Determination method for actuation touch point pressure value of a friction shift element

一种接合元件、压力值的技术,应用在带有齿的元件、离合器、机器齿轮/传动机构测试等方向,能够解决提高传动装置制造成本等问题,达到结构上简单、成本低廉的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

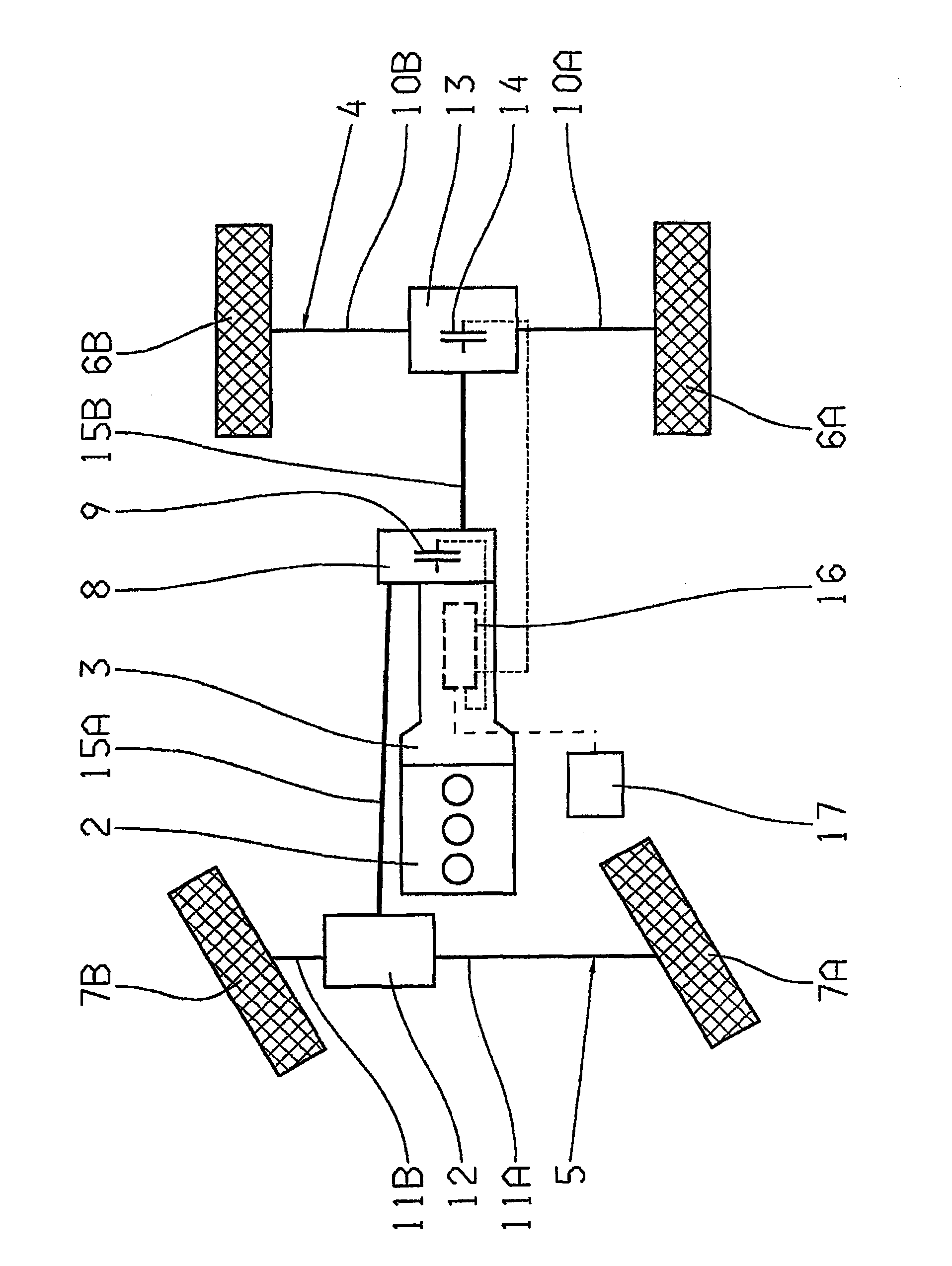

[0023] figure 1 A strongly schematic illustration of a drive train 1 of an all-wheel drive vehicle is shown. The drive train 1 comprises a drive machine 2 and a main transmission 3 , both of which can themselves be transmissions known from practice and by means of which can exhibit different transmission ratios for forward and reverse travel.

[0024] The drive train 1 has two drivable axles 4, 5, which are connected in a known manner to at least one drive wheel 6A, 6B or 7A, 7B on each vehicle side, and the axle 4 of said axles is The rear axle of the vehicle and axle 5 is the front axle of the vehicle. A transmission 8 configured as a longitudinal transfer is arranged between the main transmission 3 and the axles 4 , 5 , by means of which a first vehicle longitudinal axle 15A and a second vehicle longitudinal axle 15A between the vehicle rear axle 4 and the vehicle front axle 5 Two vehicle longitudinal shafts 15B distribute the drive torque of the drive machine 2 to an inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com