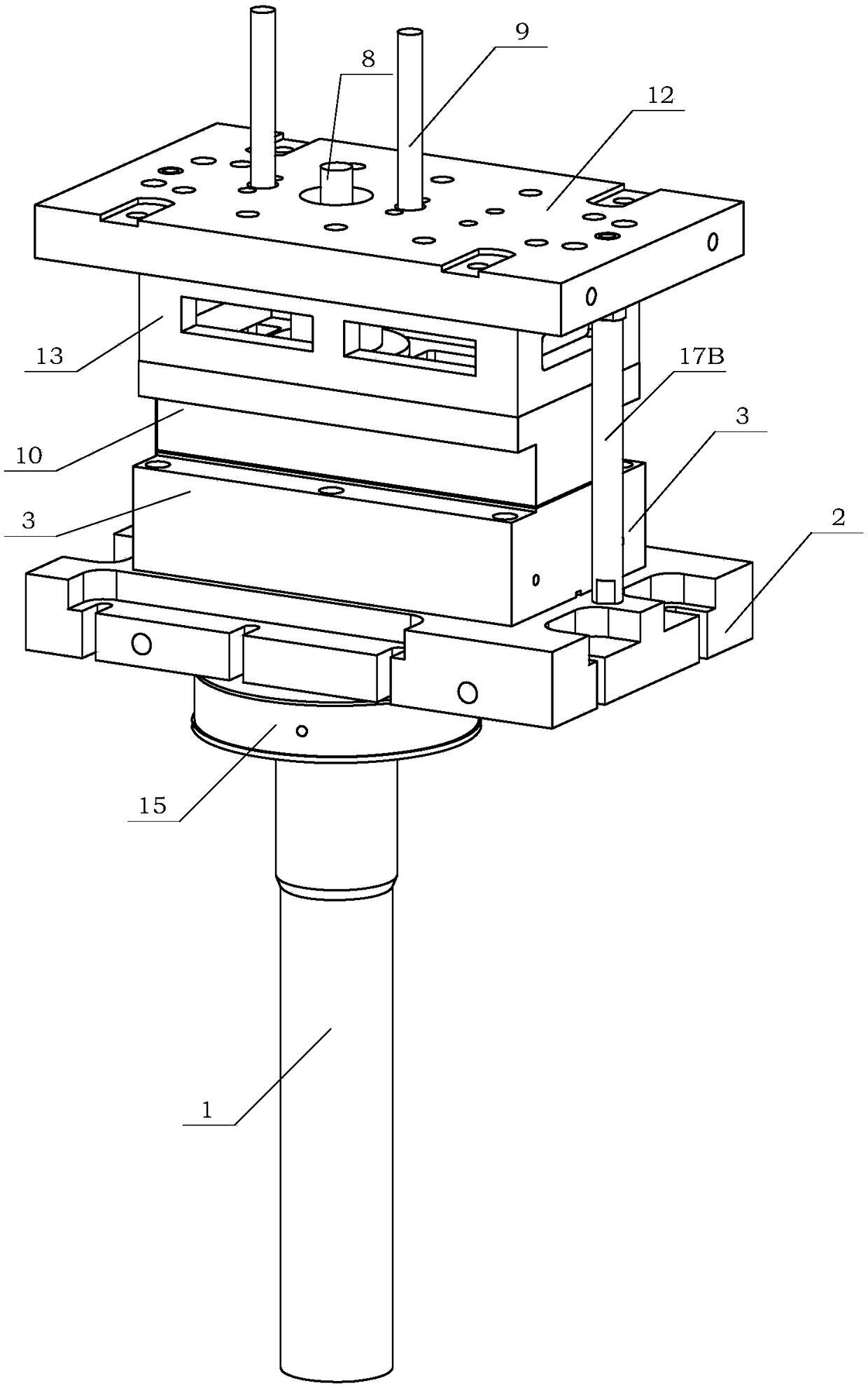

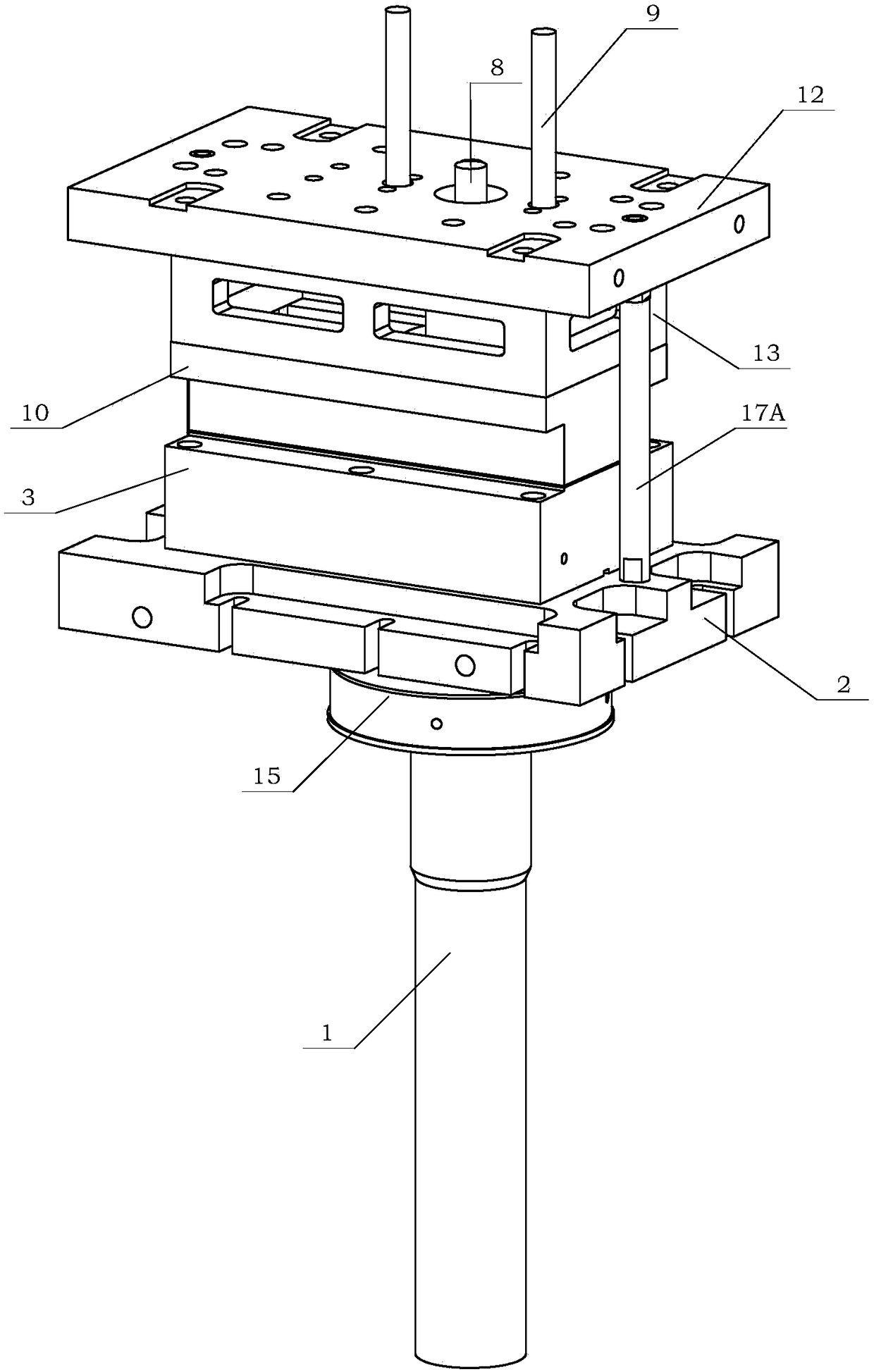

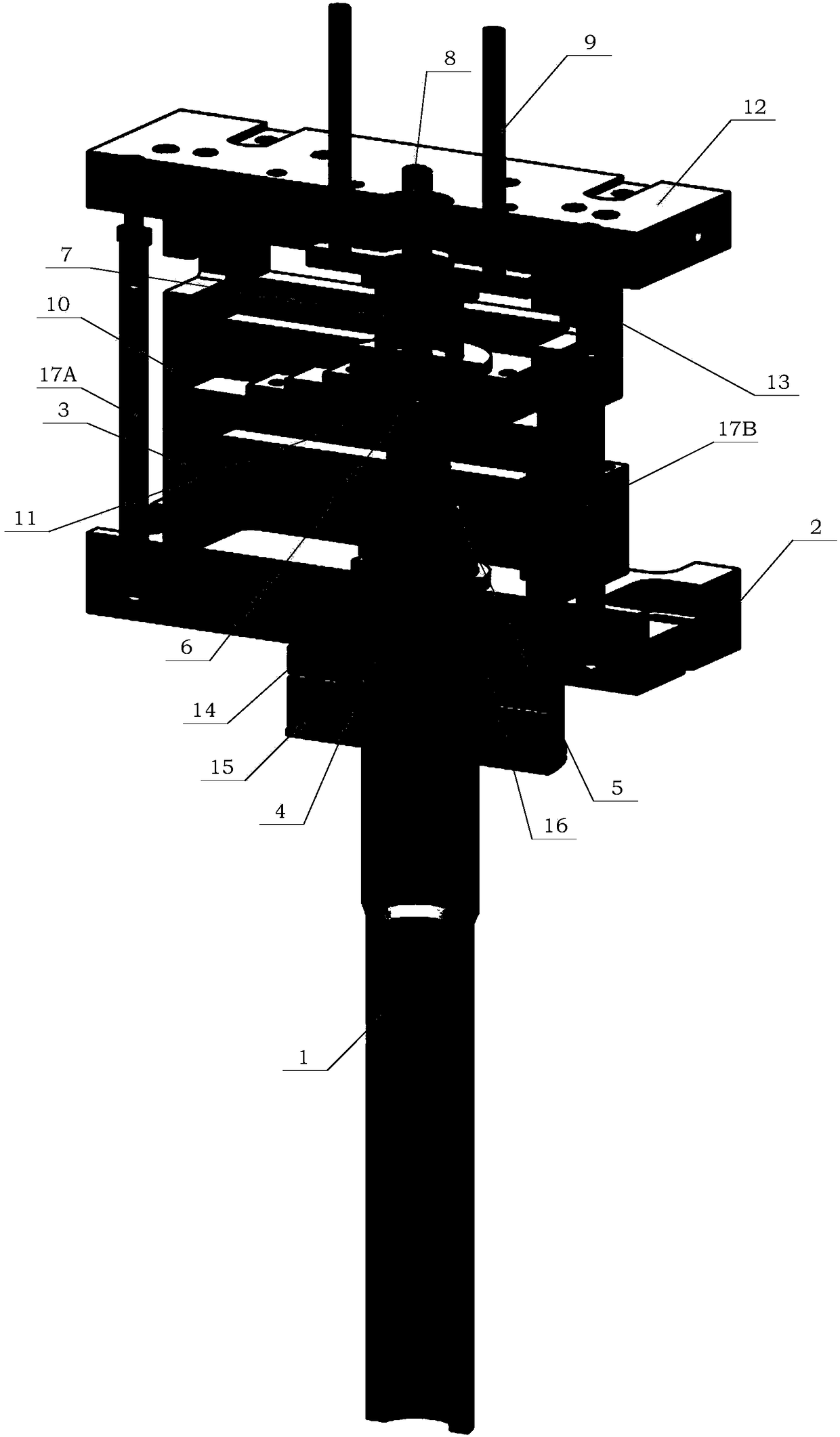

Low-pressure mold filling and high-pressure solidifying casting device and casing method for low-pressure supercharged casting machine

A low-pressure casting machine and casting machine technology, which are used in high-pressure solidification forming casting devices and low-pressure controllable filling fields, can solve the problem of insufficient liquid metal feeding, unsatisfactory casting density, strength and toughness, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] Install the low-pressure filling mold high-pressure solidification casting device of the present invention on the BH-1 type low-pressure pressurized casting machine, and carry out low-pressure pressurized casting to the high-speed rail engine motor casing casting, including the following steps:

[0111] (1) Prepare aluminum alloy according to a certain ratio, the specific mass percentage is: Si: 7.2%, Mg: 0.65%, Fe: 0.20%, Mn: 0.1%, Ti: 0.13%, Sr: 0.02%; Cu: 0.03 %, RE: 0.005%, Nb: 0.05%, Cr: 0.008%, Zr: 0.012%, B: 0.009%, Nd: 0.005%, Ni: 0.008%, Zn: 0.008%, and the balance is Al. After the alloy is melted in the melting furnace, add Al-5Ti-B refiner and Al-10Sr modifier at 760°C for refinement and modification, and add self-sinking pollution-free refining agent for degassing at 740°C Refining for 30 minutes, standing still for 30 minutes, removing slag, taking chemical composition samples, and transferring the melted aluminum alloy liquid from the pneumatic ladle to th...

Embodiment 2

[0120]The low-pressure filling and high-pressure solidification casting device of the present invention is installed on the BH-1 type low-pressure pressurized casting machine, and the low-pressure pressurized casting is carried out to the automobile auxiliary frame casting, comprising the following steps:

[0121] (1) Prepare aluminum alloy according to a certain ratio, the specific mass percentage is: Si: 6.8%, Mg: 0.35%, Fe: 0.20%, Mn: 0.1%, Ti: 0.15%, Sr: 0.03%; Cu: 0.10 %, RE: 0.15%, Nb: 0.05%, Cr: 0.005%, Zr: 0.01%, B: 0.008%, Nd: 0.008%, Ni: 0.005%, Zn: 0.005%, and the balance is Al. After the alloy is melted in the melting furnace, add Al-5Ti-B refiner and Al-10Sr modifier at 760°C for refinement and modification, and add self-sinking pollution-free refining agent for degassing at 720°C Refining for 40 minutes, standing still for 20 minutes, removing slag, taking chemical composition samples, and transferring the melted aluminum alloy liquid from the pneumatic ladle to ...

Embodiment 3

[0130] The low-pressure filling and high-pressure solidification casting device of the present invention is installed on a BH-1 type low-pressure pressurized casting machine, and the barrel-shaped motor casing casting is carried out to low-pressure pressurized casting, including the following steps:

[0131] (1) Prepare aluminum alloy according to a certain ratio, the specific mass percentage is: Si: 7.2%, Mg: 0.55%, Fe: 0.18%, Mn: 0.05%, Ti: 0.12%, Sr: 0.015%; Cu: 0.01 %, RE: 0.002%, Nb: 0.01%, Cr: 0.005%, Zr: 0.01%, B: 0.005%, Nd: 0.005%, Ni: 0.005%, Zn: 0.005%, and the balance is Al. After the alloy is melted in the melting furnace, add Al-5Ti-B refiner and Al-10Sr modifier at 755°C for refinement and modification, and add self-sinking pollution-free refining agent for degassing at 740°C Refining for 20 minutes, standing still for 30 minutes, removing slag, taking chemical composition samples, and transferring the melted aluminum alloy liquid from the pneumatic ladle to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com