Gas-lubricated bird-wing-shaped groove end face seal structure

A technology of gas lubrication and end face sealing, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve problems such as seal failure, too small opening force, and end face cannot be opened in time, so as to prevent end face wear and reduce end face wear Probability, the effect of improving the opening performance of the end face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

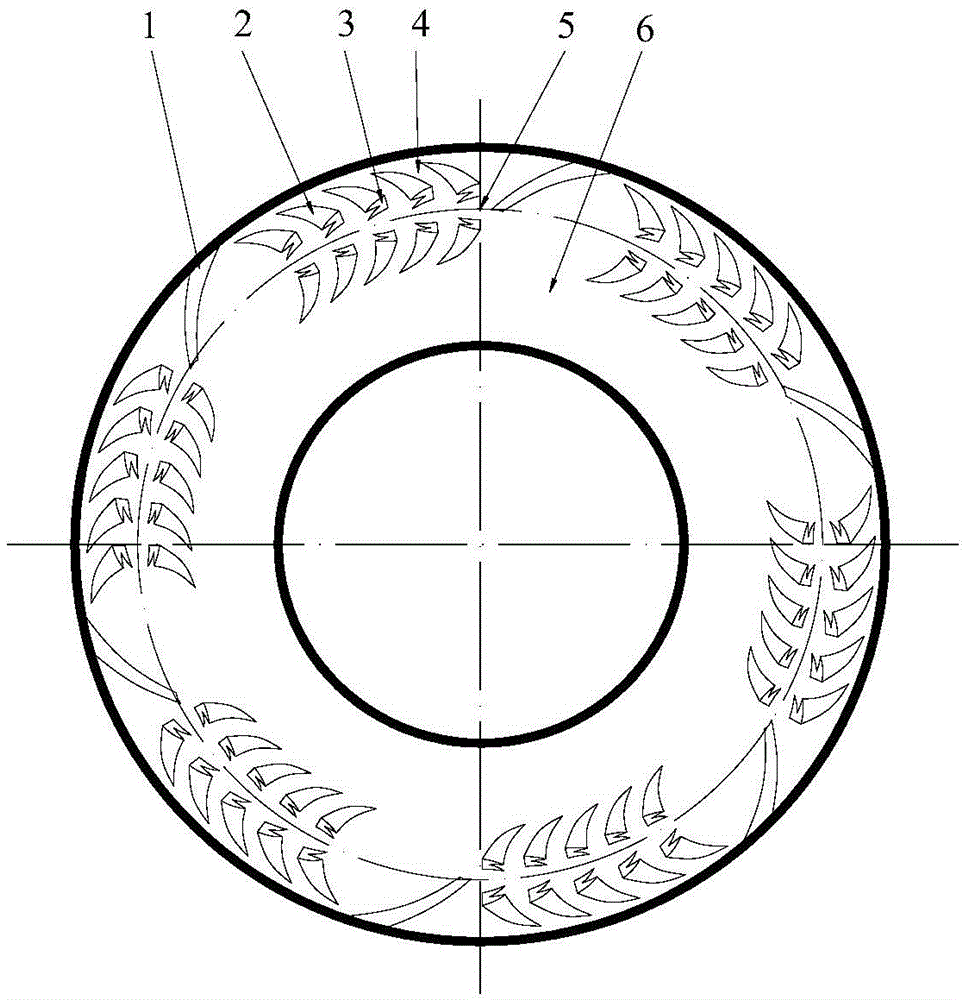

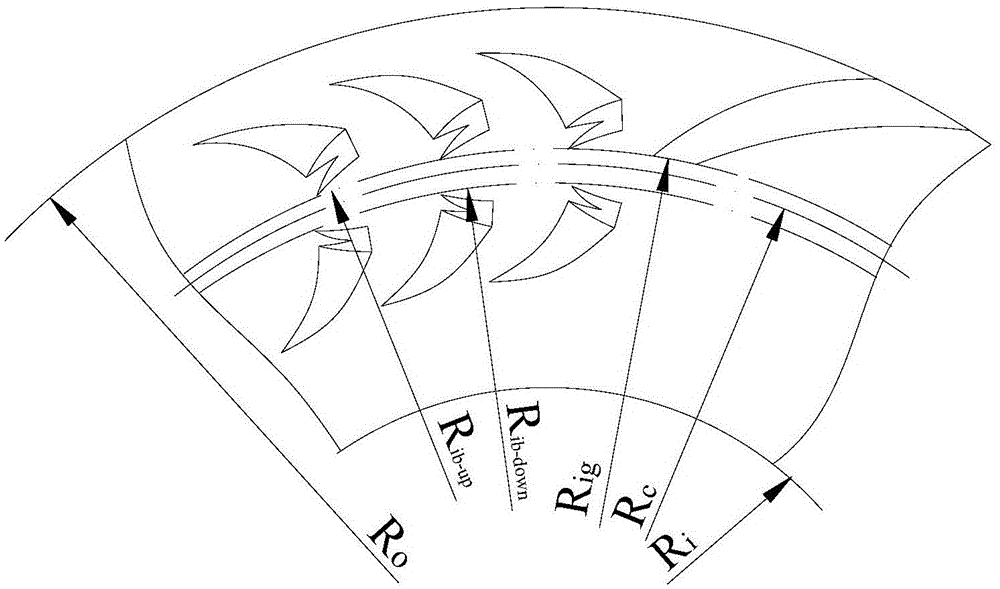

[0027] see figure 1 , 2 , a gas-lubricated imitation bird wing-shaped groove end face seal structure, which includes a moving ring and a static ring for end face sealing, and is characterized in that: at least one of the sealing rings in the moving ring and the static ring is provided with a plurality of imitation bird wings Shaped groove, the imitation bird wing shape groove is made up of imitation tail feather shape groove 3 and imitation flying feather shape groove 2, described tail feather shape groove 3 has the tail part of dovetail shape split, and described imitation The flight feather-shaped groove 2 is roughly in the shape of a cow horn with a thick end and a tail tip, and the described imitation tail feather-shaped groove 3 is arranged horizontally at the thick end of the described imitation flight feather-shaped groove 2, and the described imitation flight feather-shaped groove 2 The thick section of the groove 2 and the thick end of the imitation tail feather shap...

Embodiment 2

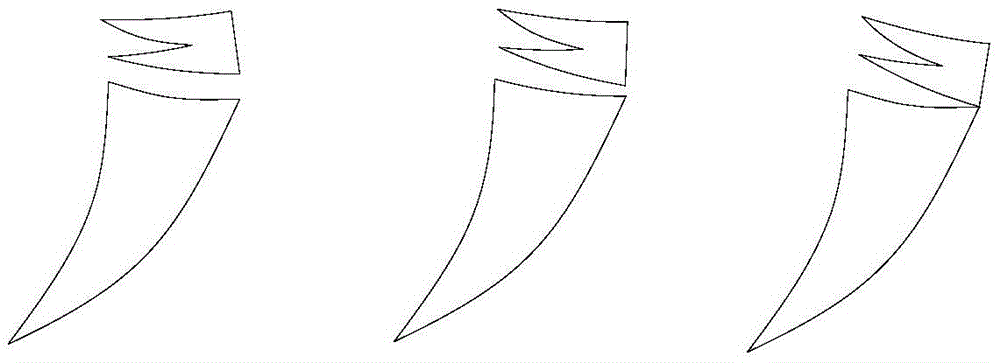

[0039] see image 3 , The difference between this embodiment and Embodiment 1 is that the connection form between the imitation tail feather-shaped groove 3 and the imitation flight feather-shaped groove 2 is one of the following: parallel separation, non-parallel separation, and partial overlap. Other structures and functions are the same as those in Embodiment 1.

Embodiment 3

[0041] see Figure 4 The difference between this embodiment and the first embodiment is that the drainage groove can be one of the following forms: rectangular groove, T-shaped groove, U-shaped groove, and V-shaped groove. Other structures and functions are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com