Patents

Literature

119results about How to "Increase the pressure value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

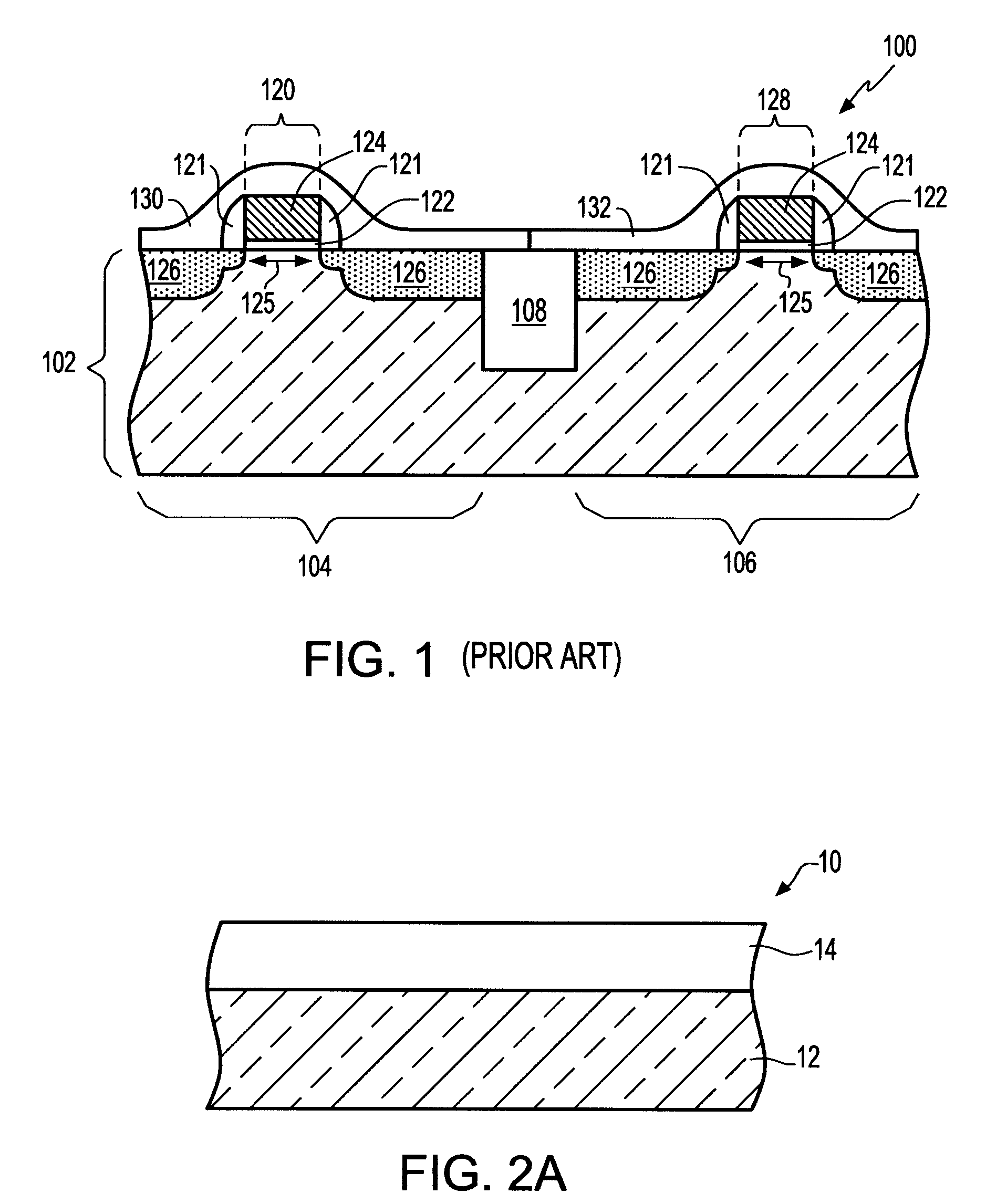

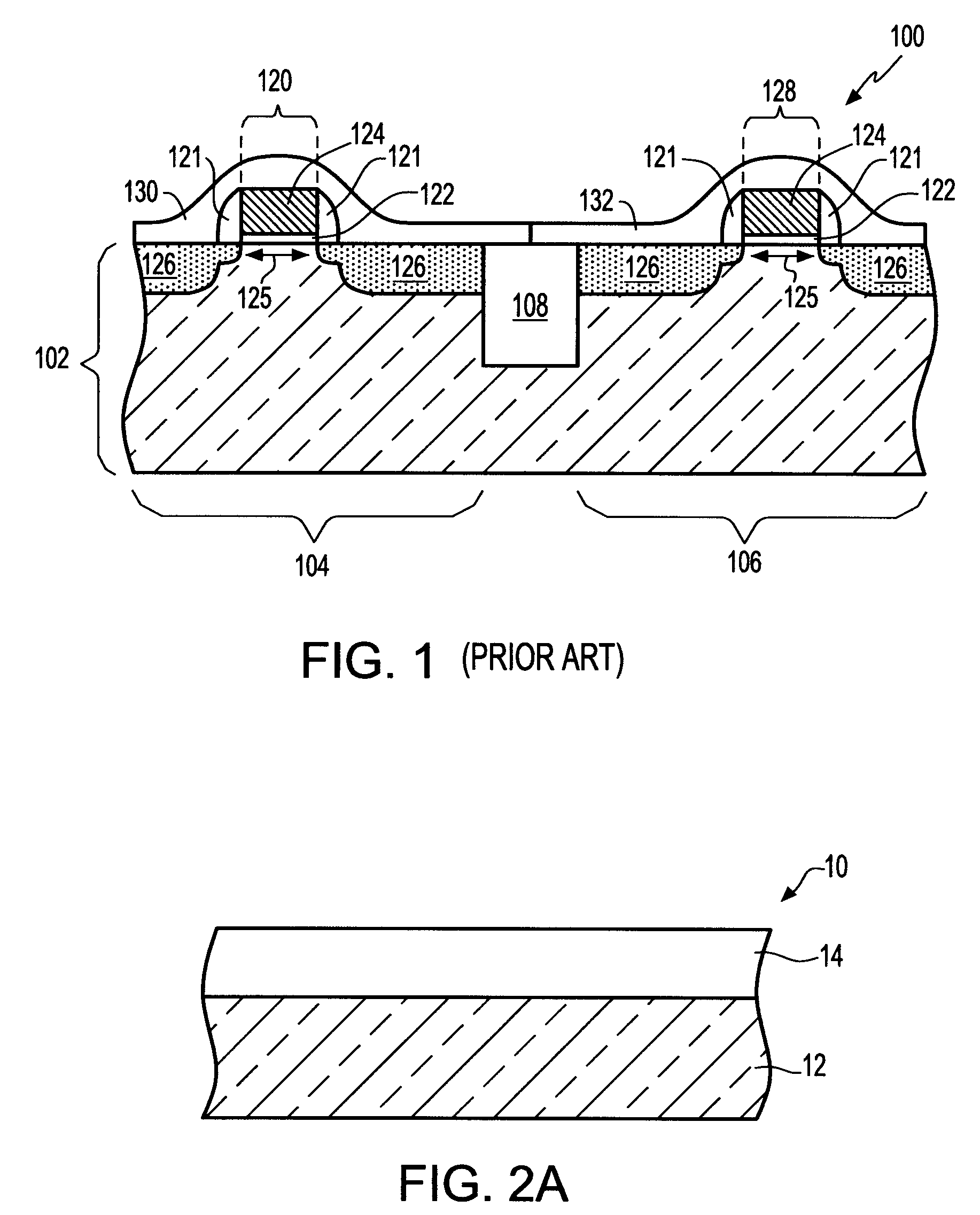

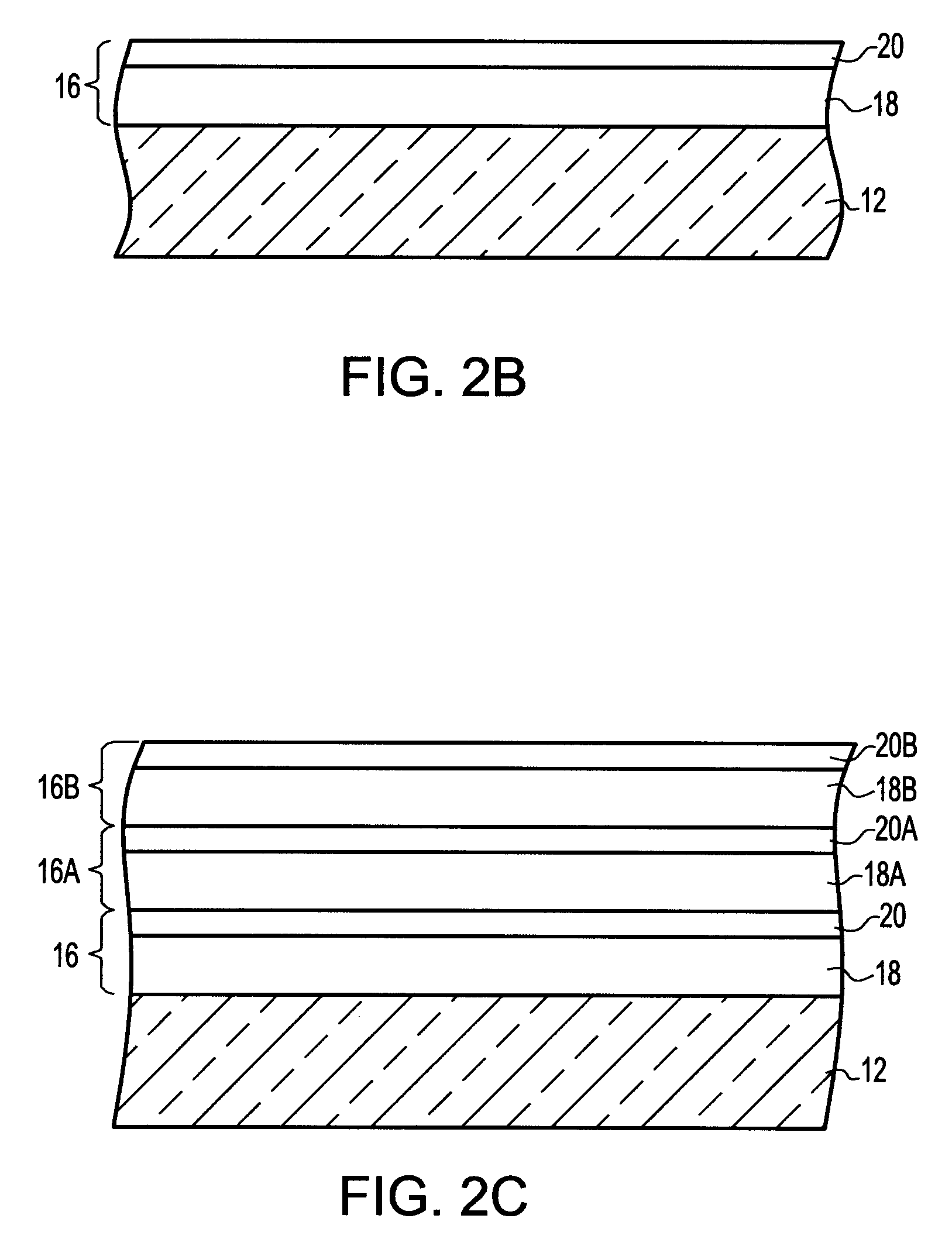

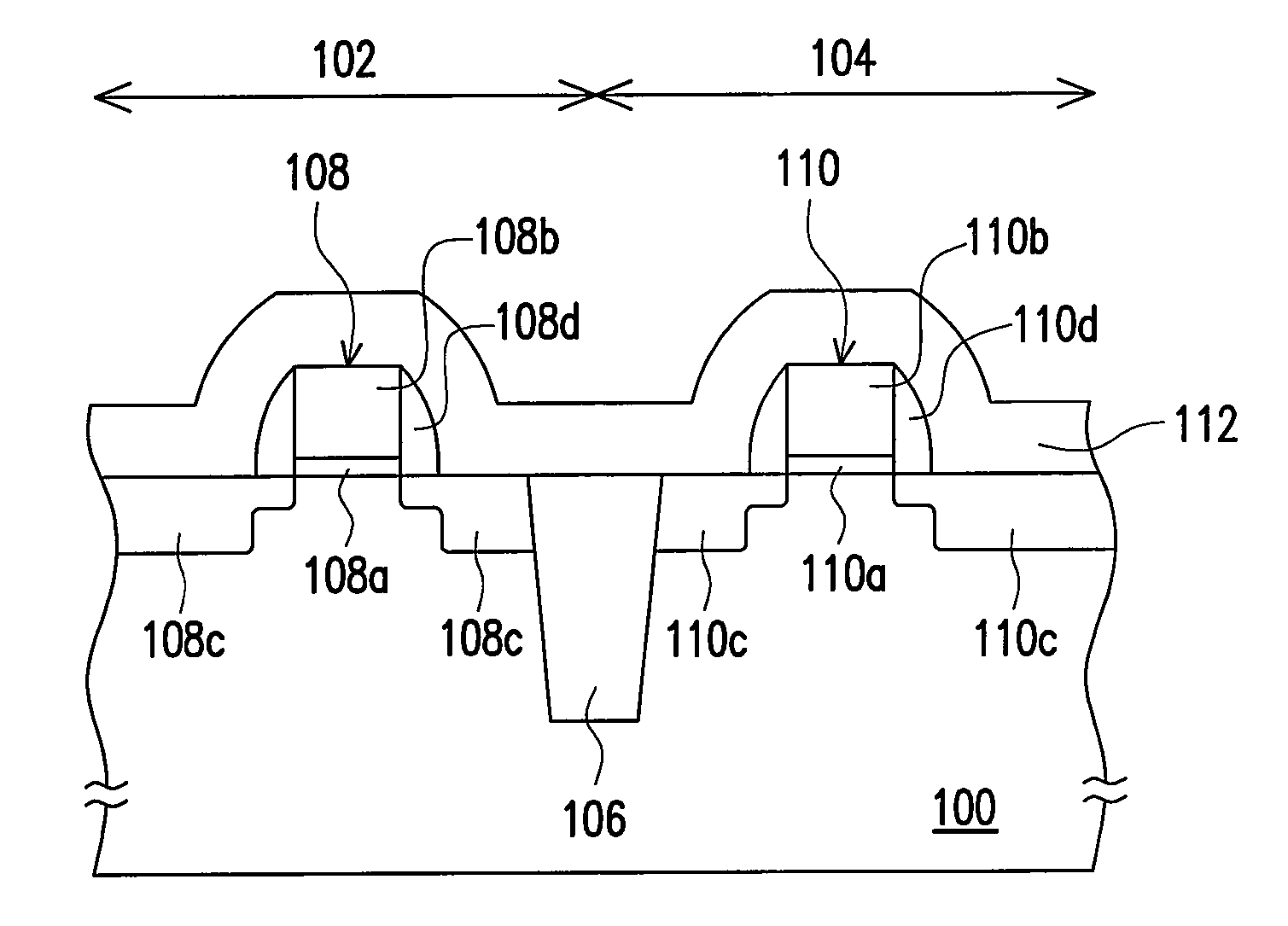

Method of producing highly strained pecvd silicon nitride thin films at low temperature

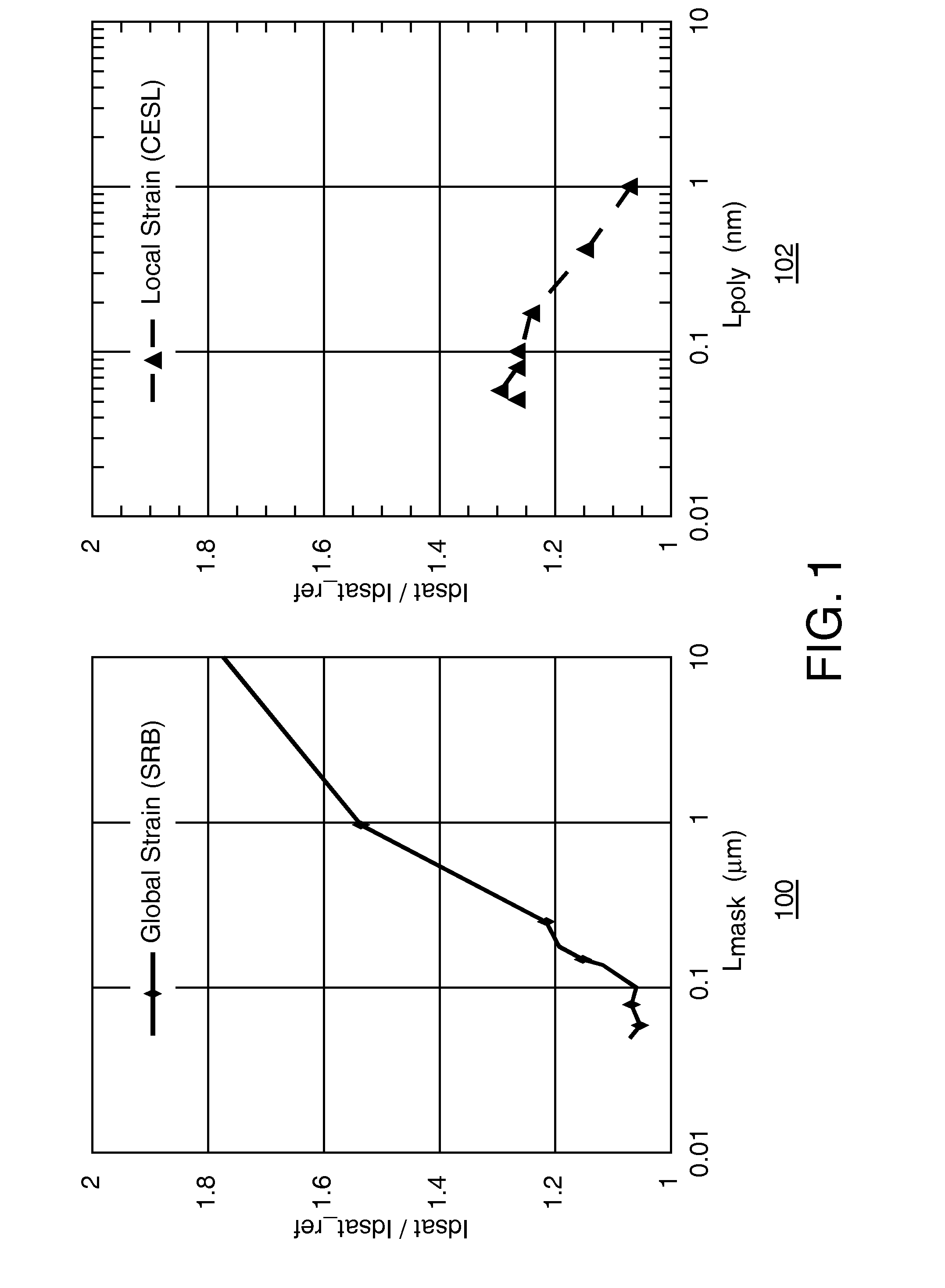

InactiveUS20060223290A1Increase pressureImprove stress conditionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingStressorMaterials science

A method for increasing the level of stress for amorphous thin film stressors by means of modifying the internal structure of such stressors is provided. The method includes first forming a first portion of an amorphous film stressor material on at least a surface of a substrate, said first portion having a first state of mechanical strain defining a first stress value. After the forming step, the first portion of the amorphous film stressor material is densified such that the first state of mechanical strain is not substantially altered, while increasing the first stress value. In some embodiments, the steps of forming and densifying are repeated any number of times to obtain a preselected and desired thickness for the stressor.

Owner:GLOBALFOUNDRIES INC

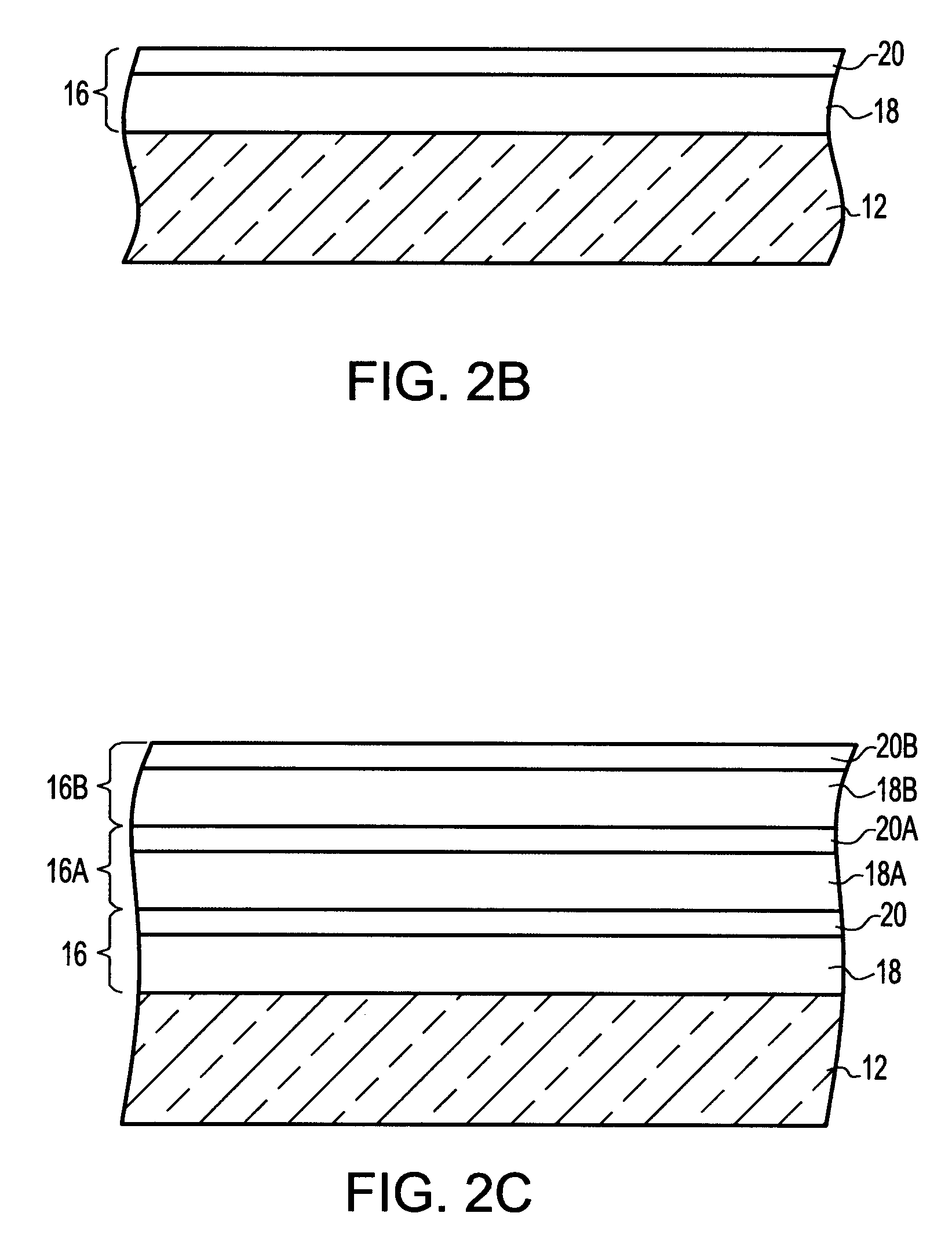

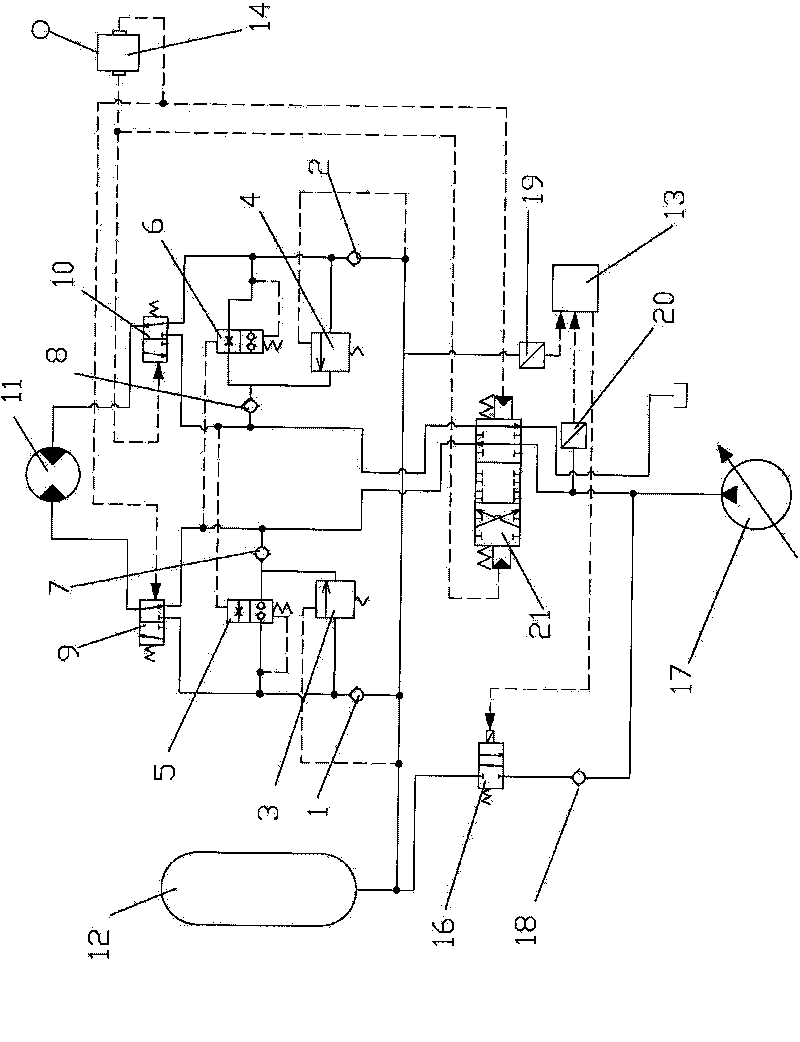

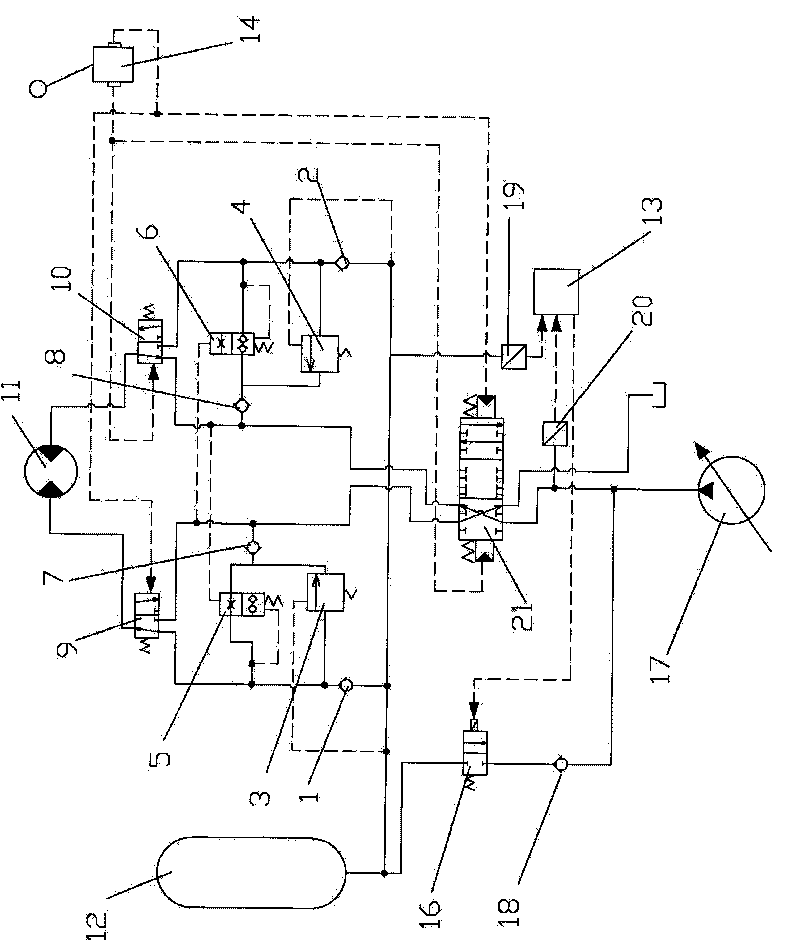

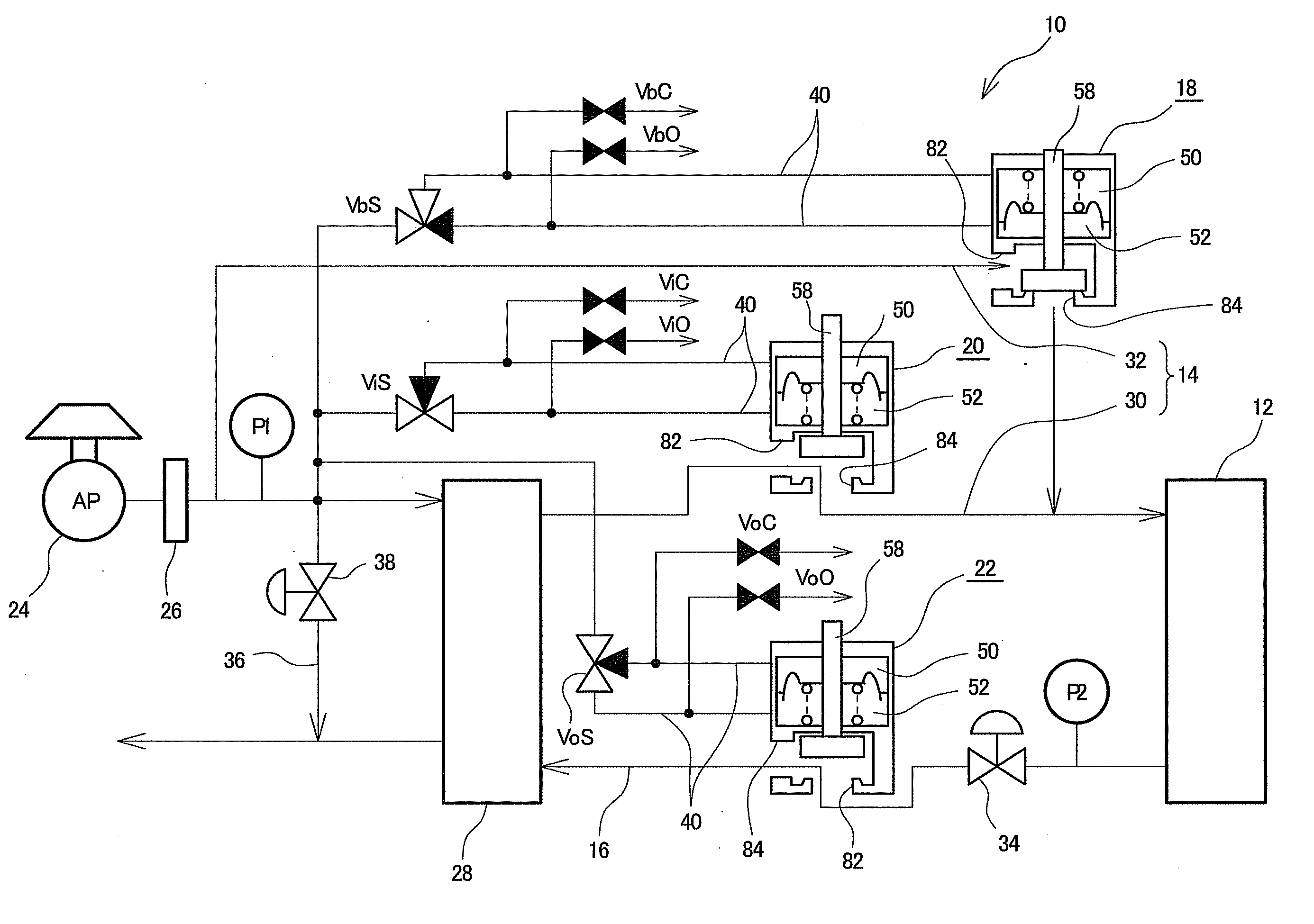

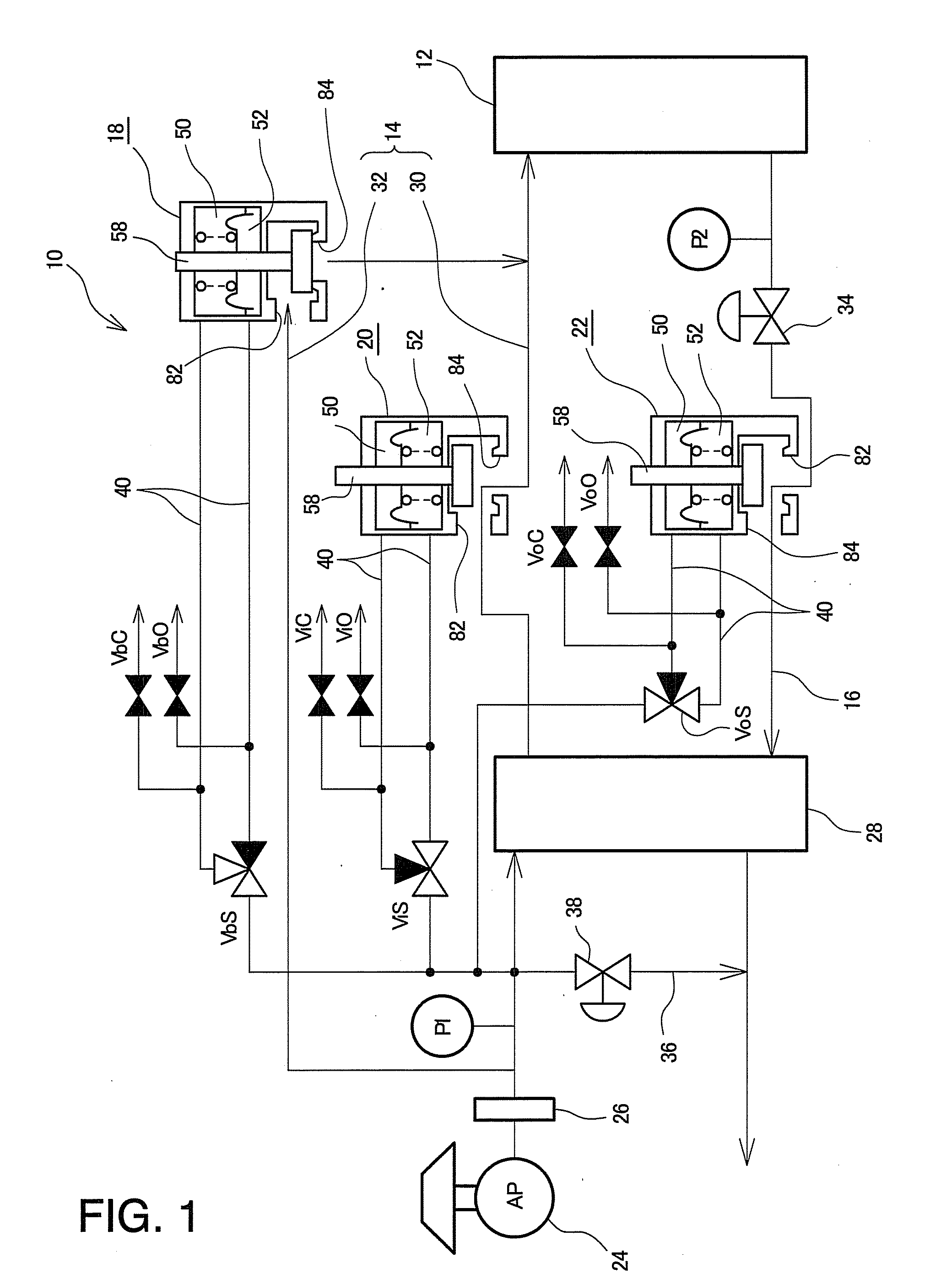

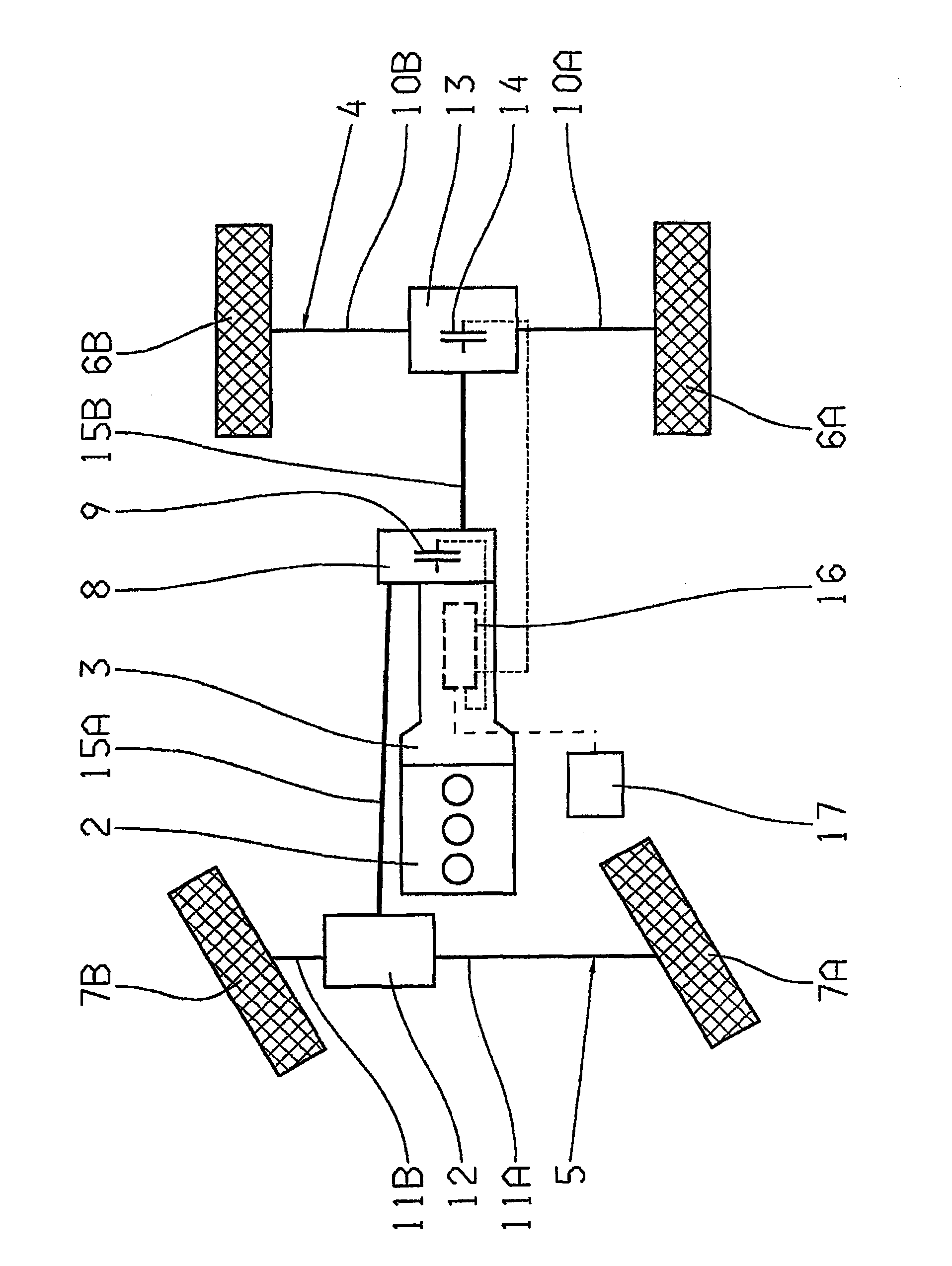

Rotary decelerating and braking energy recovery system of hydraulic excavator

InactiveCN101736771AImplement automatic conversionHigh degree of automationSoil-shifting machines/dredgersHydraulic pumpEnergy recovery

The invention discloses a rotary decelerating and braking energy recovery system of a hydraulic excavator, comprising two valve blocks. Each valve block is provided with a hydraulic control unloading valve, a hydraulic control conversion valve, a hydraulic control reversing valve and two one-way valves; in each valve block, the hydraulic control reversing valve is respectively communicated with a multi-way valve, the hydraulic control conversion valve, the hydraulic control unloading valve, the second one-way valve, a pilot oil path control handle and a rotary motor; the second one-way valve is communicated with a energy accumulator; the hydraulic control conversion valve and the hydraulic control unloading valve are communicated with the energy accumulator via the first one-way valve; the multi-way valve is respectively communicated with the hydraulic control conversion valve and the hydraulic control unloading valve via the first one-way valve; the hydraulic pump and the controller are connected with the second pressure sensor; and the energy accumulator and the controller are connected with the first pressure sensor. The invention enables the hydraulic excavator to automatically judge the motion state of the rotary system and recover the braking energy and enables the engine to work in the high-efficiency interval.

Owner:ZHEJIANG UNIV

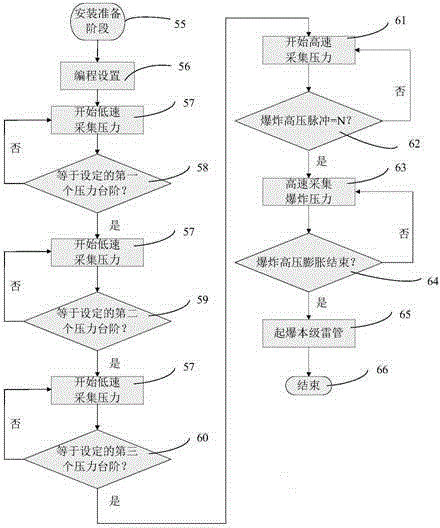

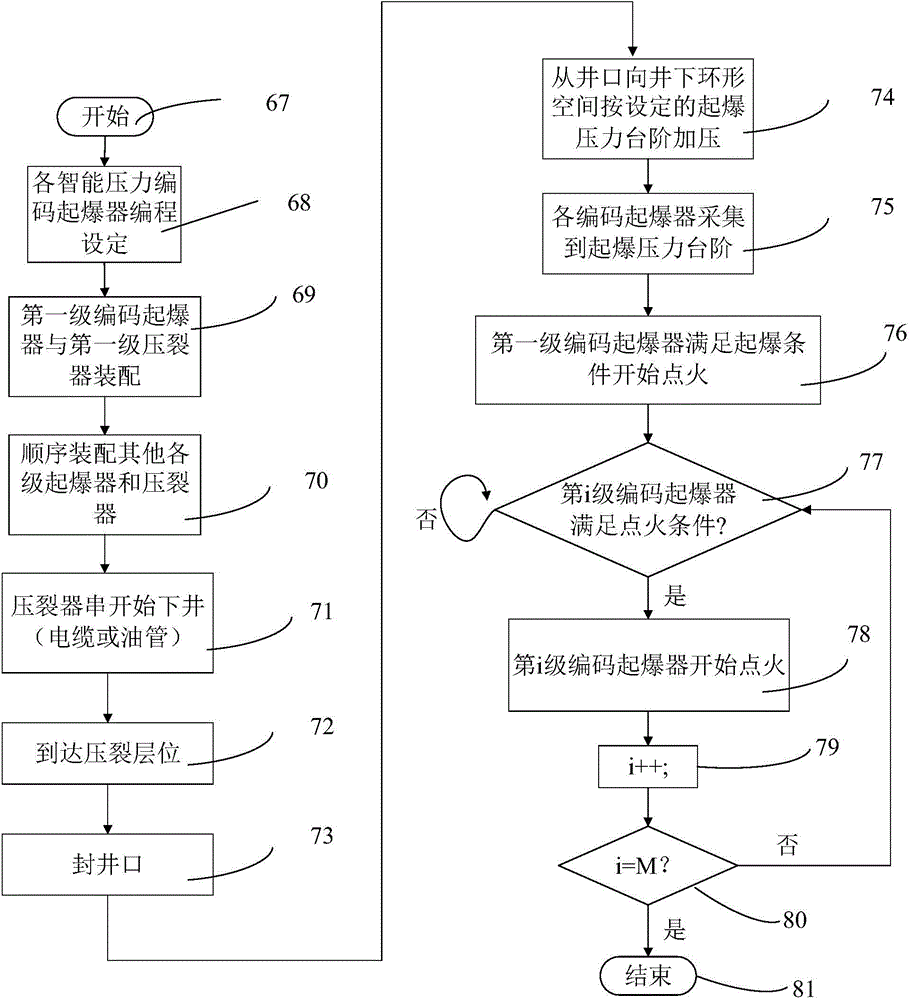

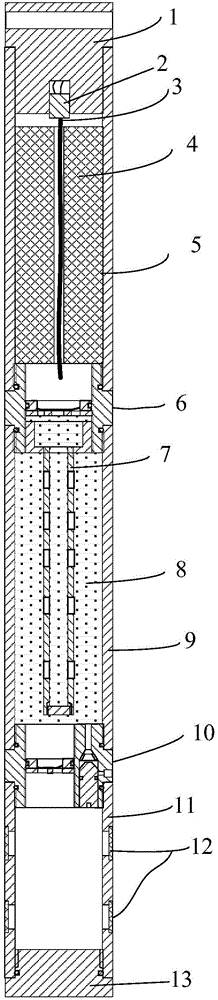

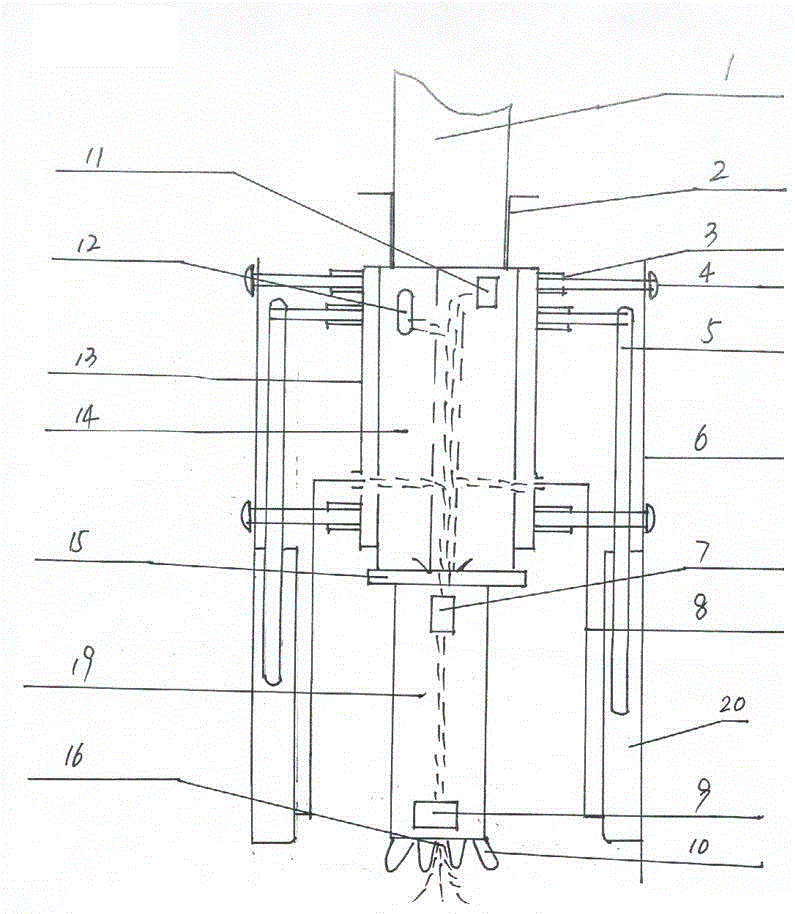

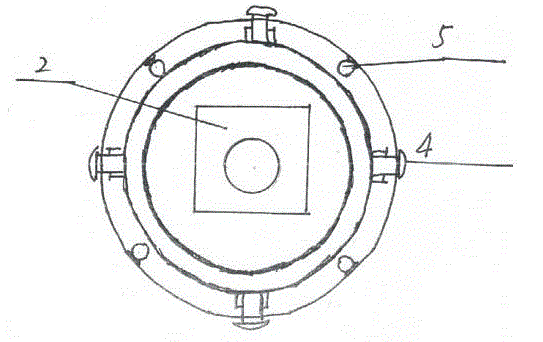

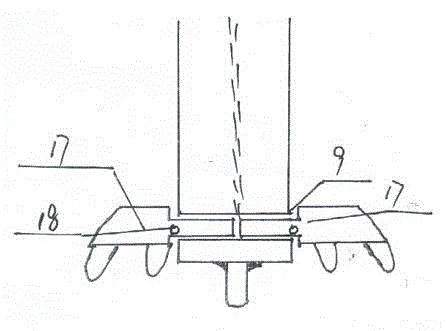

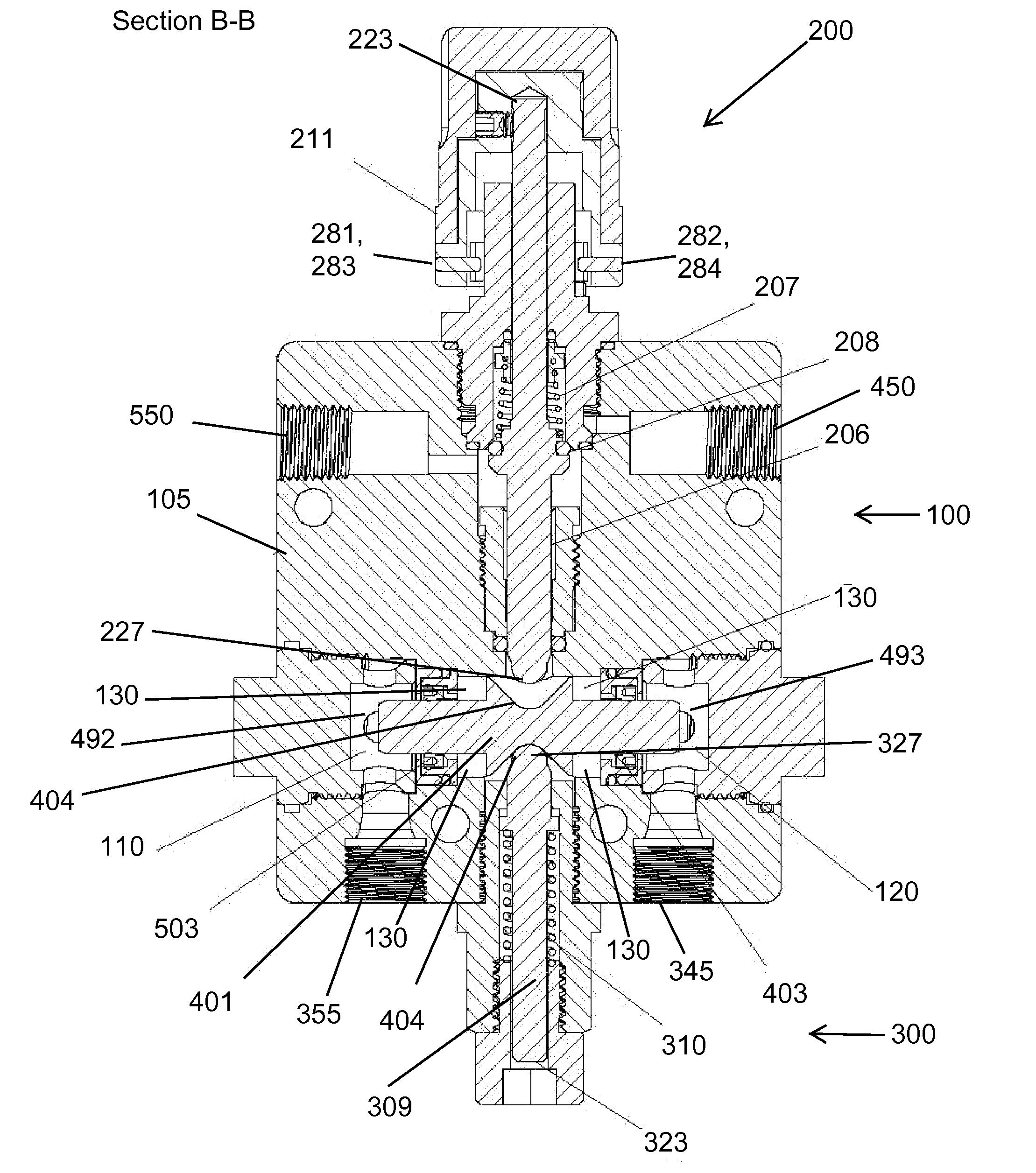

Underground multi-stage intelligent high pressure gas pulse formation fracturing device and method thereof

The invention discloses an underground multi-stage intelligent high pressure gas pulse formation fracturing device and a method thereof, belongs to the technical field of fracturing completion of oil and gas wells, and particularly relates to two technical sachems of the device and the method. The method is used for fracturing the underground layer by the underground multi-stage intelligent high pressure gas pulse formation fracturing device. The device is controlled by each stage of intelligent pressure encoding detonator to gradually detonate by stages at proper time to generate a large amount of high pressure gas according to the set working mode, the dynamic high pressure pulse pressure is formed in the well or holes of a formation, the formation is fractured to form a plurality of cracks, and the permeability of fluid in the formation is increased, so the oil and gas are easily produced. The device and the method have the advantages that the cyclic multiple pressure pulses which are controlled at proper pressure can be generated, so the formation can generate the compression-expansion-compression alternating 'resonance', the cracks are promoted to effectively extend, and a new fracturing network is formed, so the permeability of the formation is improved; the pollution to the formation and environment in the fracturing process is avoided; the method is suitable for the water-sensitive and acid-sensitive formation; the construction cycle is short, the cost is low, the equipment is simple and convenient, and the limitation by terrain and water sources is avoided.

Owner:ZHONGBEI UNIV

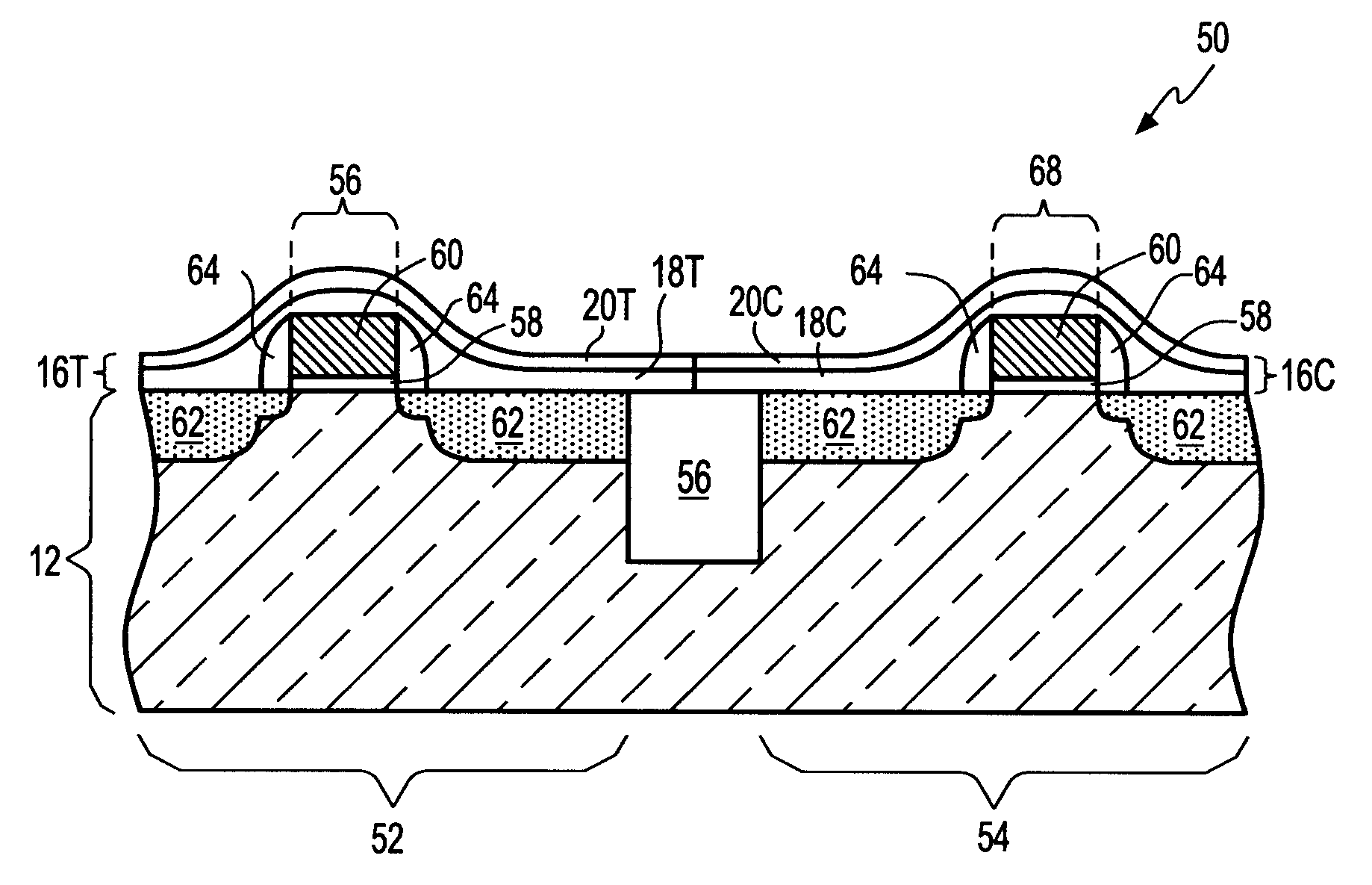

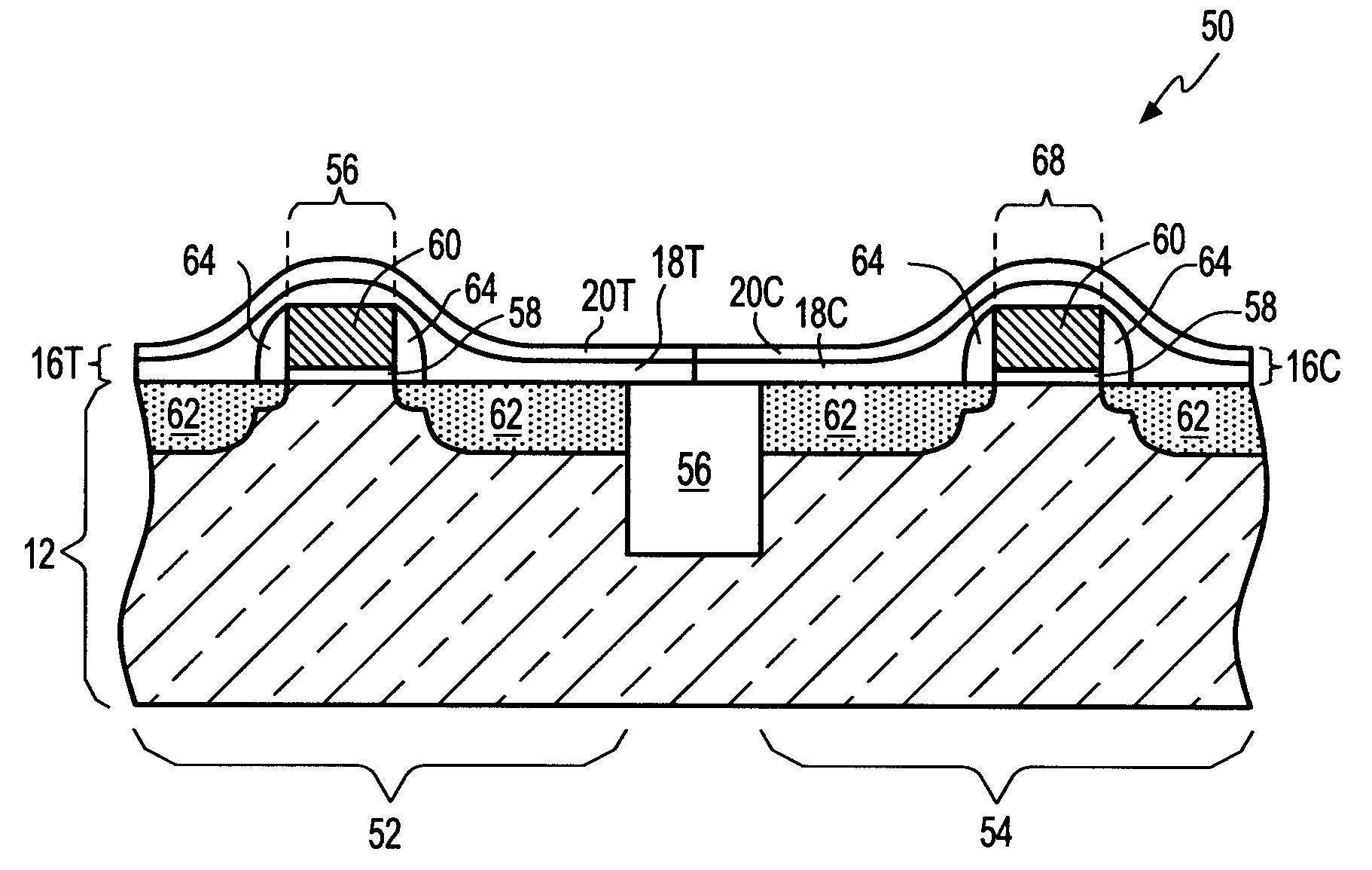

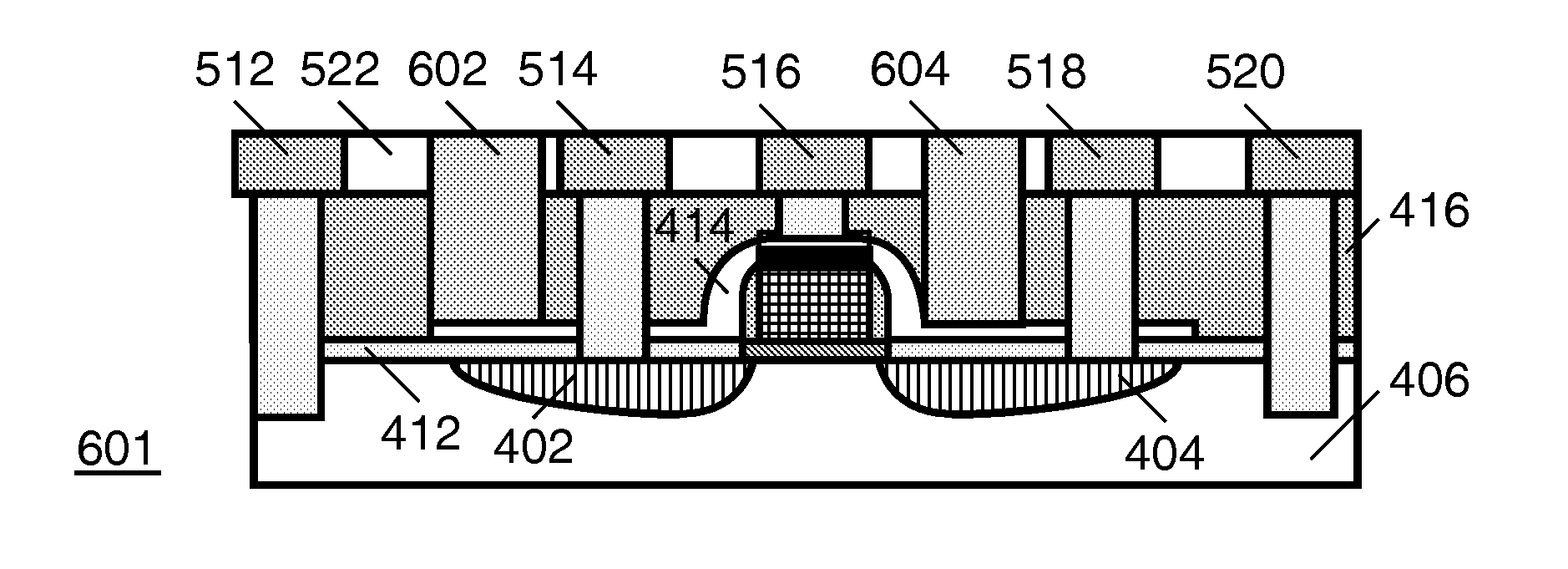

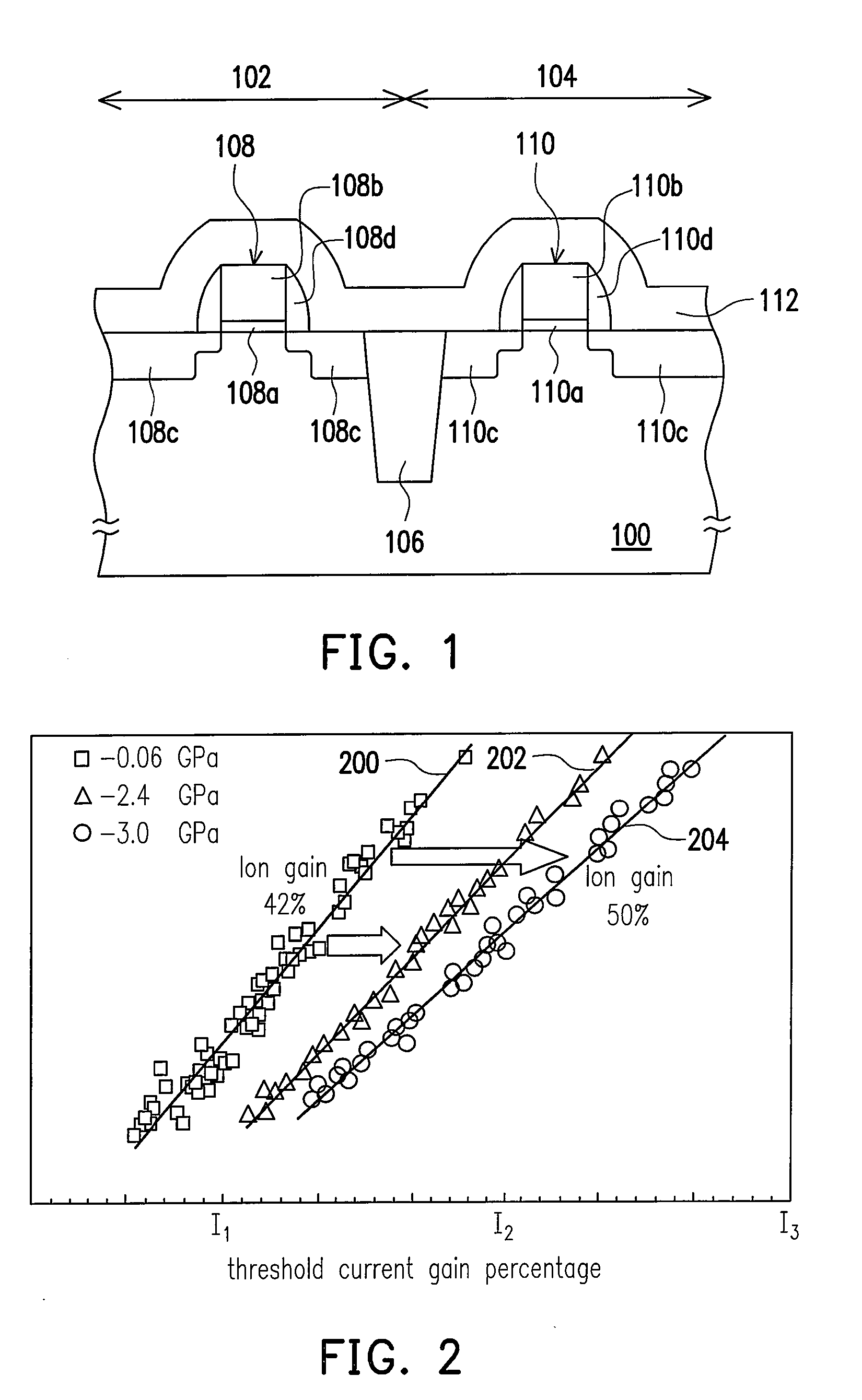

Method of producing highly strained PECVD silicon nitride thin films at low temperature

InactiveUS7585704B2Improve stress conditionIncrease the pressure valueSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThin membraneComposite material

A method for increasing the level of stress for amorphous thin film stressors by means of modifying the internal structure of such stressors is provided. The method includes first forming a first portion of an amorphous film stressor material on at least a surface of a substrate, said first portion having a first state of mechanical strain defining a first stress value. After the forming step, the first portion of the amorphous film stressor material is densified such that the first state of mechanical strain is not substantially altered, while increasing the first stress value. In some embodiments, the steps of forming and densifying are repeated any number of times to obtain a preselected and desired thickness for the stressor.

Owner:GLOBALFOUNDRIES INC

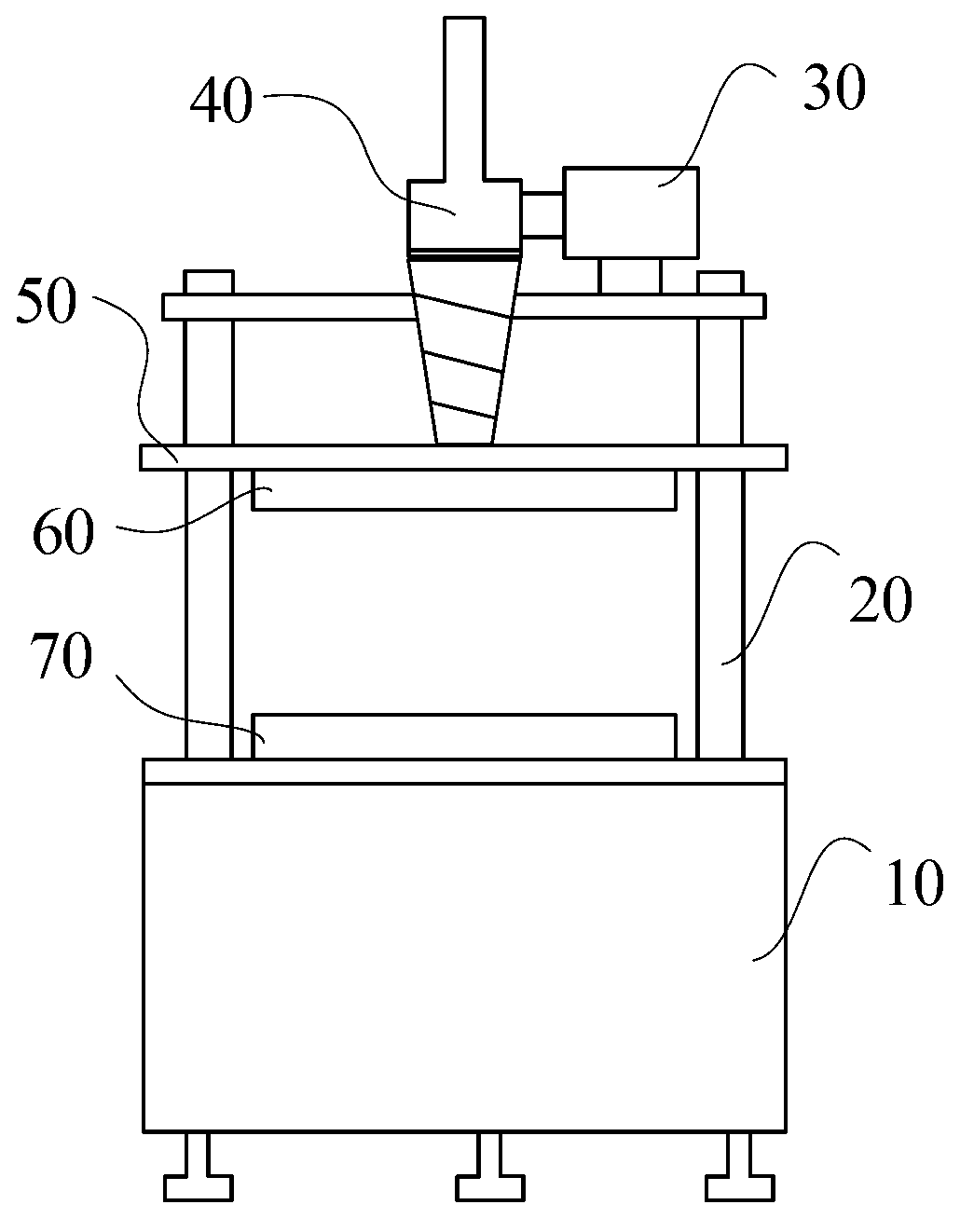

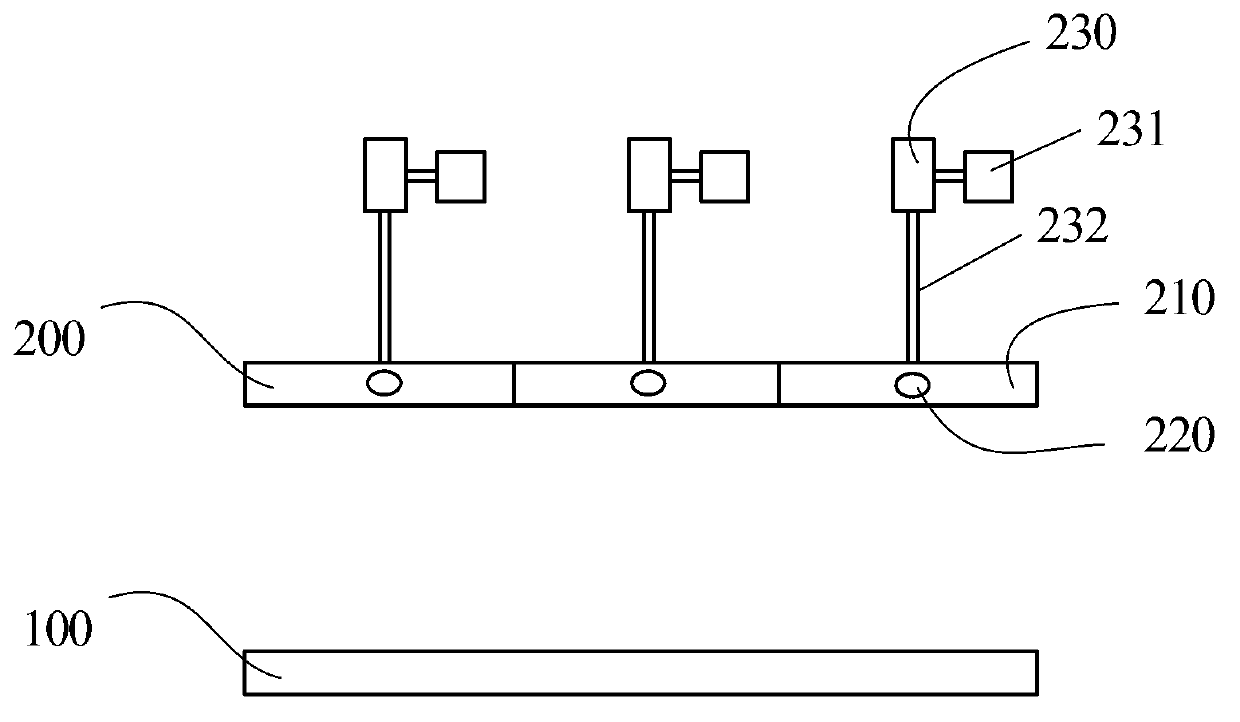

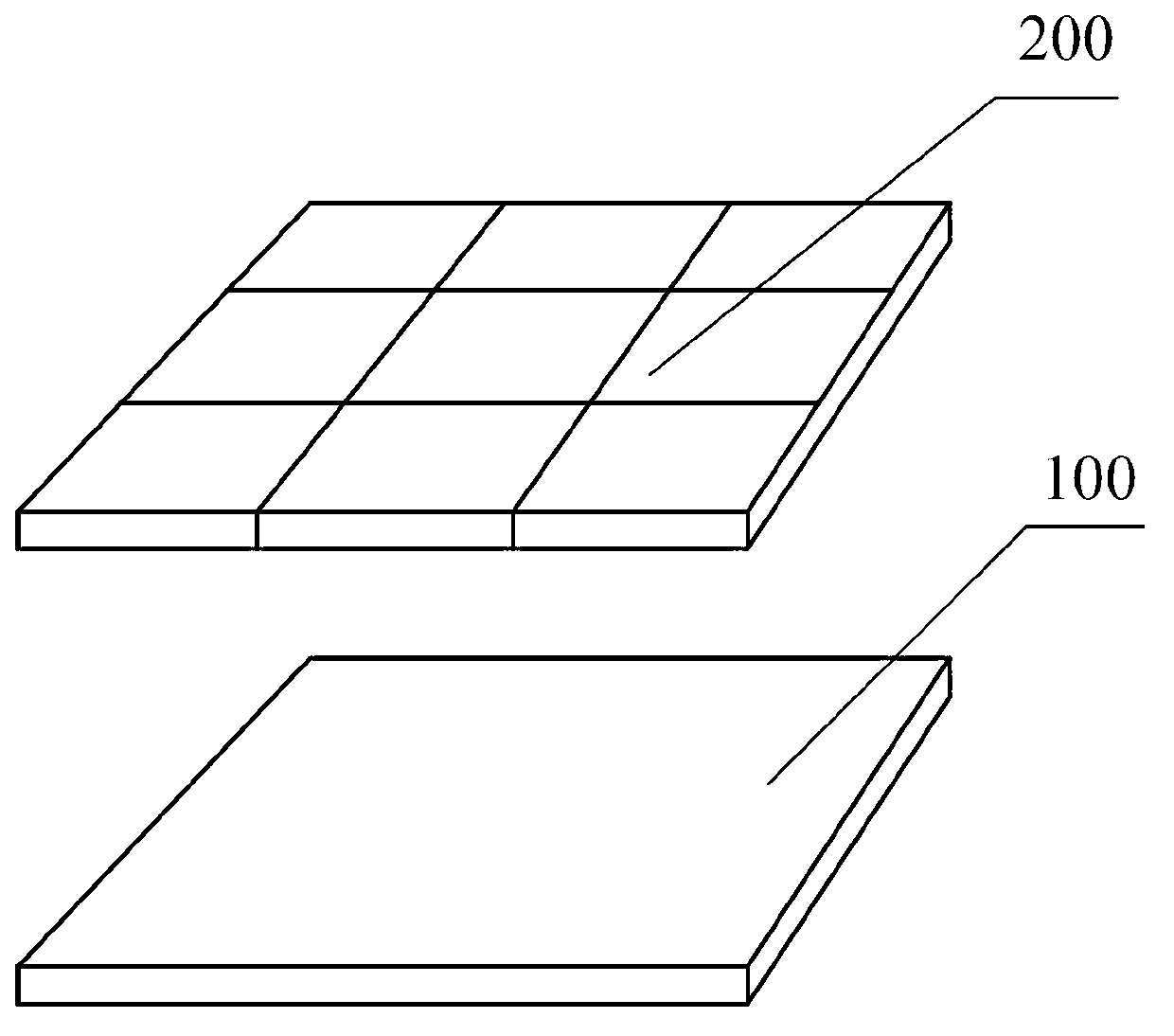

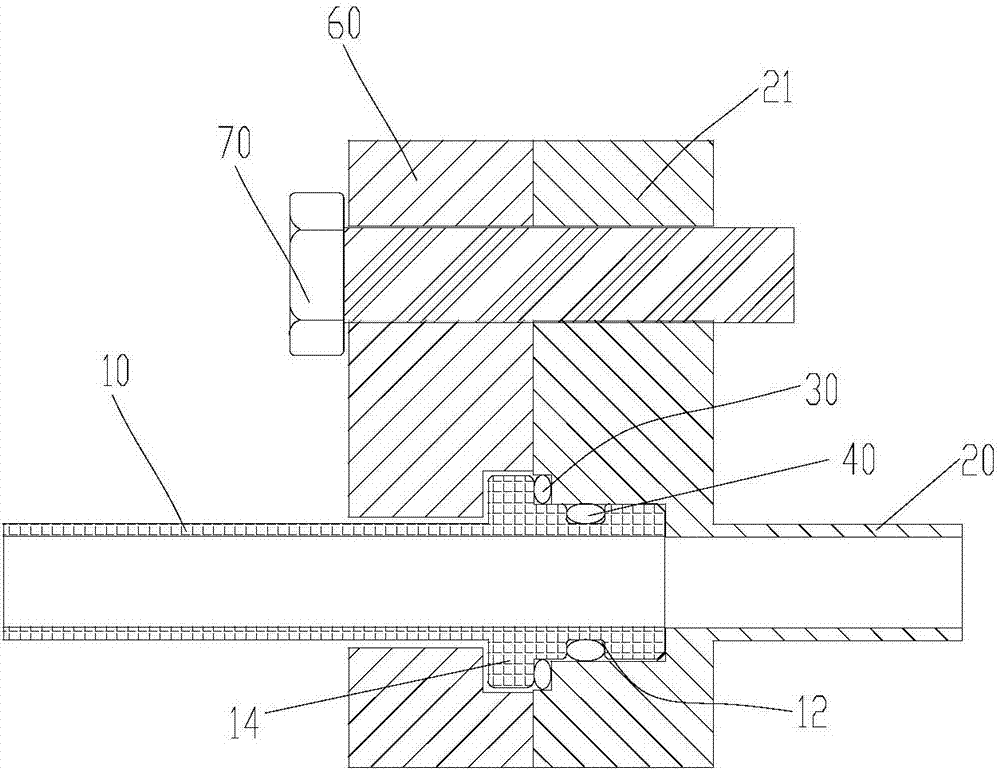

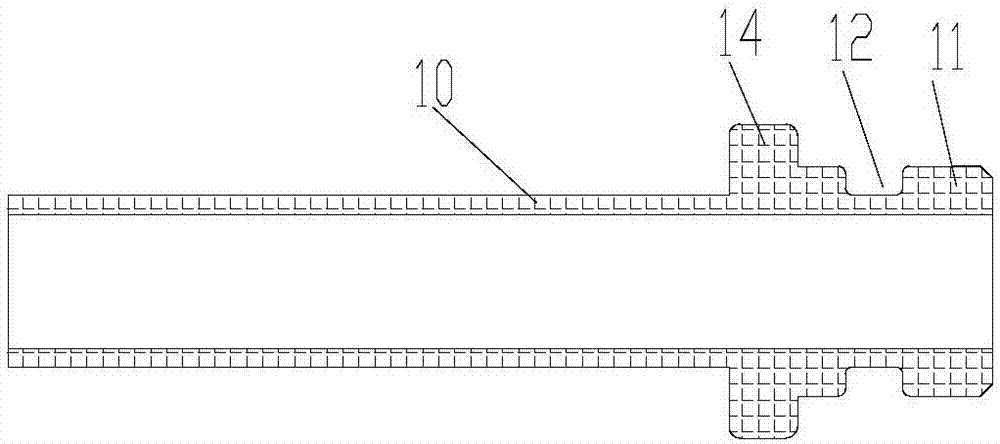

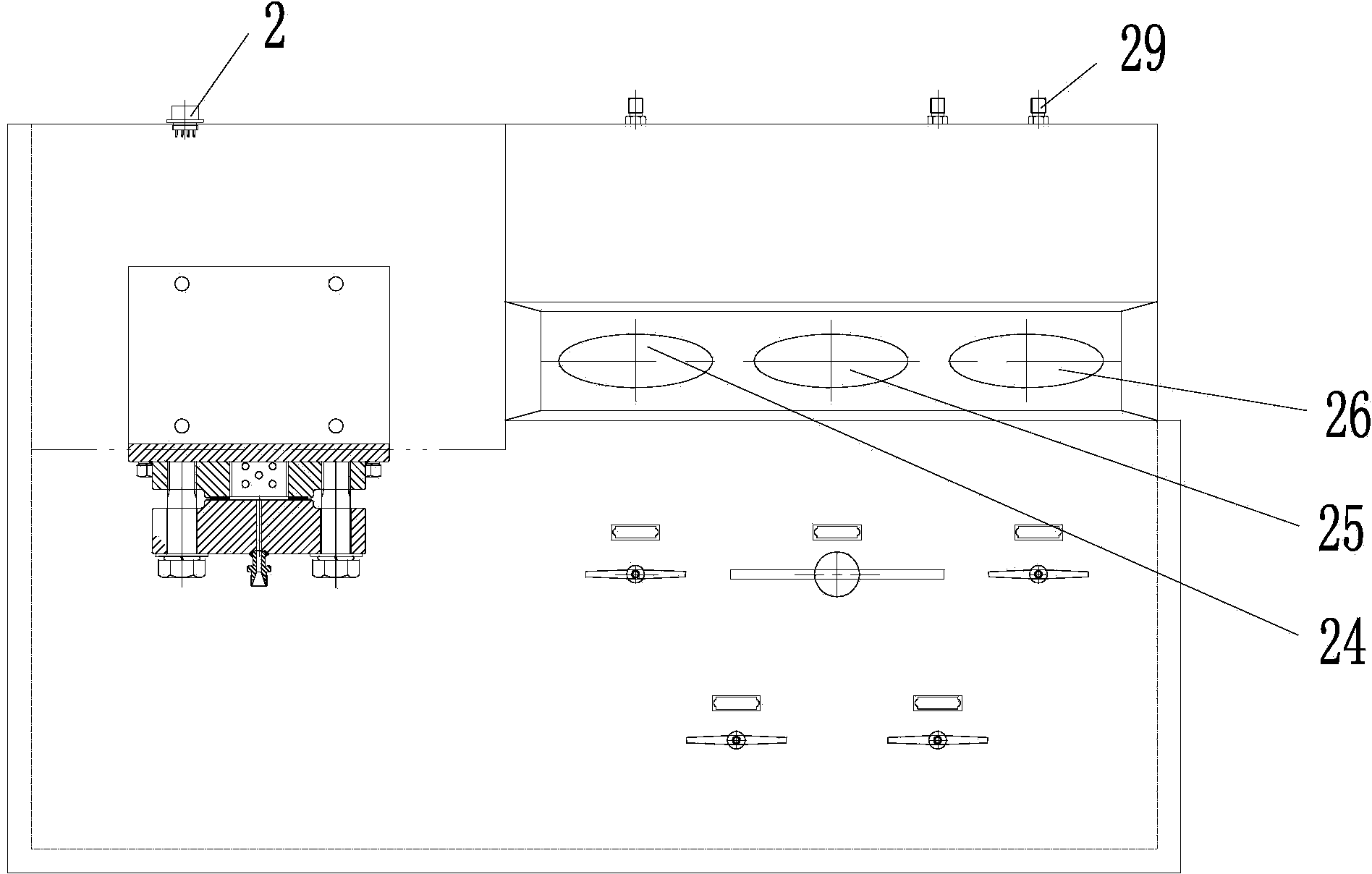

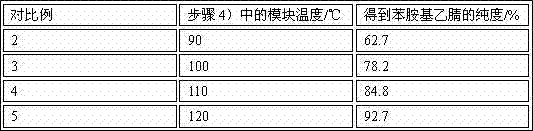

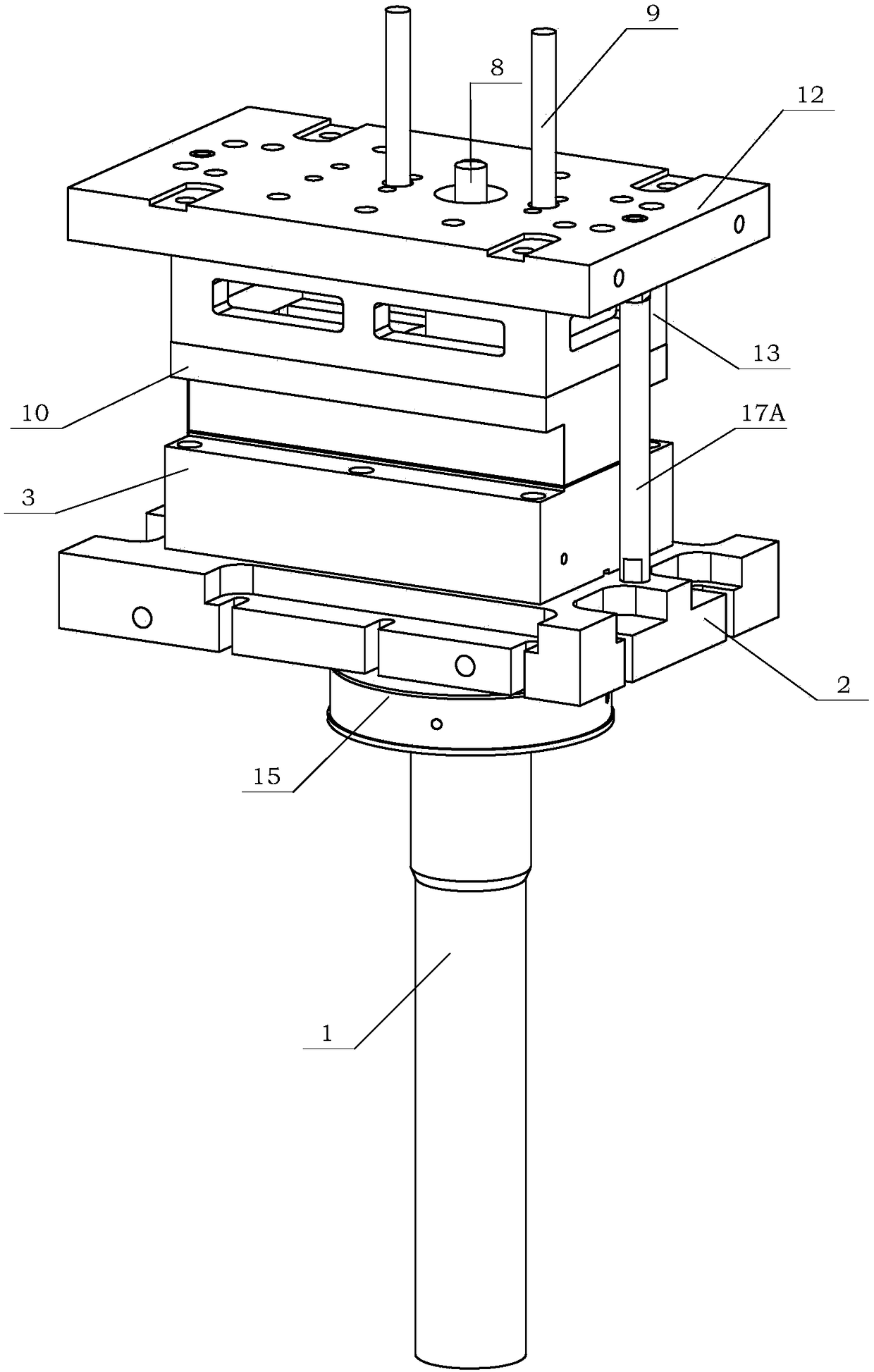

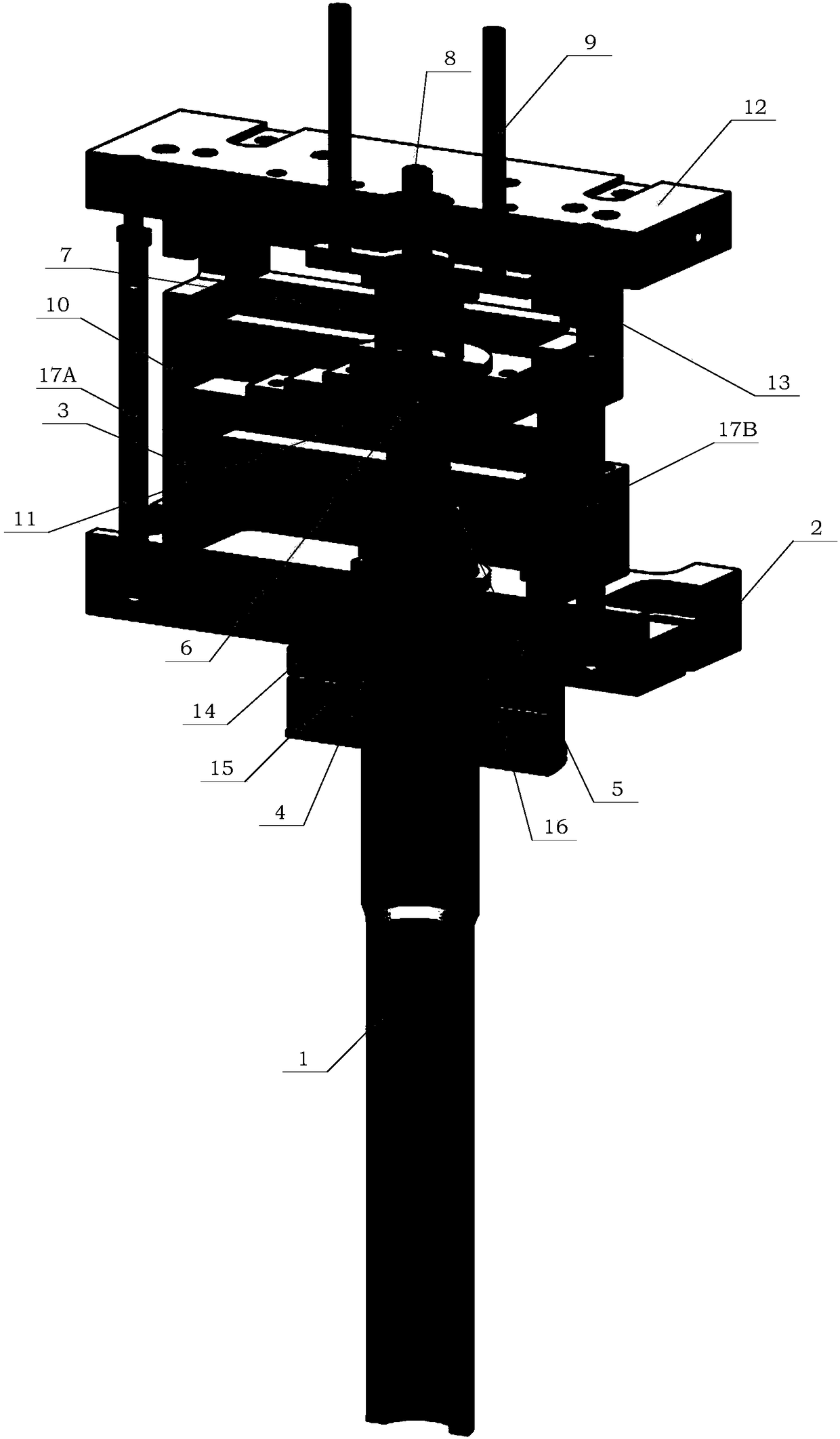

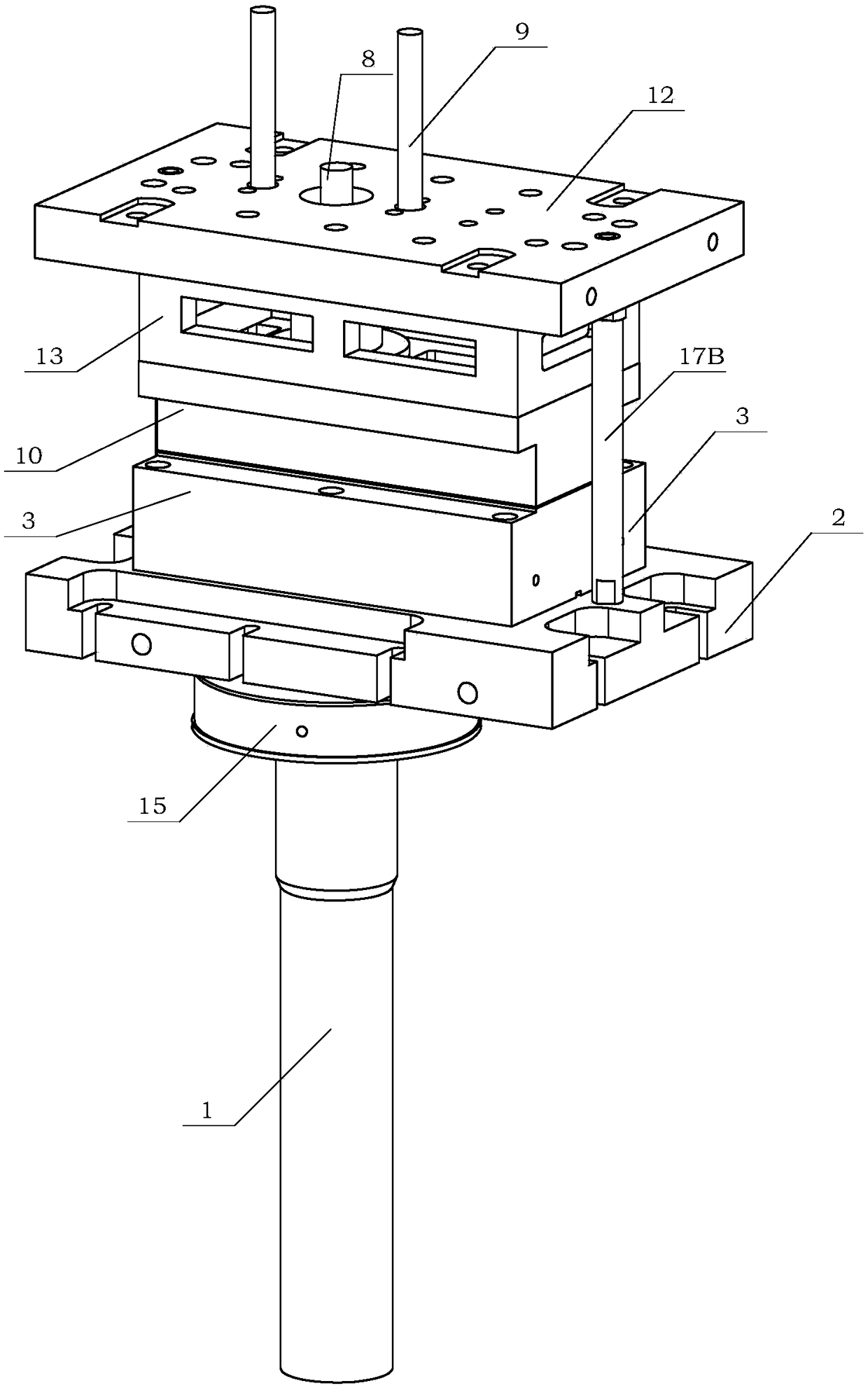

Pressure device

ActiveCN102981289AImprove pass rateLower the pressure valuePress ramNon-linear opticsDynamic pressureLiquid crystal

The invention relates to the technical field of liquid crystal panel manufacturing, in particular to a pressure device which is used for improving the percent of pass of liquid crystal panels in a press fit process. The invention discloses a pressure device comprising a static pressure plate, a dynamic pressure plate, pressure sensors, driving devices and a control device, wherein the dynamic pressure plate is arranged above the static pressure plate and is composed of a plurality of movable press blocks, the pressure sensors are respectively arranged on each of the movable press blocks, driving devices are respectively arranged corresponding to each the movable press blocks, and each driving device is fixedly connected with a movable press block and drives the corresponding movable press block. The control device is respectively connected with each driving device and each pressure sensor in a signal mode, according to pressure values detected by each of the pressure sensors, the control device judges a big or small relationship between the pressure values and a setting pressure value, outputs pressure adjustment signals to the corresponding driving devices, and adjusts the pressure values between the movable press blocks and the static pressure plate to the setting pressure value.

Owner:BOE TECH GRP CO LTD

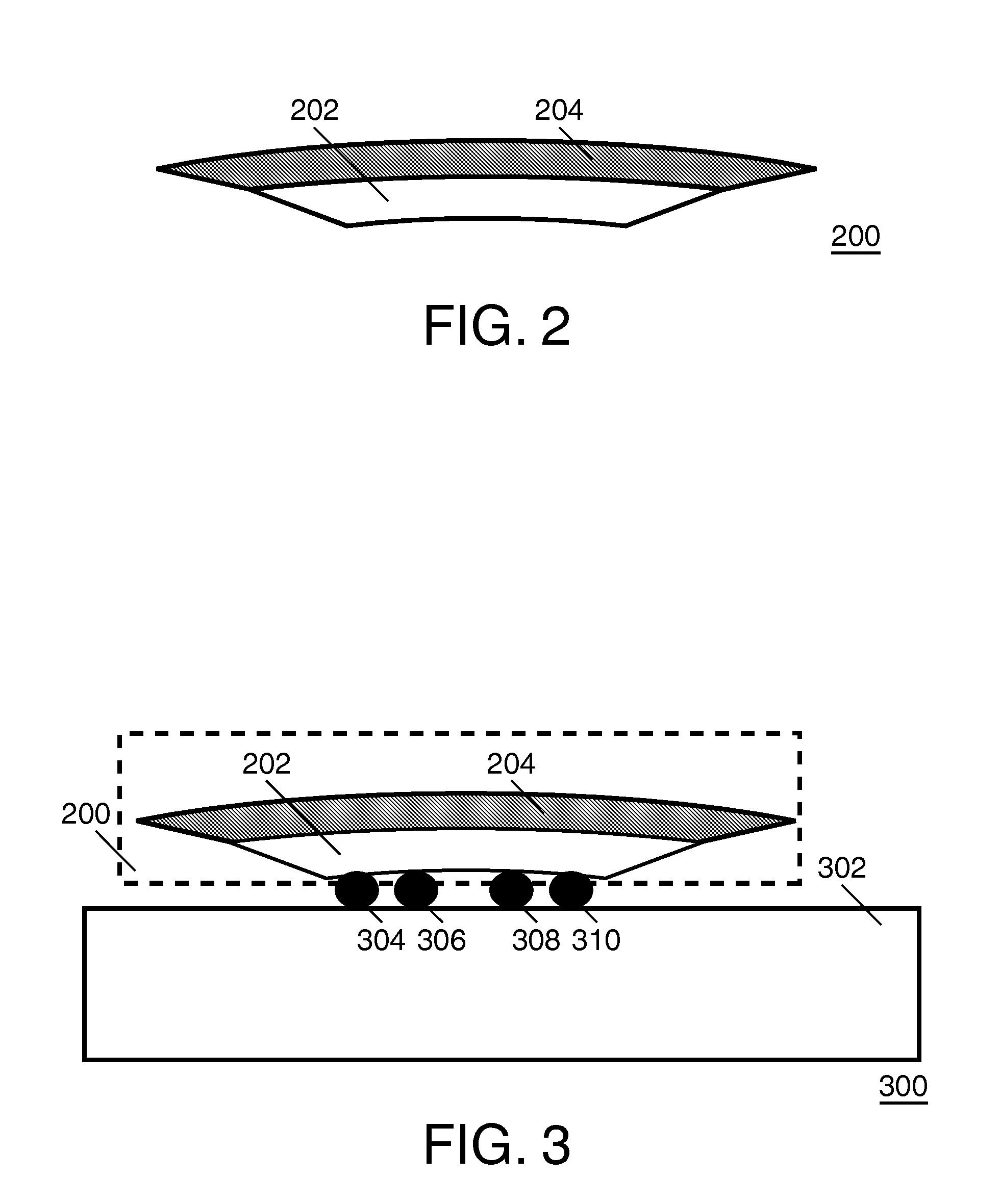

Sensing environmental parameter through stress induced in IC

ActiveUS20110127627A1Easy to manufactureAccurate valueSolid-state devicesPhotovoltaicsEngineeringStress sensing

A sensor is provided for sensing a value of a physical parameter characteristic of the sensor's environment. The sensor is implemented in semiconductor technology. A behavior of the sensor's electronic circuitry is affected by stress. The stress is induced by a film covering the circuitry or only part thereof. The stress is caused by the film's material, whose dimensions depend on a value of the parameter. This dependence is different from the 5 dependence of the circuitry's substrate on the same parameter.

Owner:NXP BV

Fuel cell system

ActiveUS20100021783A1Guaranteed uptimeMore electrical powerReactant parameters controlMotive system fuel cellsFuel cellsEngineering

A fuel cell system has an inlet shutoff valve provided in a main route forming an oxidized gas supply flow path, a humidifier bypass valve provided in a humidifier bypass route which is a route bypassing the main route, a fuel cell bypass valve provided in a fuel cell bypass route bypassing a fuel cell stack, and fuel cell bypass valve controlling unit. Under abnormal conditions in which one of the inlet shutoff valve and the humidifier bypass valve does not function even if the pressure in a valve opening pressure chamber of the one of the valves is at a first pressure value, the fuel cell bypass valve controlling unit restrict the opening of the fuel cell bypass valve to increase the pressure in the valve opening pressure chamber.

Owner:TOYOTA JIDOSHA KK

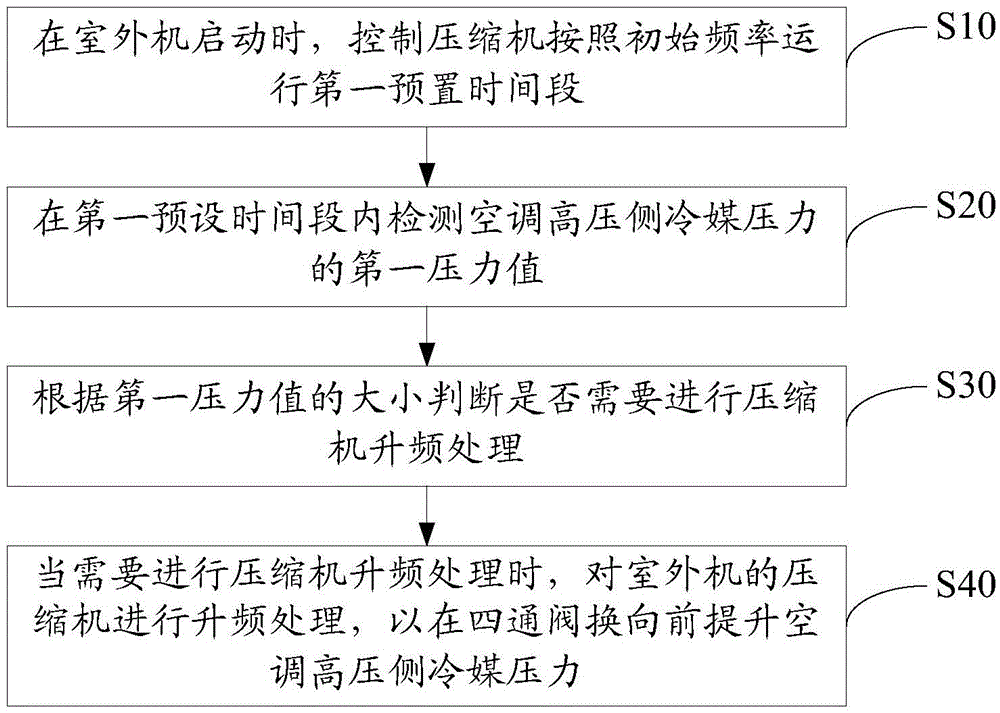

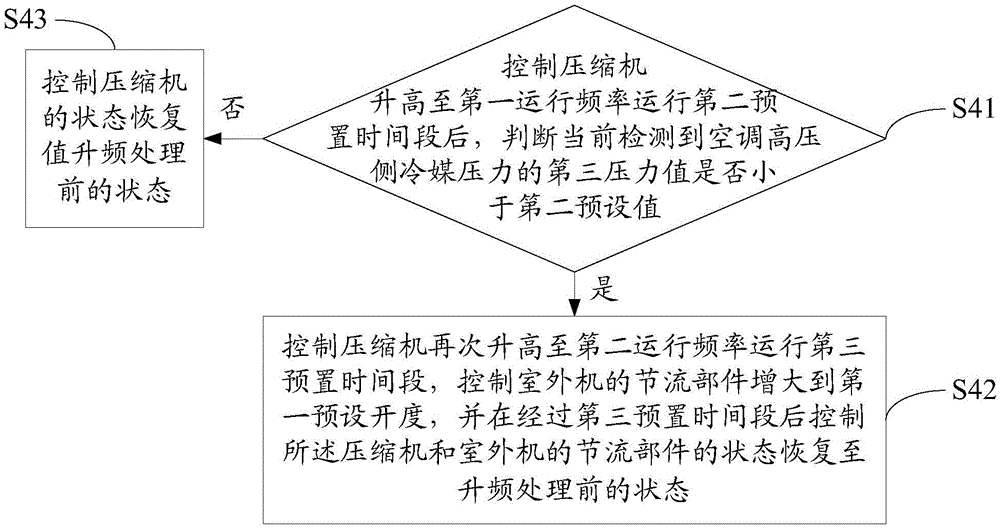

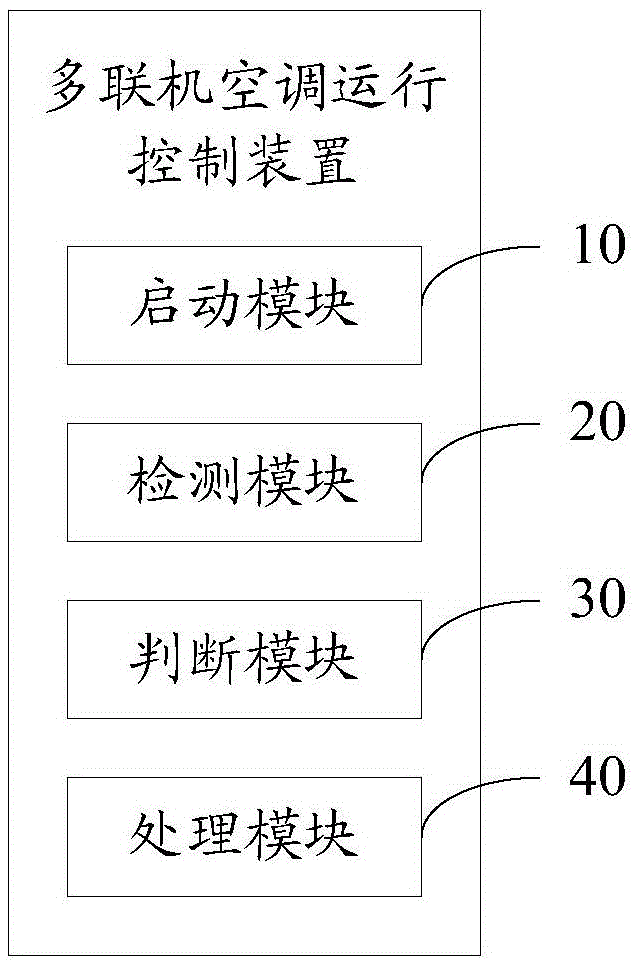

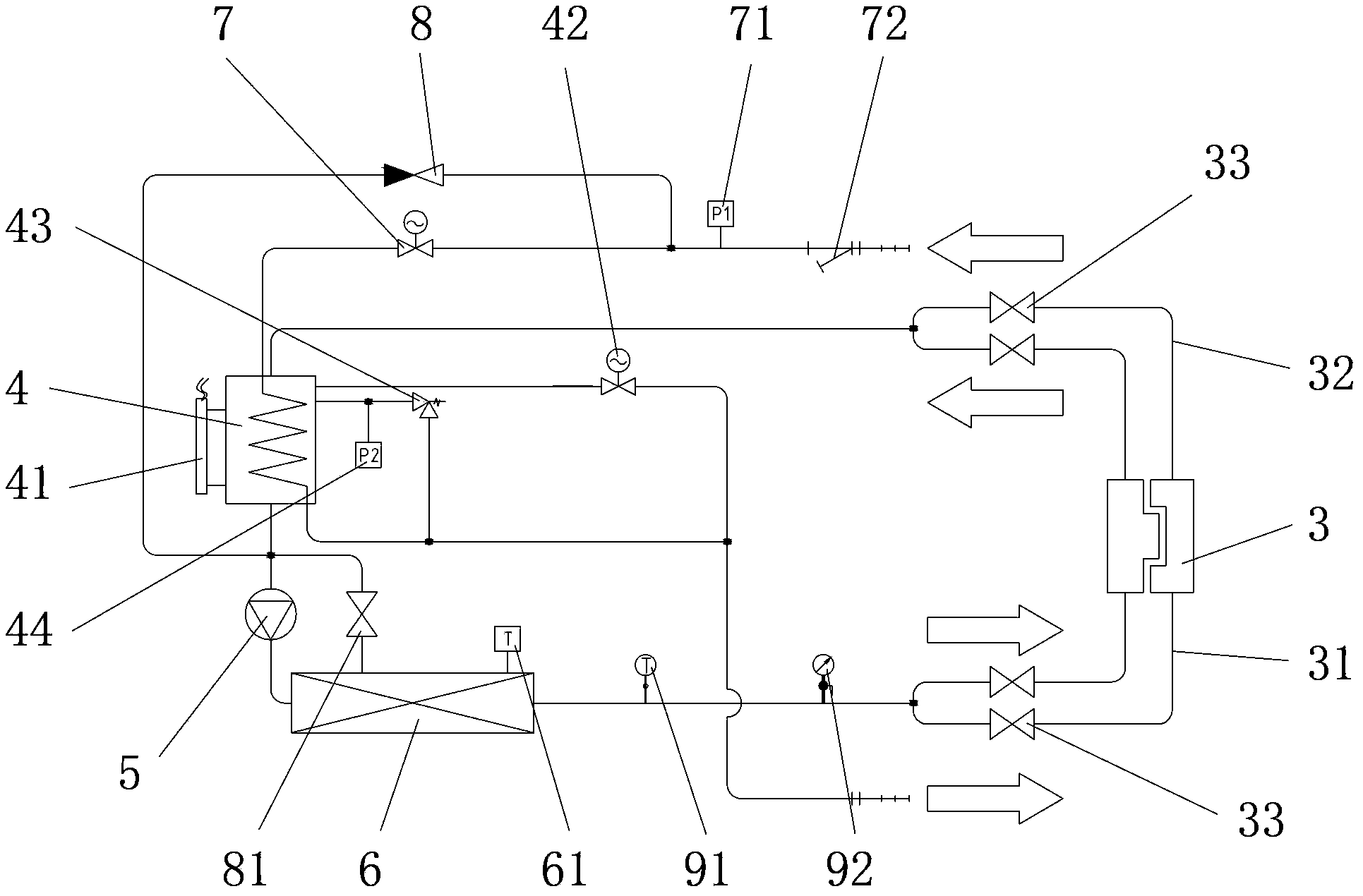

Operation control method and device for multi-split air conditioner

ActiveCN105674479AIncrease the pressure valueGuaranteed pressure valueMechanical apparatusSpace heating and ventilation safety systemsFour-way valveHigh pressure

The invention discloses an operation control method for a multi-split air conditioner. The operation control method for the multi-split air conditioner includes the following steps that when an outdoor unit is started, a compressor is controlled to operate for a first preset time period according to the initial frequency; a first pressure value of refrigerant pressure at the high-pressure side of the air conditioner is detected within the first preset time period; whether frequency increase of the compressor is needed or not is judged according to the first pressure value; and when frequency increase of the compressor is needed, the frequency of the compressor of the outdoor unit is increased, so that the refrigerant pressure at the high-pressure side of the air conditioner is increased before reversing of a four-way valve. The invention further discloses an operation control device for the multi-split air conditioner. By means of the method and device, the reliability of operation of the multi-split air conditioner is improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

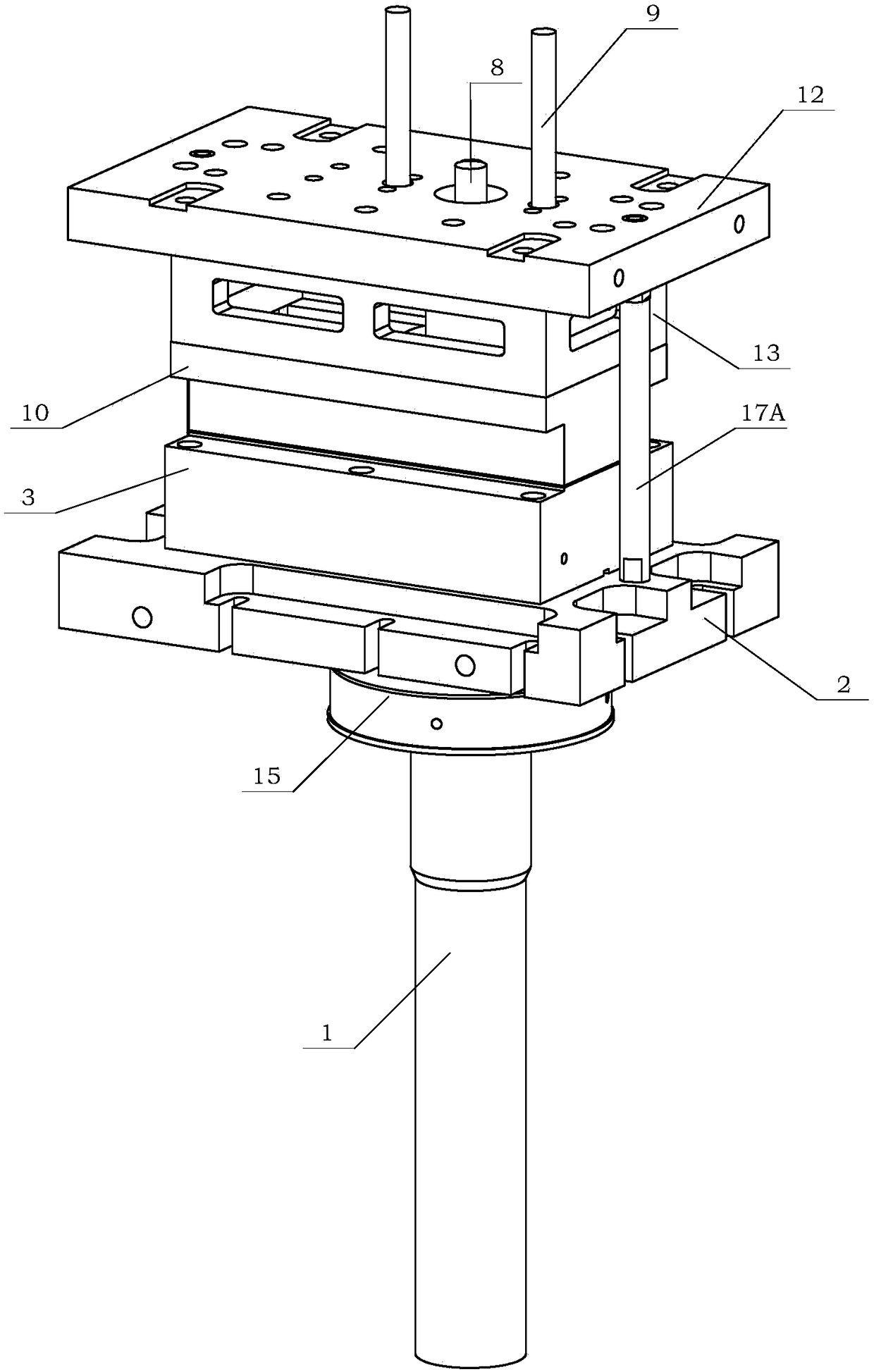

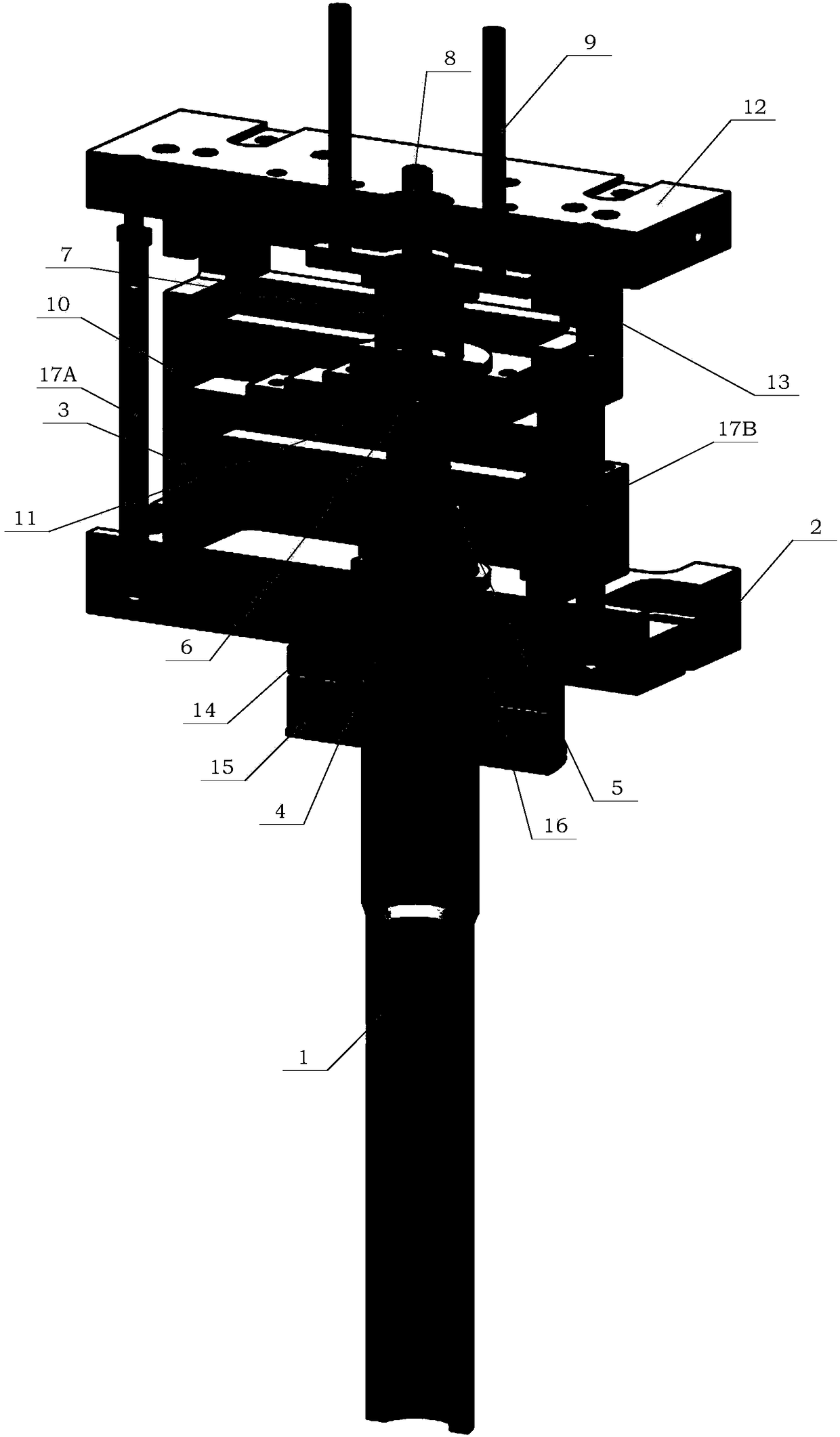

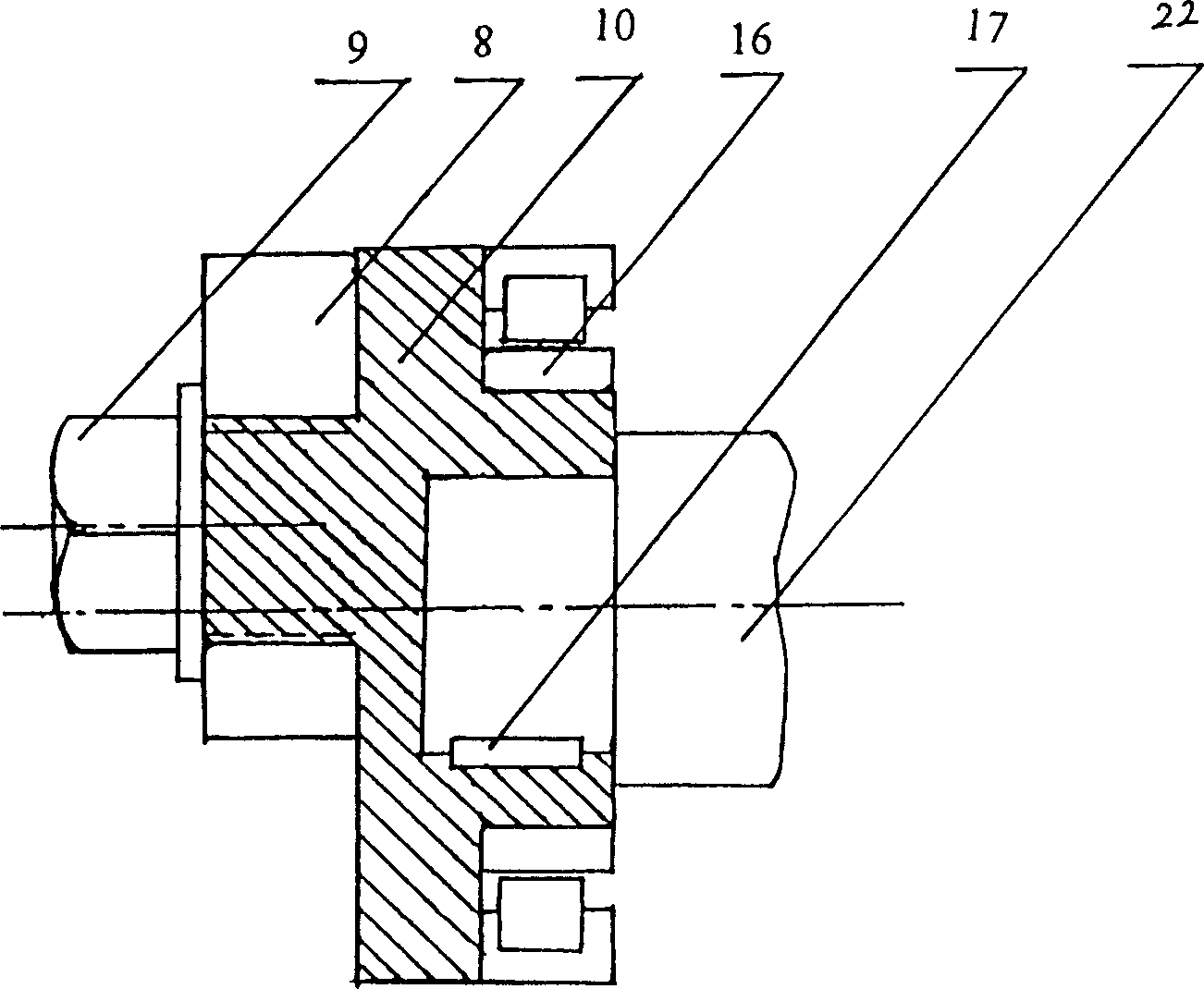

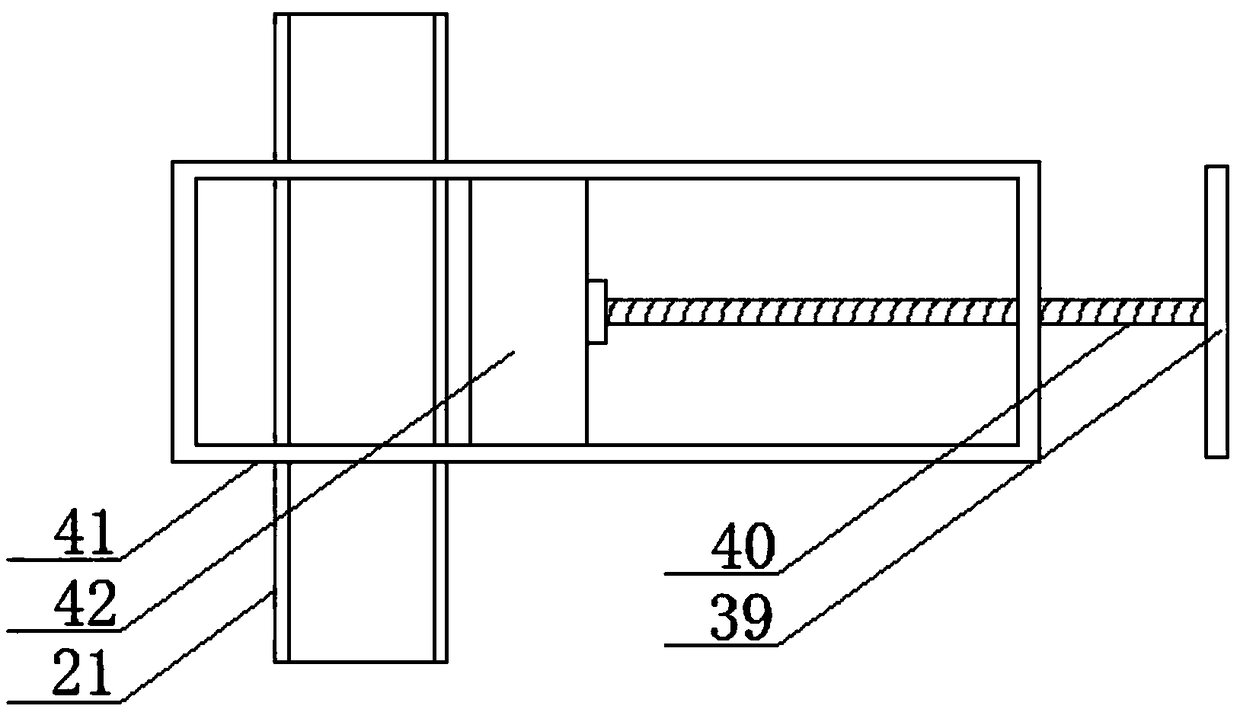

Hole bottom water injection variable-pick multifunctional rock piercing drill of rotary digging pile machine

InactiveCN103982135AIncrease the pressure valueSolve the strength problemDrilling machines and methodsPipingPiston

The invention relates to a rock piercing drill of a rotary digging pile machine, in particular to a hole bottom water injection variable-pick multifunctional rock-piercing drill of the rotary digging pile machine, mainly aiming at solving the problems that the strength of a drill pick is decreased after the drill pick of the existing rock piercing drill of the rotary digging pile machine is heated, the consumption of the drill pick is great, oil and water supply pipelines are frequently twisted on a telescopic drill rod and accidents are caused consequently. The hole bottom water injection variable-pick multifunctional rock-piercing drill of the rotary digging pile machine is characterized in that the lower end of a drill rod socket is fixedly arranged on a rotary water tank core body, the lower end of the rotary water tank core body is connected with a drill rod, a rotary water tank jacket is arranged on the outer circumference of the rotary water tank core body, a water inlet joint, a water pipe and an air exhaust and water overflow valve are arranged on the outer wall of the rotary water tank jacket, an anti-rotating casing is arranged on the outer circumference of the rotary water tank jacket, a water injector is arranged on the inner side of the lower end of the anti-rotating casing, a water injection piston of the water injector is connected onto the rotary water tank jacket, a center hole which is communicated with the rotary water tank core body is formed in the drill rod, one end of a high-pressure water pipe is connected onto the water injector, the other end of the high-pressure water pipe is connected into the water injection hole in the rotary water tank jacket and a check valve is arranged in the drill rod. The hole bottom water injection variable-pick multifunctional rock-piercing drill of the rotary digging pile machine has the advantages that the temperature of the drill pick can be kept normal, the wear is reduced, the structure is safe and reliable and the installation and the maintenance are facilitated.

Owner:高广升

Low-pressure mold filling and high-pressure solidifying casting device and casing method for low-pressure supercharged casting machine

InactiveCN108080601AReduce or eliminate casting defects such as shrinkage cavity and porosityImprove performanceSlagShrinkage porosity

The invention discloses a low-pressure controllable mold filling and high-pressure solidifying molding casting device and casting method for a low pressure and low-pressure supercharged casting machine. The device comprises a casting mold, a metal melt ascending feed channel and a flow dividing cone capable of moving up and down; the flow dividing cone can plays a role in flow dividing guidance and filter net compaction on the metal melt in the ascending feed stage, the metal melt is stably subject to mold filling in a laminar flow manner, after mold filling is finished, the flow dividing conedescends to form a seal structure, a sprue bush and a metal melt inlet of a m old cavity are closed. The metal liquid is subject to high supercharging, and is solidified under the high pressure, defects of shrinkage porosity, slag inclusion and the like can be overcome, the shape of the flow dividing cone is optimized, and metal melt low-pressure controllable stable mold filling and high-pressuresolidifying molding are ensured. The device and method can be used for casting of shell, frame, and bucket castings, and compared with traditional low-pressure casting, the strength can be improved by 10 to 50%, and the extension rate can be improved by 30 to 90%.

Owner:BEIHANG UNIV

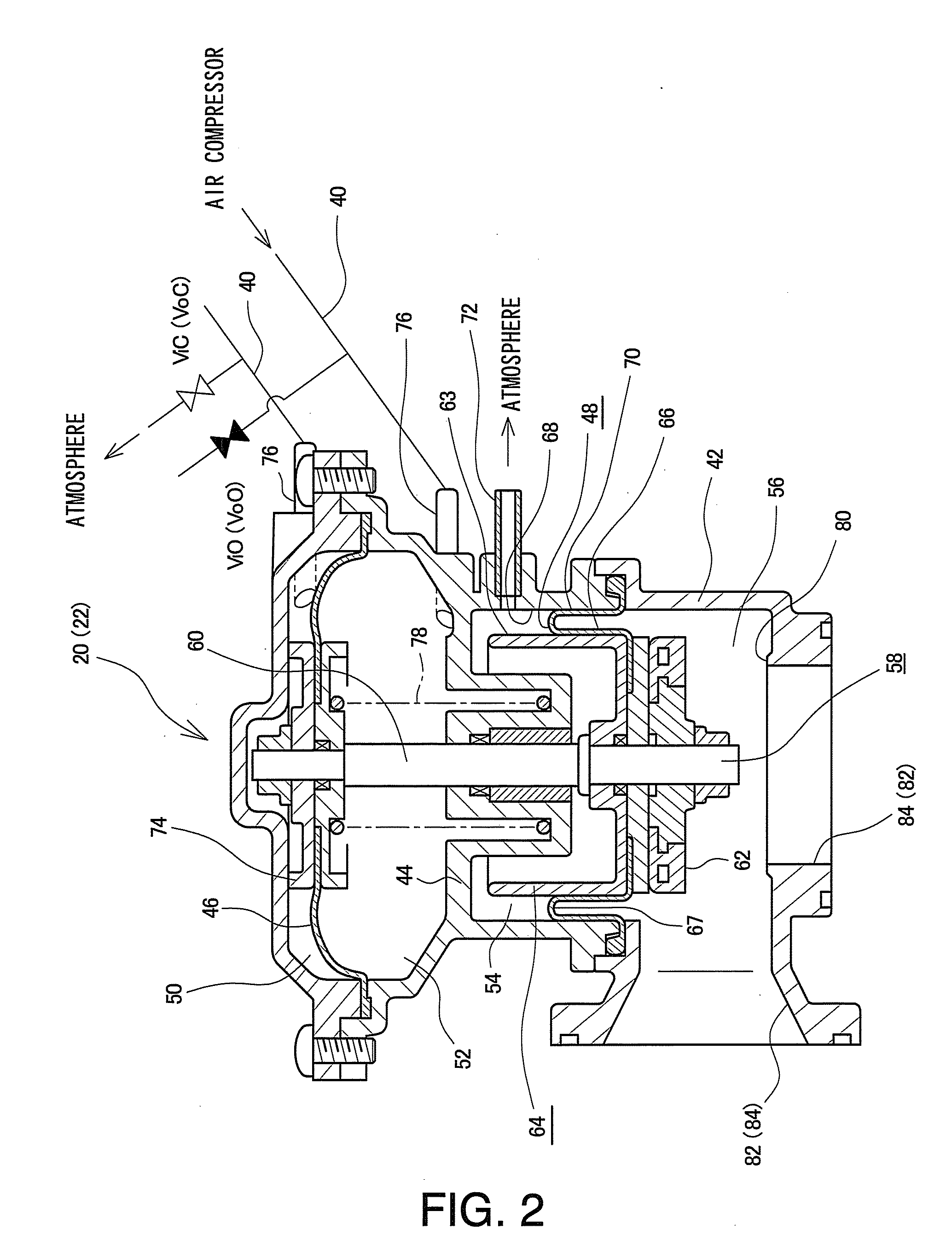

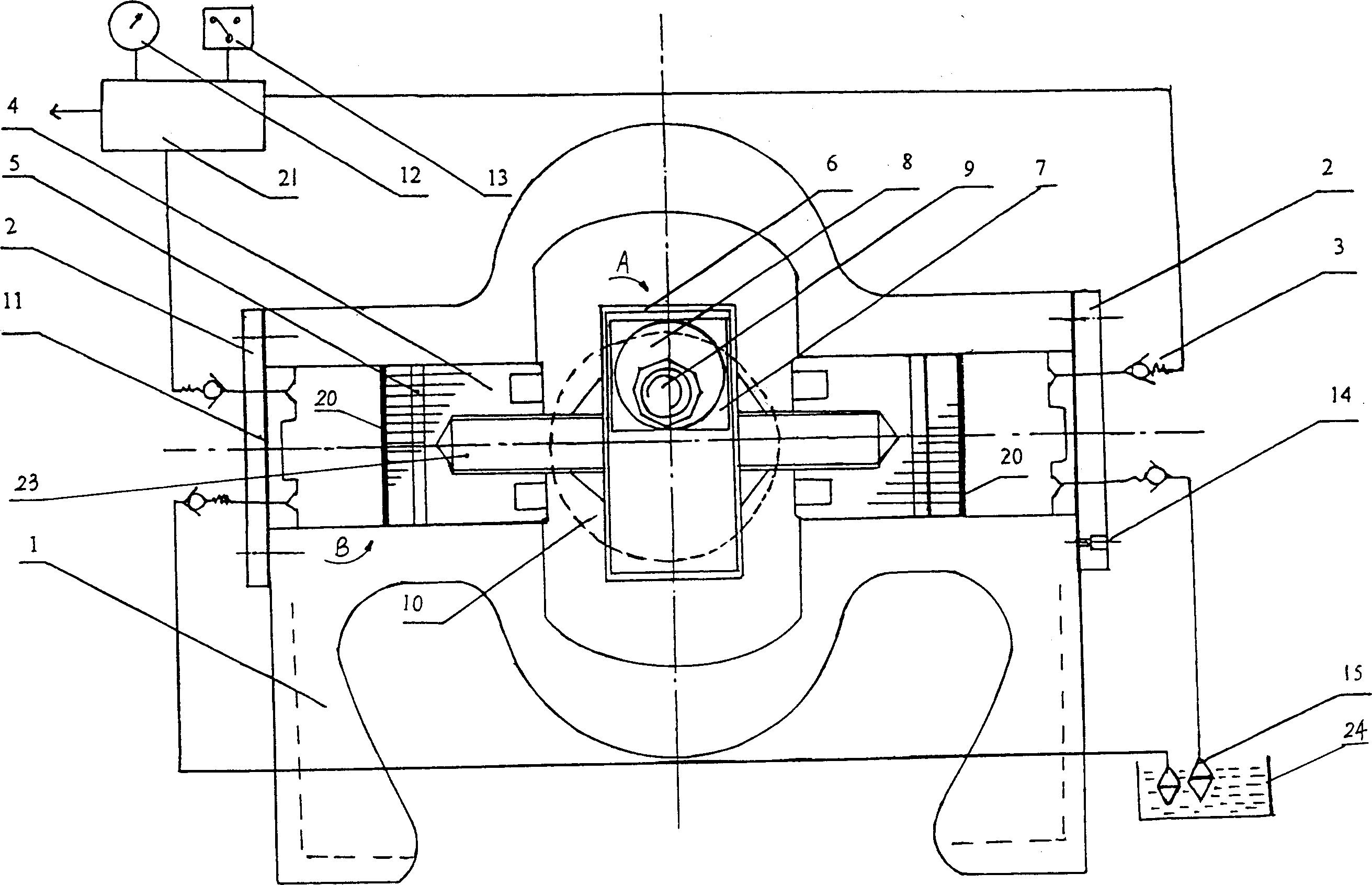

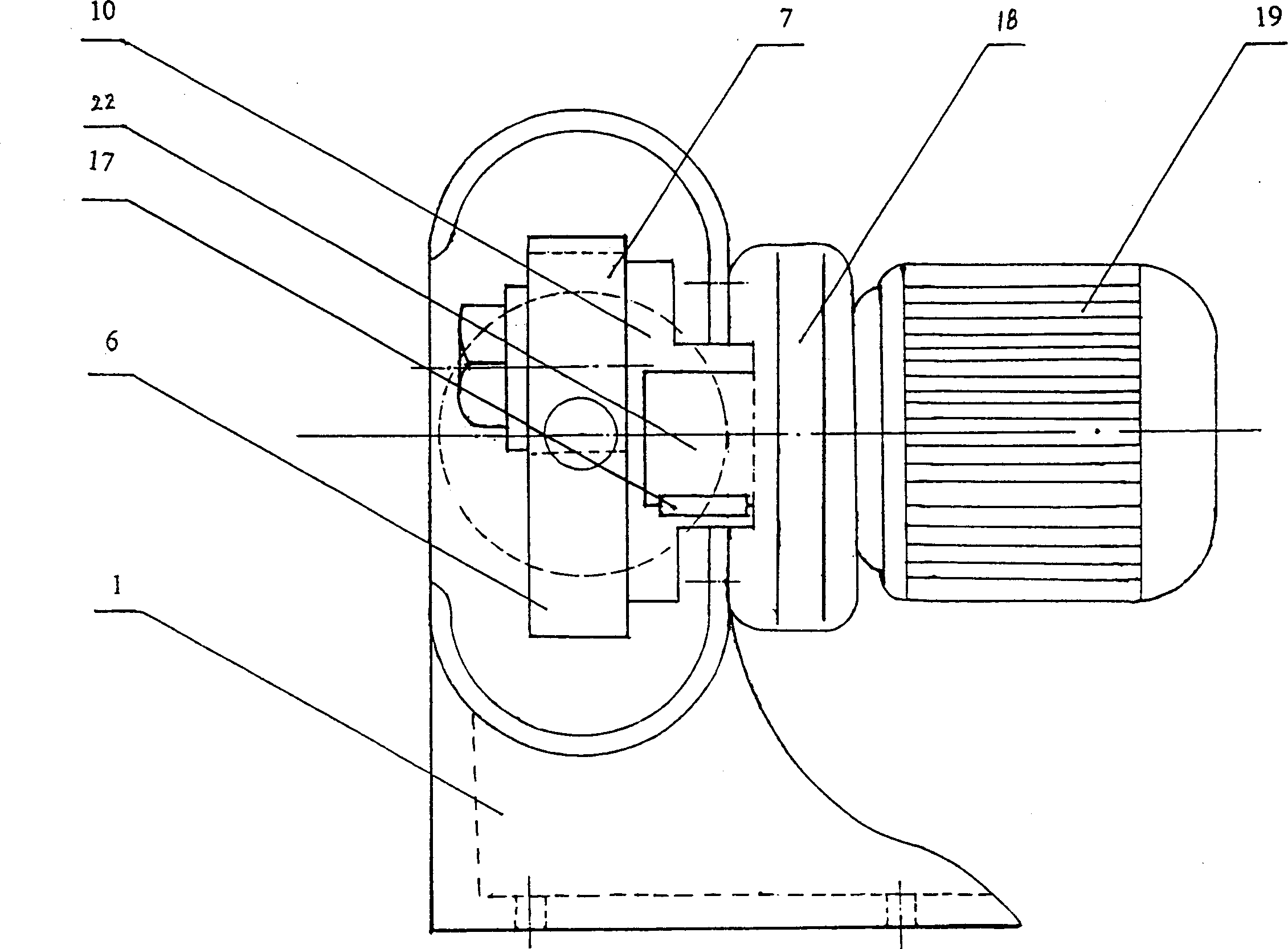

Self-aligning supercharger

InactiveCN1521396AIncrease the pressure valueMeet the needs of different pressuresPiston pumpsPositive-displacement liquid enginesHydraulic cylinderReciprocating motion

The invention relates to a center distance regulating supercharger comprising a supercharger body, a high pressure cylinder, an one-way valve and a liquid storing tank, wherein the supercharger body comprises a frame, a center distance regulating apparatus arranged in the frame, a piston hydraulic cylinder arranged on the two sides of the center distance regulating apparatus, and a cylinder cap arranged on the outboard of the piston hydraulic cylinder. The center regulating apparatus is provided with a slide block holder, a slide block reciprocating the slide block holder, a center distance wheel in movable fit with the slide block in the bore of the slide block, a sheave driving the center distance wheel rotate, the two sides of the slide block holder are connected with the piston in the piston hydraulic cylinder.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

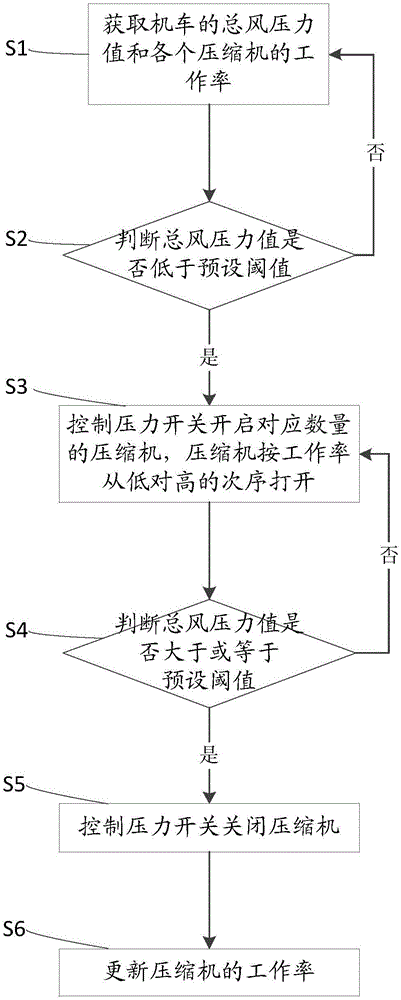

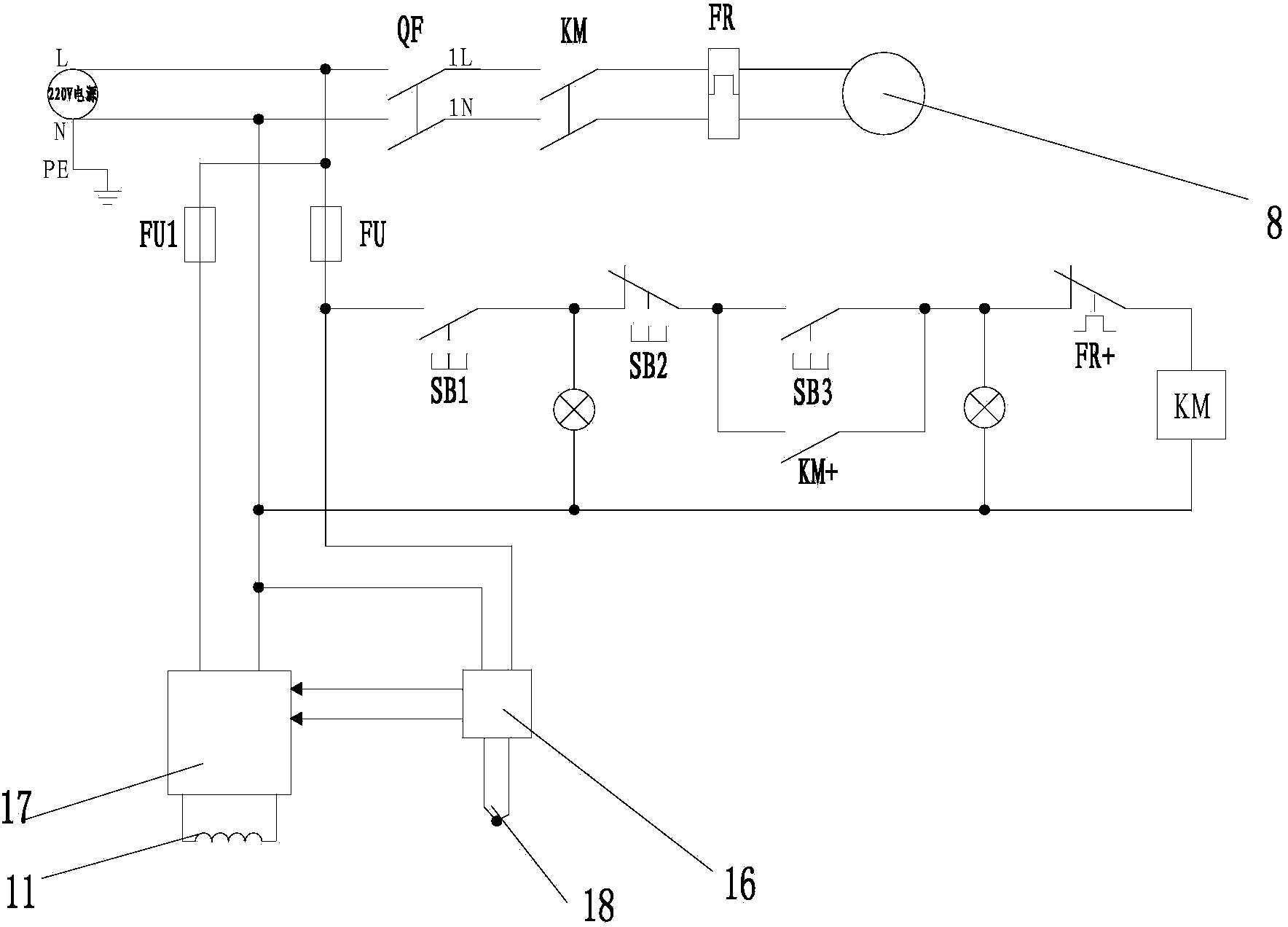

Control method and device of locomotive compressors

ActiveCN106351823AAverage work rateAvoid emulsificationPump controlPositive-displacement liquid enginesContinuous useDynamic balance

The invention discloses a control method of locomotive compressors. The control method comprises the following steps of: acquiring a total air-pressure value of a locomotive and the working rates of all compressors in advance; and judging whether the total air-pressure value is lower than a preset threshold value, if so, controlling a pressure switch to start the compressors with corresponding quantity, and starting the compressors in a sequence from low to high according to the working rates so as to increase the total air-pressure value. The control method disclosed by the invention has the advantages that the compressors with low working rates are used preferentially, so that the working efficiency of the compressors is improved; if the working rates of certain compressors are low, the actual working rates of the certain compressors are improved by the control method, and compared with the traditional starting mode, the long-time stopping without working of the certain compressors due to long-time working is avoided and the problems of oil emulsification of the compressors and the like are avoided; and due to continuous use of the compressors with low working rates, the working rates of all the compressors keep the state of dynamic balance all the time, and the working rates among the compressors are average relatively, so that the maintenance periods can be synchronous. A control device of the locomotive compressors, provided by the invention, can realize same technical effects.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

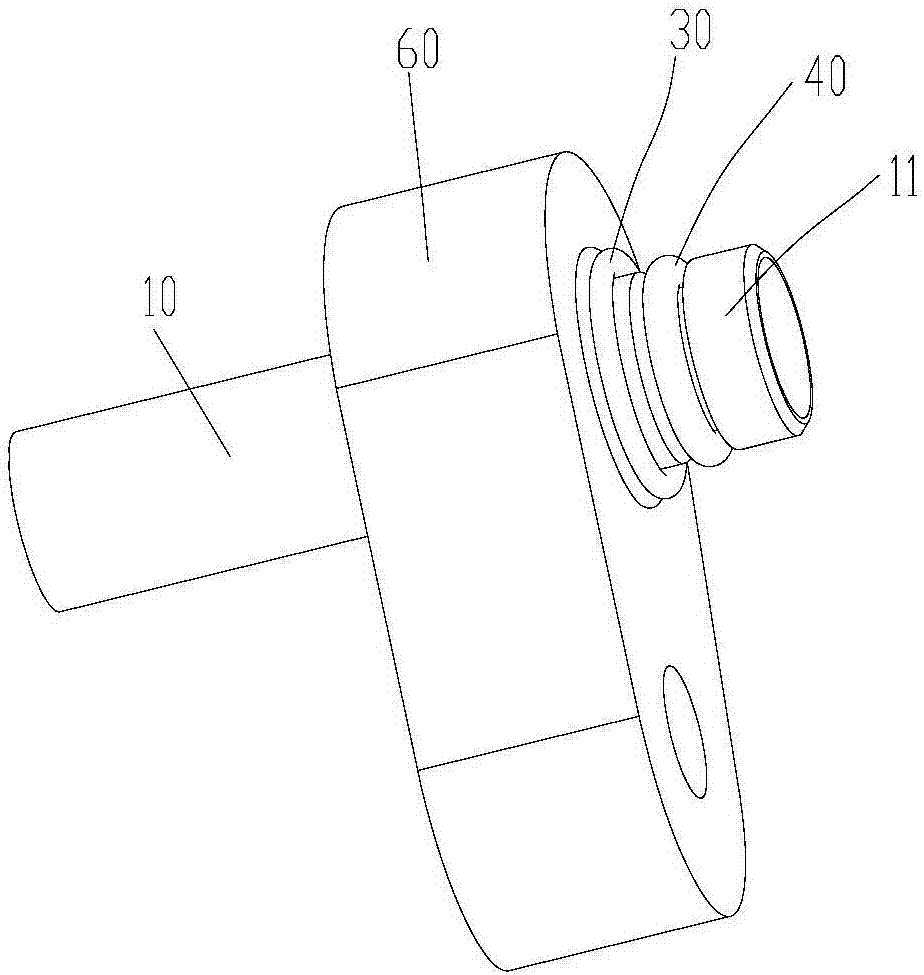

Pipe joint device and car air conditioner

PendingCN106907538AImprove sealingNo leakageSleeve/socket jointsAutomobile air conditioningSystem pressure

The invention provides a pipe joint device and a car air conditioner. The pipe joint device comprises a first pipe joint and a second pipe joint which is in butt joint with the second pipe joint, wherein the first pipe joint and the second pipe joint are sealed by an axial sealing part and a radial sealing part. The pipe joint device and the car air conditioner provided by the invention can be suitable for various road conditions in a car operation process, so that even a car is in a bumpy condition, a refrigerant leakage condition is avoided. Besides, sealing properties of the pipe joints are relatively high, so that a refrigerating system pressure resistance value of the pipe joint device can be increased, and therefore, the pipe joint device is applied to a refrigerant refrigerating system with relatively high operation pressure.

Owner:GREE ELECTRIC APPLIANCES INC

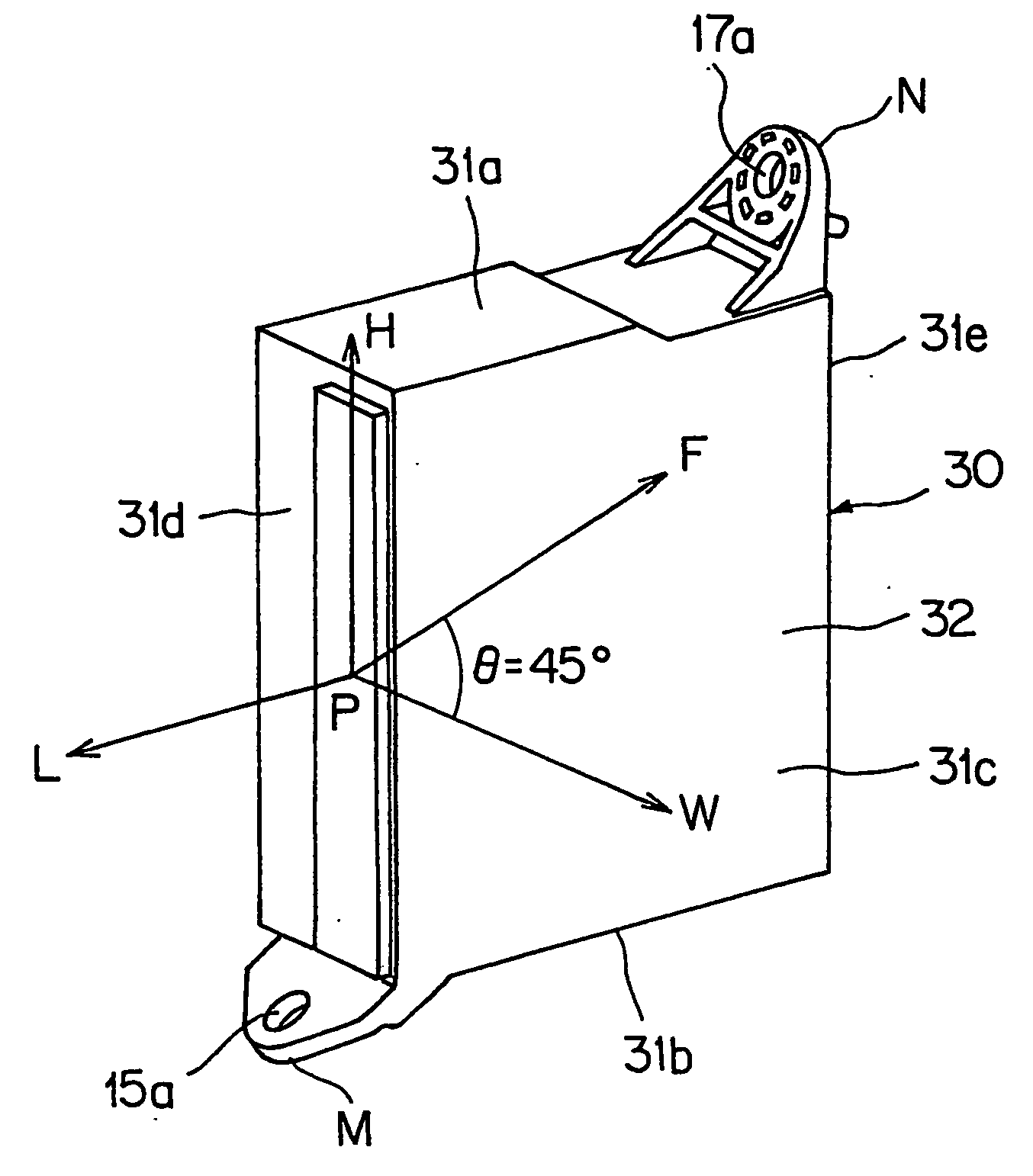

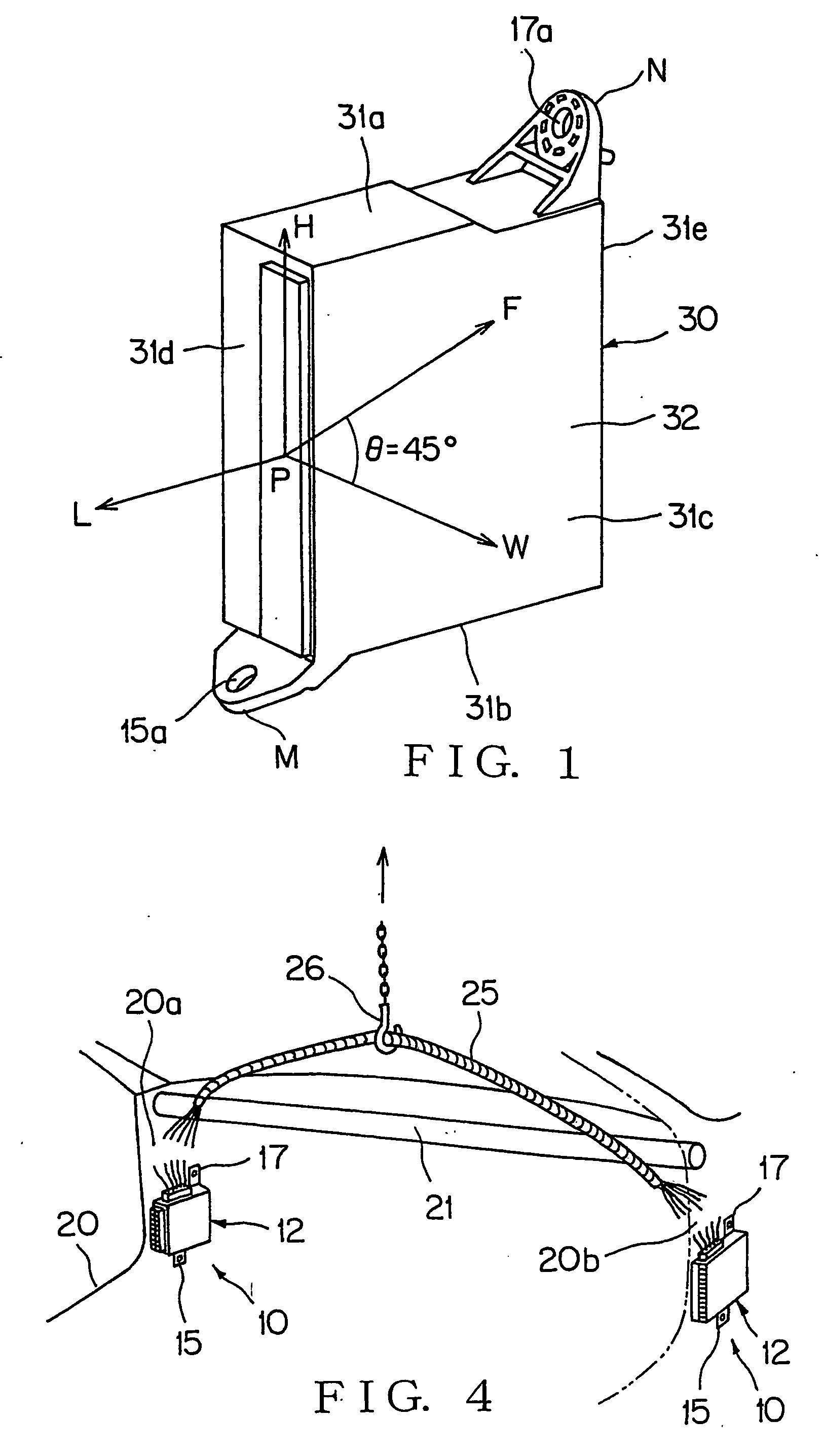

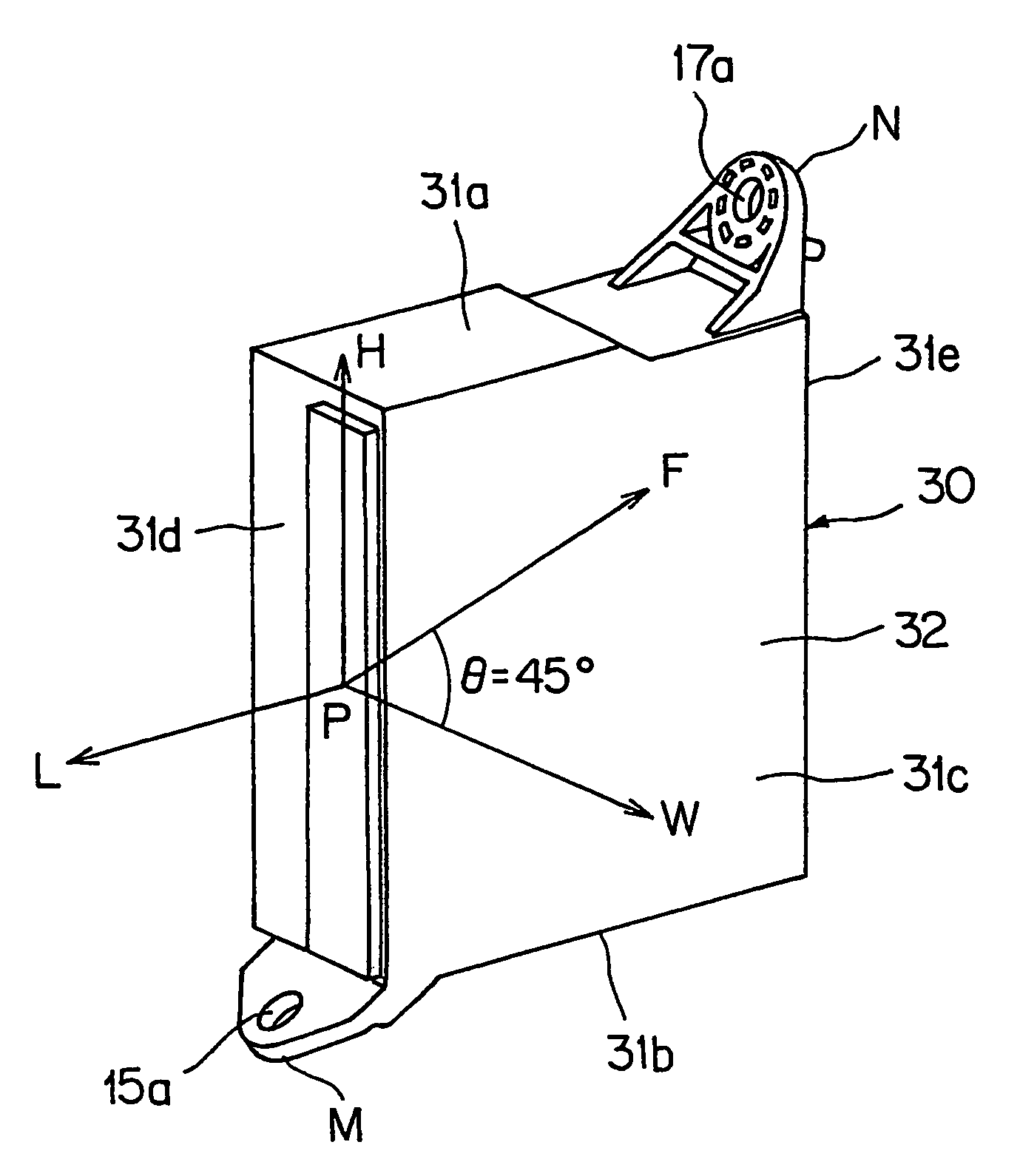

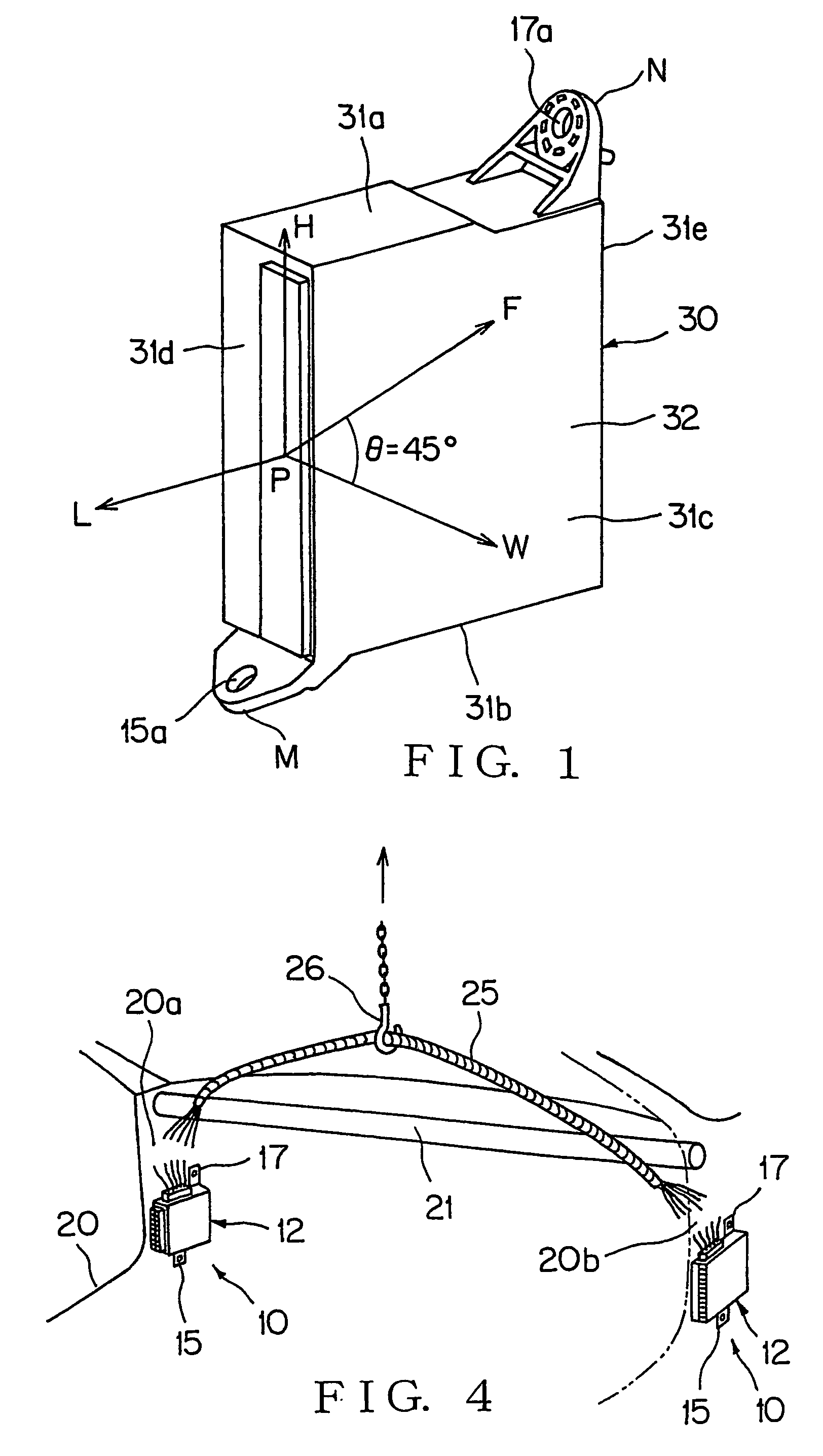

Attachment structure for electric junction box

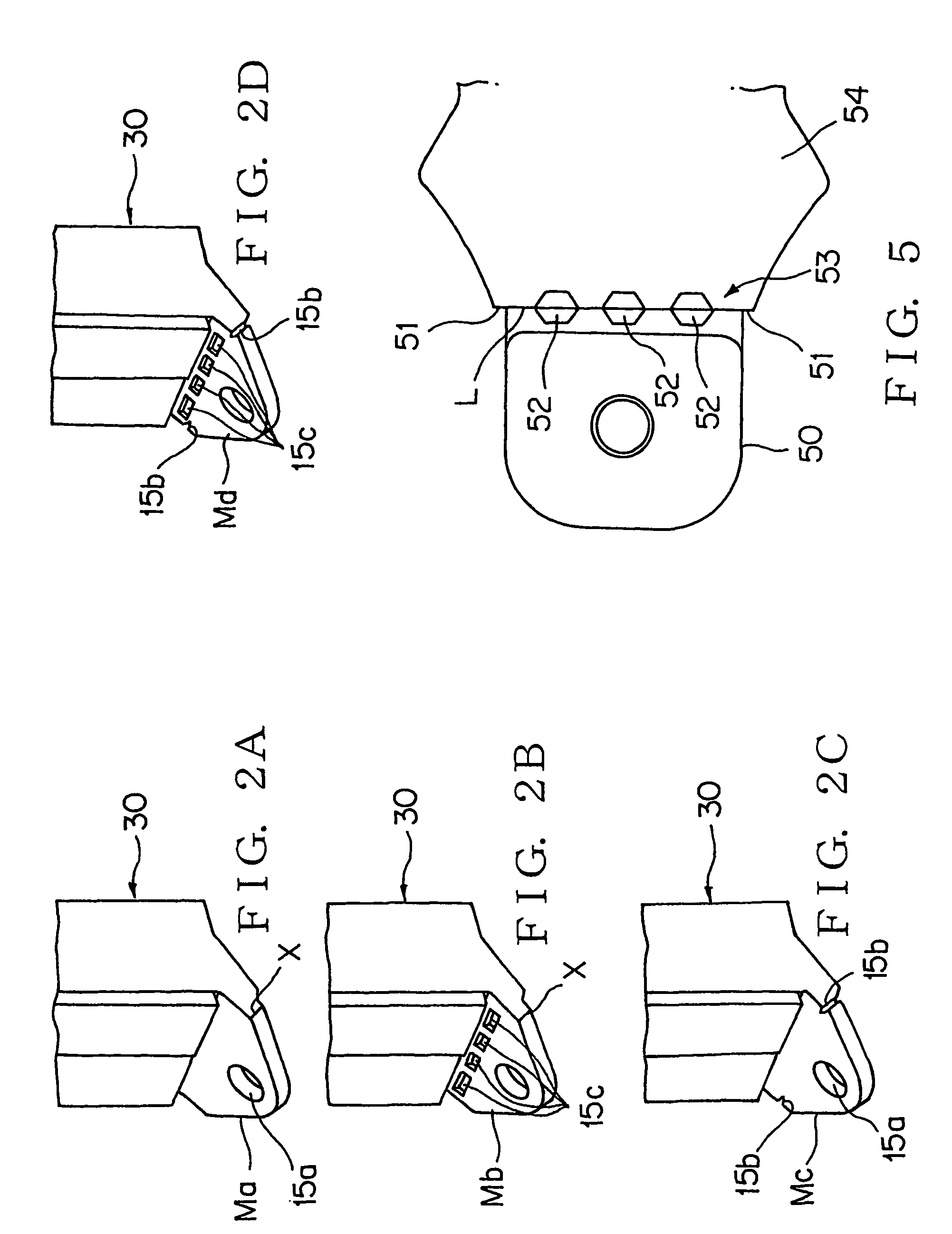

ActiveUS20060292902A1Avoid breakingIncrease the pressure valueInstallation of lighting conductorsCasings/cabinets/drawers detailsEngineeringCable harness

A junction block includes attaching brackets projected from the upper wall and lower wall of a block body. The block body is attached to a body panel through the attaching brackets. The attaching bracket to be pulled is provided with a recess 15b and / or a hole 15a for inducing rupture. When a wire harness derived from the block body is pulled in a vehicle width direction during recovery of the junction block, the block body is ruptured-separated from the attaching bracket at the recess 15b and / or hole 15c. In such a configuration, the block body can be rupture-separated only during recovery of a junction box body without being ruptured-separated owing to vibration / shock during vehicle running to improve recovery workability and recycling property

Owner:YAZAKI CORP

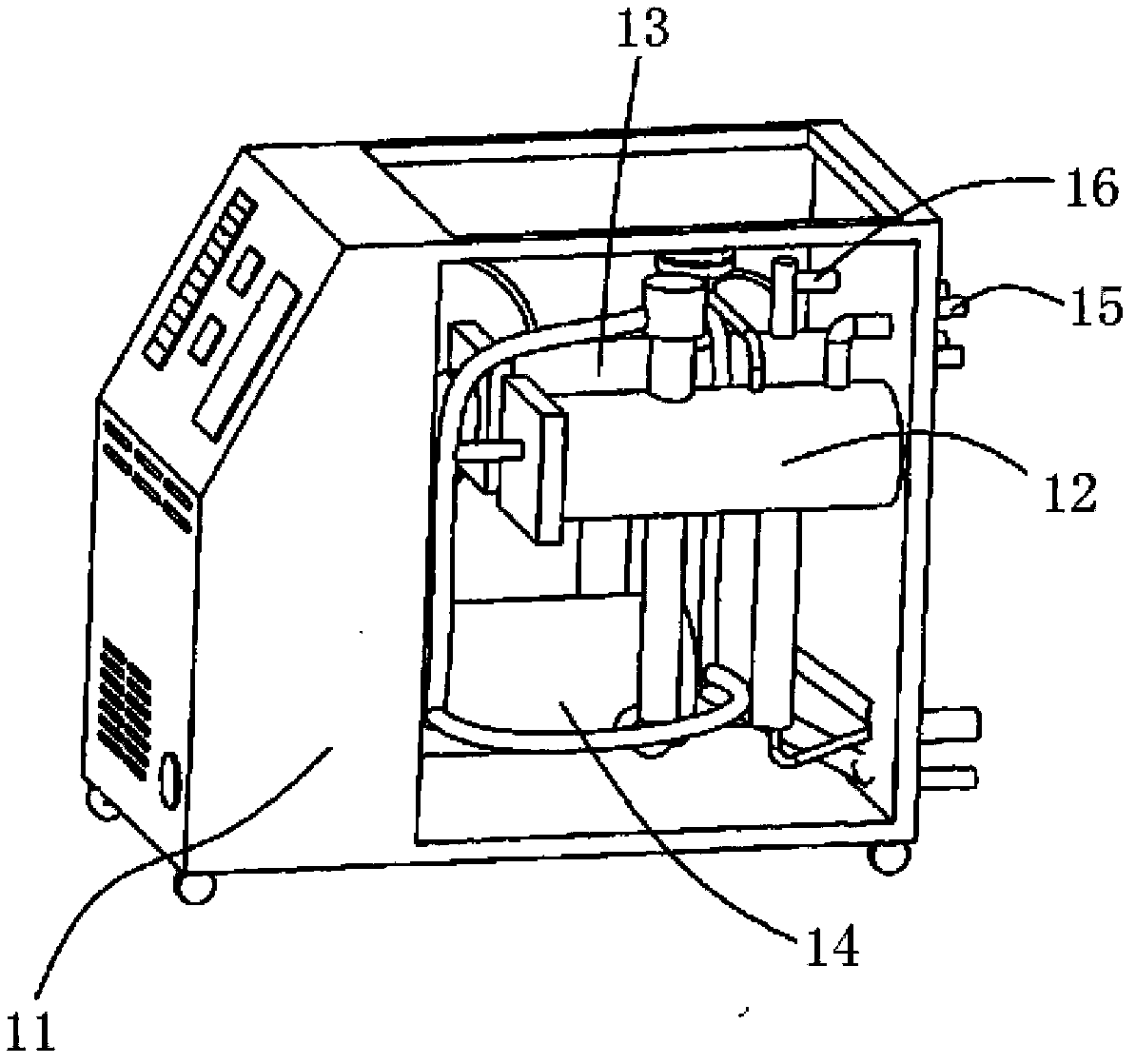

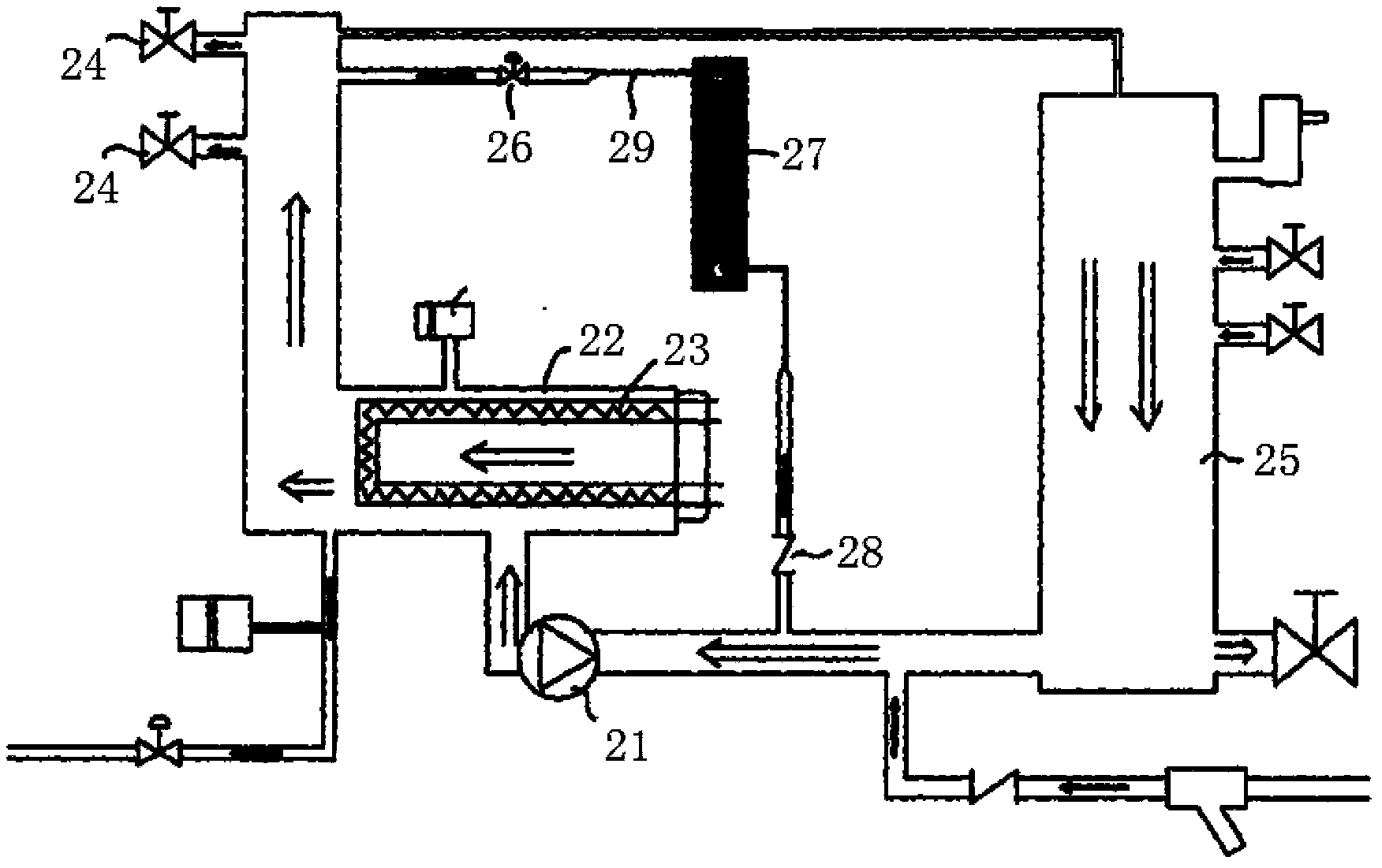

High-temperature high-pressure water-type mold temperature control system and method

The invention discloses a high-temperature high-pressure water-type mold temperature control system and method. The system comprises a water inlet pipe and a water outlet pipe, wherein one end of the water inlet pipe and one end of the water outlet pipe are respectively communicated with a mold; the other end of the water outlet pipe is connected with an inlet of a cooler; an outlet of the cooler is connected with a heater through a pump; the heater is connected with the other end of the water inlet pipe; and the water inlet pipe and the water outlet pipe are respectively provided with a ball valve. High-temperature water flowing across the mold returns to the cooler via the water outlet pipe, is transmitted to the heater after being pressurized by the pump, and is heated by the heater and circulated to the mold through the water inlet pipe, thereby enhancing the pressure and temperature in the temperature control system. The invention can effectively enhance the pressure value in the temperature control system, so that the temperature of the high-temperature water flowing across the mold can be further enhanced.

Owner:SHINI ELECTRIC HEATING MACHINERY

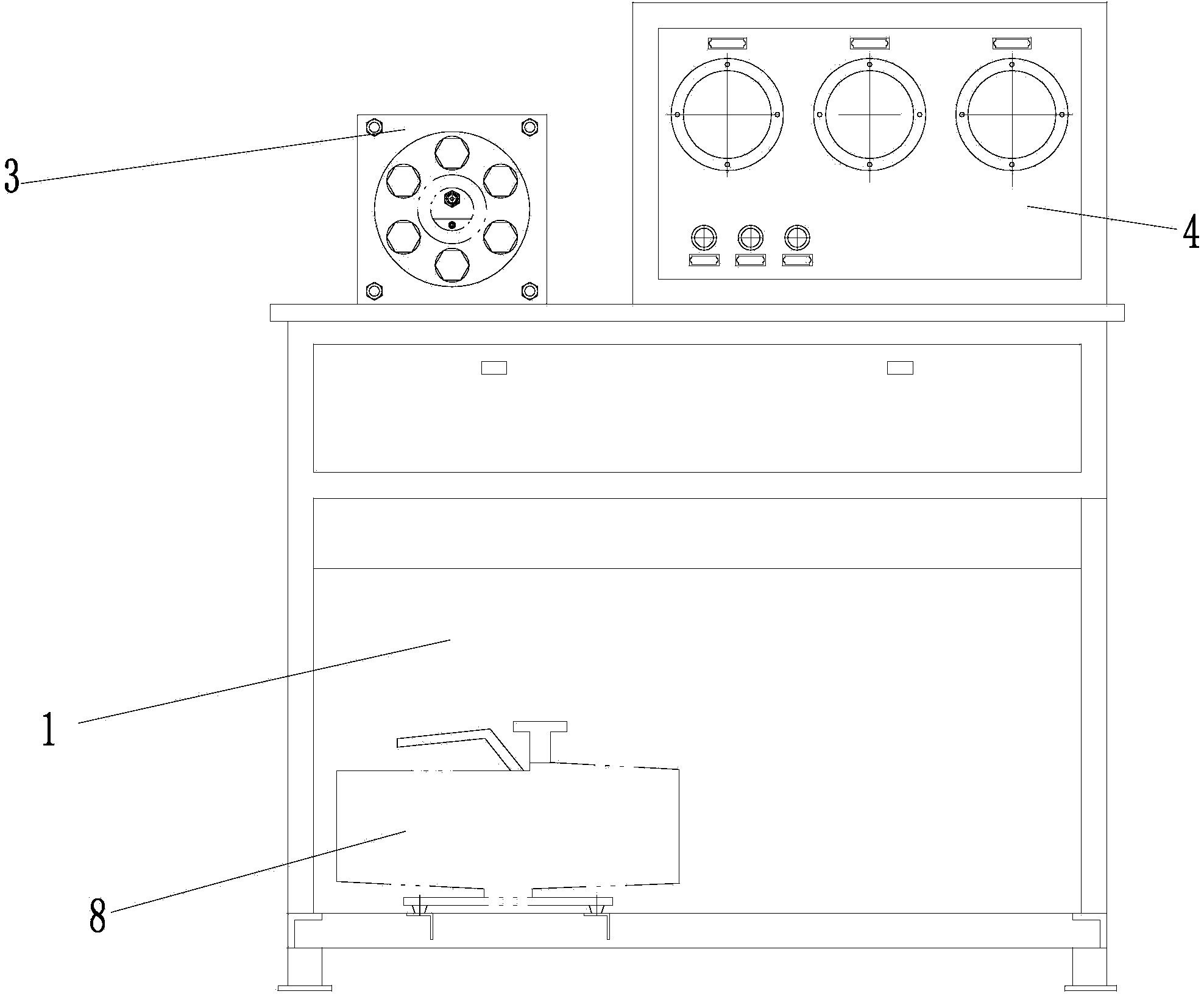

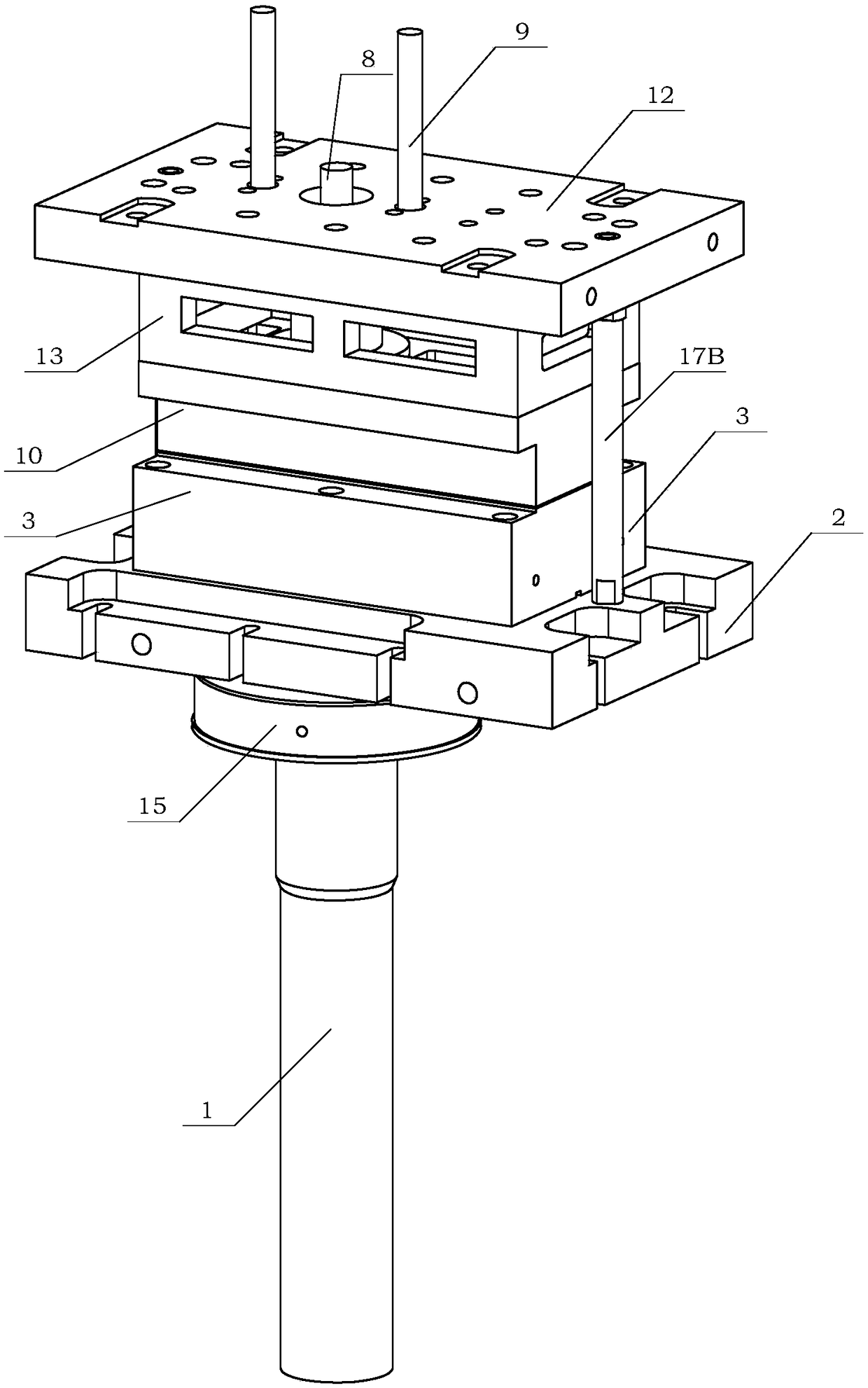

High-temperature high-pressure vacuumizing test device and operating method thereof

ActiveCN104345756AHave pursuasive powerPersuasiveSimultaneous control of multiple variablesPressure systemTest sample

The invention discloses a high-temperature high-pressure vacuumizing test device and an operating method thereof. The high-temperature high-pressure vacuumizing test device comprises a vessel holder (3), a console (4), a stander (1) for installing the vessel holder (3) and the console (4) and an interface (2), wherein a test vessel (6) which is used for arranging a test sample (5) and provided with a sealing cover is arranged in the vessel holder (3), and the high-temperature high-pressure vacuumizing test device also comprises a pressure system, a temperature system and a vacuum pump (8); the pressure system is arranged in the console (4), and the pressure system is communicated with the test vessel (6) to adjust the pressure value in the test vessel (6); the temperature system consists of a part which is arranged in the console (4) and a part which is arranged in an inner cavity of the test vessel (6), and the two parts of the temperature system are communicated with each other to adjust the temperature value in the test vessel (6); the vacuum pump (9) is arranged on the stander. The high-temperature high-pressure vacuumizing test device integrates the temperature system, the pressure system and the vacuumizing system.

Owner:NINGBO XINGJIAN SPACE MACHINERY

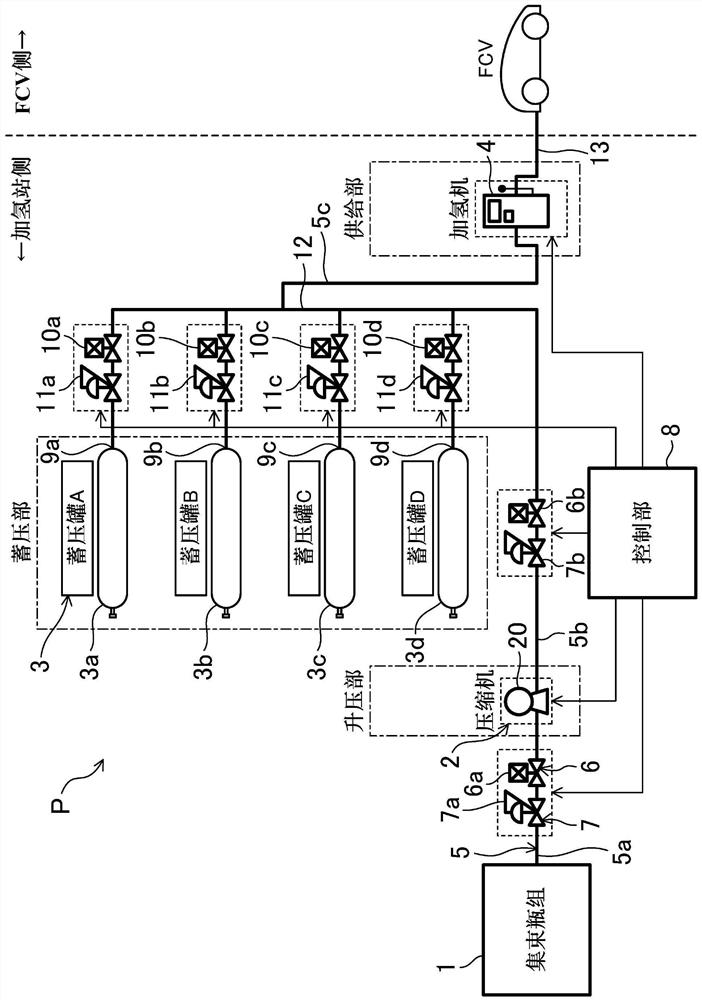

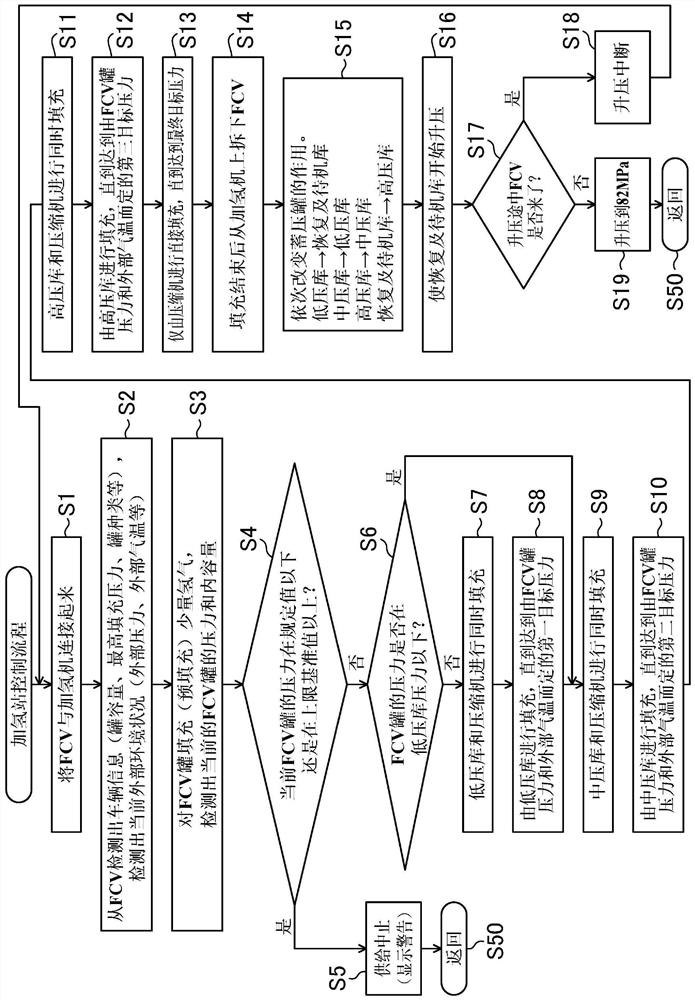

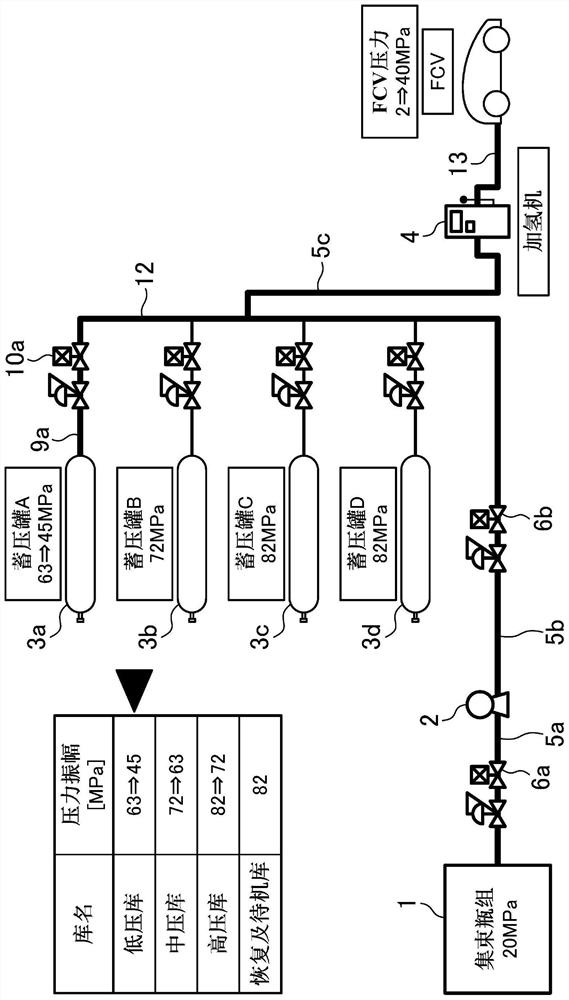

Hydrogen station and operating method for hydrogen station

PendingCN112041610AIncrease the pressure valueLower the pressure valueVessel mounting detailsGas handling applicationsControl signalMechanical engineering

In the case when a pressure accumulator tank A(3a) is used as a low-pressure bank, a control unit opens an electromagnetic on-off valve A(10a) by transmitting an opening control signal to the electromagnetic on-off valve A(10a) so as to enable hydrogen within the pressure accumulator tank A(3a) to be supplied to a filling tank (not illustrated) of a FCV. Concurrently, in order to supply hydrogen also from a compressor (2) to the filling tank of the FCV, the control unit opens a first electromagnetic on-off valve (6a) and a second electromagnetic on-off valve (6b) by transmitting an opening control signal to the first electromagnetic on-off valve (6a) and the second electromagnetic on-off valve (6b).

Owner:SAMTECH CO LTD

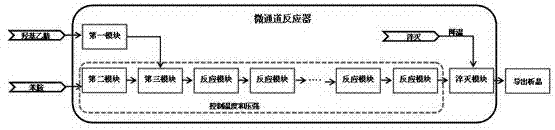

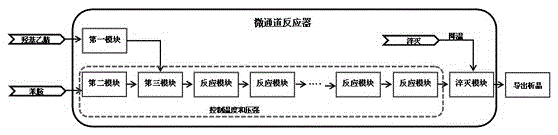

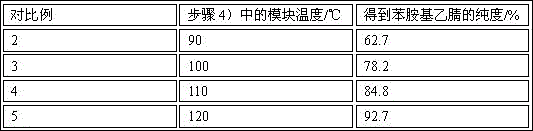

Method for preparing n-phenylglycinenitrile

ActiveCN104496848APost-processing saves time and effortReduce processCarboxylic acid nitrile preparationOrganic compound preparationAnilineOperation safety

The invention relates to a method for preparing n-phenylglycinenitrile. The method is characterized in that condensation reaction is continuously performed for aniline and glycolonitrile by a micro-channel reactor to obtain n-phenylglycinenitrile; the pH of glycolonitrile is pre-regulated to be 1.5 to 7 through a basic catalyst; the molar ratio of aniline to glycolonitrile is 1.00: 1.00-1.30. The method for preparing n-phenylglycinenitrile has the advantages that the process route is simple, and the reaction is fast, so that the working efficiency and production capacity can be ensured, and moreover, the production and operation safety of the process can also be ensured; with the adoption of the process method, the purity of a n-phenylglycinenitrile product exceeds 98.0% and the yield exceeds 99.9%.

Owner:内蒙古诚信永安化工有限公司

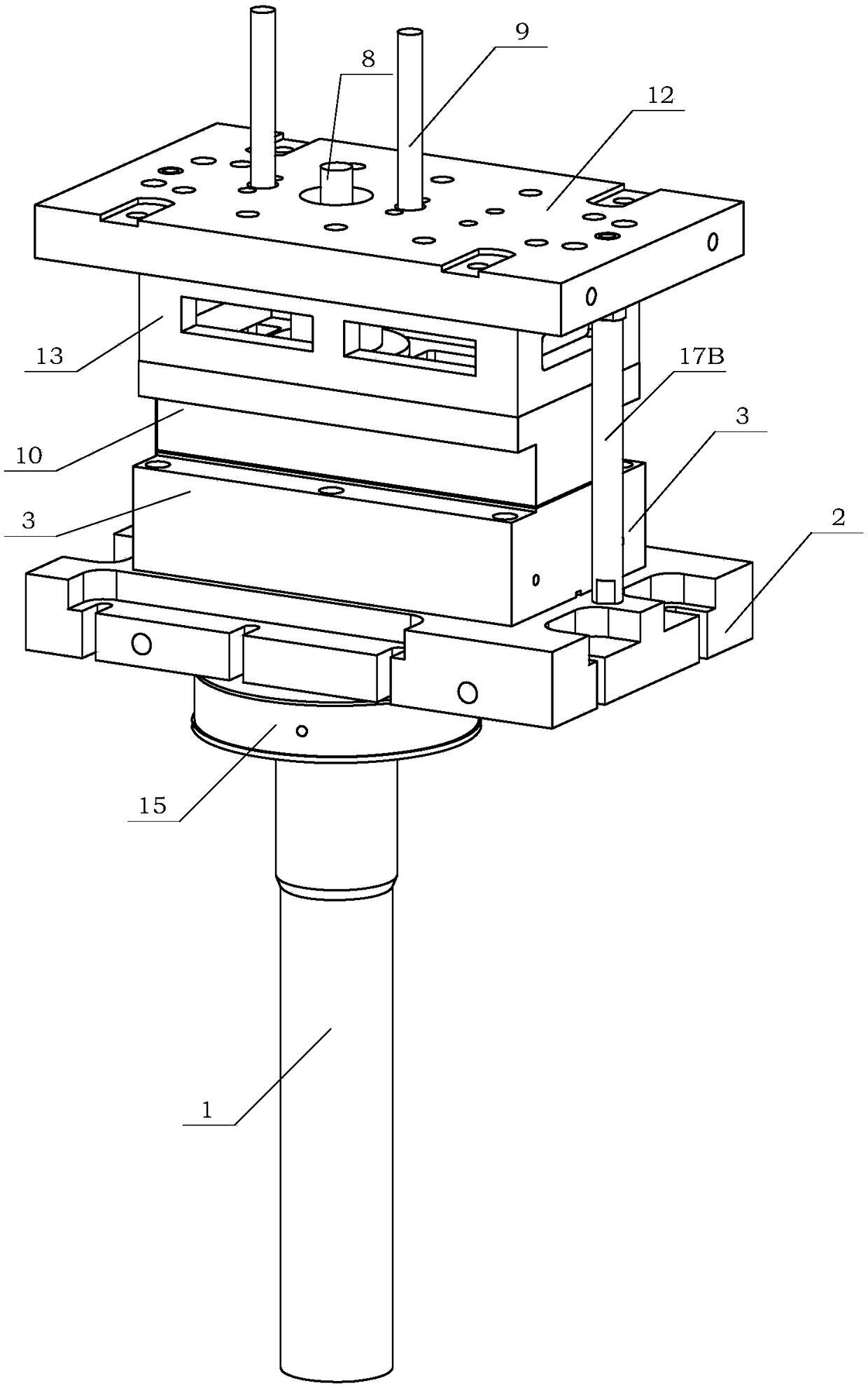

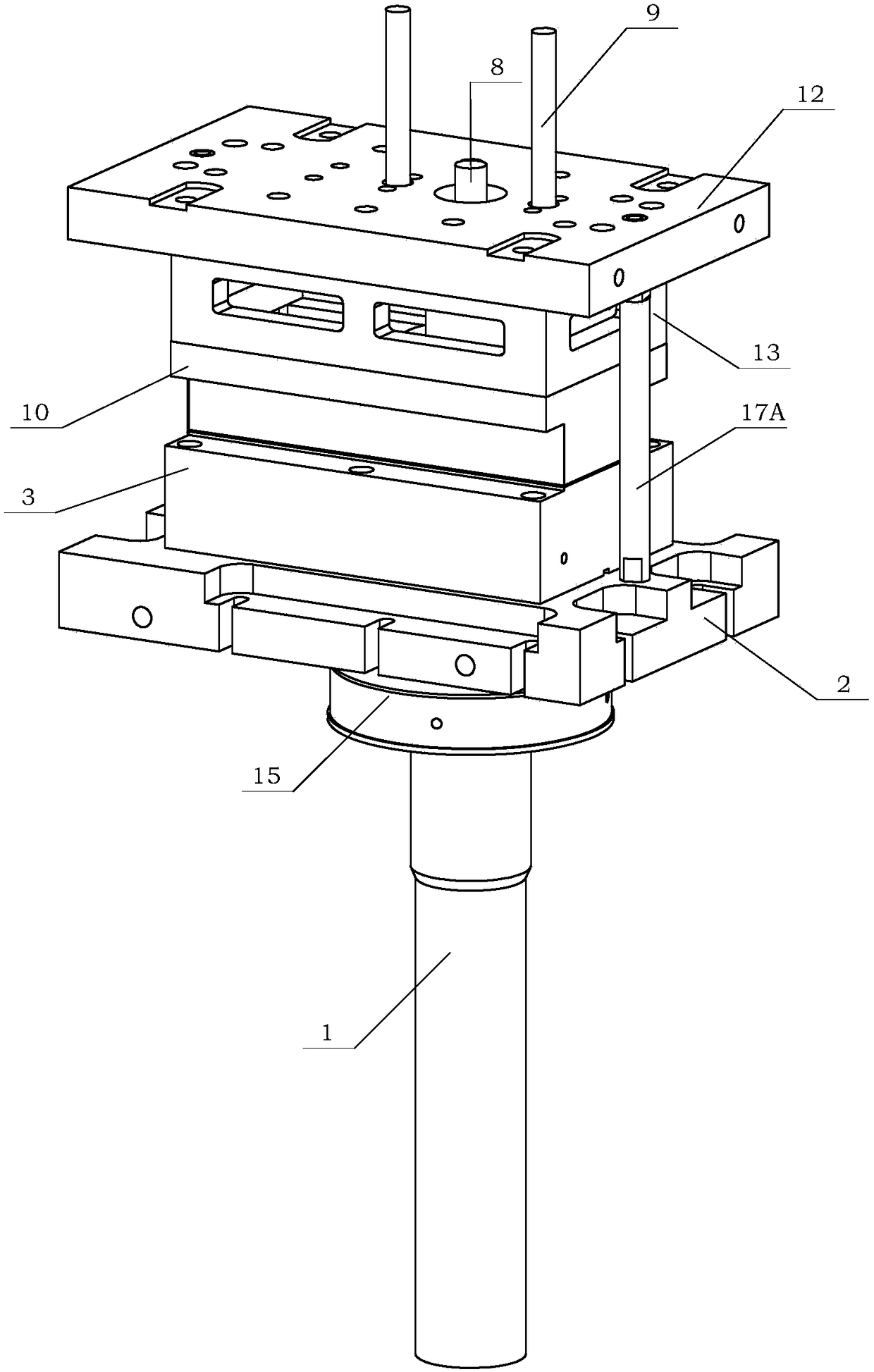

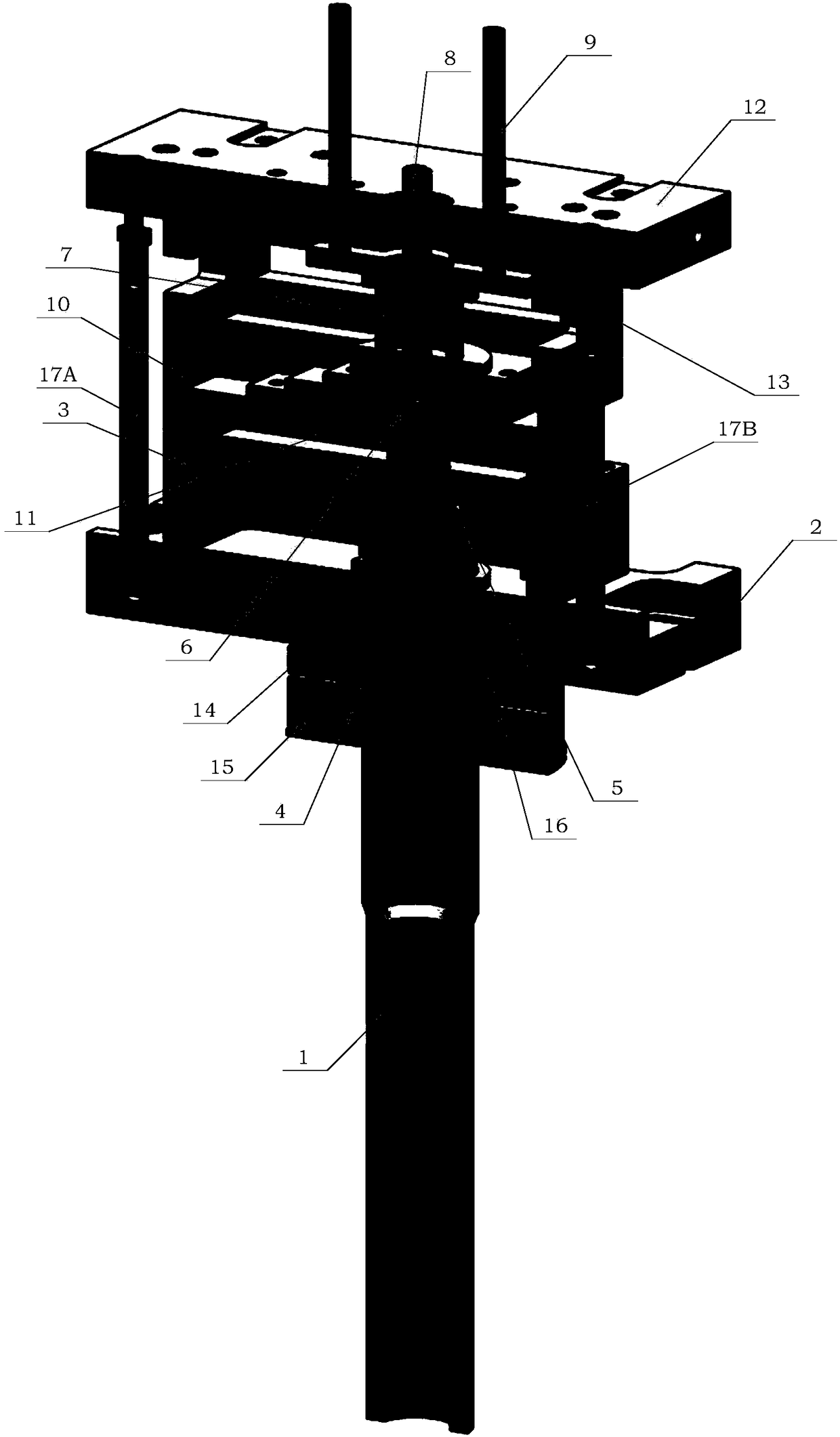

Casting device and casting method of low pressure filling type and high pressure solidification used for differential pressure pressurizing casting machine

InactiveCN108097923AReduce or eliminate casting defects such as shrinkage cavity and porosityImprove performanceSlagBody type

The invention discloses a casting device and casting method of low pressure controllable filling type and high pressure solidification molding capable of being used for differential pressure and differential pressure pressurizing casting machine. The device comprises a casting mold, a metal melt body liquid lifting channel and a shunt cone capable of moving up and down. The shunt cone plays functions of shunt guiding to a metal melt body and compacting on a filter net in the process of liquid lifting, so that the metal melt body is smoothly filled in a laminar flow mode. After filling type isfinished, the shunt cone moves downwards to form a sealing structure, and a metal melt body inlet of a pouring gate sleeve and a mold cavity is closed; then, a metal liquid is pressurized to solidifythe metal liquid under the high pressure, and the defects such as shrinkage porosity, and debris and slag inclusion are avoided; and meanwhile, the shape of the shunt cone is optimized and designed, and low pressure controllable stable filling type and high pressure solidification molding of the metal melt body are ensured. The casting device can be used for casting of casting pieces of shell type, frame type and bucket body type, compared with traditional differential pressure casting, the strength can be improved by 10-30%, and the elongation rate can be improved by 30-65%.

Owner:BEIHANG UNIV

Attachment structure for electric junction box

ActiveUS7622671B2Increase the pressure valueIncrease valueInstallation of lighting conductorsCasings/cabinets/drawers detailsEngineeringCable harness

A junction block includes attaching brackets projected from the upper wall and lower wall of a block body. The block body is attached to a body panel through the attaching brackets. The attaching bracket to be pulled is provided with a recess 15b and / or a hole 15a for inducing rupture. When a wire harness derived from the block body is pulled in a vehicle width direction during recovery of the junction block, the block body is ruptured-separated from the attaching bracket at the recess 15b and / or hole 15c. In such a configuration, the block body can be rupture-separated only during recovery of a junction box body without being ruptured-separated owing to vibration / shock during vehicle running to improve recovery workability and recycling property.

Owner:YAZAKI CORP

Low-pressure mold-filling and high-pressure solidification casting device used for pressure adjusting and pressurizing casting machine and casting method

InactiveCN108296468AReduce or eliminate casting defects such as shrinkage cavity and porosityImprove performancePorositySlag

The invention discloses a low-pressure controllable mold-filling and high-pressure solidification forming casting device capable of being used for a pressure adjusting casting machine and a pressure adjusting and pressurizing casting machine and a casting method. The low-pressure controllable mold-filling and high-pressure solidification forming casting device comprises a casting mold, a metal melt liquid-rising channel and a sprue spreader capable of moving up and down. The sprue spreader plays the roles of flow dividing guiding and compacting a filter net on metal melt at a liquid-rising stage, so that the metal melt is subjected to stable mold-filling in a laminar flow mode. After mold-filling is completed, the sprue spreader downwards moves to form a sealing structure, and metal melt inlets of a sprue bush and a mold cavity are sealed. Then a metal liquid is subjected to high pressurizing to be solidified under high pressure, so that the defects such as shrinkage cavity and porosity, and inclusions and slag inclusion are avoided. Meanwhile, the shape of the sprue spreader is subjected to optimal design, so that low-pressure controllable stable mold-filling and high-pressure solidification forming of the metal melt are ensured. The low-pressure controllable mold-filling and high-pressure solidification forming casting device capable of being used for the pressure adjusting casting machine and the pressure adjusting and pressurizing casting machine and the casting method can be used for casting of shell types, frame types and barrel types of casting pieces, and compared with traditional pressure adjusting casting, the strength can be improved by 10-40%, and the elongation rate can be increased by 30-80%.

Owner:BEIHANG UNIV

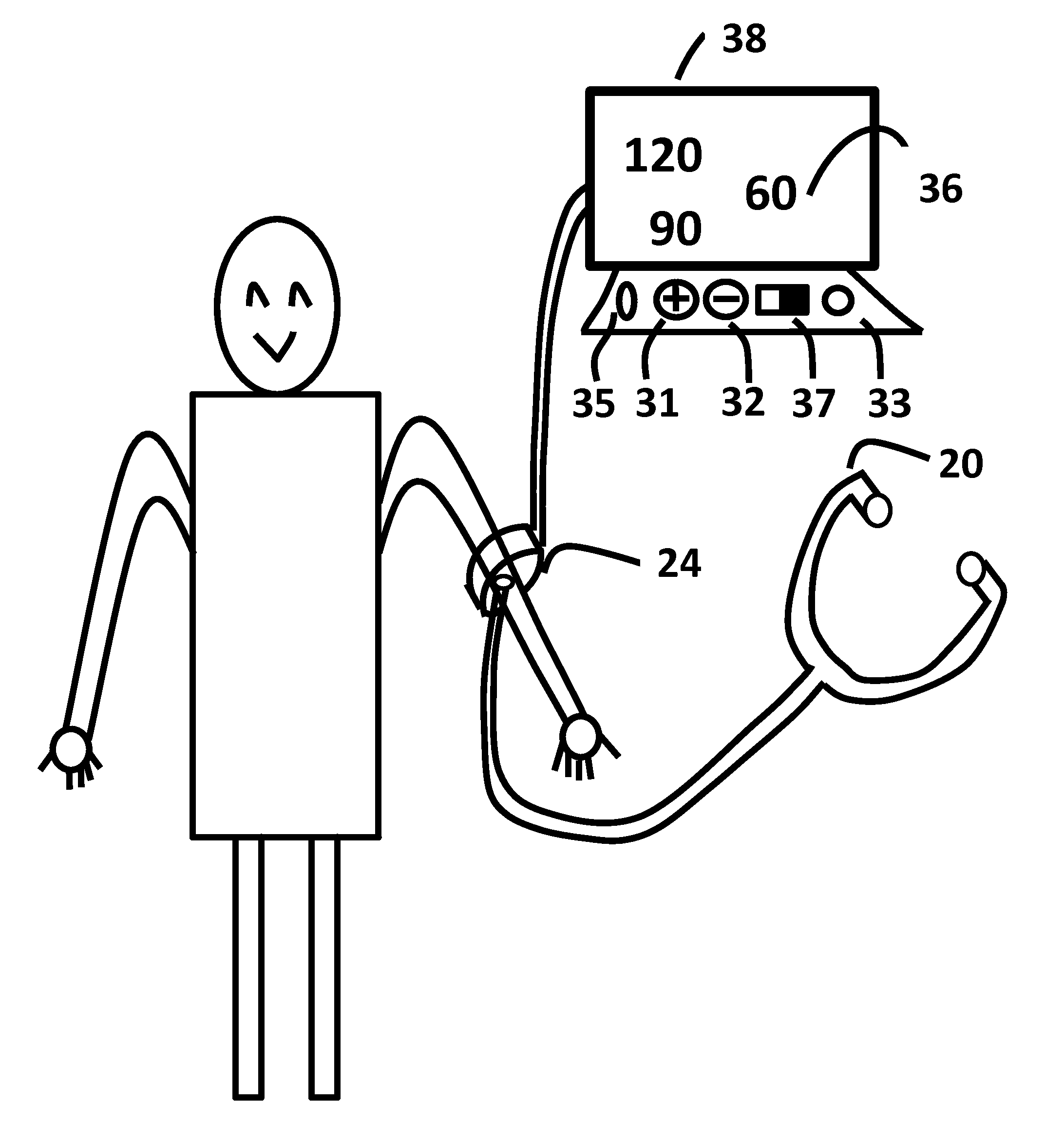

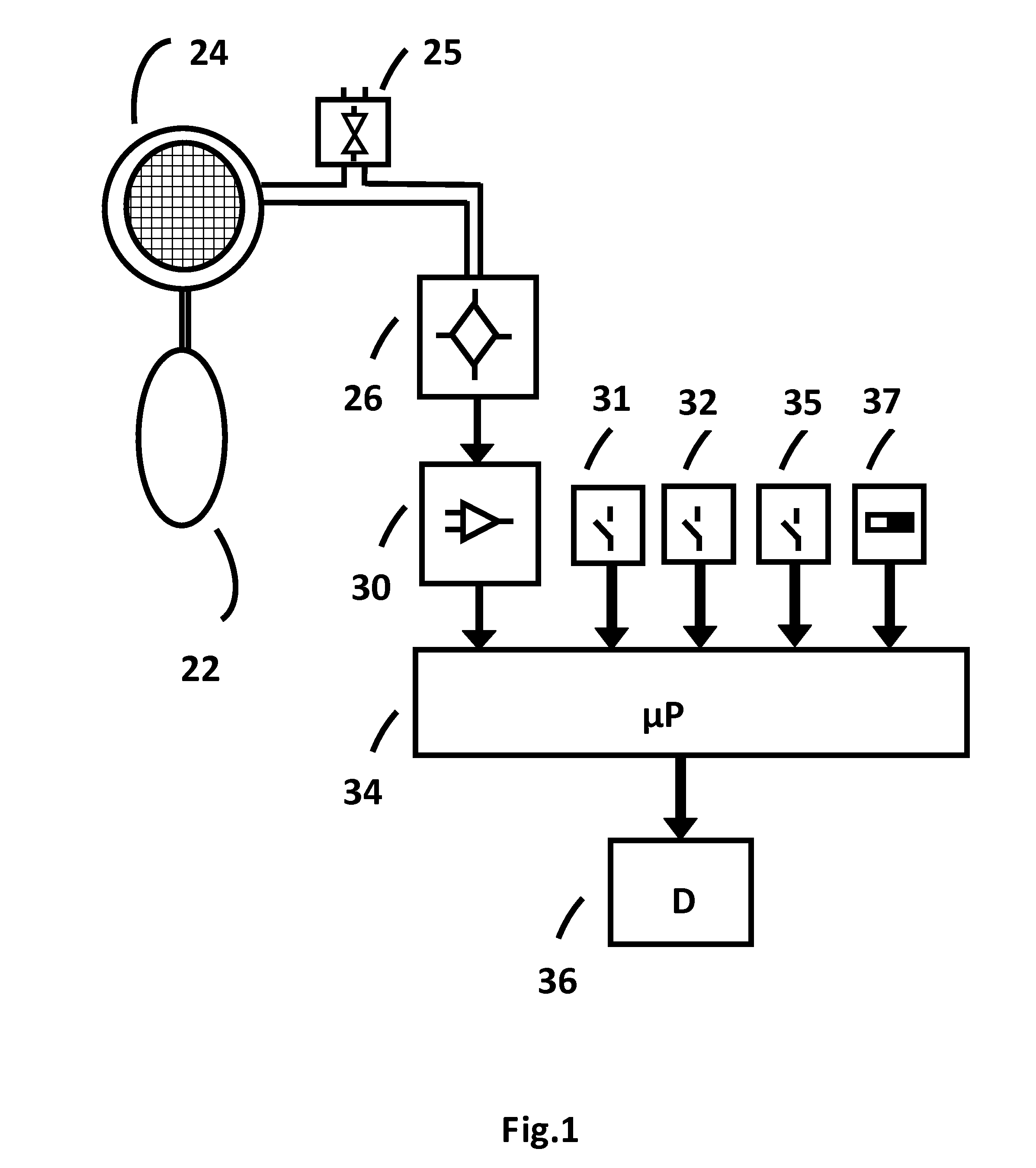

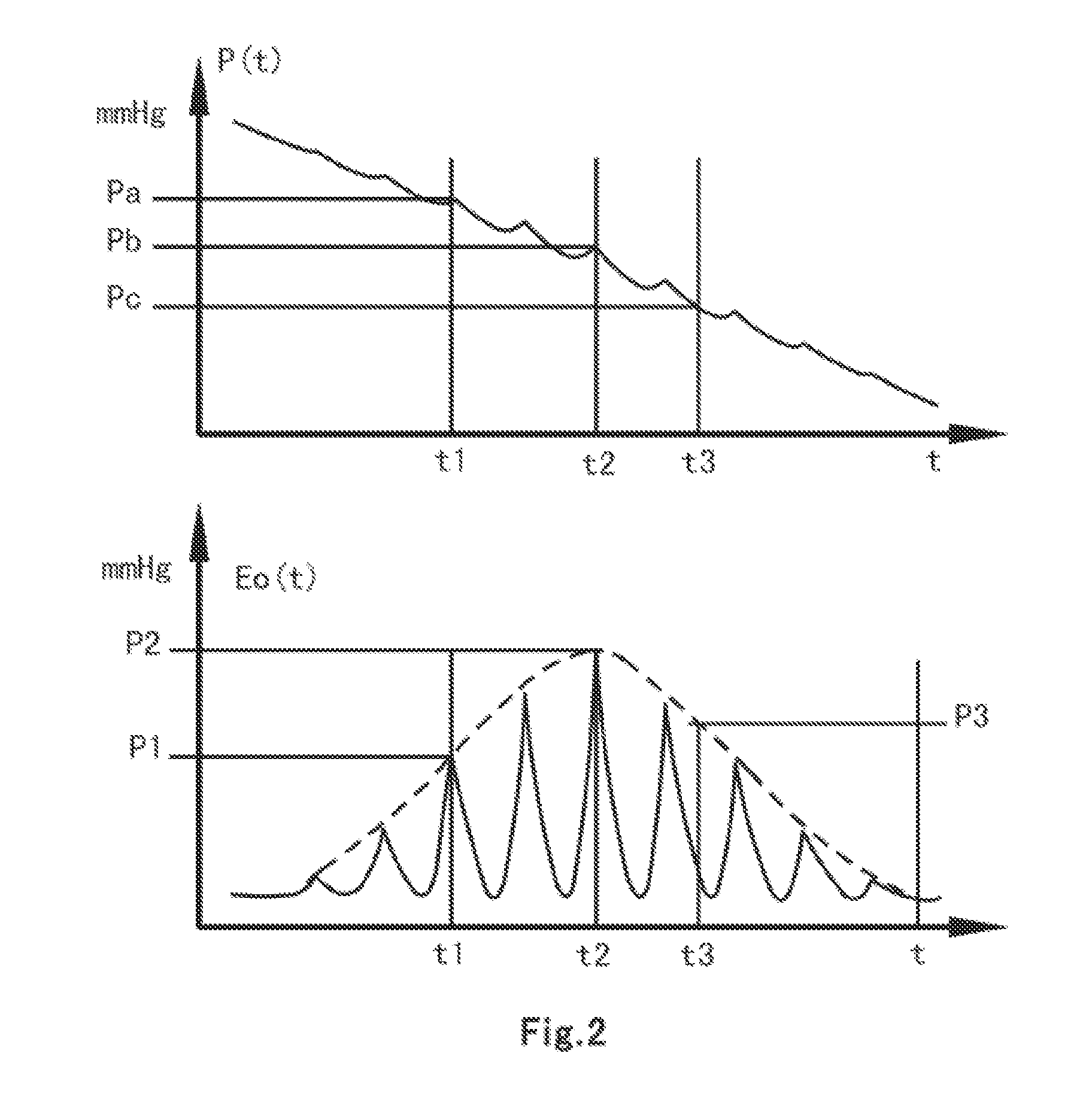

Apparatus and calibration method for blood pressure measurement

InactiveUS20120289841A1Lower the pressure valueIncrease the pressure valueEvaluation of blood vesselsCatheterBlood pressureEngineering

Apparatus and a calibration method for measurement of blood pressure are used to determine personal PIP's for a given subject and to store the personal PIP's for future personal use in blood pressure measurement in the subject. The apparatus comprises at least one button communicating with a MPU unit for entering information used to determine the personal PIP's of the subject. The method comprises the steps of obtaining information required to determining the PIP's of a subject, determining the personal PIP's of the subject, and storing the personal PIP's of the subject for future personal use for the subject.

Owner:QDEVICE MEDICAL

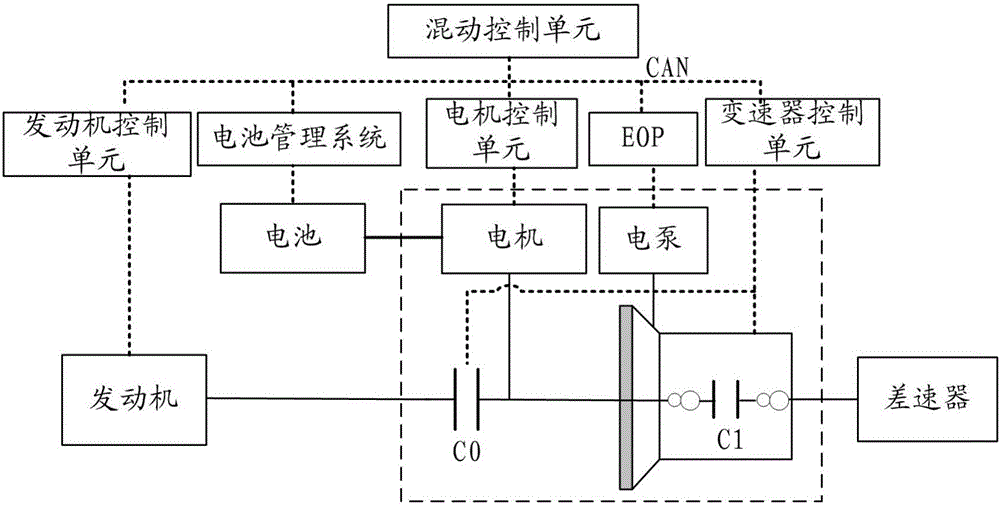

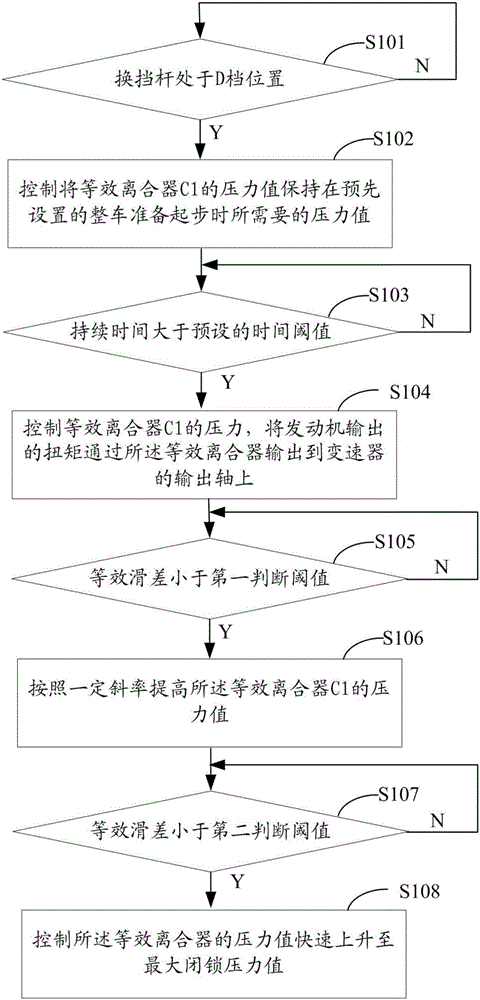

Vehicle starting method based on P2 hybrid transmission system

The invention provides a vehicle starting method based on a P2 hybrid transmission system, which relates to the technical field of power transmission. The method comprises the following steps of judging whether a gear shifting rod is in a D-gear position or not when a hybrid clutch C0 is jointed; when the gear shifting rod is in a D-gear position, controlling a pressure value of an equivalent clutch C1 to be kept at a preset pressure value, which is needed when the vehicle prepares to be started; controlling the pressure of the equivalent clutch C1; outputting a torque output by an engine to an output shaft of a transmission through the equivalent clutch; when an equivalent slip frequency Delta nslip is less than a first preset judging threshold value, increasing the pressure value of the equivalent clutch C1 according to a certain slope; and when the equivalent slip frequency Delta nslip is less than a second preset judging threshold value, controlling the pressure value of the equivalent clutch to rapidly rise to a maximum locking pressure value so as to realize stable startup of the vehicle in a pure engine mode. Therefore, the cost of the engine starting motor is saved.

Owner:SHENGRUI TRANSMISSION

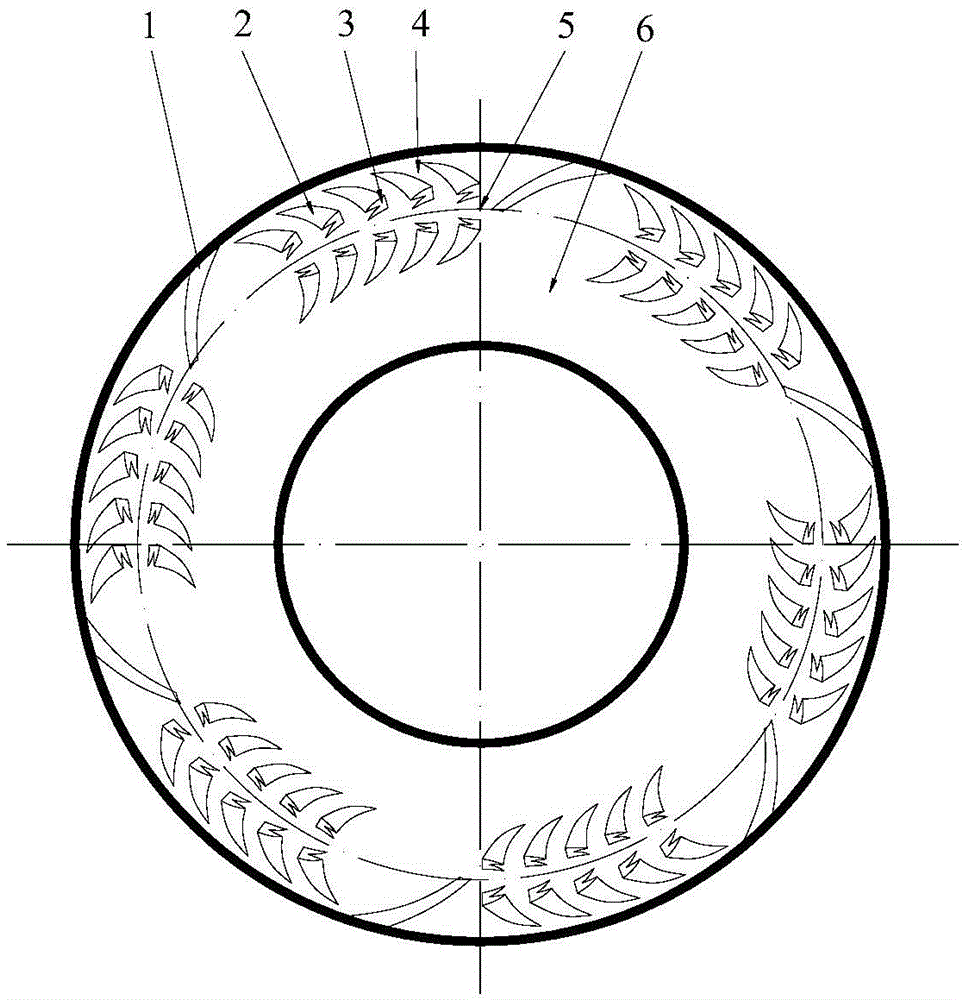

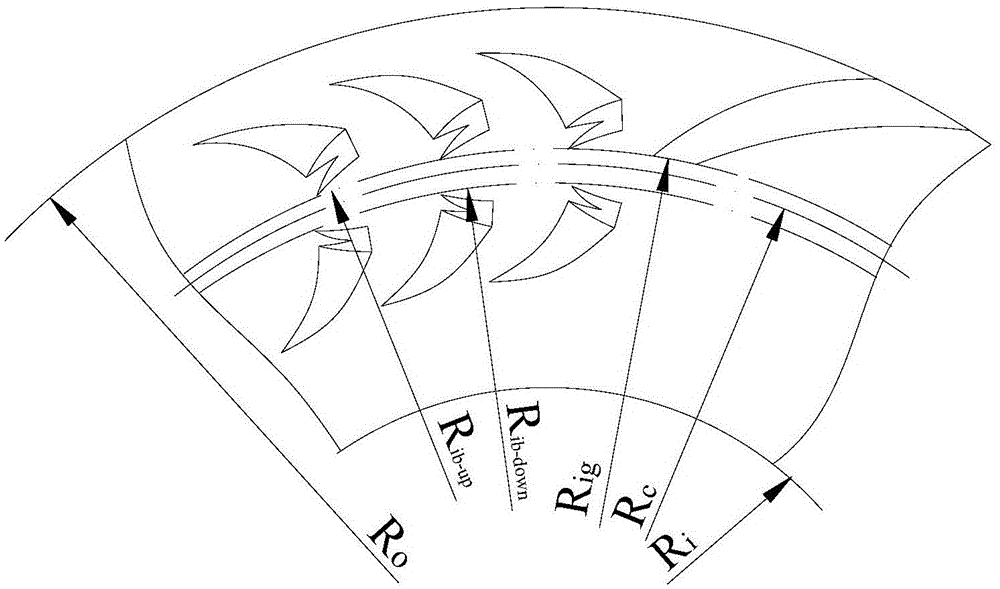

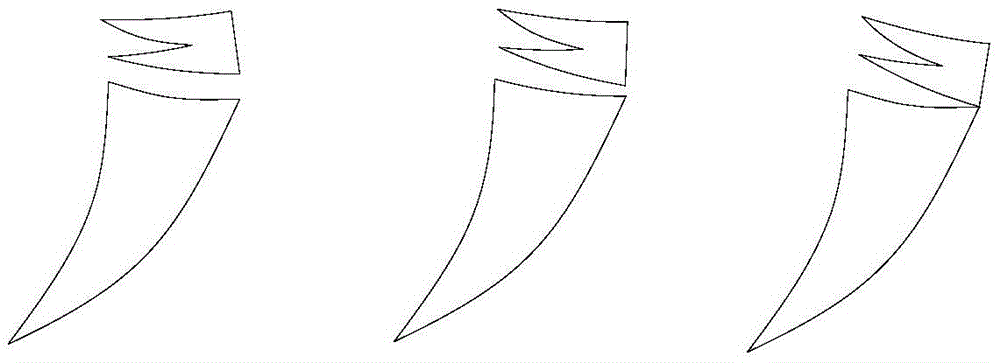

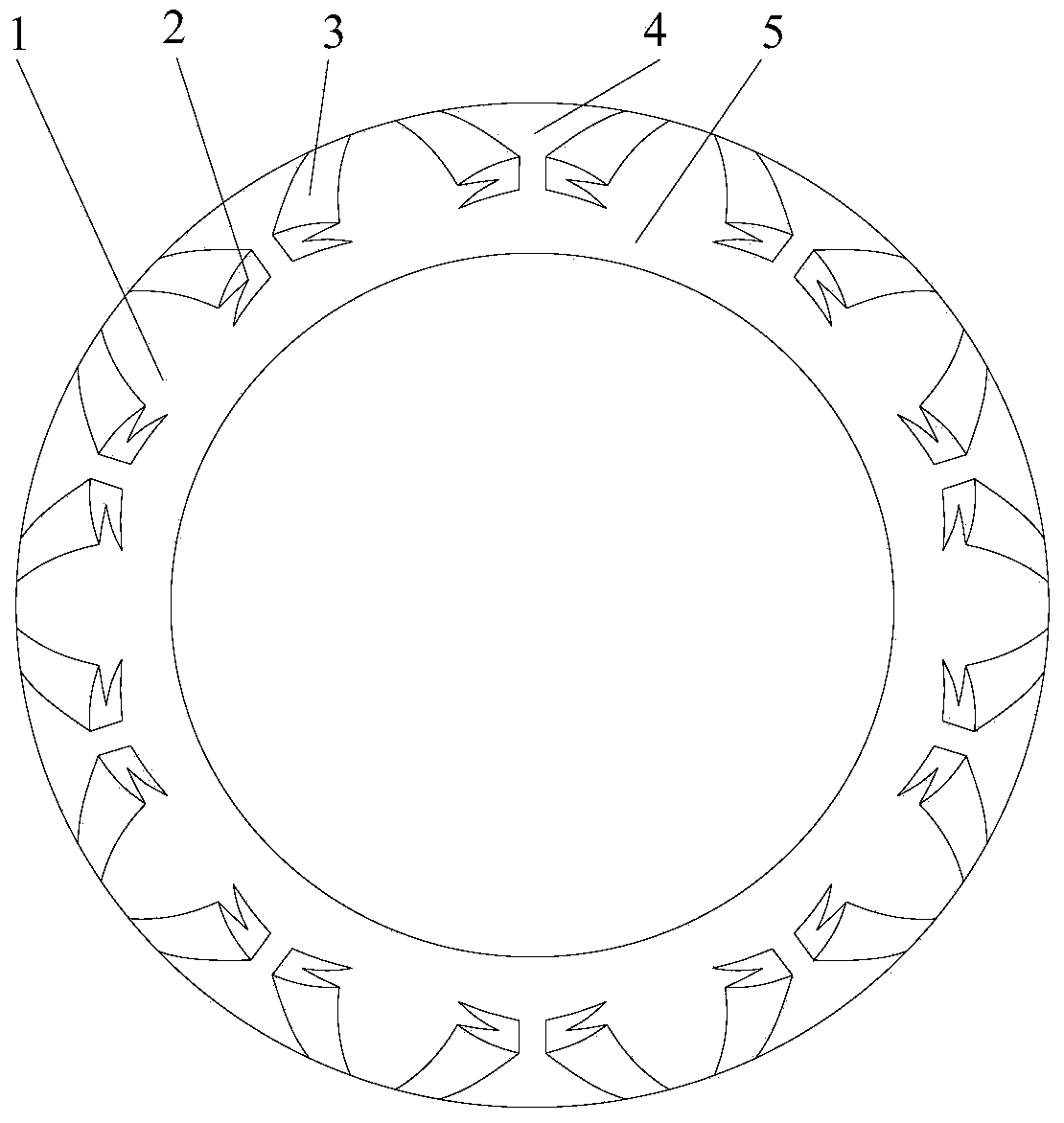

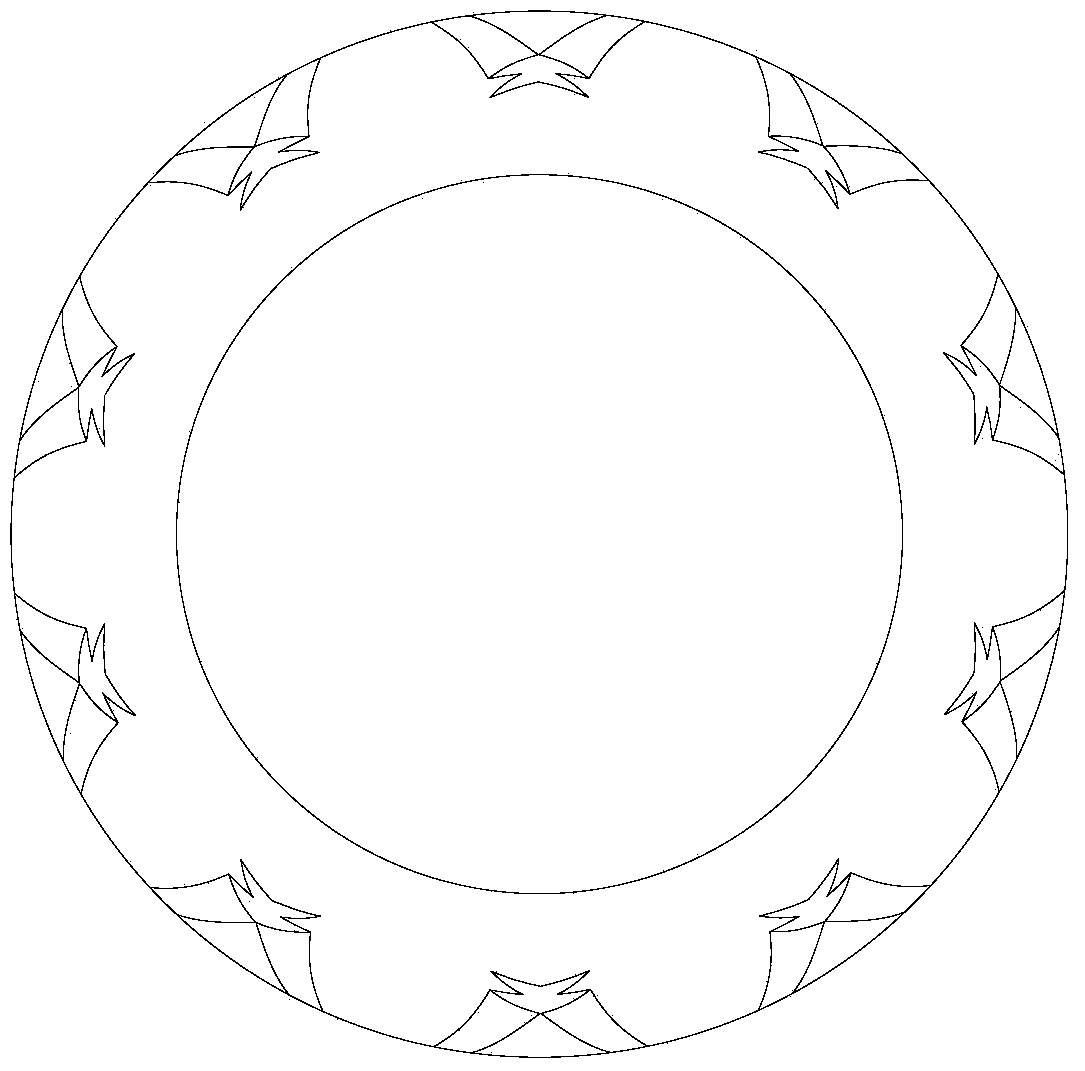

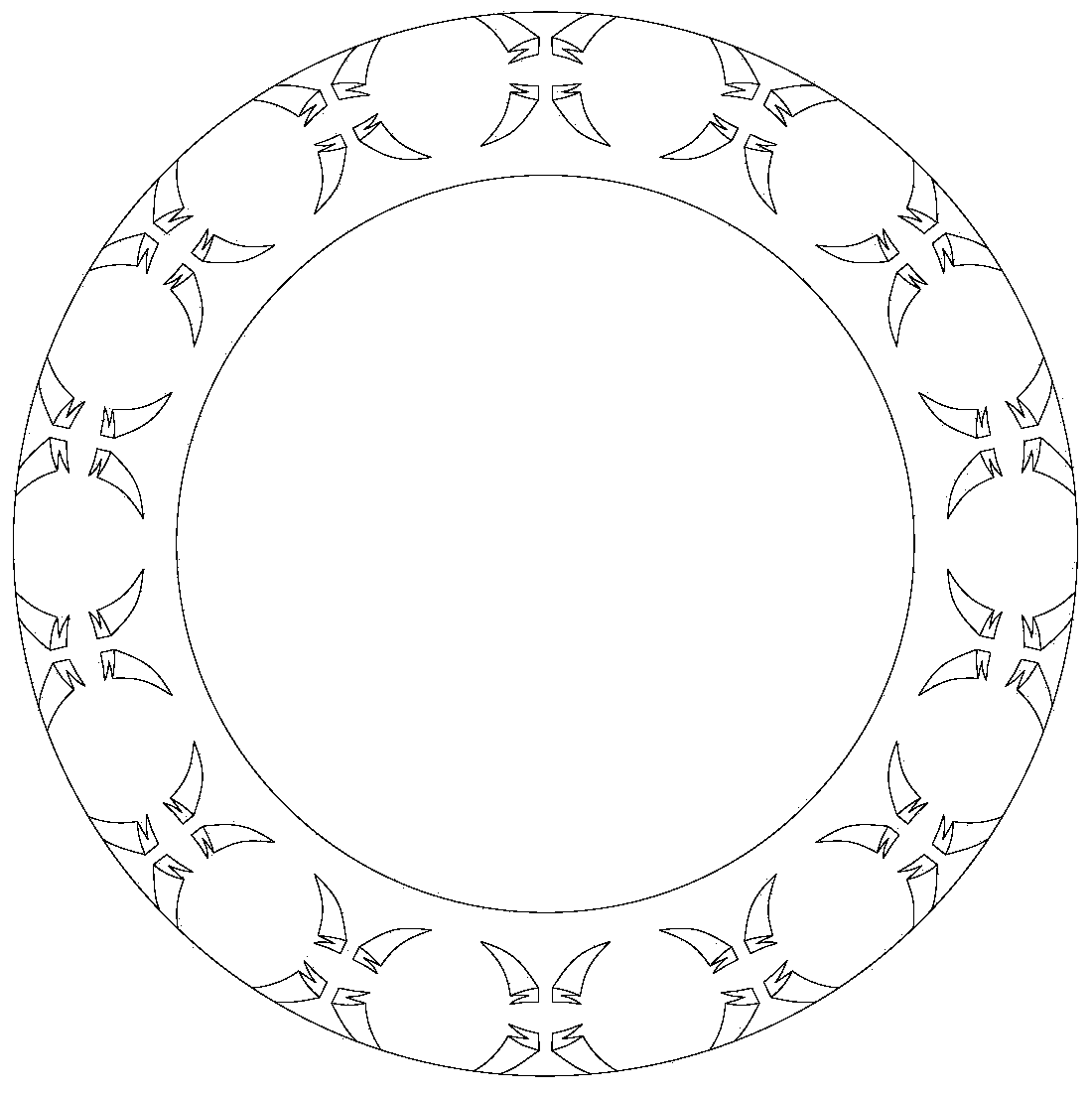

Gas-lubricated bird-wing-shaped groove end face seal structure

ActiveCN104265906BEnhance the dynamic pressure effectGood opening performanceEngine sealsGas lubricationMicrometer scale

A gas lubrication bird-wing-shape-imitation v groove end face sealing structure comprises two sealing rings with sealed end faces; the two sealing rings comprise a movable ring and a static ring; the end face of at least one of the movable ring and the static ring is provided with a plurality of bird-wing-shape-imitation v grooves; each bird-wing-shape-imitation v groove is composed of a tail-feather-shape-imitation v groove body and a flight-feather-shape-imitation v groove body; the tail-feather-shape-imitation v groove bodies are provided with swallow-tail-shaped furcal tails; the flight-feather-shape-imitation v groove bodies are roughly in a bull horn shape with the thick ends and the tail tip ends; the tail-feather-shape-imitation v groove bodies are transversely arranged at the thick ends of the flight-feather-shape-imitation v groove bodies; the thick segments of the flight-feather-shape-imitation v groove bodies and the thick ends of the tail-feather-shape-imitation v groove bodies are toward airflow; the bird-wing-shape-imitation v grooves are arranged to be bird-wing-shape-imitation v groove annular belts; secondary annular sealing dams are arranged between the bird-wing-shape-imitation v groove annular belts; annular main sealing dams are arranged on the low-pressure sides of the end faces; drainage grooves are arranged on the high-pressure sides of the end faces; the drainage grooves and the bird-wing-shape-imitation v grooves are shallow grooves of the micrometer scale; the depths of the flight-feather-shape-imitation v groove bodies are gradually decreased in the airflow direction. The sealing structure has the advantages of being good in stability and long in service life, and resisting abrasion.

Owner:ZHEJIANG UNIV OF TECH

Two-way rotating gas dynamic/static pressure mechanical seal type bird wing-shaped groove structure

ActiveCN104265900AEnhance the dynamic pressure effectStable on and runningEngine sealsMicrometer scaleStructure of the Earth

The invention discloses a two-way rotating gas dynamic / static pressure mechanical seal type bird wing-shaped groove structure. The structure comprises two mechanically sealed sealing rings-a dynamic ring and a static ring. The structure is characterized in that a plurality of bird wing-shaped grooves are formed in the end surface of at least one sealing ring of the dynamic ring and the static ring; the bird wing-shaped grooves are shallow grooves in micrometer scale, and consist of tail feather-shaped grooves and flight feather-shaped grooves; the tail feather-shaped grooves have swallow tail-shaped furcal tails; the flight feather-shaped grooves substantially take the shape of ox horns with thick ends and tail tip ends; the tail feather-shaped grooves are transversely arranged at the thick ends of the flight feather-shaped grooves; every two bird wing-shaped grooves form groove pairs in a splayed shape; multiple groove pairs are evenly arranged peripherally to form a bird wing-shaped groove ring belt; the bird wing-shaped groove ring belt is arranged at the high-pressure side of the end surface; and the depths of the flight feather-shaped grooves are gradually decreased in the airflow direction. The structure has the characteristics of two-way rotation, excellent opening character, good stability, wear resistance and long service life.

Owner:ZHEJIANG UNIV OF TECH

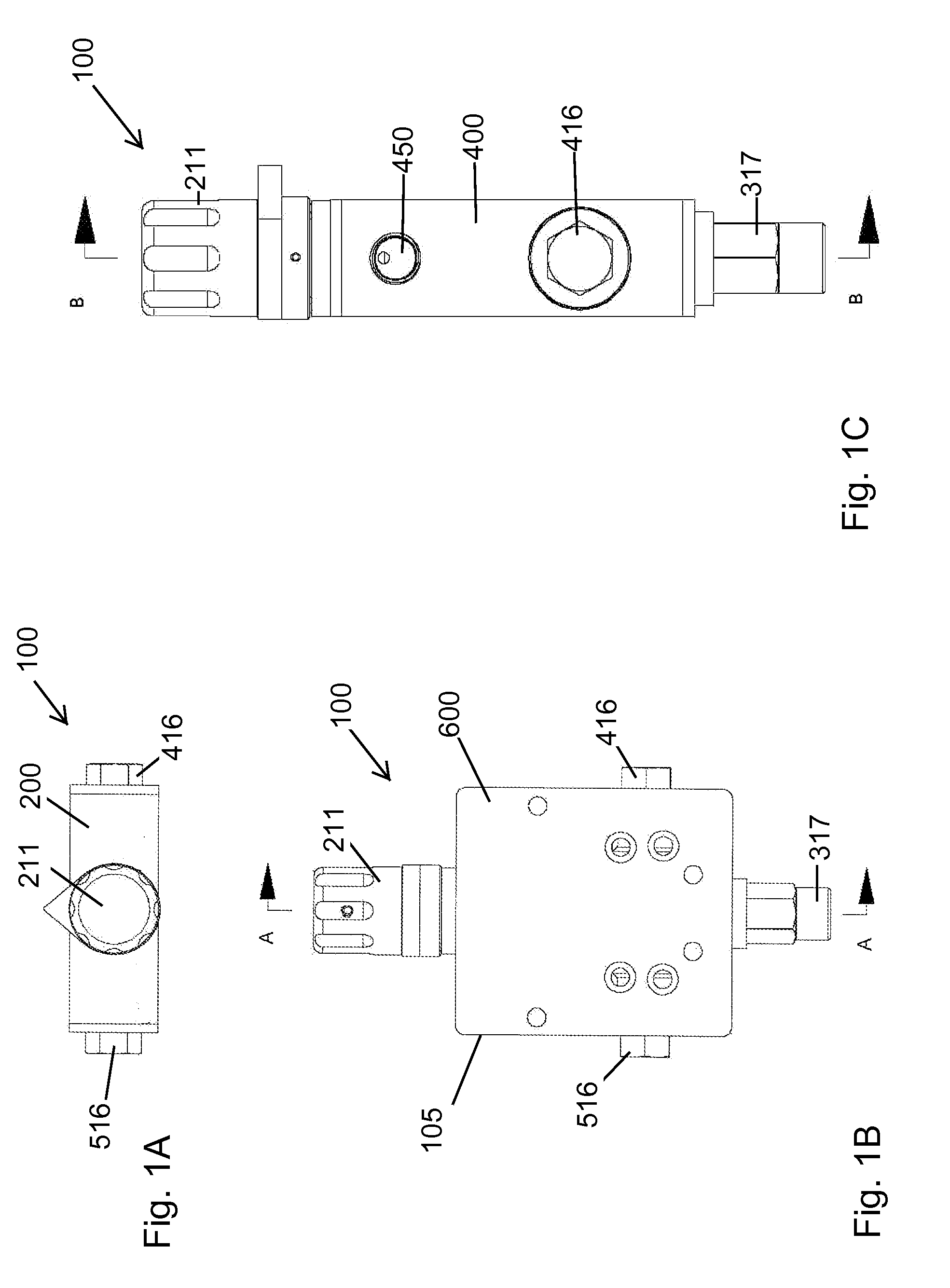

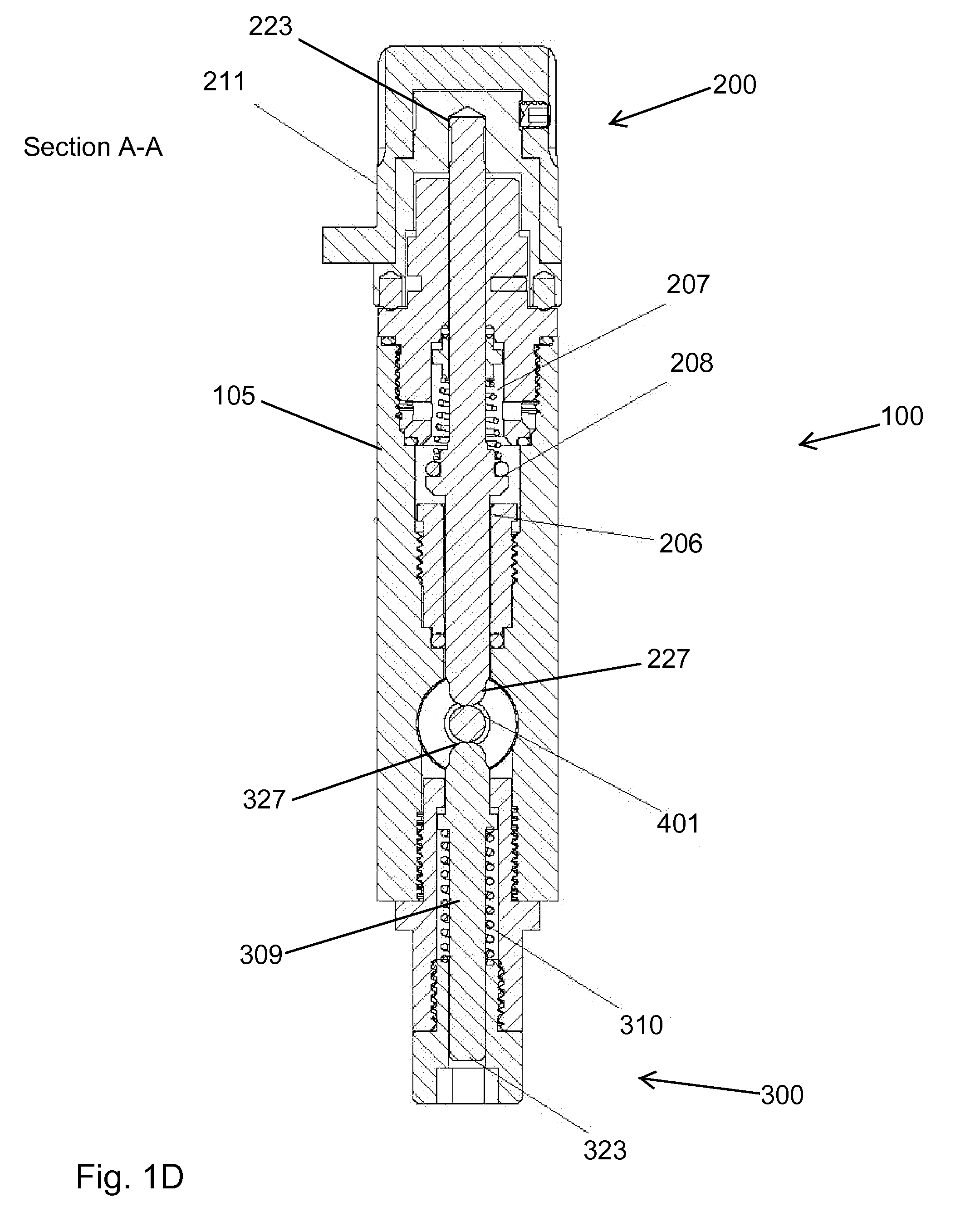

Device and method to prevent improper fluid mixing ratios in two component materials

InactiveUS20120180874A1Increase the pressure valueControl using interconnected flow control elementsPipeline systemsEngineeringPressure difference

The present invention relates to an apparatus and method for maintaining a fluid mixing ratio. The apparatus according to various embodiments prevents a fluid flow imbalance between two proportionate fluid streams based on a pressure difference, and may be configured to alert the user and / or stop the fluid flow in the event of a fluid flow imbalance. The apparatus is formed such that two plunger components engage a shuttle piston, the shuttle piston configured to move one or more plunger components given a selectable fluid flow imbalance.

Owner:MELLETTE ROBERT RAY

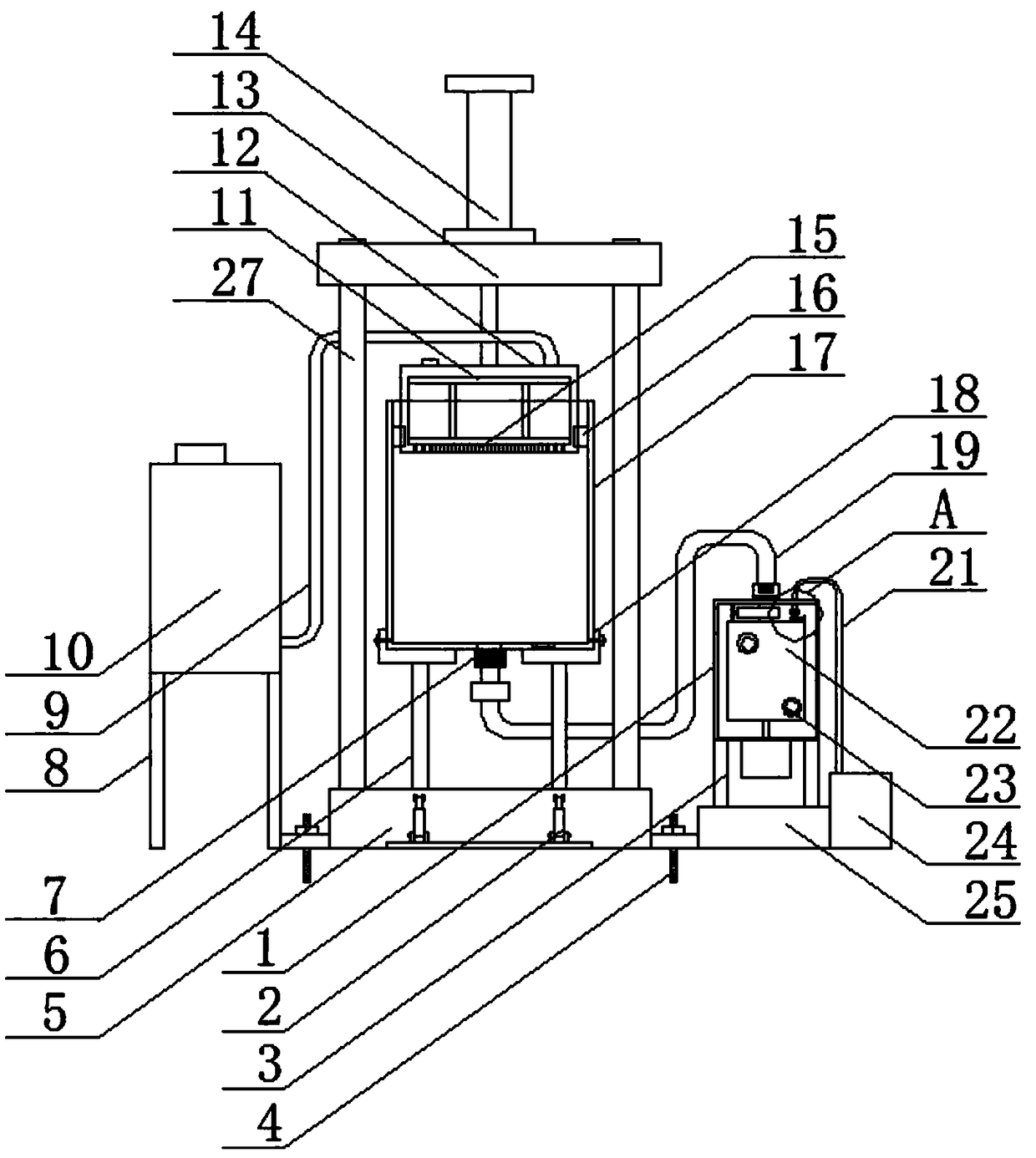

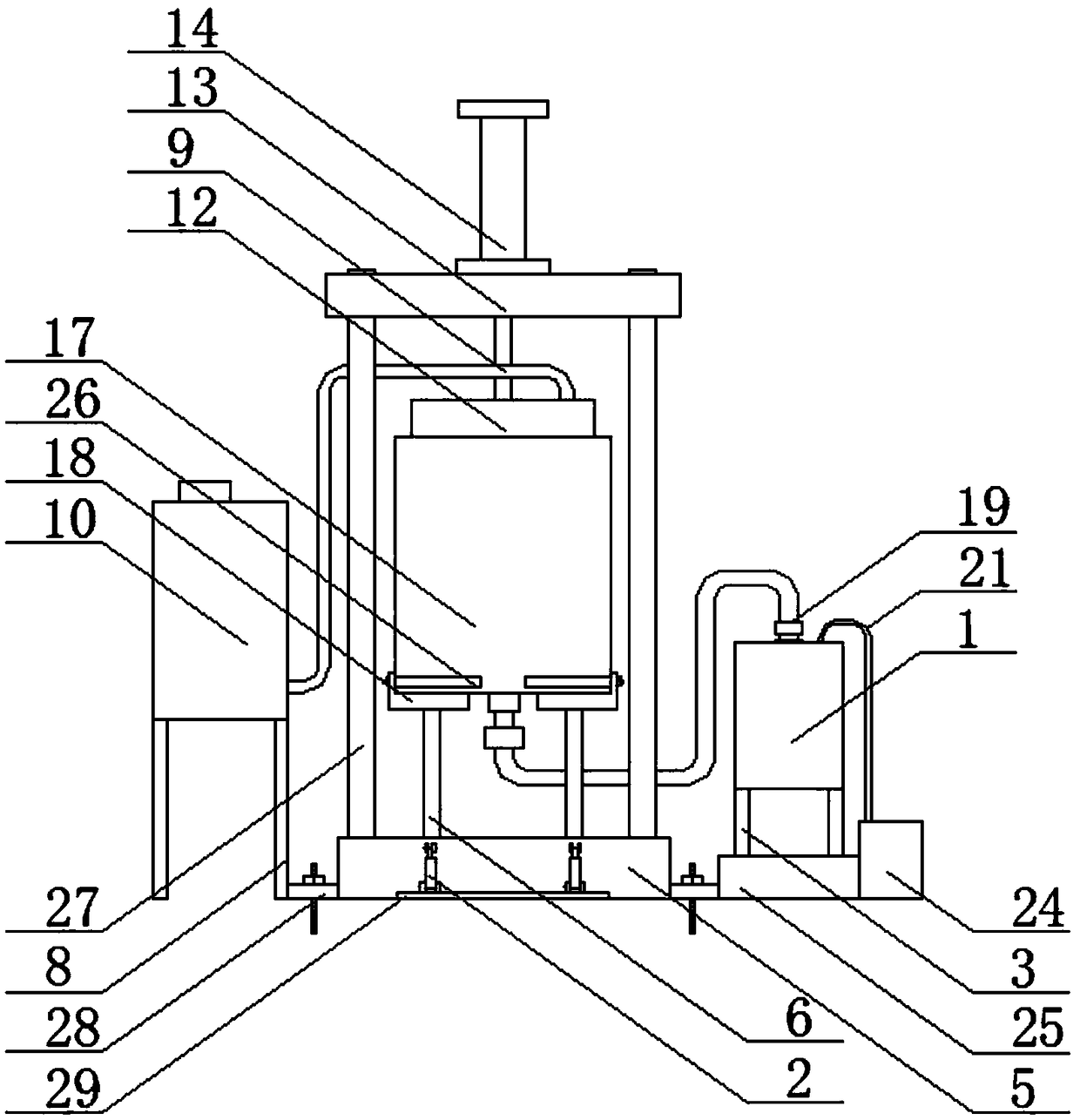

Water and sand separation and measurement device in water and sand uprush test system

ActiveCN109085085AAddressing stress deficitsIncrease the pressure valueWeighing by removing componentWeighing apparatus for materials with special property/formMeasurement deviceEngineering

The invention discloses a water and sand separation and measurement device in a water and sand uprush test system. The water and sand separation and measurement device comprises an operation platform,and four fixing rods are fixedly arranged at the upper end of the operation platform. The upper ends of the four fixing rods are together fixedly provided with a cross beam, and an oil cylinder is fixed to the upper end of the cross beam. A piston rod of the oil cylinder penetrates through the side wall of the cross beam and extends to the lower end of the cross beam, and four bearing rods are fixed to the upper end of the operation platform. Clamping devices are arranged at the upper ends of the bearing rods, and the four clamping devices are all arranged on one side of a test chamber in a butting mode. A water sump is arranged at the upper end of the test chamber in a penetrating mode, the tail end of the piston rod of the oil cylinder is fixed at the upper end of the water sump, and anair outlet hole is formed in the upper end of the water sump. Through the water and sand separation and measurement device, the problem of insufficient pressure during testing is solved, the problemthat sand soil can not be compacted is also solved, the function of respectively measuring the water uprush amount and the sand uprush amount is achieved, the accuracy of testing data is improved, operation is simple, and using is convenient.

Owner:LINYI UNIVERSITY

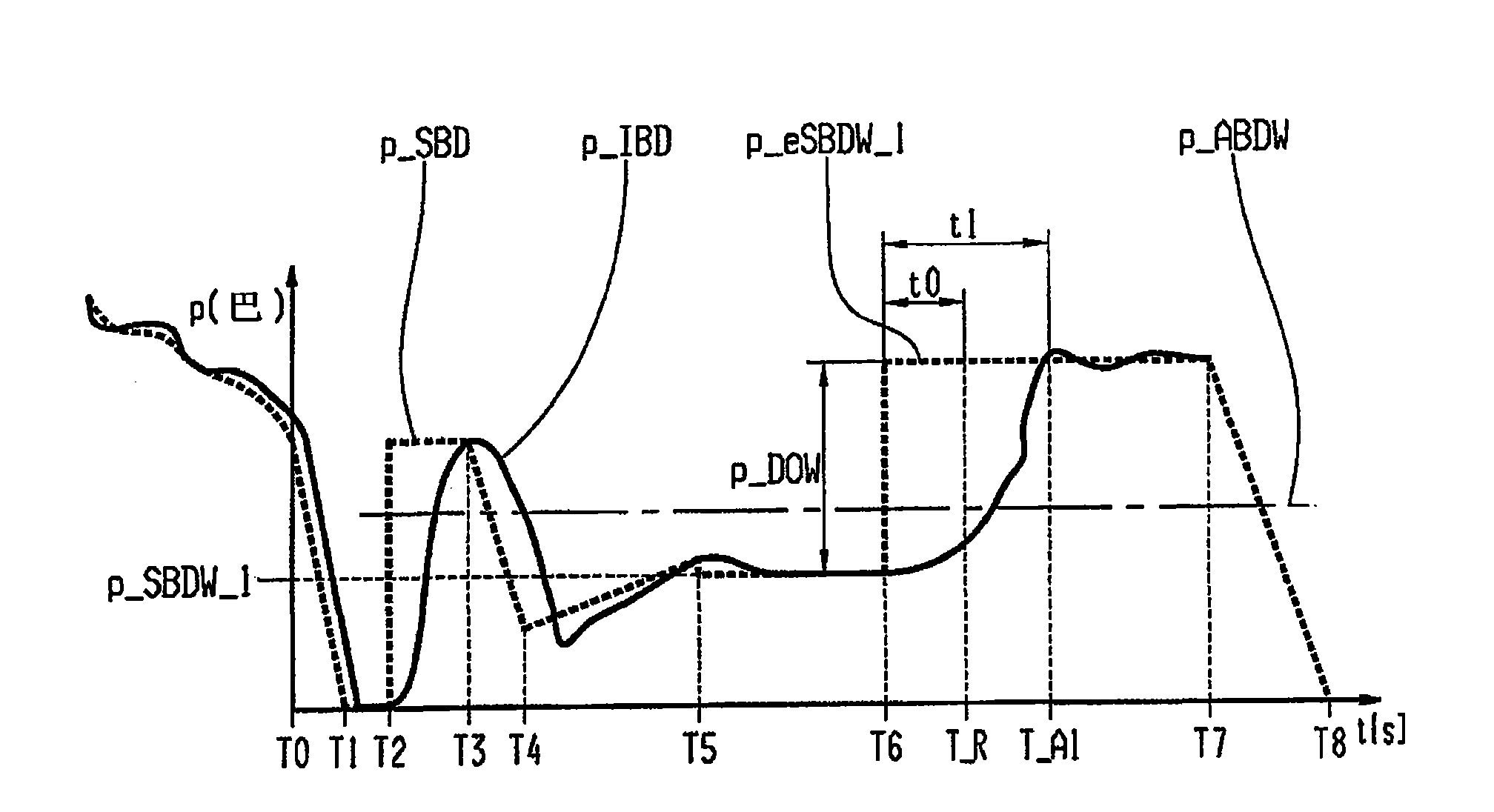

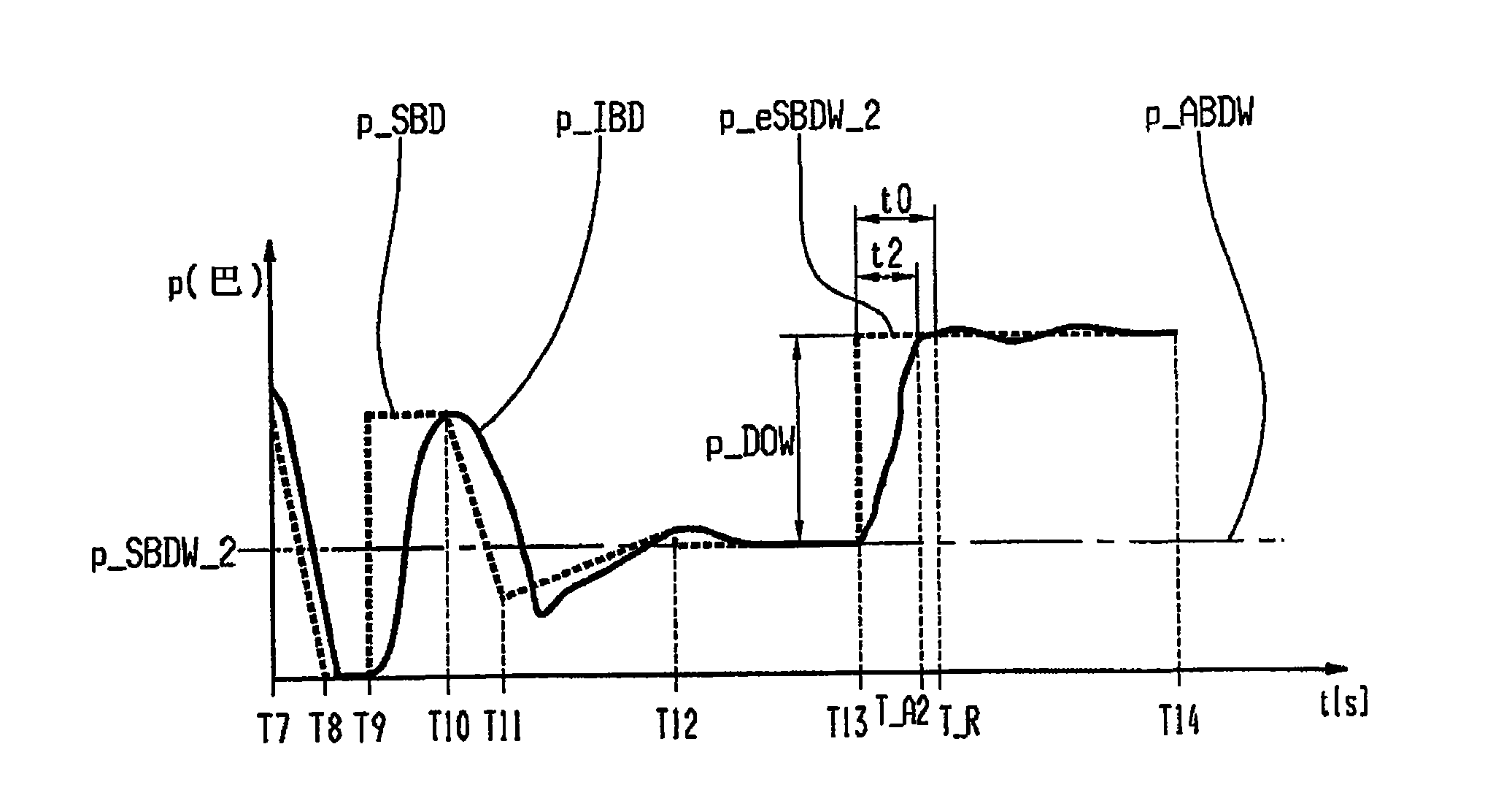

Determination method for actuation touch point pressure value of a friction shift element

ActiveCN102426098AManipulating pressure value risesImprove the delivery effectClutchesMachine gearing/transmission testingReference PeriodPressure curve

A method of determining an applied actuation touch point pressure value of a frictionally engaged shift element of a transmission at which transmission, via the shift element, is approximately zero, and an increase in pressure relates to an increase of the power transmission via the shift element. The method includes supplying a predefined pressure to the shift element at which power transmission is zero. Increasing the target pressure by an offset pressure to transfer the shift element into a predefined operating state which initiates time monitoring. Determining a characteristic of the actual pressure. After a testing time, a monitoring period is compared with a reference period. When the monitoring period is less than or equal to the reference period, the applied pressure is set to be equivalent with the target pressure.

Owner:ZF FRIEDRICHSHAFEN AG

A kind of method for preparing anilinoacetonitrile

ActiveCN104496848BPost-processing saves time and effortReduce processCarboxylic acid nitrile preparationOrganic compound preparationAcetonitrileAniline

The invention relates to a method for preparing n-phenylglycinenitrile. The method is characterized in that condensation reaction is continuously performed for aniline and glycolonitrile by a micro-channel reactor to obtain n-phenylglycinenitrile; the pH of glycolonitrile is pre-regulated to be 1.5 to 7 through a basic catalyst; the molar ratio of aniline to glycolonitrile is 1.00: 1.00-1.30. The method for preparing n-phenylglycinenitrile has the advantages that the process route is simple, and the reaction is fast, so that the working efficiency and production capacity can be ensured, and moreover, the production and operation safety of the process can also be ensured; with the adoption of the process method, the purity of a n-phenylglycinenitrile product exceeds 98.0% and the yield exceeds 99.9%.

Owner:内蒙古诚信永安化工有限公司

Method for increasing film stress and method for forming high stress layer

InactiveUS20080160786A1Film stress is increasedAvoid collisionSemiconductor/solid-state device manufacturingSemiconductor devicesHigh stressNitrogen gas

A method for forming a high stress layer is provided. According to the method, a substrate is put into a reactor of a PECVD machine and a reaction gas is added into the reactor. Then, an assistant reaction gas which has the molecular weight greater than or equal to the molecular weight of nitrogen gas is added into the reactor. Next, a carrier gas which has the molecular weight smaller than the molecular weight of nitrogen gas is added into the reactor to increase the bombarding efficiency in film deposition. Thereby, the high stress layer is formed on the substrate.

Owner:UNITED MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com