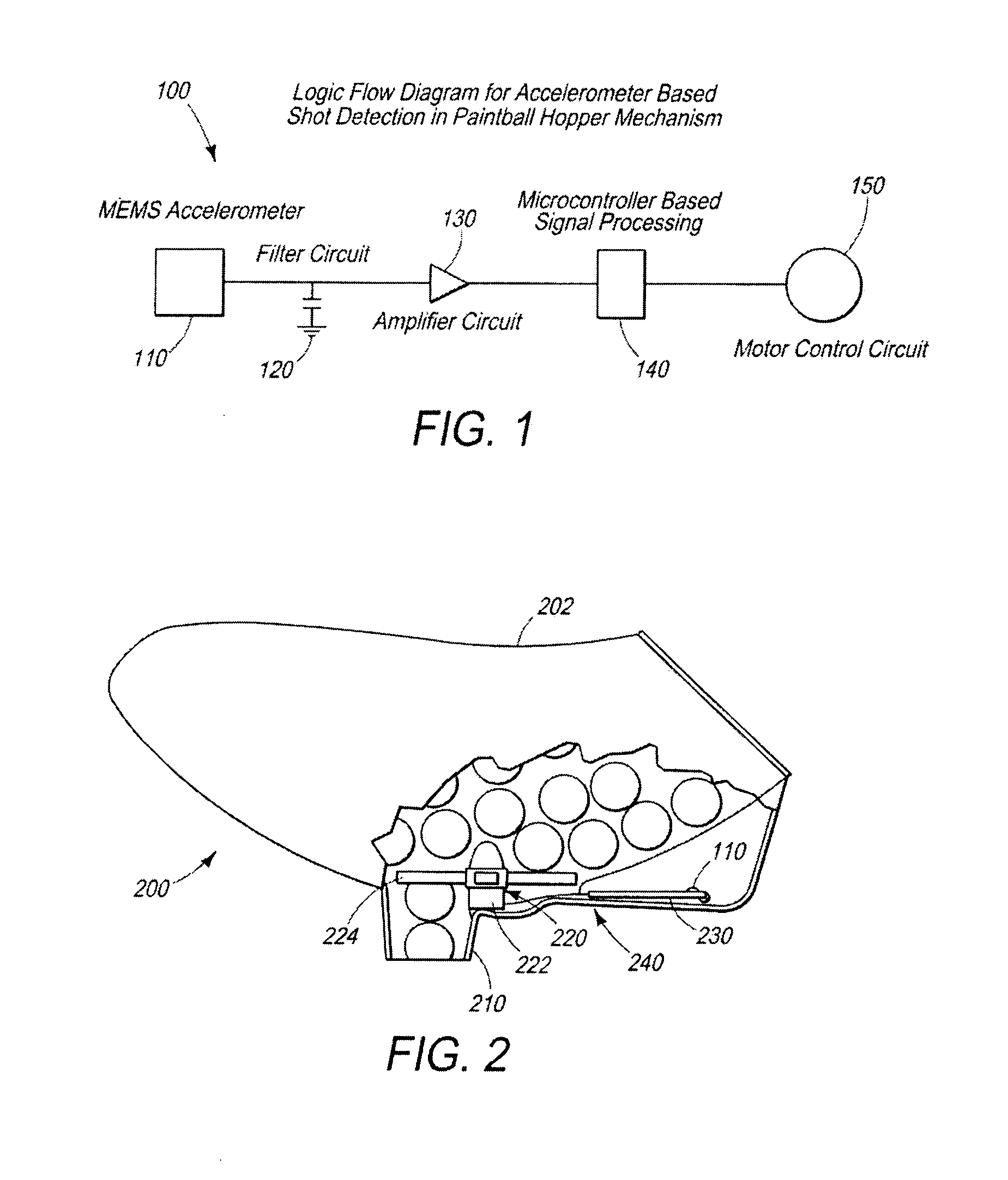

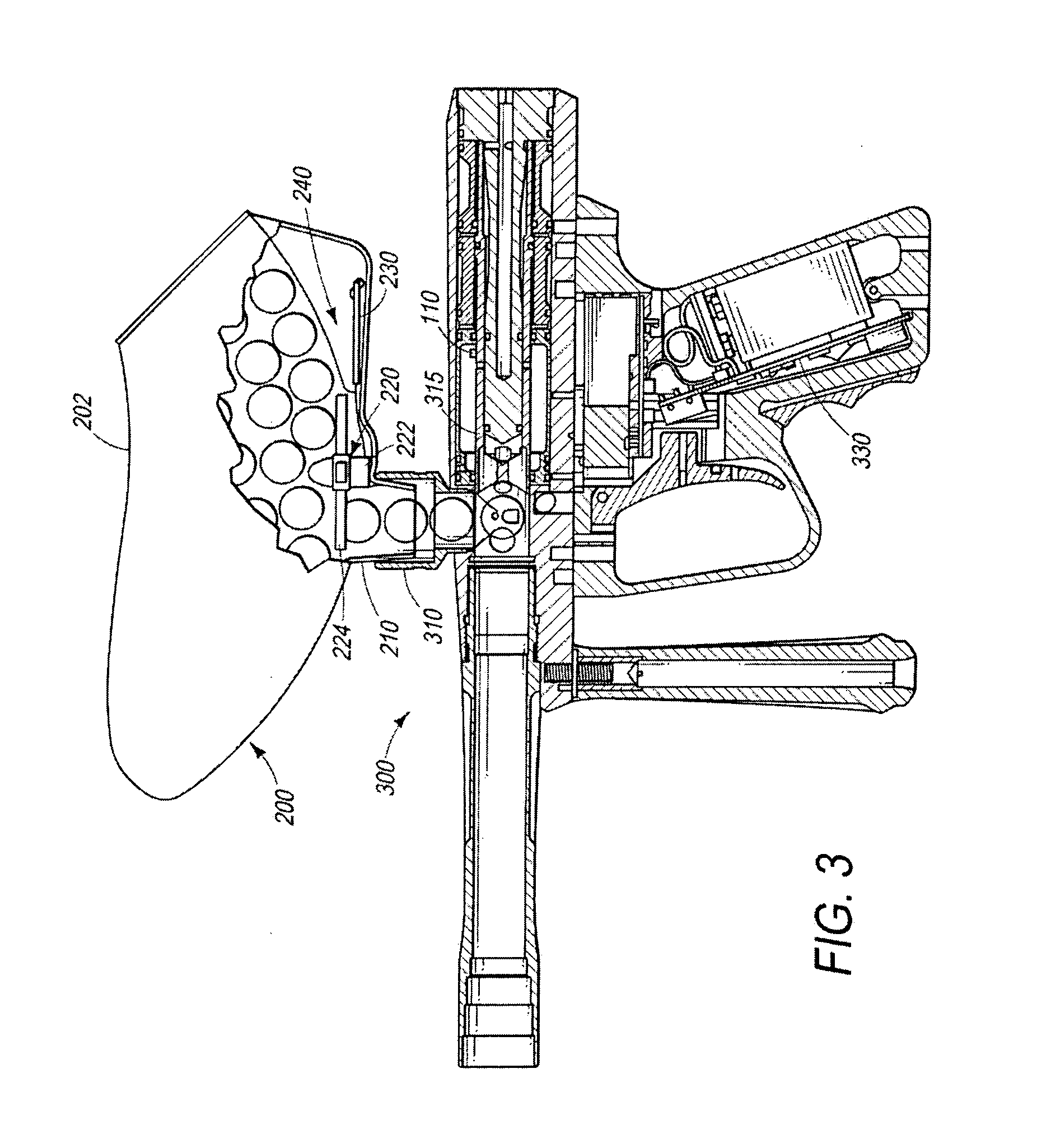

[0013]In the following detailed description, reference is made to the accompanying drawings, which form part thereof, and in which are shown, by way of illustration, exemplary, non-limiting embodiments illustrating various principles of the present invention and how it may be practiced.

[0014]FIG. 1 is a schematic block diagram of a loader activation circuit 100 implementing an acceleration sensor 110 according to principles of the present invention. Referring to FIG. 1, a loader activation circuit 100 preferably includes an acceleration sensor 110 (e.g., a MEMS accelerometer), a filter circuit 120 (e.g., a RC low pass filter), an amplifier circuit 130 (e.g., an op-amp based amplifier), a signal processing circuit 140 (e.g., a microcontroller-based processor), and a motor control circuit 150 (e.g., a bidirectional DC motor control system).

[0015]The acceleration sensor 110 is preferably configured to detect movement of the loader, a paintball marker, and / or an operating component of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com