Preparation method and application for natural latex packing

A natural latex and gel technology, applied in the field of natural latex fillers, can solve the problems of poor mechanical properties of impregnated rubber products, easy to breed bacteria, etc., and achieve the effect of improving antibacterial properties and improving easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

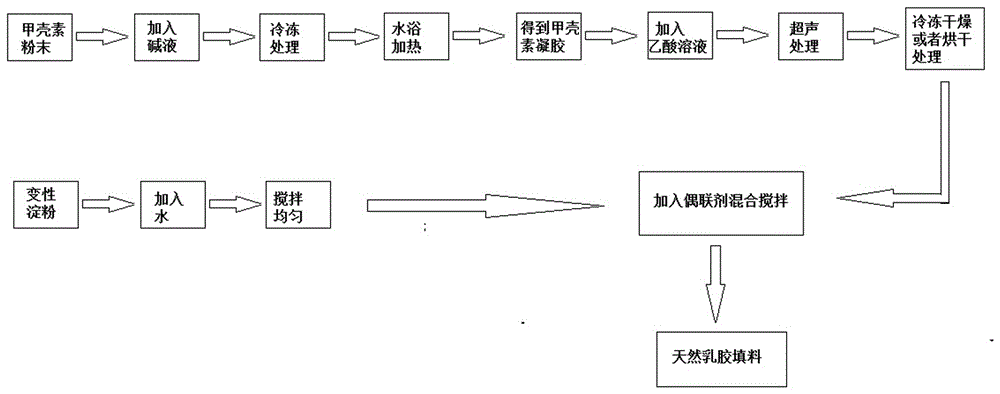

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of natural latex filler, the steps are as follows:

[0032] (1) Weigh a certain amount of chitin powder, add lye at a ratio of 0.5% by mass to volume, and mix evenly;

[0033] (2) Freeze the lye containing chitin powder at a low temperature of -20°C to -50°C for 12 hours, then take out the lye containing chitin powder, and heat it in a water bath at 50°C for 60 minutes to obtain chitin gel;

[0034] (3) Weigh the above-mentioned chitin gel, add acetic acid solution with a volume fraction of 1% according to the proportion of mass volume ratio of 0.5%, and mix well to obtain a mixed solution;

[0035] (4) Ultrasonic treatment of the mixed solution for 0.5 h to obtain an ultrasonically modified chitin gel;

[0036] (5) Soak the obtained ultrasonically modified chitin gel in liquid nitrogen, then transfer it to a freeze dryer, and freeze-dry it at -50°C for 24 hours before use;

[0037] (6) Take the modified starch, add water and mix according to the ...

Embodiment 2

[0046] A preparation method of natural latex filler, the steps are as follows:

[0047] (1) Weigh a certain amount of chitin powder, add lye in a ratio of 2% by mass to volume, and mix evenly;

[0048] (2) Freeze the lye containing chitin powder at a low temperature of -20°C to -50°C for 15 hours, then take out the lye containing chitin powder and heat it in a water bath at 60°C for 50 minutes to obtain chitin gel;

[0049] (3) Weigh the above-mentioned chitin gel, add the acetic acid solution with a volume fraction of 1% according to the mass volume ratio of 1%, and mix well to obtain a mixed solution;

[0050] (4) Ultrasonic treatment of the mixture for 2 hours to obtain an ultrasonically modified chitin gel;

[0051] (5) Dry the obtained ultrasonically modified chitin gel at 40-60°C before use;

[0052] (6) Take the modified starch, mix it with water according to the weight ratio of modified starch:water of 0.3:1, and stir evenly to obtain a modified starch solution;

[...

Embodiment 3

[0061] A preparation method of natural latex filler, the steps are as follows:

[0062] (1) Weigh a certain amount of chitin powder, add lye in a ratio of 5% by mass to volume, and mix evenly;

[0063] (2) Freeze the lye containing chitin powder at a low temperature of -20°C to -50°C for 18 hours, then take out the lye containing chitin powder, and heat it in a water bath at 70°C for 40 minutes to obtain chitin gel;

[0064] (3) Weigh the above-mentioned chitin gel, add the acetic acid solution with a volume fraction of 1% according to the mass volume ratio of 2%, and mix well to obtain a mixed solution;

[0065] (4) Ultrasonic treatment of the mixed solution for 3.5 hours to obtain an ultrasonically modified chitin gel;

[0066] (5) Soak the obtained ultrasonically modified chitin gel in liquid nitrogen, then transfer it to a freeze dryer, and freeze-dry it at -50°C for 25 hours before use;

[0067] (6) Take the modified starch, add water and mix according to the weight rat...

PUM

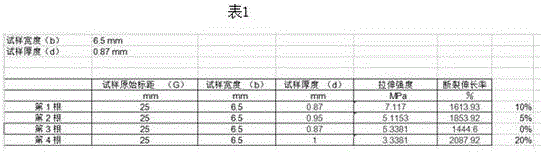

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com