Housing used for vehicle transmission

A transmission housing and transmission technology, applied in the direction of toothed components, transmission parts, belts/chains/gears, etc., can solve the problems of hot transmission oil outflow, failure, high fire risk, etc., to prevent vehicle body from breaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

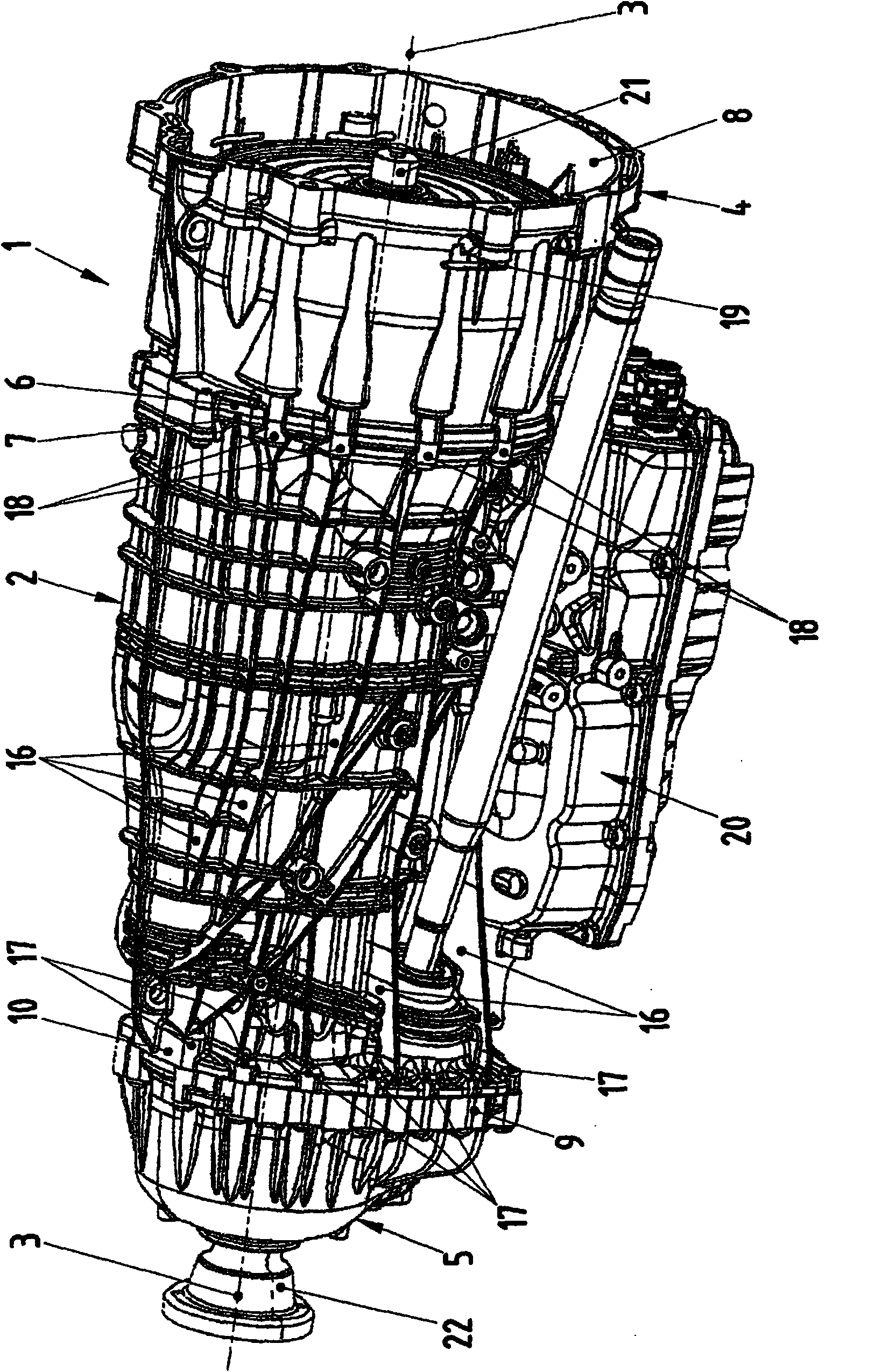

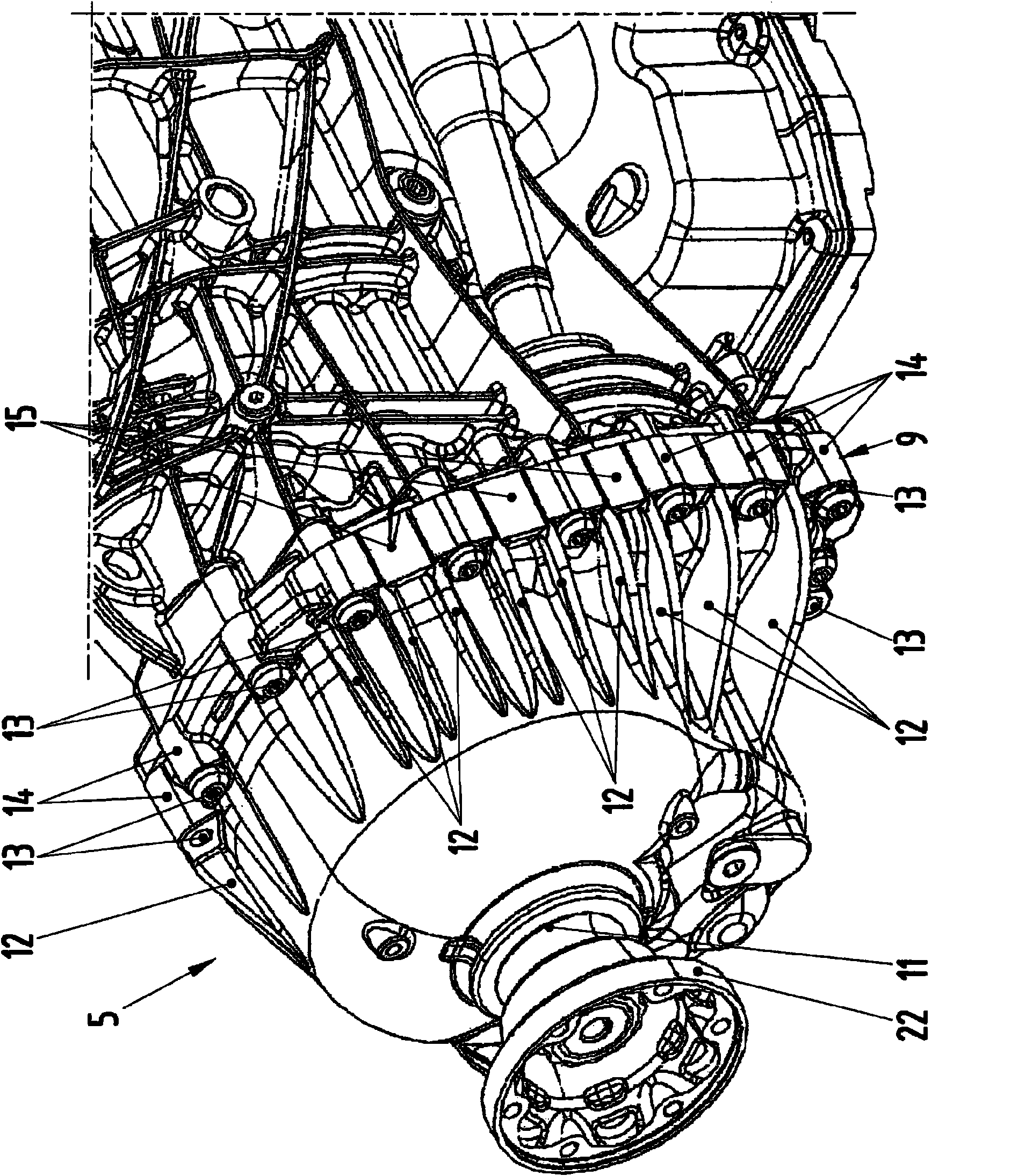

[0024] according to figure 1 , the transmission housing 1 comprises a main housing 2 which extends in a longitudinal direction 3 . The transmission housing 1 is used to accommodate the transmission (not visible here) of a motor vehicle, which may be a passenger car in particular. The longitudinal axis 3 of the transmission housing 1 is generally defined by the axis of rotation of the drive shaft 21 and / or output shaft 22 of the transmission. At the axial ends of the main housing 2 , the transmission housing 1 has a transmission cover 4 on one side and an end cover 5 on the other side. The transmission housing 4 is flanged to the main housing 2 via a main housing-side flange 6 , for which purpose the main housing has a complementary housing-side flange 7 . In addition, the transmission housing 4 has an engine-side flange 8 via which the transmission housing 4 and thus the entire transmission housing 1 can be flanged to the engine block of the internal combustion engine of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com