Preparation method for composite material of nano-concave-convex stick stone/silicon dioxide

A technology of nano attapulgite and silicon dioxide, which is applied in the deep processing field of non-metallic minerals, can solve the problems of restricting industrial production and wide application, the reinforcement effect is not as good as that of fibrous materials, and the production process is complicated, so as to achieve economic benefits and social benefits. Remarkable benefit, good reinforcing effect, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

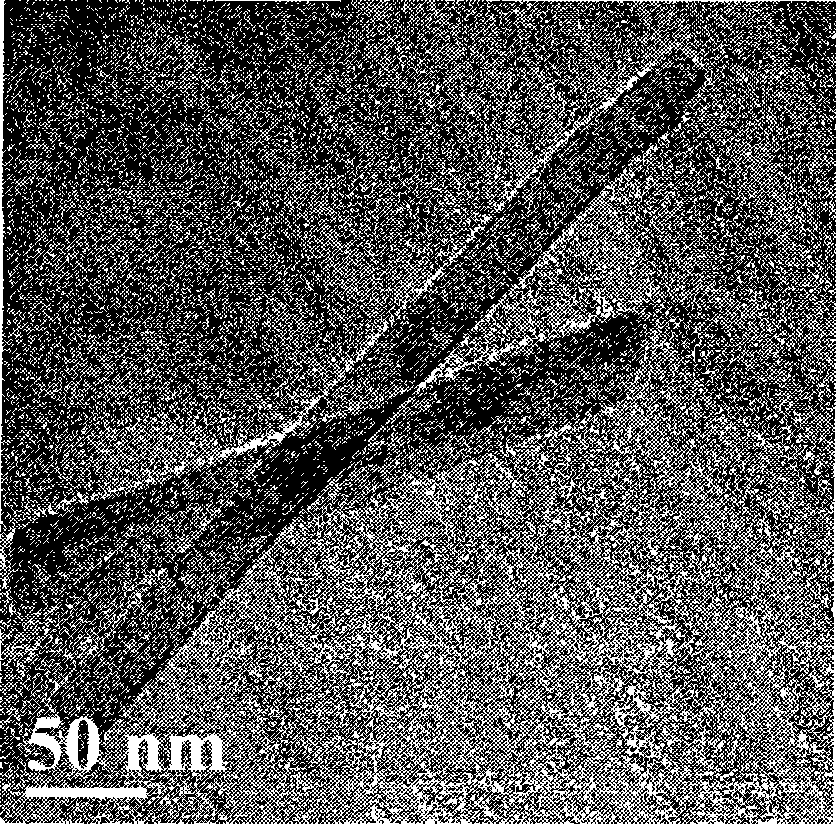

[0026] Attapulgite was added to deionized water to prepare 1000 kg of a suspension with a solid content of 5% (mass percentage, the same below), and placed in a 3000L stirred enamel reaction kettle. Start the stirring device, add 20% (mass percentage, the same below) sodium silicate solution 1183kg in the reactor, the consumption of sodium silicate is m (SiO 2 ):m (attapulgite)=1:1. Maintain the reaction temperature at 70°C, add 10% sulfuric acid solution, adjust the pH value of the attapulgite suspension to 10.0, mature for 0.5h, then adjust the pH value of the system to 6.0 with 10% sulfuric acid solution, continue stirring, and mature 24h. Filtrate, wash with deionized water to remove soluble salts, dry, and airflow pulverize to obtain nano attapulgite / silicon dioxide composite material. TEM photos such as figure 2 , the whiteness of the nano-attapulgite / silica composite is 90.

Embodiment 2

[0028] Attapulgite was added to deionized water to prepare 1000kg of a suspension with a solid content of 5%, and placed in a 3000L stirred enamel reaction kettle. Start the stirring device, maintain the reaction temperature of the system at 70°C, add dropwise 20% sodium silicate solution and 10% sulfuric acid solution respectively in the reactor, maintain the system pH=10.0, and the consumption of the sodium silicate solution is 1183kg, i.e. m(SiO 2 ):m (attapulgite)=1:1. After adding the sodium silicate solution, mature for 0.5h, then adjust the pH of the system to 6.0 with 10% sulfuric acid solution, continue stirring, and mature for 24h. Filtrate, wash with deionized water to remove soluble salts, dry, and airflow pulverize to obtain nano attapulgite / silicon dioxide composite material. TEM photos such as image 3 , the whiteness of the nano-attapulgite / silica composite is 91.

Embodiment 3

[0030] Add attapulgite to deionized water to prepare 500 kg of a suspension with a solid content of 2%, and place it in a 3000L enamel reaction kettle with stirring. Start stirring device, add 10% sodium silicate solution 1419kg in the suspension, the consumption of sodium silicate is m (SiO 2 ):m (attapulgite)=3:1. Maintain the reaction temperature at 50°C, add 3% hydrochloric acid solution, adjust the pH value of the attapulgite suspension to 8.0, mature for 2 hours, then adjust the pH value of the system to 7.0 with 3% hydrochloric acid solution, continue stirring, and mature for 12 hours. Filtrate, wash with deionized water to remove soluble salts, dry, and airflow pulverize to obtain nano attapulgite / silicon dioxide composite material. The whiteness of nano-attapulgite / silica composite is 93.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com