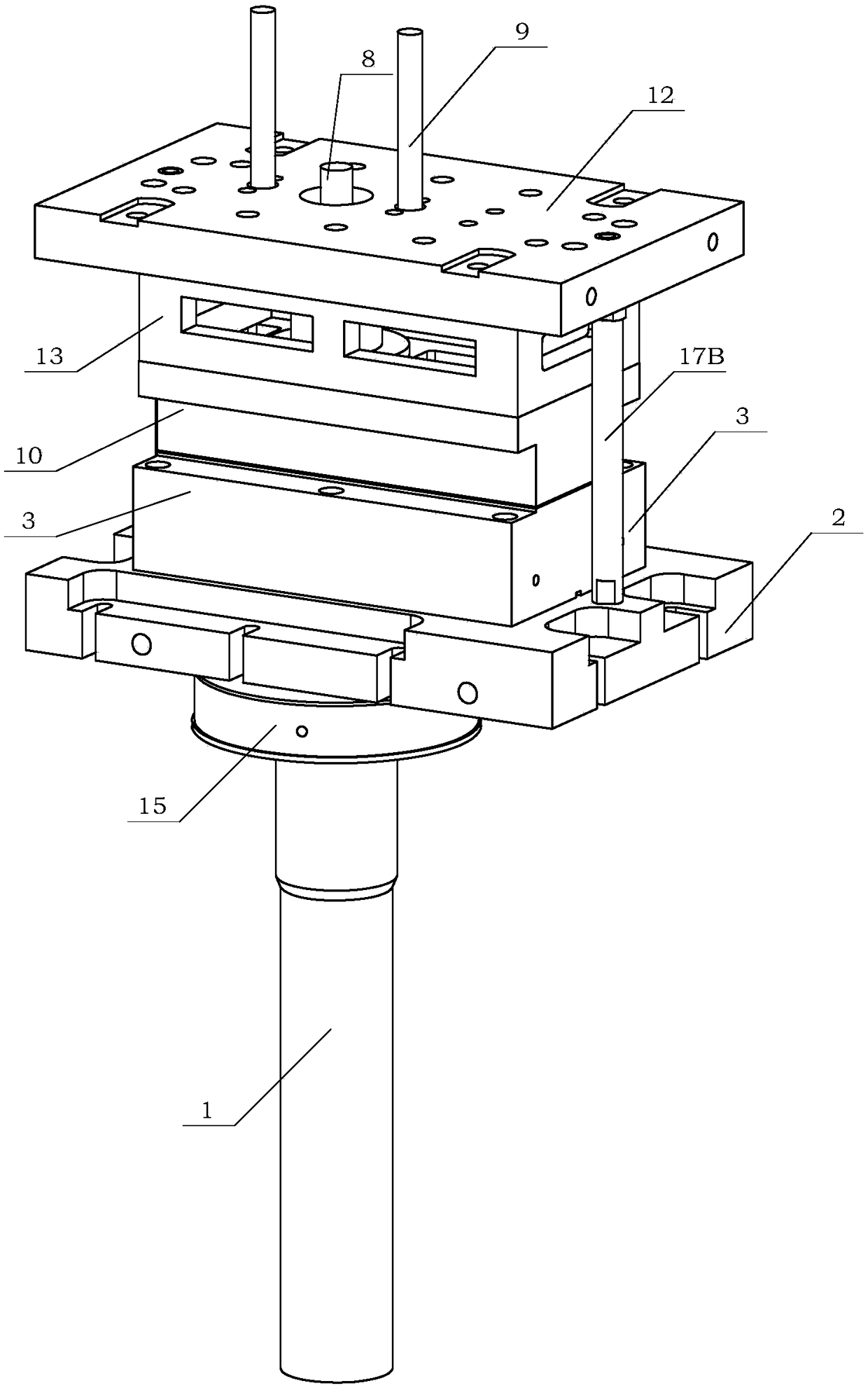

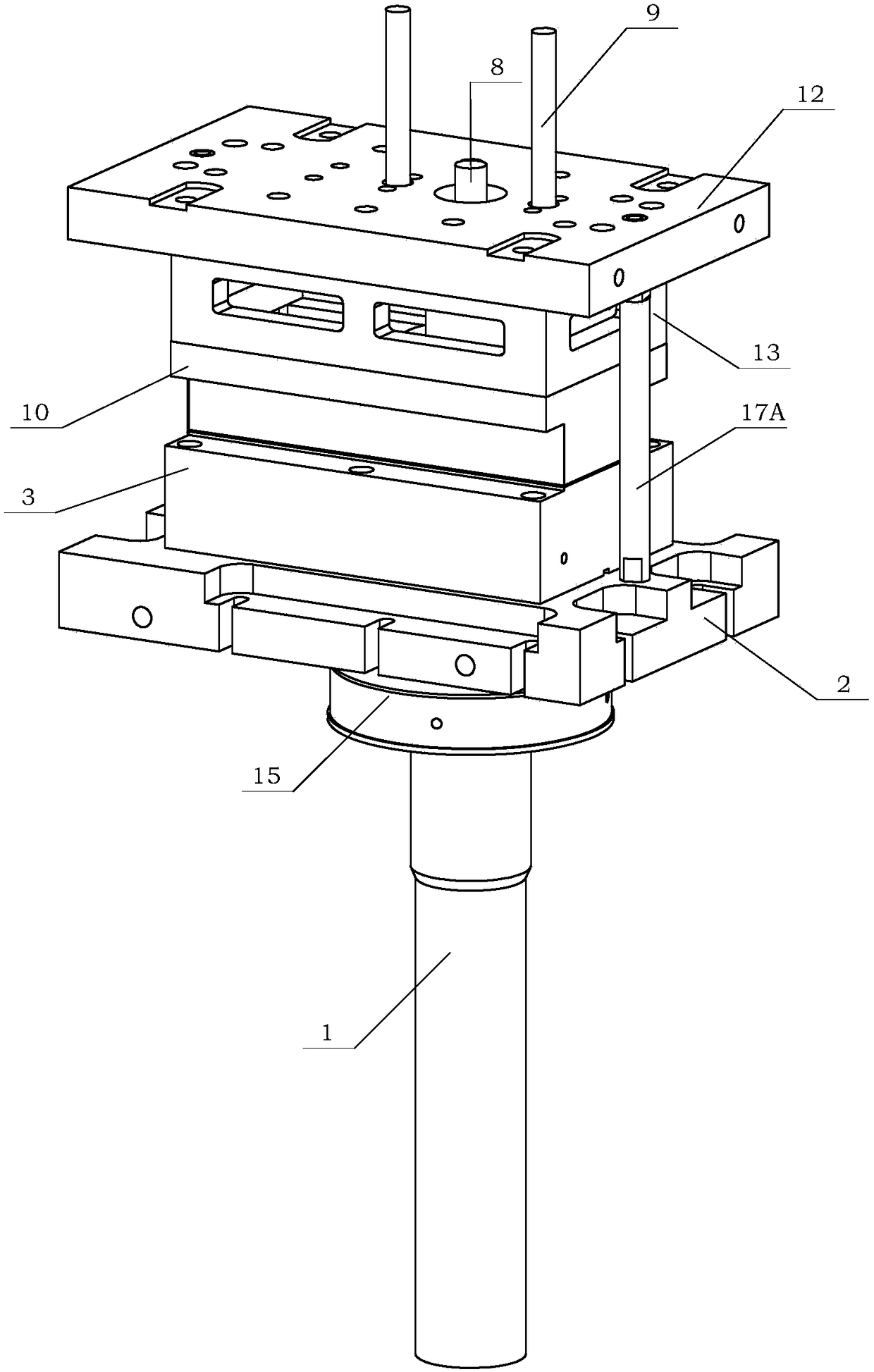

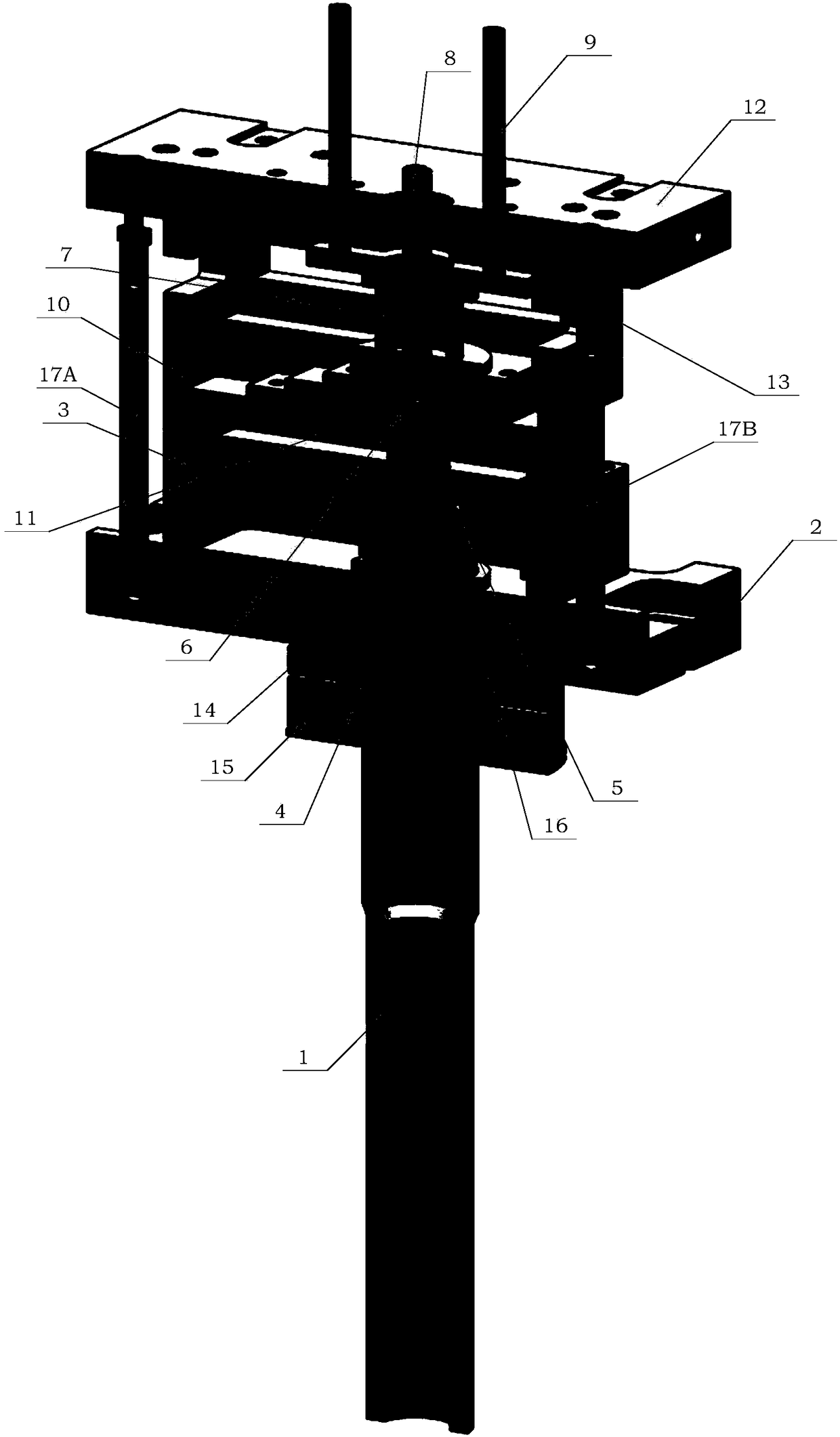

Low-pressure mold-filling and high-pressure solidification casting device used for pressure adjusting and pressurizing casting machine and casting method

A casting machine and low-pressure technology, applied in the field of casting, can solve the problems of unsatisfactory density, strength and toughness of castings, insufficient increase of feeding and solidification pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] The low-pressure filling and high-pressure solidification casting device of the present invention is installed on the APC3000 pressure regulating and supercharging casting machine, and the pressure regulating and supercharging casting is performed on the automobile engine motor shell casting, including the following steps:

[0106] (1) Prepare aluminum alloy according to a certain ratio, the specific mass percentages are: Si: 6.8%, Mg: 0.40%, Fe: 0.12%, Mn: 0.1%, Ti: 0.14%, Sr: 0.06%; Cu: 0.08 %, RE: 0.05%, Nb: 0.04%; Cr: 0.005%, Zr: 0.01%, B: 0.005%, Nd: 0.005%, Ni: 0.005%, Zn: 0.005%, and the balance is Al. After the alloy is melted in the melting furnace, Al-5Ti-B refiner and Al-10Sr modifier are added at 760℃ for refining and modification, and self-sinking pollution-free refining agent is added at 730℃ for degassing Refining for 40 minutes, slag removal after standing for 30 minutes, take chemical composition samples, after the composition is qualified, transfer the...

Embodiment 2

[0115] The low-pressure filling and high-pressure solidification casting device of the present invention is installed on a CY-3000 type pressure-regulated and pressurized casting machine, and the pressure-regulated and pressurized casting is performed on frame castings such as frames for high-speed rail, including the following steps:

[0116] (1) The aluminum alloy is prepared according to a certain ratio, and the specific mass percentages are: Si: 7.5%, Mg: 0.65%, Fe: 0.20%, Mn: 0.1%, Ti: 0.15%, Sr: 0.05%; Cu: 0.20 %, RE: 0.30%, Nb: 0.05%; Cr: 0.005%, Zr: 0.01%, B: 0.005%, Nd: 0.002%, Ni: 0.001%, Zn: 0.001%, and the balance is Al. After the alloy is melted in the melting furnace, Al-5Ti-B refiner and Al-10Sr modifier are added at 750°C for refining and modification, and self-sinking pollution-free refining agent is added at 730°C for degassing Refining for 30min, after standing for 20min, the slag was removed, and the chemical composition sample was taken. After the composit...

Embodiment 3

[0125] The low-pressure filling and high-pressure solidification casting device of the present invention is installed on the APC4000A pressure-regulated and pressurized casting machine, and the pressure-regulated and pressurized casting is performed on the aero-engine barrel-shaped casing casting, including the following steps:

[0126] (1) The aluminum alloy is prepared according to a certain ratio, and the specific mass percentages are: Si: 7.3%, Mg: 0.65%, Fe: 0.20%, Mn: 0.05%, Ti: 0.12%, Sr: 0.01%; Cu: 0.01 %, RE: 0.008%, Nb: 0.01%; Cr: 0.001%, Zr: 0.01, B: 0.005%, Nd: 0.005%, Ni: 0.005%, Zn: 0.005%, and the balance is Al. After the alloy is melted in the melting furnace, Al-5Ti-B refiner and Al-10Sr modifier are added at 760℃ for refining and modification, and self-sinking pollution-free refining agent is added at 740℃ for degassing Refining for 20 minutes, slag removal after standing for 20 minutes, take chemical composition samples, after the composition is qualified, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com